Patents

Literature

56results about How to "Low film resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

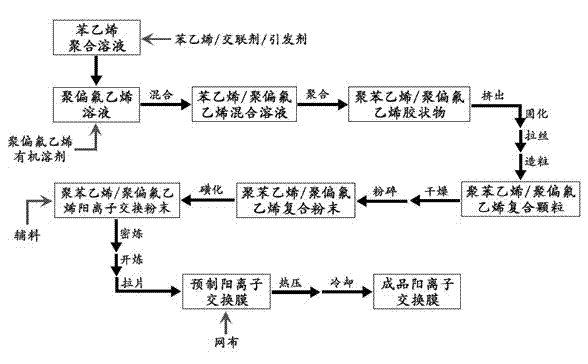

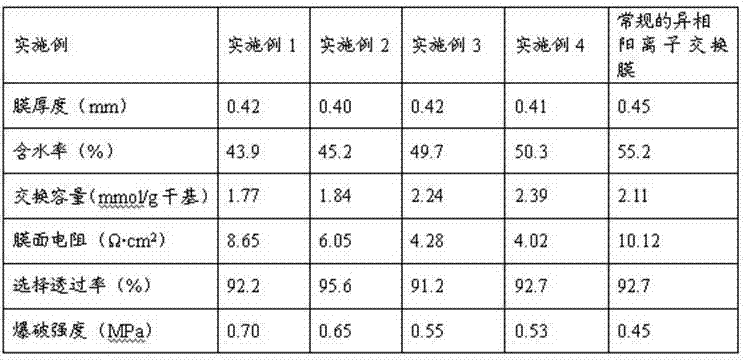

Preparation method for polystyrene/polyvinylidene fluoride cation exchange membrane

ActiveCN102814125AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluorideIon-exchange membranes

The invention discloses a preparation method for a polystyrene / polyvinylidene fluoride cation exchange membrane. According to the method, polyvinylidene fluoride is used as a matrix material for the membrane. The method comprises the following steps: dissolving polyvinylidene fluoride and then fully mixing dissolved polyvinylidene fluoride with styrene and a cross-linking agent so as to obtain a homogeneous polymer solution; carrying out heat-initiated crosslinking copolymerization so as to obtain gelatinoid with an interpenetrating network structure; subjecting the gelatinoid to polymer physical processing so as to obtain polystyrene / polyvinylidene composite powder; then preparing cation exchange powder by using a sulfonation method for a storng-acid cation exchange resin as reference; and finally preparing the cation exchange membrane by using a hot pressing molding method for a heterogeneous cation exchange membrane. The polystyrene / polyvinylidene fluoride cation exchange composite high polymer membrane prepared in the invention has the interpenetrating network structure, so the structural defect of incompatibility between cation exchange resin powder and a high polymer binder in conventional heterogeneous cation exchange membranes is eradicated, membrane resistance is substantially reduced, and comprehensive properties of the polystyrene / polyvinylidene fluoride cation exchange membrane in the invention are closer to comprehensive properties of cation exchange membranes.

Owner:辽宁易辰膜科技有限公司

Perfluoro ion exchange solvation reinfercing film and its preparation method

InactiveCN1624202AExtended service lifeImprove bindingOrganic diaphragmsFilm resistancePolymer science

A reinforced perfluoro ion exchange film is composed of at least two layers of ionic film, which prepared from perfluoro ion exchange resin and fused together without interface, at least one layer of perfluoro polymer mesh as reinforcing material and the perfluoro polymer microfibres added to said filming resin. It is prepared through sequential coating. Its advantages are low film resistance, high electric current efficiency, and high mechanical strength and size stability.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

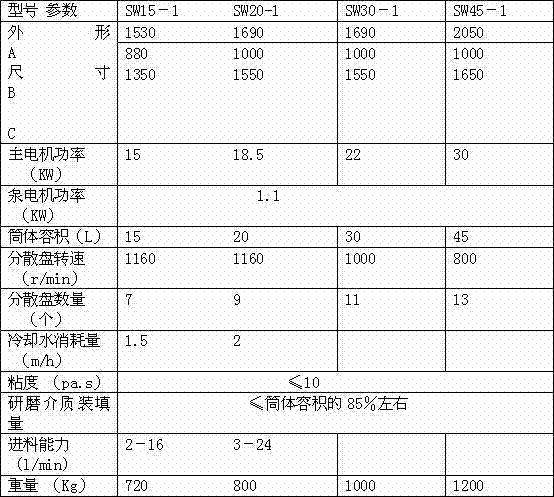

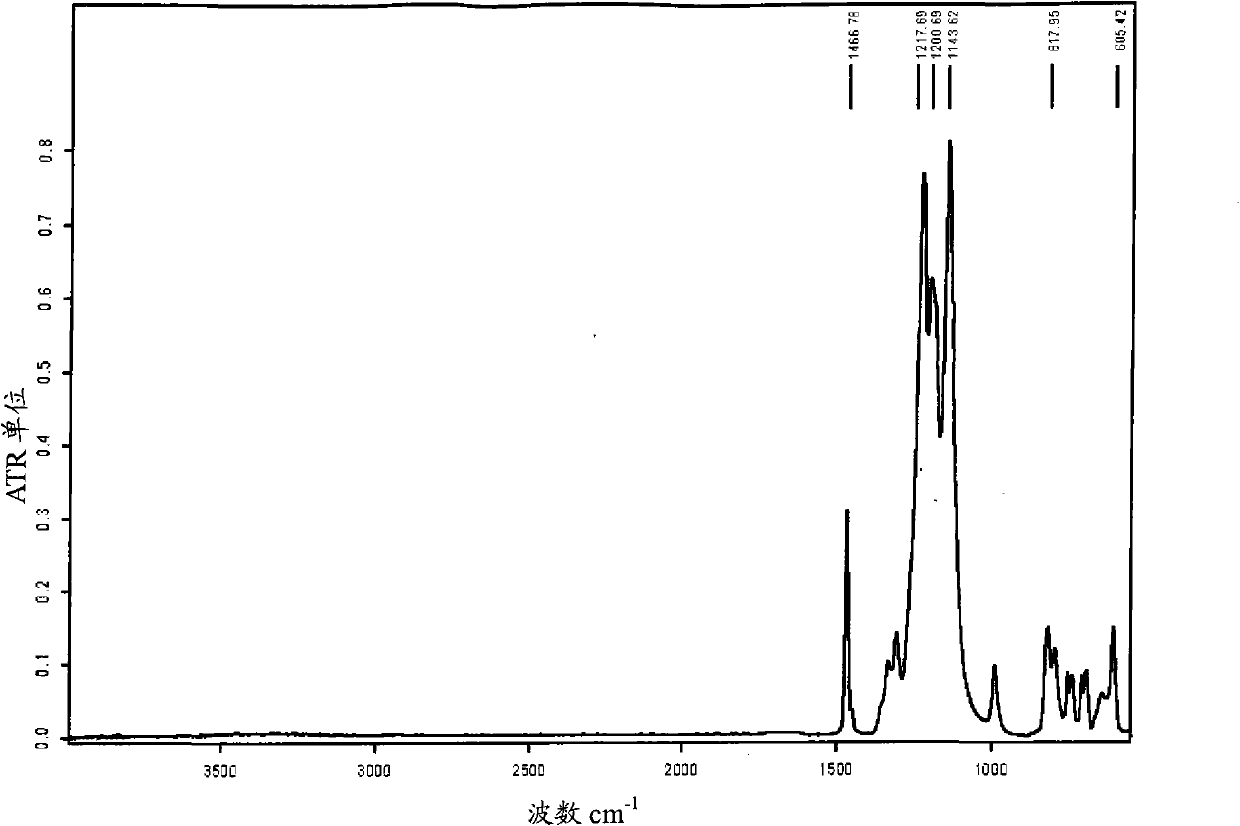

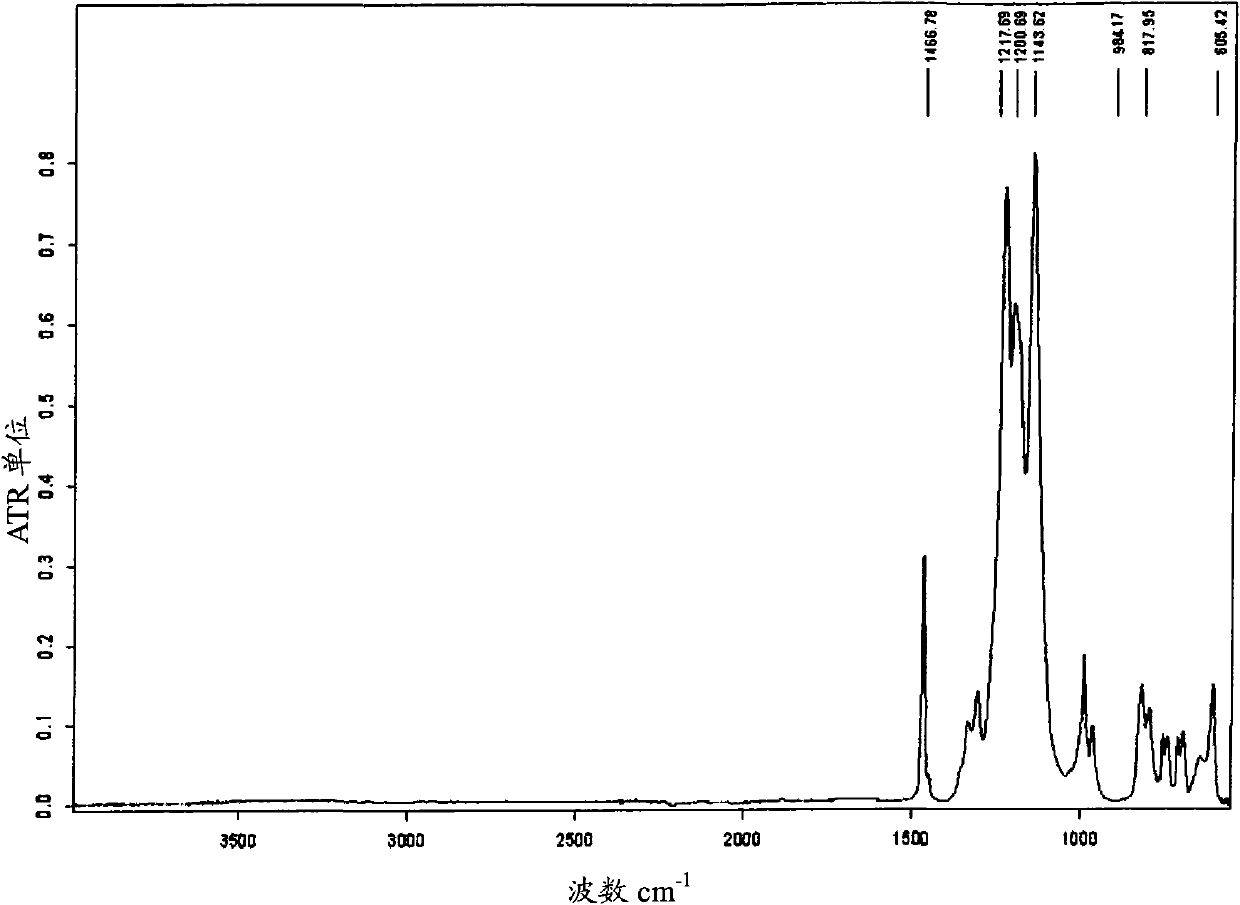

Aqueous transparent heat insulation paint and its preparation method

The invention relates to an aqueous transparent heat insulation paint, which contains, by weight, 2.0-5.0 parts of a nanometer ITO compound powder, 37.5-40.5 parts of distilled water, 44-55 parts of a waterborne FEVE fluorocarbon resin emulsion and 7.5-8.5 parts of an HDI curing agent, wherein the grain size range of the ITO compound powder is 20-50nm. The preparation method provided by the invention comprises the following steps of: adding distilled water into a reaction container, adding the nanometer ITO compound powder into distilled water by high speed dispersion for 15-50 minutes until the powder becomes a paste, adding the obtained paste into the FEVE emulsion, followed by middle speed dispersion for 15-50 minutes to obtain an intermediate product, adding the HDT curing agent into the intermediate product with stirring, followed by middle speed dispersion for 15-50 minutes to obtain the product. The product provided by the invention has excellent heat insulation performance and low price, can be used for microwave attenuation and can also be used in fields such as a glass paint for buildings.

