Patents

Literature

36results about How to "Improve resistance to liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

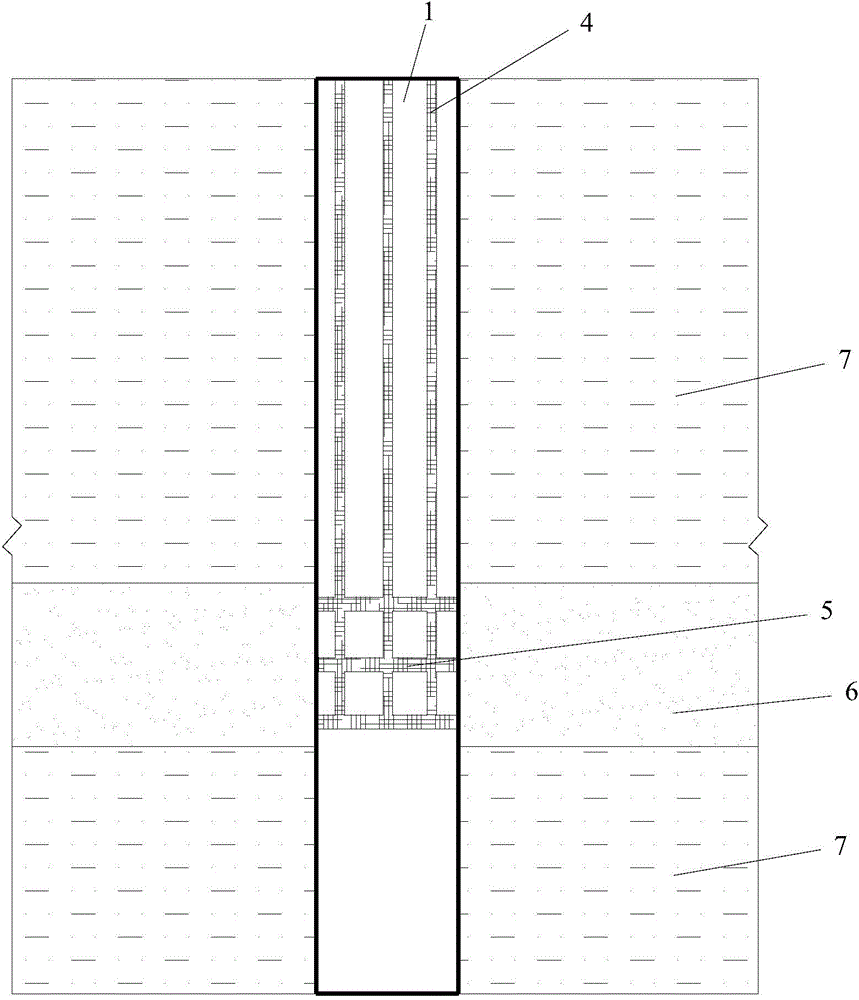

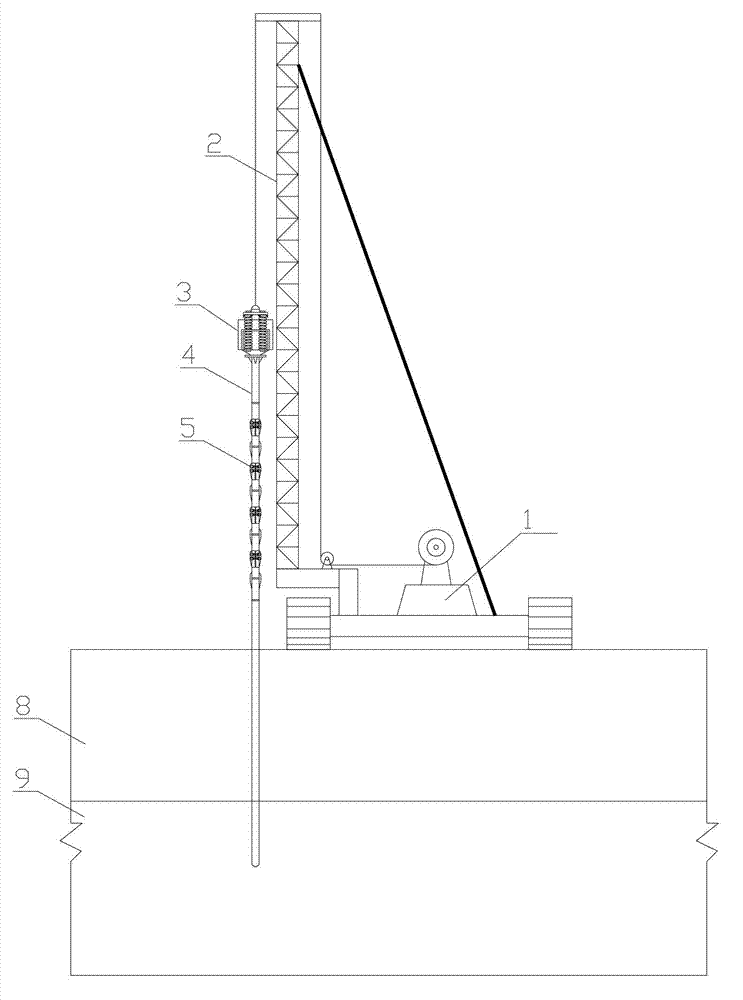

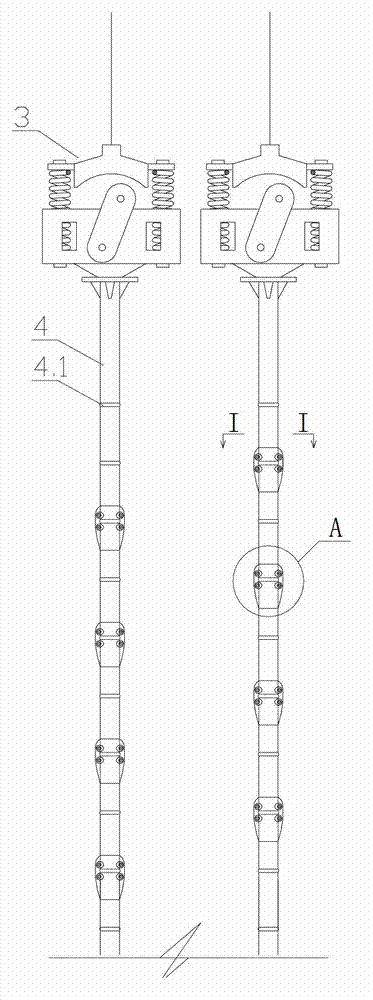

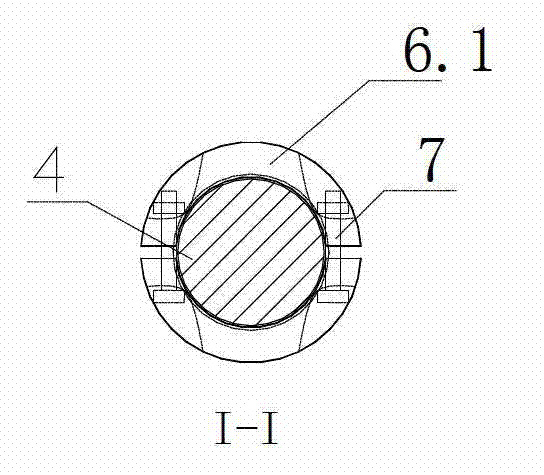

Microorganism slab grouting device and method used for reinforcing liquefiable foundation

ActiveCN105507232AAvoid cloggingGood injectabilitySoil preservationMicroorganismStructural engineering

