Coal ash soil composite material for highway subgrade and preparation method thereof

A composite material and fly ash technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as easy liquefaction of pure fly ash, unsatisfactory effect, unstable roadbed, etc., to achieve Good liquefaction resistance, obvious social and economic benefits, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

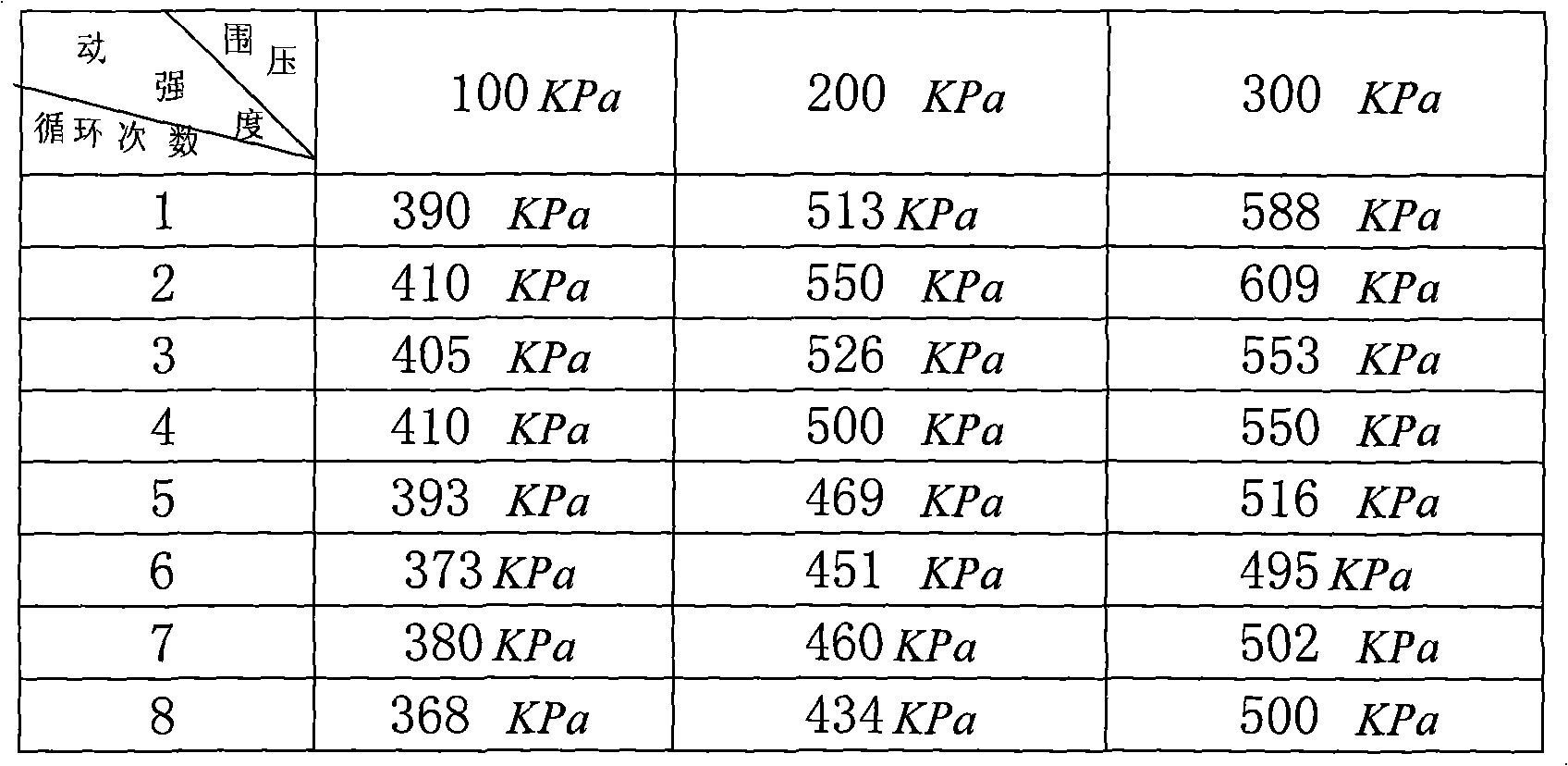

Image

Examples

Embodiment 1

[0022] Embodiment 1: 28.3% of fly ash is mixed with 71.7% of the soil that is dried, crushed and sieved, and in the mixed fly ash soil, it is 0.5% by mass of polypropylene fiber, the Stir the fiber and fly ash soil evenly, add water to prepare the water content to 18%, make a test piece, and let it stand in a humidifier for 24 hours. Its unconfined compressive strength was measured to be 0.34MPa.

Embodiment 2

[0023] Embodiment 2: the fly ash of 38.3% is mixed with the soil of 61.7% through drying, crushing and sieving, and in the fly ash soil after mixing, it is 1% polypropylene fiber by mass percentage, and the Stir the fiber and fly ash soil evenly, add water to prepare the water content to 23%, make a test piece, and let it stand in a humidifier for 24 hours. Its unconfined compressive strength was measured to be 0.47MPa.

Embodiment 3

[0024] Embodiment 3: 33.3% fly ash is mixed with 66.7% of the soil that is dried, crushed and sieved, and in the mixed fly ash soil, it is 2% by mass of polypropylene fiber, and the Stir the fiber and fly ash soil evenly, then add water to prepare the water content to 22%, make a test piece, and let it stand in a humidifier for 24 hours. Its unconfined compressive strength was measured to be 0.35MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com