Patents

Literature

166results about How to "The preparation process is stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyaniline-manganese dioxide-titanium nitride nanowire array composite material and preparation method and application thereof

InactiveCN104240967AExtensive practical application valueExtensive productivityHybrid capacitor electrodesHybrid/EDL manufactureTitanium nitrideSupercapacitor

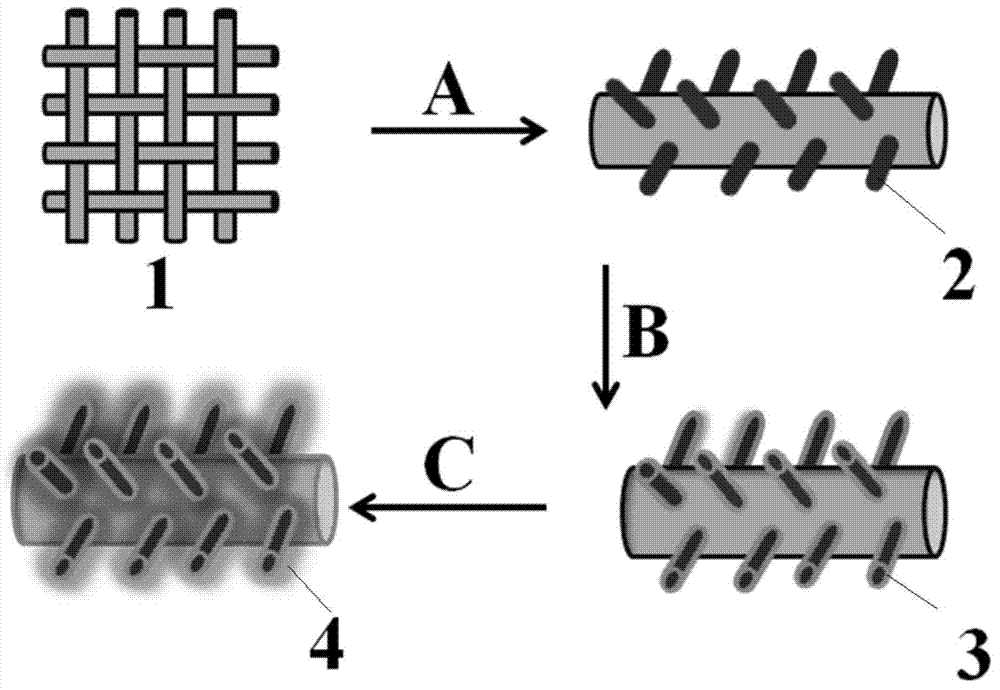

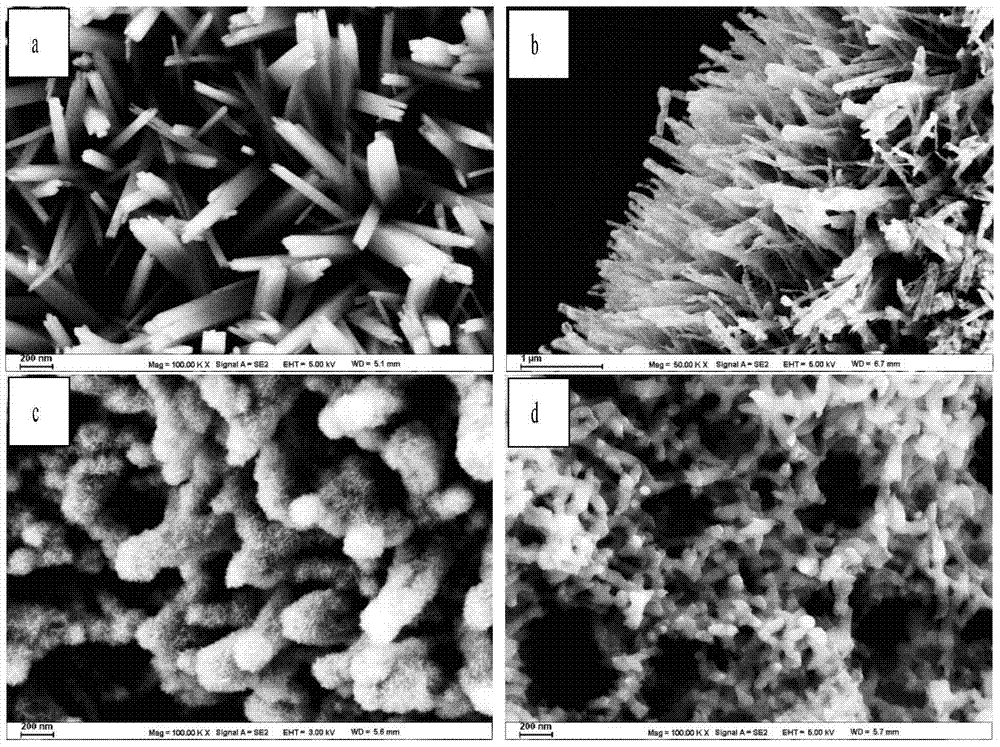

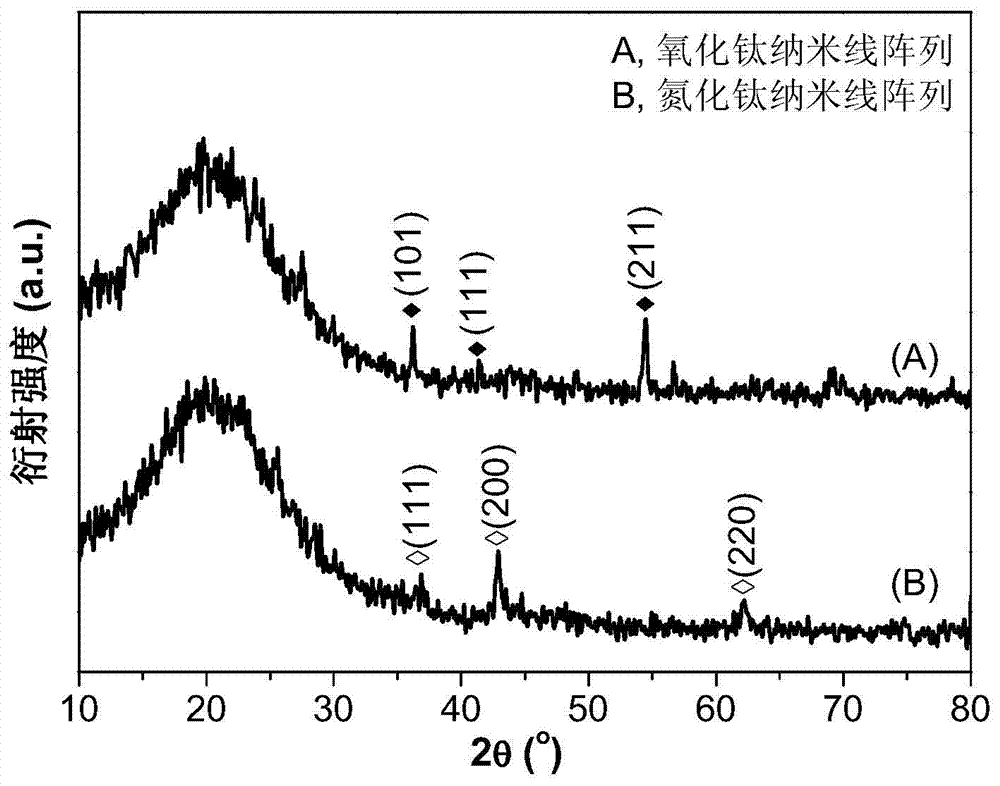

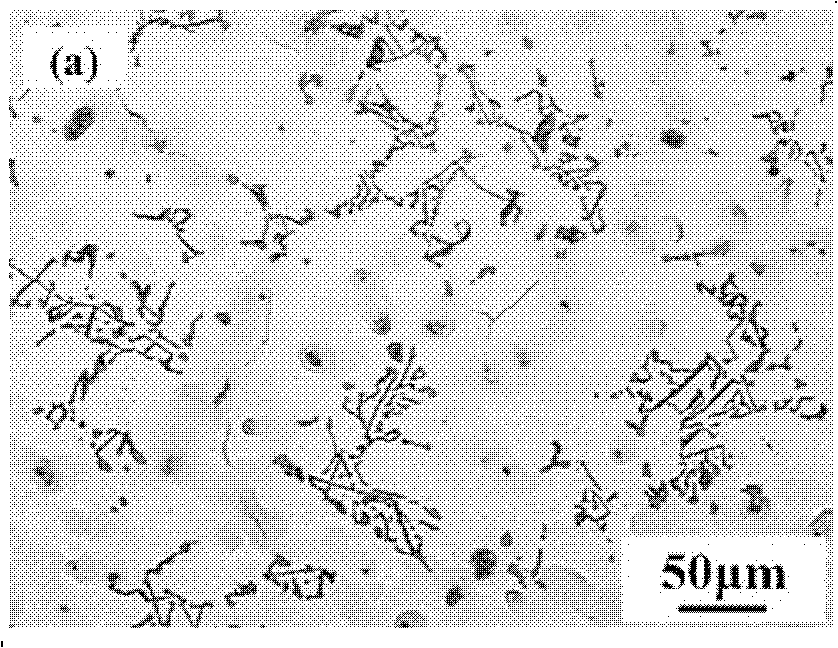

The invention provides a polyaniline-manganese dioxide-titanium nitride nanowire array composite material which comprises a carbon substrate (1), a titanium nitride nanowire array (2), a villiform manganese dioxide nano-film (3) and a coralliform polyaniline nanofiber (4). The titanium nitride nanowire array (2) is perpendicularly arranged on the surface of the carbon substrate (1) and connected with the carbon substrate (1) to form an integral structure, the manganese dioxide nano-film (3) coats the surface of the titanium nitride nanowire array (2), and the coralliform polyaniline nanofiber (4) is adhered on the surface of the manganese dioxide nano-film (3). The invention further provides a preparation method of the composite material and application of the composite material in a supercapacitor. The polyaniline-manganese dioxide-titanium nitride nanowire array composite material has features of an orderly-arranged porous structure, is regular and controllable in shape and appearance, can be directly applied to an electrode material of the supercapacitor and has wide actual application value and industrial production prospect.

Owner:SOUTHEAST UNIV

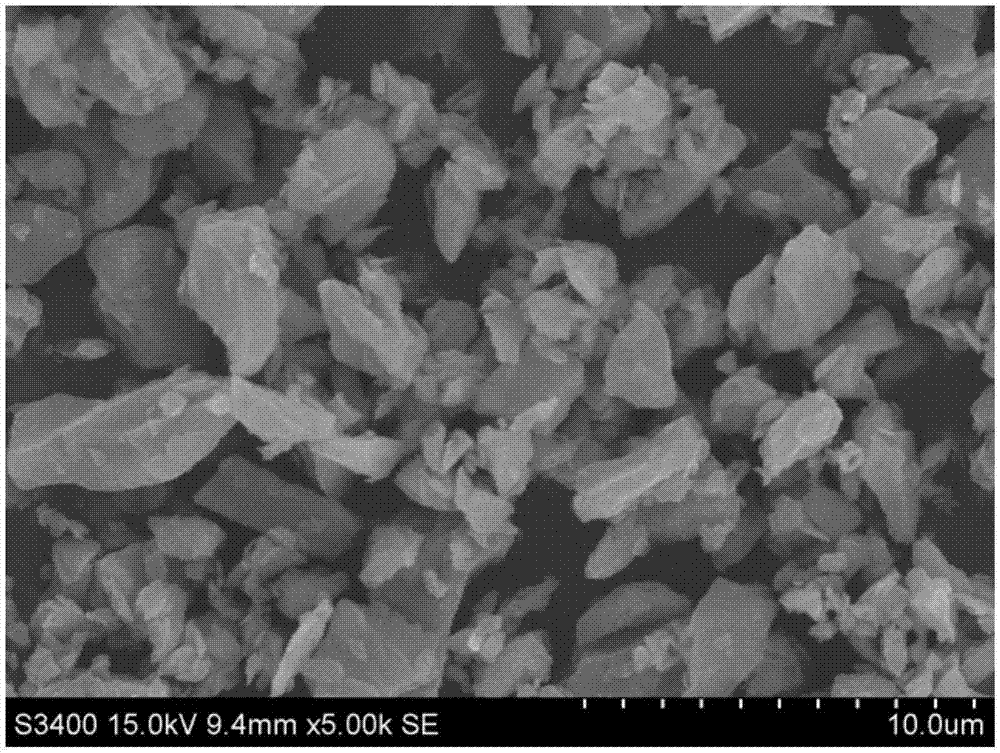

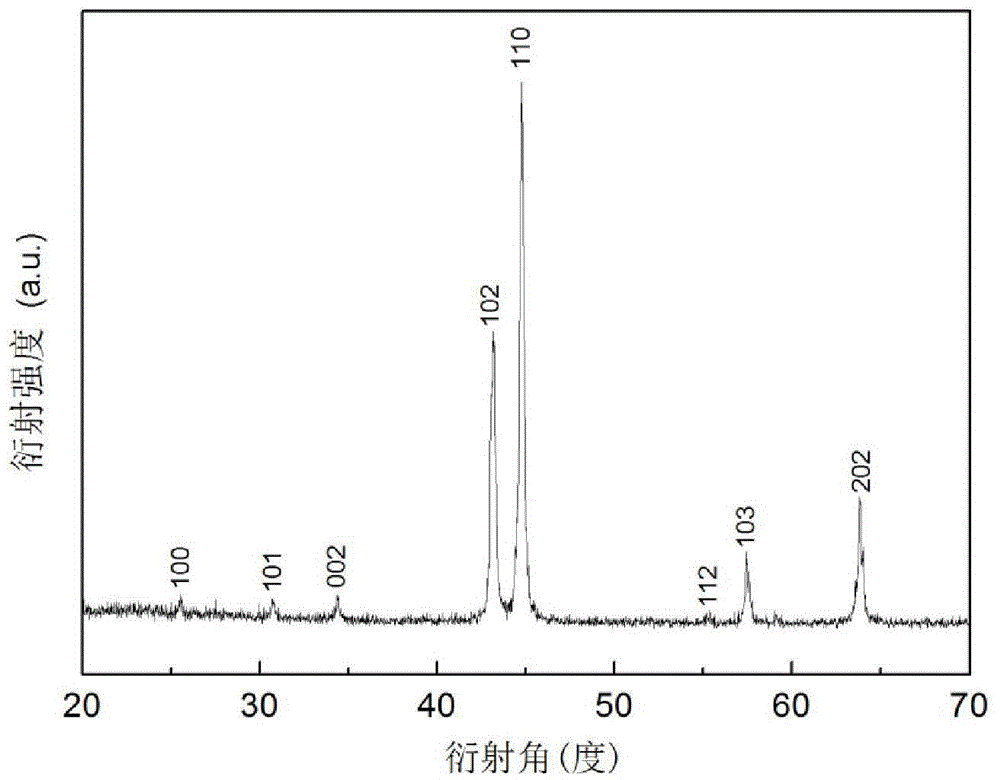

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

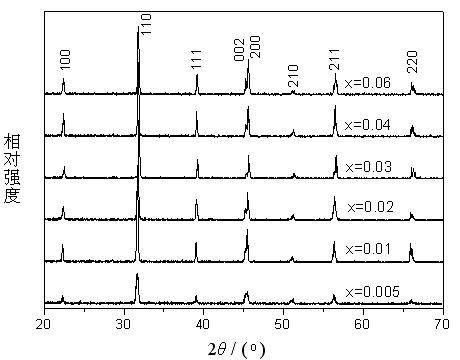

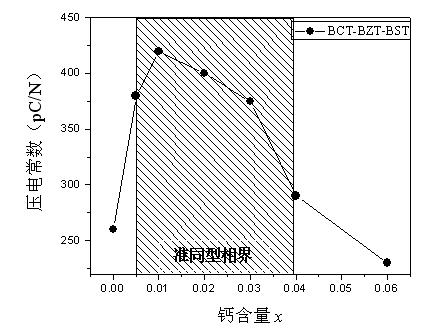

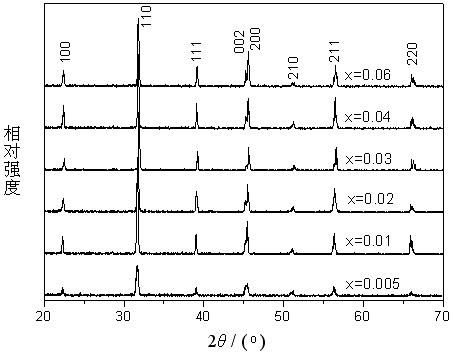

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

Carbon nanotube filling composite membrane with alcohol penetration priority and preparation method thereof

InactiveCN103223309AEvenly dispersedHigh mechanical strengthDistillationPolyesterSeparation technology

The invention discloses a carbon nanotube filling composite membrane with alcohol penetration priority in the field of penetration vaporization membrane separation technology and preparation method thereof. The preparation method of the composite membrane comprises the following steps: casting polyvinylidene fluoride on a polyester non-woven fabric, scraping membrane by an immersion phase inversion method for obtaining a supporting layer; And then stirring the carbon nanotube and the polydimethylsiloxane by ultrasound for uniform dispersion, adding cross-linking agent and catalyst for reacting and forming a membrane casting solution, casting onto the bottom membrane and obtaining a separating layer. The membrane obtained by the method has the advantages of improved mechanical strength, penetration throughtput and selectivity, especially substantially increased hydroxylate multi-wall carbon nanotube hydrophobicity after trichlorosilane modification, improved polydimethylsiloxane compatibility and separating factor. The invention has the advantages of reliable and stable method, simple preparation technology, enhanced mechanical performance of pure polydimethylsiloxane membrane, improved penetration throughput and separating factor, and good industrial application prospect.

Owner:TSINGHUA UNIV +1

Method for preparation of indium oxide transparent film with high electron mobility

InactiveCN101514440AStrong adhesionSmooth film surfaceVacuum evaporation coatingSputtering coatingIndiumRadio frequency magnetron sputtering

A method for the preparation of the indium oxide transparent film with high electron mobility adopts the double-chamber high- vacuum radio-frequency magnetron sputtering method, wherein the high-purity indium oxide with the purity of 99. 99 27634872s taken as the target material, the glass is taken as the substrate, one or two of the high-purity argon and oxygen with the purity of 99. 99 5869744s taken as the sputtering gas, the sputtering growth is performed in the magnetron sputtering device, thus the n-typed transparent In2O3semiconductor film material with different electron concentration and high electron mobility is obtained. The method has the advantages of easy control of the deposition parameter, reliable preparing process, good repetitiveness and lower cost of manufacture.

