Method for preparing GH4169 high-temperature alloy TEM (transmission electron microscopy) sample

A GH4169, transmission electron microscope sample technology, applied in the direction of material analysis, measurement device, instrument, etc. using wave/particle radiation, can solve problems such as low efficiency and insufficient quality, and achieve easy control, strong quality controllability, and improved quality. The effect of sample preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

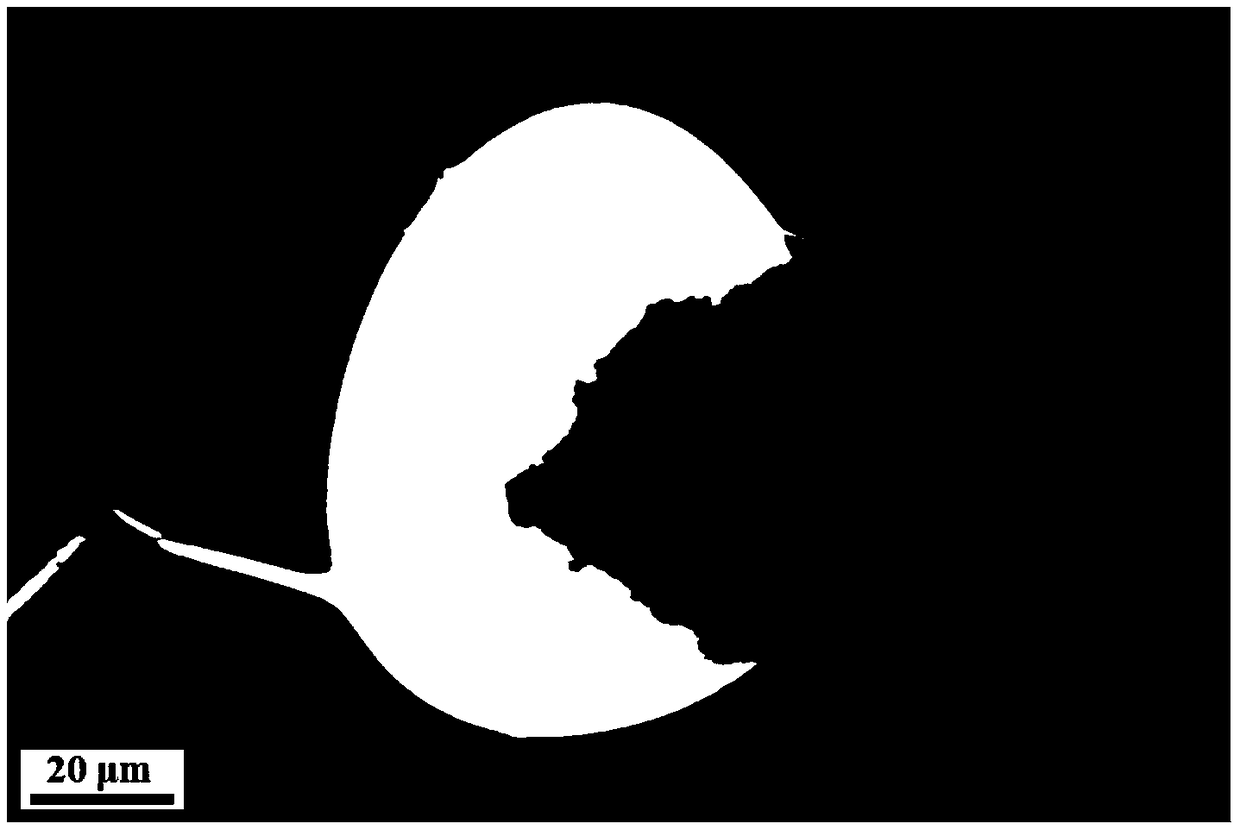

Embodiment 1

[0036] Wire cutting processes the sample into thin slices with a thickness of 0.5mm. Using Buehler EcoMet250 automatic grinding and polishing equipment, the slices are passed through 400#, 600#, 800#, 1200#, 1600# at a pressure of 200N and a speed of 300 rpm. The metallographic sandpaper is mechanically thinned to 70μm, and then the sample is punched into a circular sheet with a diameter of 3mm using a punching instrument. Use StruersTenuPol-5 electrolytic double spray equipment for electrochemical thinning, the electrolyte used is a mixed solution of 10% perchloric acid + 90% absolute ethanol, the electrolytic voltage of the thinning process is 35V, and the electrolyte temperature is controlled by liquid nitrogen At -10°C, the electrochemical thinning until the system automatically stops. After the sample is prepared, take it out immediately and place it in a number of alcohol vessels for full washing. The resulting thin area tissue is like image 3 As shown, the light-transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com