Ion exchange membrane for alkali chloride electrolysis, and alkali chloride electrolysis apparatus

An alkali metal chloride, ion exchange membrane technology, applied in ion exchange treatment device, ion exchange, cation exchange and other directions, can solve the problems of electrolysis voltage rise, ion exchange membrane membrane resistance increase, etc., to achieve low electrolysis voltage, improve membrane Strength, the effect of reducing the electrolytic voltage

Active Publication Date: 2017-05-10

ASAHI GLASS CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the membrane resistance of the ion exchange membrane having a reinforcing material formed of PTFE filament etc. becomes high, and the electrolysis voltage rises

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0280] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these examples. Examples 1-4, 9 and 14 are examples, and examples 5-8 and 10-13 are comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

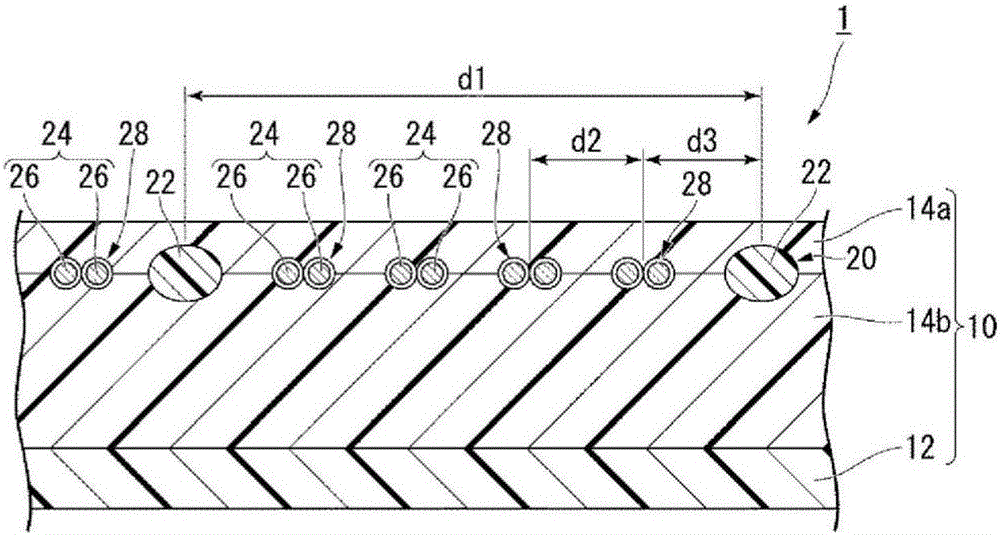

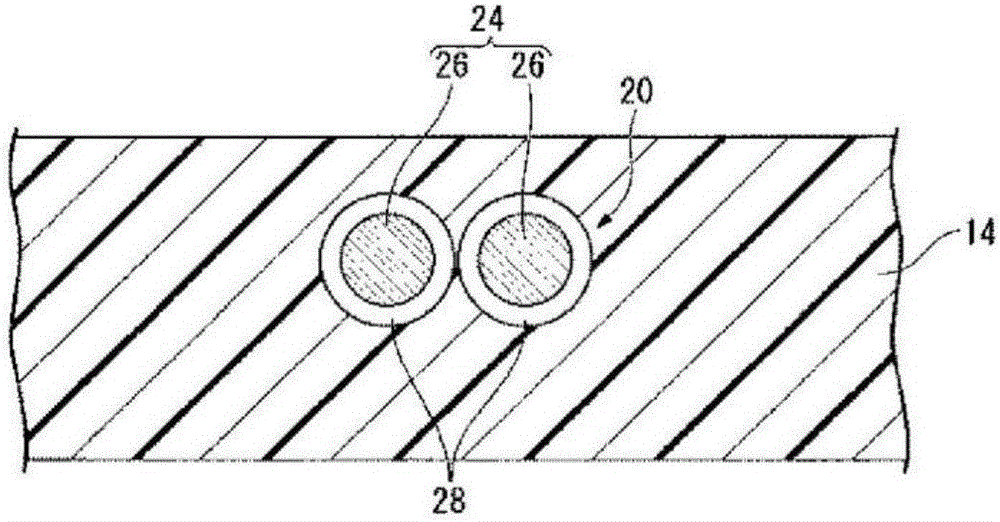

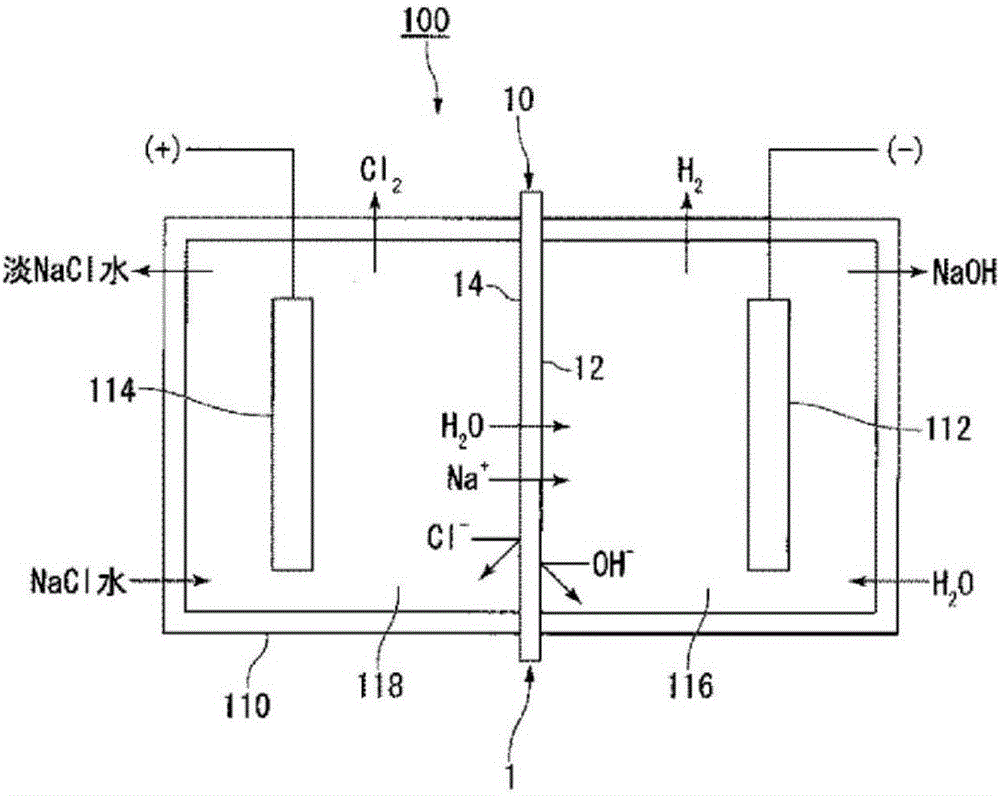

Provided is an ion exchange membrane for alkali chloride electrolysis, the ion exchange membrane exhibiting low membrane resistance and reducing the electrolysis voltage during alkali chloride electrolysis, even when the space between reinforcing fibers is narrow and membrane strength is high. This ion exchange membrane 1 for alkali chloride electrolysis has: a fluorine-based polymer that contains ion exchange groups; a reinforcing material formed from reinforcing fibers embedded within the fluorine based polymer, and optionally included sacrificial fibers; and elution holes for the sacrificial fibers present between the reinforcing fibers. In a cross-section orthogonal to the lengthwise direction of the reinforcing fibers forming