Low-quality potash feldspar iron removal purification method

A low-quality potassium feldspar technology, applied in the field of iron removal and purification of low-quality potassium feldspar, can solve the problems of inability to achieve whitening, high processing costs, air pollution, etc., and achieve convenient operation, low cost, and accelerated dissociation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

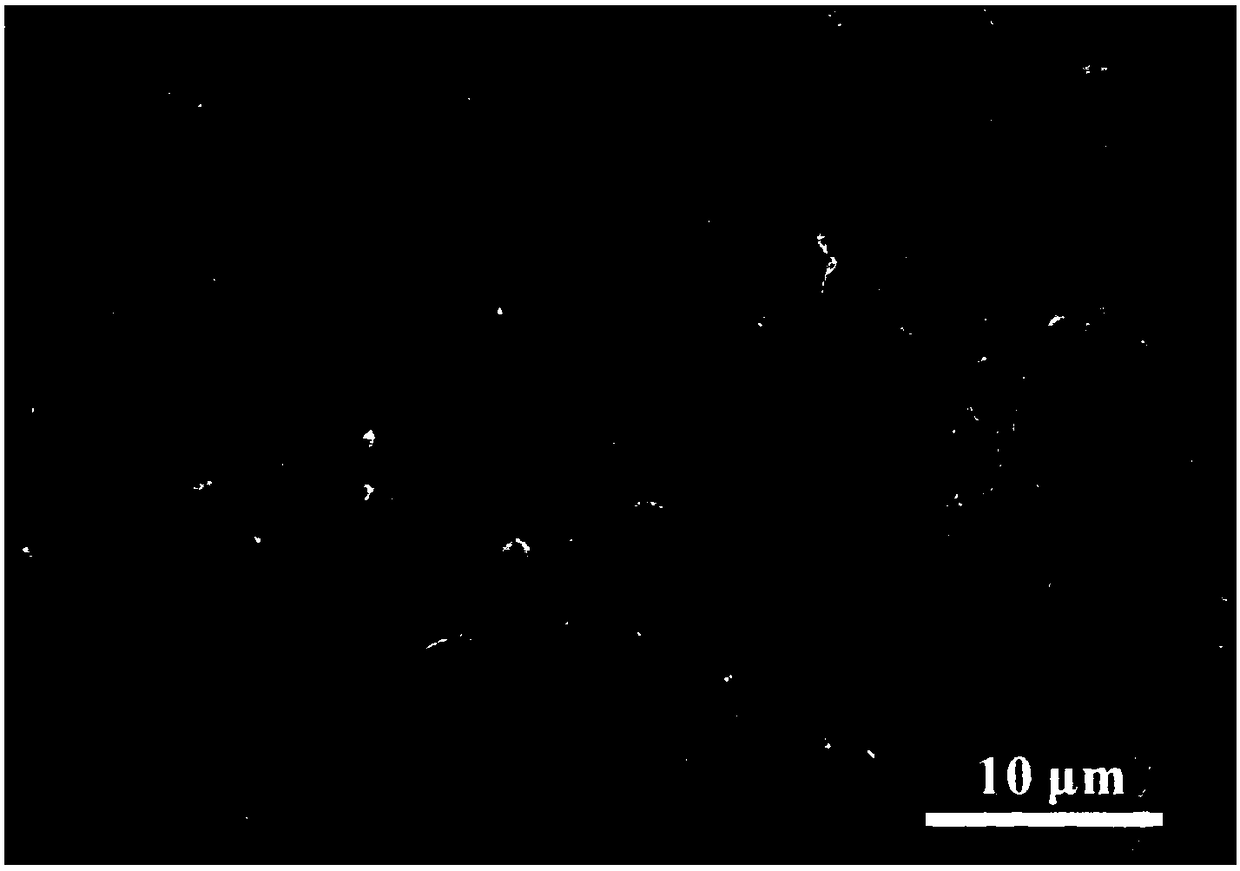

Image

Examples

Embodiment 1

[0025] Potassium feldspar mineral raw materials are first crushed into potassium feldspar particles with a particle size of less than 6mm by a crusher, and then sent to a drum sieve to screen to remove impurities such as mica, fine mud and large particles, and then the screened potassium feldspar particles are ball milled, Get 80-200 mesh potassium feldspar sand powder, then send the potassium feldspar sand powder into the spiral chute for separation and sorting, select the sediment, and obtain potassium feldspar fine powder, and finally put the potassium feldspar fine powder into microwave water Hot pickling treatment to complete the purification. Among them, the process parameters of microwave hydrothermal pickling treatment are: sulfuric acid is used as the pickling agent, and the mass concentration of sulfuric acid is 10%, the mass ratio of sulfuric acid to potassium feldspar powder is 2:1, and the microwave hydrothermal temperature is 150°C , Microwave water heating time ...