Owner:ZHEJIANG UNIV

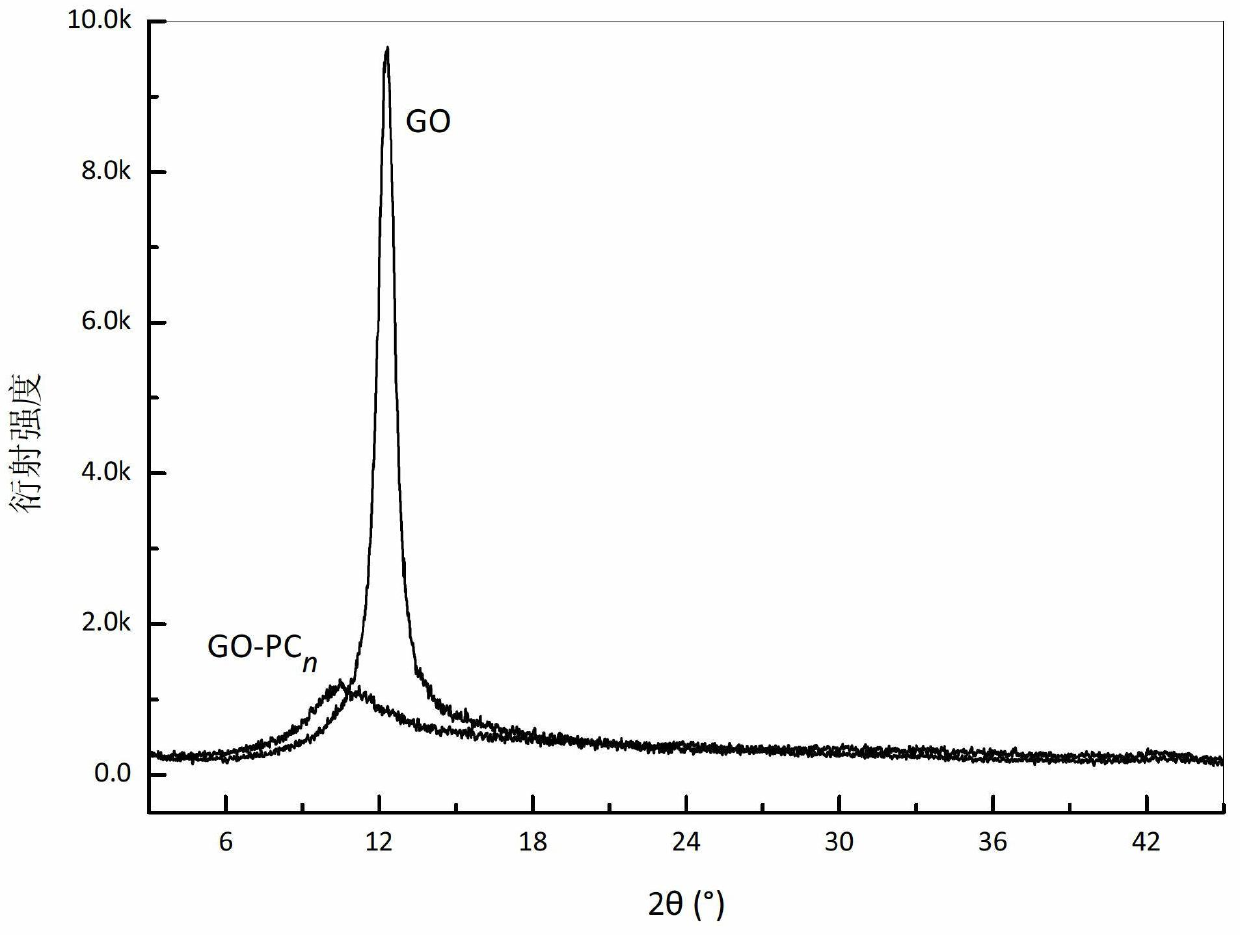

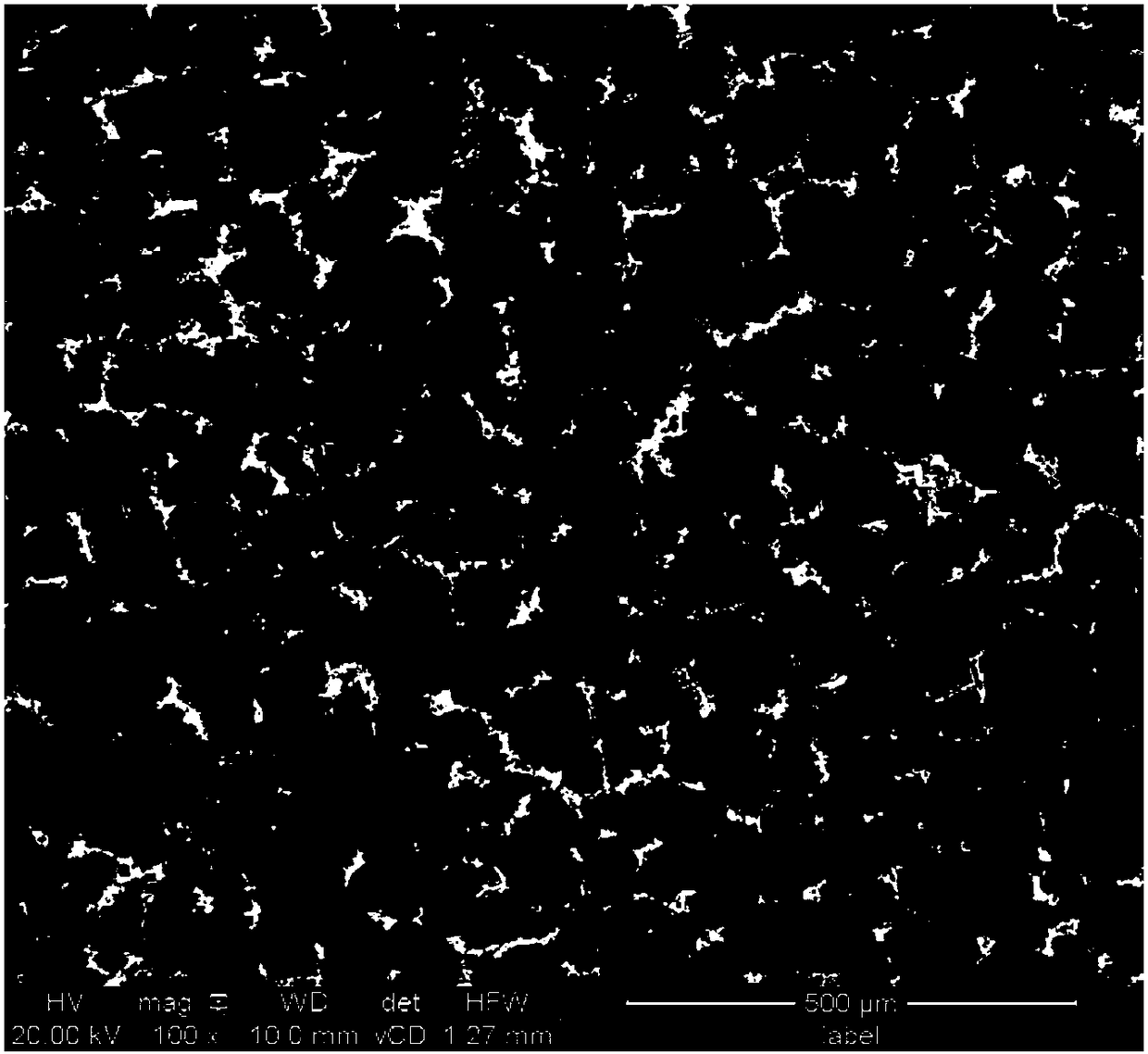

Phosphorylcholine structure-modified graphene oxide and preparation method thereof

InactiveCN102674336ABiocompatibleGood dispersion and stabilityCarbon compoundsOligomerPhosphorylcholine

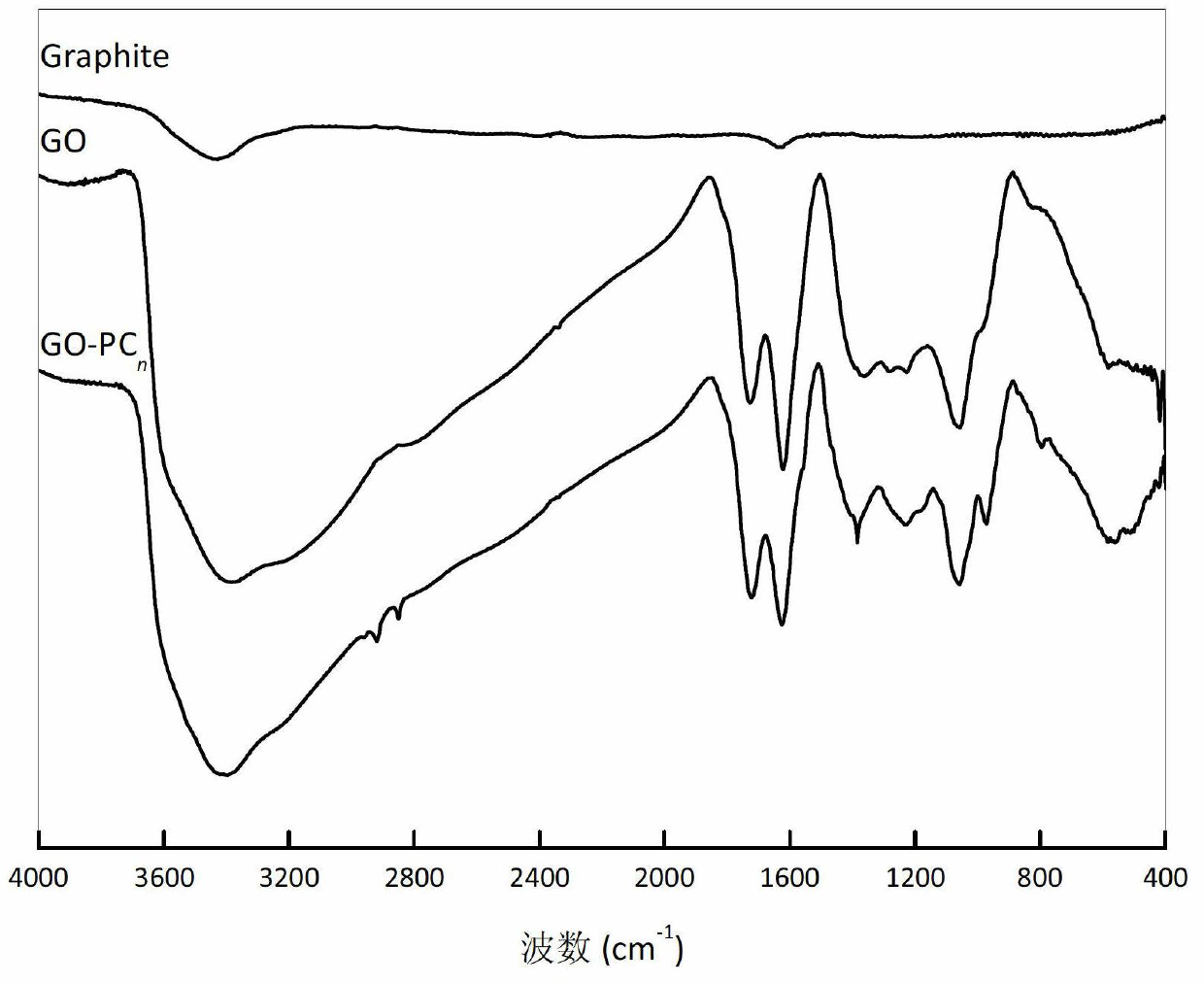

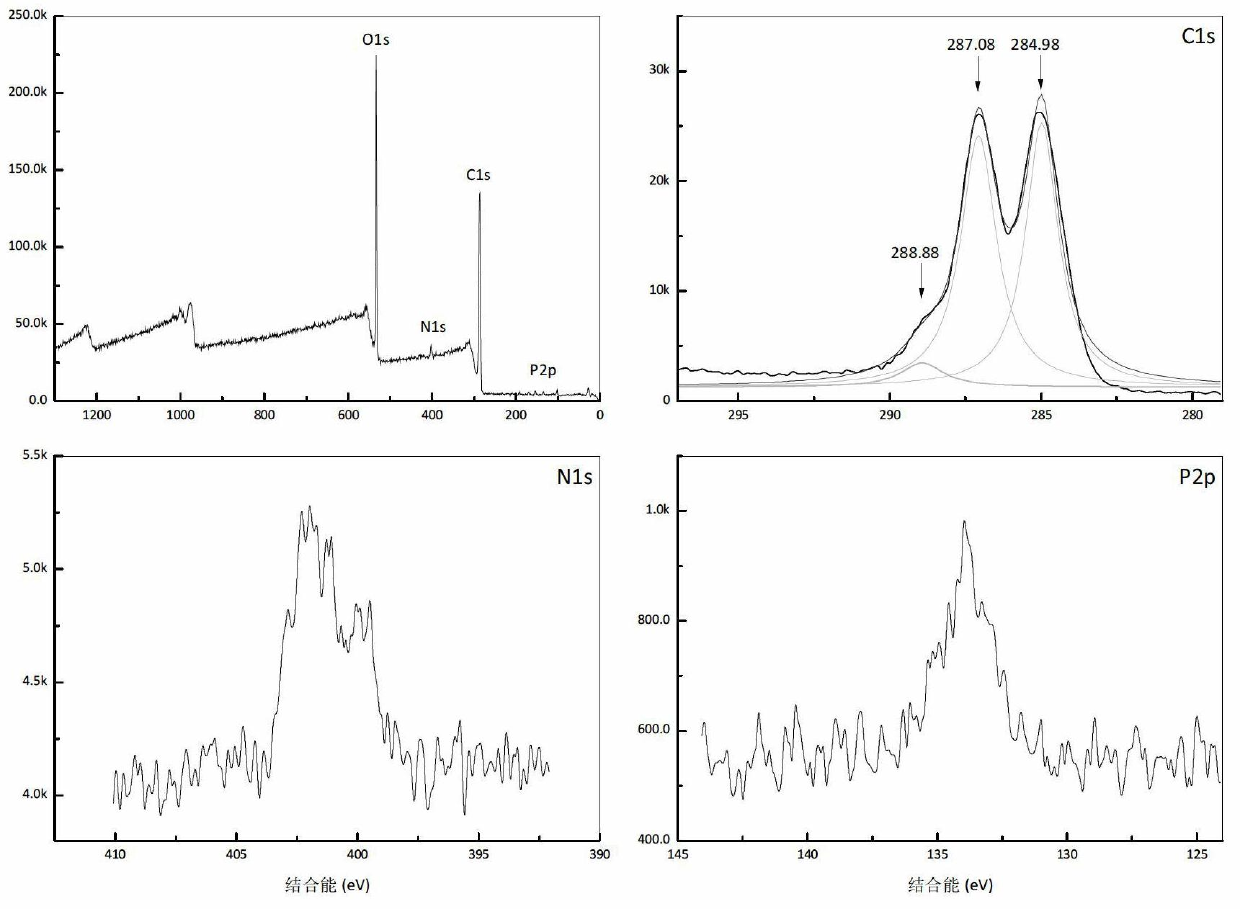

The invention discloses phosphorylcholine structure-modified graphene oxide and a preparation method thereof. The phosphorylcholine structure-modified graphene oxide is formed by connecting at least one oligomer containing a phosphorylcholine structure to a graphene oxide slice by a chemical grafting mode. The phosphorylcholine structure-modified graphene oxide is chemically grafted with the hydrophilic phosphorylcholine structure, so that the phosphorylcholine structure-modified graphene oxide is high in dispersibility and stable in water, saline and cell culture fluid, and can be placed at room temperature for a long term and does not have precipitate. The phosphorylcholine structure is an inherent compound such as a part of phospholipid in an organism, so that the phosphorylcholine structure-modified graphene oxide possibly has biocompatibility and is possibly applied to the biomedical field. The preparation method for the phosphorylcholine structure modified graphene oxide is simple, convenient and reliable and is easy to implement.

Owner:NANJING UNIV

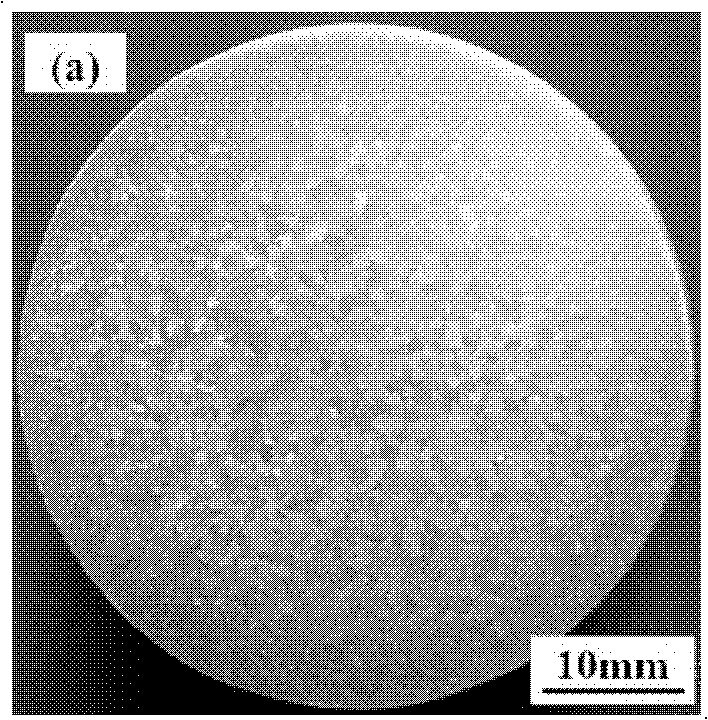

High-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof

ActiveCN108305735AHigh resistivitySmall sizeInorganic material magnetismInductances/transformers/magnets manufactureSamarium–cobalt magnetHigh resistivity

The invention provides a high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof. The chemical formula of the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material is Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z>, wherein a is more than 0 but less than 0.5, b is more than 0 but less than 0.15, c is more than 0 but less than or equal to 0.025, y is more than 0 but less than 0.04, z is more than 6.5 but less than 8.5, and M is a high-resistivity element. The preparation method comprises thestep of sequentially performing processes of directional formation, sintering, thermal processing and equal-temperature aging on alloy with the chemical formula being Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z> to obtain the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material. Compared with the prior art, the samarium-cobalt permanent-magnet material has the advantages that a high-resistivity compound is combined without a complicated process, the process flow of the sintered samarium-cobalt magnet is not needed to be changed, the production cost is low, and theresistivity of the magnet can be obviously improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