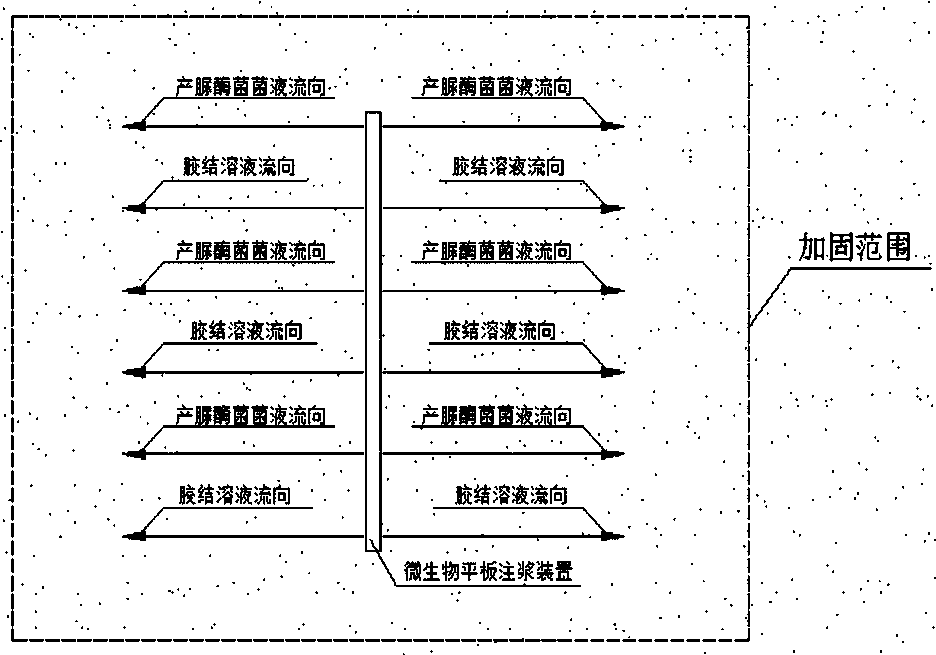

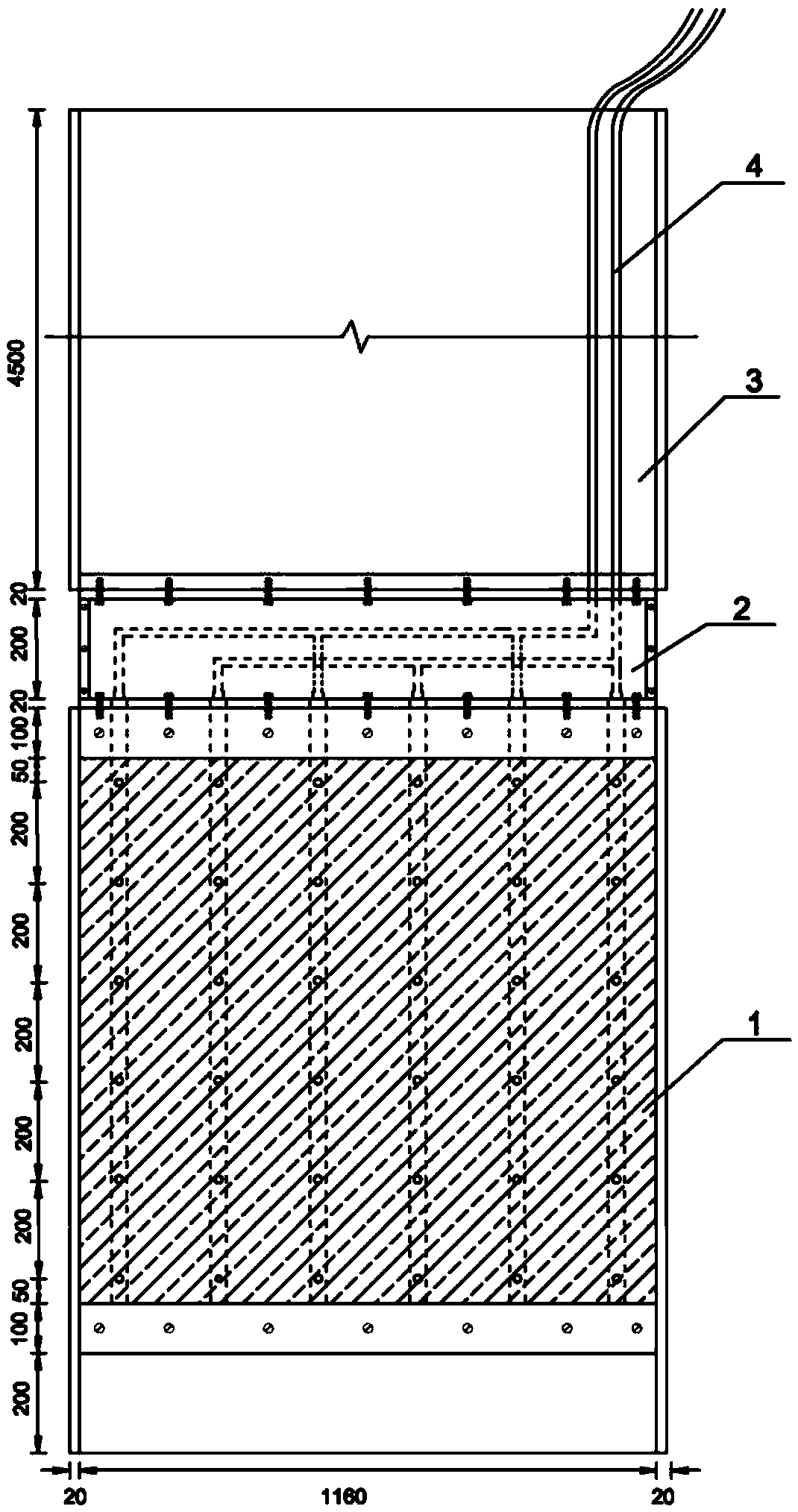

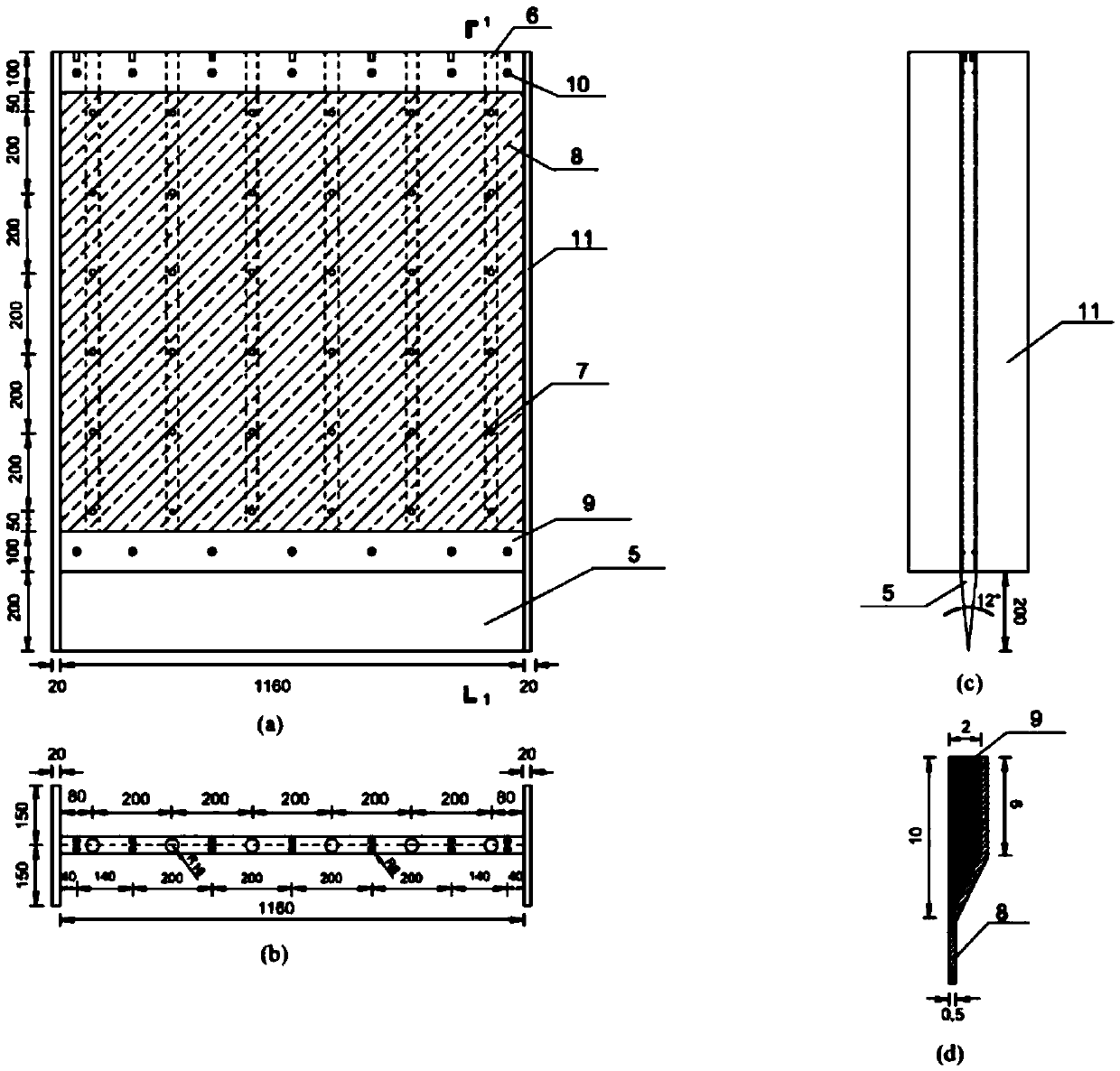