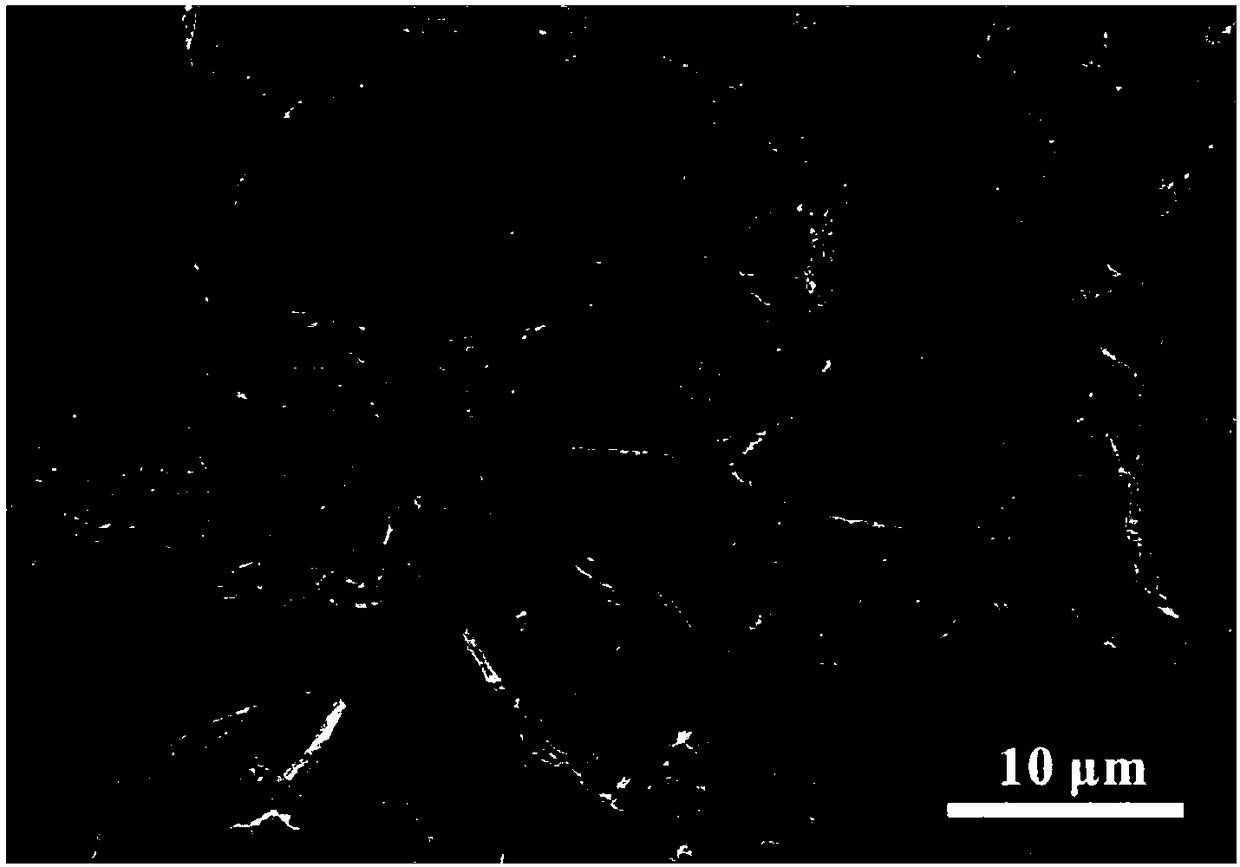

Embodiment 2

[0029] Potassium feldspar mineral raw materials are first crushed into potassium feldspar particles with a particle size of less than 6mm by a crusher, and then sent to a drum sieve to screen to remove impurities such as mica, fine mud and large particles, and then the screened potassium feldspar particles are ball milled, Get 80-200 mesh potassium feldspar sand powder, then send the potassium feldspar sand powder into the spiral chute for separation and sorting, select the sediment, and obtain potassium feldspar fine powder, and finally put the potassium feldspar fine powder into microwave water Hot pickling treatment to complete the purification. Among them, the process parameters of microwave hydrothermal pickling treatment are: sulfuric acid is used as the pickling agent, and the mass concentration of sulfuric acid is 20%, the mass ratio of sulfuric acid to potassium feldspar powder is 2:1, and the microwave hydrothermal temperature is 140°C , Microwave water heating time ...