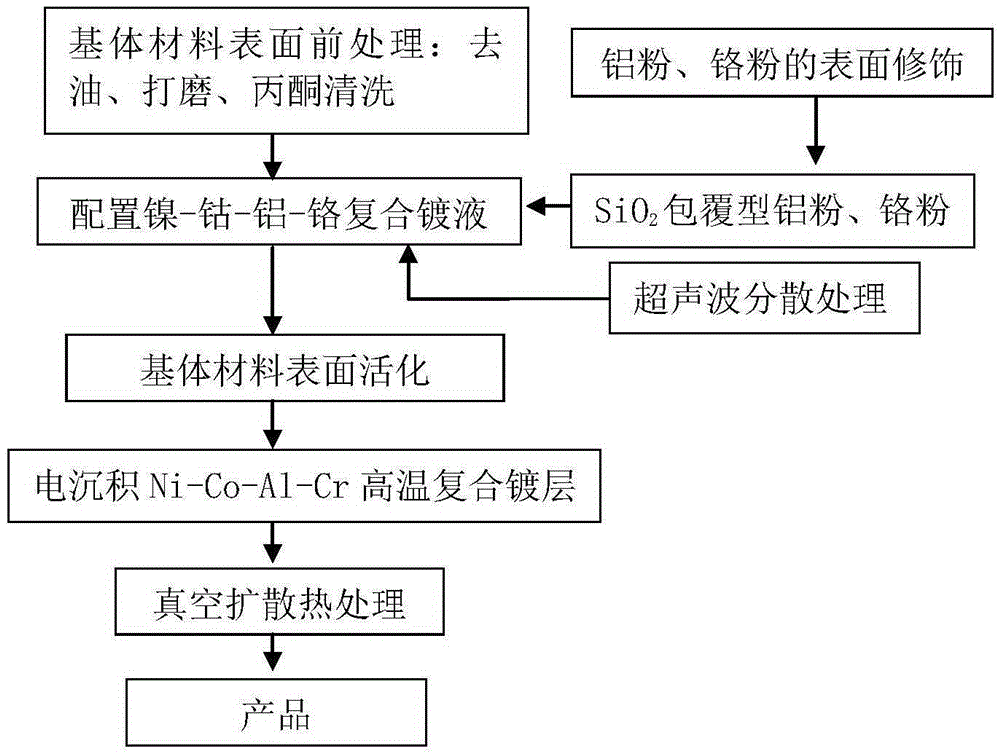

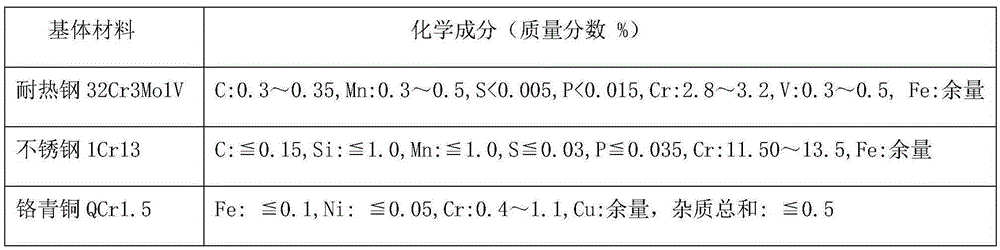

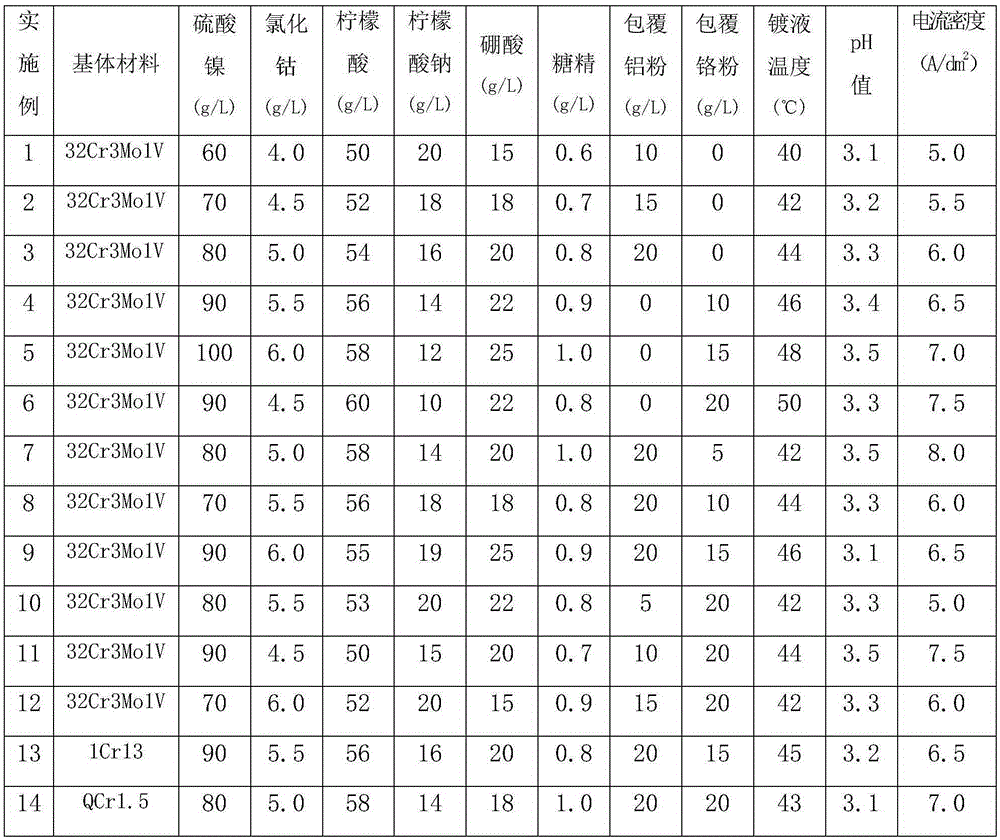

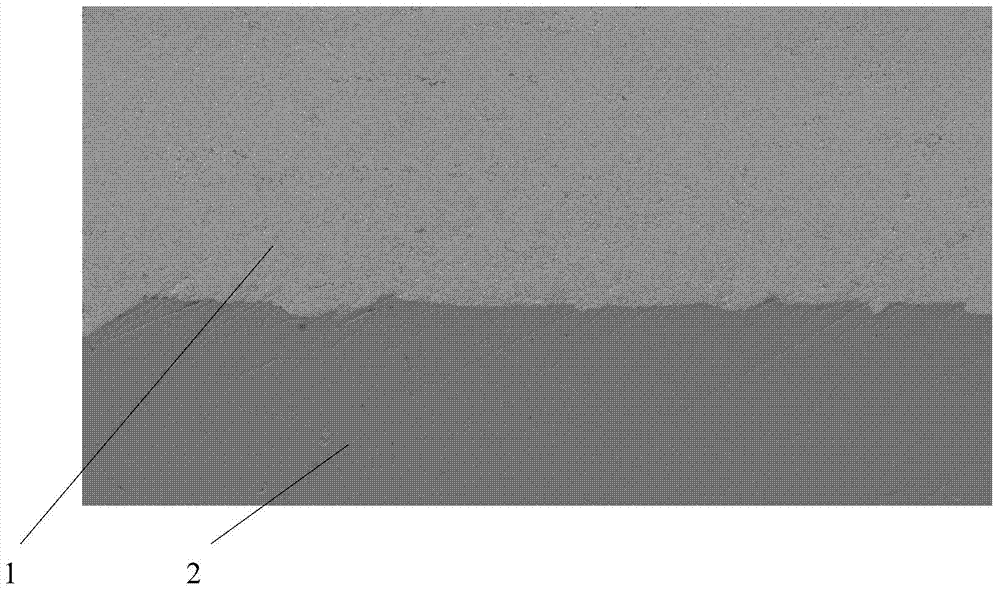

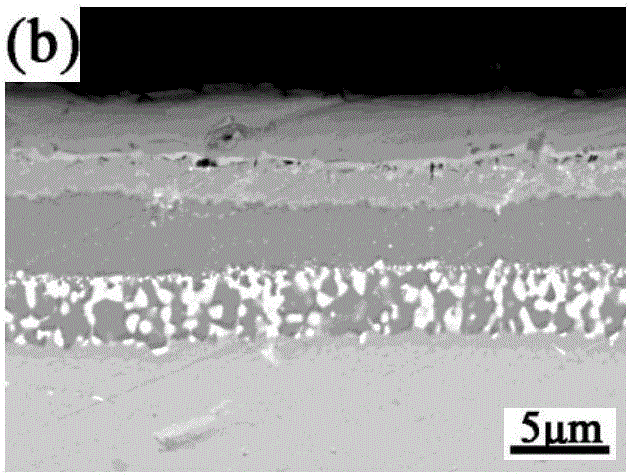

Electrodeposited Ni-Co-Al-Cr high-temperature composite coating and preparation method thereof

The invention discloses an electrodeposited Ni-Co-Al-Cr high-temperature composite coating and a preparation method thereof. The electrodeposited Ni-Co-Al-Cr high-temperature composite coating is characterized in that the electrodeposited Ni-Co-Al-Cr high-temperature composite coating adopts a metal material as a matrix; the surface of the matrix is pretreated; then a composite plating solution taking nickel sulfate and cobalt chloride as main components and taking aluminium powder and chromium powder as dispersion phases is compounded; the composite plating solution is subjected to ultrasonic dispersion treatment; by reasonably setting electrodeposition parameters, intensive mixing is carried out to allow aluminium powder particles and chromium powder particles to be uniformly dispersed in the composite plating solution; and in an electric current applied state, the aluminium powder particles, the chromium powder particles, and matrix Ni and Co are subjected to codeposition and vacuum diffusion heat treatment to form the electrodeposited Ni-Co-Al-Cr high-temperature composite coating. The element contents of Al and Cr in the electrodeposited Ni-Co-Al-Cr high-temperature composite coating are higher; the electrodeposited Ni-Co-Al-Cr high-temperature composite coating has excellent high-temperature oxidation resistance at 1100 degrees; the defects that a hot spraying MCrAlY (M=Ni, Co, Fe or alloys of Ni, Co and Fe) coating is high in porosity and the interface bonding strength is low are overcome; the high-temperature mechanical properties and the high-temperature oxidation resistance of the conventional Ni-Cr, Ni-Al and Ni-Cr-Al composite coatings are improved; and the electrodeposited Ni-Co-Al-Cr high-temperature composite coating is suitable for surface protection of high-temperature working components and parts in the fields of aviation, metallurgy, chemical engineering, heat energy, etc.

Owner:HUNAN UNIV OF SCI & TECH

Rare earth doped nanometer composite ceramic coating and production technology thereof

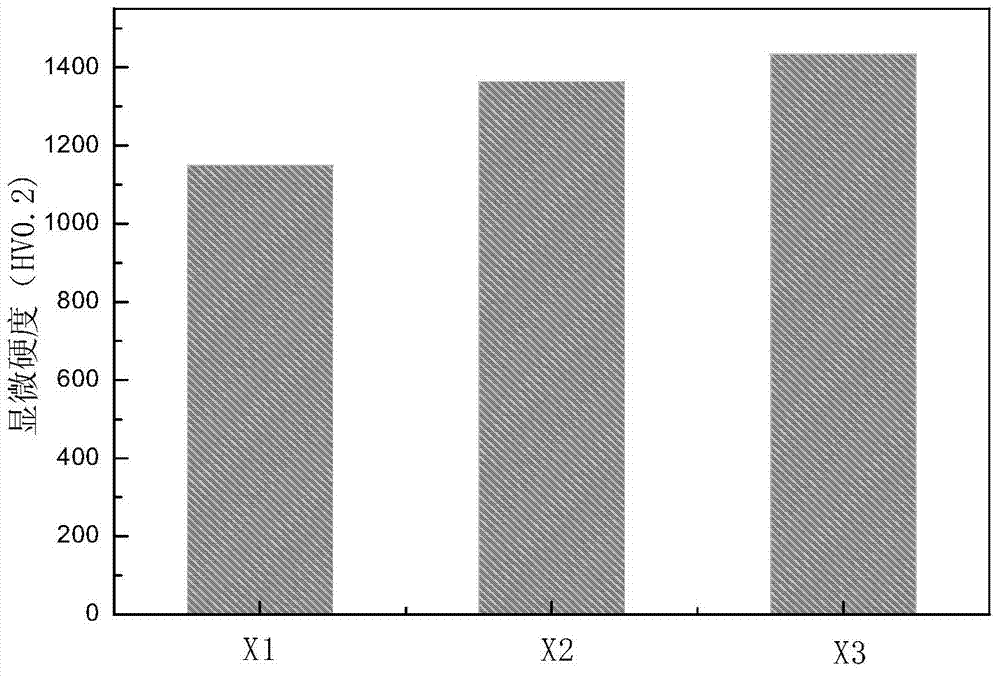

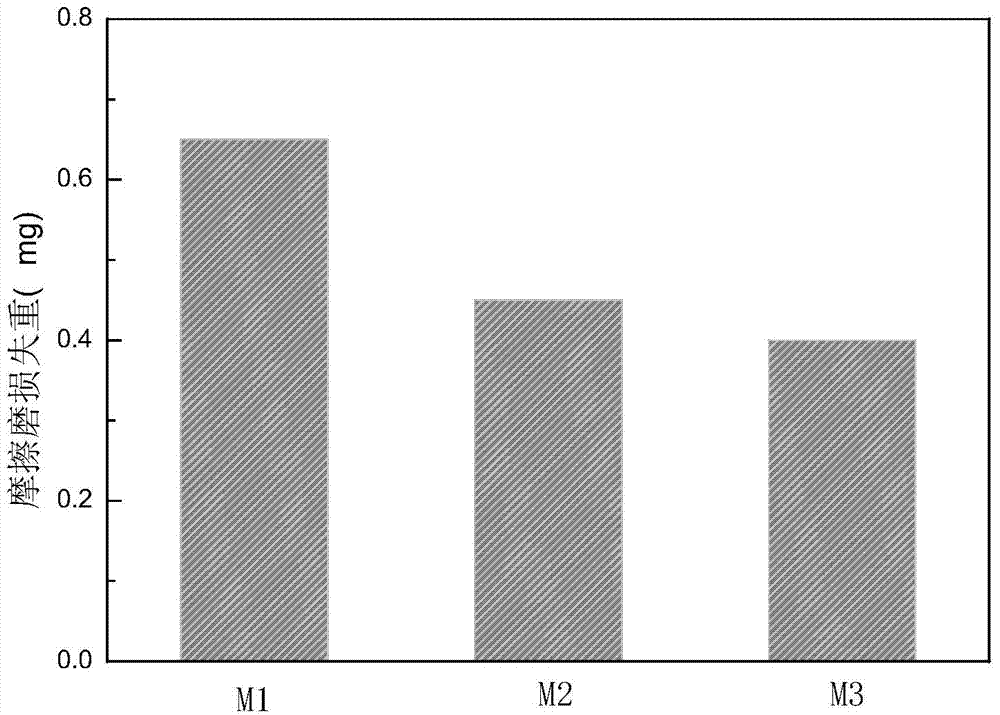

ActiveCN104513944AImprove erosion resistanceIncreased microhardnessMolten spray coatingCorrosionBonding strength

A rare earth doped nanometer composite ceramic coating comprises a spray coating, the spray material of the spray coating is rare earth oxide component doped nanometer tungsten carbide powder, the nanometer tungsten carbide powder is nanometer WC-10Co4Cr powder, and the particle size of the particle size of the powder is 15-53[mu]m; and the doped rare earth oxide is Sc2O3, La2O3 or Ce2O3, and the content of the doped rare earth oxide is 0.5-3wt%. The microscopic hardness of the above wear resistant coating is 1350-1450HV0.2, the surface wear resistance of the coating is above 140 times that of ZG06Cr13Ni4Mo, the self corrosion potential and the self corrosion current density of the coating are smaller than those of a common tungsten carbide coating, and the coating provided by the invention has large microscopic hardness, bonding strength and small amount of porosity. A water turbine with the surface sprayed with the coating provided by the invention has greatly improved erosion and corrosion resistance, and the coating prolongs the service life of the surface material of the water turbine 12.5-25 times.

Owner:水利部产品质量标准研究所 +1

Bottled grease micro emulsion freeze-dried preparation with 13 composite vitamins

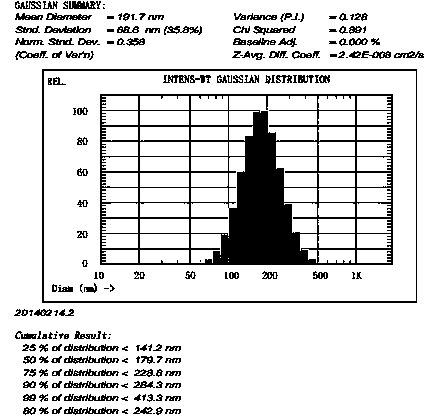

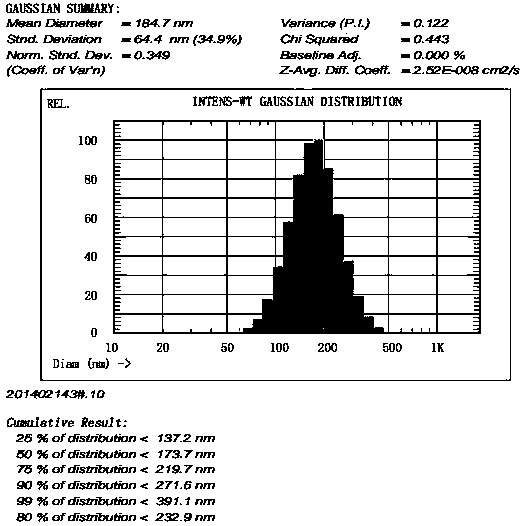

ActiveCN104337829AImprove stabilitySolve the problem of co-dissolutionPowder deliveryHydroxy compound active ingredientsBiotechnologyVitamin A Alcohol

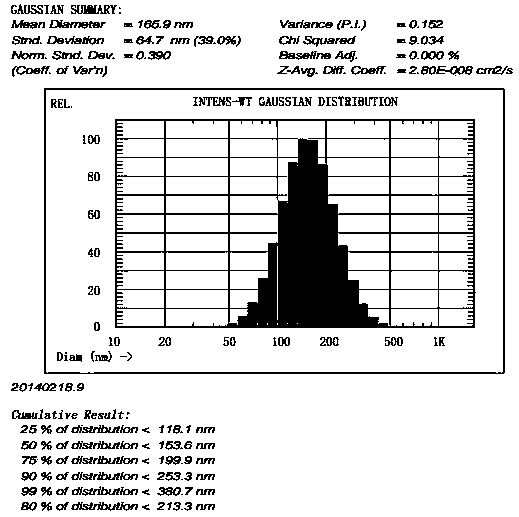

The invention discloses a bottled grease micro emulsion freeze-dried preparation with 13 composite vitamins. The preparation is prepared by wrapping lipid-soluble vitamins A, D, E and K in grease micro emulsion of which the particle size is smaller than 120nm, mixing with water-soluble vitamins B and C, folic acid, nicotinamide and the like, adding a freeze-drying forming agent and a redissolution additive, and freeze-drying. The novel freeze-dried preparation, which contains 13 vitamins and is developed according to the above formula and the preparation method, is simple in process, the stability of the vitamins can be improved, and the side effect caused by medicine decomposition and decomposition products is alleviated; the problem of codissolution of lipid-soluble vitamins and water-soluble vitamins is effectively solved, sufficient dissolution of medicine compounds is ensured, and the side effect of undissolved substances on human bodies is avoided.