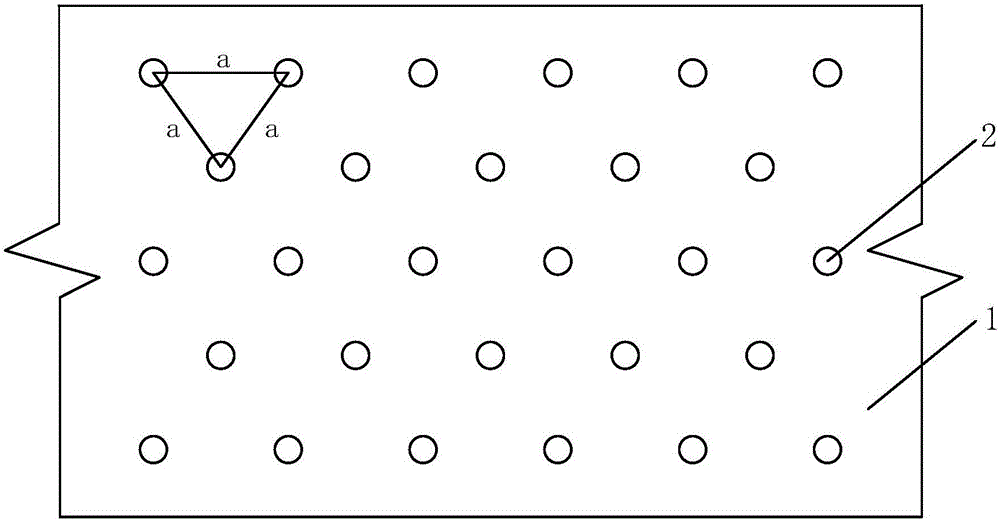

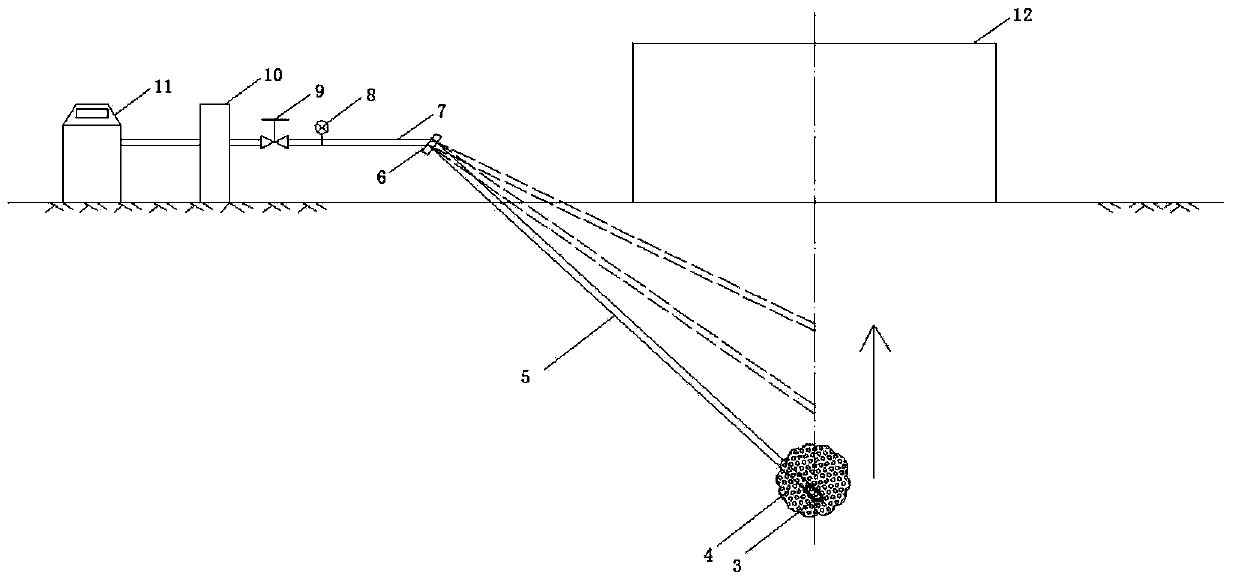