Owner:深圳佳德威油漆有限公司

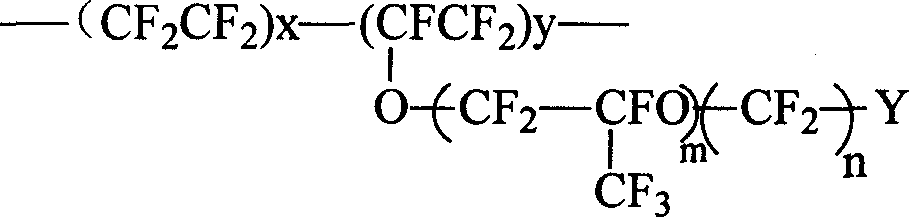

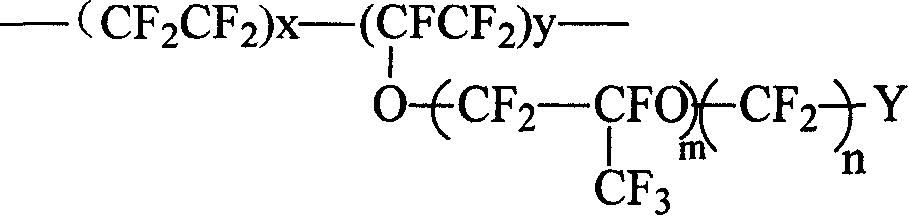

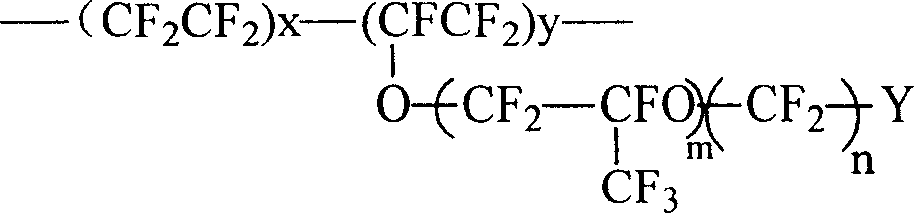

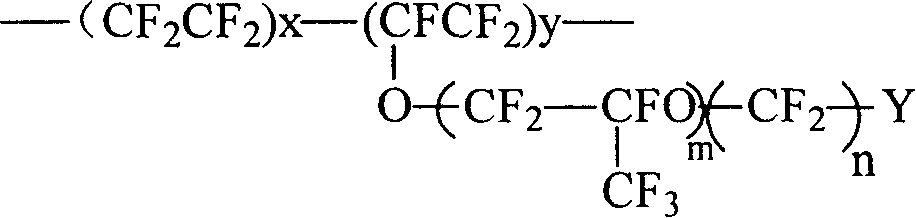

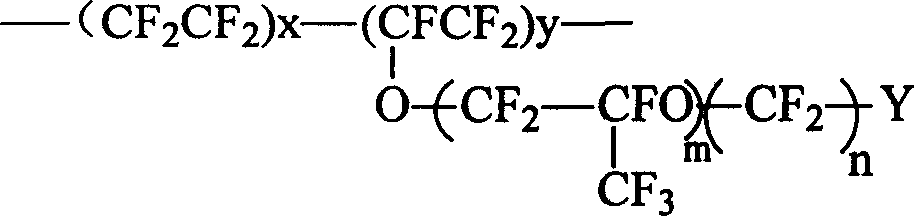

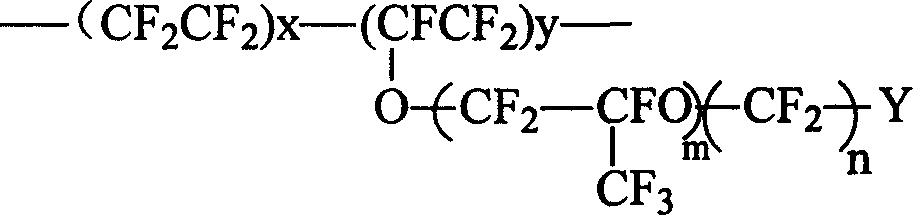

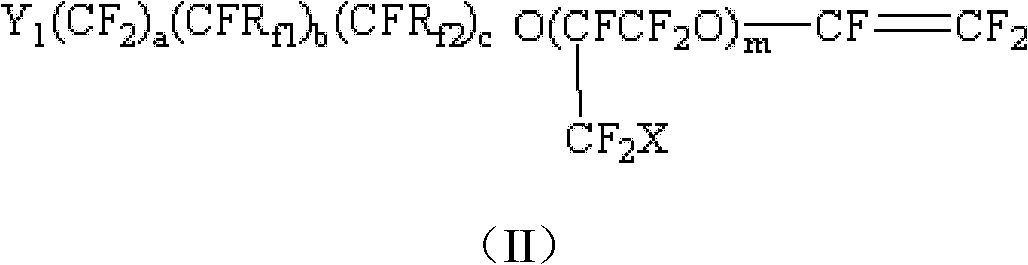

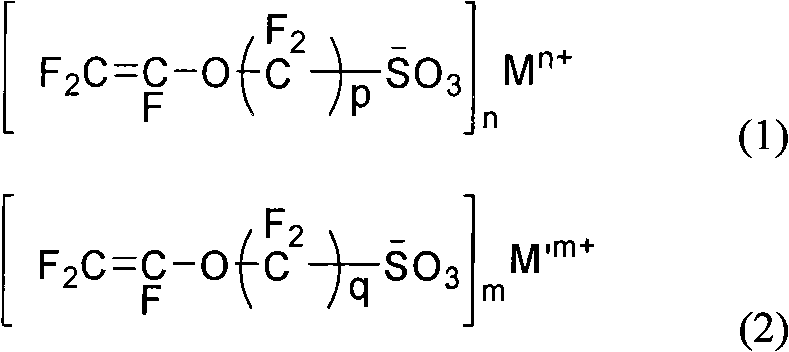

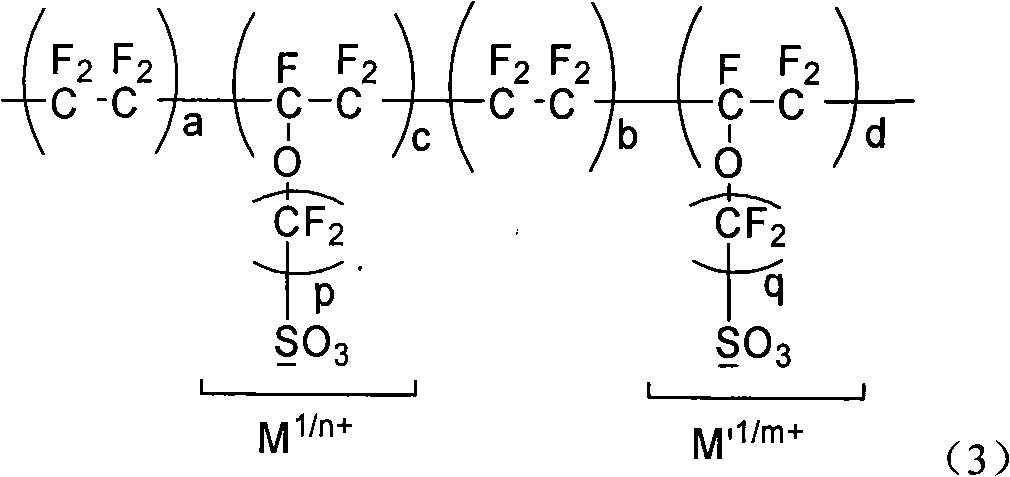

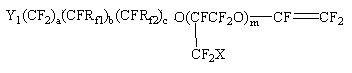

Perfluorinated ion exchange resin as well as preparation method and application thereof

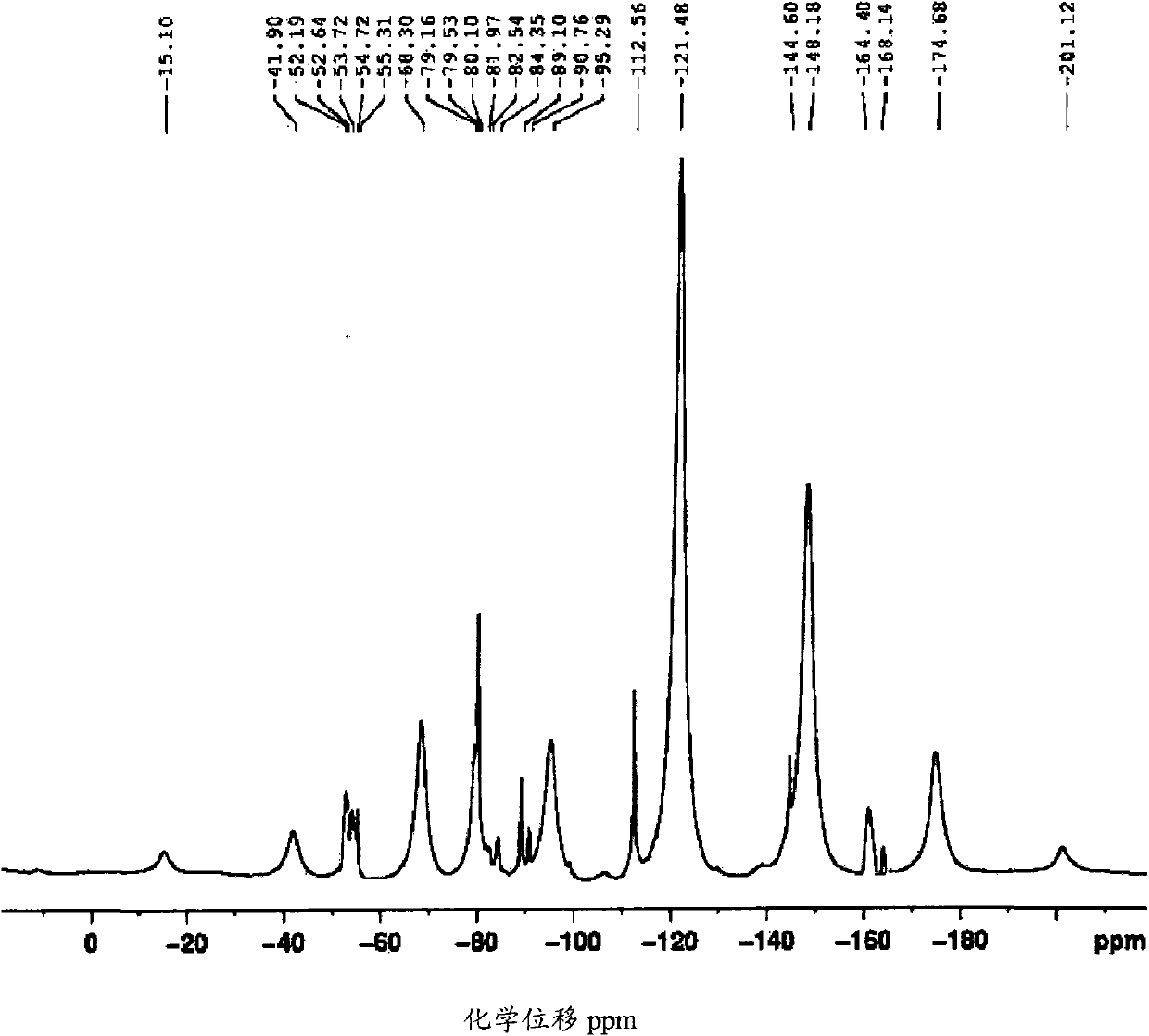

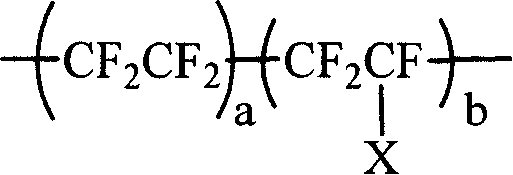

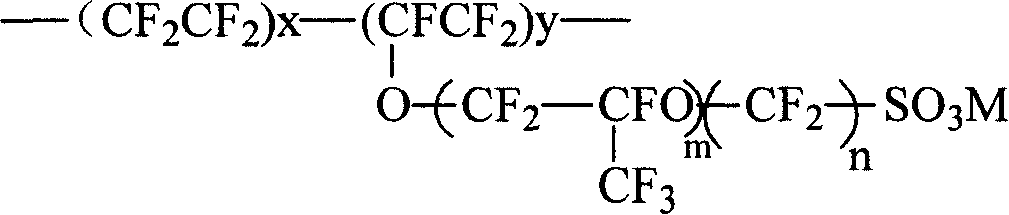

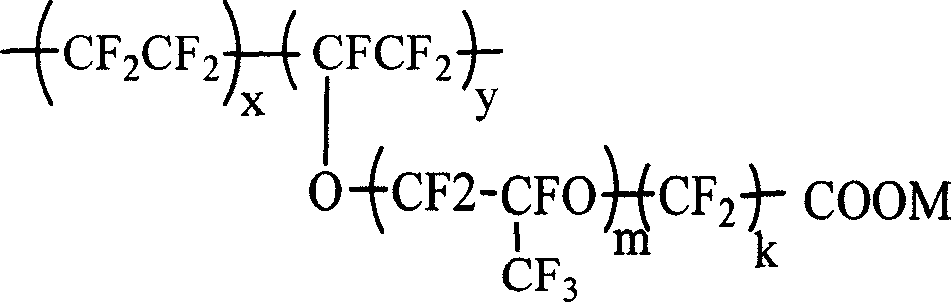

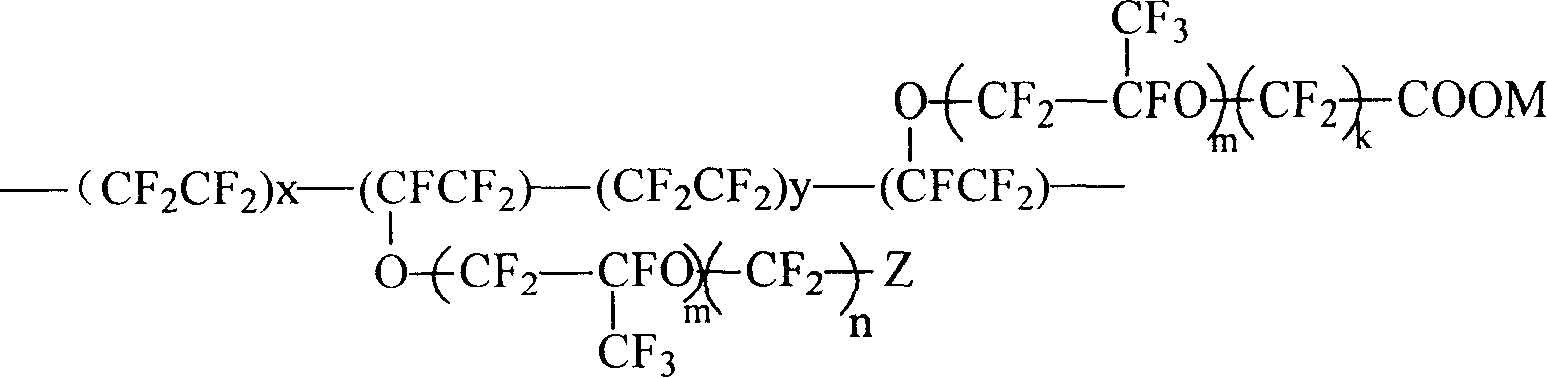

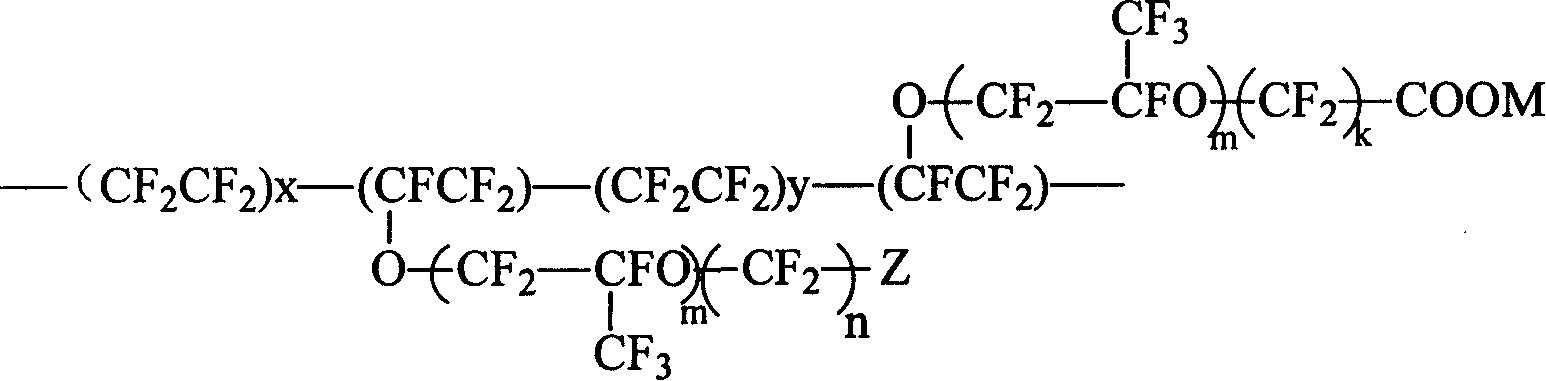

ActiveCN101768236ASolve the problem of insufficient molecular weightAct as a dispersantSemi-permeable membranesCell electrodesTetrafluoroethylenePolymer science

The invention provides a perfluorinated ion exchange resin as well as a preparation method and application thereof, wherein the perfluorinated ion exchange resin is provided with a phosphonate side group and sulfonyl fluoride short side groups with two different structures and has the function of high exchange capacity. The perfluorinated ion exchange resin is formed by tetrafluoroethylene, sulfonyl fluoride alkene ether monomers with the short side groups in two different structures, and a phosphonate side group alkene ether monomer through multi-copolymerization, and the repeated unit is represented by the following formula. An ion exchange membrane made of the resin can not only have various chemical media resistance, but also have high iron exchange capacity, high conductivity, high mechanical strength, high dimensional stability, low membrane resistance and long service life and is applicable for a fuel cell and a high-temperature fuel cell.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Single slice type ambipolar ion-exchange membrane and preparation method thereof

InactiveCN101497001AFacilitates delivery and dissociationLow film resistanceSemi-permeable membranesIon-exchange membranesFunctional monomer

The invention relates to a uniwafer type bipolar ion exchange membrane and a method for preparing the same. An anion exchange layer and a cation exchange layer of a bipolar membrane are combined on two sides of the same carrier material respectively or the same side of a uniwafer type ion exchange membrane. The preparation method comprises the following steps that: a, according to certain proportion, an evocating agent, a functional monomer, a comonomer, a crosslinking agent and other additional compositions are prepared into a reaction solution of the corresponding ion exchange layer; and b, according to different carriers, the method carries out single side or double side coating treatment, that is the reaction solution is coated on the carrier material with certain thickness; the carrier material is positioned in an ultraviolet source and is radiated so that the carrier material is cured to obtain the ion exchange layer of one side; the other side of the ion exchange layer is coated with another reaction solution, positioned in the ultraviolet source and is radiated and cured, and according to requirements, cured membrane is positioned in a corresponding ionized treating solution and treated to obtain an ion exchange layer; and the bipolar membrane of the uniwafer type ion exchange layer is finally obtained. The voltage drop of two sides of the membrane is reduced; and the method has low cost and rapid reaction speed and is simple and feasible.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Perfluorinated ion exchange casting enhancement member and preparing method thereof

InactiveCN101054445ALower resistanceHigh peel strengthOrganic diaphragmsExtremely goodCarboxylic acid

A perfluorinated ion exchange membrane fusing-casting reinforced film includes reinforced substrate and ion change layer. Said reinforced substrate is a perfluorinated polymer biaxially oriented film. Said ion change layer is formed by solution casting method, having the perfluorinated ion exchange resin containing sulfonic acid group and / or carboxylic acid group as film forming resin. The film without abrupt interface between the ion exchange layers is formed by the means of solution casting and program coating so as to make the ion exchange group concentration between the ion exchange layers and different ion exchange layers achieve molecule horizontal combination and greatly improve the interface compatibility. The ion exchange membrane has a lower film resistor, a higher current efficiency, a high film planeness, extremely good mechanical strength and dimensional stability. The invention also provides producing method thereof.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

