Patents

Literature

52 results about "Soda pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soda pulping is a chemical process for making wood pulp with sodium hydroxide as the cooking chemical. In the Soda-AQ process, anthraquinone (AQ) may be used as a pulping additive to decrease the carbohydrate degradation. The soda process gives pulp with lower tear strength than other chemical pulping processes (sulfite process and kraft process), but has still limited use for easy pulped materials like straw and some hardwoods.

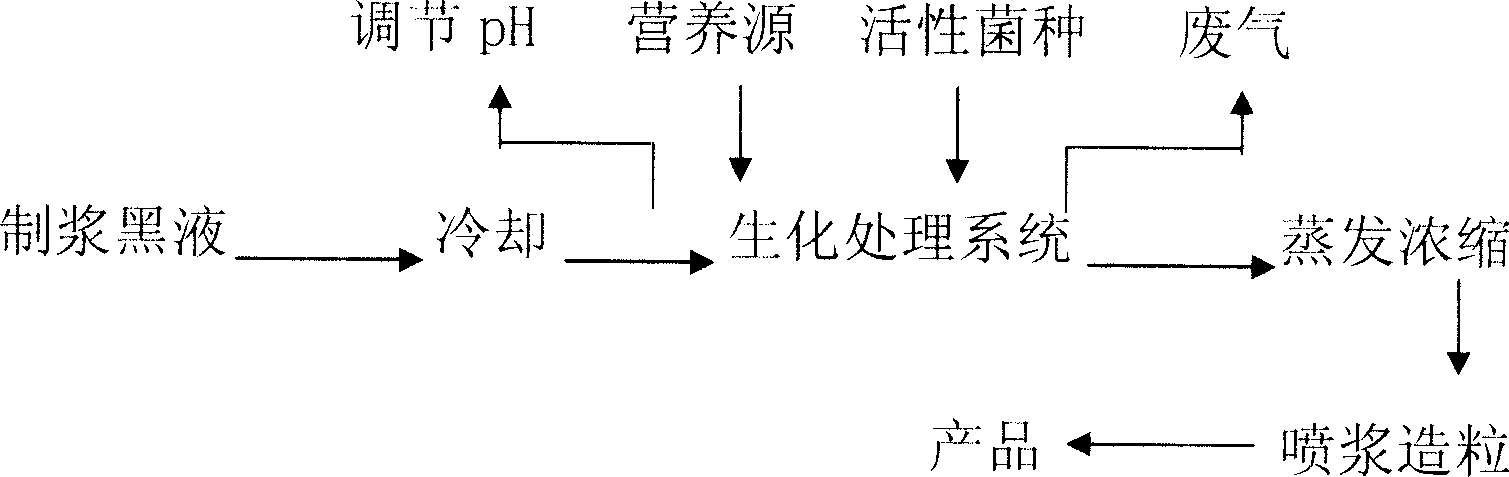

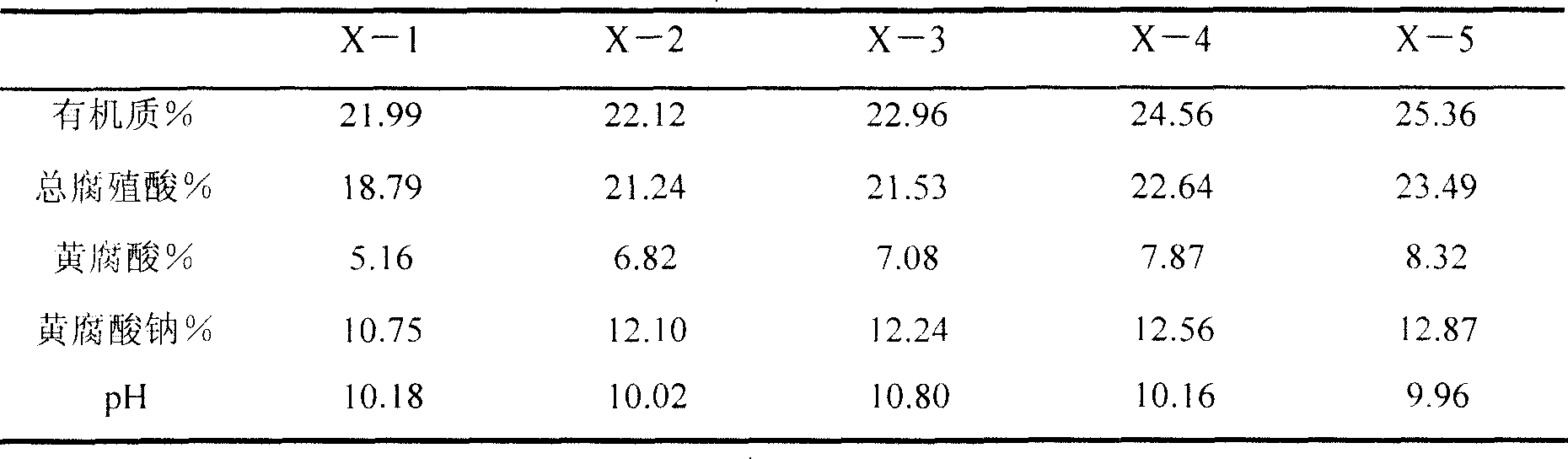

Method for producing fulvic acids fertilizer by using alkaline process black liquor

ActiveCN101209932AImprove liquidityGood for spray granulationBio-organic fraction processingSewage/sludge fertilisersBlack liquorEvaporation

The invention discloses a preparation method and the products of a fulvic acid fertilizer, pertaining to the organic fertilizer field. The organic fertilizer adopts an alkaline pulping black liquid as material, and is made by cooling, biochemical treatment, evaporation and concentration, and guniting and granulation. The manufactured organic fertilizers have high fulvic acid content, apparent soil improvement and fertility functions, and comprehensive and uniform nutritional components of the organic fertilizer, and have dramatic effects on improving the quality of crops and yield capacity, long fertilizer effect time, strong late effect, no pollution, and the drought resistance, disease resistance and insect resistance can be enhanced after the organic fertilizer is used.