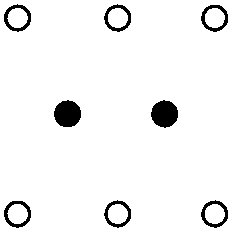

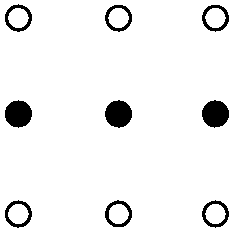

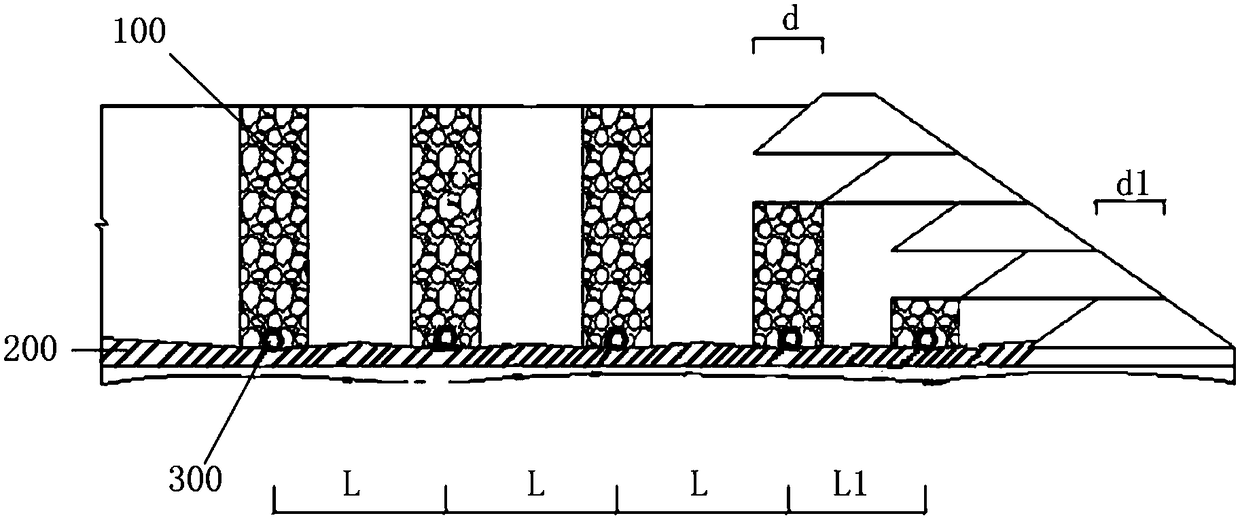