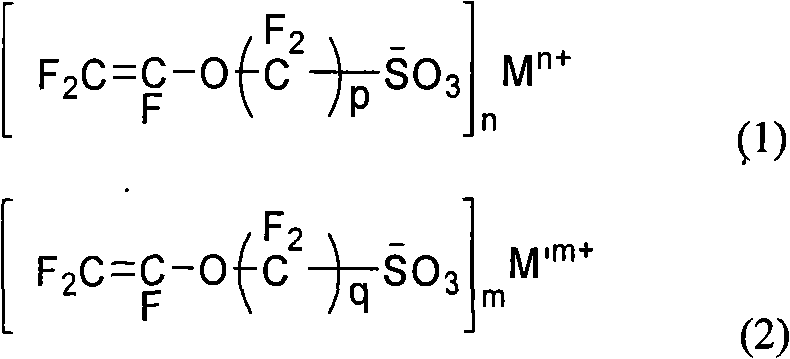

Perfluorinated ion exchange resin with high exchange capacity, preparation method and application thereof

ActiveCN101709101ASolve the ion exchange capacitySolve the strength problemSemi-permeable membranesOrganic diaphragmsVinyl etherSulfonyl fluoride

The invention provides a high exchange capacity perfluorinated resin of two types of short side-radical sulfonyl fluoride with different structures and bromine side-radical. The resin is a polyprotonic copolymer comprising the following components in total molar fraction: 50-85 percent of tetrafluoroethylene polymerization unit, 5-49 percent of the polymerization unit of the two types of short side-radical sulfonyl fluoride vinyl ether provided with different structures, and1-10 percent of bromine side-radical vinyl ether polymerization unit. A perfluorinated ion exchange membrane prepared by the resin not only has resistance to various chemical reagents, but also has high ion exchange capacity, electric conductivity, mechanical strength and dimensional stability, low membrane resistance and long service life, and is suitable for usage in fuel cells or high-temperature fuel cells. The invention also provides a preparation method and applications of the resin.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Perfluorinated resin with high exchange capacity as well as preparation method and application thereof

ActiveCN101709102ASolve the ion exchange capacitySolve the strength problemSemi-permeable membranesOrganic diaphragmsVinyl etherTetrafluoroethylene

The invention provides a high exchange capacity perfluorinated resin of two types of short side-radical sulfonyl fluoride with different structures and cyan side-radical. The resin is a polyprotonic copolymer comprising the following components in total molar fraction: 50-85 percent of tetrafluoroethylene polymerization unit, 5-49 percent of the polymerization unit of the two types of short side-radical sulfonyl fluoride vinyl ether with two different structures, and1-10 percent of cyan side-radical vinyl ether polymerization unit. A perfluorinated ion exchange membrane prepared by the resin not only has resistance to various chemical reagents, but also has high ion exchange capacity, electric conductivity, mechanical strength and dimensional stability, low membrane resistance and long service life, and is suitable for usage in fuel cells or high-temperature fuel cells. The invention also provides a preparation method and applications of the resin.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Perfluoro ion exchange solvated film used for electolysis and its preparation method

A perfluoro-ion exchange membrane for electrolysis is prepared from the perfluoro-ion exchange resin containing sulfo and / or carboxy radicals through dissolving it in volatile solvent and program controlled coating of the solution on the template several times to form a multi-layer membrane containing the perfluoropolymer fibres as reinforcing material in at least one layer. Its advantages are low membrane resistance for high electric current efficiency and high mechanical strength and stability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL +1