Owner:XIAN LIBANG ZHAOXIN BIOTECH CO LTD

Long-acting sustained-release pellet and preparation method thereof

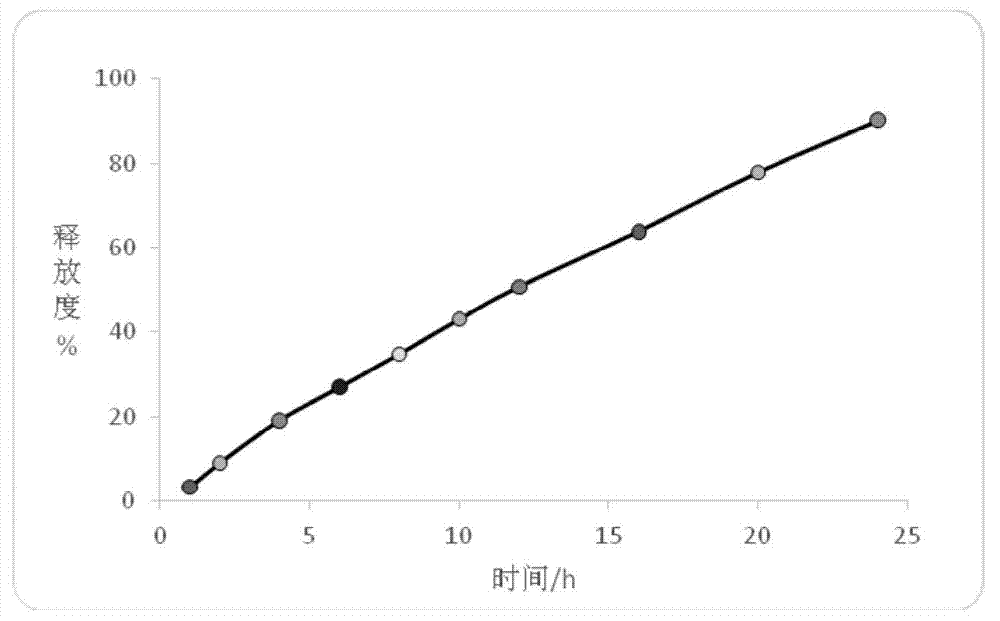

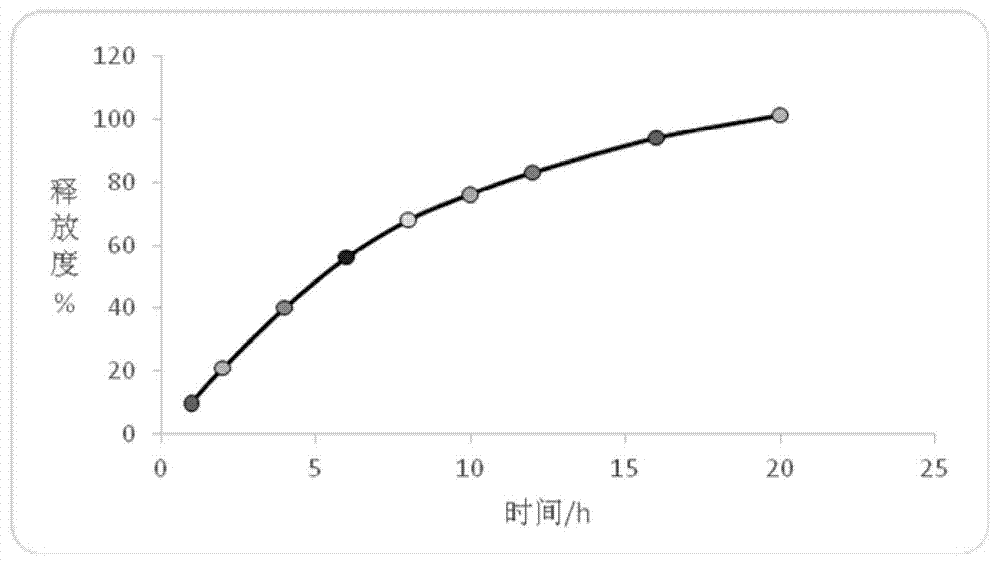

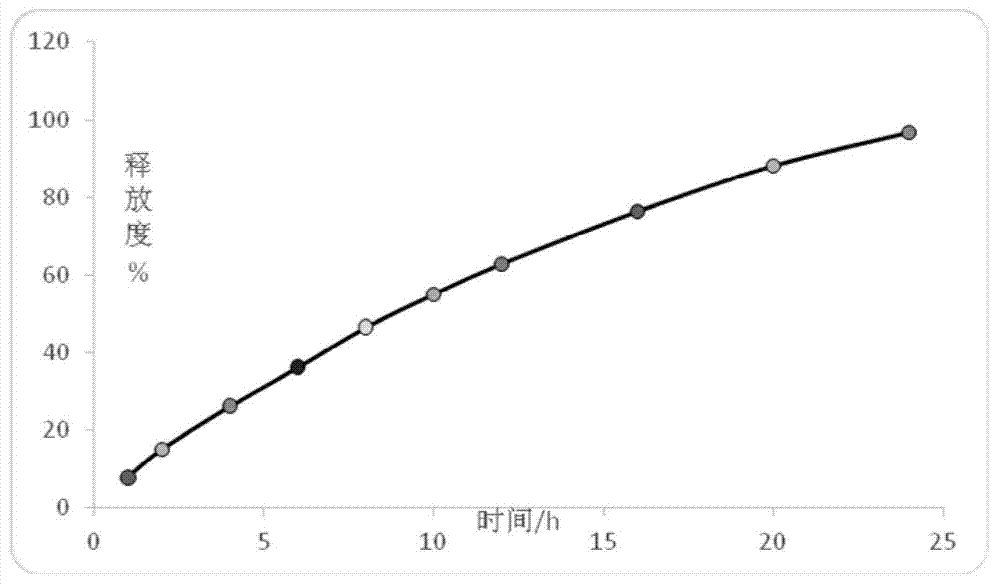

InactiveCN103565751AEvenly wrappedReduced release rateOrganic active ingredientsGranular deliverySustained release pelletsBlood concentration

The invention discloses a long-acting sustained-release pellet and a preparation method thereof. The long-acting trimetazidine hydrochloride sustained-release pellet comprises a drug-containing core and a sustained-release coating layer from inside to outside sequentially, wherein an optional isolation coating layer is arranged between the drug-containing core and the sustained-release coating layer; the isolation coating layer accounts for 0-15 percent of the mass of the drug-containing core, and the sustained-release coating layer accounts for 5-30 percent of the mass of the drug-containing core; a gastrointestinal adhesive is contained in the sustained-release coating layer. According to the trimetazidine hydrochloride sustained-release pellet, the prescription is meticulously designed, the drug-containing core is uniformly coated by utilizing the sustained-release coating material, so that slow and uniform drug release of the drug-containing core can be maintained, the active component releasing speed can be reduced, the time for reaching the peak can be postponed, the pellet can be constantly and stably released in 24 hours, the blood concentration stability can be maintained, and the phenomenon of insufficient blood concentration in morning ischemia can be avoided. The administration frequency can be reduced to once a day, and the compliance of patients can be improved.

Owner:AC PHARMA CO LTD

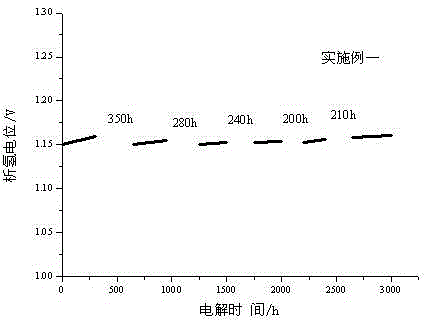

Composite hydrogen evolution negative pole with micropore hydrogen storage layer and preparing method for composite hydrogen evolution negative pole

InactiveCN105350015ALarge specific surface areaImprove bindingMolten spray coatingElectrodesElectrolysisThermal spraying

The invention discloses a composite hydrogen evolution negative pole with a micropore hydrogen storage layer and a preparing method for the composite hydrogen evolution negative pole. The method includes the steps that (1) base body pretreatment, wherein a base body is subject to alkali soaking and washing, and then sand blasting is carried out; (2) a hydrogen storage middle layer is prepared, wherein the step includes the steps: (2.1) plasma thermal spraying treatment is carried out, a Ni50A150 alloy and hydrogen storage alloy powder are evenly mixed according to the weight ratio being (0.95-0.8): (0.05-0.2), and a plasma spraying device is used for spraying; and (2.2) activating treatment is carried out, the base body treated in the step (2.1) is placed into a first alkaline solution to be soaked, excitation is carried out, and the micropore middle layer with the high specific surface area and the high hydrogen storage performance is obtained; and (3) a thermal decomposition method is adopted for preparing a catalyst layer on the hydrogen storage middle layer. The preparing method is simple and reliable in preparation process, the commercial process is easily achieved; and the prepared composite hydrogen evolution pole has the beneficial effects that the hydrogen evolution catalytic activity is high; during continuous electrolysis, the countercurrent resisting capacity is high, and the service life of the pole is long.

Owner:派新(上海)能源技术有限公司

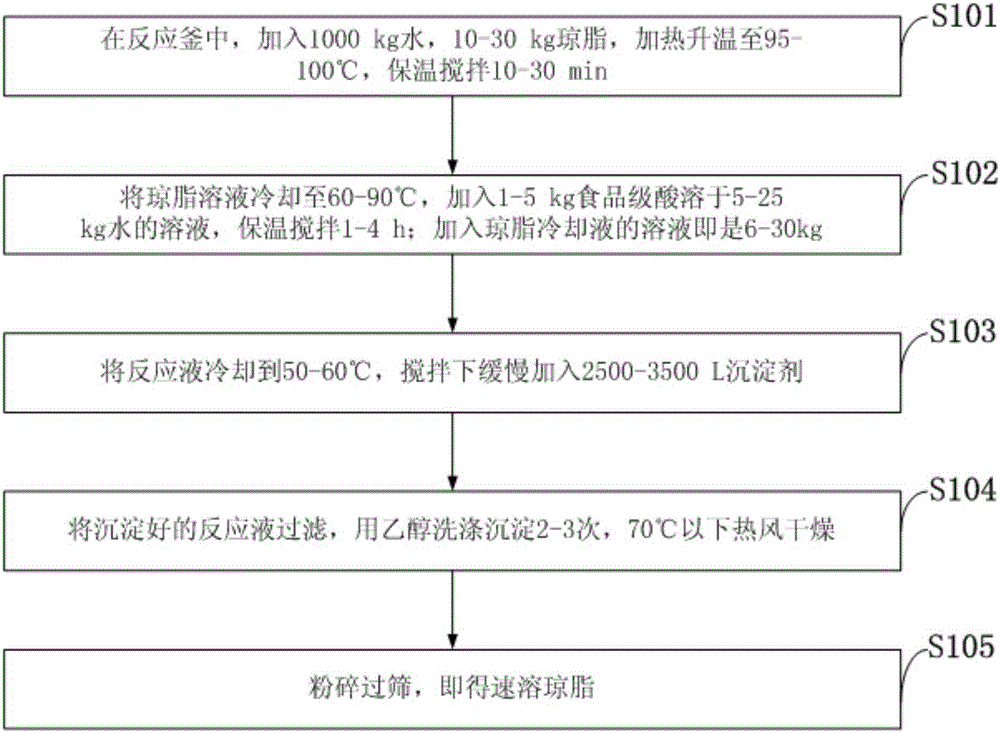

Preparation method of instant agar

The invention discloses a preparation method of instant agar. The preparation method comprises: sequentially adding water and agar to a reaction kettle, stirring, and heating until full dissolution; cooling the agar solution to a certain temperature, then adding food-grade acid, insulating heat and stirring for a period of time; cooling a reaction liquid to a certain temperature, and slowly adding a precipitating agent under stirring; filtering a precipitated reaction liquid, washing precipitate with ethanol for 2-3 times, and drying in hot air; and crushing and screening to obtain the instant agar. According to the preparation method, an innovated process is used for modifying the agar to obtain agar capable of being quickly dissolved in hot water of 70-80 DEG C, the problem that common agar can only be dissolved in hot water of more than or equal to 95 DEG C is solved, and great convenience is provided for application of agar in the production fields of foods, medicines, chemical industry and the like.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Special grouting material for micro-expanded assembled construction bar connecting sleeve and preparation method thereof

The invention relates to a special grouting material for micro-expanded assembled construction bar connecting sleeve and a preparation method thereof. The grouting material comprises a dry powder of the grouting material and water, wherein the dry powder of the grouting material comprises main materials and additives; the main materials include 30-45% of portland cement, 10-25% of a superfine granulated blast furnace slag powder, and 45-50% of a quartz powder, wherein the sum of the abovementioned three components is 100%; the additives include gypsum, a composite crack resisting shrinkage reducing agent, a defoaming agent, a composite early strength agent, a stabilizing agent, micro steel fibers, a corrosion inhibitor and a polycarboxylate superplasticizer. The preparation method comprises the following steps: weighing raw materials based on matching ratio; uniformly stirring to obtain the dry powder of the grouting material; preparing 100 parts of the dry powder; adding 13-15 parts of water; fully stirring through a mortar stirring machine to obtain the grouting material. The grouting material has the characteristics of being high in mobility, high in intensity, micro-expanded, and high in corrosion resistance; the bar can be firmly combined with the sleeve after grouting; moreover, the grouting material is high in durability.

Owner:LUOYANG INST OF SCI & TECH

Magnesium-strontium-rare earth interalloy and preparation method thereof

The invention relates to a magnesium-strontium-rare earth interalloy and a preparation method thereof, belonging to the fields of metal materials and metallurgy. The interalloy provided by the invention is prepared from the following components in percentage by weight: 60.0-90.0% of magnesium, 5.0-20.0% of strontium and 5.0-20.0% of rare earth, wherein the rare earth is one or more of cerium-richmixed rare earth, lanthanum-rich mixed rare earth, cerium, yttrium, lanthanum, praseodymium, samarium, europium, terbium, holmium, erbium, thulium, dysprosium and gadolinium. The preparation technique provided by the invention comprises the following steps: under the gas protection, melting a pure magnesium ingot, proportionally adding strontium (or magnesium-strontium interalloy) and rare earth (or magnesium-rare earth interalloy) into the melt, stirring while keeping the temperature until the melt composition becomes uniform, and casting into an alloy ingot or extruding into a wire or rod. The interalloy has the advantages of excellent refinement and modification effects, long effective period, simple preparation technique, high reliability, low cost and the like.

Owner:山东山科智镁新材料科技有限公司

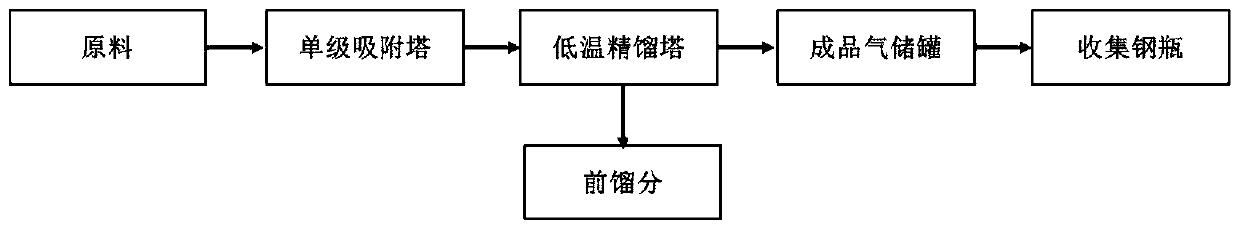

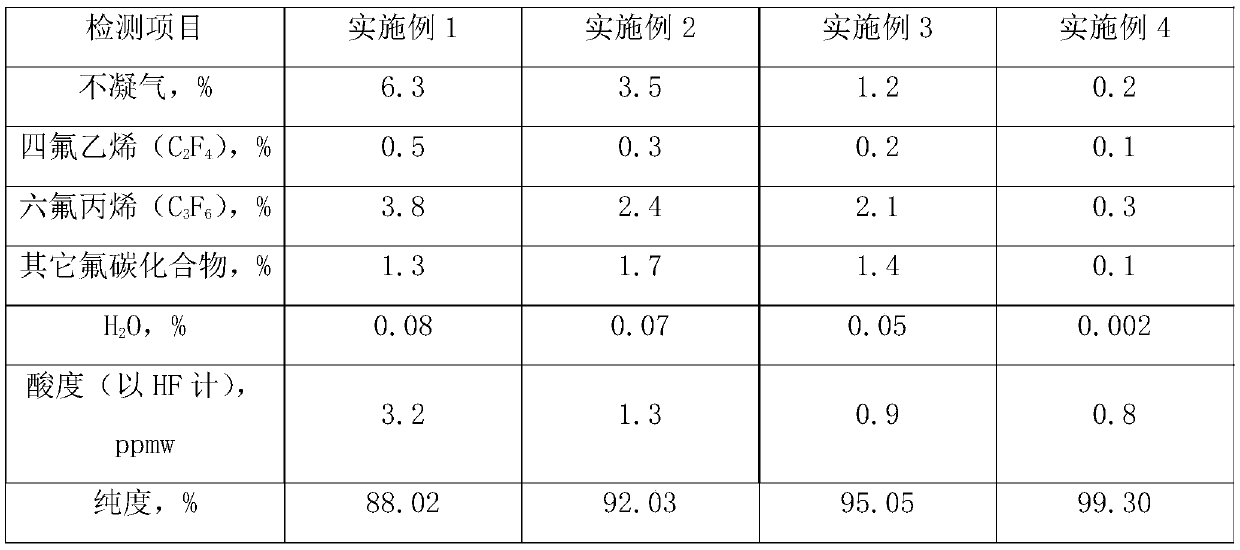

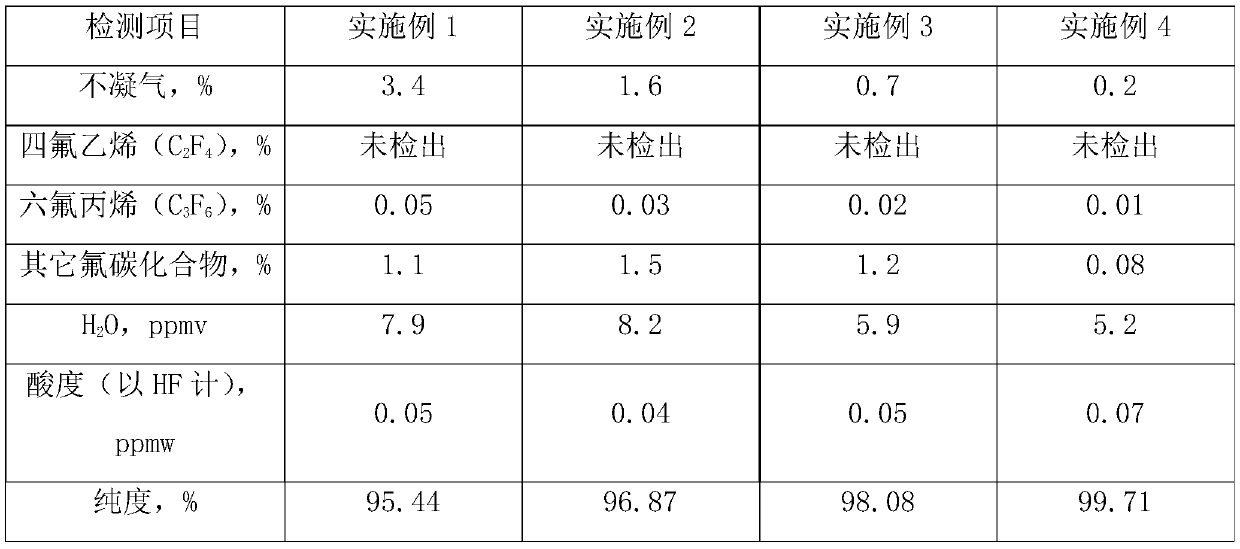

Method for preparing high-purity perfluoroisobutyronitrile

The invention discloses a method for preparing high-purity perfluoroisobutyronitrile. The method comprises the steps that the raw material perfluoroisobutyronitrile passes through a single-stage adsorption tower at a certain flow rate under a certain temperature and pressure by using a mass flowmeter; and after most water and a small amount of acidic matter are adsorbed and removed, the raw material perfluoroisobutyronitrile enters a rectifying tower, then batch rectification is carried out at a low temperature, and impurities such as nitrogen, oxygen, carbon dioxide, carbon monoxide, halogenated alkane, halogenated olefin and fluorocarbon are removed by emptying the tower top, so that the high-purity perfluoroisobutyronitrile with the purity of more than 99.99% is obtained. The method isreasonable in process and simple to operate, and is an ideal technology for preparing the high-purity perfluoroisobutyronitrile.