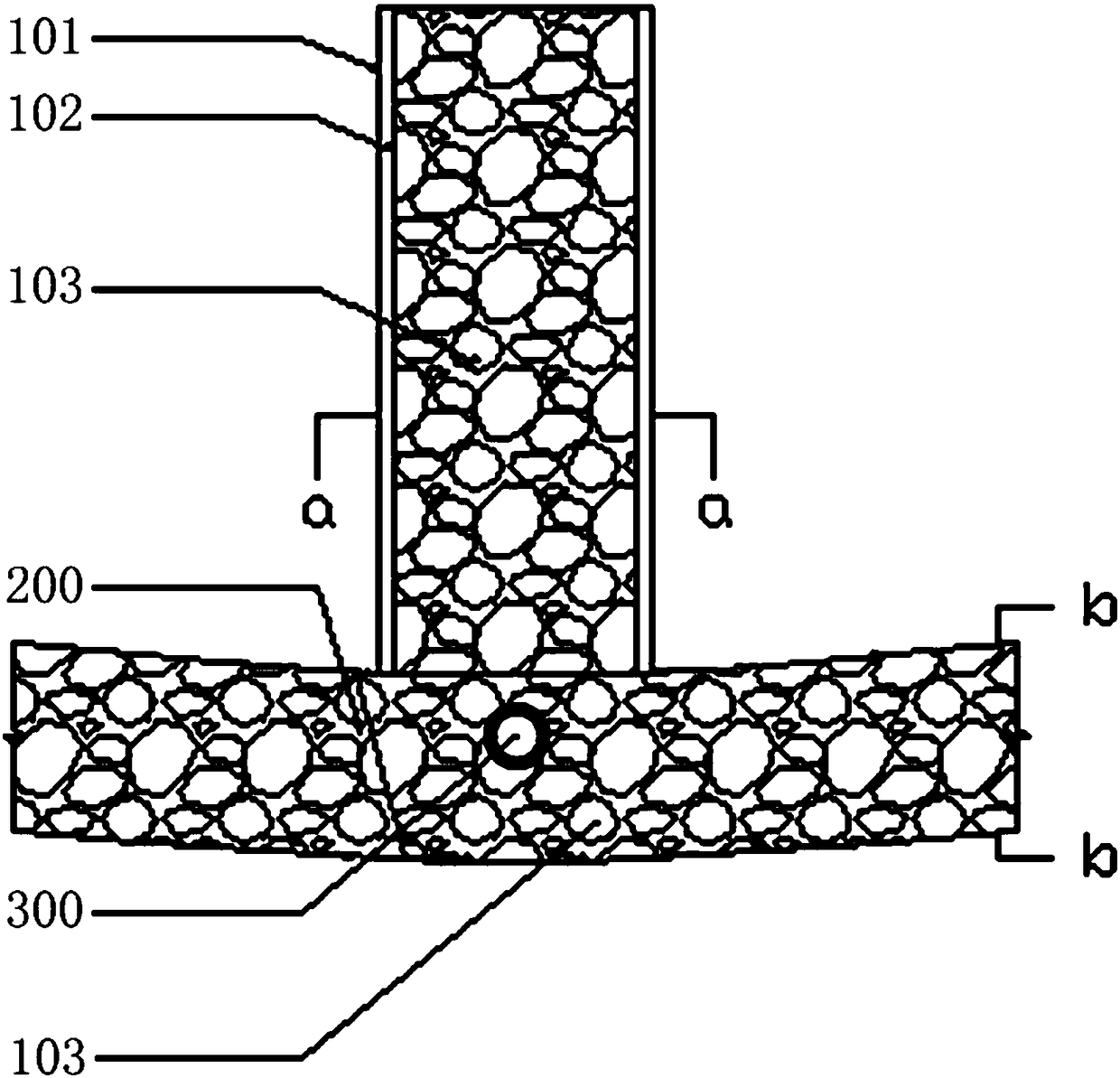

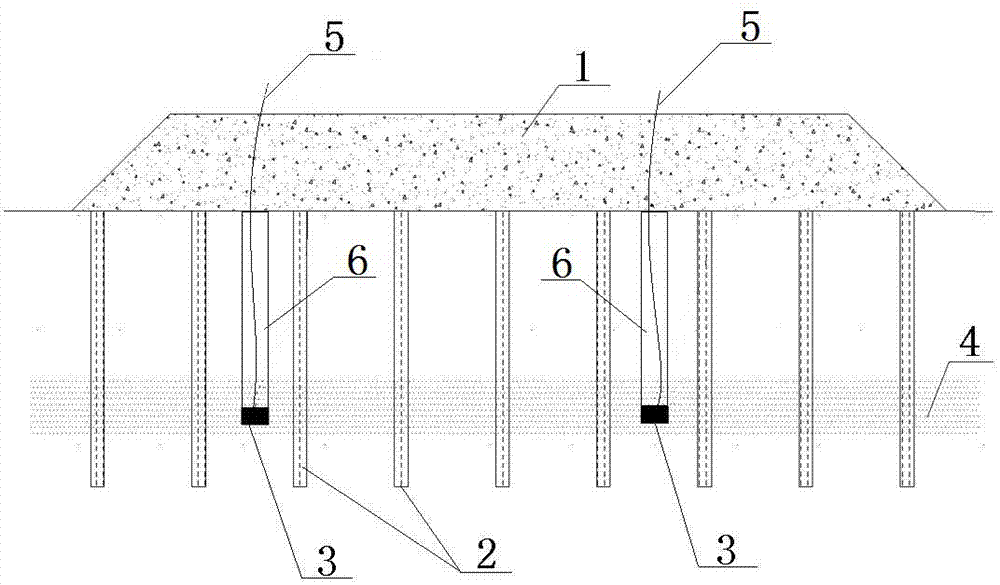

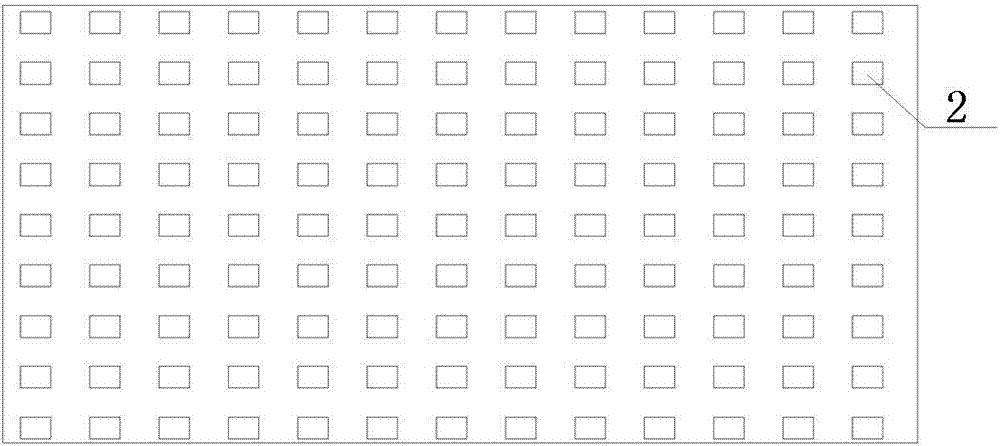