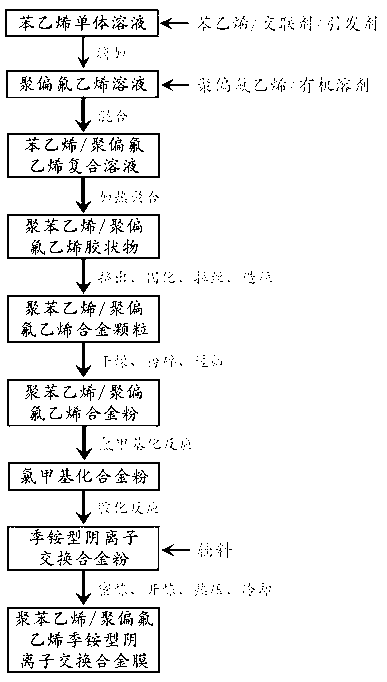

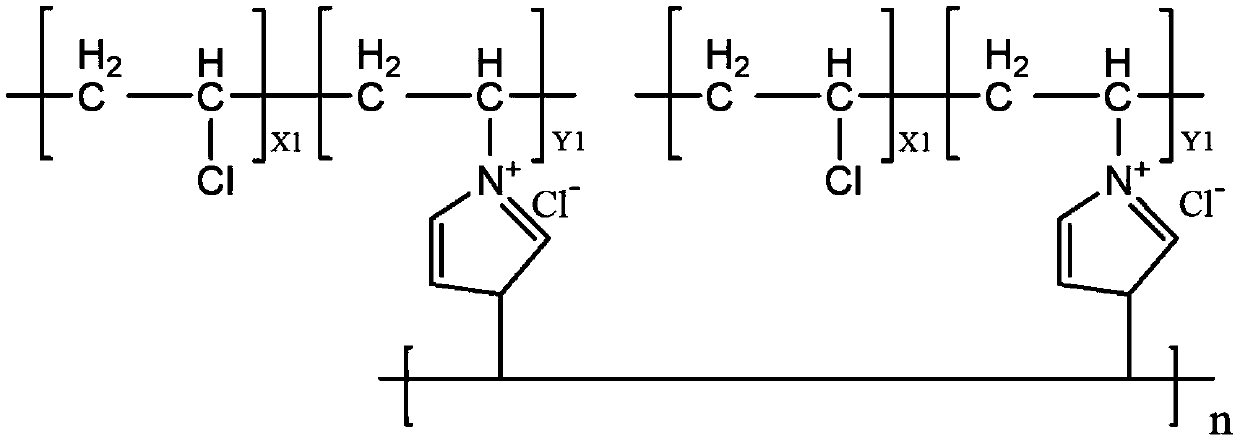

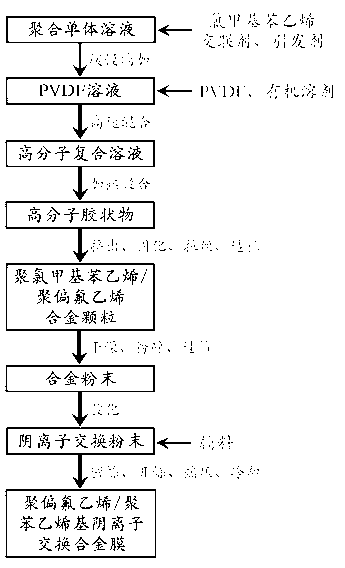

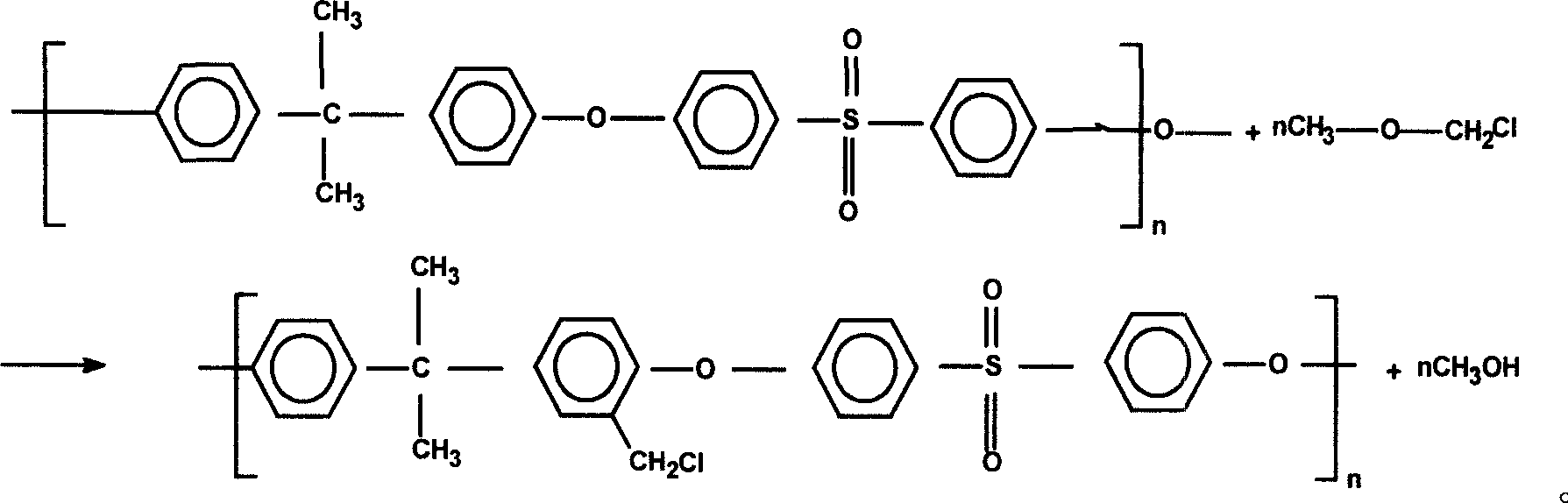

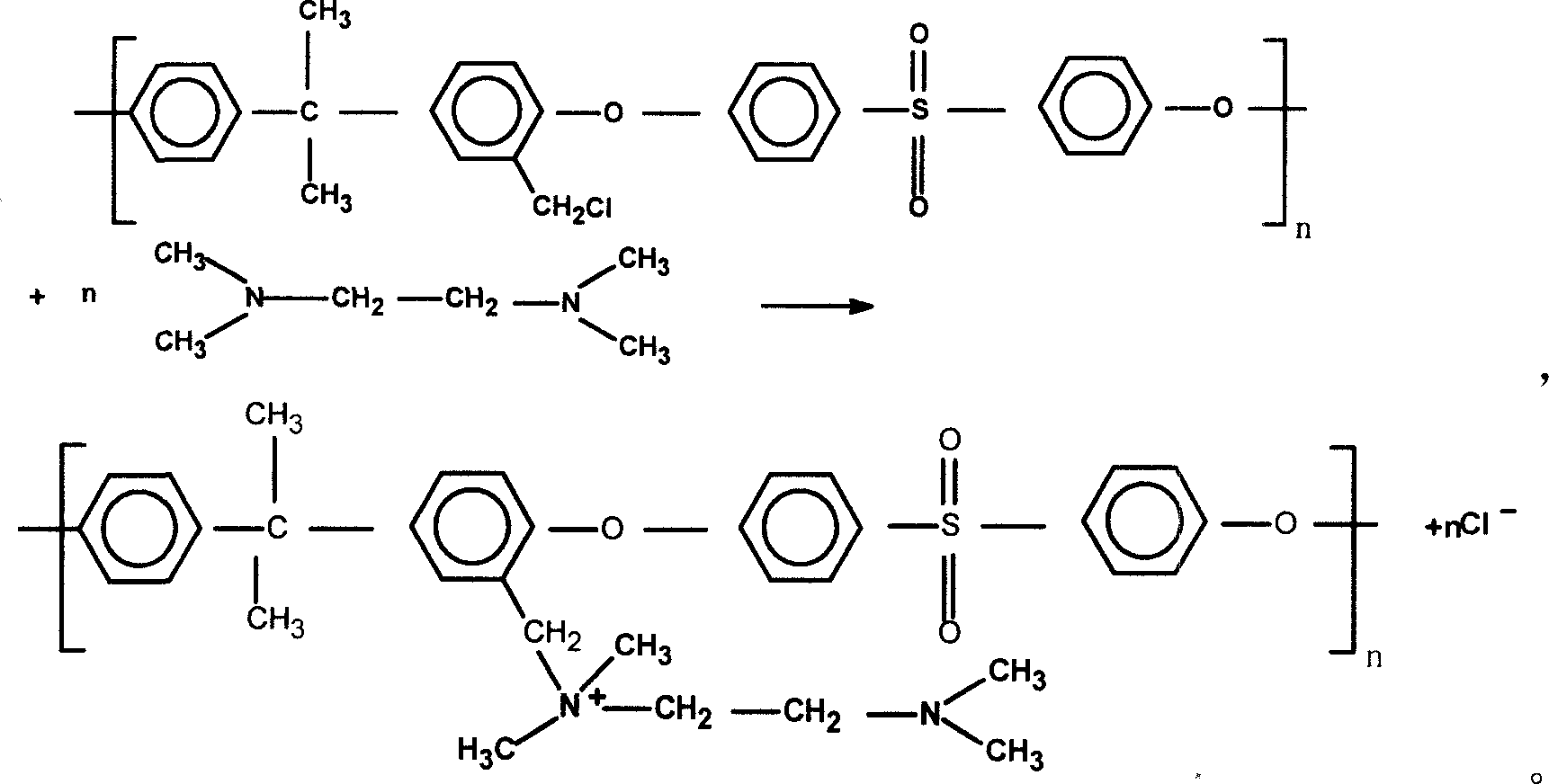

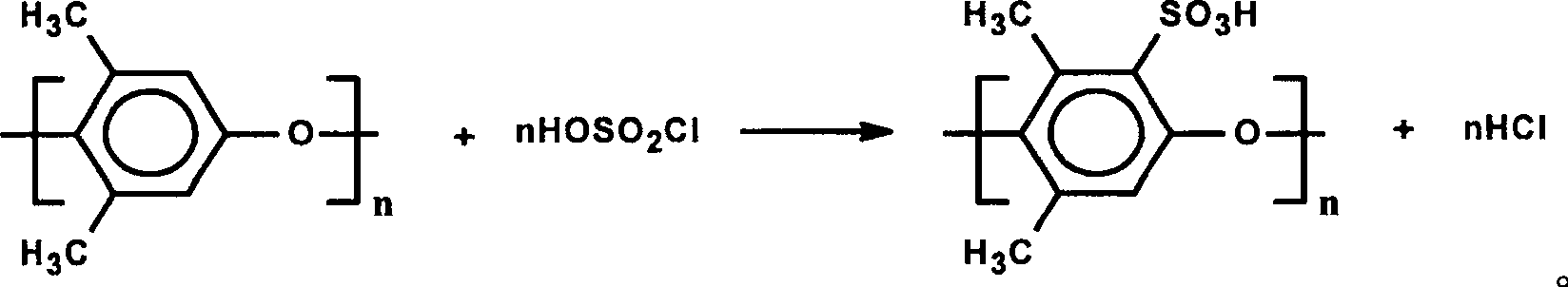

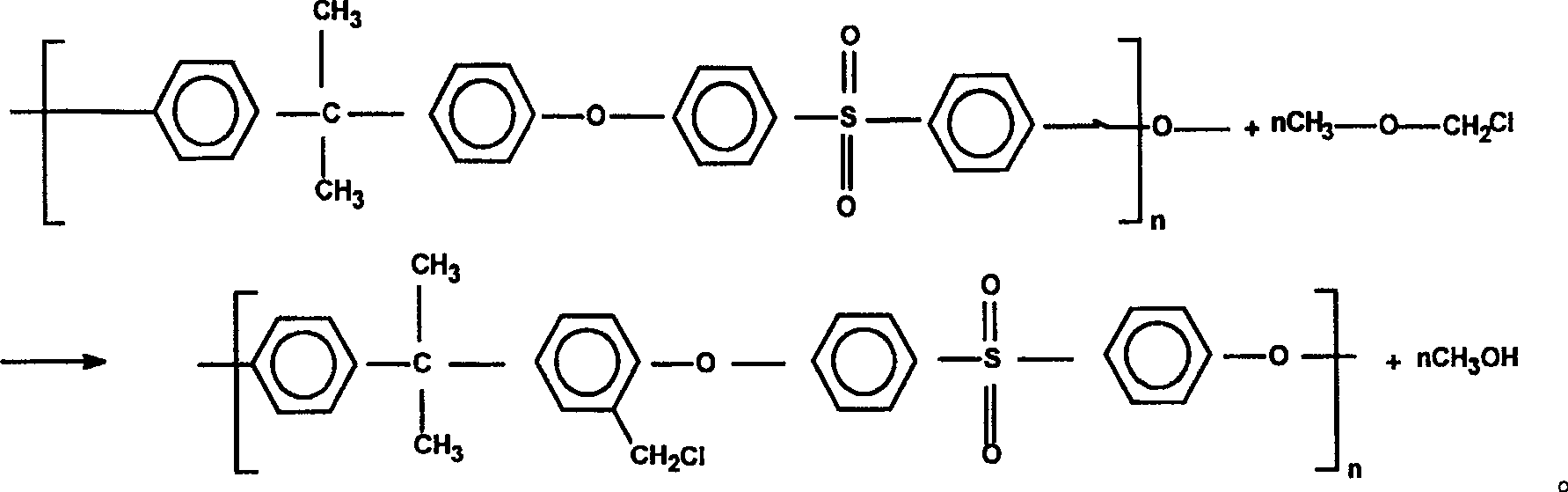

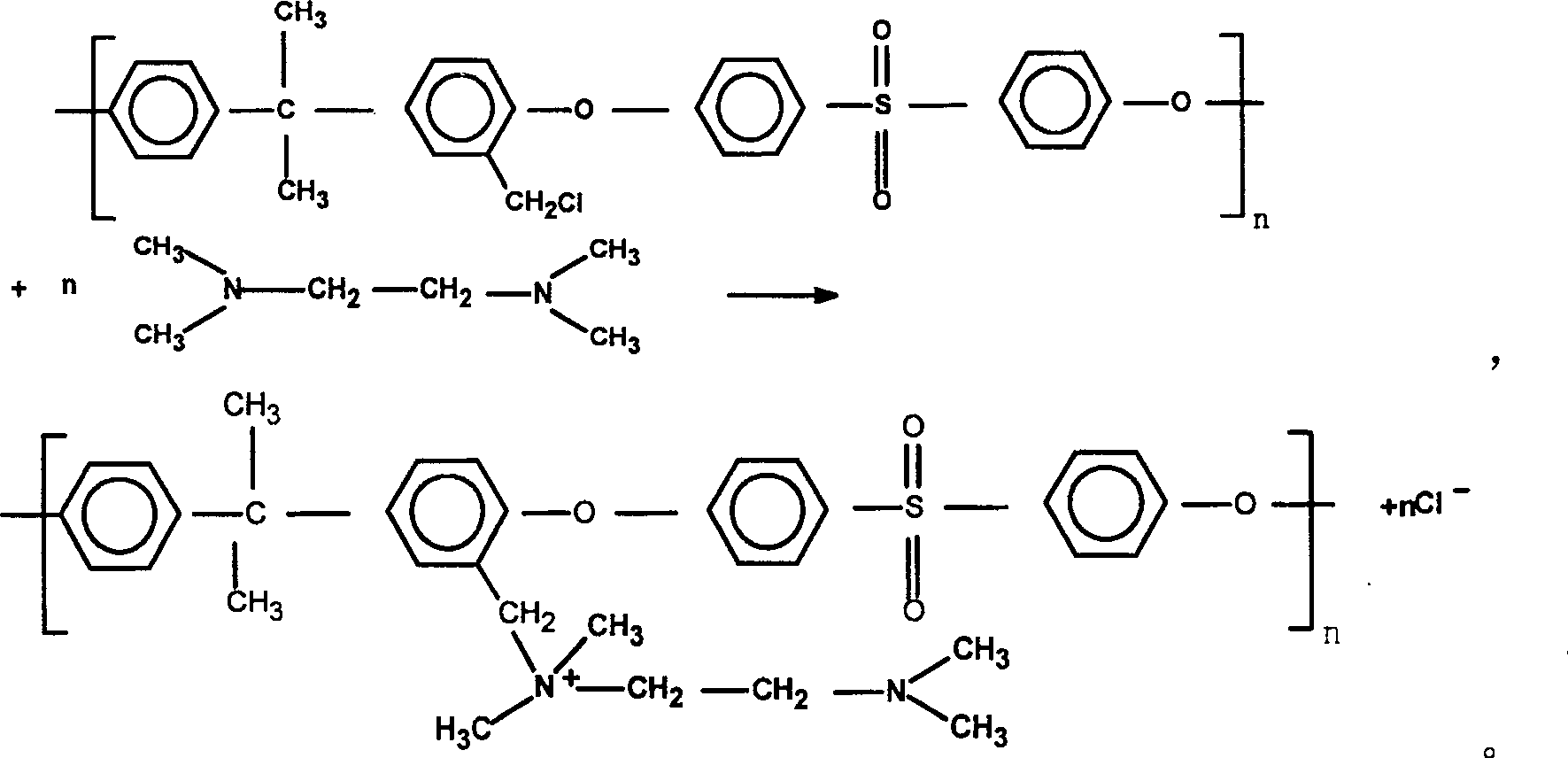

Polystyrene/polyvinylidene fluoride quaternary ammonium type anion exchange alloy film preparation method

InactiveCN103223305AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluoridePolystyrene

The invention discloses a polystyrene / polyvinylidene fluoride quaternary ammonium type anion exchange alloy film preparation method, which comprises the following steps: dissolving polyvinylidene fluoride firstly, uniformly mixing the polyvinylidene fluoride and a polymerized monomer solution containing styrene, a cross-linking agent and an initiator, and then heating for copolymerization, extruding, solidifying, granulating, drying, crushing and other steps for obtaining polystyrene / polyvinylidene fluoride alloy powder; obtaining a quaternary ammonium type anion exchange alloy powder by applying chloromethylation reaction and amination reaction to alloy powder finally using a hot pressing moulding method, adding auxiliary material, banburying, milling, pulling sheet, hot pressing, cooling and obtaining polystyrene / polyvinylidene fluoride quaternary ammonium type anion exchange alloy membrane. The quaternary ammonium type anion exchange alloy membrane prepared by the invention has the advantages of high-molecular interpenetrating network structure, which completely eliminates the structure defect that the anion exchange resin powder and the high-molecular binder in the traditional interphase anion exchange membrane are not compatible with low resistor.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Perfluoro ion exchange solvated film used for electolysis and its preparation method

ActiveCN1619017AEliminate the problemExtended service lifeOrganic diaphragmsElectrolysisCarboxylic acid

A perfluoro-ion exchange membrane for electrolysis is prepared from the perfluoro-ion exchange resin containing sulfo and / or carboxy radicals through dissolving it in volatile solvent and program controlled coating of the solution on the template several times to form a multi-layer membrane containing the perfluoropolymer fibres as reinforcing material in at least one layer. Its advantages are low membrane resistance for high electric current efficiency and high mechanical strength and stability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL +1

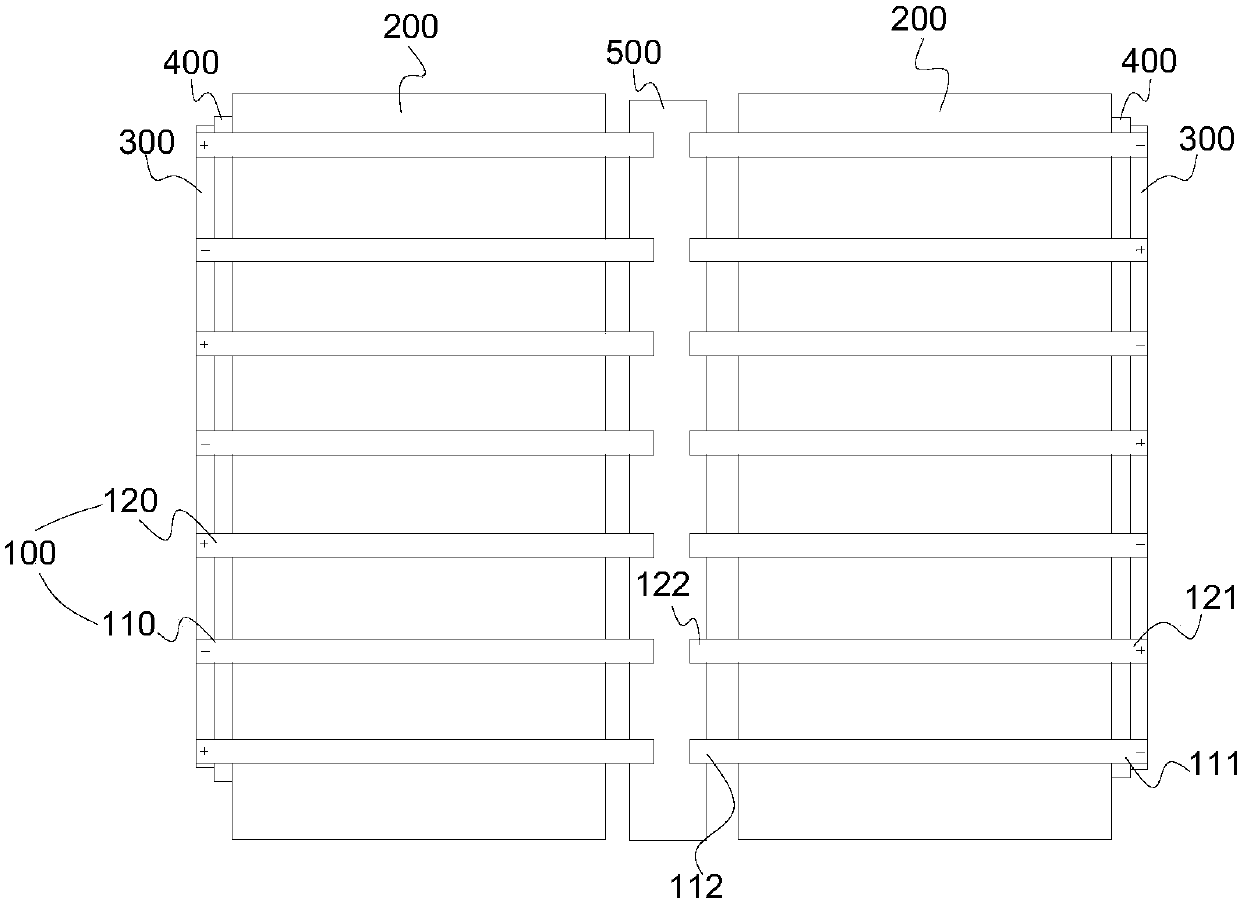

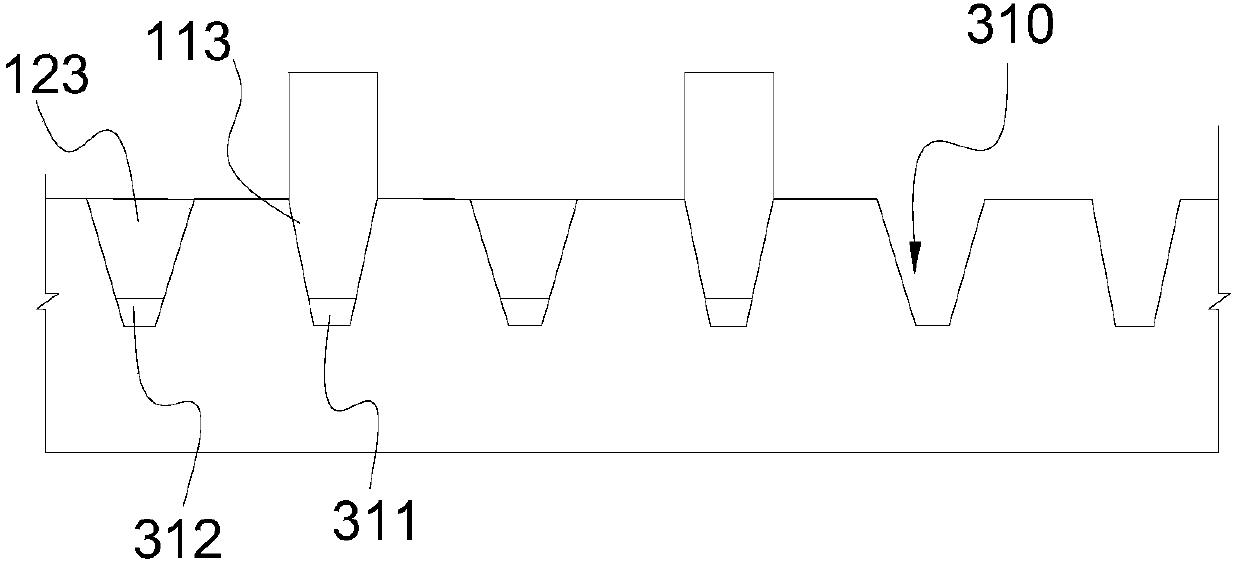

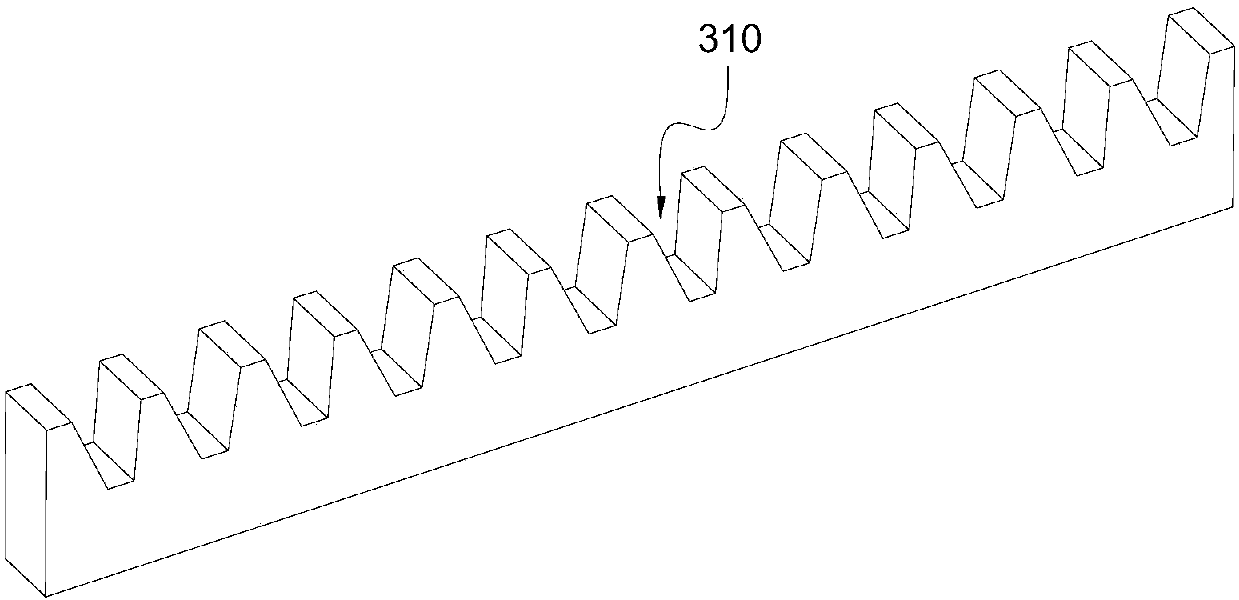

Method for improving contact resistance reduction caused by conductive contact means during zinc electrolysis

InactiveCN107916440AImproving the conductive contact mode of zinc electrolysisImprove contactPhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceElectrolysis

The invention belongs to the technical field of improvements on electrolysis equipment, and provides a method for improving a contact resistance reduction caused by a conductive contact means during zinc electrolysis. According to the method, the conventional single-sided contact is changed into the inter-groove copper-bar grooved contact, and the wedged double-sided contact is adopted for both electrode plates; and the grooved conductive copper bar and wedged conductive head design is converted from the original horizontal contact into the bevel contact. By adoption of the method, the technical problem that a lap conductive head is high in contact resistance, high in temperature, easy to oxidize and easy to deform during a conventional process of zinc electrodeposition based on wet zinc smelting can be solved; meanwhile, the total voltage of electrodeposition and the waste of electric energy can be reduced; and furthermore, the contact resistance can be greatly reduced, the easy cleaning operation and the low dirt adhesion possibility can be achieved, and the electric energy consumption can be greatly reduced.

