Bleaching method of cotton stalk chemical pulp

A technology of chemical pulp and cotton stalks, which is applied in pulp bleaching, chemical/chemical mechanical pulping, pulping with inorganic alkali, etc., can solve the problems of unsatisfactory pulp whiteness, etc., and achieve the goal of alleviating the shortage of wood resources and good bleaching performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Yield

[0045] Electricity

[0046] A total of 7 balls were produced in the test, with an output of 11.0644 tons, a dry cotton stem consumption of 29.32 tons, and a harvest rate of 37.74%.

experiment example 1

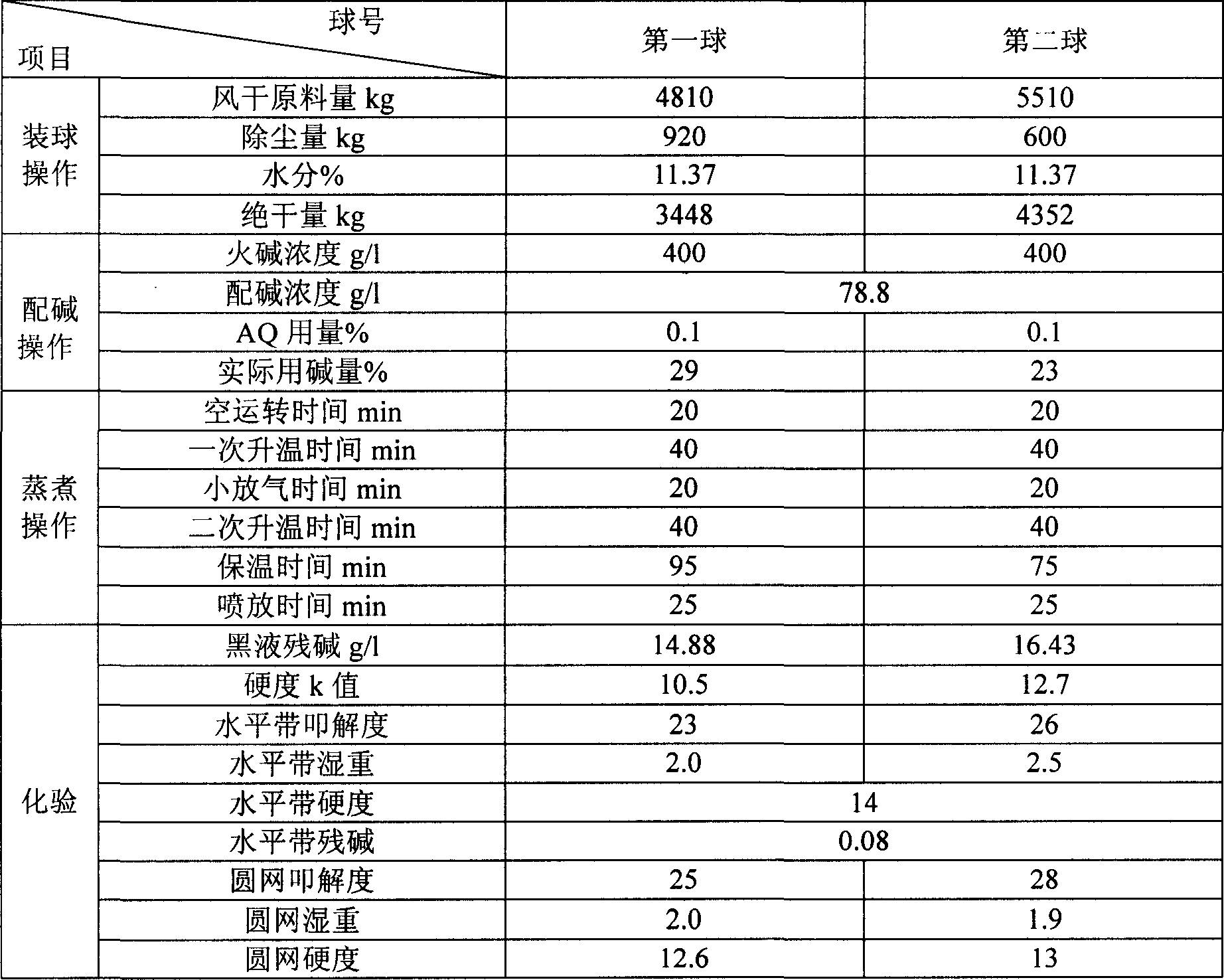

[0048] A cooking operation record data sheet:

[0049]