Owner:泉州宇极新材料科技有限公司

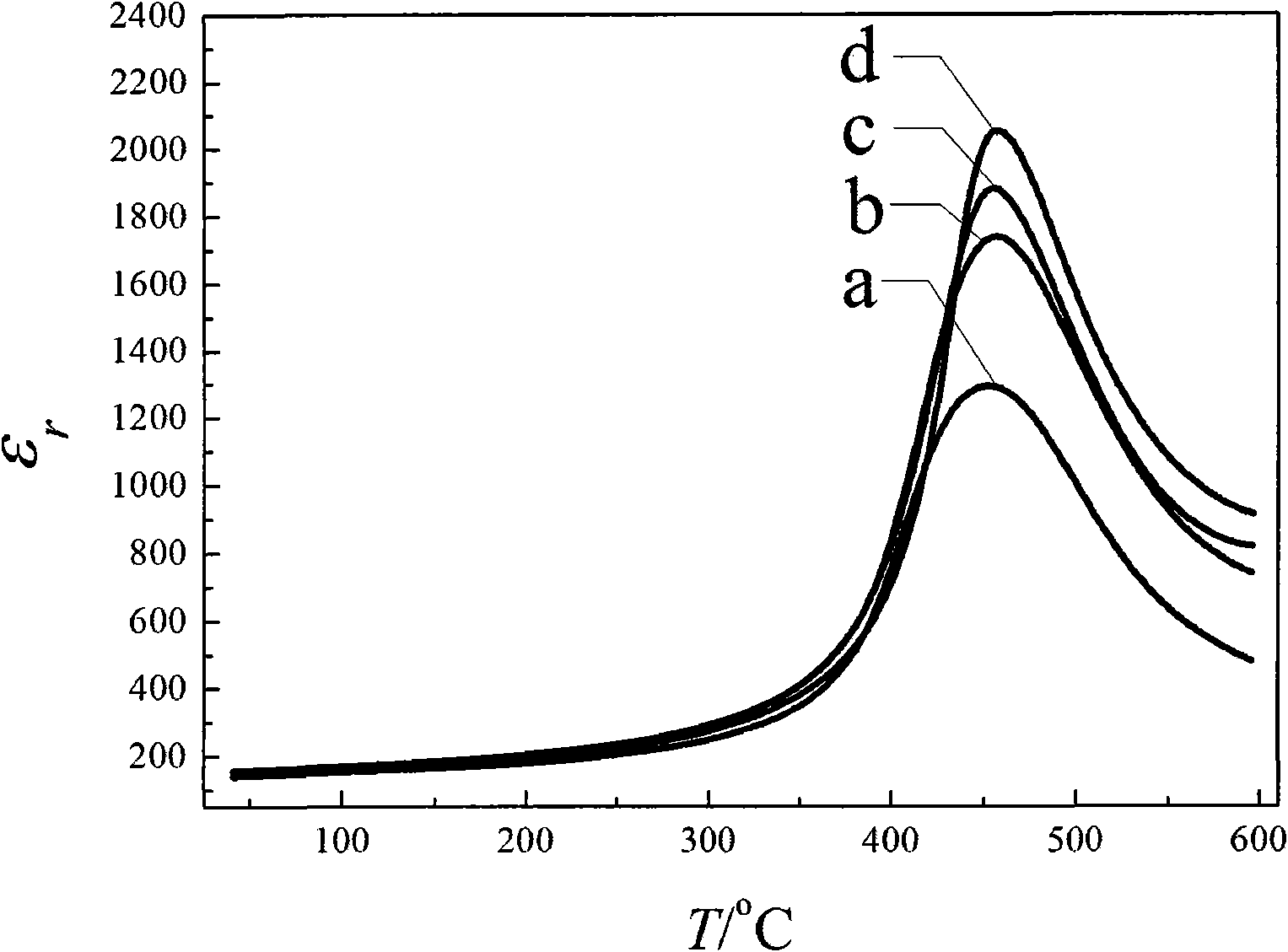

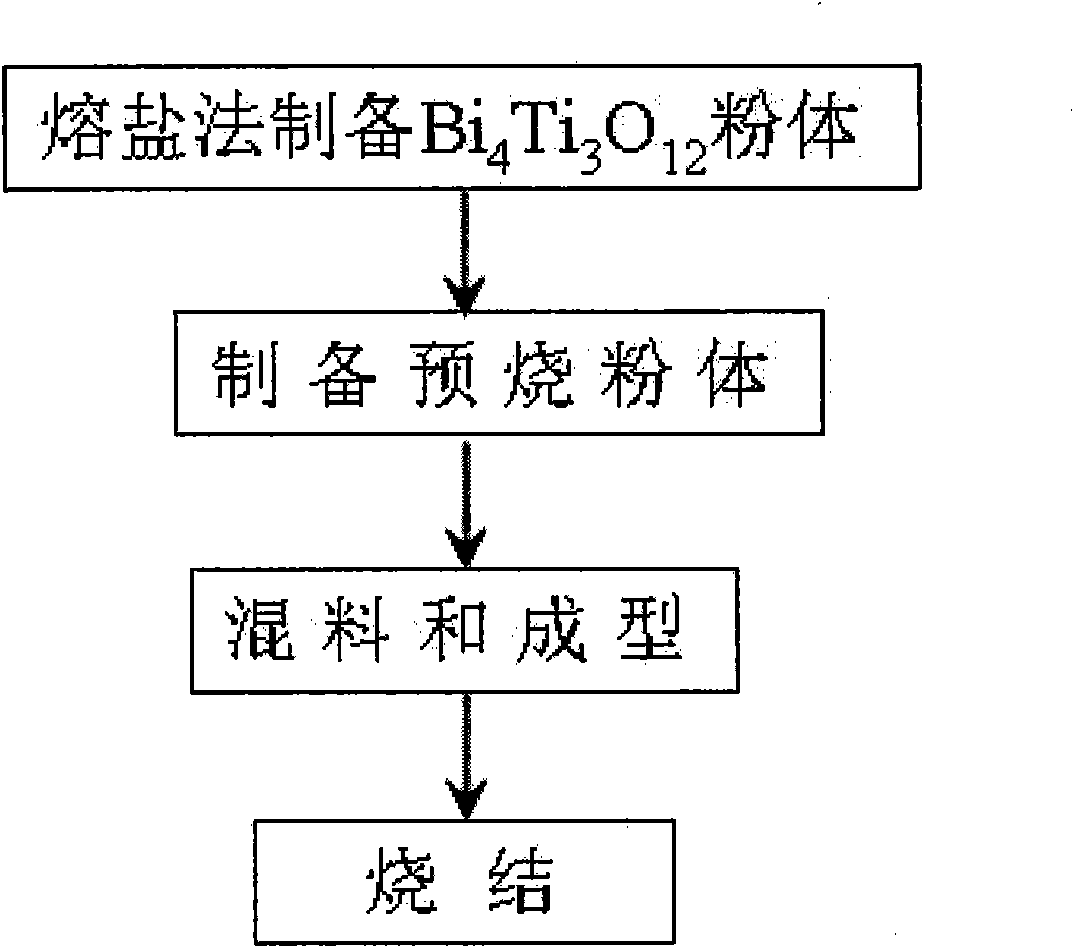

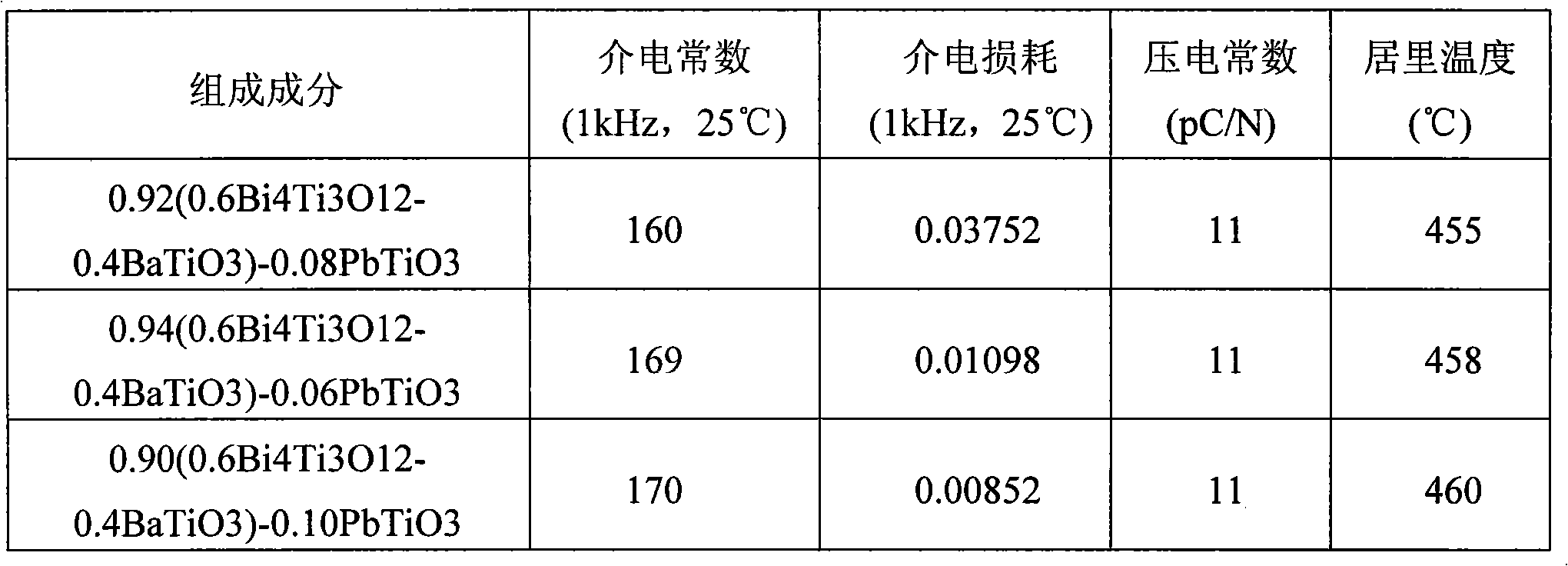

Bismuth titanate based piezoelectric ceramic with high curie temperature and preparation method thereof

ActiveCN101913860AThe preparation process is stable and reliableHigh curie temperatureMolten saltCurie temperature

The invention provides bismuth titanate based piezoelectric ceramic with high curie temperature and a preparation method thereof. (1-x)(0.6Bi4Ti3O12-0.4BaTiO3)-xPbTiO3 ceramic is prepared by the traditional solid-phase sintering method, wherein x=0.02-0.10. The piezoelectric ceramic with the high curie temperature is prepared from Bi4Ti3O12 prepared by a molten salt method and analytical pure BaTiO3, Pb3O4 and TiO2 serving as raw materials by the steps that powder is mixed, ball-milled, dried, presintered, secondarily ball-milled, pelleted, molded and batched sequentially and is finally sintered for 2-4 hours at the temperature of 1,050 to 1,100 DEG C. The piezoelectric ceramic is prepared by the traditional piezoelectric ceramic preparation method. The prepared BaBi4Ti4O15 based piezoelectric ceramic has the curie temperature of over 450 DEG C, a stable and reliable preparation process, an electrical property which meets the requirement on the practicability of the piezoelectric ceramic and application to special high-temperature environments such as aerospace, petrochemical industry and the like.

Owner:深圳智胜高技术发展有限公司

High-purity ginkgolide composition

InactiveCN102293790AProduct quality is stable and controllableSimple preparation processNervous disorderGinkgophyta medical ingredientsDesorptionGinkgolide

The invention relates to a high-purity ginkgolide and its composition. It is a white powder with slightly bitter taste. The content of ginkgolide A is 10-20%, the content of ginkgolide B is 10-20%, and the content of ginkgolide C is 10-20%. 5-15%, the bilobalide content is 30-50%, and the total lactone content is 80-95%. Ginkgo biloba is used as raw material, heated and refluxed with ethanol solution with a mass fraction of 20-80% to extract, the extract is concentrated to recover ethanol, separated by a macroporous resin column, desorbed by ethanol, diluted with water, and then passed through a gel-type hydrogen bond Adsorption and desorption of the adsorption resin, collection of effluent and desorption liquid, concentration, drying, ethanol dissolution, activated carbon decolorization, concentration and drying. The preparation process is simple, reliable, low in cost and high in yield, and no toxic organic solvent is used in the process, which is an environment-friendly process. The high-purity ginkgolide is used as an active ingredient to prepare a composition that can be used as various preparations (capsules, tablets, oral liquids, granules, powders, injections, etc.) of ginkgolide medicines or health care products.

Owner:TIANJIN TAIYANG PHARMA

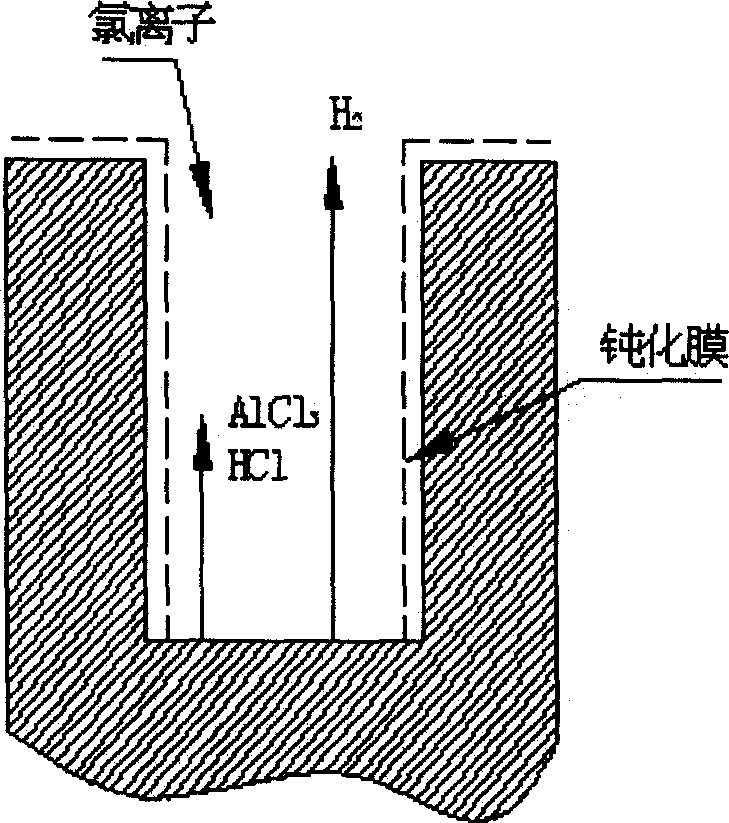

Preparation process of metal aluminium template for assembling nano-micron array material

InactiveCN1807701AResilientThe preparation process is stable and reliableAnodisationNanostructure manufactureAcid concentrationVolumetric Mass Density

The invention discloses a form preparing method for assembling nanometer-micrometre array material, which is characterized by the following: pre-processing 70%(100)high-purity aluminium foil; putting high-purity aluminium foil into acid solution with chloride ion to etch (aluminum foil for anode, ampere density applied by aluminum foil: 0. 1í‡104-7. 0í‡107A / m2, chloride ion solution strength of etching liquor: 0. 5molíñL-1-6. 0molíñL-1, acid concentration: 0. 1molíñL-1-5. 0molíñL-1, etching temperature: 60-02 deg. c, etching time: 2-200s); washing aluminum foil with plenty of clear water; scouring off etching liquor on the surface; drying the aluminum foil after washing; getting aluminium tunnel pore mold with bore diameter of 100nm-2000nm.