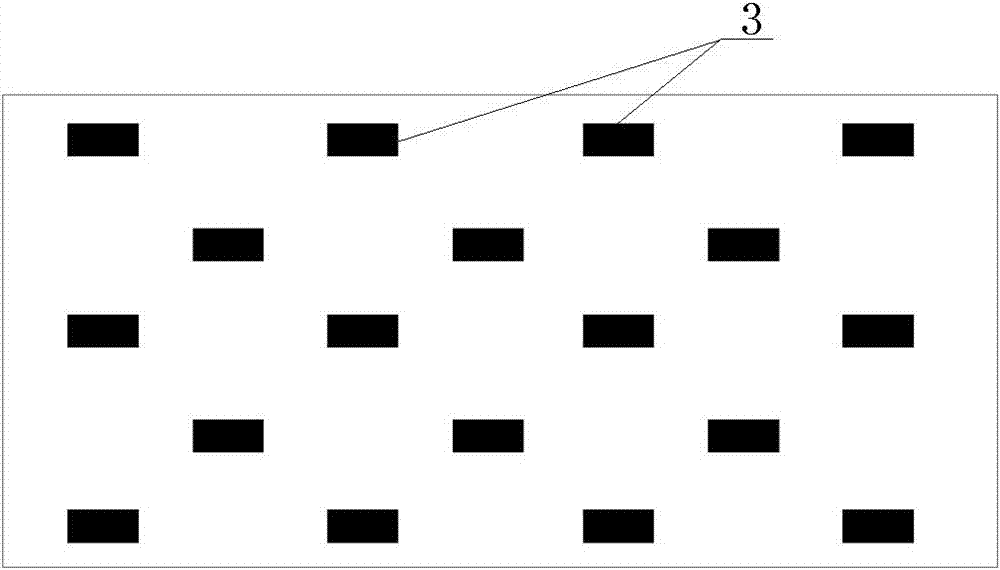

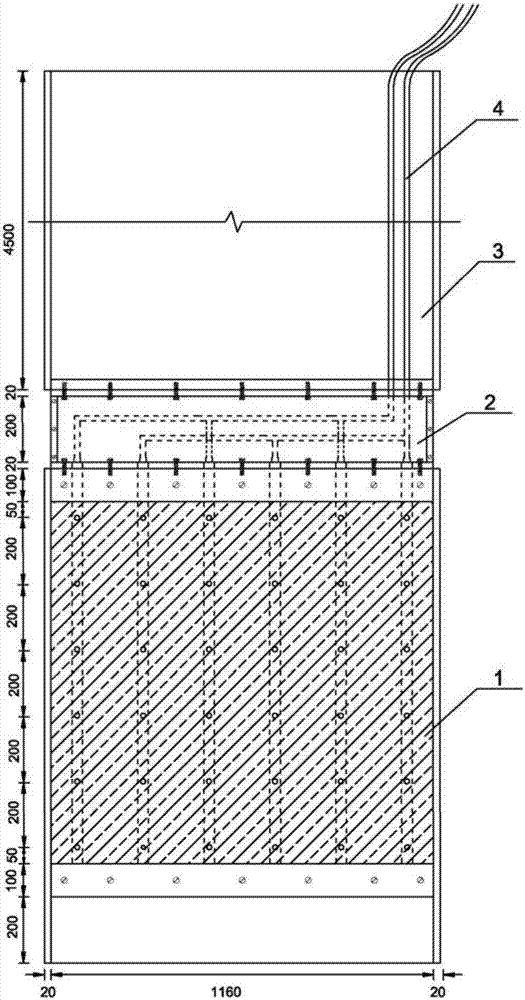

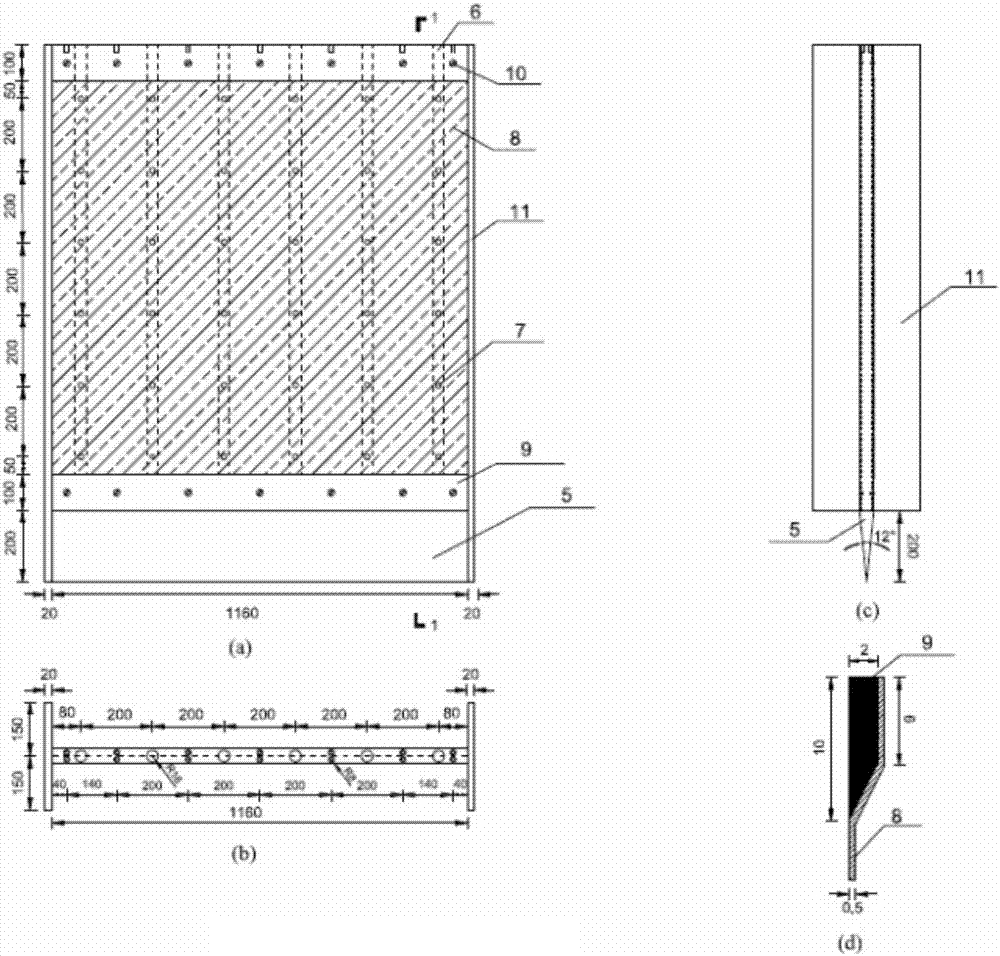