Owner:吉林泉德秸秆综合利用有限公司

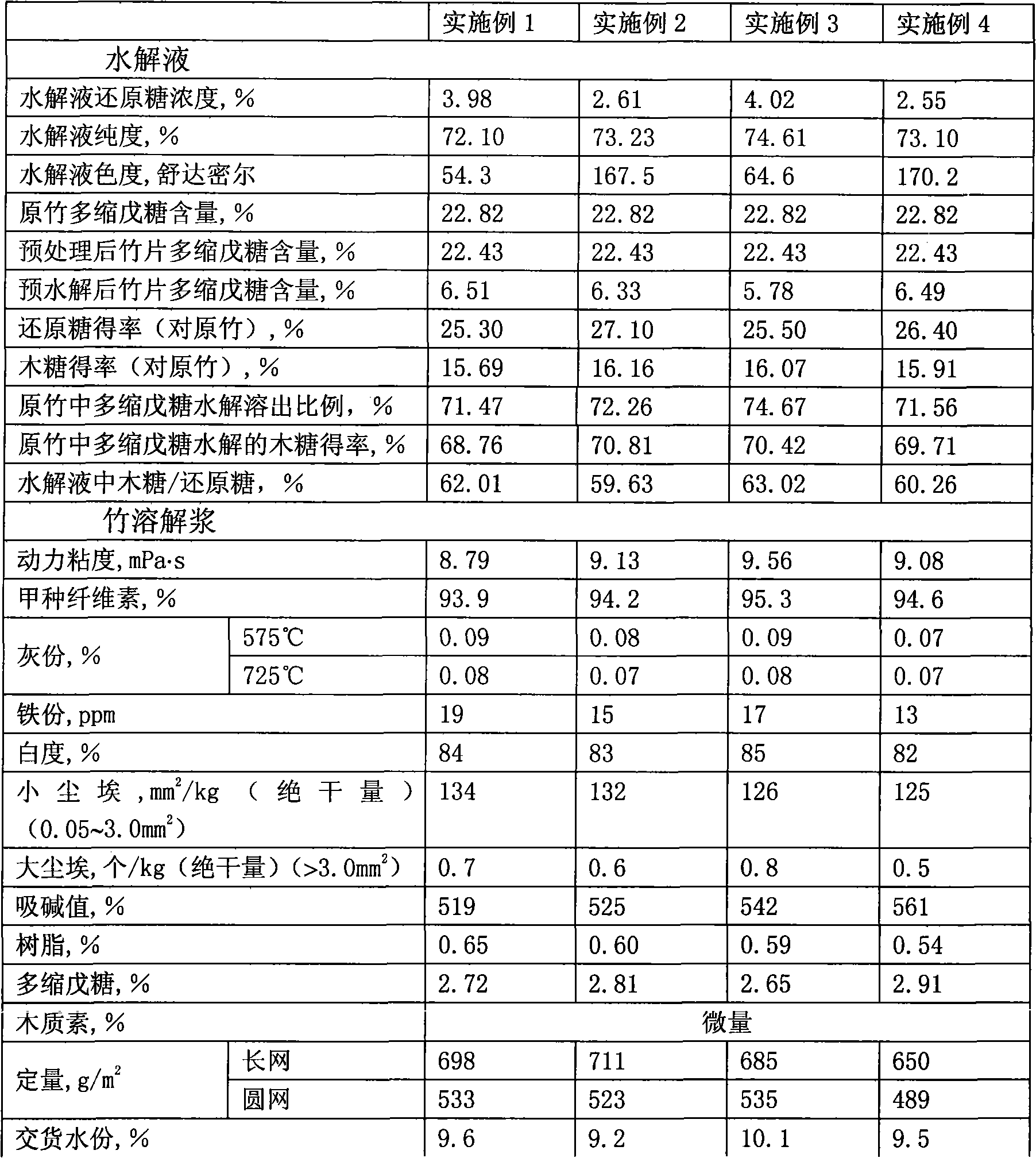

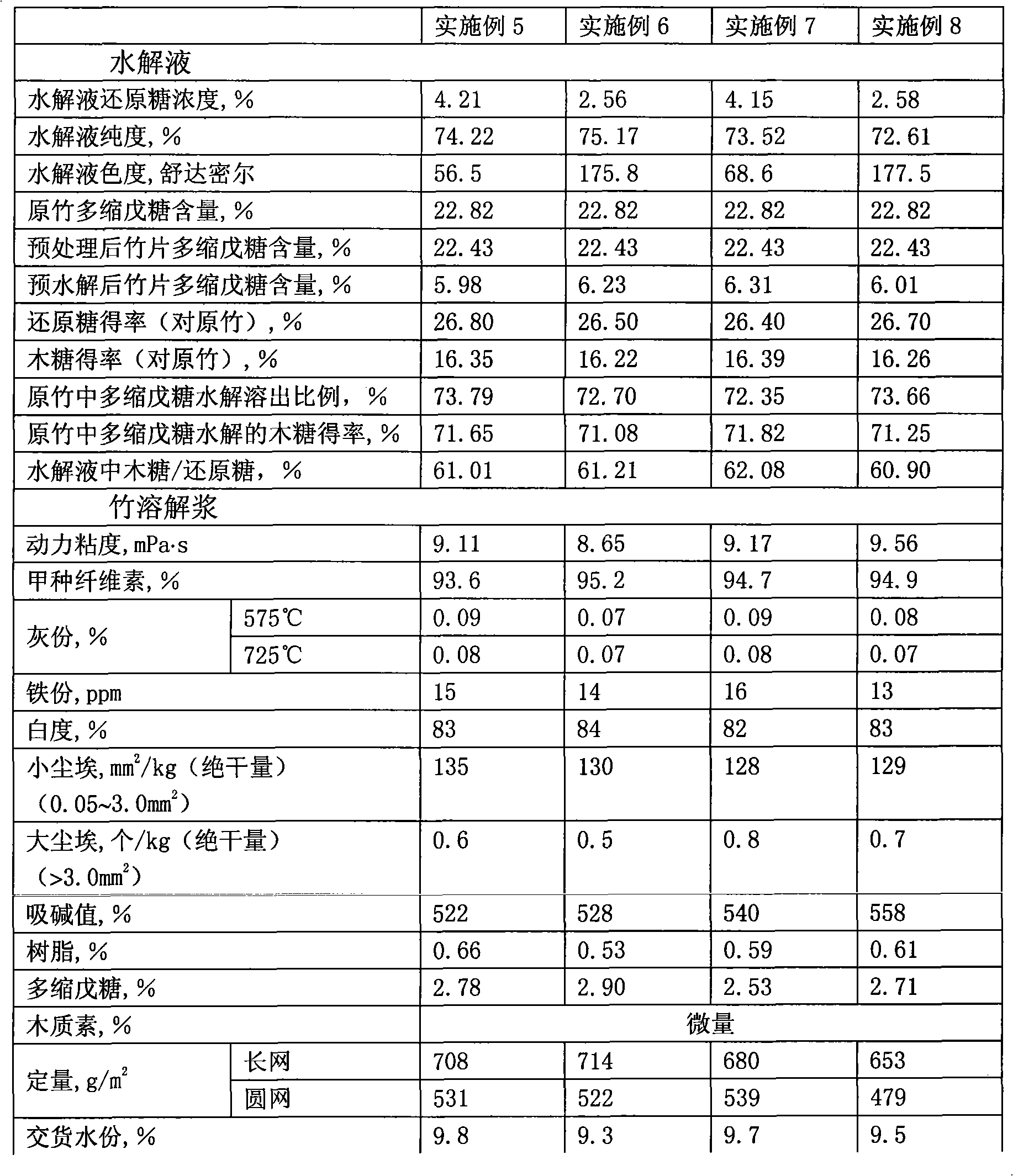

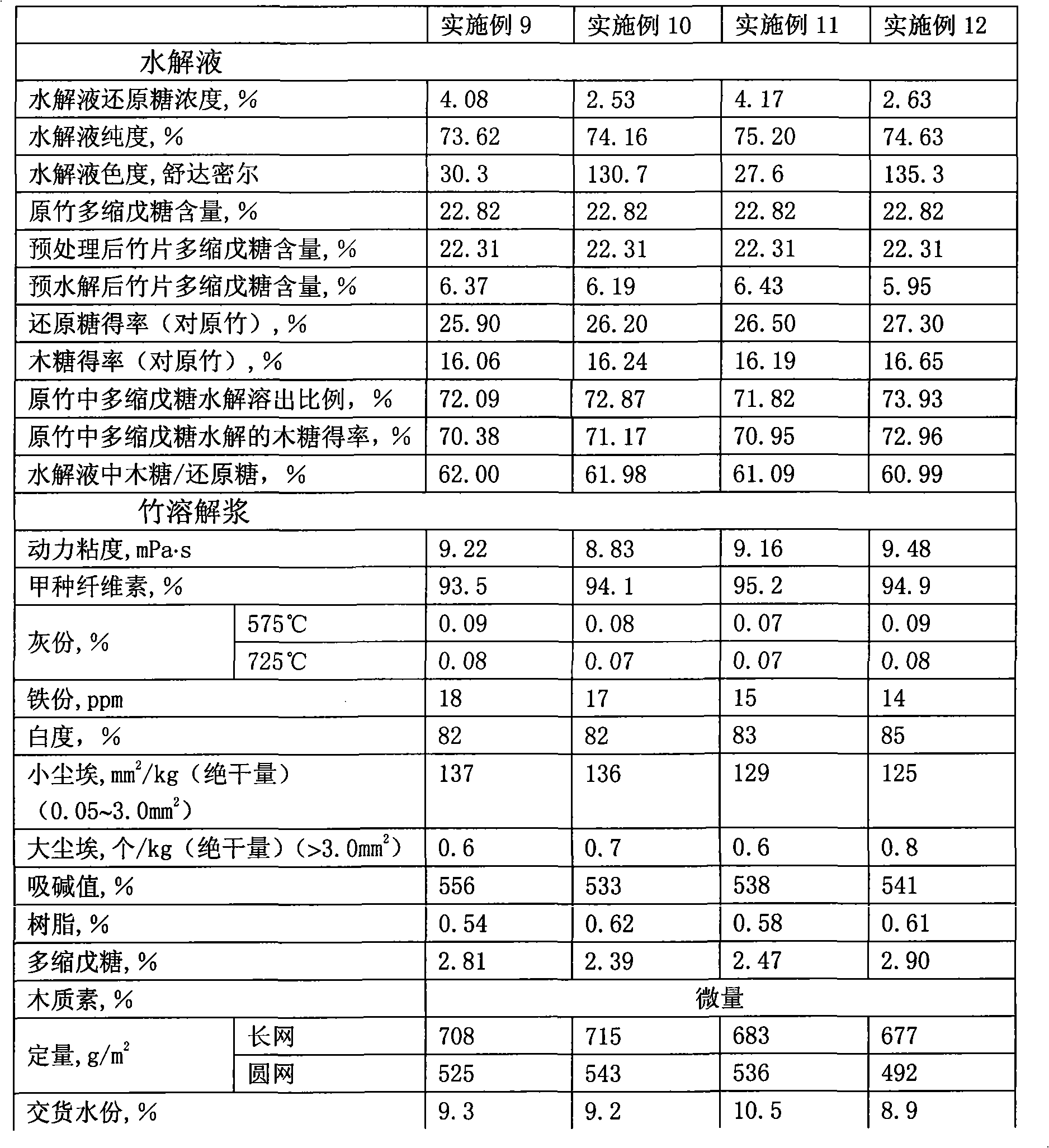

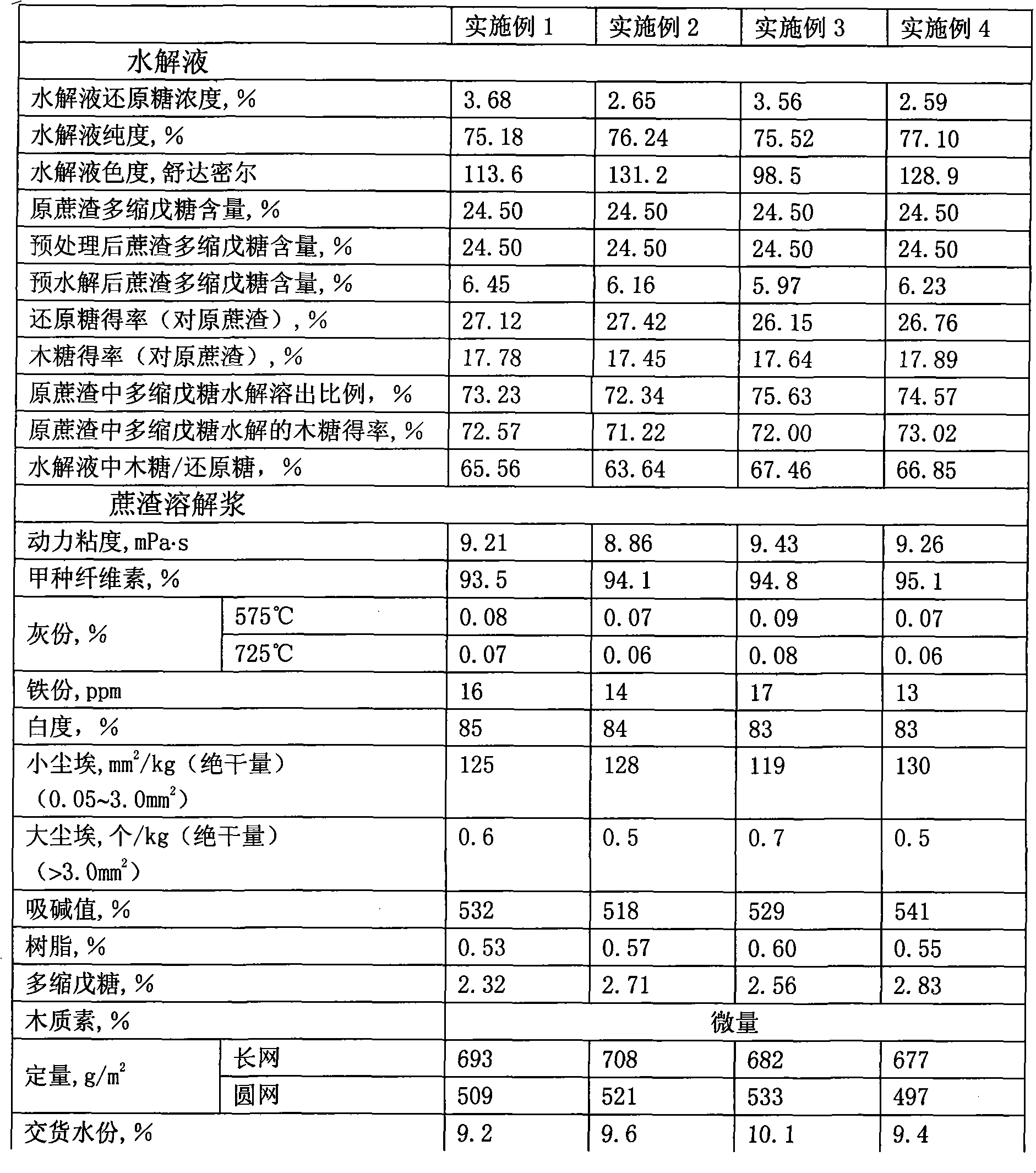

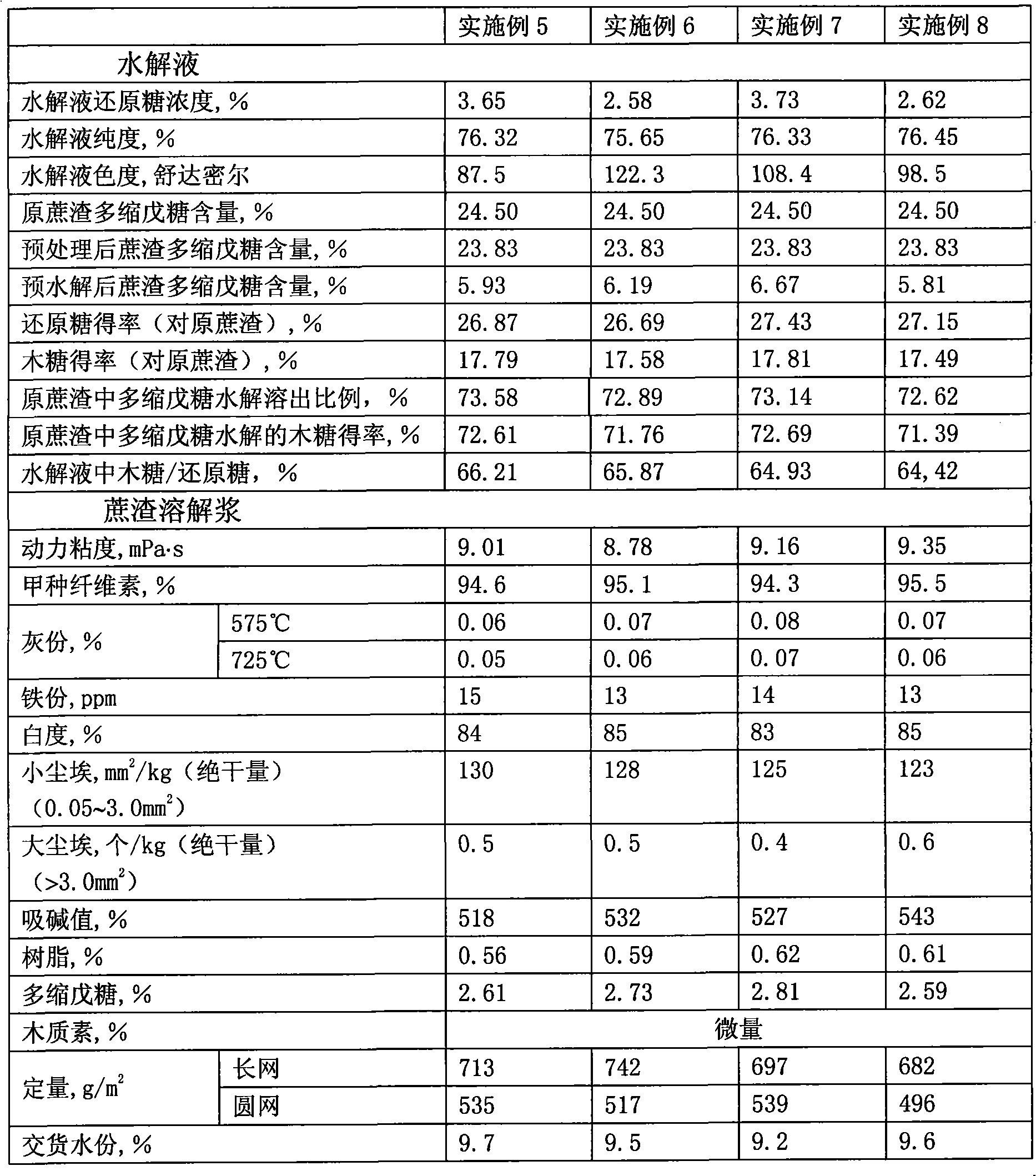

Method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process and product thereof

InactiveCN101514529AReasonable range of hydrolyzed reducing sugar concentrationReasonable range of purityPretreatment with acid reacting compoundsPulping with inorganic basesHydrolysatePerformance index

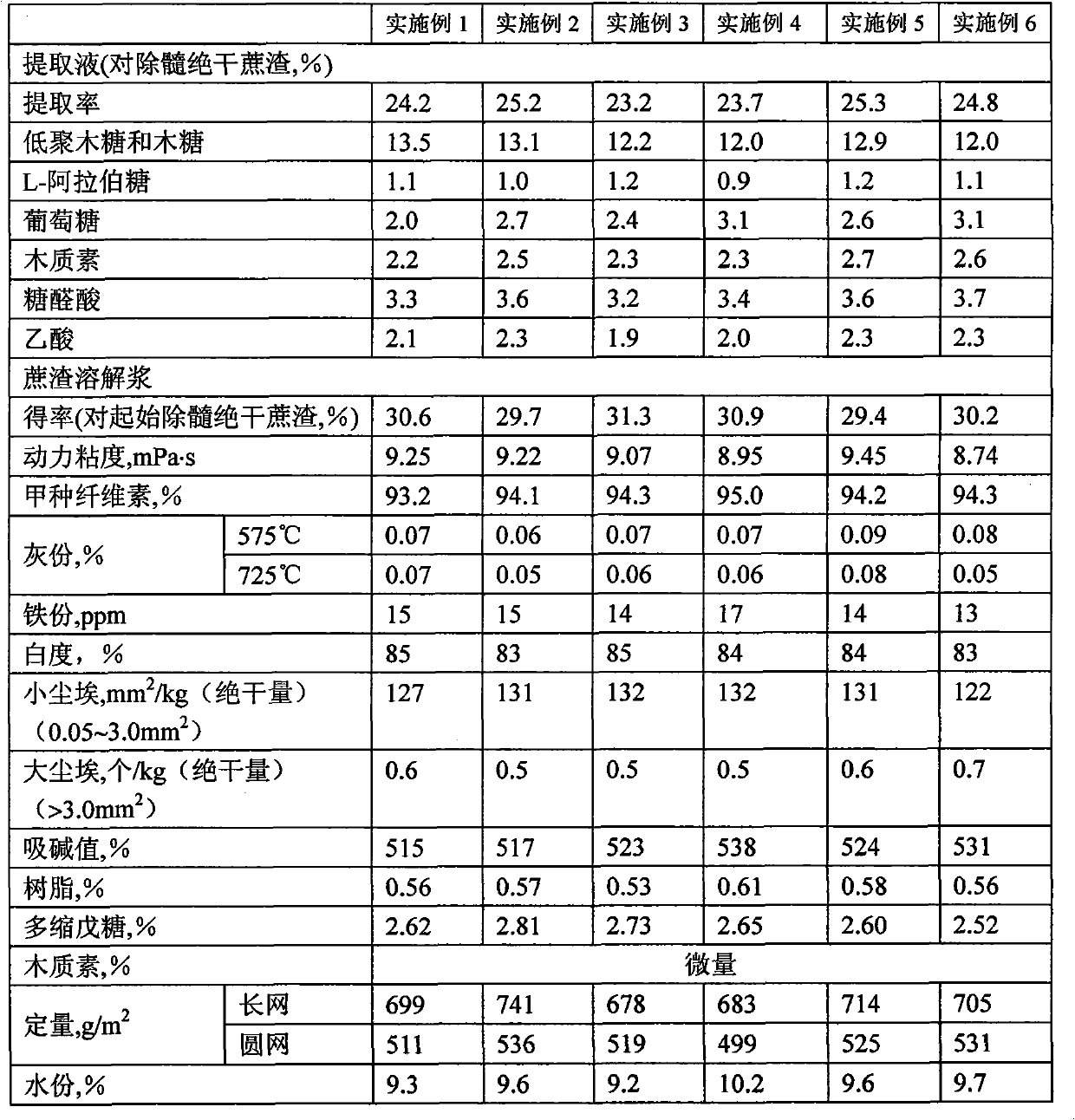

The invention relates to a method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process, which comprises the following steps of: bamboo material preparation, in which bamboo is made into bamboo sheets and bamboo threads, the bamboo sheets and threads are washed to remove impurities and dust; pretreatment, which is for removing more organic and nonorganic impurities, and in which the loss of pentosan is less than 2 percent; prehydrolysis, which is carried out at an acid concentration of sulphuric acid and hydrochloric acid of 0.1 to 10.0 weight percent, a temperature of between 80 and 14 DEG C and a liquor ratio of 1:4-15 for 30 to 400 minutes; and alkaline process. The method has the advantages that: the performance index of the bamboo dissolving pulp meets the requirements of viscose fibre pulp and the like; the improved prehydrolysis process allows the major part of pentosan in the bamboo to be hydrolyzed; the hydrolysate can be used as a raw material for xylose, xylitol, L-Arabinitol, ethanol and other products; the improved prehydrolysis process lays a good foundation for cooking and improving the reaction performance of the dissolving pulp; little production cost is added, the treatment load and cost of waste are reduced with the recovery of the products of the prehydrolysis, and the comprehensive cost is the lowest; and the comprehensive utilization of the components of biomass is realized during the pulping process of the dissolving pump.