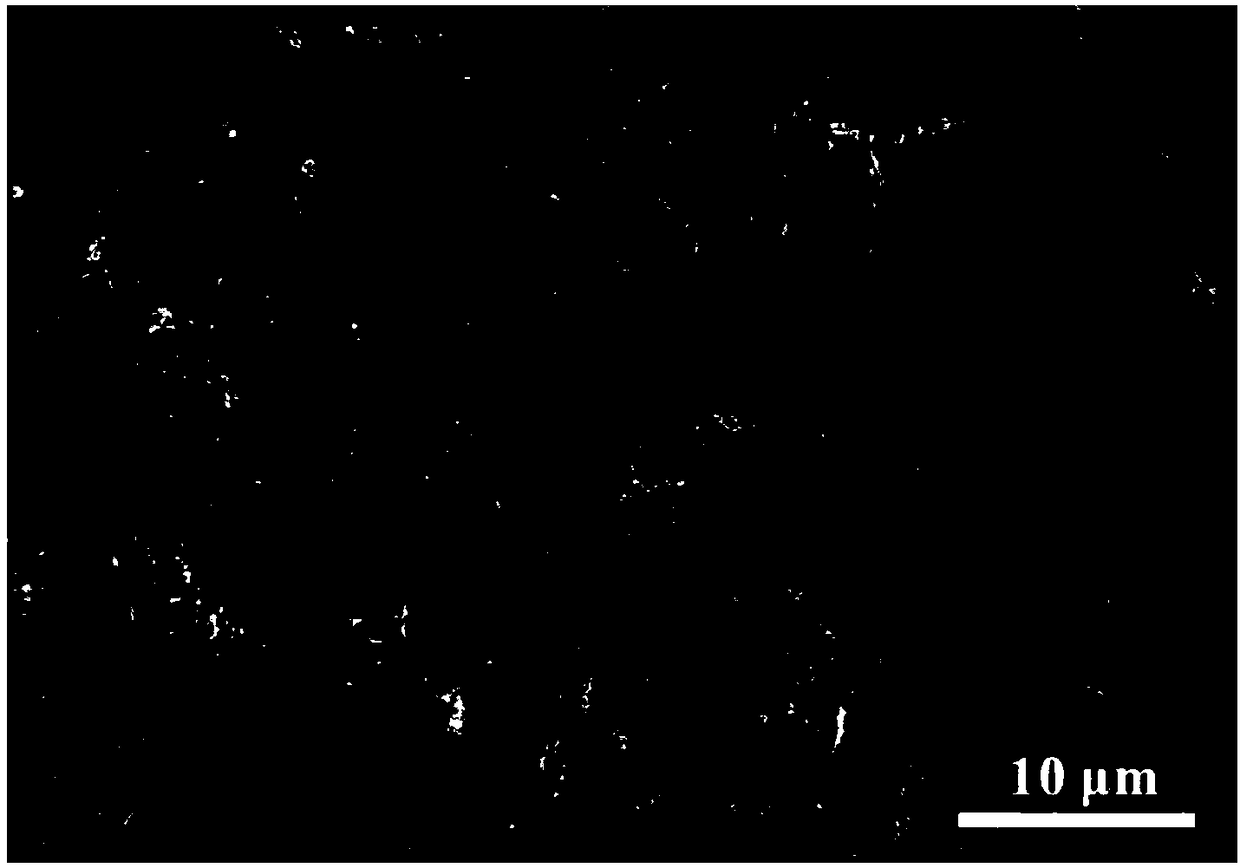

Embodiment 3

[0033]Potassium feldspar mineral raw materials are first crushed into potassium feldspar particles with a particle size of less than 6mm by a crusher, and then sent to a drum sieve to screen to remove impurities such as mica, fine mud and large particles, and then the screened potassium feldspar particles are ball milled, Get 80-200 mesh potassium feldspar sand powder, then send the potassium feldspar sand powder into the spiral chute for separation and sorting, select the sediment, and obtain potassium feldspar fine powder, and finally put the potassium feldspar fine powder into microwave water Hot pickling treatment to complete the purification. Among them, the process parameters of microwave hydrothermal pickling treatment are: sulfuric acid is used as the pickling agent, and the mass concentration of sulfuric acid is 30%, the mass ratio of sulfuric acid to potassium feldspar powder is 2:1, and the microwave hydrothermal temperature is 130°C , Microwave water heating time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com