Owner:SICHUAN UNIV

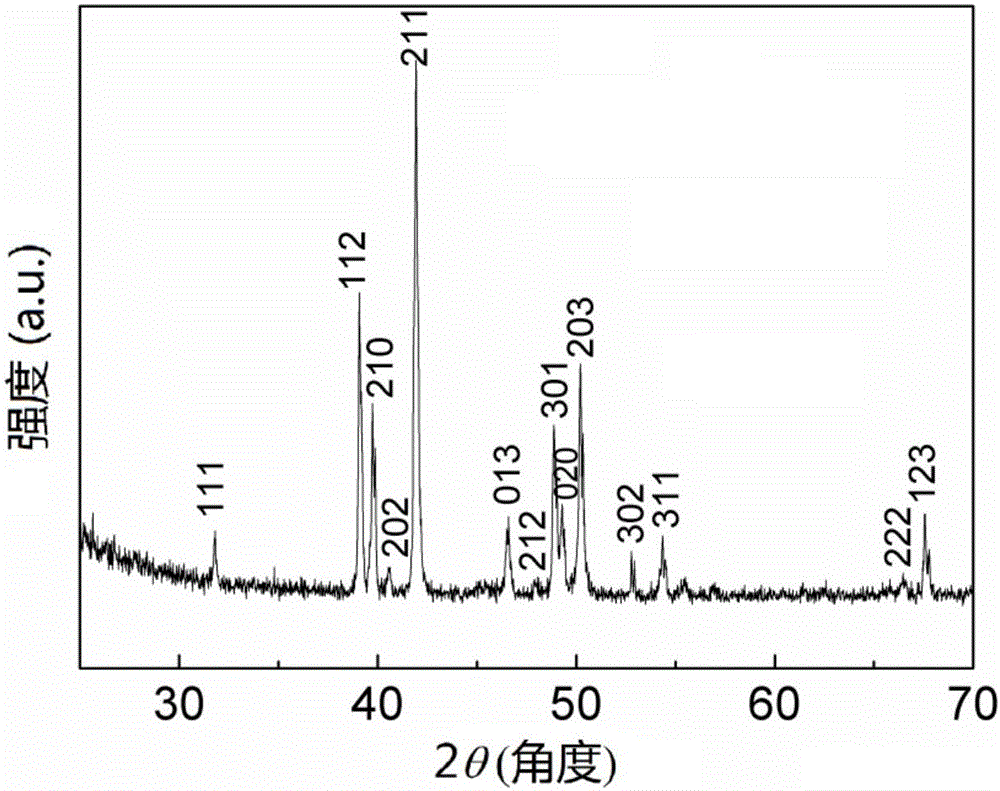

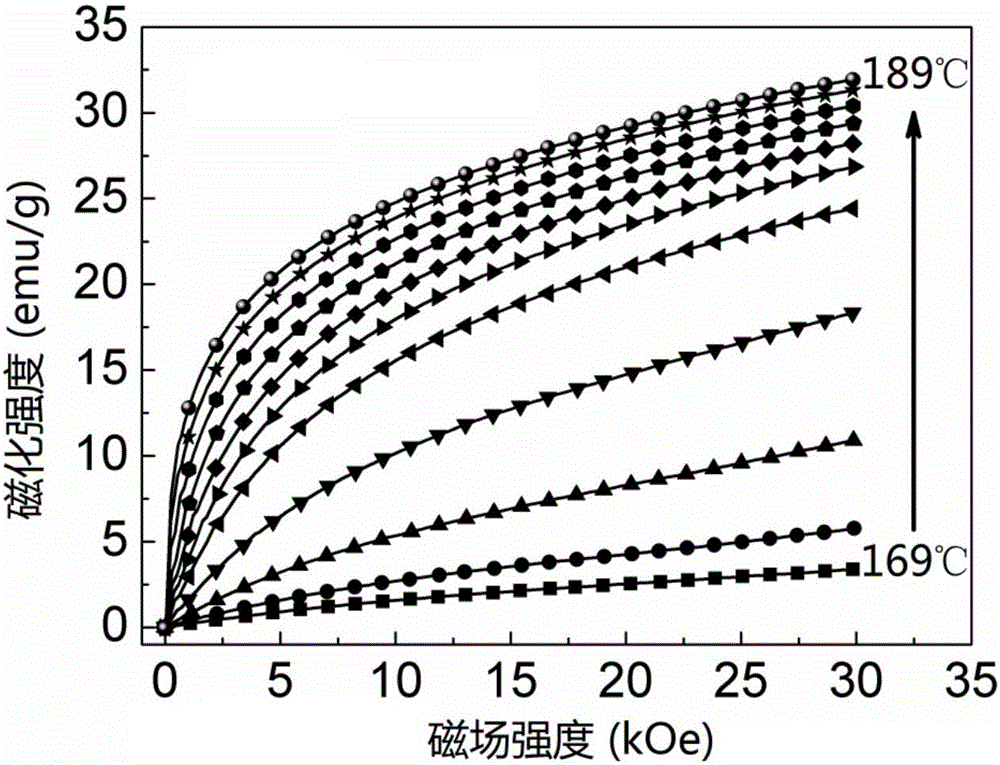

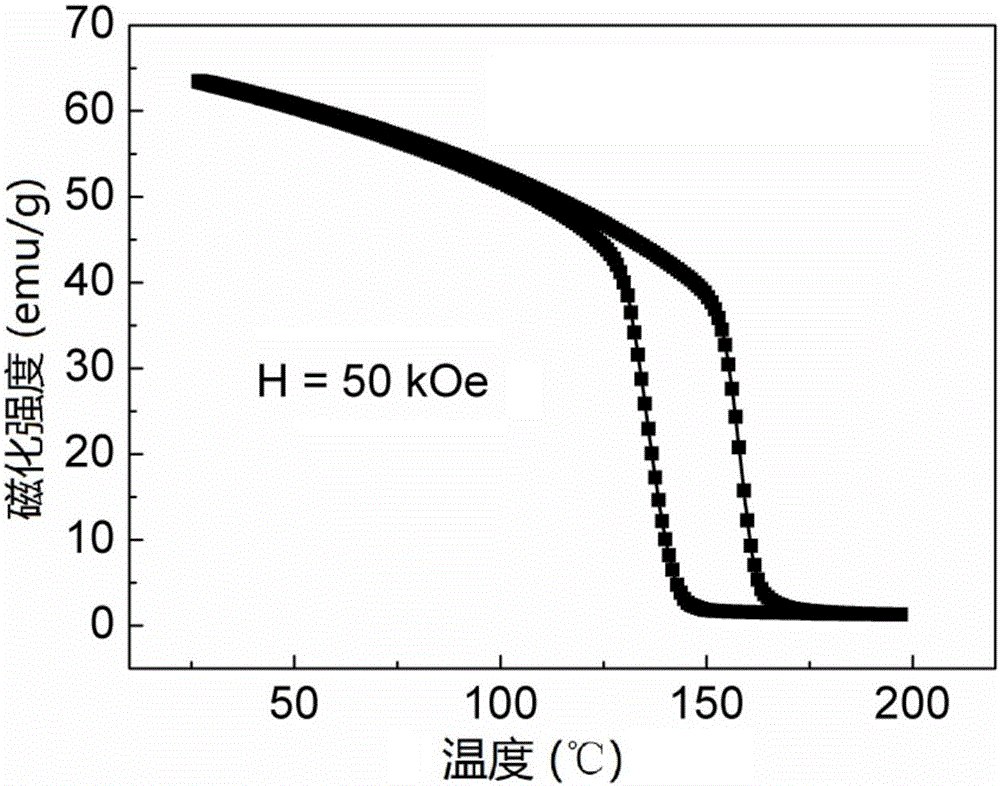

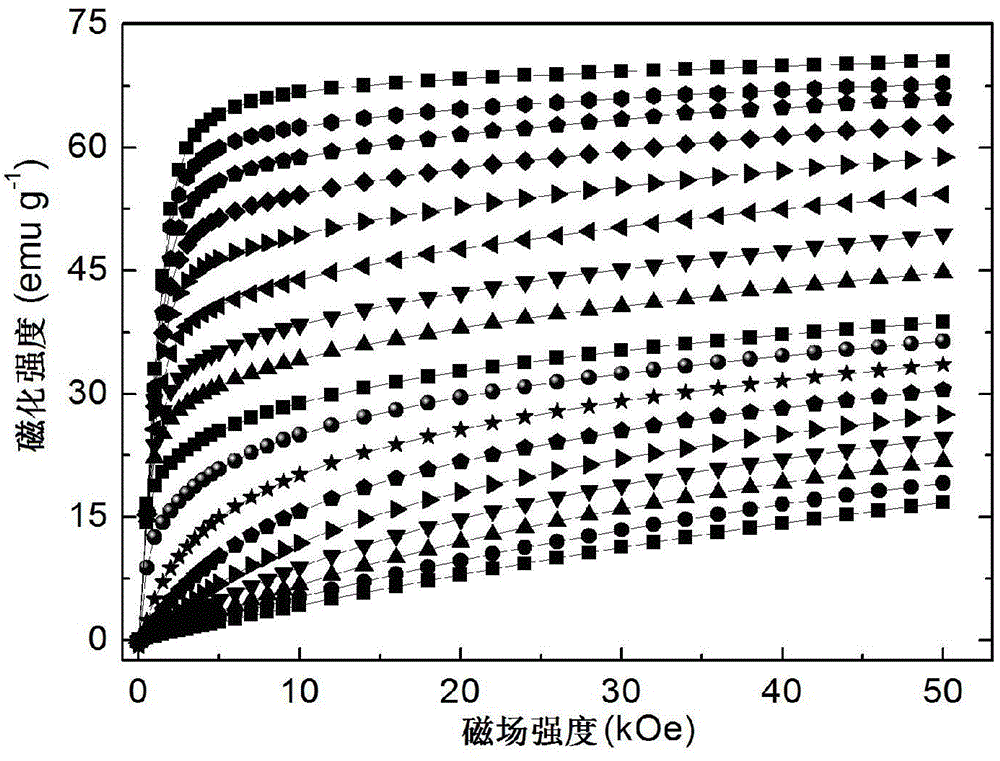

Magnetic phase change alloy

ActiveCN106191616AImprove thermal effectIncreased magnetic heating or energy conversion efficiencyInorganic material magnetismInductances/transformers/magnets manufactureMagnetic phaseHeat pump

The invention discloses a magnetic phase change alloy. The magnetic phase change alloy has a formula of (Mn1-alpha M alpha)xNiy(Ge1-beta Si beta)z; M=Fe or Co; x is not more than 36 and not less than 30; y is not more than 36 and not less than 30; z is not more than 36 and not less than 30; x+y+z=100; alpha is more than 0 and less than 0.8; and beta is not more than 1 and not less than 0. The magnetic phase change alloy has high-temperature huge magnetic heat effect, and widens the temperature range of a magnetic heating material; needed raw materials are rich in storage, easy to store and low in cost; and a preparation process is simple and reliable, is excellent in stability, and is easy to industrial produce. The magnetic phase change alloy is excellent in comprehensive performance, and is an ideal Mn base non-rare earth magnetic heat pump and thermomagnetic power generation candidate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

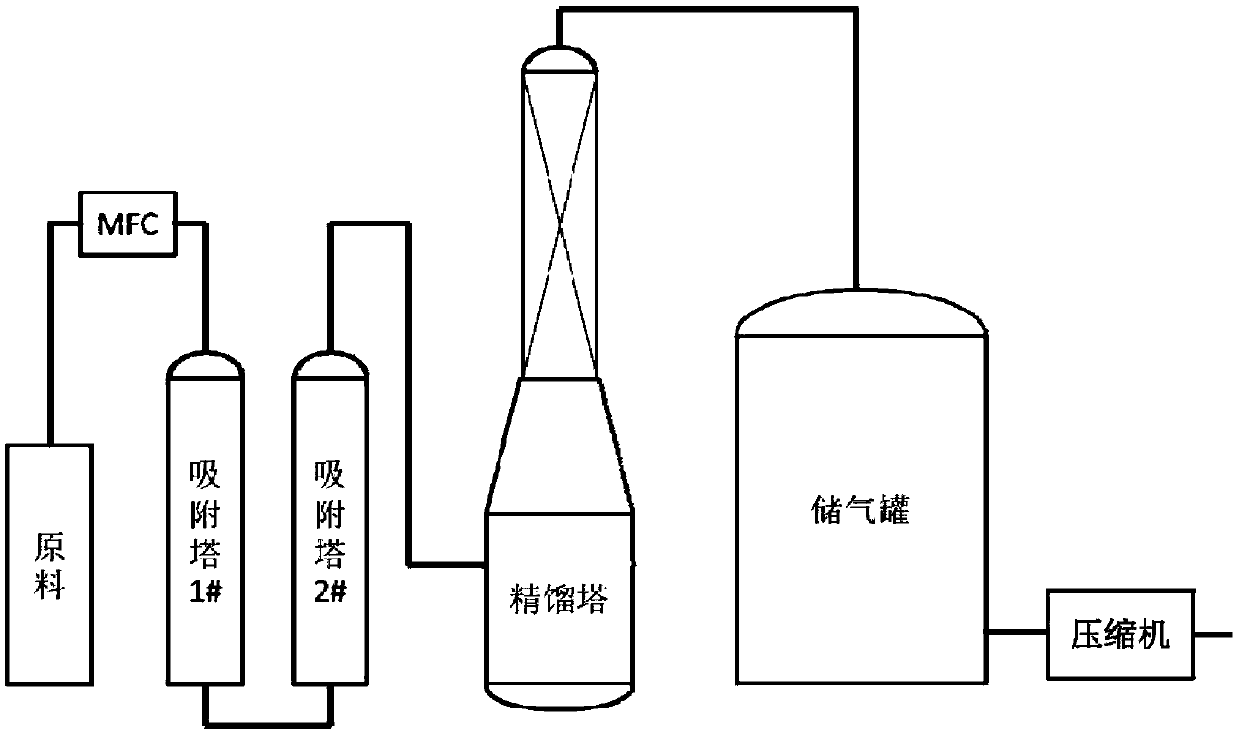

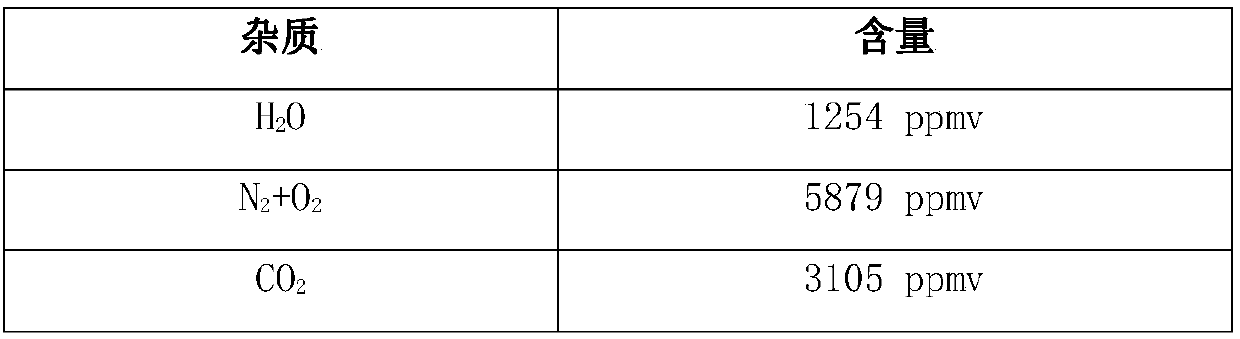

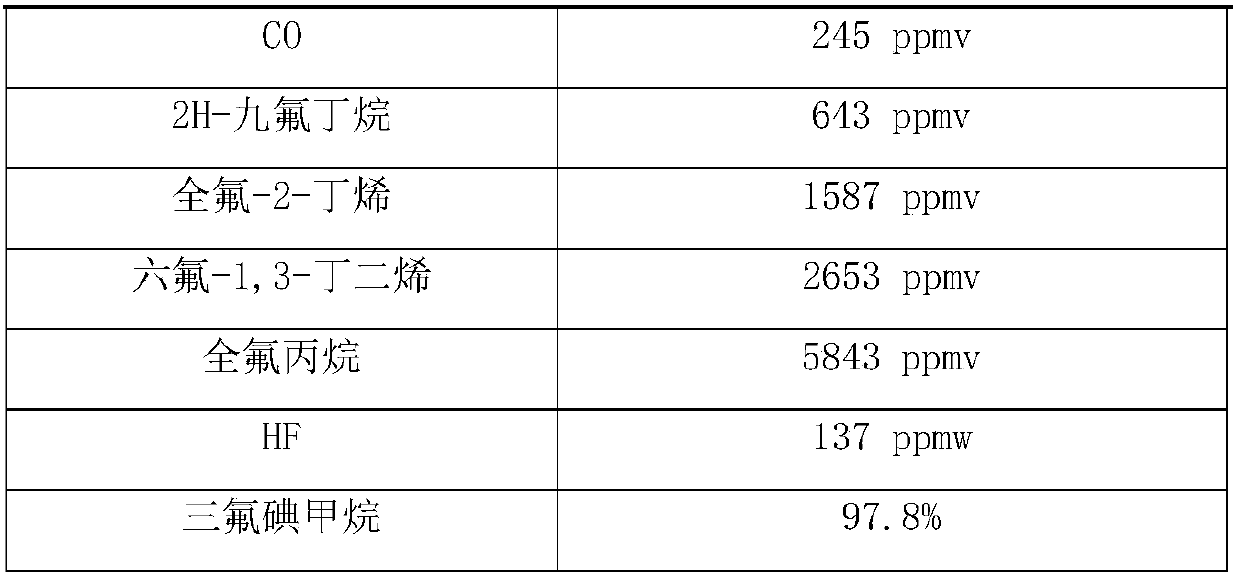

Method for preparing high-purity trifluoroiodomethane

The invention discloses a method for preparing high-purity trifluoroiodomethane. The method comprises the steps that: raw material trifluoroiodomethane passes through a two-stage adsorption column ata certain temperature and pressure and at a certain flow rate to remove most of the water and some organic impurities, then trifluoroiodomethane enters a rectification tower, batch rectification is conducted at low temperature, and tower top is emptied to remove impurities of halogenated alkanes, halogenated olefins, halogenated alkynes, nitrogen, oxygen, carbon dioxide, carbon monoxide and the like of C1 to C5, thereby obtaining the high-purity trifluoroiodomethane with a purity greater than 99.99%, wherein the H2O content is less than 30 ppmv, HF content is less than 1ppmw, and requirementsof the semiconductor etching and electrical insulation industries are met. The method is reasonable in process and simple in operation, and is an ideal technique for preparing the high-purity trifluoroiodomethane.

Owner:泉州宇极新材料科技有限公司

Preparation and application of di(2-ethyl hexyl) phthalate surface molecular imprinting magnetic nanometer material

ActiveCN105498728AEasy to makeMake fastComponent separationOther chemical processesPolyethylene glycolEthyl group

The invention relates to preparation and application of a di(2-ethyl hexyl) phthalate surface molecular imprinting magnetic nanometer material, and belongs to the technical field of nanometer materials. The preparation method includes the steps of conducting ultrasonic stirring under protection of N2, adding a polyethylene glycol solution to a mixed solution of Fe(NO3)3 and FeSO4, regulating pH, separating out flocculent magnetic fluid through a magnet, dispersing the flocculent magnetic fluid in ethyl alcohol, evenly mixing the mixture with an acetone solution of tetraethyl orthosilicate, and adding strong ammonia water to form black gel; obtaining an Fe3O4-SiO2 material after ageing and drying are conducted on the gel; dissolving DEHP and phenyl trimethoxy silane in methyl alcohol, adding the activated Fe3O4-SiO2 material, tetraethyl orthosilicate and acetic acid after oscillation, and conducting stirring at the room temperature; obtaining the DEHP imprinting magnetic nanometer material after trichloromethane washing, magnetic separation and vacuum drying, wherein the average grain diameter is about 33 nm, and the saturation magnetization strength is 14.9 emu.g<-1>. When the material is added to an environment water sample or a beverage sample containing DEHP, DEHP can be efficiently enriched, the processing speed is high, and selectivity is good; the material can be repeatedly used.

Owner:GUANGDONG UNIV OF TECH

Astragalus glycoside fatty emulsion and its preparation technology

A lipid emulsion of astragaloside A is proportional prepared from astragaloside A, oil, surfactant, isotonic regulator, cosolvent and water for injection. Its preparing process is also disclosed.