Owner:上海士林纤维材料有限公司

Non-wood raw material clean pulping method

InactiveCN103243597AHigh whitenessAchieve recyclingPulp bleachingPulp beating/refining methodsChemistryPre treatment

The invention provides a non-wood raw material clean pulping method. Main agents used in the invention comprise a bio-enzyme, an alkaline salt, a surfactant-1, a surfactant-2, an oxidant and the like. The non-wood raw material pulping method comprises a step 1 of raw material pretreatment, a step 2 of kneading devillicate, a step 3 of pulping dipping, a step 4 of defibering pulping; a step 5 of pulp refining, a step 6 of enhanced bleaching, a step 7 of screening, and a step 8 of wastewater reuse, wherein the above pulping agents are used in the step 1 and the step 3. The pulping agents provided in the invention are utilized to pulp non-wood raw materials, and the non-wood raw materials mainly comprise cotton stalks, Caragana microphylla, Salix cheilophila, bamboos, reeds and the like. Compared with traditional alkaline pulping methods, the pulping method provided by the invention has the advantages of substantial yield increase, great whiteness increase, realization of recycling the pulping agents, reduction of the consumption of chemical agents, and reduction of the environmental pollution.

Owner:王新军

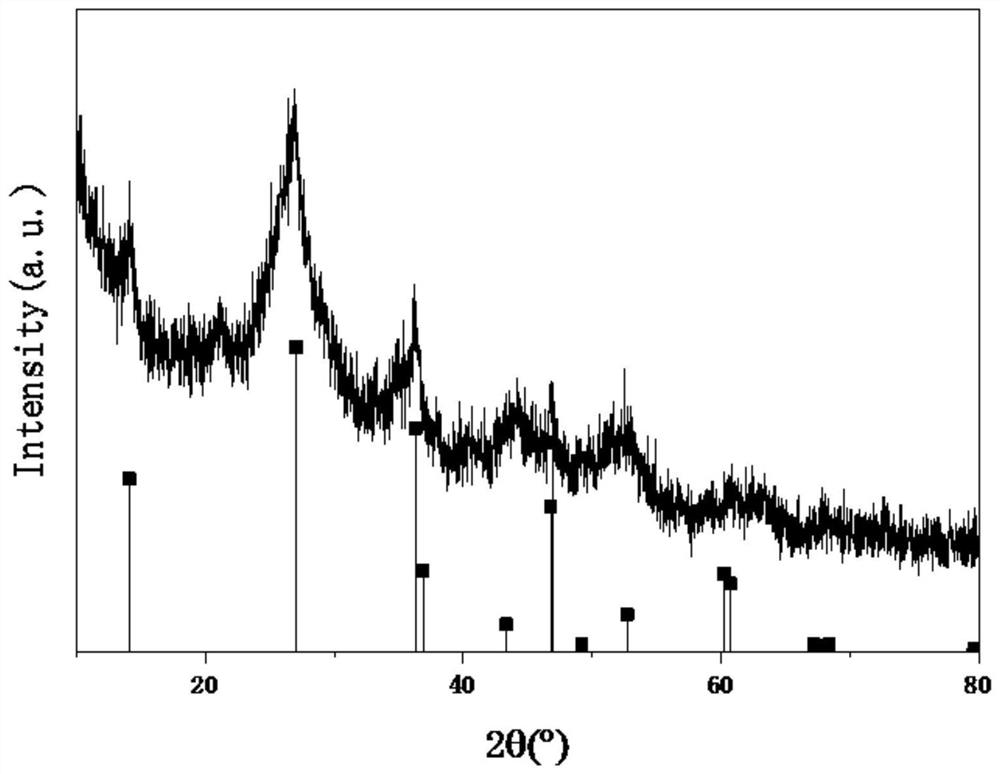

Method for producing calcium carbonate

InactiveUS20030049194A1Promote precipitationReduce the ratioCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

