Antiskid floor board and manufacturing method thereof

A floor and anti-slip film technology, applied in chemical instruments and methods, building structure, lamination and other directions, can solve the problems of easy to cause personnel slides, lack of anti-skid, inconvenient disassembly of plastic floors, etc., and is not easy to deform. and sliding phenomenon, simple manufacturing method, convenient laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

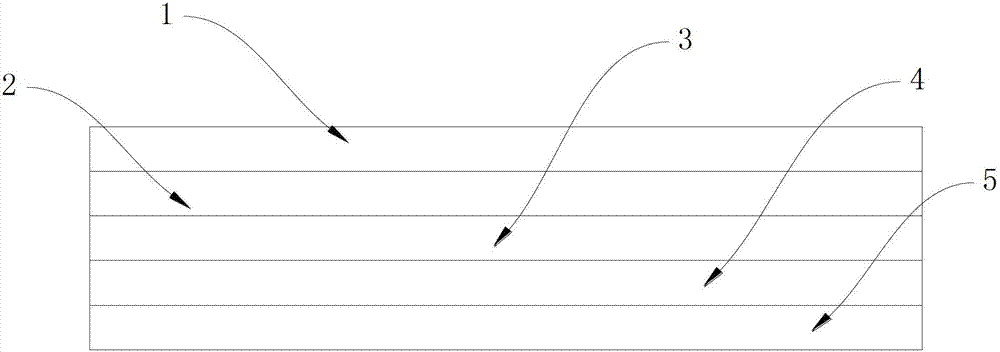

[0012] Such as figure 1 As shown, the non-slip floor described in this embodiment includes a wear-resistant layer 1, a printed color film layer 2, a middle PVC material layer 3, a lower PVC material layer 4 and an anti-slip film layer 5 from top to bottom. The bottom of the anti-skid layer 5 is provided with protrusions, which are used to increase the surface friction and increase the anti-skid strength; the middle layer PVC material layer 3 is made of PVC, calcium carbonate, DOTP plasticizer, wherein PVC is 21%, calcium carbonate It is 67%, DOTP plasticizer is 12%.

[0013] Manufacturing method: the first step is to produce the middle layer of PVC material layer 3 and the lower layer of PVC material layer 4, and put the raw materials into the kneading and kneading equipment for processing and molding, and the processing temperature is 160°C; the second step is to put the wear-resistant layer 1, printing The color film layer 2, the middle PVC material layer 3, the lower PVC m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com