Owner:JIANGSU QINGJIANG PHARMA

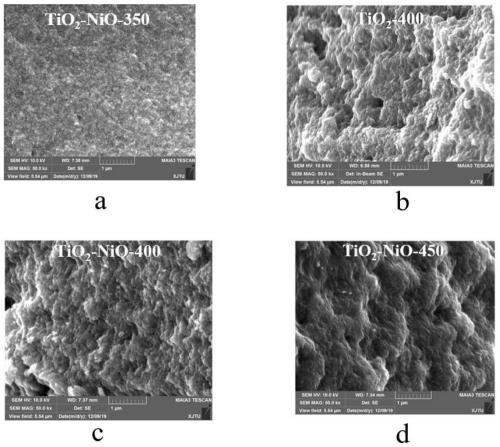

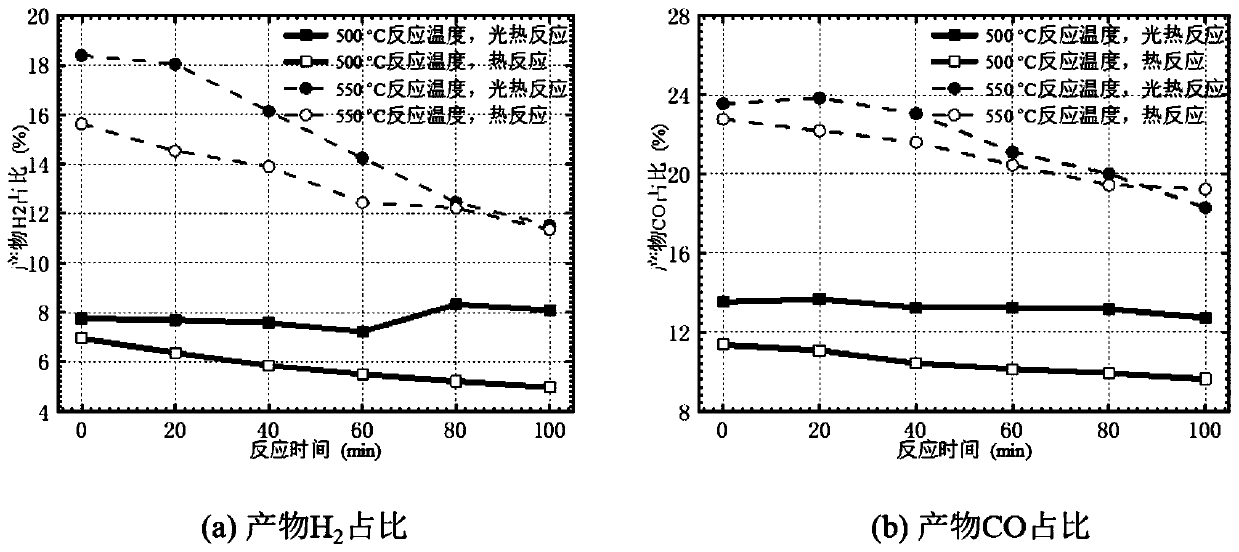

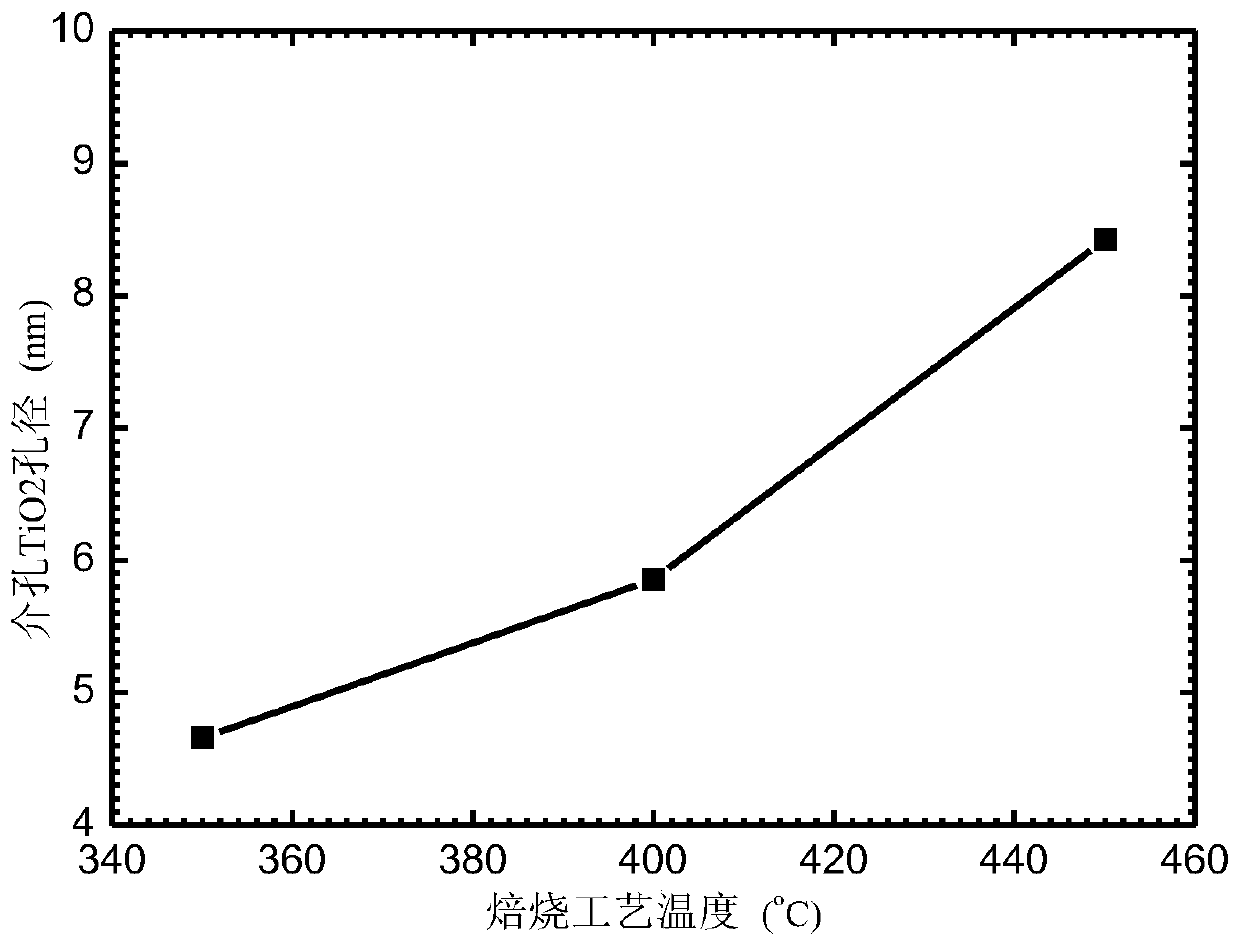

Mesoporous photo-thermal catalyst for dry reforming of medium-high temperature methane as well as preparation method and application thereof

InactiveCN111111669AControllable pore structureGood dispersionHydrogenCatalyst activation/preparationPtru catalystPhoto catalytic

The invention discloses a mesoporous photo-thermal catalyst for medium-high temperature methane dry reforming as well as a preparation method and application thereof. The preparation method belongs tothe field of solar photo-thermal conversion and photo-thermal catalyst preparation methods, and adopts an impregnation method to load a thermal catalyst Ni to the surface of a mesoporous TiO2 photocatalyst, so as to form the Ni-mesoporous TiO2 photo-thermal catalyst with nano Ni particles loaded on the surface of mesoporous TiO2. The medium-high temperature methane dry reforming photo-thermal synergistic catalyst provided by the invention is simple to prepare and easy to operate, has good photo-thermal synergistic catalytic activity at 400-600 DEG C, and has obviously improved activity compared with the traditional Ni-based thermal catalyst, so that the catalyst has higher industrial application level and prospect.

Owner:XI AN JIAOTONG UNIV

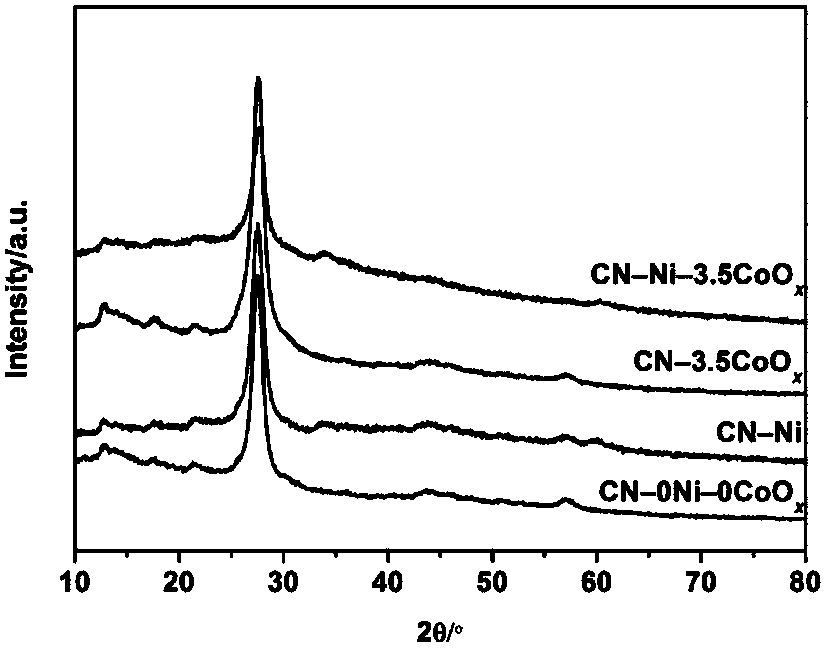

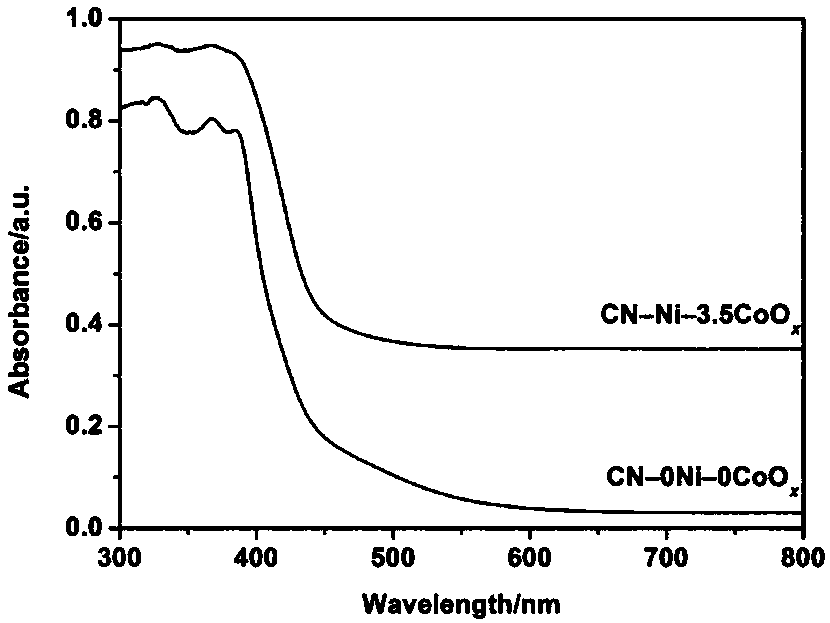

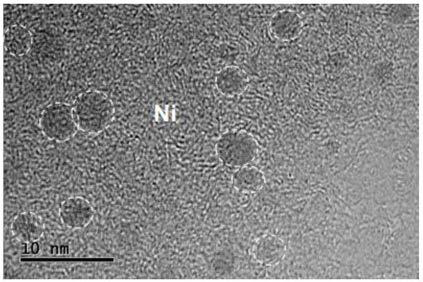

Photocatalyst for complete water decomposition, preparation method and application thereof, reaction method for complete water decomposition by photocatalysis and catalytic mixed solution

ActiveCN110116015AHigh activityLow costCatalyst activation/preparationHydrogen productionPhotocatalytic reactionDecomposition

The invention discloses a catalyst and a reaction method for photocatalytic complete water decomposition based on non-noble metal supported graphite-phase carbon nitride. According to the method, graphite-phase carbon nitride, metal nickel nanoparticles and a cobalt precursor are directly added into pure water, the cobalt precursor is converted into CoOx through photoreaction, and the metal nickelnanoparticles and the CoOx act synergistically as a cocatalyst, so that the visible light catalysis of the non-noble metal supported graphite-phase carbon nitride is achieved, and water is completelydecomposed to produce hydrogen and oxygen. The method is simple to operate and good in repeatability, all related materials are low in preparation cost, the solid phase can be recovered from a reaction system after reaction to obtain the photocatalyst, and the photocatalyst is used for photocatalytic reaction for complete water decomposition. According to the catalyst and the reaction method, noble metals are not used, the construction system is simple and convenient, and the cost of the photocatalytic reaction for complete water decomposition can be reduced.

Owner:XI AN JIAOTONG UNIV

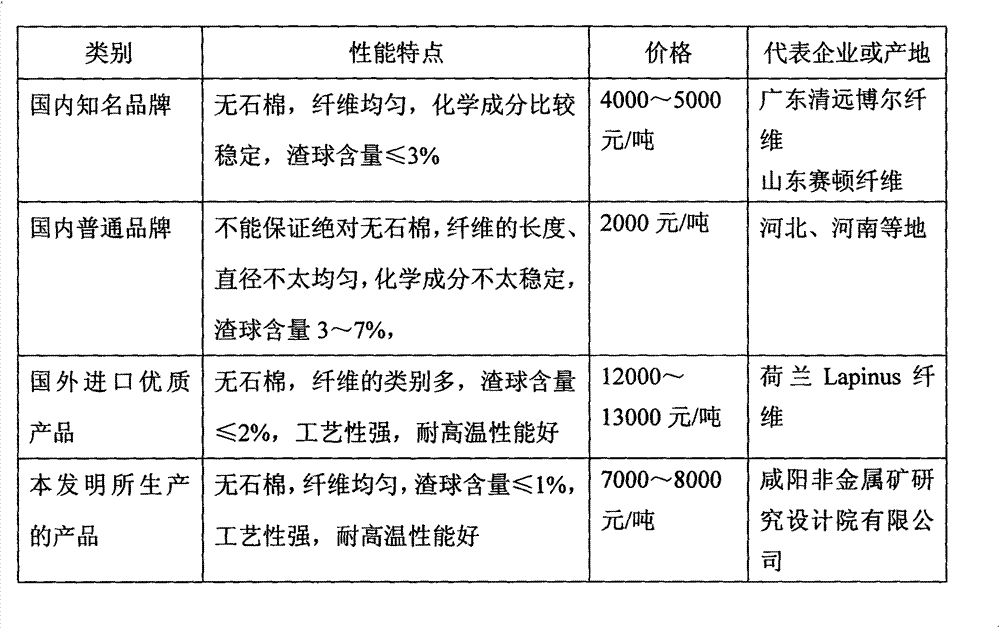

Non-asbestos composite fiber and preparation method thereof

InactiveCN103194172AThe preparation process is simple and reliableLow costOther chemical processesFiber strengthPolyresin

The invention discloses a non-asbestos composite fiber and a preparation method of the on-asbestos composite fiber, and belongs to the technical field of chemical material manufacturing. The non-asbestos composite fiber has the main technical characteristics that: the fiber is composed of the following raw material compositions in percentage by weight: 62-80% of a fiber material, 17-34% of a powder material, and 3-6% of a modifier, wherein the fiber material is a non-natural fiber material subjected to high-temperature treatment, the powder material is selected from talcum powder, bentonite, vermiculite and mica powder and the like in silicate materials, the particle size of the powder material enables the powder material to achieve 100% of passing rate at 100 meshes, and the modifier is a polymer resin or a combination thereof. The composite fiber disclosed by the invention is simple in material production process and low in cost, and has good comprehensive performances such as low shot content, small fiber diameter and high fiber strength and the like; and the used fiber does not contain asbestos and asbestos fiber, therefore, the non-asbestos composite fiber is nonpoisonous, and has no harm to the human body and environment. Therefore, both in production and use, the safety and reliability can be ensured, so the non-asbestos composite fiber is an environmental-friendly novel composite fiber material.

Owner:咸阳非金属矿研究设计院有限公司

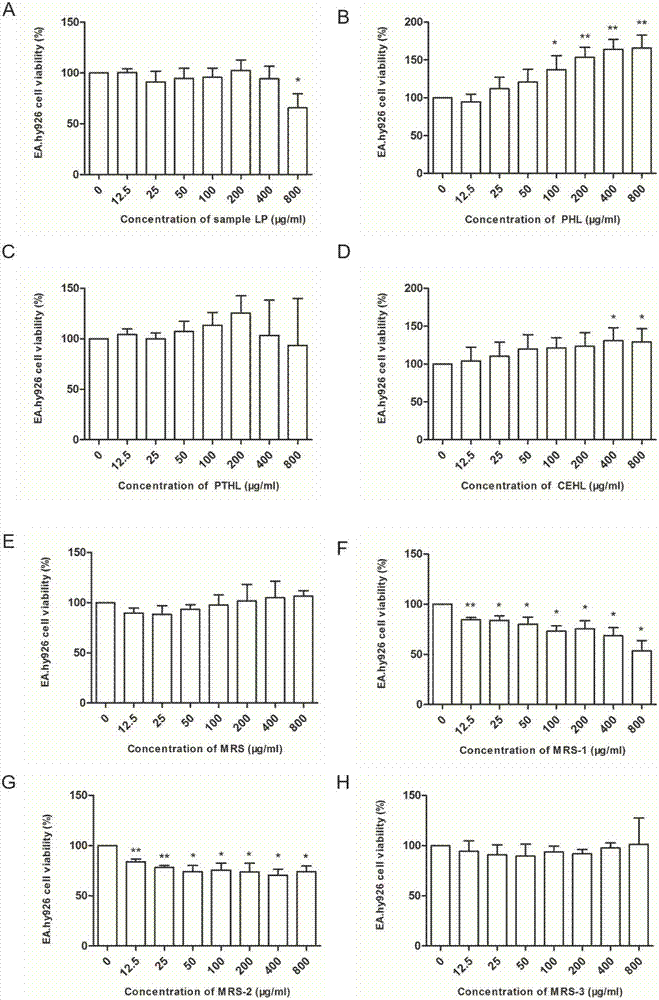

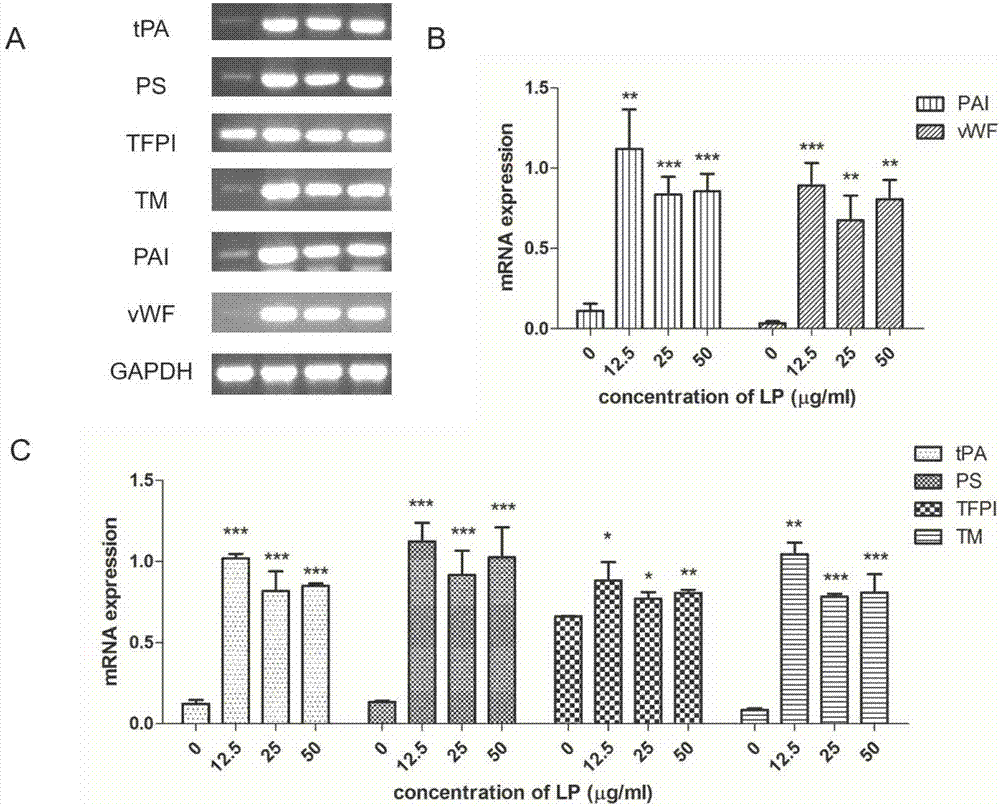

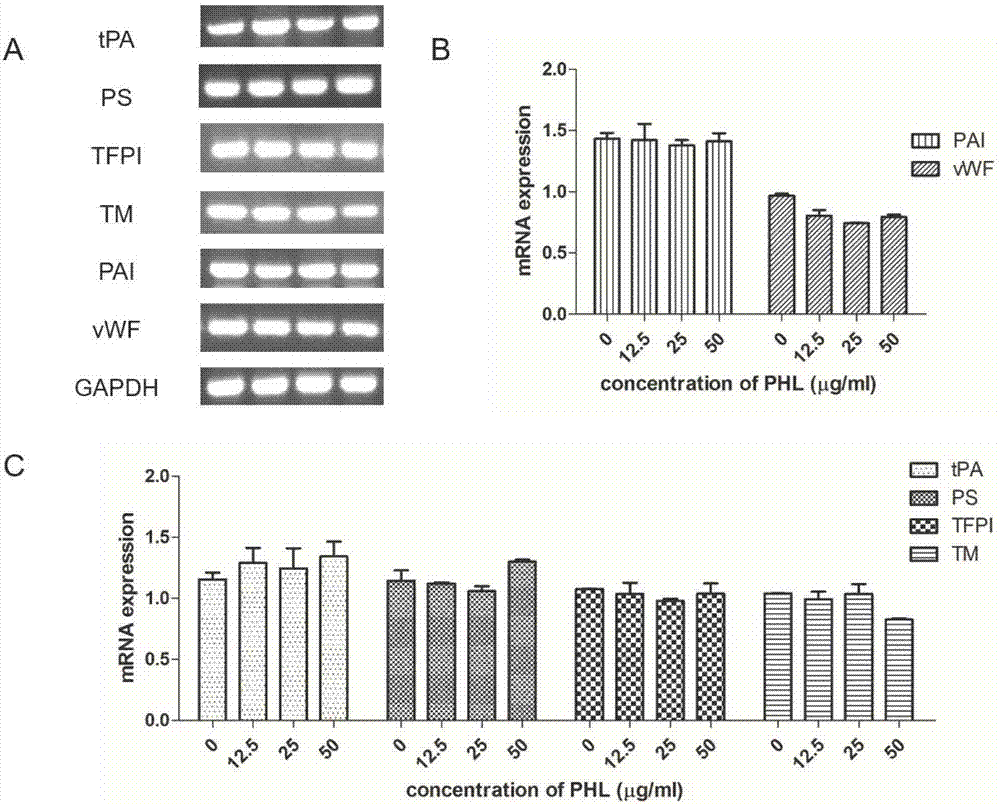

Process for preparing hirudin peptide for reducing harmful bleeding reaction of hirudo