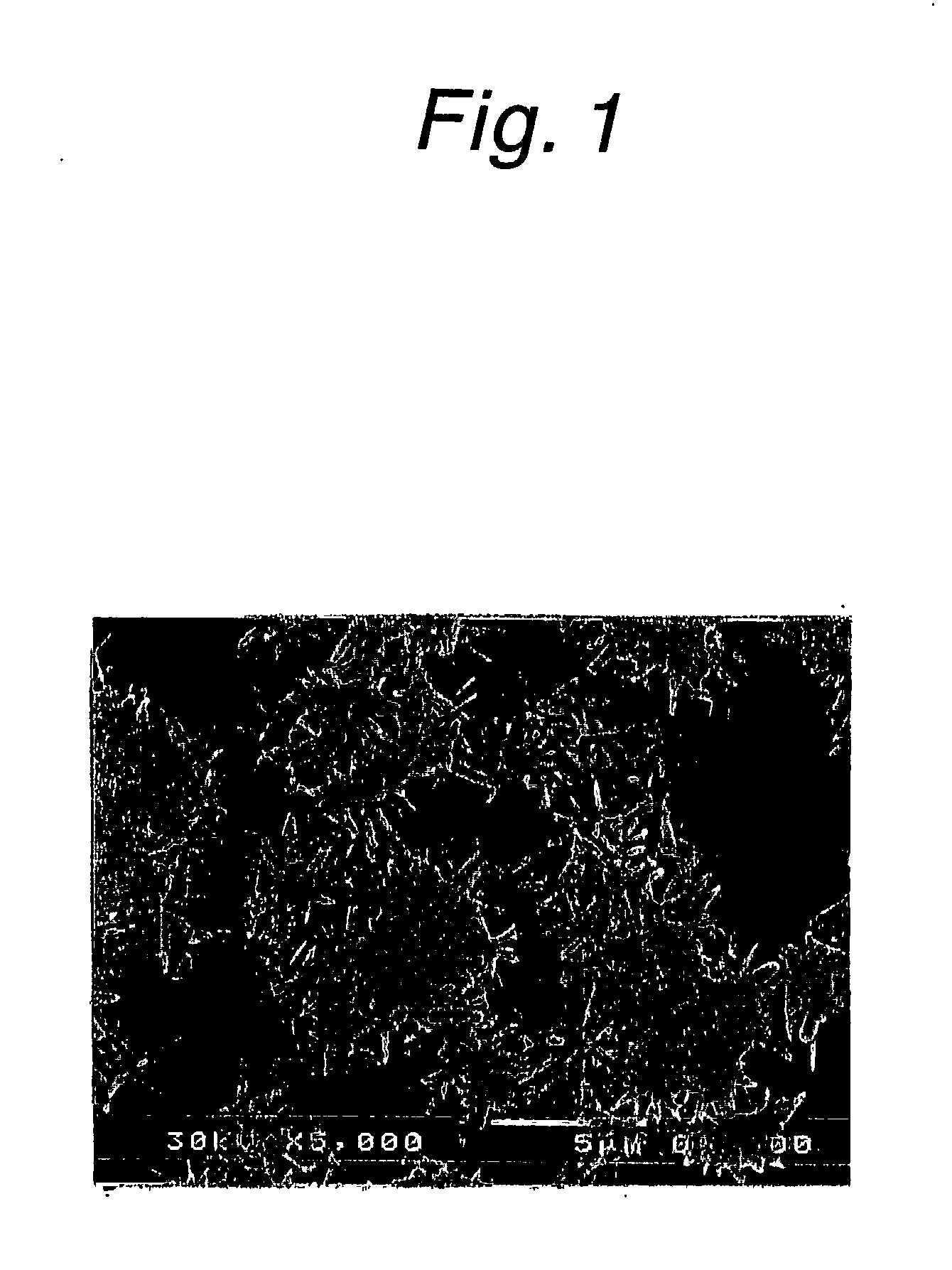

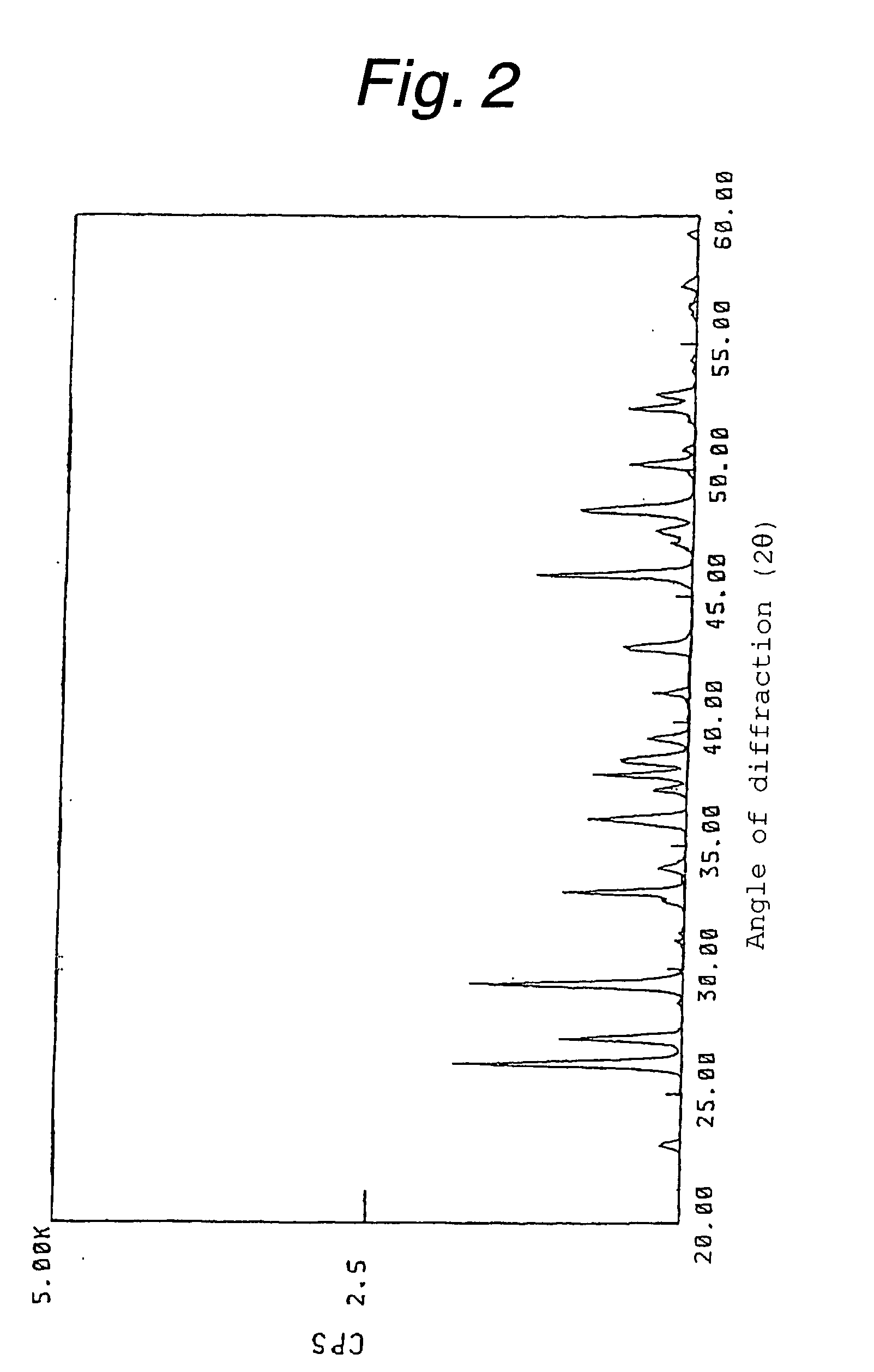

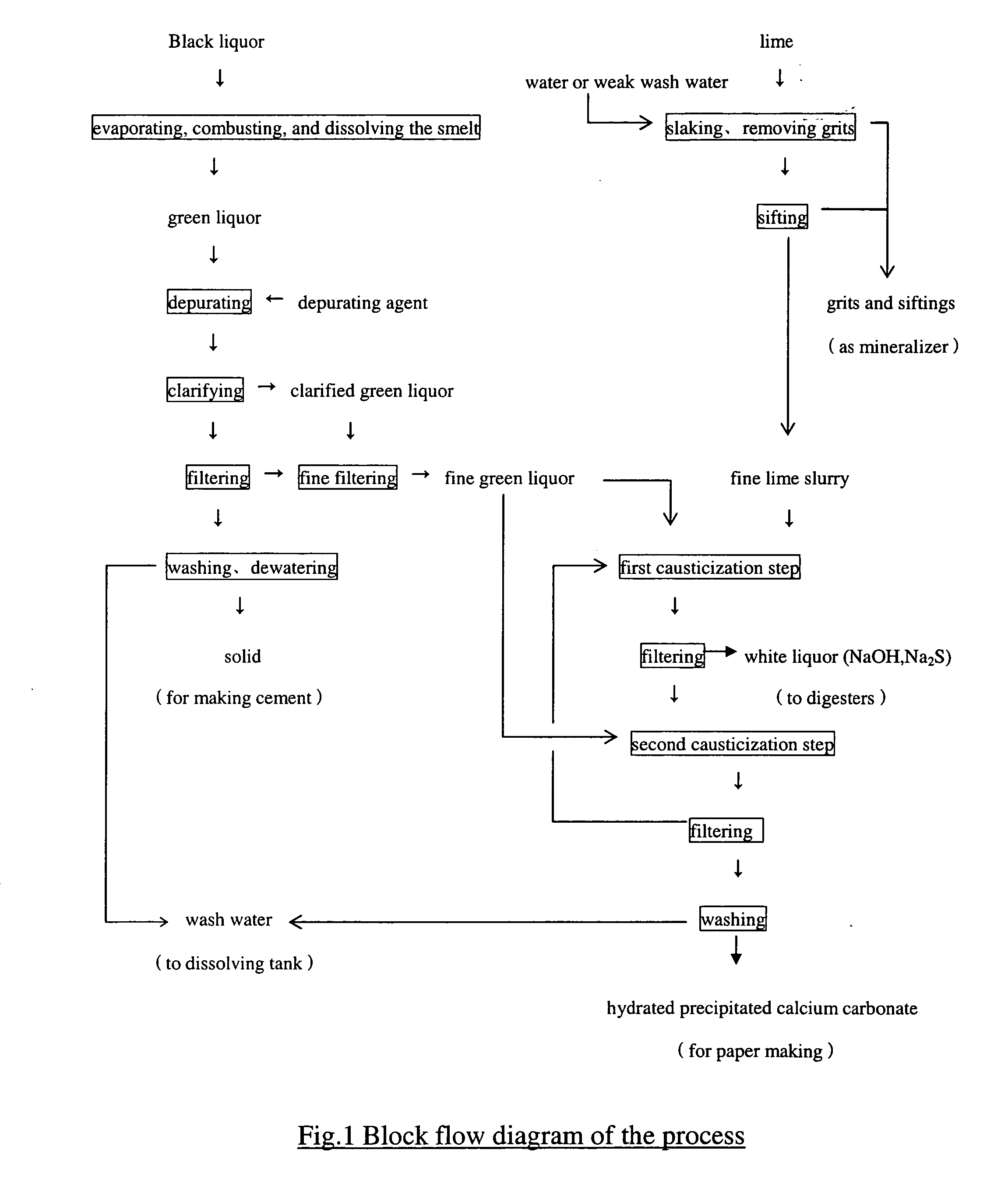

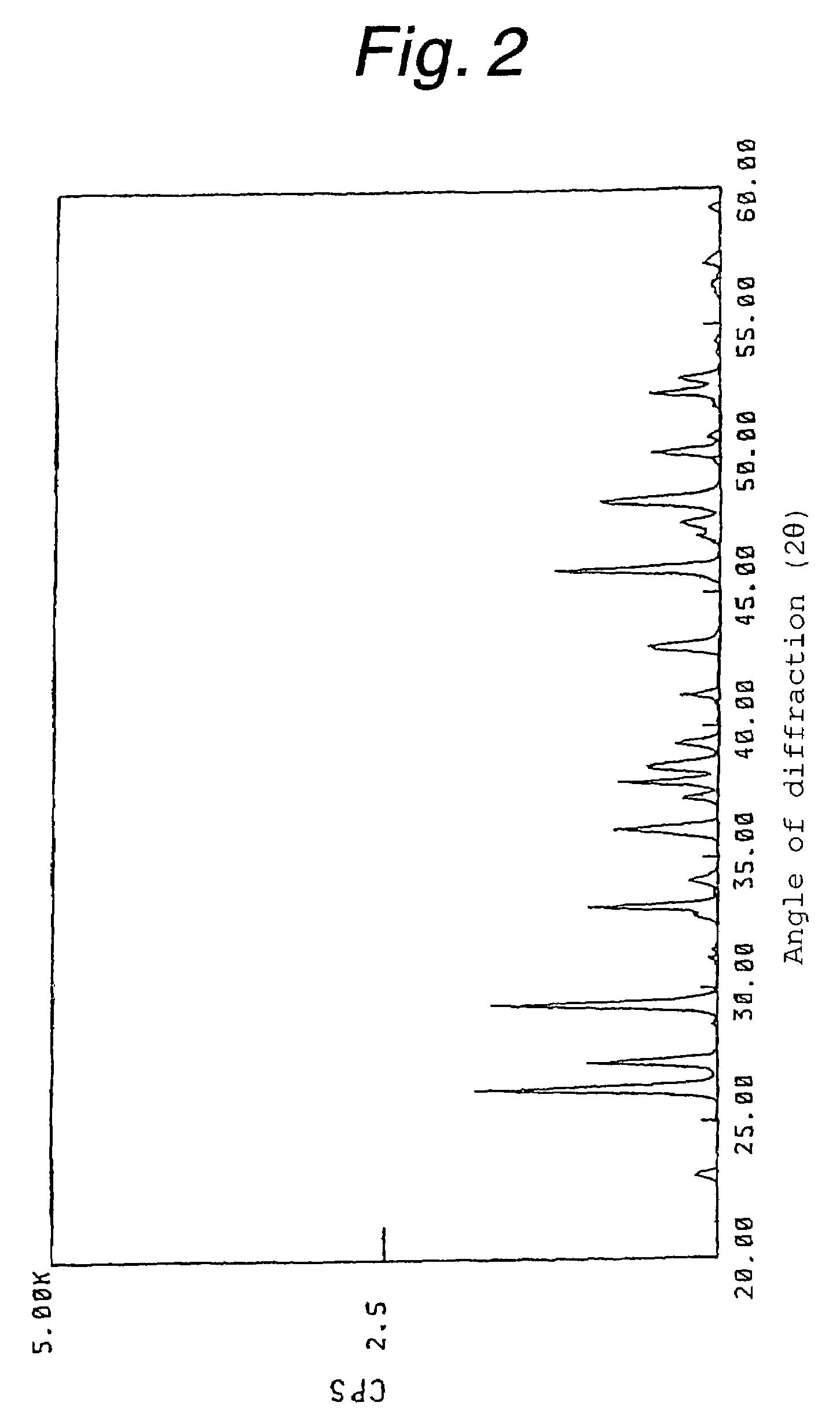

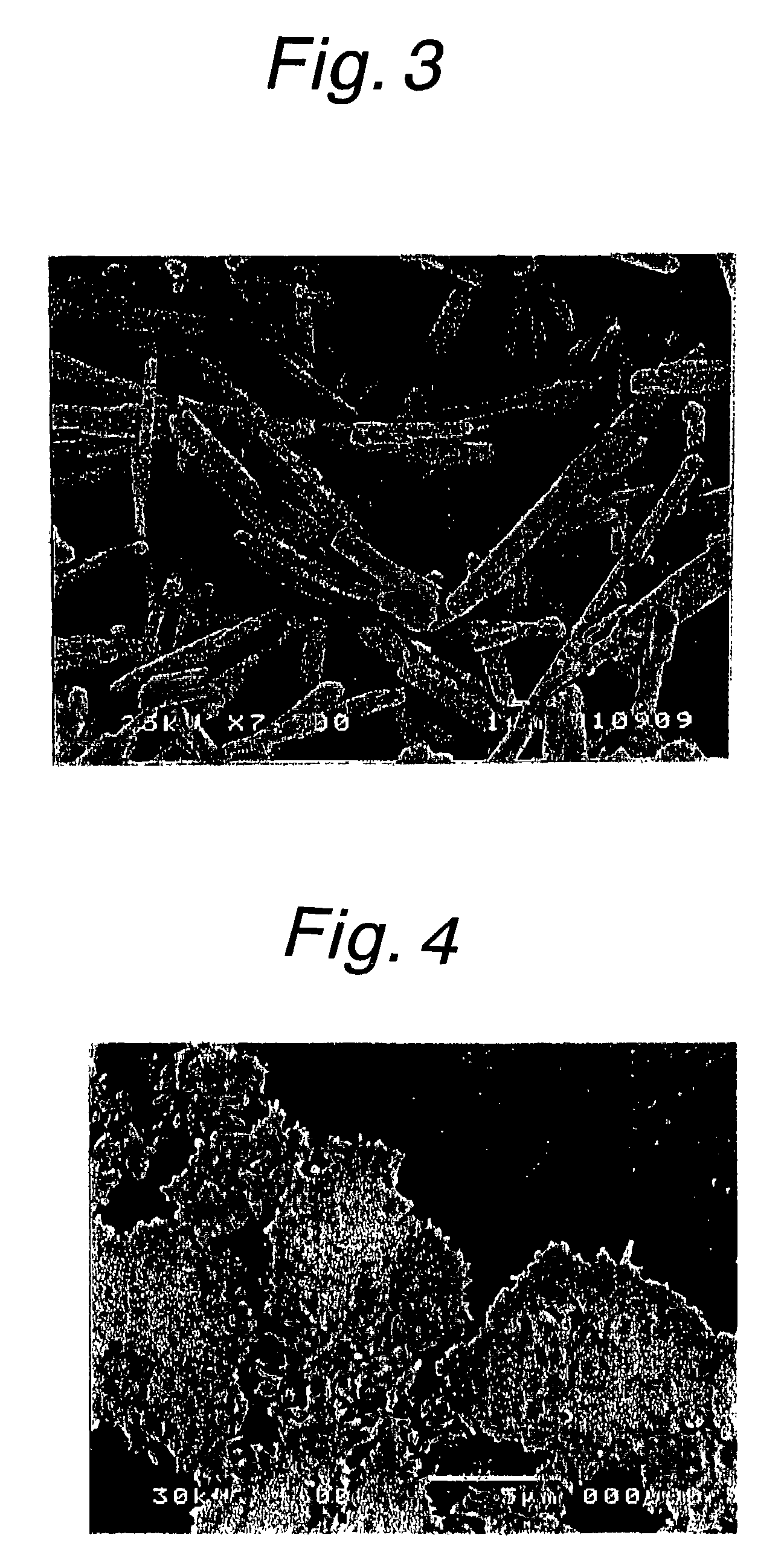

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1-60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002-0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30-105° C.

Owner:NIPPON PAPER IND CO LTD

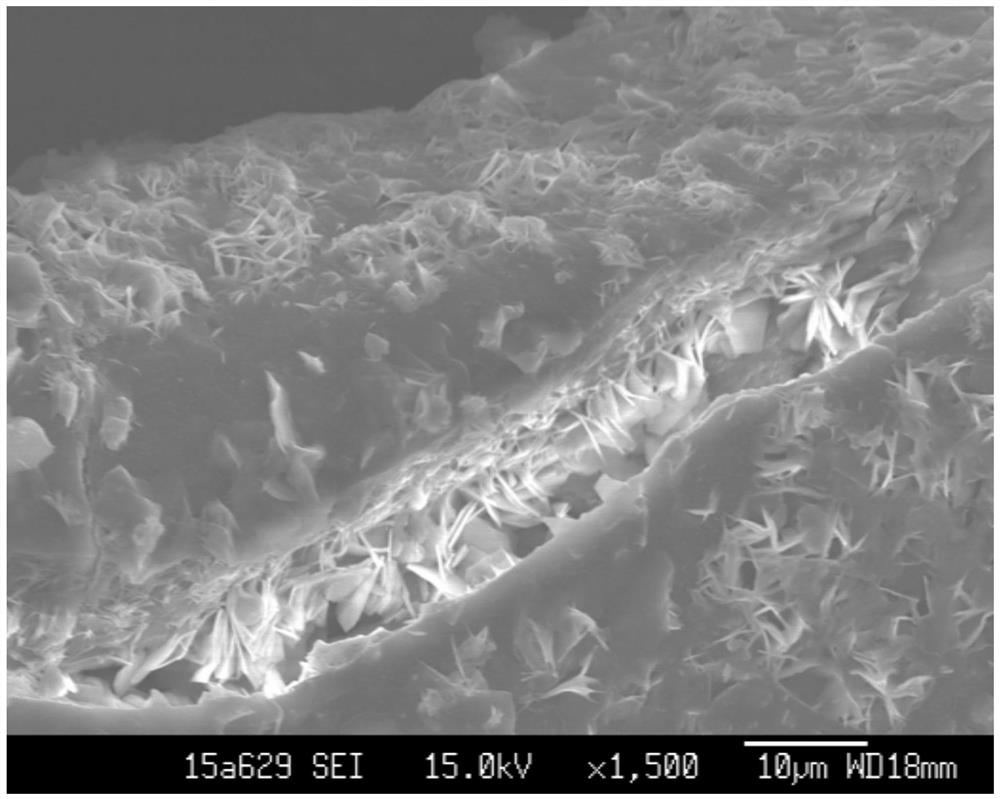

Process of recovering alkali from black liquor of papermaking

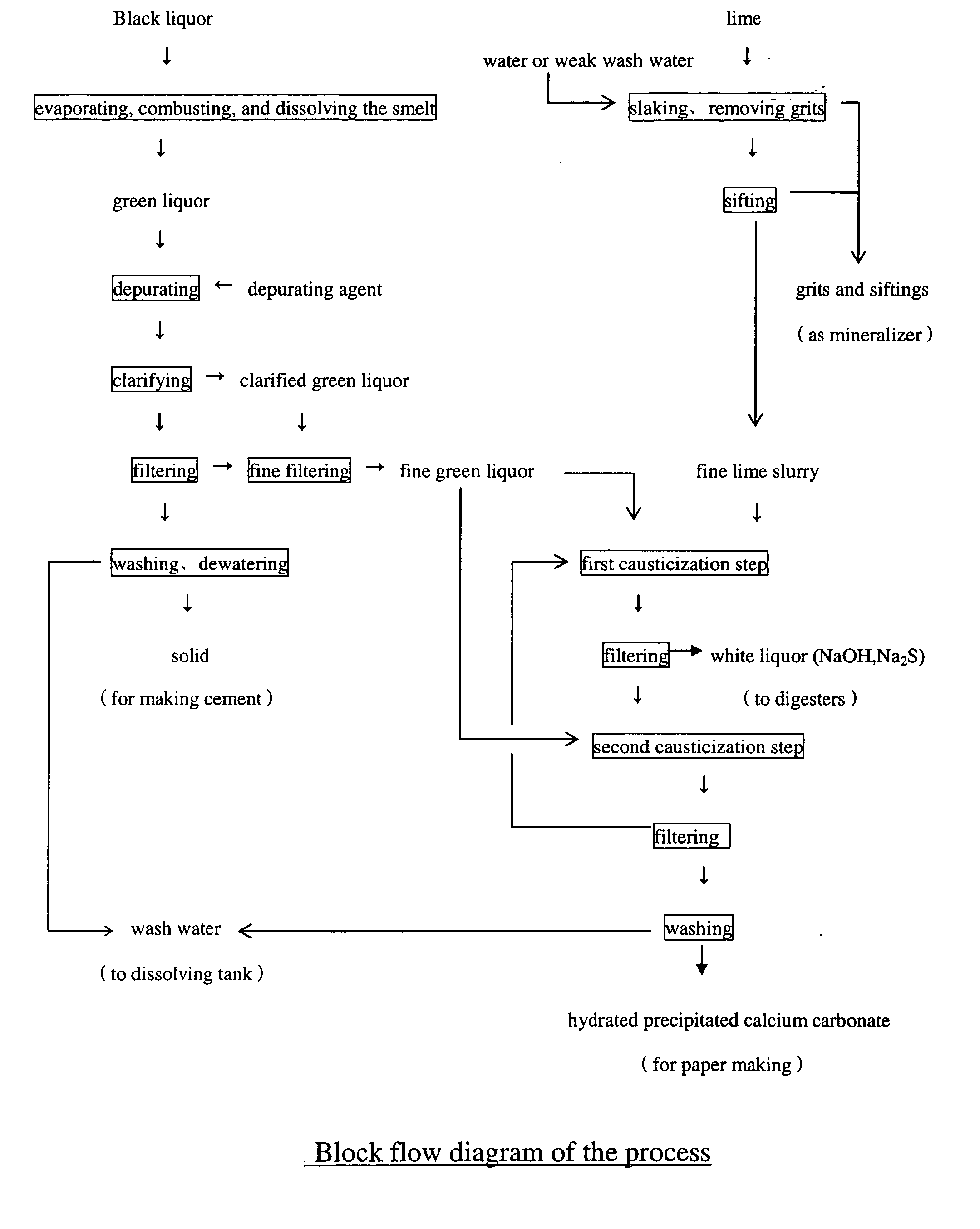

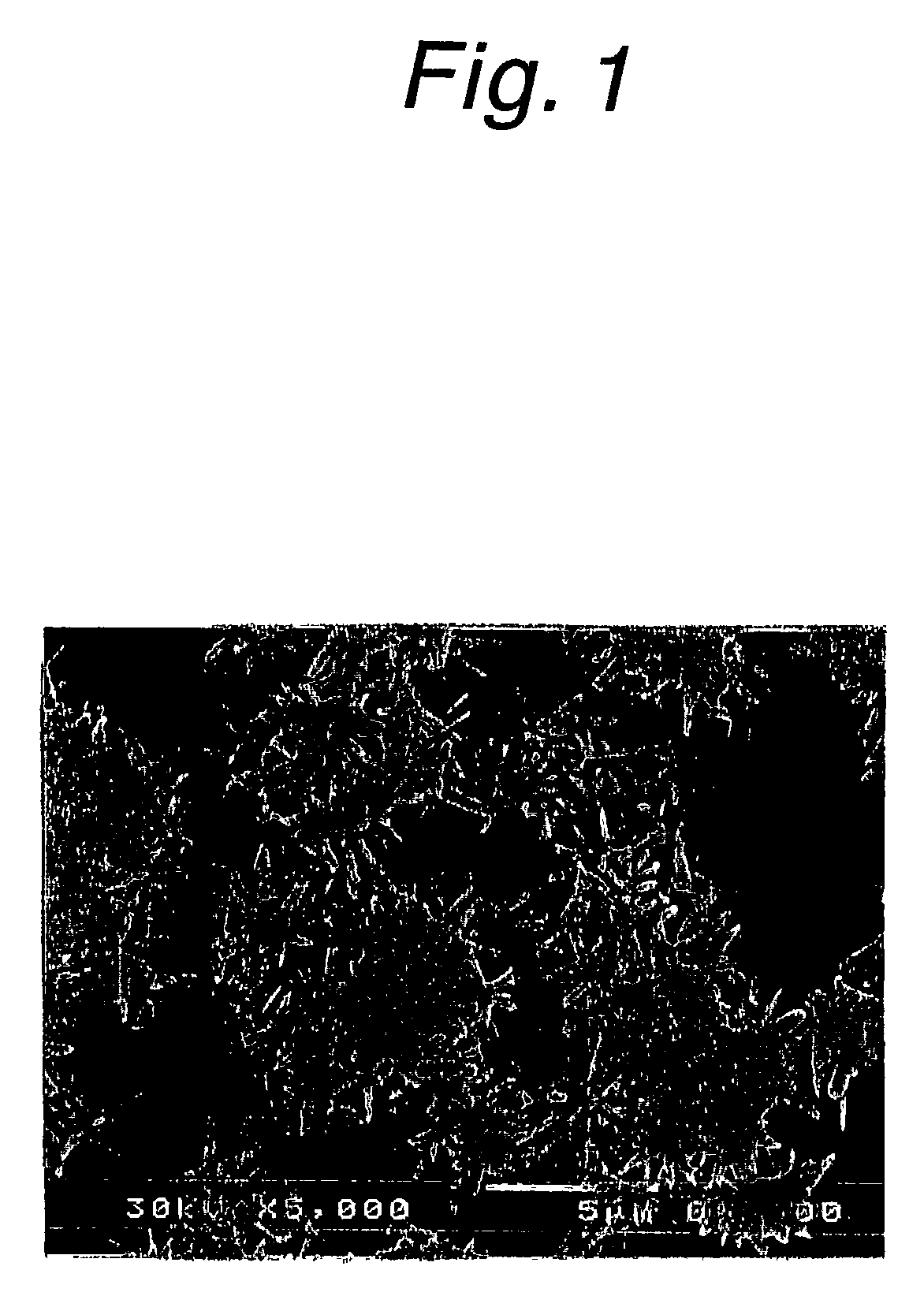

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

Method for producing calcium carbonate

InactiveUS7097819B2Proportion of aragonite crystals tends to be loweredPromote precipitationCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1–60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002–0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30–105° C.