Owner:四川四环锌锗科技有限公司

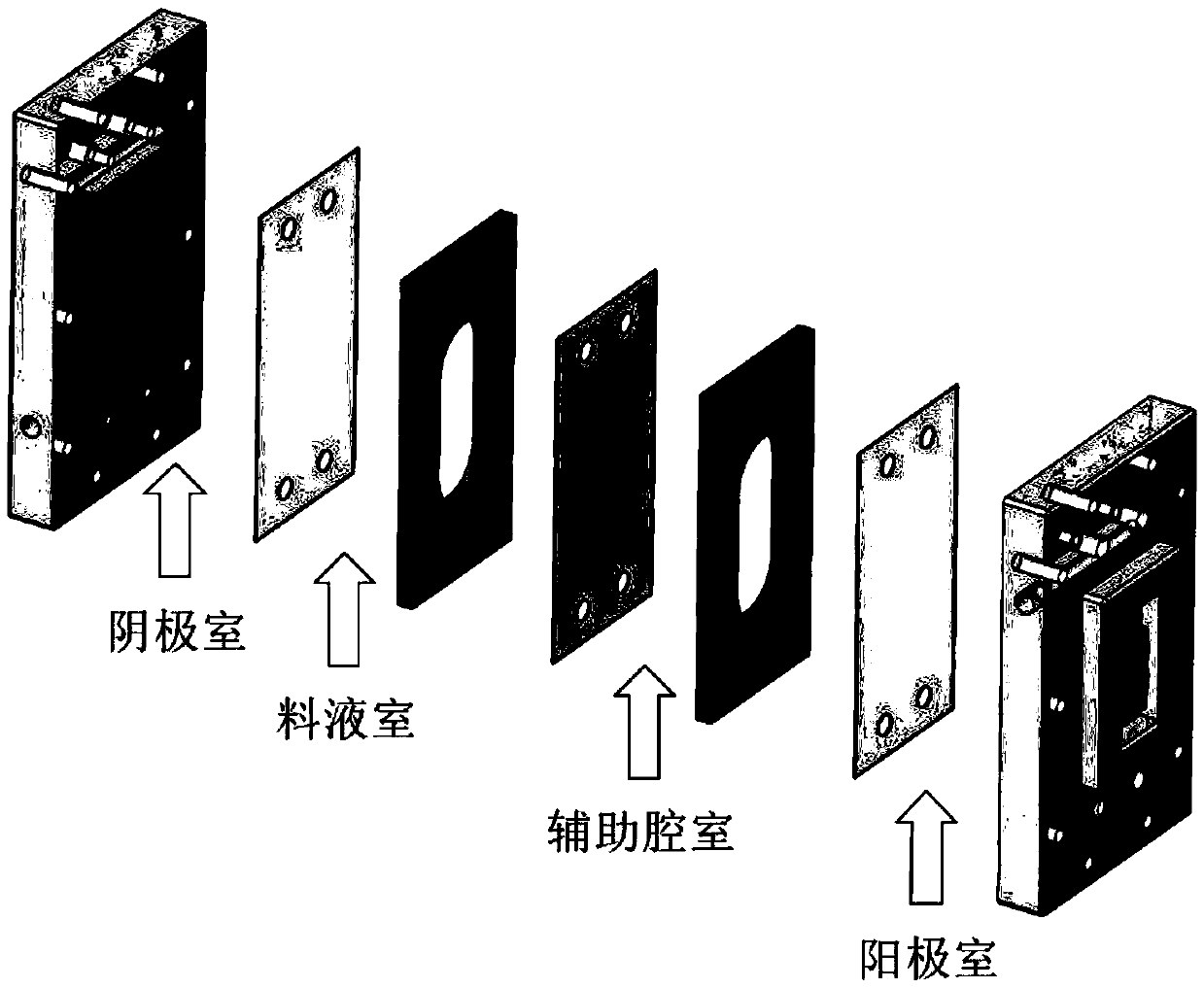

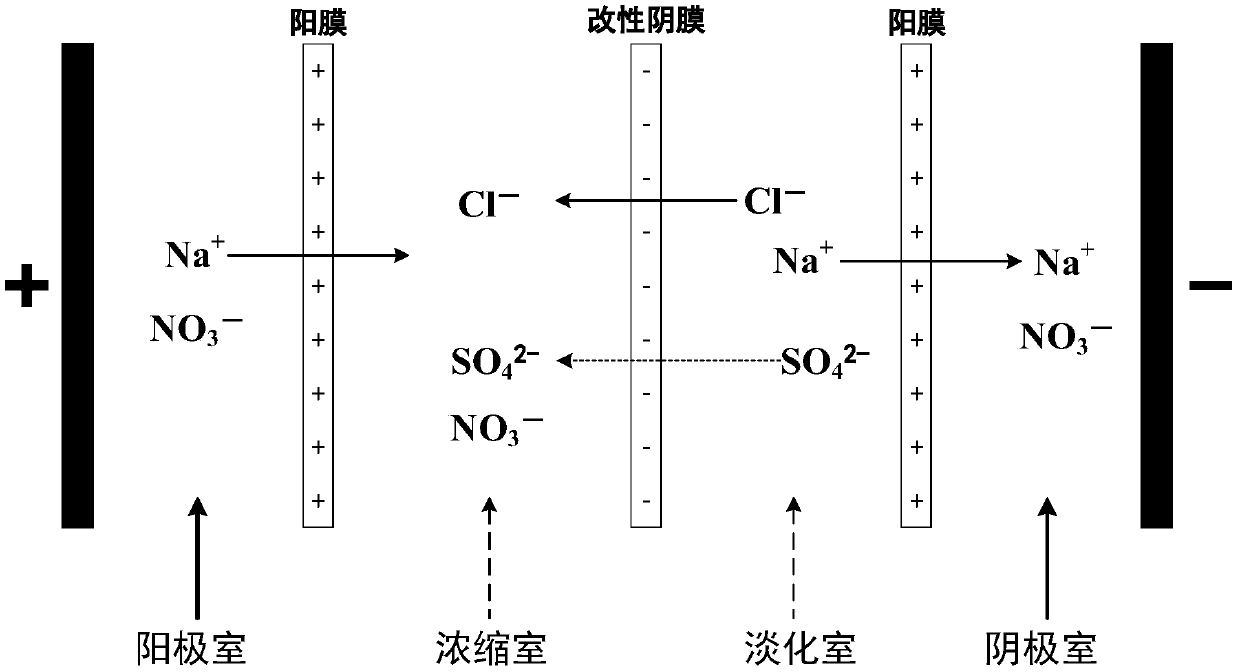

Method for preparing mono-/multi-valent ion exchange membrane by membrane fouling and electrodialysis deposition

ActiveCN108905658APrecise thickness controlTight bondSemi-permeable membranesMembranesVolumetric Mass DensityElectrodialysis

The invention discloses a method for preparing a mono- / multi-valent ion exchange membrane by membrane fouling and electrodialysis deposition. The method utilizes a phenomenon that an electrolyte in asolution performs fouling on an ion exchange membrane, and employs an electrodialysis process to foul the surface or interior of a to-be-modified ion exchange membrane by a target pollutant so as to enable the ion exchange membrane to have a mono- / multi-valent ion selective permeability, so that the mono- / multi-valent ion exchange membrane is obtained. According to the method of the invention, through chemical bond combination between the target pollutant and the ion exchange membrane main structure, the surface resistance is effectively reduced, the limiting current density under electrodialysis operating conditions is improved, and peeling of a modification compound from a membrane matrix is avoided during long-term operation. The method has a simple operation process, is easy to industrialize, has a wide range of raw materials, and has low cost in the membrane modification process.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of homogeneous PVC-based anion exchange membrane

ActiveCN110860211AHigh strengthGood dimensional stabilityMembranesSemi-permeable membranesPolymer scienceOrganosolv

The invention discloses a preparation method of a homogeneous PVC-based anion exchange membrane. The method includes the steps of: dissolving PVC in an organic solvent to form a PVC membrane casting solution, carrying out ultrasonic defoaming, then coating the membrane casting solution on a reinforced gridding cloth, and passing the membrane through a hot water tank to remove the organic solvent to obtain a continuous PVC-based membrane; preparing 1-vinylimidazole and an initiator into a uniform monomer mixed solution; subjecting the PVC-based membrane to absorption and impregnation of the monomer mixed solution under certain conditions, and then carrying out high-temperature polymerization on the PVC-based membrane subjected to monomer absorption and impregnation, thus obtaining the homogeneous PVC-based anion exchange membrane at the end of polymerization. According to the preparation method of the homogeneous PVC-based anion exchange membrane, active vinyl polymerization is carriedout to form a cross-linked structure of a PVC molecular chain, so that the membrane has low membrane resistance, high strength and good dimensional stability, also the membrane preparation process issimple, can achieve continuous roll production can be realized, meanwhile, the use of highly toxic chloromethyl ether is avoided, and the PVC raw materials are low in price and easily available.

Owner:海丝节水科技(天津)有限公司

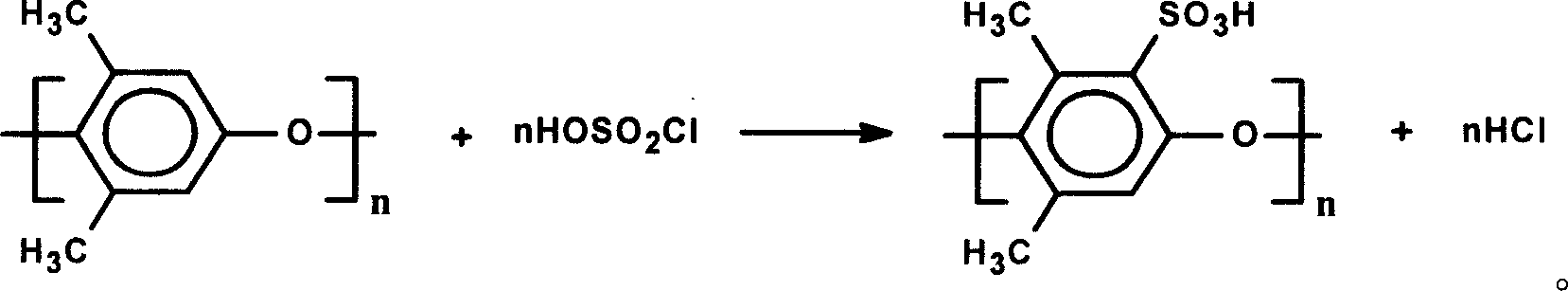

Polystyrene /polystyrene anion exchange alloy film preparation method

InactiveCN103223306AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluorideIon-exchange membranes

The invention discloses a polystyrene / polystyrene anion exchange alloy film preparation method, which comprises the following steps: adding a polymerized monomer solution which is composed of 1-(chloromethyl)-4-ethenylbenzene, a cross-linking agent and an initiator into a polyvinylidene fluoride solution, and then heating for copolymerization, extruding, solidifying, granulating, drying, crushing and other steps for obtaining PCMS / polyvinylidene fluoride alloy powder; reacting the alloy powder and the amination solution, washing, transforming, drying and obtaining the anion exchange powder; finally using a hot pressing moulding method, adding auxiliary material, banburying, milling, pulling sheet, hot pressing and obtaining polyvinylidene fluoride / polystyrene anion exchange alloy membrane. The anion exchange alloy membrane manufactured by the invention has the advantages of high-molecular interpenetrating network structure, whose membrane area resistance is greatly lower than the traditional interphase anion exchange membrane, and the comprehensive properties of the membrane approaches to the homogeneous anion exchange membrane. The invention avoids the usage of carcinogenic reagent chloromethyl ether, and is easy for realization of industrial production.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Dipolar membranes of middle boundary layer of complexation metal catalysis, and preparation method

A bipolar membrane combined with anionic and cationic exchange films for converting ammunium lactate to lactic acid while recovering ammonia water is composed of cationic exchange film, middle interface layer containing complexing metallic catalyst, and anionic exchange film.

