Preparation method for hemp full-stem paper straw

A straw and marijuana technology, which is applied in the field of preparation of hemp full-rod paper straws, can solve the problems of a large number of toxic and harmful gases, pollute the atmosphere, and cannot be decomposed, achieve good economic and social effects, reduce white pollution, and improve user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

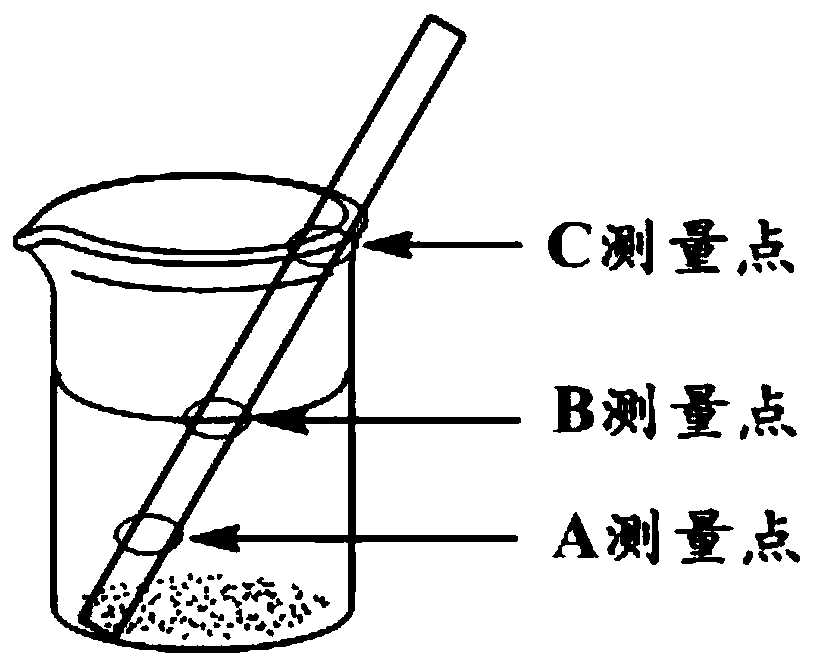

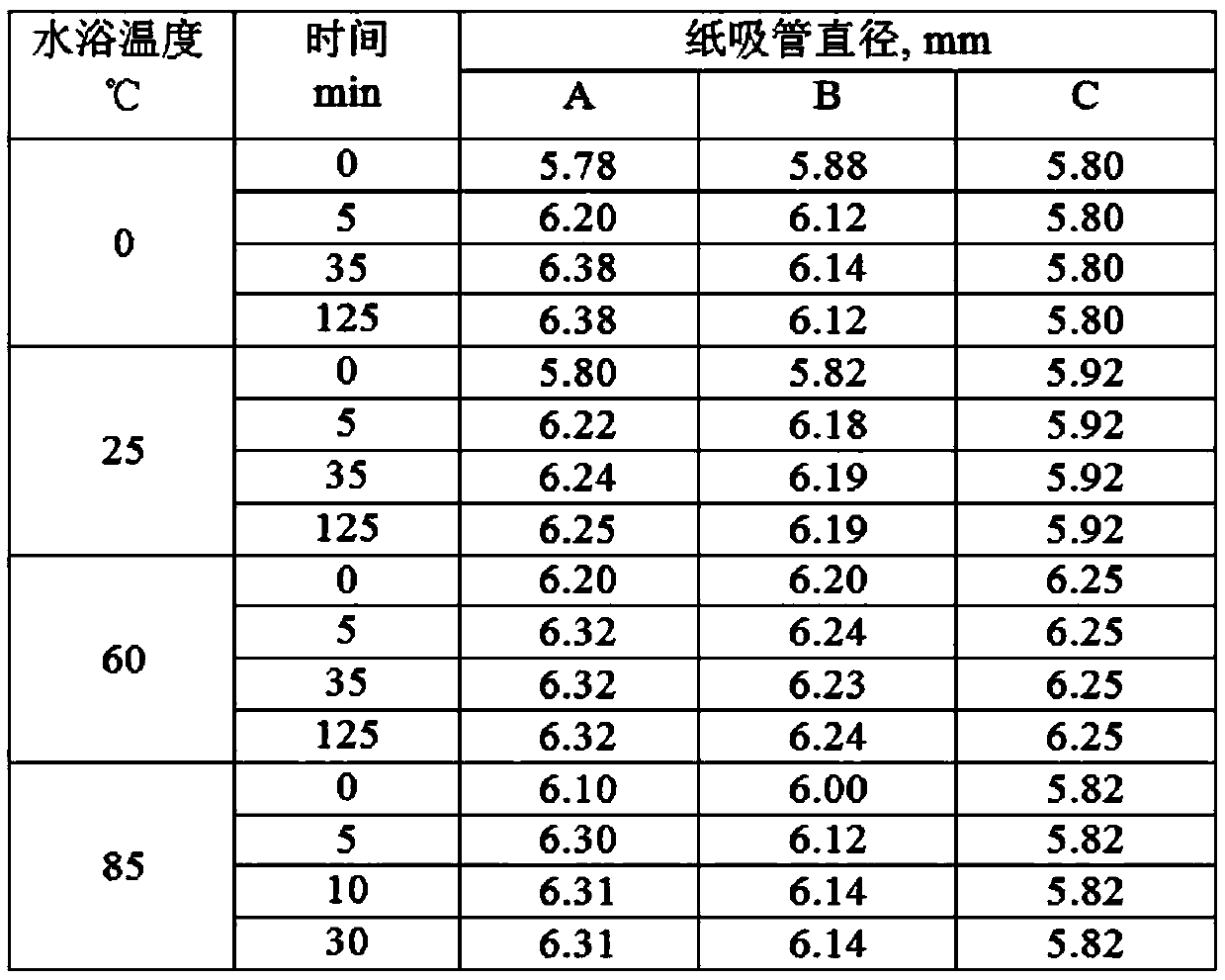

Image

Examples

Embodiment 1

[0019] A preparation method for a hemp rod-based paper straw, specifically comprising the following steps:

[0020] (1) The specific process of preparing straw paper in the present embodiment is: after refining the whole stem pulp of hemp, the degree of beating is respectively: 40 ° SR; Strong agent and 1% sizing agent (the addition of defoamer, wet strength agent and sizing agent accounts for 0.1%, 2% and 1% of the hemp slurry gross mass, the calculation of additive addition in the following examples The method is the same as here), and after mixing evenly, papermaking is carried out to obtain a paper weight of 70g / m 2 and 80g / m 2 paper straws.

[0021] (2) Weigh 2g of styrene-acrylic latex and 40g of cornstarch, add them into a three-necked flask, add 400mL of water, add 2g of aluminum sulfate and 0.1g of ammonium persulfate, stir at 85°C for 10min, and then Raise the temperature to 110°C for 15 minutes to obtain a surface sizing agent; the obtained surface sizing agent i...

Embodiment 2

[0026] A preparation method for a hemp rod-based paper straw, specifically comprising the following steps:

[0027] (1) The specific process of preparing straw paper in the present embodiment is: the beating degree of hemp whole stem pulp is respectively: 55 ° SR after refining treatment; Strong agent and 2% sizing agent, after mixing evenly, papermaking is carried out to obtain a paper weight of 50g / m 2 and 120g / m 2 paper straws.

[0028] (2) Weigh 2g of styrene-acrylic latex and 40g of cornstarch, add them into a three-necked flask, add 400mL of water, add 2g of aluminum sulfate and 0.1g of ammonium persulfate, stir at 85°C for 10min, and then Raise the temperature to 110°C for 15 minutes to obtain a surface sizing agent. The surface sizing agent that obtains carries out straw paper base paper (quantity is respectively 80g / m2) 2 and 50g / m 2 ) surface sizing treatment, the amount of sizing is controlled at 1kg styrene-acrylic latex / t paper, after the surface gluing, the ...

Embodiment 3

[0033] A preparation method for a hemp rod-based paper straw, specifically comprising the following steps:

[0034] (1) The specific process of preparing straw paper in the present embodiment is: after refining the hemp whole rod pulp, the degree of beating is respectively: 70 ° SR; Strengthening agent and 3% sizing agent, after mixing evenly, papermaking is carried out to obtain a paper weight of 60g / m 2 and 110g / m 2 paper straws.

[0035] (2) Weigh 2g of styrene-acrylic latex and 40g of cornstarch, add them into a three-necked flask, add 400mL of water, add 2g of aluminum sulfate and 0.1g of ammonium persulfate, stir at 85°C for 10min, and then Raise the temperature to 110°C for 15 minutes to obtain a surface sizing agent. The surface sizing agent that obtains carries out straw paper base paper (quantitatively is 100g / m 2 and 70g / m 2 ) surface sizing treatment, the amount of sizing is controlled at 4kg styrene-acrylic latex / t paper, after the surface glue, the paper sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com