Owner:NIPPON PAPER IND CO LTD

Process for preparing white mud calcium carbonate from green liquor recovered from wood pulp sulfate-method pulping alkali

InactiveCN102659161AHigh whitenessSimple processCalcium/strontium/barium carbonatesRegeneration of alkali lyeBlack liquorSulfide

The invention relates to the field of recovering black liquor in alkaline method pulping in the technical field of pulping and papermaking, in particular to a process for preparing white mud calcium carbonate from green liquor recovered from wood pulp sulfate-method pulping alkali. The process comprises the following steps of: (1) purifying the green liquor; (2) purifying calcined lime; (3) pre-causticizing the green liquor; and (4) causticizing the green liquor. According to the process, most of divalent ferrum ions in the green liquor are masked by adding an aid, trivalent ferrum ions in the calcined lime are masked by purifying the calcined lime, reaction of the trivalent ferrum ions in the calcined lime and the divalent ferrum ions in the green liquor is inhibited, and the generation quantity of hydroxides or sulfides of divalent ferrum in the causticizing process is reduced, so that the high-whiteness white mud calcium carbonate is obtained. The green liquor recovered from the wood pulp sulfate-method pulping alkali is treated by the process, a process flow is simple, and used chemicals are clean and environment-friendly.

Owner:QILU UNIV OF TECH

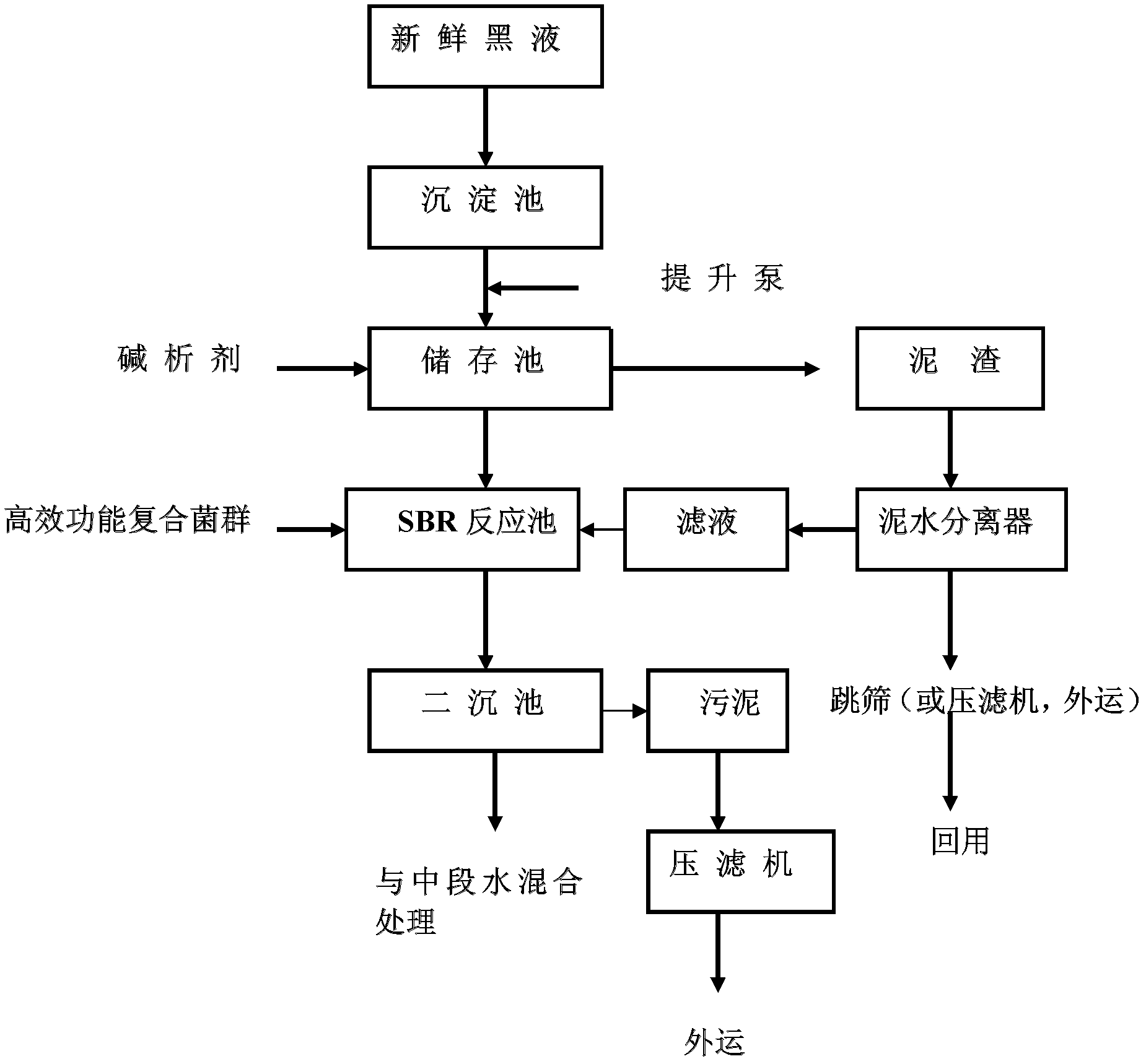

Treatment method of papermaking black liquor

The invention relates to a treatment method which is suitable for papermaking black liquor (in particular to alkaline pulping papermaking black liquor which takes wheat straw hood as raw material). The treatment method comprises the following steps of: firstly performing standing treatment on the fresh black liquor, adding a high-efficient alkaline separation agent into the black liquor after treatment, separating out lignin, and further performing biological strengthening technical treatment on filtrate. According to the process disclosed by the invention, after the combined treatment of thestanding treatment, an alkaline separation method and a biological strengthening system is performed on the black liquor with initial COD (chemical oxygen demand) of 83,000mg / l, pH of 13.1 and chromaticity of 225,000CU, the COD and chromaticity of outlet water are respectively reduced to below 15% and 7% of the original black liquor (namely the COD total removal rate and chromaticity total removal rate of the whole system are about 85% and 93% respectively), the outlet water can be mixed with a quite large quantity of middle-stage wastewater in a papermaking factory, and the treatment can be performed according to the existing comparatively mature middle-stage wastewater treatment method. The process has the characteristics of low investment and operation cost and capability of recycling the lignin, and is suitable for wheat straw pulp papermaking factories above 5000 tons.

Owner:CENT SOUTH UNIV

Method for preparing bagasse dissolving pulp by improved prehydrolysis alkaline process and product thereof

InactiveCN101514530AReasonable range of hydrolyzed reducing sugar concentrationReasonable range of purityPretreatment with acid reacting compoundsPulping with inorganic basesHydrolysatePerformance index

The invention relates to a method for preparing bagasse dissolving pulp by improved prehydrolysis alkaline process, which comprises the following steps of: bagasse preparation, in which bagasse is subjected to depithing and washing; prehydrolysis, which is carried out in a hydrolyzer or a hydrolysis tank in the presence of a hydrolysis catalyst of sulphuric acid or hydrochloric acid at an acid concentration of 0.1 to 10.0 weight percent, a temperature of between 80 and 140 DEG C and a liquor ratio of 1:4-15 for 30 to 400 minutes; and alkaline process. The method has the advantages that: the performance index of the bagasse dissolving pulp meets the requirements of viscose fibre pulp and the like; the improved prehydrolysis process allows the major part of pentosan in the bagasse to be hydrolyzed; the hydrolysate can be used as a raw material for xylose, xylitol, L-Arabinitol, ethanol and other products; the improved prehydrolysis process lays a good foundation for cooking and improving the reaction performance of the dissolving pulp; little production cost is added, the treatment load and cost of waste are reduced with the recovery of the products of the prehydrolysis, and the comprehensive cost is the lowest; and the comprehensive utilization of the components of biomass is realized during the pulping process of the dissolving pump.

Owner:上海士林纤维材料有限公司

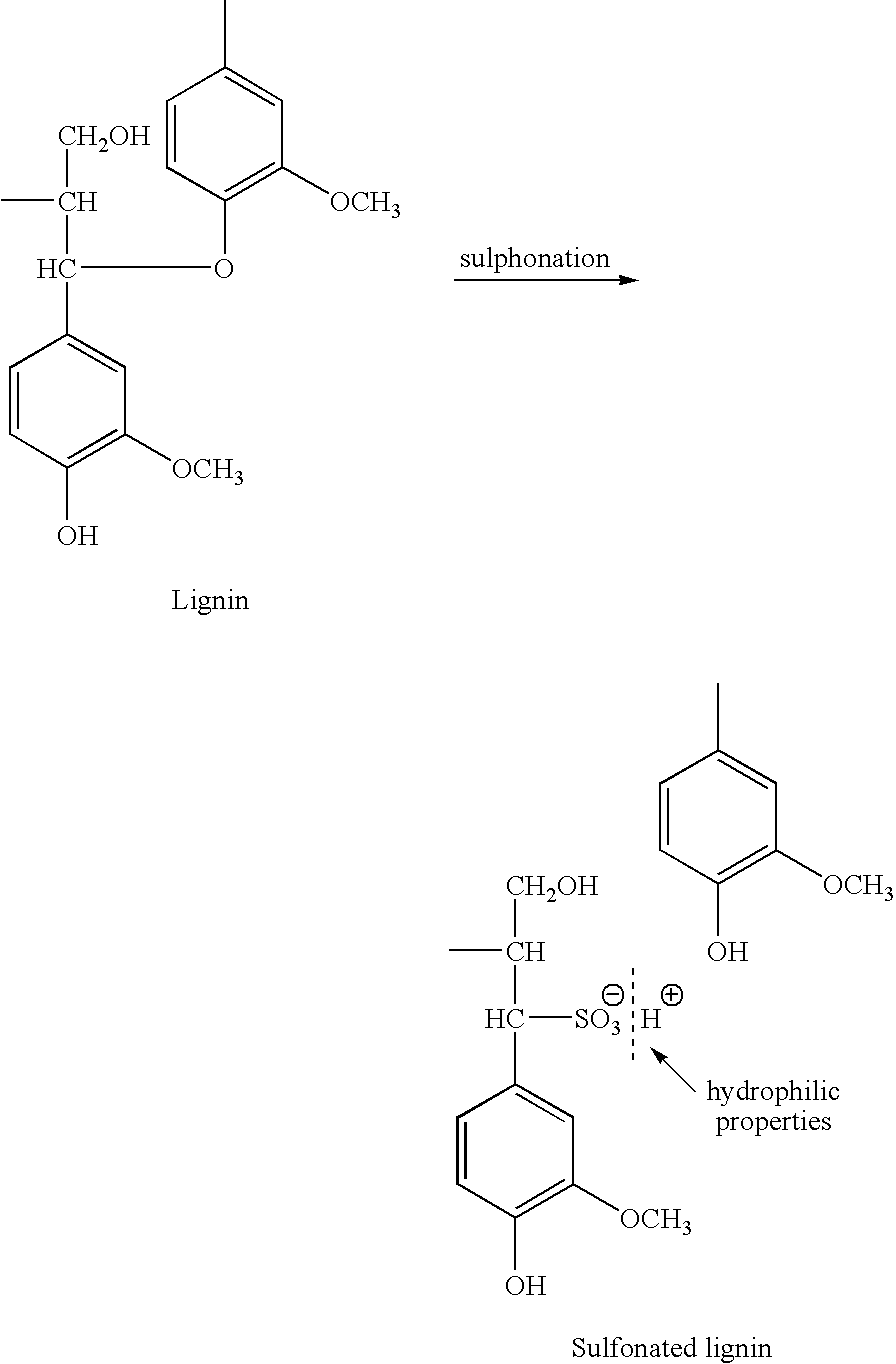

Preparation method of low-contamination lignosulfonate

The invention discloses a preparation method of low-contamination lignosulfonate. The method comprises the steps as follows: after precipitating slurrying waste liquor for 0.5-2 h, removing water insoluble matter and cellulose impurities by a filter; condensing the slurrying waste liquor by membrane filter equipment to increase the concentration of the slurrying waste liquor from 8wt%-15wt% to 15wt%-30wt%; putting a sulfonating agent accounting for 5wt%-40wt% of concentrated liquor and a condensing agent accounting for 5wt%-40wt% of concentrated liquor once, conducting a reaction at 70-100 DEGC for 1-6 h, and performing sulfonation and polycondensation on the concentrated liquor; adding 0-10wt% of a reaction reagent to the concentrated liquor after sulfonation and polycondensation reaction, and conducting a reaction at 40-80 DEG C for 1-5 h; performing spray drying by a hot blast stove reaction solution to obtain lignosulfonate powder with finer particles. The invention also relates to lignosulfonate prepared with the preparation method. The low-contamination lignosulfonate is prepared from the slurrying waste liquor, particularly soda process slurrying waste liquor, waste utilization is realized, and the lignosulfonate has high thermal stability, good dispersity and low contamination while environmental pollution is reduced.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Organic fertilizer prepared from papermaking black liquor produced in alkaline pulping process and preparation method of organic fertilizer

InactiveCN109423902AImprove adsorption capacityImprove bindingClimate change adaptationSewage/sludge fertilisersNutrientChemistry

The invention discloses an organic fertilizer. The organic fertilizer is prepared from papermaking black liquor produced in an alkaline pulping process. According to the preparation process of the organic fertilizer, the difficult-to-treat black liquid generated in the pulping process is fully utilized, so that the pollution problem in the pulping process is solved from the source, the environment-friendly chemistry standard is realized, organic matter and inorganic elements in the black liquor are effectively utilized, and the prepared fertilizer meets the national standard. The organic matter content of the pulping black liquor is stable, the requirements of various nutrient elements in the fertilizer can be met, and the utilization rate of the black liquor is high. The prepared fertilizer is high in fertilizer efficiency and balanced in nutrition and is suitable for plant growth, wherein the organic matter contained in the fertilizer can effectively improve physical, chemical and biological characteristics of soil, and the soil can be cured.