Owner:HARBIN INST OF TECH

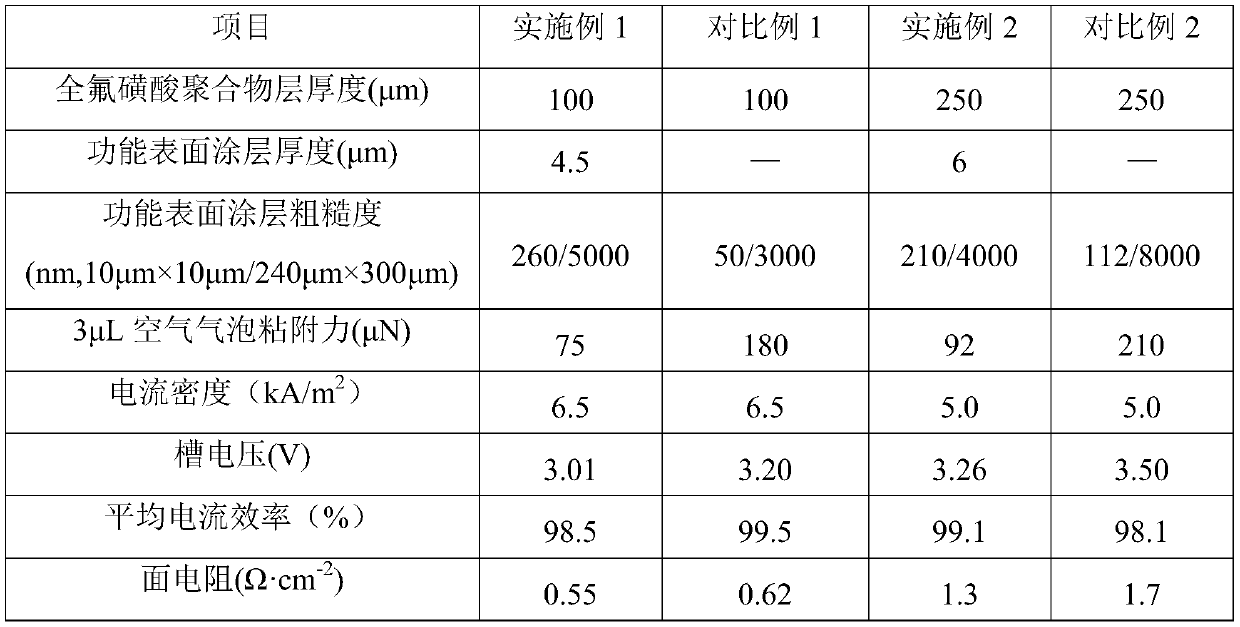

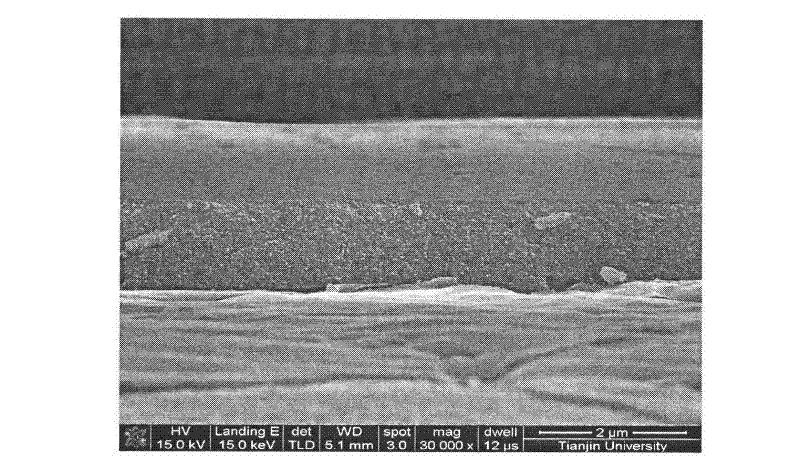

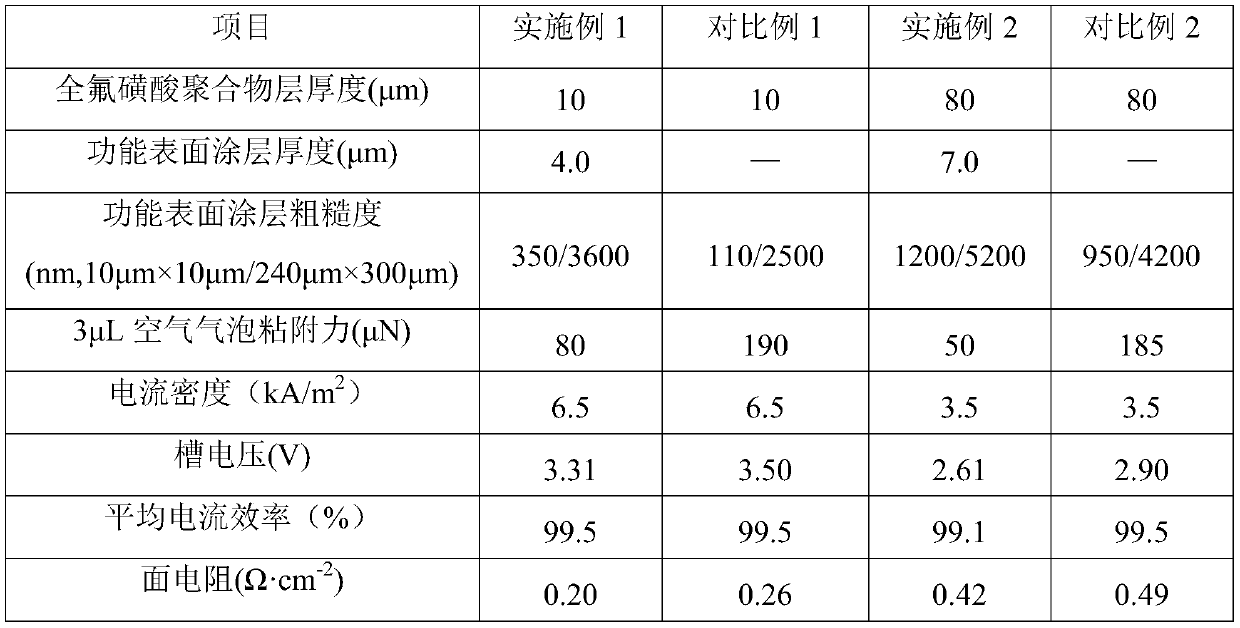

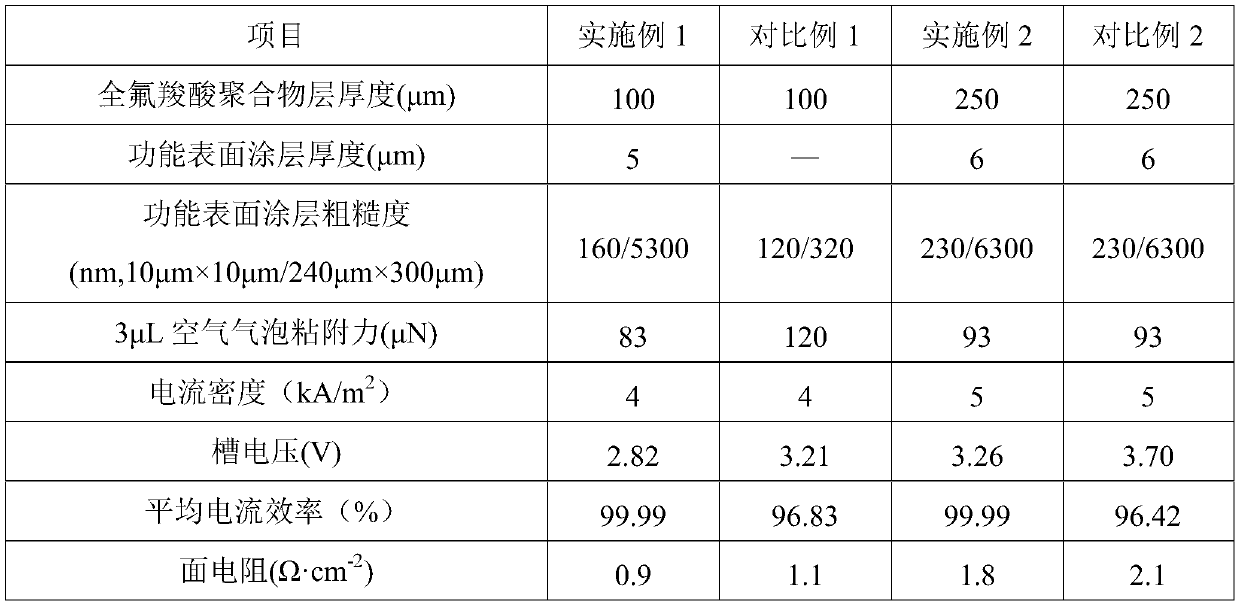

Reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis, and preparation method thereof

InactiveCN111188065AImprove mechanical propertiesLow film resistanceOrganic diaphragmsFilm resistancePhysical chemistry

The invention belongs to the technical field of ion exchange membranes, and particularly relates to a reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis, and a preparation method thereof. The perfluorosulfonic acid ion exchange membrane comprises a perfluorosulfonic acid polymer layer, wherein the surface of the perfluorosulfonic acid polymer layer is coated with a functional surface coating, the functional surface coating is composed of a perfluoropolymer and has a porous rough structure, a reinforcing material layer is embedded in the perfluorosulfonic acid polymer layer, and the reinforcing material layer is provided with a hollow tunnel structure. According to the invention, a perfluoropolymer reinforcing net is added in a perfluorosulfonic acid base membrane while a hollow tunnel is prepared in the membrane, so that the membrane has good mechanical property and low film resistance; a perfluorinated ionic polymer with ion conduction function is adopted to replace the perfluorinated sulfonic acid coating containing the metal oxide in the existing product, and the formed porous channel can improve the surface roughness of the membrane so as to improve the anti-foaming performance of the membrane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

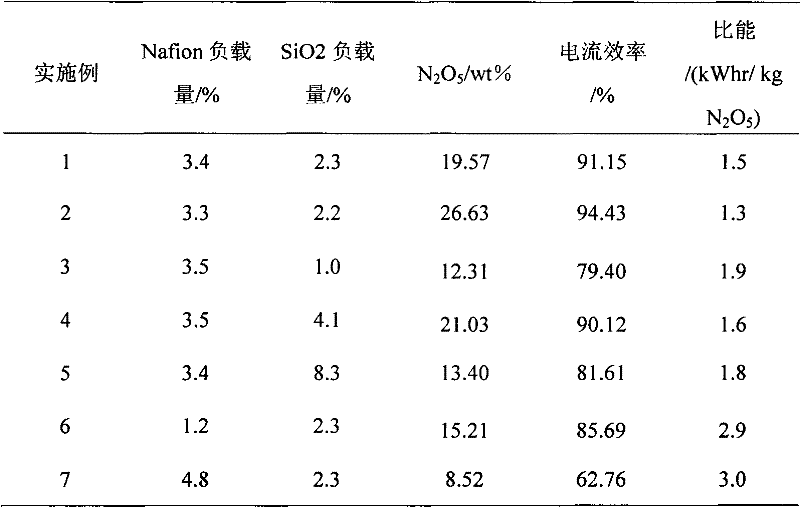

Diaphragm for electrochemical synthesis of dinitrogen pentoxide and preparation method thereof

ActiveCN102268690AReduce hydrophobicityImprove water resistanceOrganic diaphragmsTetrafluoroethyleneElectrochemistry

The invention discloses a diaphragm for electrochemical synthesis of dinitrogen pentoxide and a preparation method thereof. The diaphragm is compounded by a membrane formed by a porous polytetrafluoroethylene substrate membrane, a loaded highly-fluorinated ion exchange resin and SiO2, and an expanded polytetrafluoroethylene membrane, and has a thickness of 80-120 microns. The preparation process comprises the following steps: treating the porous polytetrafluoroethylene substrate membrane in concentrated nitric acid; loading the treated substrate membrane in a highly-fluorinated ion exchange resin solution, loading the substrate membrane loaded with highly-fluorinated ion exchange resin in SiO2 sol to obtain a porous polytetrafluoroethylene-highly-fluorinated ion exchange resin-SiO2 membrane, and pressing the membrane with an expanded polytetrafluoroethylene membrane to obtain a diaphragm for the electrochemical synthesis of dinitrogen pentoxide. The advantages of the invention are that: the diaphragm has the characteristics of low membrane resistance, high water-blocking performance, and high current efficiency; the preparation condition is mild; the production cost is low; and the preparation method facilitates industrialization.