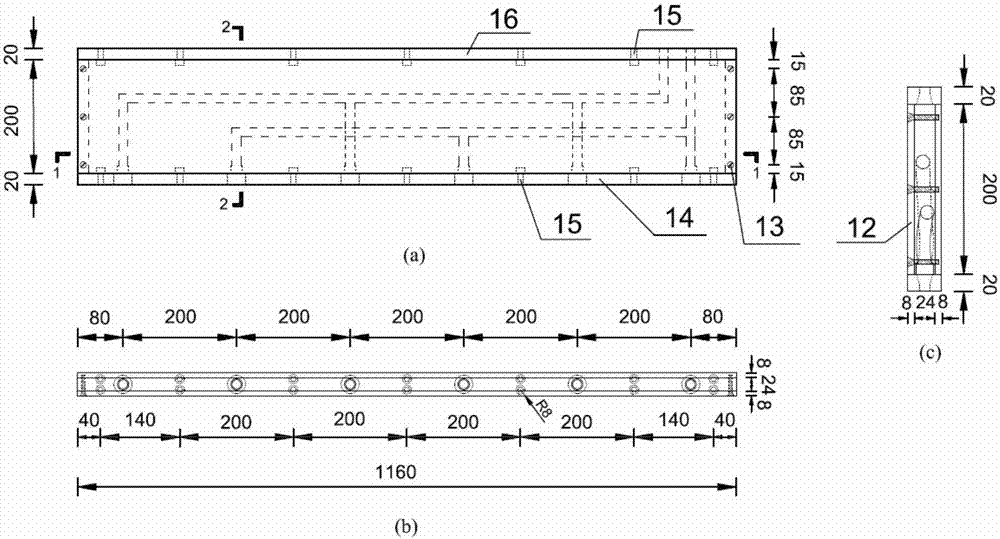

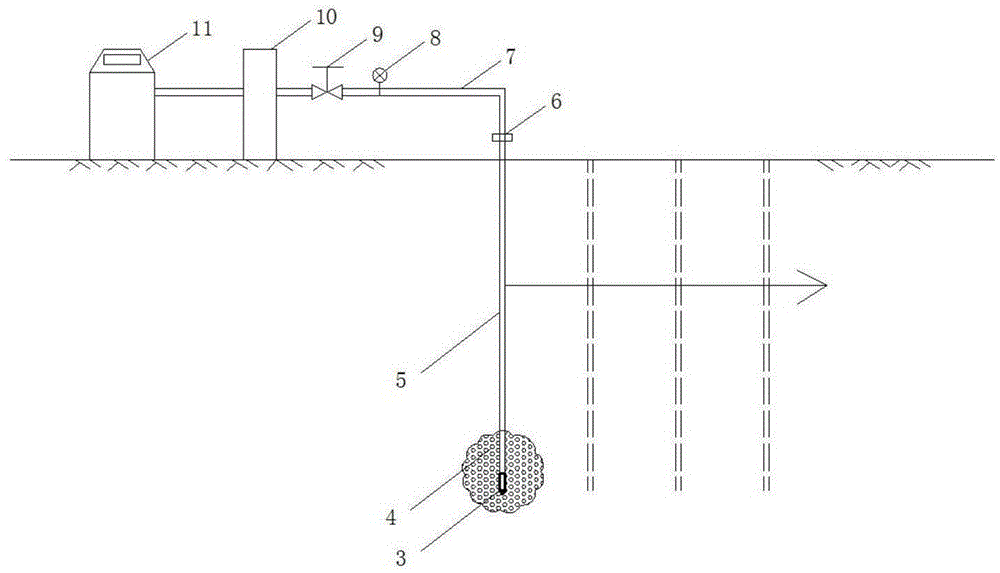