Owner:黑龙江如柏科技有限公司

Bleaching method of cotton stalk chemical pulp

ActiveCN1718920AImprove bleaching effectMeet preparation requirementsPulp bleachingPulping with inorganic basesFiberPulp and paper industry

The present invention provides a bleaching method of cotton stalk chemical pulp. The described paper pulp to be bleached is obtained by using cotton stalk as fibre raw material through alkaline process. Before multistage bleaching operation a thermophilic fatty bacillus is added into the paper pulp to make pretreatment, and its added quantity is 5-50g / cu.m, and the bacterial strain number is AS 1.999. The whiteness of bleached pulp can be up to above 78%.

Owner:SHANDONG TRALIN PAPER

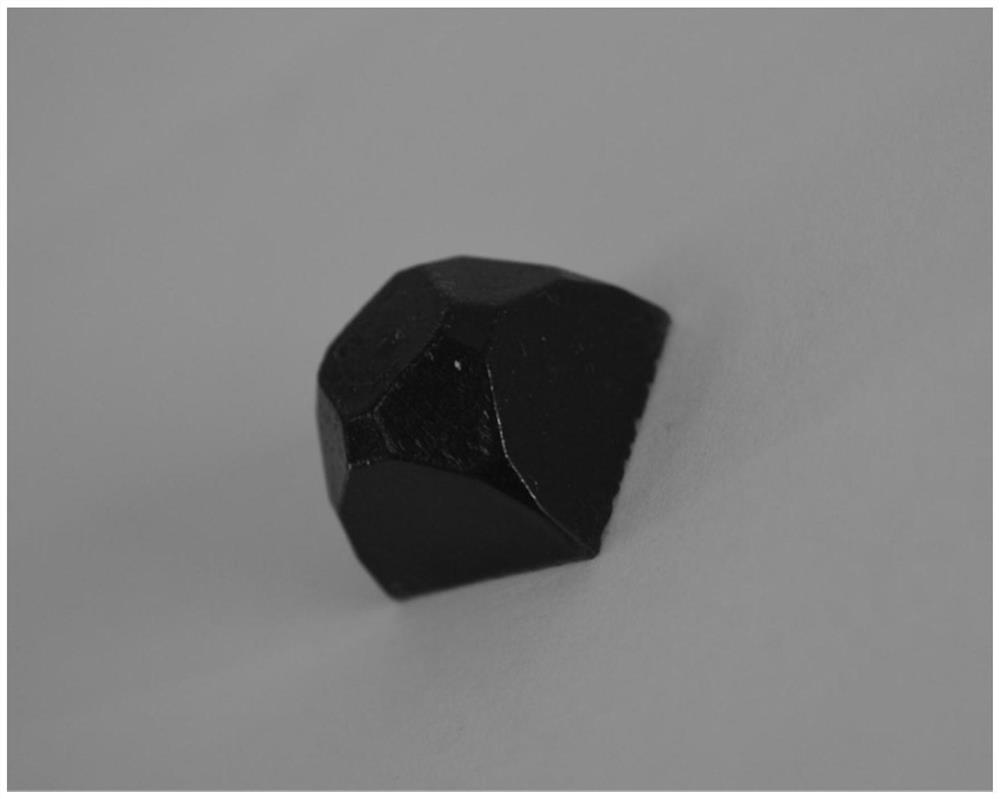

Black liquid bamboo charcoal and manufacturing method thereof

InactiveCN103131499ACarbonization production cycle is shortUnbreakableBiofuelsSolid fuelsCompression moldingBlack liquor

The invention provides black liquid bamboo charcoal. The two components of bamboo processing residues and alkali lignin are mixed, and then compression molding is conducted through a pressing machine, and carbonization is conducted so that the black liquid bamboo charcoal is made. Bamboo processing residues such as bamboo branches of truncated bamboo shoots are hard to be utilized by machine-made charcoal manufacturing and are usually burned off, the alkali lignin is also a problem in black liquid recycling management, the alkali lignin is produced by soda pulping or sulfate pulping through acidification, the alkali lignin has the characteristics of high-viscosity and high-calorific value, the two components of the bamboo processing residues and the alkali lignin are mixed and then the compression molding is conducted through the pressing machine, and carbonization is conducted so that the black liquid bamboo charcoal is made. A manner that materials are carbonized in a mold is adopted by the carbonization process, the perfect combination of thermal conditions and anaerobic conditions of the carbonization process is achieved, the produced black liquid bamboo charcoal is high in caloric value, not prone to crushing, regular in products, high in capacity of compression molding, short in production cycle of carbonization in the mold, and capable of being produced in large scale.

Owner:仇峰

Softening agent for papermaking and low-carbon pulping technology

ActiveCN105088841ANo pollution in the processReduce water consumptionPulp bleachingPulping with inorganic basesHydrofluoric acidMolecular sieve

Owner:于翔

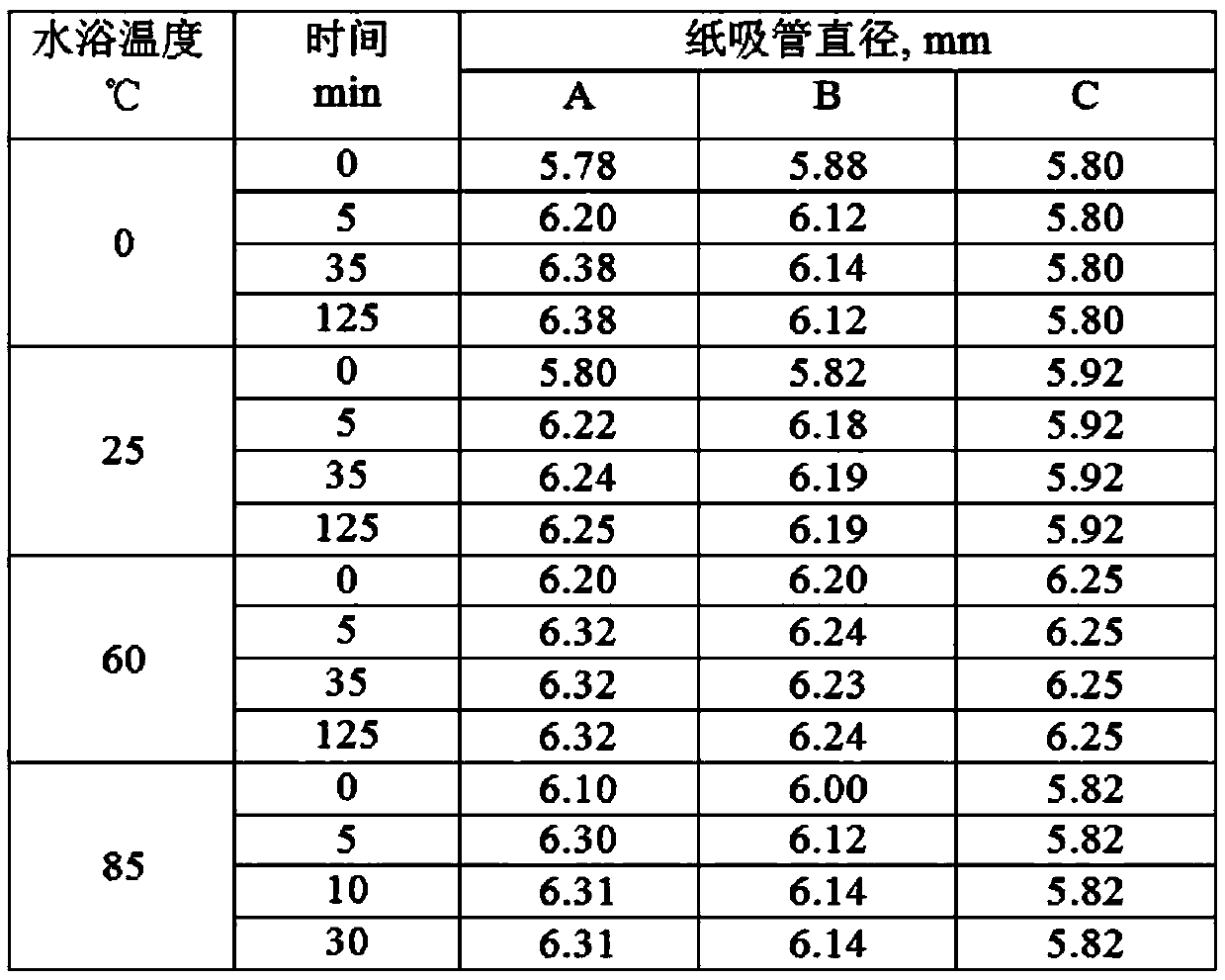

Preparation method for hemp full-stem paper straw

InactiveCN110820414AImprove antibacterial propertiesWill not polluteWater-repelling agents additionPaper/cardboardAdhesiveAnti bacteria

The invention discloses a preparation method for a hemp stem-based paper straw, and belongs to the technical field of straw production. The raw paper of the paper straw provided by the invention is made of a hemp full-stem pulp obtained by pulping through a solid oxygen-alkali method, wherein the quantification of inner-layer raw paper is 80 to 120 g / m2; and the quantification of outer-layer raw paper is 50 to 70 g / m2. According to the invention, the raw paper is cut after single-face sizing treatment; straw rolling is then performed on a straw mold, wherein oblique-angle wrapping is adopted for rolling, and the angle is in a range of 30 to 50 degrees; two layers of straw paper are bonded through a synthetic casein environmentally-friendly degradable paper straw hot-water-resistant adhesive; drying treatment is then performed at 110 DEG C for 5 min; and cutting is performed according to set parameters. The hemp stem pulp used for straw paper making is obtained by adopting a solid oxygen-alkali pulping technology which is mild in conditions and friendly to the environment, so natural antibacterial components of hemp stems are greatly retained; the load of environmental pollution isreduced; the paper straw is endowed with a natural antibacterial effect and caters to a sustainable development strategy advocated by the nation; and the paper straw has good economic effect and social effect.

Owner:云南天木生物科技有限公司 +1

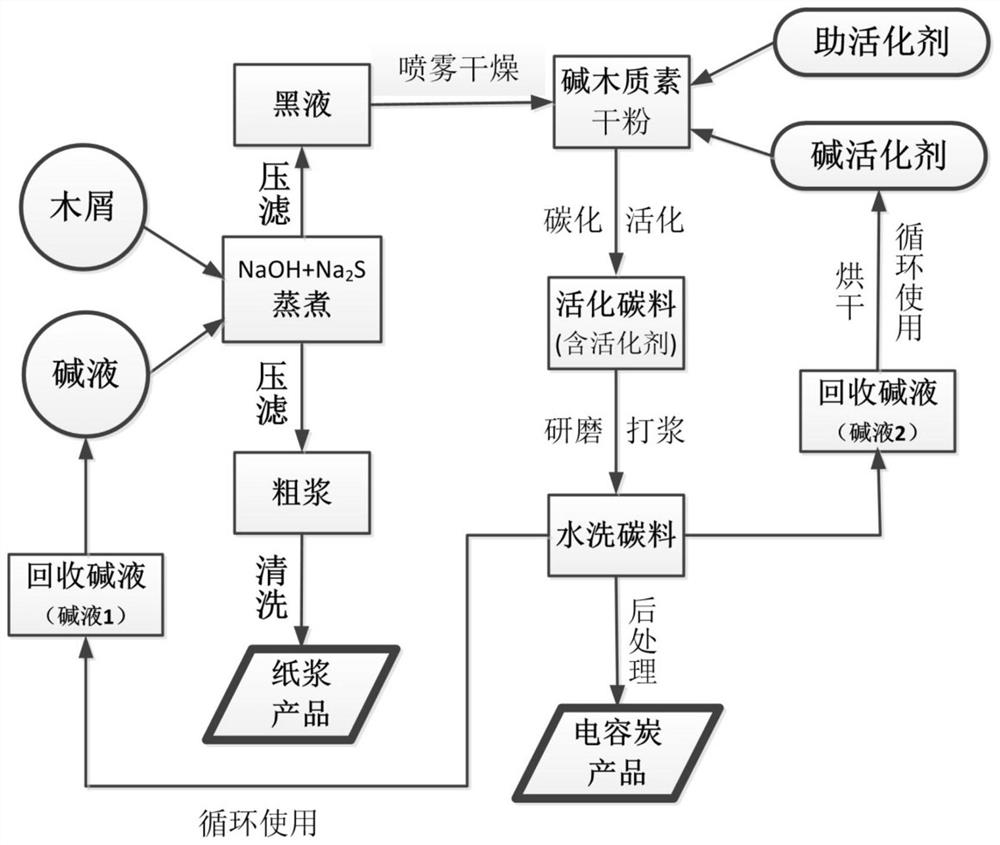

Paper pulp-capacitance carbon joint production method

PendingCN113247894ALong processIncrease costCarbon compoundsPulping with inorganic basesBlack liquorCarbonization

The invention discloses a paper pulp-capacitance carbon joint production method, and belongs to the technical field of paper pulp and carbon materials. The method comprises the following steps: (1) pulping papermaking raw materials by using an alkaline method, carrying out filter pressing separation, and cleaning paper pulp; (2) concentrating, drying and grinding a black liquor to obtain alkali lignin dry powder; (3) mixing the alkali lignin dry powder with an alkali activator and a co-activator, grinding, and aging; (4) performing high-temperature carbonization-activation on the mixture; (5) performing post-treatment on the carbonized material to obtain capacitor carbon; and (6) recovering alkali from the water washing liquid of the carbonized material, and circularly using the alkali liquid for pulping and the alkali activator of the capacitor carbon. The byproduct alkali lignin generated by alkaline pulping is directly used as the raw material for manufacturing the capacitor carbon, the alkali is recovered and circularly used as the alkali liquor for pulping and the activator of the capacitor carbon, pollution and waste are not generated, 80% or more of the alkali activator can be recycled, good environment-friendly and ecological benefits are achieved, and very high social and economic benefits can be generated.

Owner:GUANGXI ACAD OF SCI

Black liquid charcoal and manufacturing method thereof

InactiveCN103131497ACarbonization production cycle is shortUnbreakableBiofuelsSolid fuelsCarbonizationPapermaking

The invention provides black liquid charcoal. The raw materials of the charcoal comprise at least fuel wood, shrubs, branches, barks, wood processing residues or deserted artificial boards and the like, two components of the raw materials and alkali lignin are mixed, and then cooling compression molding is conducted through a pressing machine, and carbonization is conducted so that the black liquid charcoal is made. The fuel wood, the shrubs, the branches, the barks, the wood processing residues or the deserted artificial boards and the like are hard to be utilized by machine-made charcoal manufacturing and are usually burned off or rotted, utilization degree is low, the alkali lignin is also a problem in black liquid recycling management, the alkali lignin is produced by soda pulping or sulfate pulping through acidification, the alkali lignin has the characteristics of high-viscosity and high-calorific value, the two components of the raw materials and the alkali lignin are mixed and then the cooling compression molding is conducted through the pressing machine, and carbonization is conducted so that the black liquid charcoal is made. The produced carbon is high in caloric value, not prone to crushing, high in application range and utilization rate, in addition a large number of alkali lignin resources produced in the process of pulping and papermaking can be utilized sufficiently, and therefore the pressure of environmental management is relieved.