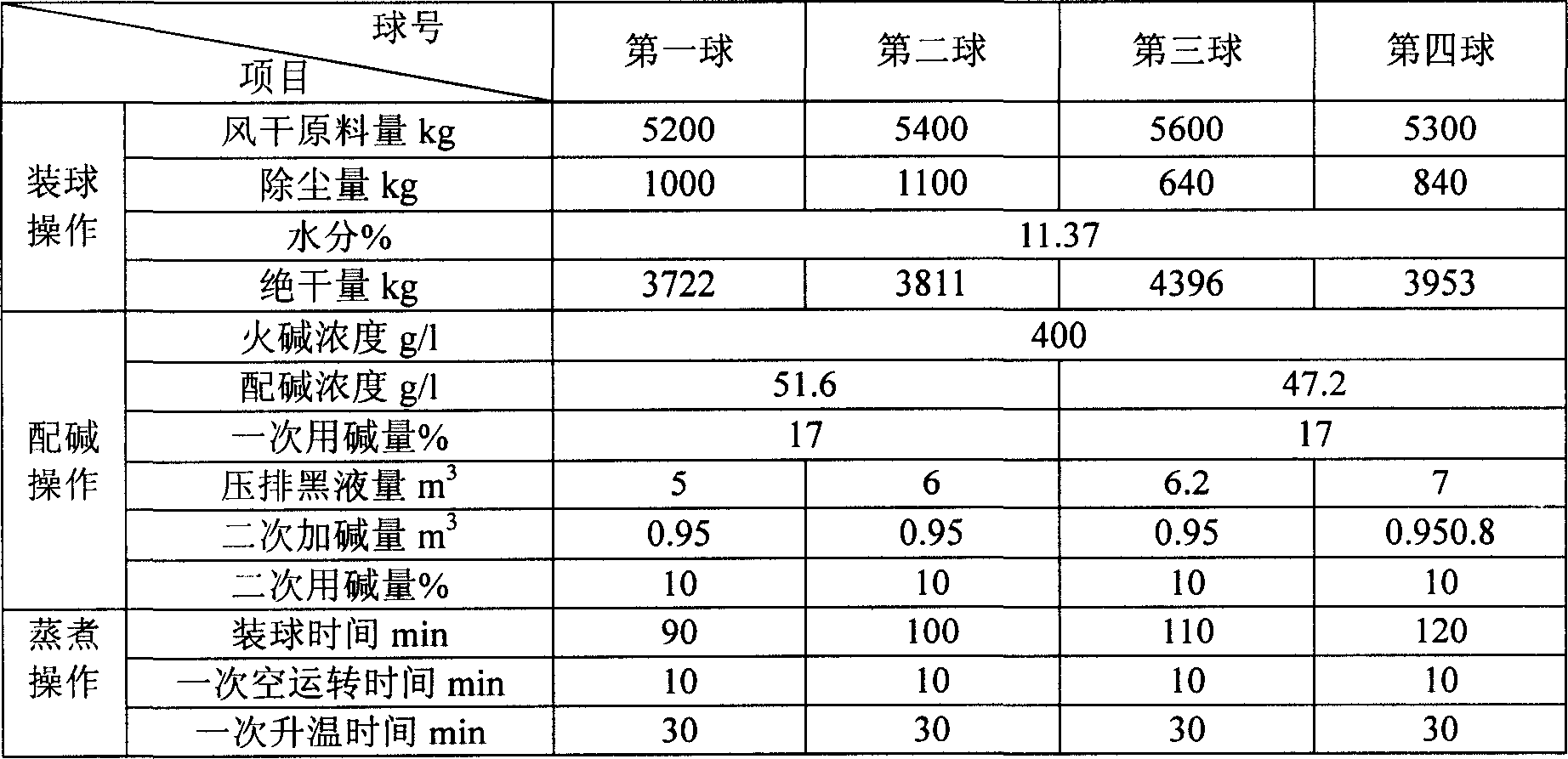

[0050] Secondary cooking operation record data sheet:

[0051]

[0052] A small deflation time min

10

10

10

10

Second heating time min

40

40

40

40

Static pressure black liquor discharge time min

90

90

90

90

Secondary alkali addition min

20

20

20

20

three heating min

60

60

40

40

Second holding time min

110

130

100

100

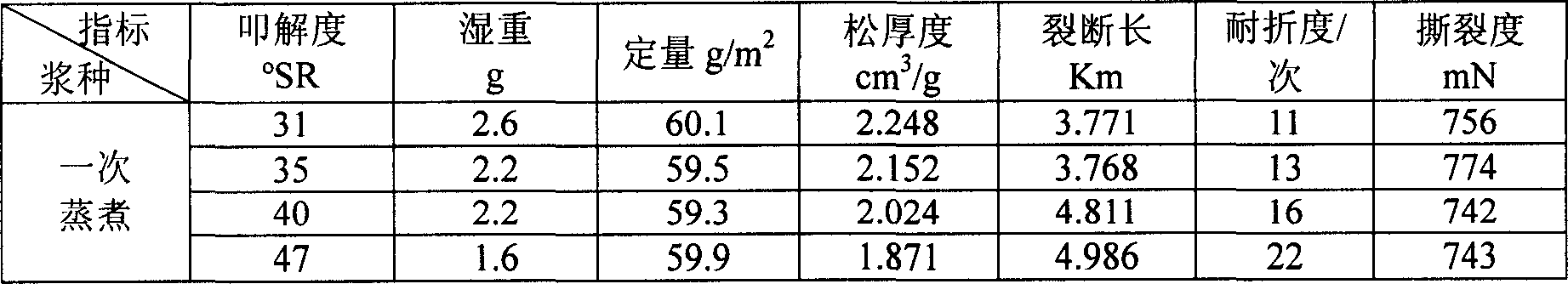

test

Discharge time min

20

20

15

15

full time

8:00

8:30

7:45

7:55

Cooking residual alkali g / l

17.8

19.22

20.59

21.21

Hardness k value

12.2

13.4

15

11.8

Horizontal band percussion

25

23

22

23

horizontal with wet weight...

experiment example 2

[0057] Drift Pond

[0058] Bleaching end time

[0059] Pool No. 1 is primary cooking pulp, and the rest are secondary cooking pulp. The pulp whiteness after bleaching is: 78.9%, 79.7%, 82.0%, and 80.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com