Degradable mulching film coated with waterproof layer

A technology for degrading mulch and waterproof layer, which is applied in plant protection, application, horticulture, etc. It can solve problems such as water vapor accumulation, burns of plants touching the mulch, and plant growth defects, so as to improve surface water storage capacity, improve heat preservation and water retention, and maintain effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Polypropylene 10g / m 2 , coated with degradable polyurethane layer 3g / m 2 , calcium carbonate 1g / m 2.

[0046] For the cultivation of flue-cured tobacco

[0047] Steps: (1) raising seedlings; (2) transplanting; transplanting into the soil, using a single ridge planting; (3) fertilizing and watering; (4) pest control; (5) topping and wiping; (6) mature picking ;

[0048] Transplanting under the film is adopted, in which, the white shell degradable plastic film is covered on the growth area of the tobacco plant, and the black new degradable plastic film is covered on both sides of the growth area to prevent the growth of weeds.

[0049] The steps of raising seedlings, transplanting, fertilizing and watering, controlling diseases and insect pests, topping and wiping branches, and mature picking are carried out according to the general agricultural work.

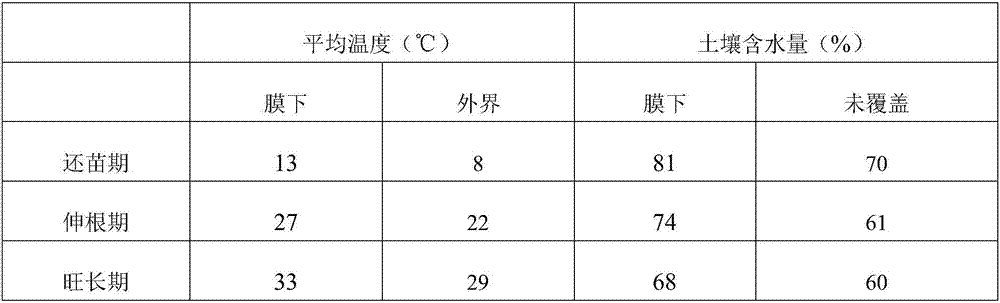

[0050] The heat preservation and water retention effects are tested in the following table:

[0051]

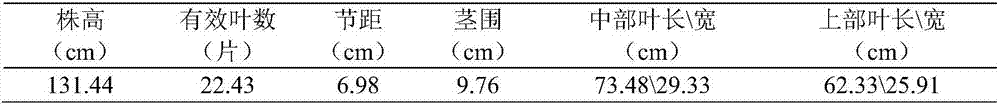

[0052]...

Embodiment 2

[0059] Polypropylene 10g / m 2 , coated with flexible polymer cement-based waterproof coating 4g / m 2 , calcium carbonate 3g / m 2 .

[0060] For growing strawberries

[0061] Covering time: after strawberry planting in autumn

[0062] Before mulching, apply some nitrogen, phosphorus, and potassium compound fertilizers, and remove dead branches and leaves. When covering the film, it should be selected in calm weather, and the plastic film should be spread on the strawberry plants in a straight line, so that the film surface is stretched without wrinkling, and the soil around the film is tightly covered. If the furrow surface is too long, it can be pressed horizontally at a certain distance to prevent the film from being blown up by the wind and broken. In cold regions, another layer of straw or wheat orange can be covered to play the role of thermal insulation film.

[0063] Membrane rupture and removal: After the soil thaws in spring, first remove the anti-cold material on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com