Heat conduction adhesive sheet and preparation method thereof, electronic element and household appliance

A technology of thermally conductive adhesive and thermally conductive adhesive layer, which is applied in the direction of adhesives, epoxy resin adhesives, polymer adhesive additives, etc., can solve the problems that high adhesion cannot be guaranteed, and thermally conductive adhesive products have not yet appeared, so as to improve the heat dissipation effect , improve insulation, and the effect of being friendly to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] It is used to illustrate the thermal conductive adhesive composition, thermal conductive film and preparation method thereof of the present invention.

[0063] (1) The first thermal conductive adhesive composition: epoxy resin NPEL-127100 parts, cationic curing agent TC-363210 parts, toughening resin J125667 parts, thermal powder TP-33800 parts, silane coupling agent A1715 parts, butanone 60 parts , Defoamer D103;

[0064] (2) Second thermal conductive adhesive composition: epoxy resin NPEL-127100 parts, cationic curing agent TC-36327 parts, toughening resin J125653 parts, thermal powder TP-33520 parts, silane coupling agent A1717 parts, butanone 60 parts , Defoamer D102;

[0065] (3) Preparation method of thermal conductive film:

[0066] The raw materials in the first thermally conductive adhesive composition were mixed in proportion for 30 minutes (the stirring speed was 1000 r / min), coated on the release film, and dried (80° C.) to obtain the first adhesive film b...

Embodiment 2-5

[0070] It is used to illustrate the thermal conductive adhesive composition, thermal conductive film and preparation method thereof of the present invention.

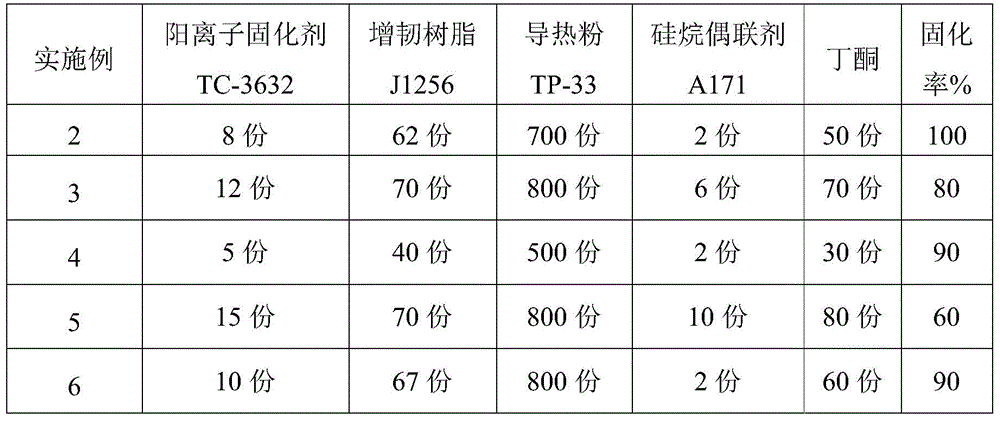

[0071] (1) The first thermally conductive adhesive composition: with reference to Example 1, the difference lies in the following table:

[0072]

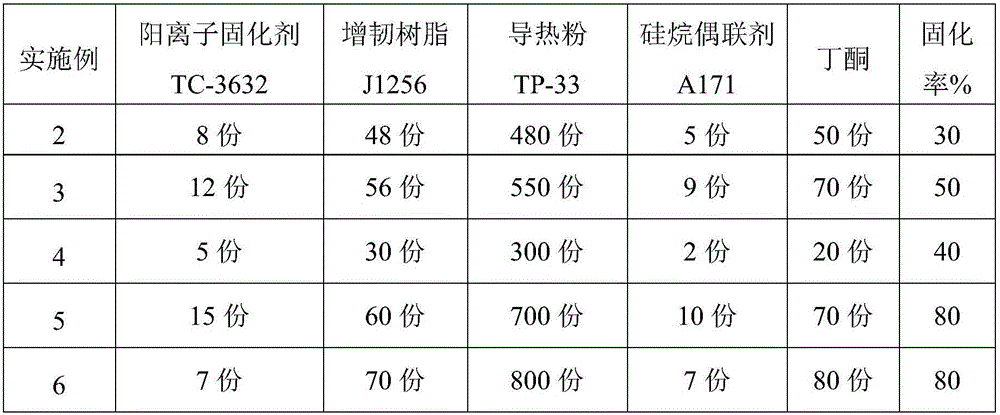

[0073] (2) Second thermally conductive adhesive composition: with reference to Example 1, the difference is: the consumption of cationic curing agent, toughening resin, thermally conductive powder, silane coupling agent and butanone is shown in the following table:

[0074]

[0075] (3) Preparation method of thermally conductive film: the same as in Example 1, the prepared thermally conductive film is S2 to S6.

Embodiment 7

[0077] It is used to illustrate the thermal conductive adhesive composition, thermal conductive film and preparation method thereof of the present invention.

[0078] (1) The first thermally conductive adhesive composition: the same as in Example 1;

[0079] (2) The second thermally conductive adhesive composition: the same as in Example 1;

[0080] (3) Preparation method of thermal conductive film:

[0081] The raw materials in the first thermally conductive adhesive composition were mixed in proportion for 30 minutes (the stirring speed was 1000 r / min), coated on the release film, and dried (80° C.) to obtain the first adhesive film blank. A plastic film body is thermally bonded (temperature 90°C, pressure 3kg, time 40s) to a copper plate, and is cured (100°C, 1h) to form a first thermally conductive adhesive layer (thickness 80μm, curing rate 100%);

[0082] The raw materials in the second thermally conductive adhesive composition are mixed in proportion for 30 minutes (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com