InactiveCN107287269AThe preparation process is stable and reliableInhibits the progression of atherosclerosisPeptide/protein ingredientsPeptide preparation methodsAlcoholHydrolysate

The invention discloses a process for preparing hirudin peptide for reducing harmful bleeding reaction of hirudo. The process comprises the following steps: grinding and homogenating dried hirudo, adding 10000NFU / g of pepsin at 36-38 DEG C and pH of 2.0, and performing enzymolysis for 8 hours and above; performing alcohol precipitation on enzymatic hydrolysate, and concentrating and lyophilizing the filtrate to obtain hirudo extract. The hirudo extract PHL prepared by using the method can be used for inhibiting the process of atherosclerosis on the premise of not influencing the blood coagulation factor of endothelial cells. A reliable preparation process is provided to a safe and reliable novel oral preparation which can be clinically used for preventing atherosclerosis for a long time and has weak harmful bleeding reaction.

Owner:SHANDONG UNIV

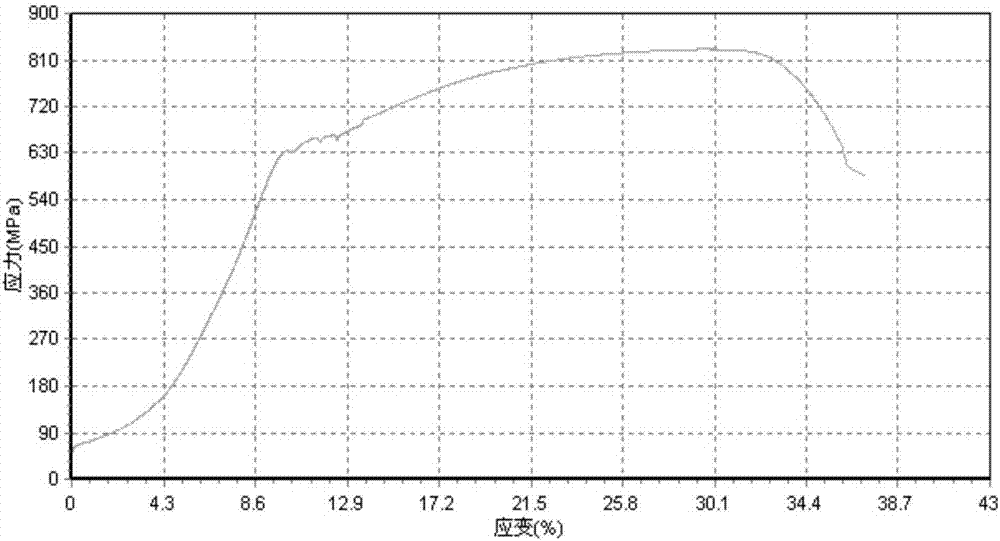

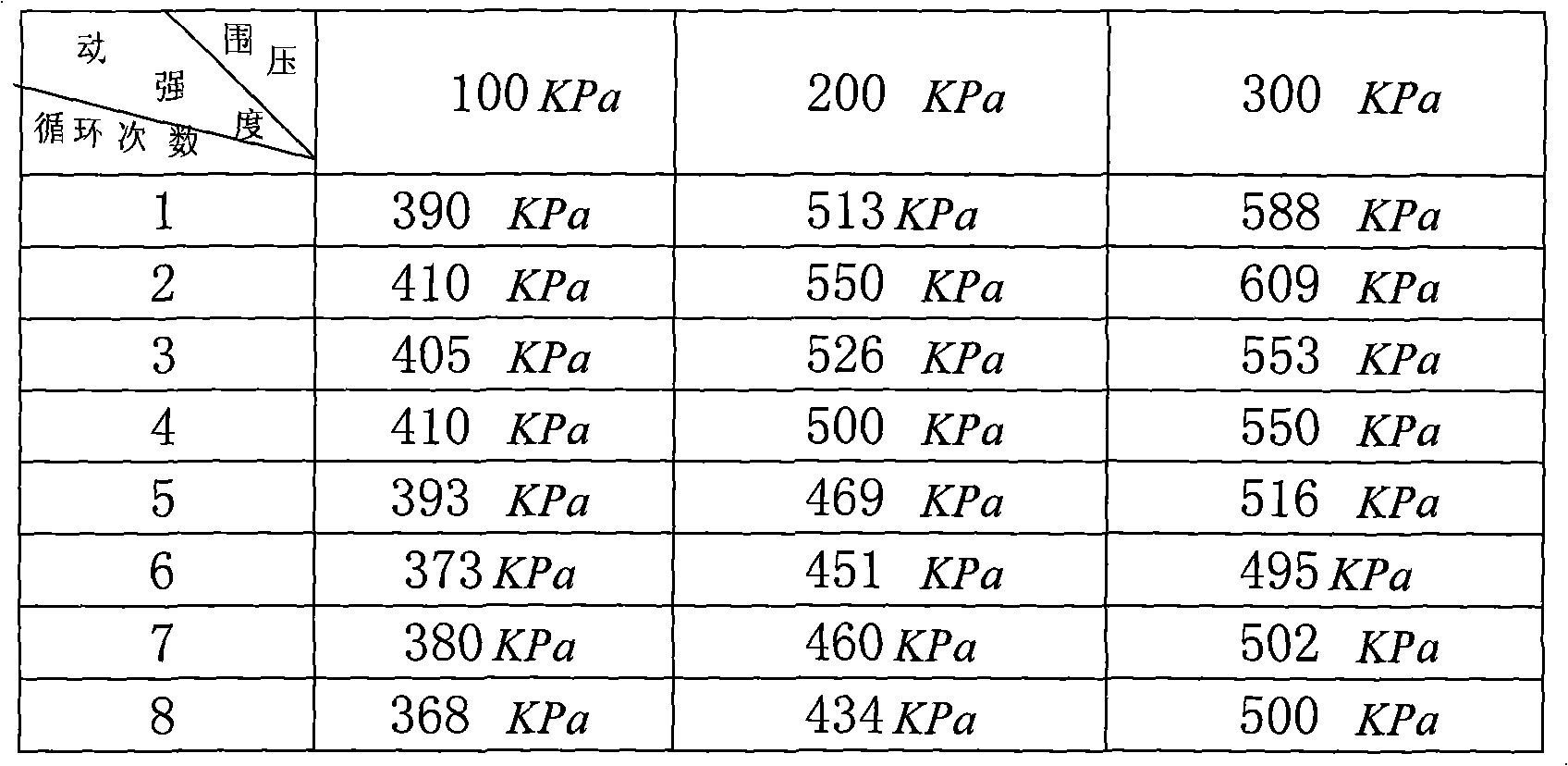

Coal ash soil composite material for highway subgrade and preparation method thereof

The invention relates to a fly ash and soil composite material used in highway roadbed and is characterized in that the material consists of fly ash, soil and polypropylene fiber; the technique is simple and reliable to ensure that the fly ash and soil composite material has good frost resistance property; the unconfined compressive strength of the fly ash and soil which is doped with the polypropylene fiber is 1.26 to 1.74 times higher than the unconfined compressive strength of pure fly ash and soil. According to the characteristics of roadbed freezing injury mechanism and structural style in seasonal frozen areas, the fly ash and soil composite material of the invention adopts novel materials which have the advantages of good resistance to freezing and thawing, high strength, low cost and environmental protection as the roadbed filler, which not only has theoretical guidance meaning, but also has direct practical meaning for solving engineering problems.

Owner:JILIN UNIV

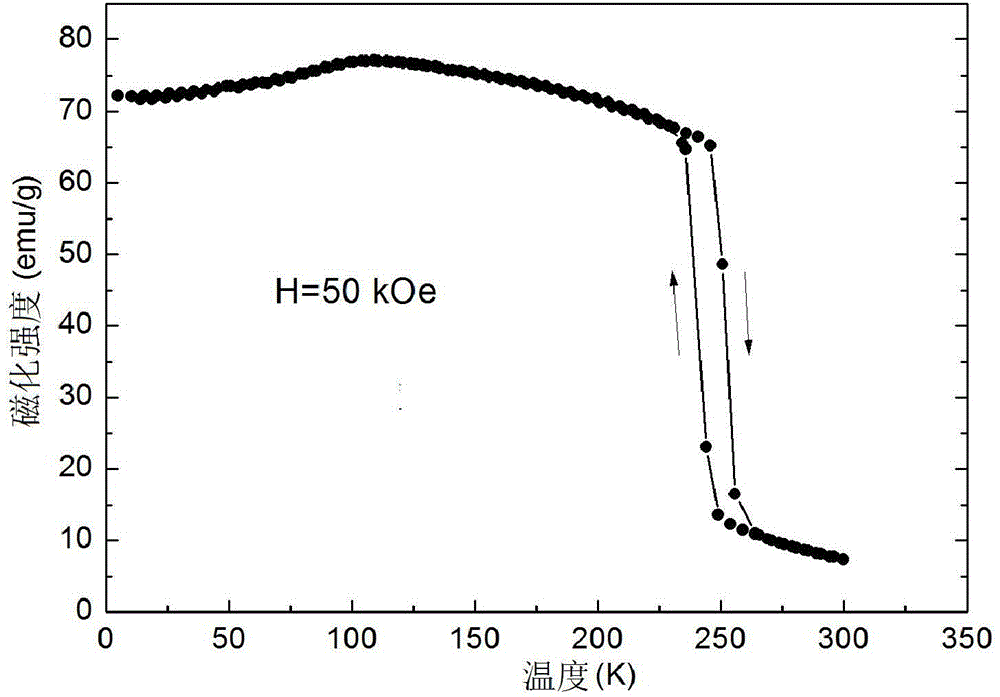

Magnetic alloy serving as magnetic refrigeration material

ActiveCN103334043ALarge magnetic differenceImprove the magnetocaloric effectHeat-exchange elementsRare earthMagnetic refrigeration

The invention discloses a magnetic alloy. The chemical general formula of the magnetic alloy is (Mn100-deltaCodelta) alphaNibetaGegamma, wherein alpha is more than or equal to 25 and less than or equal to 40, beta is more than or equal to 25 and less than or equal to 40, gamma is more than or equal to 25 and less than or equal to 40, alpha+beta+gamma is equal to 100, delta is more than 0 and less than 50, and alpha, beta, gamma and delta refer to the atomic percent content. The magnetic alloy has a huge magnetocaloric effect and high magnetic refrigeration efficiency and can stably operate in a wide temperature range temperature area by serving as a magnetic refrigeration working medium. The required raw materials Mn, Co, Ni and Ge are the conventional metal elements which are low in price, rich in reserves and easy to store. The material is simple and reliable in preparation process, high in process stability and easy to industrially produce. The provided magnetic material (Mn100-deltaCodelta) alphaNibetaGegamma with the huge magnetocaloric effect has excellent comprehensive performance and is an ideal Mn-based non-rare earth magnetic refrigeration candidate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

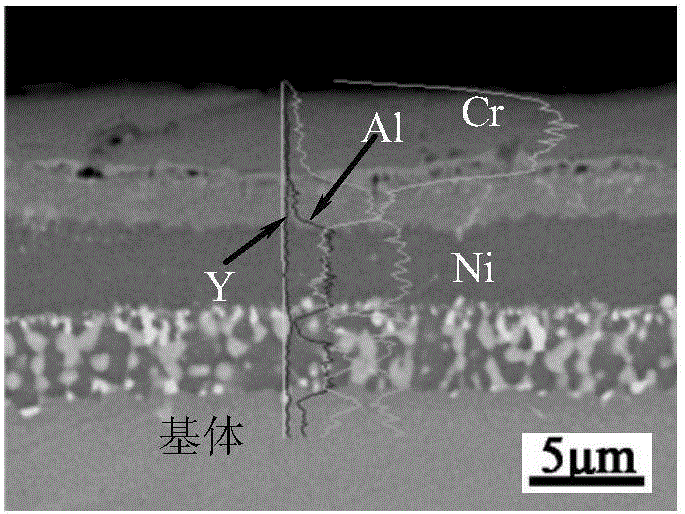

High-temperature alloy oxidation-resistance and corrosion-resistant protective coating

InactiveCN105839048ARealize ternary co-infiltrationImprove high temperature and corrosion resistanceSolid state diffusion coatingRoom temperatureOxidation resistant

The invention discloses a nickel-based high-temperature alloy oxidation-resistance and corrosion-resistant protective coating and a preparation technique thereof. The protective coating is prepared from three elements including Cr, Al and Y through a pack cementation method. The protective coating is prepared from, by weight, 5-10% of Cr, 10-20% of Al, 1-2% of Y2O3, 6-10% of NH4Cl and the balance Al2O3. The preparation technique comprises the steps that raw materials are weighed accurately according to the weight percentage for preparation of the protective coating; then ball milling and drying are conducted; the raw materials are placed into a crucible after being dried; the raw materials are placed in a muffle furnace after being sealed and charged; and the muffle furnace is heated for 40-60 min to the temperature of 1050-1070 DEG C, heat preservation is conducted at the temperature of 1050-1070 DEG C for 2-3 h, then the temperature is decreased to 600 DEG C with the furnace, the raw materials are taken out and cooled to the room temperature, and finally, the protective coating can be obtained through cleaning and drying. According to the protective coating, a Cr-Al-Y coboronising layer is prepared on the surface of the nickel-based alloy, the technical problem that the nickel-based alloy is poor in high-temperature resistance and corrosion resistance is solved, the preparation technique is stable and reliable, the coating is good in binding force, uniform in structure and compact, and the coating thickness is controllable; and the preparation technique has the advantages of being simple, convenient to operate, high in efficiency, low in cost, easy to implement and the like.

Owner:BEIFANG UNIV OF NATITIES

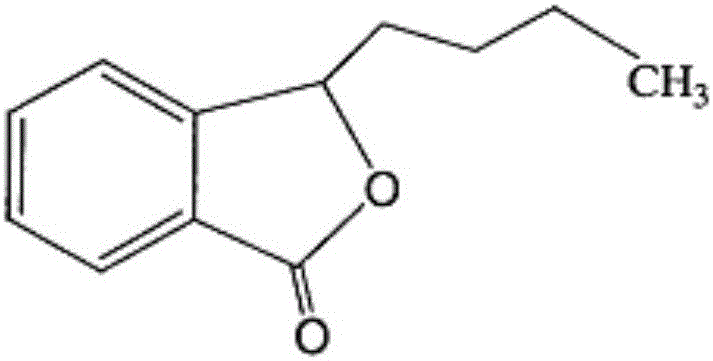

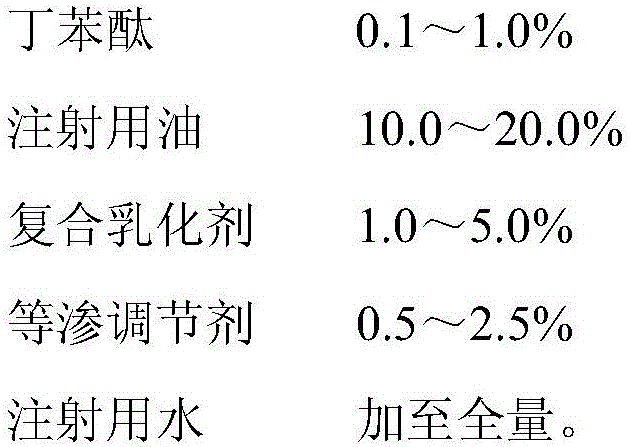

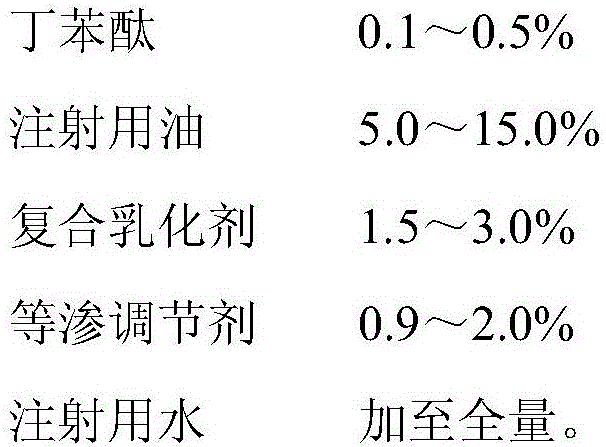

Butylphthalide fat emulsion injection and preparation process thereof

InactiveCN105796486AGood solubilization effectAccurate doseOrganic active ingredientsPharmaceutical non-active ingredientsSide effectMicrometer

The invention discloses a butylphthalide fat emulsion injection and a preparation process thereof.The butylphthalide fat emulsion injection is prepared from 0.1-1.0% of refined butylphthalide, 10.0-20.0% of oil for injection, 1.0-5.0% of a compound emulsifier, 0.5-2.5% of an isotonic regulator and the balance water for injection, wherein the grain size of an obtained milk white emulsion solution ranges from 0.1 micrometer to 1.0 micrometer.Butylphthalide is dissolved in an oil phase, a better solubilization effect can be achieved after the oil phase and a water phase are fully emulsified under the action of the compound emulsifier at a specific proportion, the divided dose is accurate, and no solubilizer or cosolvent needs to be added; meanwhile, stability is improved, and the toxic and side effects of the butylphthalide fat emulsion injection are reduced.

Owner:NANJING TIANXIANG PHARMA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com