Owner:TIANJIN UNIV

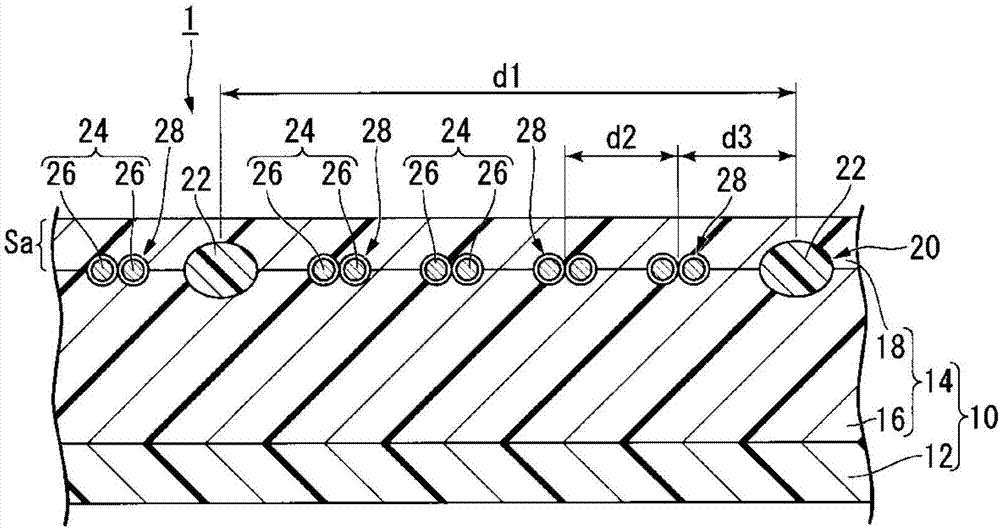

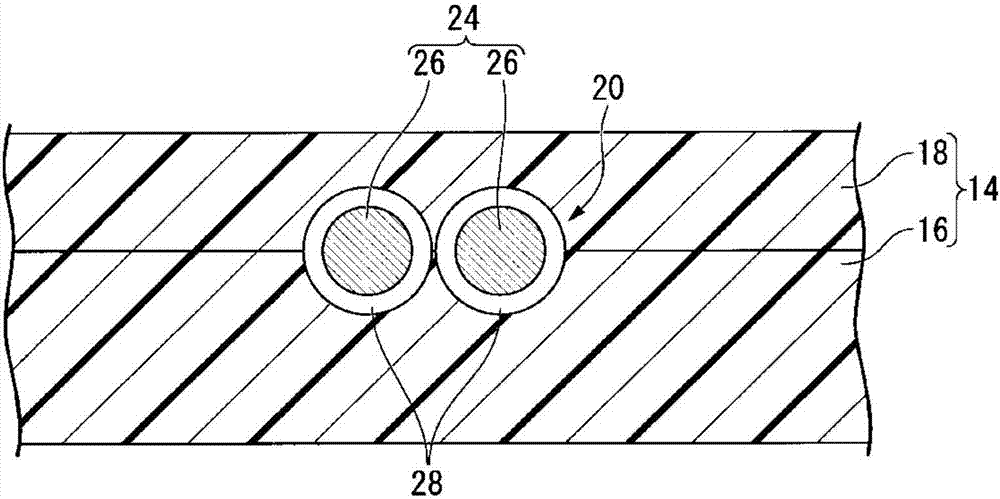

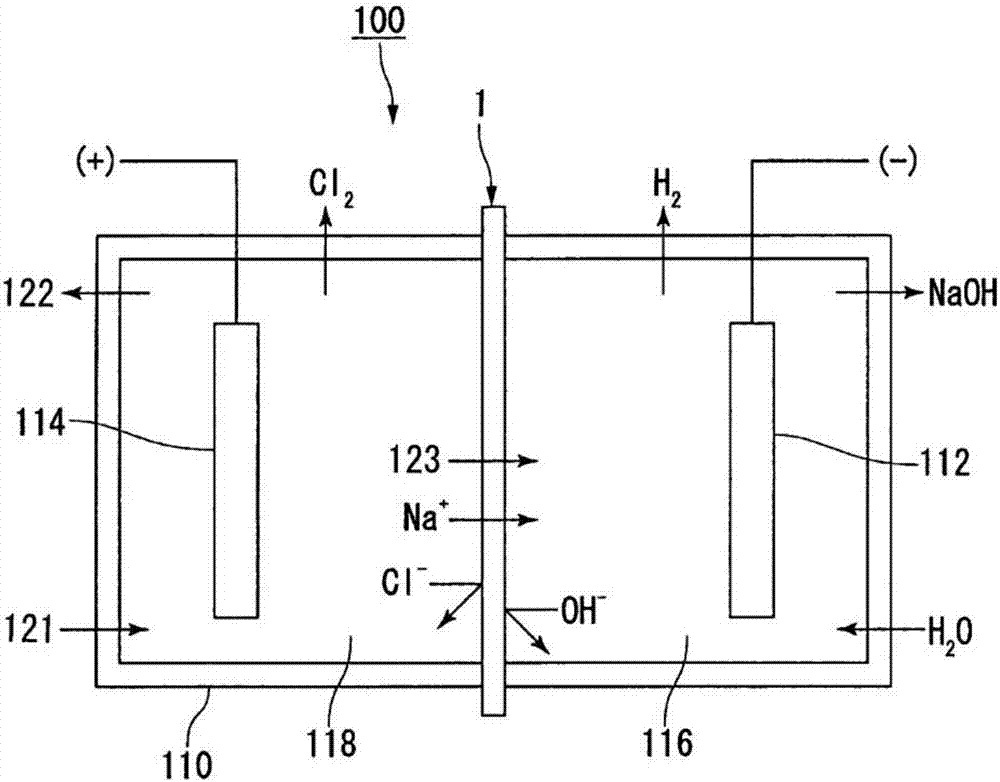

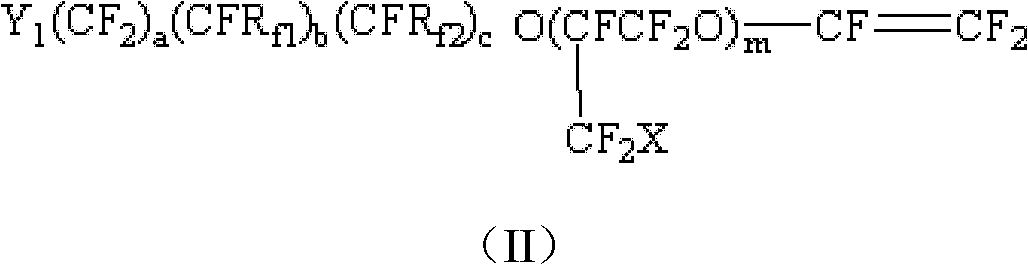

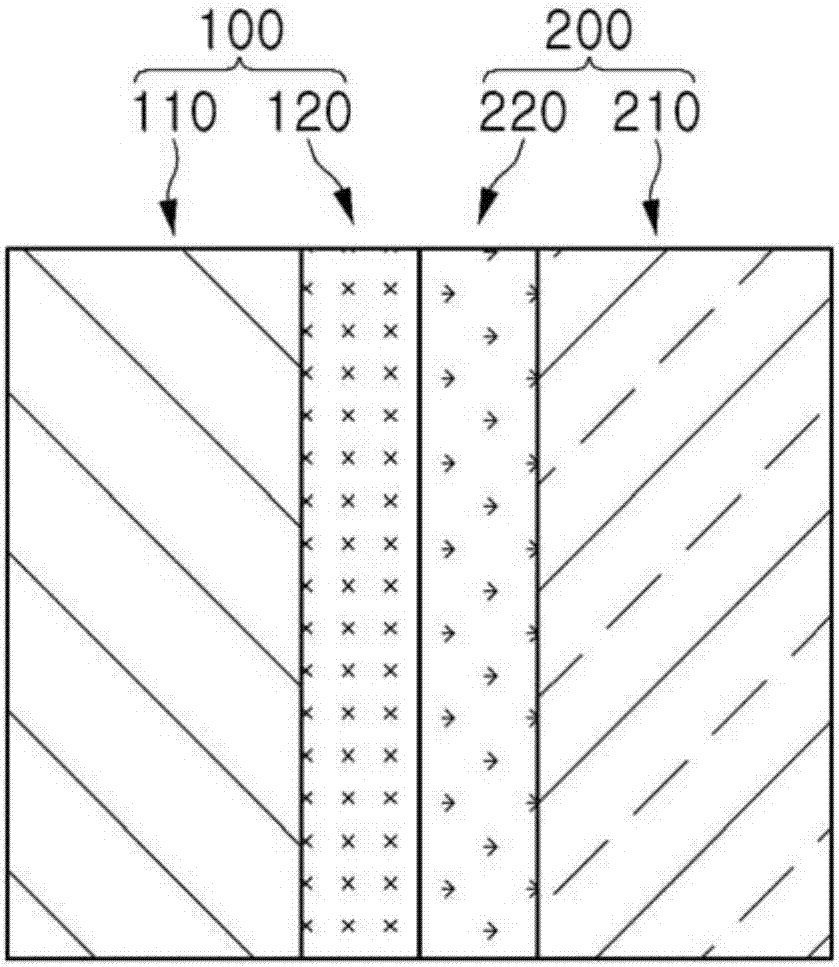

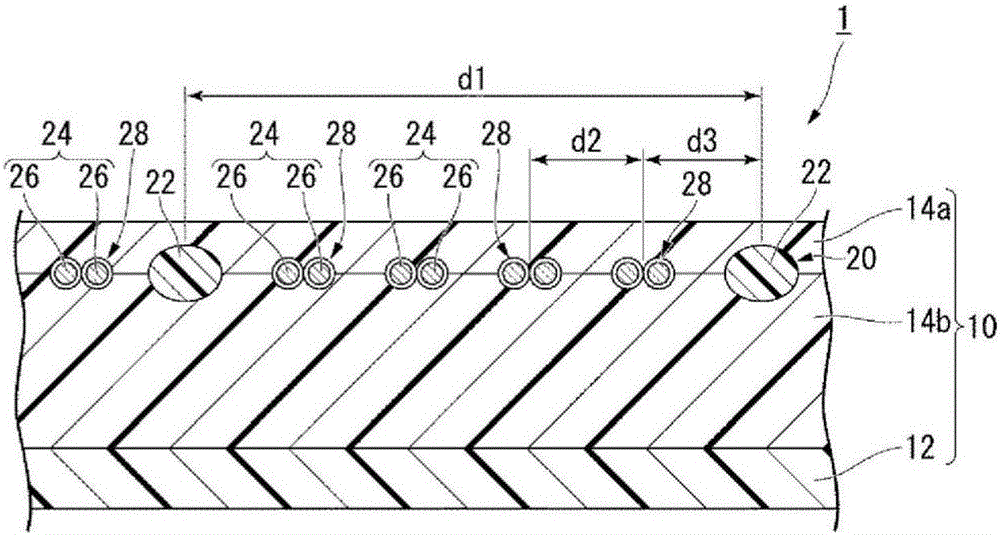

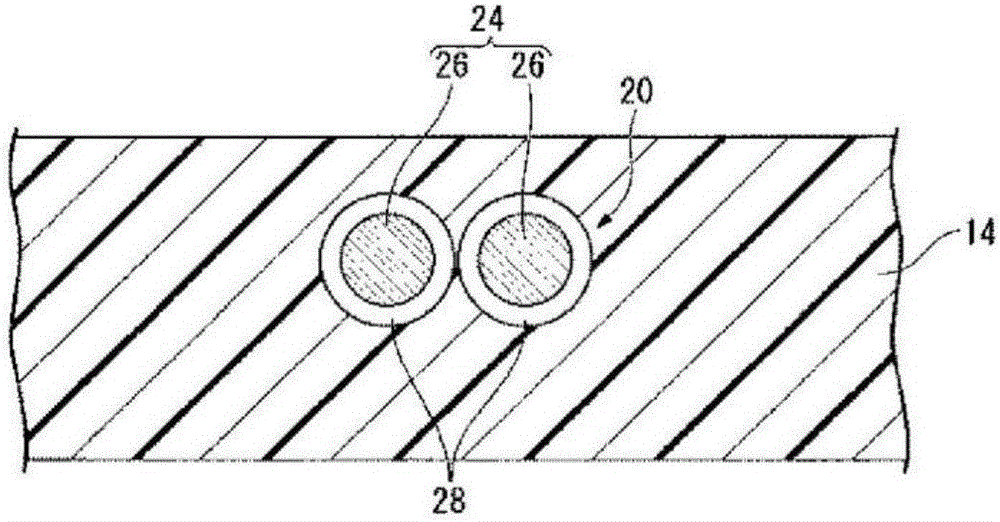

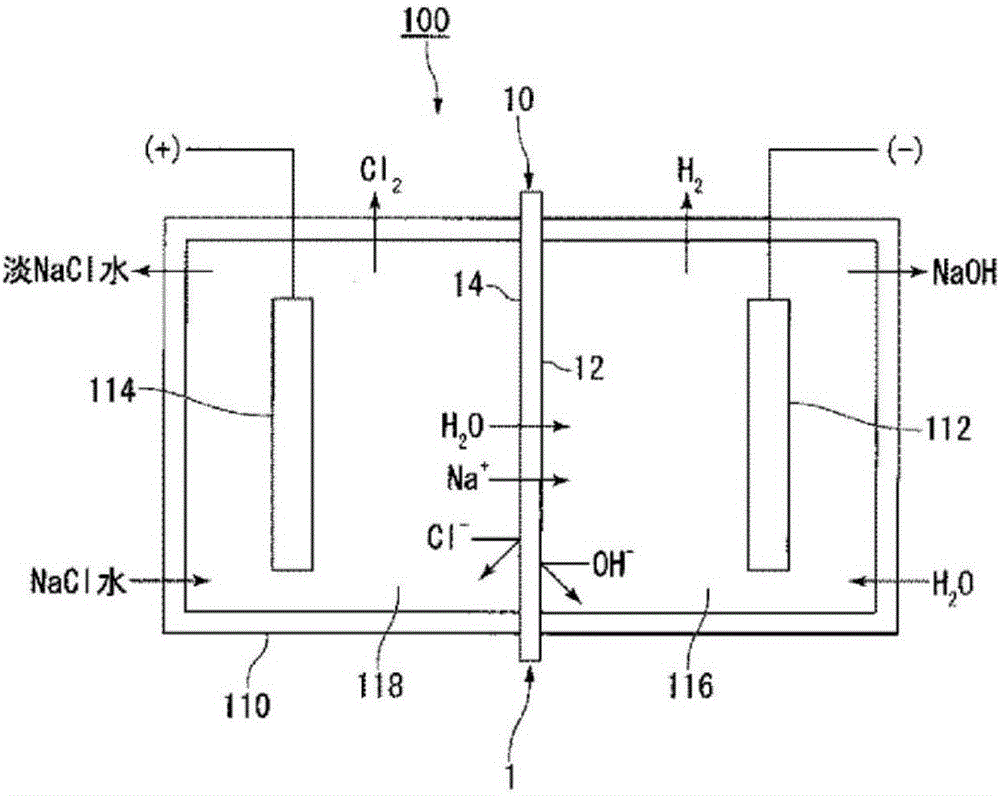

Ion-exchange membrane for alkali chloride electrolysis, manufacturing method, and alkali chloride electrolysis device

ActiveCN107109673AReduce the electrolysis voltageHigh strengthIon-exchange process apparatusCellsMetal chlorideElectrical resistance and conductance

Provided is an ion-exchange membrane for alkali chloride electrolysis which has increased membrane strength and reduced membrane resistance, thereby reducing the electrolysis voltage for alkali chloride electrolysis. In this ion-exchange membrane (1) for alkali chloride electrolysis, a reinforcing material (20) formed by weaving reinforcing threads (22) and sacrificial threads (24) is disposed in a layer (S) (14), and layer (S) (14) comprises elution parts (28) which are formed by elution of at least portions of the sacrificial threads (24). In a cross section perpendicular to the warp threads of the reinforcing threads, the average distance (d1) from the center of a reinforcing thread (22) to the center of an adjacent reinforcing thread (22), the total area (P) obtained by adding the cross-sectional areas of the elution parts (28) and the cross-sectional areas of the remaining sacrificial threads (24) in the elution parts (28), the number (n) of elution parts between adjacent reinforcing threads (22), and the ion exchange capacity of a layer (Sa) in layer (S) (14) closest to the positive electrode side upon alkali chloride electrolysis are controlled within specific ranges.

Owner:ASAHI GLASS CO LTD

Diaphragm for flow battery and preparation method thereof

ActiveCN102522574AGood chemical stabilityExtend working lifeCell component detailsFuel cell detailsImideIon-exchange membranes

The invention relates to a diaphragm for a flow battery and a preparation method thereof. The diaphragm is filmed by perfluorinated resin; at least one of the two surfaces of the perfluorinated resin film is provided with an imide or sulfimide condensation polymer modification layer; and the modification layer is formed from intermolecular condensation reaction between two varieties of fluorocarbon chain double functional group substances. The surface modified perfluorinated ion exchange membrane can be used as a diaphragm for a vanadium flow battery and overcome defects of high permeability of vanadium ion and huge water mobility of a Nafion ion exchange membrane; meanwhile, the diaphragm has excellent chemical stability and long service life in the battery. The invention also provides the preparation method of the diaphragm for the flow battery.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

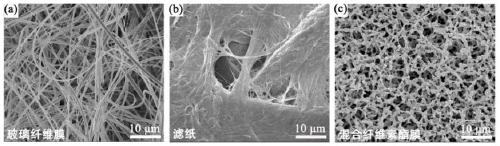

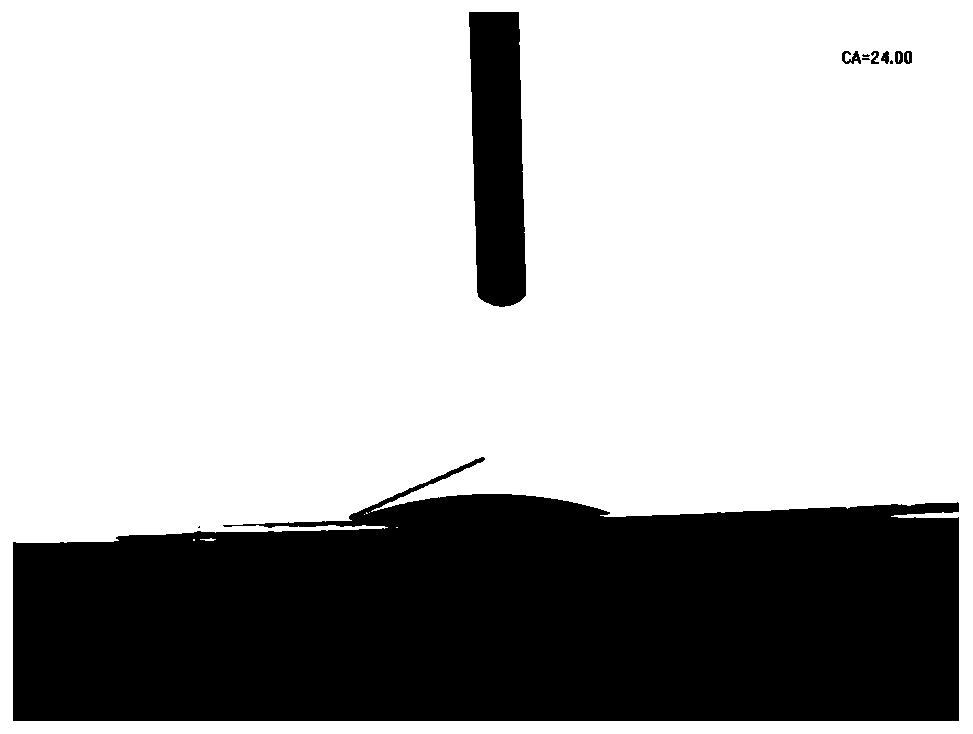

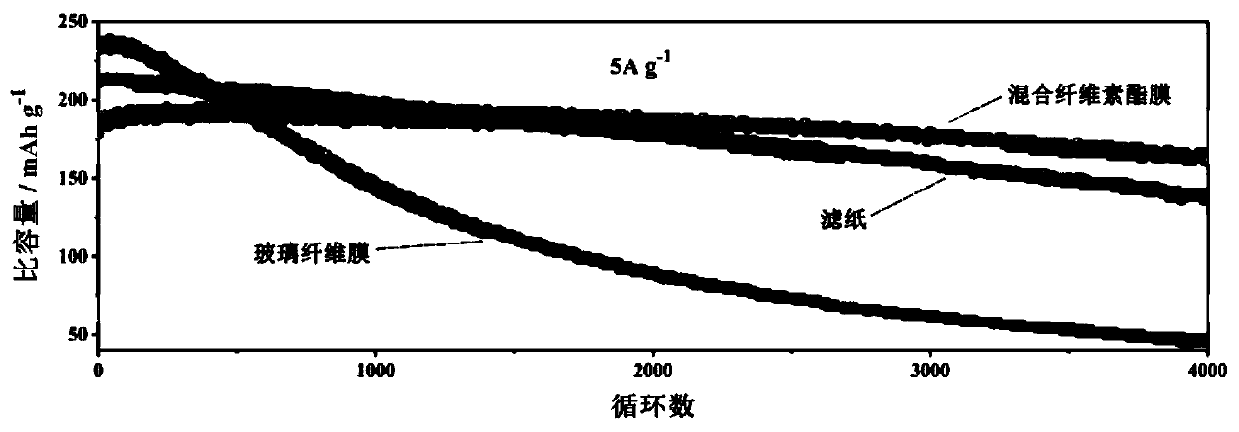

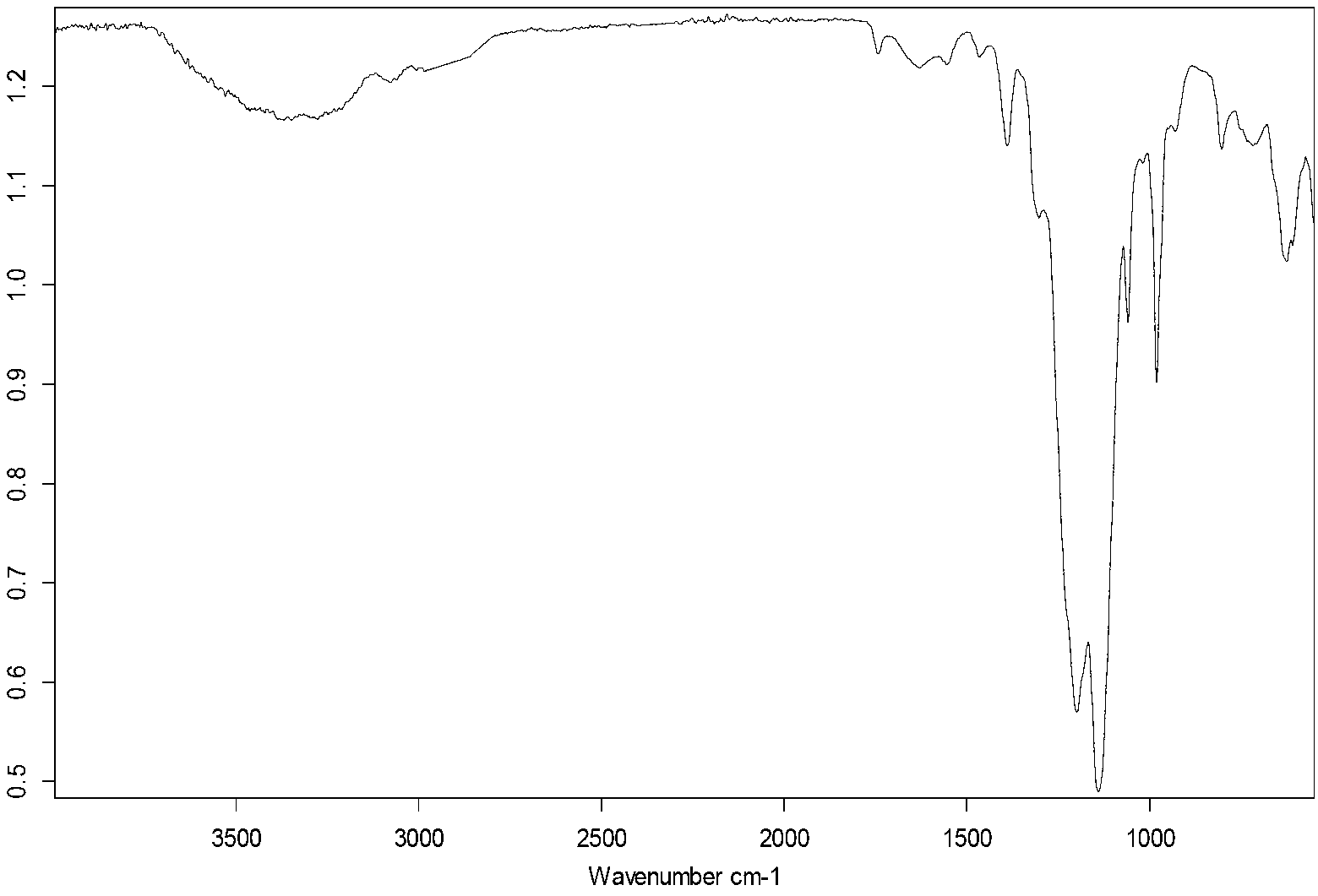

Application of mixed cellulose ester film, prepared battery and preparation method

ActiveCN111584810ALow film resistanceImprove cycle lifeFinal product manufactureCylindrical casing cells/batteryElectrical batteryCyclic stability

The invention discloses the application of a mixed cellulose ester film, a prepared battery and a preparation method. The film shows very excellent electrochemical performance as a diaphragm of an aqueous zinc-ion battery. And under the large current density of 5A g<-1>, the capacity retention ratio is still as high as 91.8% after circulation for 4000 circles, and the coulombic efficiency is closeto 100%. The novel diaphragm provided by the invention can greatly prolong the cycle life of the aqueous zinc-ion battery and improve the cycle stability of the aqueous zinc-ion battery, and is beneficial to promoting the development and application of the aqueous zinc-ion battery.