Owner:仇峰

Sulfonation of pulp produced by alkali pulping process

ActiveUS20100269992A1Washing/displacing pulp-treating liquorsPulping with acid salts/anhydridesCelluloseSoda pulping

Owner:INT PAPER CO

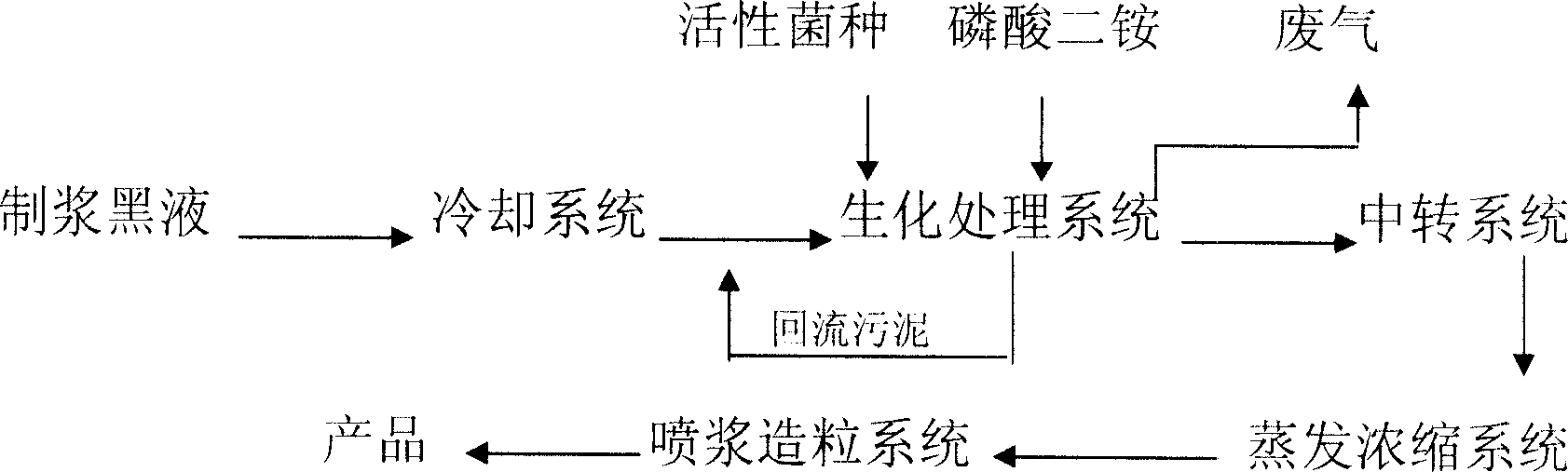

Method for producing organic fertilizer from reed soda pulping process black liquor and corn fermentation glutamic acid waste liquor

InactiveCN105819916AHigh active organic matterGood physical propertiesBioloigcal waste fertilisersSewage/sludge fertilisersBlack liquorOrganic manure

The invention discloses a method for producing an organic fertilizer from reed soda pulping process black liquor and corn fermentation glutamic acid waste liquor and belongs to the field of organic fertilizers. The method comprises the procedures of mixing the black liquor collected from the reed soda pulping process with the waste liquor collected from the process of producing glutamic acid through corn fermentation and producing the organic fertilizer. The procedure of mixing the black liquor collected from the reed soda pulping process with the waste liquor collected from the process of producing the glutamic acid through corn fermentation comprises the steps of storage of the black liquor, storage of the waste liquor and mixing of the black liquor and the waste liquor. The procedure of producing the organic fertilizer comprises the steps of evaporation and concentration, spraying granulation, cooling, sieving and film coverage, so that an organic fertilizer finished product is obtained. According to the method, the black liquor generated through the reed soda pulping process is alkaline and rich in organic matter, natural fulvic acid and other elements; the waste liquor generated in the process of producing the glutamic acid through corn fermentation is acidic and high in nitrogen content. The black liquor and the waste liquor are mixed in a certain proportion, so that the PH values and nutrition of the two types of liquor supplement one another, and after the concentration is raised through evaporation and concentration, the organic fertilizer high in content of the organic matter and nutrition is produced through the spraying granulation technology.

Owner:宁夏同创秸科生物科技有限公司

Method for extracting and separating lignin from cooking liquid of caustic soda pulping

InactiveCN108951252AFull recoveryImprove resource utilizationPulping with acid salts/anhydridesPulping with inorganic basesHydrogen SulfateSodium bisulfate

The invention provides a method for extracting and separating lignin from a cooking liquid of caustic soda pulping. The method comprises the following steps: carrying out standing on a cooking liquidof caustic soda pulping for 4-6 hours to settle impurities; adding flue gas of sulfur ore incineration or liquefied sulfur dioxide, and reducing the pH value of the cooking liquid of caustic soda pulping to 4.5-6.5 for a first time; adding sulfuric acid or a mixed solution of sulfuric acid and sodium hydrogen sulfate, and reducing the pH value of the cooking liquid of caustic soda pulping to 1.5-3.5 for a second time; and then adding a flocculant water solution and a coagulant aid water solution, fully carrying out stirring, carrying out heating, preserving heat, carrying out cooling to separate out lignin, and finally carrying out centrifugal separation to obtain the lignin. Through the implementation of the method, the one-time extraction rate of lignin is remarkably improved to 95% or above, and the highest extraction rate can be up to 98%. In addition, the method is simple to operate, is low in investment cost, is beneficial to environmental protection, and thus has a wide application prospect.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

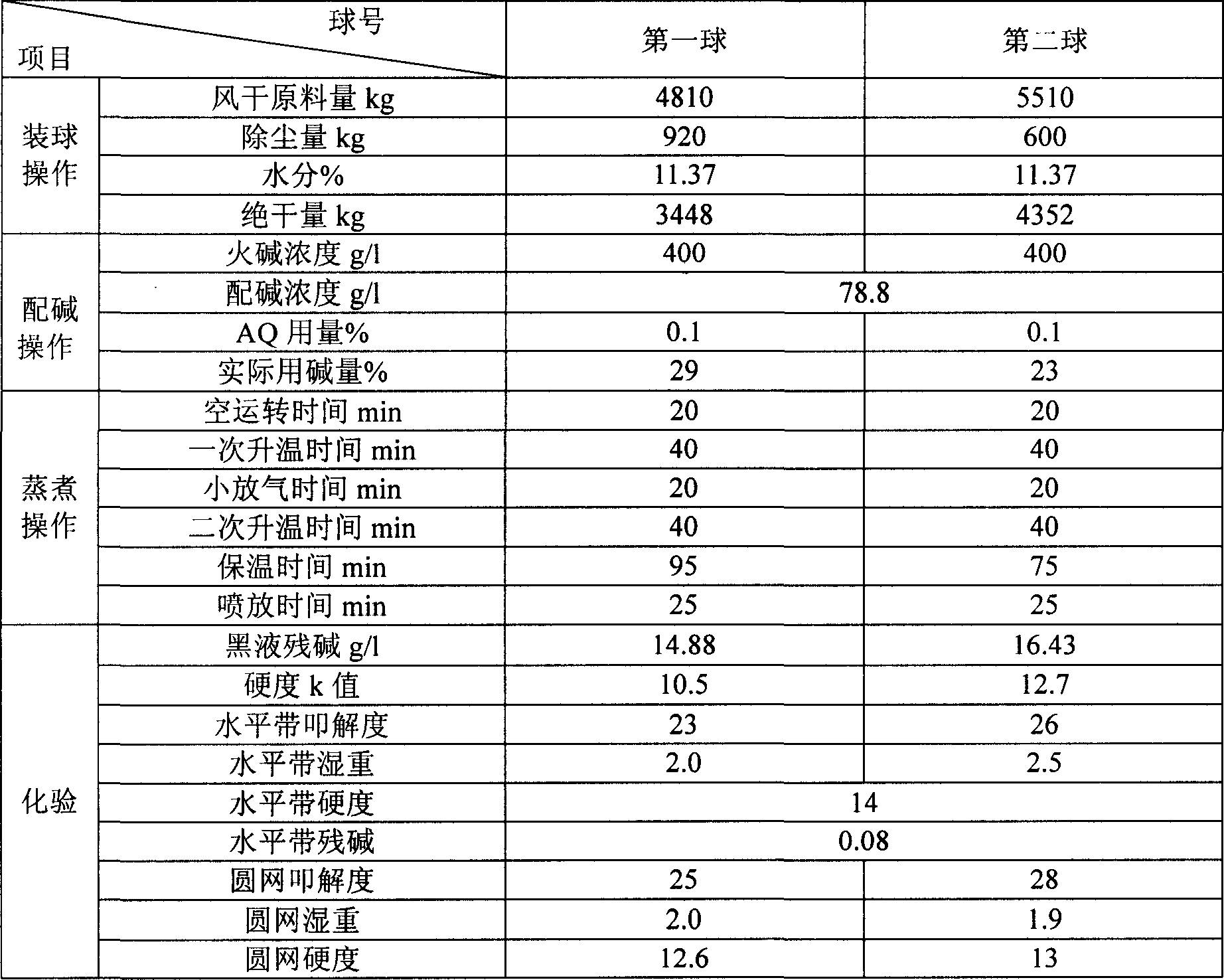

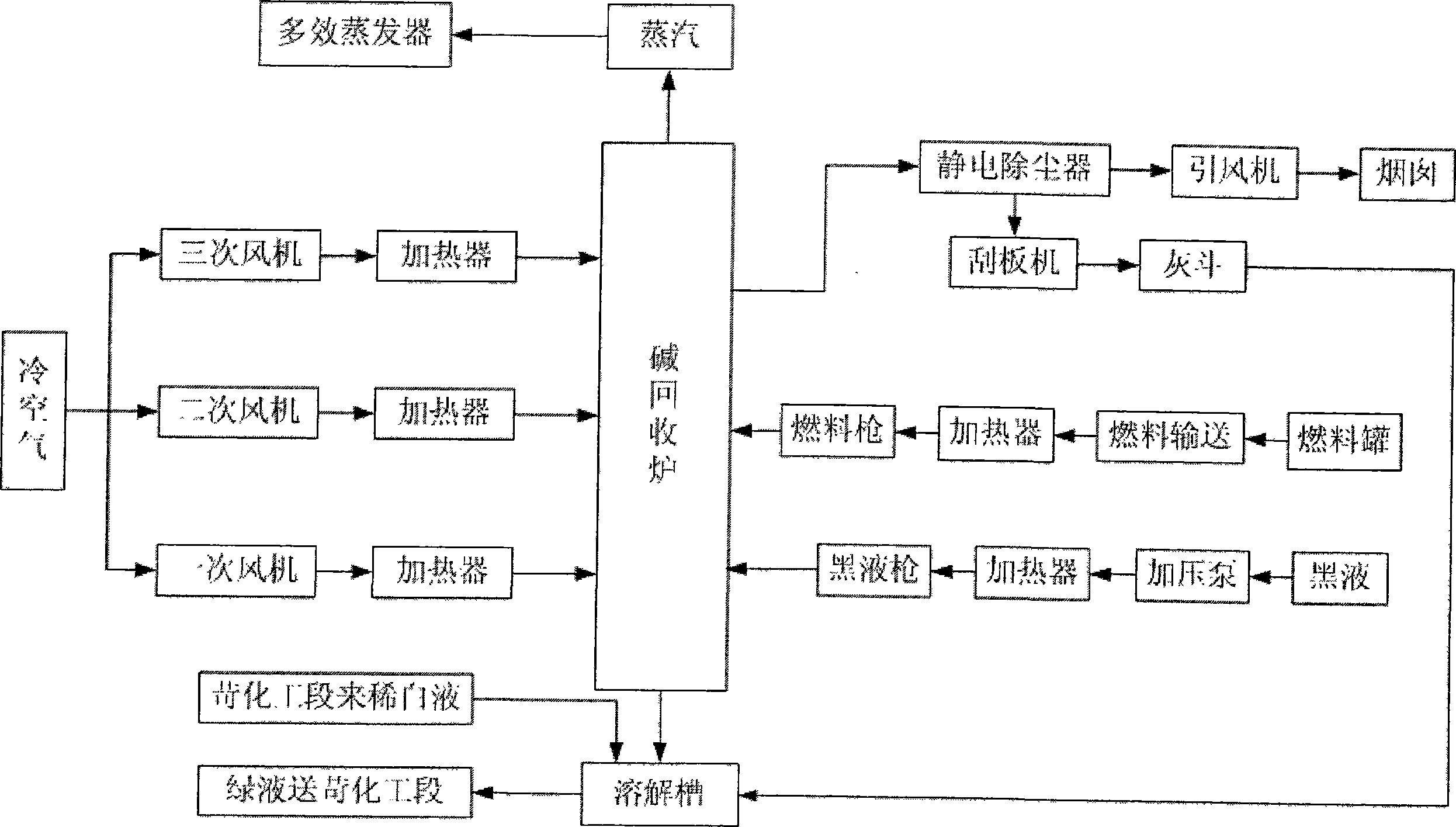

Alkali recovery process for cotton linter soda pulping black liquor

The invention discloses a cotton linter caustic soda method pulping black liquor alkali recovery technique; firstly cotton pulp black liquor with the concentration of 40 to 60 percent is pressurized to 2.0 mpa by a pump and heated to 100 to 120 DEG C, then the cotton pulp black liquor is atomized by a black liquor gun and sent to a burner for combustion; when the black liquor is burned, fuel is added to the burner for combustion by an auxiliary burner in order that the temperature of the bottom of the hearth can keep above 900 DEG C; organic matter in the black liquor is burned to create H2O and CO2; inorganic matter is recovered to a dissolving tank to dissolve into green liquor which is then sent to a causticization plant to create alkali for recycling use. One part of heat energy for the condensation of the cotton pulp black liquor is taken from the heat energy of steam produced by the combustion in the technique. The invention has the advantages that the invention has simple technique and good effect on processing the cotton linter black liquor, makes full use of waste, avoids the recontamination on environment drastically and has low comprehensive cost.

Owner:XINXIANG RUNYANG CHEM FIBER

Method for preparing unbleached paper for dining table from crop straw by adopting biological enzyme and alkaline pulping

InactiveCN106012635APromote dissolutionIncreased ability to be extractedPulping with inorganic basesCellulose treatment using microorganisms/enzymesMaterials preparationPapermaking

The invention relates to a method for producing uncolored table paper by pulping agricultural crop straws by biological enzyme and alkali method, belonging to the technical field of papermaking. The method includes two parts: bio-enzyme pretreatment of crop stalks and alkaline pulping and papermaking, wherein the bio-enzyme pre-treatment includes wet material preparation, bio-enzyme pre-treatment and extrusion treatment. Alkali pulping and papermaking include: batch cooking, coarse stock countercurrent washing, screening and purification washing, pulp refining, and papermaking. The living paper produced by the invention is uncolored table paper, and after countercurrent washing of coarse pulp, oxygen delignification is carried out to further remove lignin, so as to meet the conditions for producing uncolored living paper pulp. No bleaching process is required in the production process, which saves manpower, material resources and production costs, and no absorbable organic chlorine is produced, which is more environmentally friendly and healthier.

