High-efficiency composite PBT heat conduction and dispersion material, and preparation method and applications thereof

A technology of heat dissipation material and preheating temperature, which is applied in the field of high-efficiency composite PBT heat conduction and heat dissipation materials and its preparation, can solve the problems of failing to pass the UL94V0 thin-wall test standard and low flame retardant level, and achieve good mechanical properties, high insulation, and easy The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

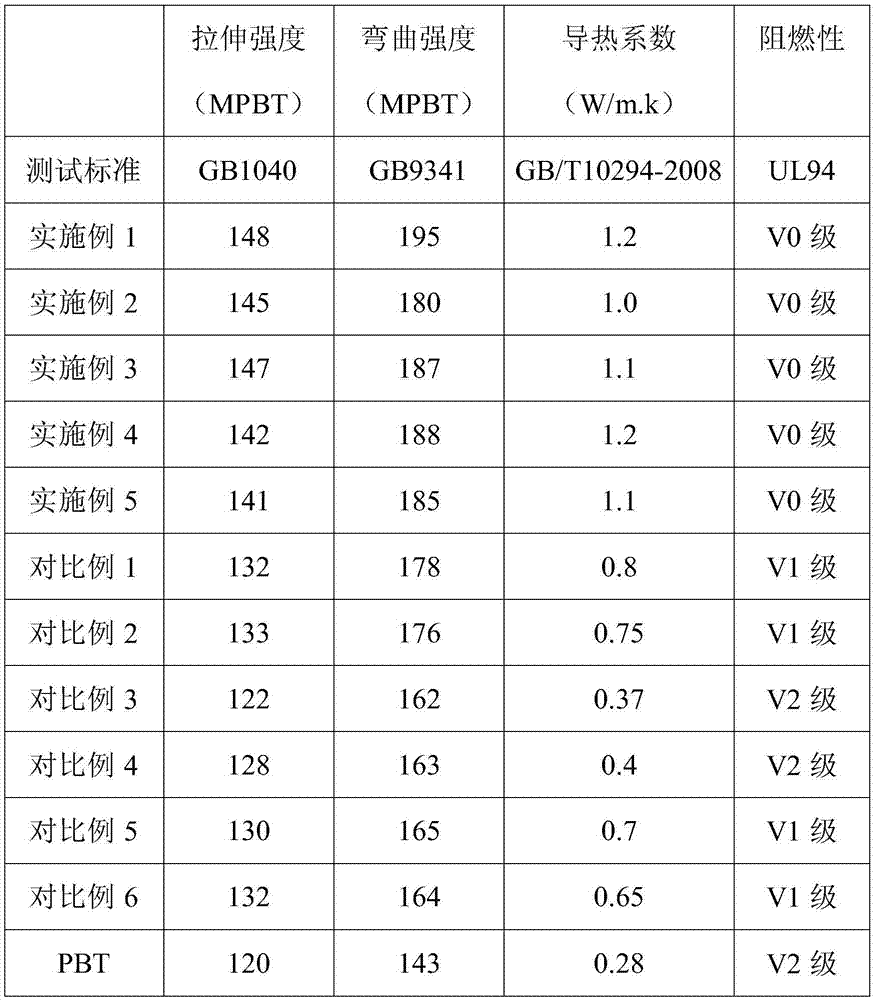

Examples

Embodiment 1

[0037] In this example, the PBT heat conduction material is prepared from PBT with a mass ratio of 8:2 and the heat conduction masterbatch, wherein the heat conduction masterbatch is prepared from the following raw materials:

[0038] Polyester 70%

[0040] Nitride 10%

[0041] The preparation method is as follows:

[0042](1) Metal oxides, nitrides and polyester fibers are blended and doped at a stirring rate of 80r / min, and are extruded by a twin-screw extruder, and the preheating temperature in the screw region of the twin-screw extruder is: 200°C, the screw speed is 200r / min, and the heat conduction masterbatch is obtained;

[0043] (2) Blend and dope PBT and heat-conducting masterbatch at a stirring rate of 100r / min, and extrude using a twin-screw extruder. The preheating temperature in the screw area of the twin-screw extruder is 300°C. The screw speed of the twin-screw extruder was 300r / min to obtain the PBT conduction and heat dissipation...

Embodiment 2

[0045] In this example, the PBT heat conduction material is prepared from PBT with a mass ratio of 7.5:2.5 and the heat conduction masterbatch, wherein the heat conduction masterbatch is prepared from the following raw materials:

[0046] Polyester 65%

[0048] Nitride 20%

[0049] The preparation method is as follows:

[0050] (1) Metal oxides, nitrides and polyester fibers are blended and doped at a stirring rate of 80r / min, and are extruded by a twin-screw extruder, and the preheating temperature in the screw region of the twin-screw extruder is: 300°C, the screw speed is 150r / min, and the heat conduction masterbatch is obtained;

[0051] (2) Blend and dope PBT and heat-conducting masterbatch at a stirring rate of 150r / min, and extrude with a twin-screw extruder. The preheating temperature in the screw area of the twin-screw extruder is 260°C. The screw speed of the twin-screw extruder is 250r / min to obtain the PBT conduction and heat dissipat...

Embodiment 3

[0053] In this example, the PBT heat conduction material is prepared from PBT with a mass ratio of 8.5:1.5 and the heat conduction masterbatch, wherein the heat conduction masterbatch is prepared from the following raw materials:

[0054] Polyester 75%

[0055] Metal Oxide 15%

[0056] Nitride 10%

[0057] The preparation method is as follows:

[0058] (1) Metal oxides, nitrides and polyester fibers are blended and doped at a stirring speed of 70r / min, and are extruded by a twin-screw extruder, and the preheating temperature of the screw region of the twin-screw extruder is: 250°C, the screw speed is 180r / min, and the heat conduction masterbatch is obtained;

[0059] (2) Blend and dope PBT and heat conduction masterbatch at a stirring rate of 150r / min, and extrude with a twin-screw extruder. The preheating temperature in the screw area of the twin-screw extruder is 380°C, so The screw speed of the twin-screw extruder is 250r / min to obtain the PBT conduction and heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com