Owner:CENT SOUTH UNIV

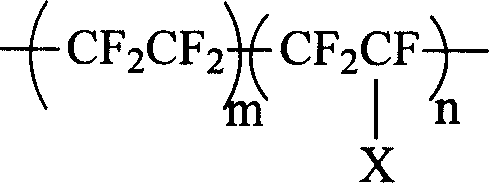

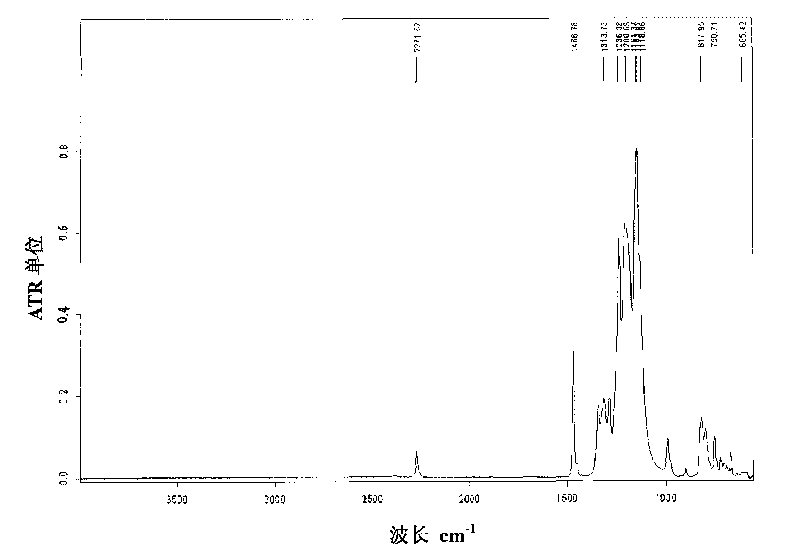

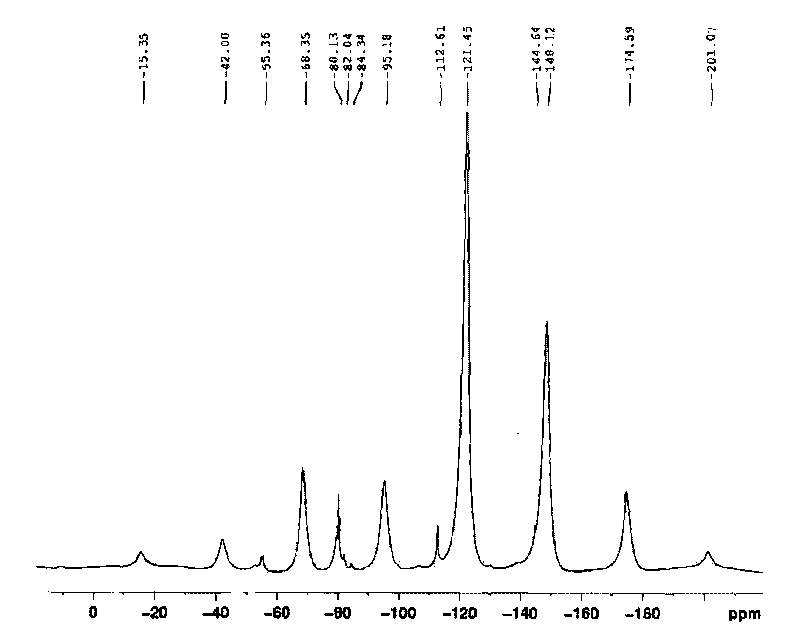

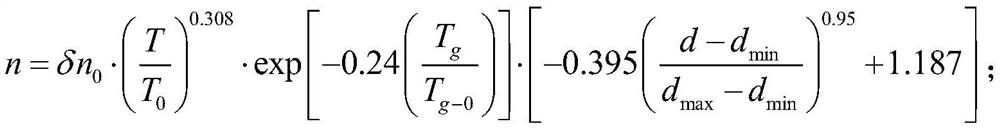

Perfluorinated ion exchange resin and preparation method thereof

ActiveCN102936310AHigh mechanical strengthStay acidicCation exchanger materialsFunctional monomerGraft reaction

The invention provides a perfluorinated ion exchange resin and a preparation method thereof. The perfluorinated ion exchange resin has a structure shown in a formula (I). The preparation method of the perfluorinated ion exchange resin comprises the following step: performing complete or partial grafting reaction on a precursor resin and a functional monomer under certain conditions. The perfluorinated ion exchange resin synthesized by the invention can simultaneously meet the requirements for high ion exchange capacity and large mechanical strength, and has wide applicability; and by regulating the ratio of the functional monomer in the raw materials, perfluorinated ion exchange resins which have different ion exchange capacities and mechanical properties to meet various requirements can be prepared.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Heating element based on thermo-electronic film and preparation method thereof

PendingCN111970772AHigh emissivityReduced energy storageHeating element materialsNickel sesquioxideSesquioxide

The invention discloses a heating element based on a thermo-electronic film and a preparation method thereof. The preparation method comprises the following steps that 1, SnCl4.5H2O is added into a mixed solution of ethyl alcohol and deionized water, heating and stirring are conducted till the SnCl4. 5H2O is fully dissolved, antimony trichloride, bismuth trichloride and titanium tetrachloride areadded and stirred to be uniform, and an electric heating film solution is obtained; 2, the preheated tubular base body is placed in a high-temperature furnace, vaporous electrothermal film liquid is introduced into the high-temperature furnace, the vaporous electrothermal film liquid is deposited on the surface of the tubular base body, heat preservation is conducted, then natural cooling is conducted, and an electrothermal film layer is obtained; wherein the tubular base body rotates around the central axis of the tubular base body in the high-temperature furnace; and 3, manganese dioxide, nickel sesquioxide, cobalt sesquioxide and chromium oxide are mixed, and the mixture is sprayed on the outer side of the electrothermal film layer to obtain the infrared emission film layer.

Owner:长春电子科技学院

Hydrophilic fluorinated polymer and preparation method thereof

ActiveCN101768233AGood chemical stabilityImprove current efficiencyOrganic diaphragmsCell component detailsVinyl etherTetrafluoroethylene

The invention provides a hydrophilic fluorinated polymer with a sulphonate side group, which is prepared by performing multi-component copolymerization on tetrafluoroethylene and two types of sulphonate side group vinyl ether monomers with different structures. A perfluorinated ion exchange membrane prepared by the assistance of the fluorinated polymer not only has resistance to various chemical mediums, but also has high electrical conductivity, high mechanical intensity, high size stability, low membrane resistance and long service life, and is suitable to be used in a fuel cell or a chlorine-alkali electrolytic cell. The invention also provides a preparation method and application of the hydrophilic fluorinated polymer.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Separator for a flow battery and preparation method thereof

ActiveCN102522574BLarge cluster structureImprove water absorptionCell component detailsFuel cell detailsImideWorking life

The invention relates to a diaphragm for a liquid flow battery and a preparation method thereof. The diaphragm is formed of a perfluorosulfonic acid resin, and at least one of the two surfaces of the perfluorosulfonic acid resin film has imide or sulfonyl The modified layer of imine condensation polymer is formed by intermolecular condensation reaction of two kinds of substances with bifunctional groups of fluorocarbon chains. The surface-modified perfluorosulfonic acid ion exchange membrane of the present invention is used as the diaphragm of the vanadium redox flow battery, which overcomes the defects of high vanadium ion permeability and large water mobility of the Nafion ion exchange membrane, and at the same time, the diaphragm has excellent chemical stability in the battery and long working life. The invention also provides a preparation method of the battery diaphragm.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

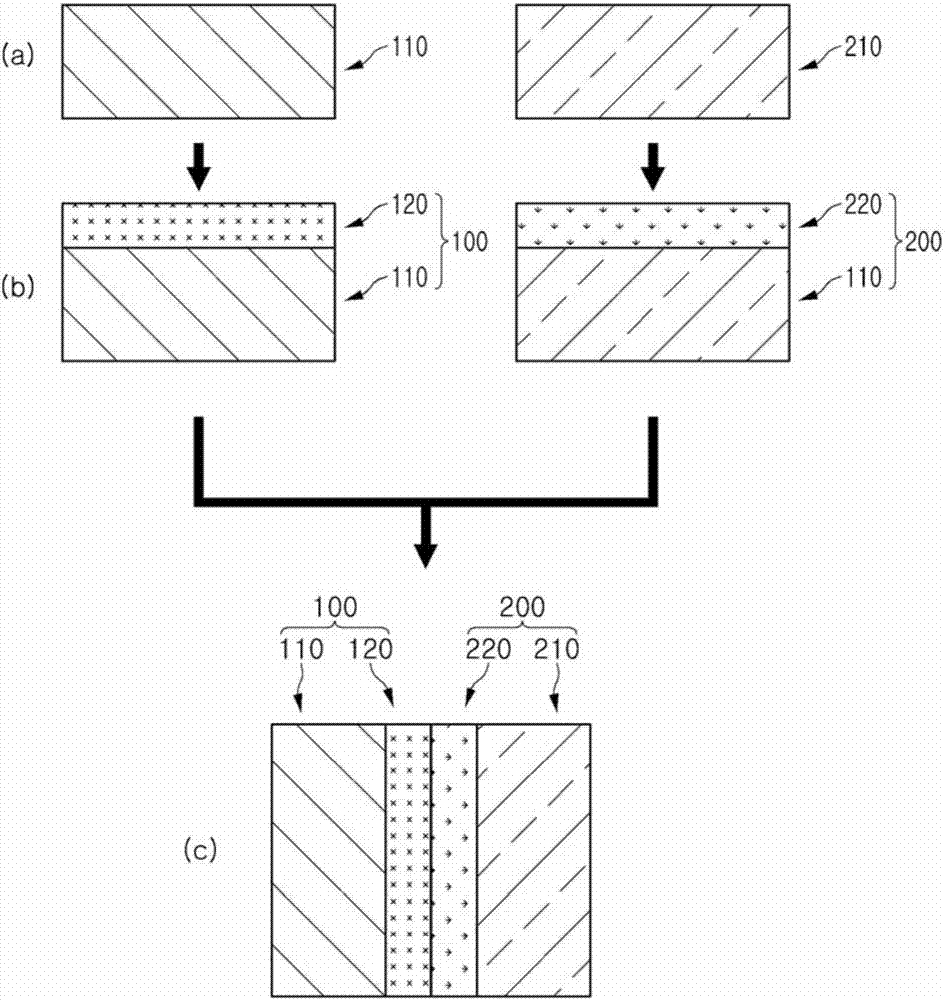

Bipolar ion exchange sheet and manufacturing method therefor

InactiveCN106999925ALow film resistanceImprove efficiencyMembranesOrganic anion exchangersPolymer scienceIon-exchange membranes

The present invention relates to a bipolar ion exchange sheet and a manufacturing method therefor, the bipolar ion exchange sheet comprising: a cation exchange film comprising a cation adsorption sheet and a cation exchange coating layer formed on one side of the cation adsorption sheet; and an anion exchange film comprising an anion adsorption sheet and an anion exchange coating layer formed on one side of the anion adsorption sheet, wherein the cation exchange film and the anion exchange film are bonded so that the cation exchange coating layer and the anion exchange coating layer face each other.

Owner:COWAY CO LTD

Ultrathin perfluorosulfonic acid ion exchange membrane for alkali metal chloride electrolysis, and preparation method thereof

ActiveCN111188050AImprove mechanical propertiesLow film resistanceOrganic diaphragmsPhysical chemistryIon-exchange membranes

The invention belongs to the technical field of ion exchange membranes, and particularly relates to an ultrathin perfluorosulfonic acid ion exchange membrane for alkali metal chloride electrolysis, and a preparation method thereof. The ultrathin perfluorosulfonic acid ion exchange membrane comprises a perfluorosulfonic acid polymer layer, wherein the surface of the perfluorosulfonic acid polymer layer is coated with a functional surface coating, the functional surface coating is composed of a perfluoropolymer and has a porous rough structure, and a porous non-woven polymer layer is embedded inthe perfluorosulfonic acid polymer layer. According to the invention, an ultrathin porous non-woven polymer is used as a reinforcing material, so that the membrane has good mechanical properties andlow membrane resistance; by adopting a perfluorosulfonic acid polymer with ion conduction function, the surface roughness of the membrane can be improved so as to improve the anti-foaming performanceof the membrane, so that the membrane is suitable for running in a zero-polar-distance electrolytic cell under a novel high-current-density condition, and the cell voltage can be remarkably reduced; and the preparation method provided by the invention is simple and reasonable in process and easy for industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Dipolar membranes of middle boundary layer of complexation metal catalysis, and preparation method

InactiveCN100482328CLow film resistanceStrong adhesionElectrodialysisPtru catalystPhysical chemistry

A bipolar membrane combined with anionic and cationic exchange films for converting ammunium lactate to lactic acid while recovering ammonia water is composed of cationic exchange film, middle interface layer containing complexing metallic catalyst, and anionic exchange film.

Owner:HARBIN INST OF TECH

Reinforced perfluorocarboxylic acid ion exchange membrane with bubble thinning function and preparation method thereof

InactiveCN111118543AHinder reverse migrationSmall ion channelOrganic diaphragmsPhysical chemistryCarboxylic acid

The invention belongs to the technical field of ion exchange membranes, and particularly relates to a reinforced perfluorocarboxylic acid ion exchange membrane with a bubble dredging function and a preparation method thereof. The reinforced perfluorocarboxylic acid ion exchange membrane with the bubble thinning function is composed of a perfluorocarboxylic acid polymer layer, a porous reinforcingmaterial layer and functional surface coatings, the functional surface coatings are located on the upper surface and the lower surface of the perfluorocarboxylic acid polymer layer, the porous reinforcing material layer is embedded in the perfluorocarboxylic acid polymer layer, and the functional surface coating is of a porous rough structure composed of a perfluorinated ionic polymer. The reinforced perfluorocarboxylic acid ion exchange membrane with the bubble thinning function can effectively reduce the cell voltage, reduce the electrolysis energy consumption and reduce the production costin a novel zero-polar-distance electrolytic cell under the condition of high current density, and is suitable for the field of electrolysis of sodium chloride and potassium chloride; the invention also provides a preparation method thereof.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Ion exchange membrane for alkali chloride electrolysis, and alkali chloride electrolysis apparatus

ActiveCN106661746AReduce the electrolysis voltageHigh strengthIon-exchange process apparatusCellsFiberElectrolysis

Provided is an ion exchange membrane for alkali chloride electrolysis, the ion exchange membrane exhibiting low membrane resistance and reducing the electrolysis voltage during alkali chloride electrolysis, even when the space between reinforcing fibers is narrow and membrane strength is high. This ion exchange membrane 1 for alkali chloride electrolysis has: a fluorine-based polymer that contains ion exchange groups; a reinforcing material formed from reinforcing fibers embedded within the fluorine based polymer, and optionally included sacrificial fibers; and elution holes for the sacrificial fibers present between the reinforcing fibers. In a cross-section orthogonal to the lengthwise direction of the reinforcing fibers forming the reinforcing material, the average distance (d1) from the center of a reinforcing fiber 22 to the center of a neighboring reinforcing fiber 22 is 750-1,000 [Mu]m, the total area (S) calculated by adding the cross-sectional area of an elution hole 28 and the cross-sectional area of sacrificial fiber 24 remaining in the elution hole 28 is 500-5,000 [Mu]m2 per elution hole, and the number n of elution holes 28 between neighboring reinforcing fibers 22 is 4-6.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com