Owner:NINGXIA ZIJINGHUA PAPER IND

Method for preparing organic-inorganic mixed fertilizers from corn stalks by using pulping black liquid by KOH and NaOH mixed soda pulping process

InactiveCN106192521AStable organic matter contentEnhanced efficacy of organic-inorganic compound fertilizerSewage/sludge fertilisersPulp by-products recoveryBlack liquorSlurry

Owner:NINGXIA ZIJINGHUA PAPER IND

Method for preparing organic-inorganic mixed fertilizer by using KOH and NaOH mixed soda pulping process black liquor for reeds

InactiveCN106192519AStable organic matter contentImprove efficacyPulp liquor regenerationSewage/sludge fertilisersBlack liquorPapermaking

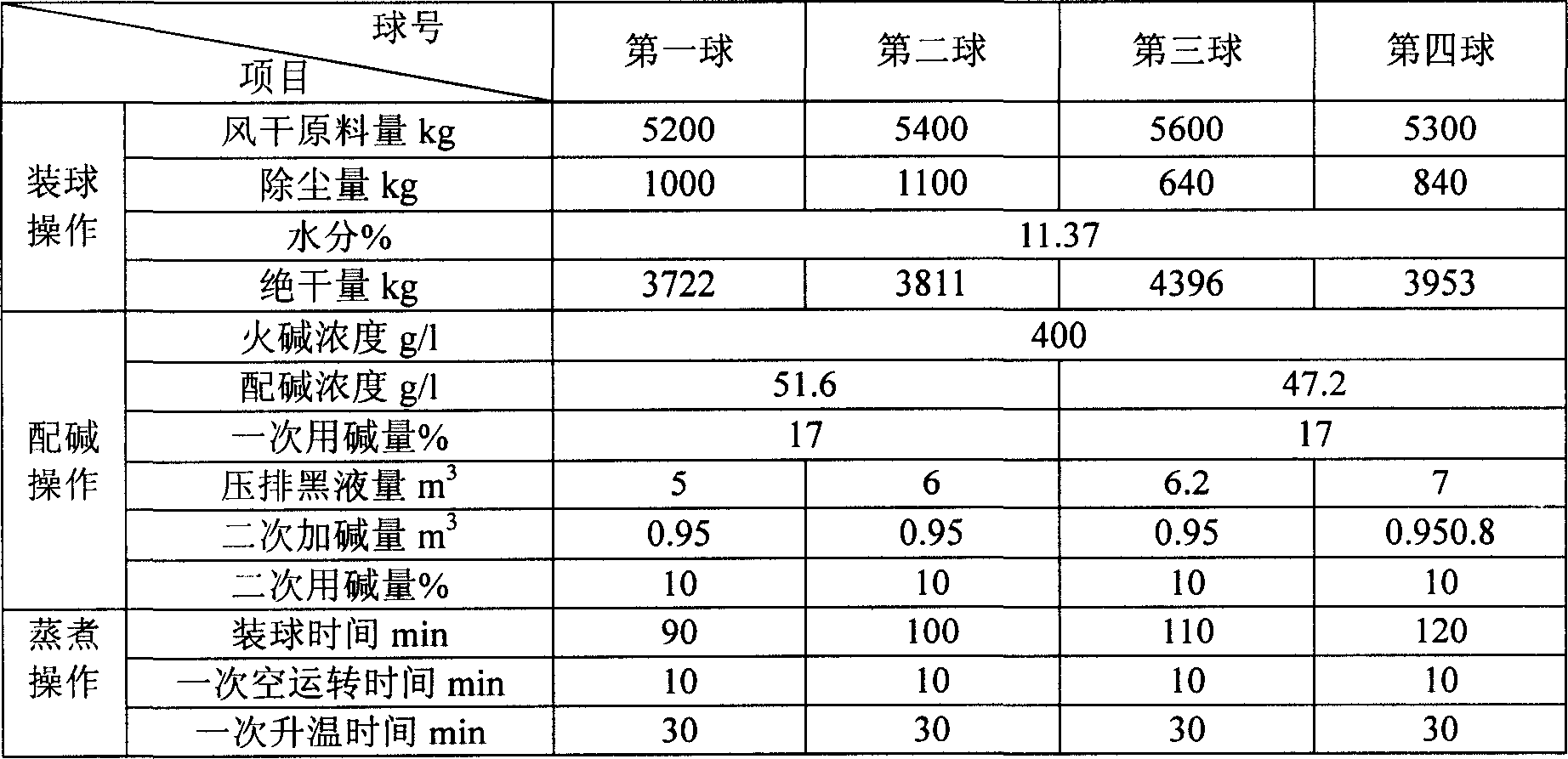

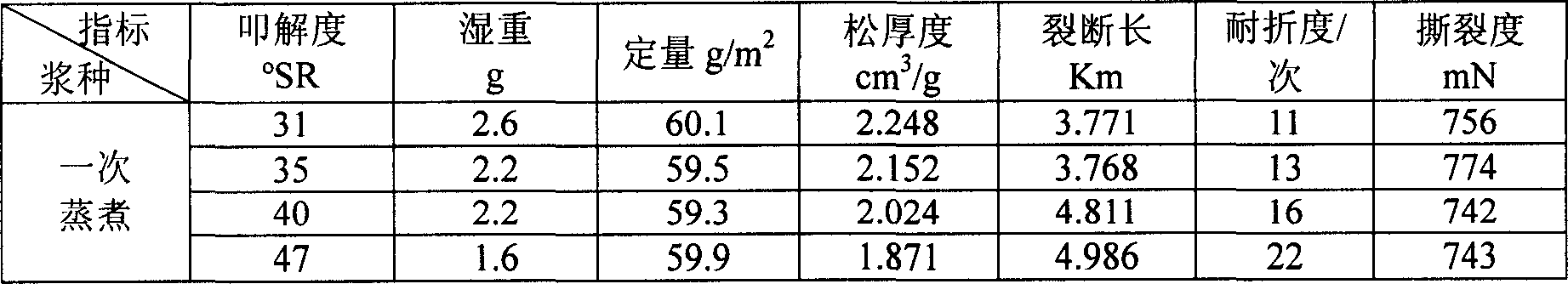

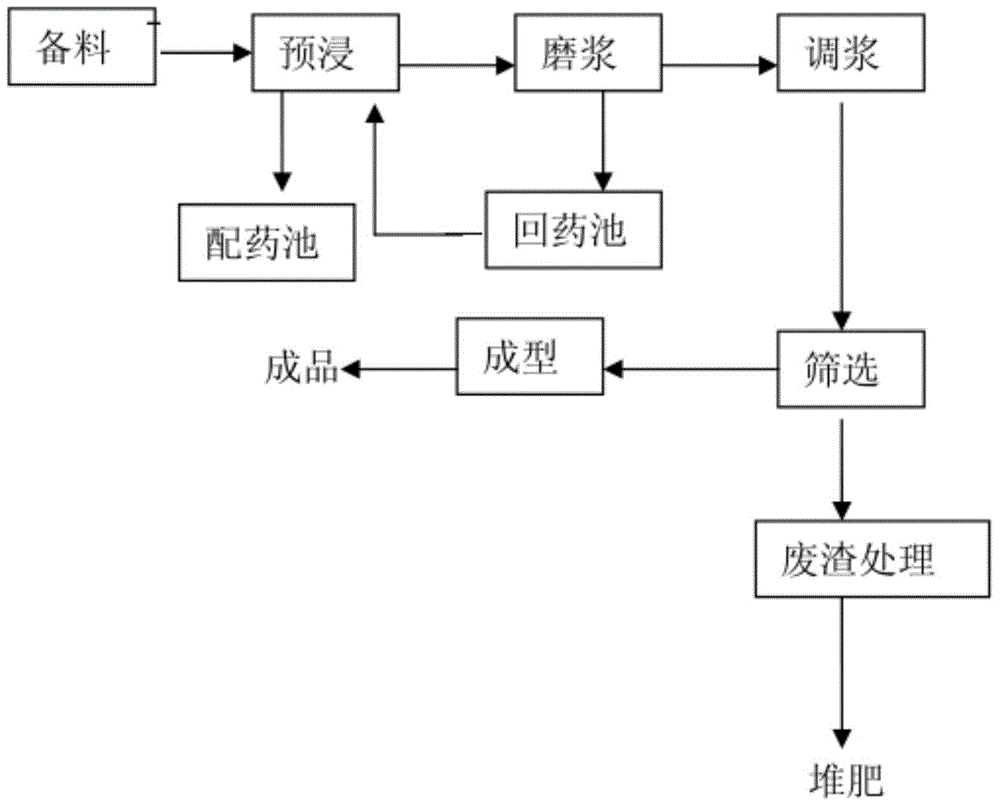

The invention discloses a method for preparing an organic-inorganic mixed fertilizer by using a KOH and NaOH mixed soda pulping process black liquid for reeds, and belongs to the fields of papermaking and fertilizer production. The main technological process of the method comprises the following steps: preparing a reed raw material, feeding the material into a roller type hay cutter for cutting, feeding chopped grass into a dust collector for dust collection after cutting, conveying the chopped grass by using a scraper conveyer, feeding the chopped grass into a spiral prepreg machine for soaking, carrying out intermittent cooking by means of a rotary spherical digester, enabling the chopped grass to enter a blowing cabin for coarse pulp blowing, extruding a black liquid by using a single-screw press master, storing the black liquid in an underground pulp storage pool, and feeding the black liquid into an organic fertilizer shop to prepare an organic fertilizer. The organic-inorganic mixed fertilizer prepared by the method is an organic fertilizer with multiple fertilizer effects, and the organic fertilizer is high in fertilizer effects and complete in functions.

Owner:宁夏同创秸科生物科技有限公司

Method for extracting lignin from soda pulping black liquid

InactiveCN108864440AHigh extraction rate at one timeShort processing timeAluminium chlorohydrateChloride

The invention discloses a method for extracting lignin from soda pulping black liquid. The method comprises the following steps of lowering the temperature of the high-temperature soda pulping black liquid obtained through pulping to 80 to 100 DEG C; regulating the pH value to 1.5 to 3.5; adding a proper amount of polyacrylamide and poly aluminum chloride; performing mixing, still standing temperature lowering and still standing precipitation for a certain time; performing filtering and separation to obtain the lignin. When the method provided by the invention is used for extracting the ligninfrom the soda pulping black liquid, the lignin one-step extraction rate is as high as more than 85 percent; the treatment time is short; the treatment equipment is simple; the direct viewing is realized in the reaction process; the operation is simple and convenient; the process investment is low; the cost is low.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Treatment method of digesting waste steam produced by soda pulping process

ActiveCN102517952AEliminate odorImprove desulfurization effectDispersed particle separationPulp gases treatmentEmulsionPulp and paper industry

The invention discloses a treatment method of digesting waste steam produced by soda pulping process. The digesting waste steam produced by the soda pulping process is fed into a de-sulfurizing tower to be mixed with lime emulsion sprayed by the de-sulfurizing tower and boiler smoke entering the de-sulfurizing tower in the de-sulfurizing tower, thereby enabling Na content in the smoke discharged from the de-sulfurizing tower is less than 100mg / m3 and enabling K content in the smoke is less than 50mg / m3. The method is simple and easy to operate, de-sulfuration of the lime emulsion is further assisted while eliminating alkaline air peculiar smell of the digesting waste steam, and de-sulfuration effect to the smoke is improved.

Owner:山东光华纸业集团有限公司

A kind of nano iron oxyhydroxide gel composite material and its preparation method and application

ActiveCN113121758BReduce pollutionLow costOther chemical processesWater contaminantsCross linkerIron oxyhydroxide

The invention provides a nano-iron oxyhydroxide gel composite material and a preparation method and application thereof. The present invention uses alkaline pulping and papermaking black liquor and acrylamide, maleic anhydride, crosslinking agent and initiator to prepare a gel composite material with crosslinked interpenetrating network macromolecules and high permeability, and passes the The method of in-situ synthesis produces nano-iron oxyhydroxide, and the preparation method is simple and feasible, and innovatively realizes the recycling and utilization of alkaline pulping and papermaking black liquor, saves costs and reduces environmental pollution. The nano-iron oxyhydroxide is evenly distributed in the composite material obtained by the present invention, and the interpenetrating network structure of the composite material effectively prevents the aggregation and shedding of the nano-iron oxyhydroxide, and provides a suitable place for the dispersion and fixation of the nano-iron oxyhydroxide , the adsorption and removal effect on heavy metals is obvious, and it has broad application prospects in the field of heavy metal removal.

Owner:SOUTH CHINA AGRI UNIV +1

Treatment method of digesting waste steam produced by soda pulping process

ActiveCN102517952BEliminate odorImprove desulfurization effectDispersed particle separationPulp gases treatmentEmulsionPulp and paper industry

The invention discloses a treatment method of digesting waste steam produced by soda pulping process. The digesting waste steam produced by the soda pulping process is fed into a de-sulfurizing tower to be mixed with lime emulsion sprayed by the de-sulfurizing tower and boiler smoke entering the de-sulfurizing tower in the de-sulfurizing tower, thereby enabling Na content in the smoke discharged from the de-sulfurizing tower is less than 100mg / m3 and enabling K content in the smoke is less than 50mg / m3. The method is simple and easy to operate, de-sulfuration of the lime emulsion is further assisted while eliminating alkaline air peculiar smell of the digesting waste steam, and de-sulfuration effect to the smoke is improved.

Owner:山东光华纸业集团有限公司

Gas-liquid two-phase sulfonated alkaline pulping waste lye to prepare coal-water slurry additive

Owner:萧县沃德化工科技有限公司 +1

Method for preparing bagasse dissolving pulp and pre-extracting hemicellulose and product thereof

InactiveCN101613970BHigh extraction rateReduce the content of non-sugar organic debrisSugar derivativesPretreatment with acid reacting compoundsHydrolysateDissolving pulp

The invention relates to a method for preparing bagasse dissolving pulp and pre-extracting hemicelluloses. The method comprises the following steps: bagasse preparation, wherein bagasse is subjected to depithing and washing; prehydrolysis carried out in a globe digester or a hydrolysis boiler with the process conditions during the process for depithing and oven-drying bagasse as follows: 1:0.4-8.0 adopted as the solid-to-liquid ratio, 100-200 DEG C adopted as the hydrolysis temperature, 15-240 minutes adopted as the hydrolysis time, 2-5 adopted as the pH value of the end point of hydrolysis so as to control the hydrolysis process and obtain the hydrolysate with xylo-oligosaccharide as the main component thereof and a small amount of xylose; solid-to-liquid separation and washing, wherein the filtrate is collected to prepare an extracting solution; dissolving pulp prepared by residue alkali method. By adopting the method, bagasse dissolving pulp and bagasse extracting solution which is used to prepare oligosaccharides are obtained. Most of pentosan in bagasse can be extracted by controlling the process conditions of the prehydrolysis. The technical route and the process conditions have strong pertinence, so that the reactivity and the uniformity of bagasse dissolving pulp can be improved. By improving the traditional dissolving pulp alkali method for pulping, bagasse biorefinery based on dissolving pulp pulping can be realized in engineering, so that the production costs for preparing bagasse dissolving pulp and pre-extracting hemicellulose are reduced.

Owner:上海士林纤维材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com