the reinforcing material, the average distance (d1) from the center of a reinforcing fiber 22 to the center of a neighboring reinforcing fiber 22 is 750-1,000 [Mu]m, the total area (S) calculated by adding the cross-sectional area of an elution hole 28 and the cross-sectional area of sacrificial fiber 24 remaining in the elution hole 28 is 500-5,000 [Mu]m2 per elution hole, and the number n of elution holes 28 between neighboring reinforcing fibers 22 is 4-6.

Description

technical field [0001] The present invention relates to an ion exchange membrane for electrolysis of alkali metal chloride and an electrolysis device for alkali metal chloride. Background technique [0002] As the ion exchange membrane used in the alkali metal chloride electrolysis method for producing alkali metal hydroxide and chlorine by electrolyzing an aqueous solution of alkali metal chloride such as seawater, there are known: Salt base, and sulfonic acid or sulfonate) fluorine-based polymer electrolyte membrane. [0003] The electrolyte membrane is usually reinforced with a reinforcing material made of reinforcing wire (polytetrafluoroethylene (hereinafter, referred to as PTFE) wire, etc.) from the viewpoint of maintaining mechanical strength and dimensional stability. However, the membrane resistance of the ion exchange membrane having a reinforcing material formed of PTFE yarn or the like becomes high, and the electrolysis voltage increases. [0004] Therefore, it...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25B13/08B01J39/00B01J47/12C08J5/22C25B9/00

CPCB01J39/20B01J47/12B32B15/00B32B15/06B32B15/10B32B15/12B32B21/00B32B27/00B32B29/00B32B2250/02B32B2307/306B32B2451/00C08J5/2237C08J2327/18C25B1/46C25B13/08C08J5/2281C08J2329/10C08J2427/18C08J2467/00C25B9/00

Inventor 金子隆之草野博光山木泰西尾拓久央

Owner ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com