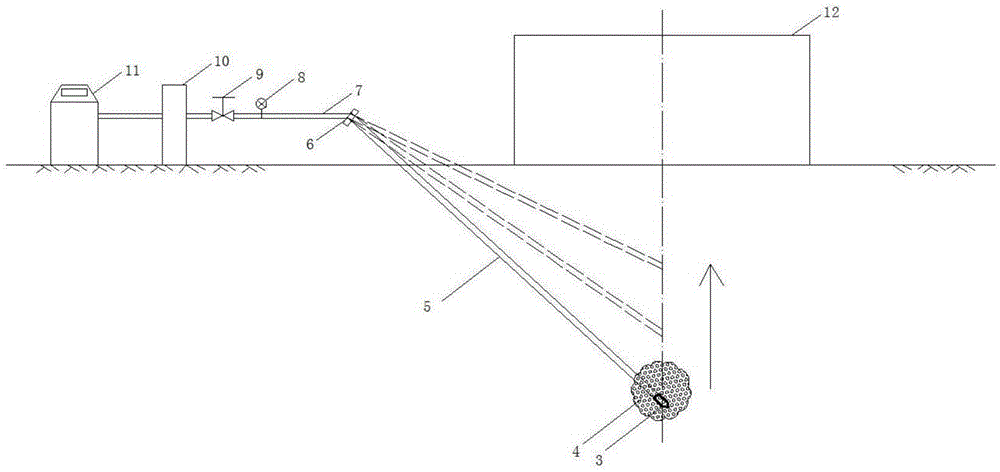

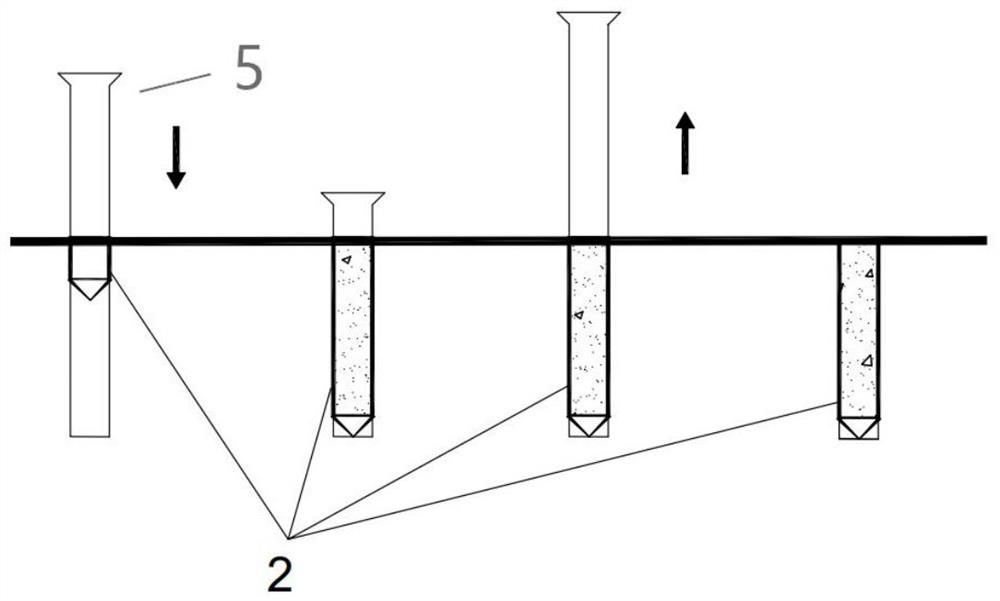

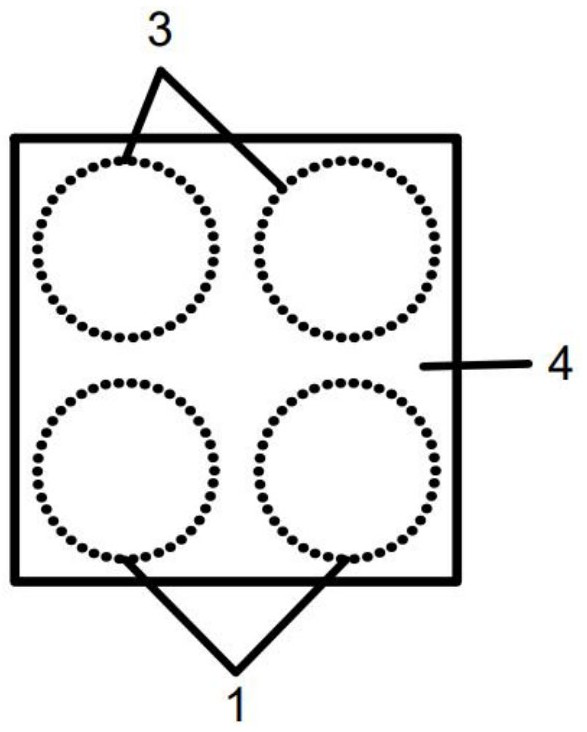

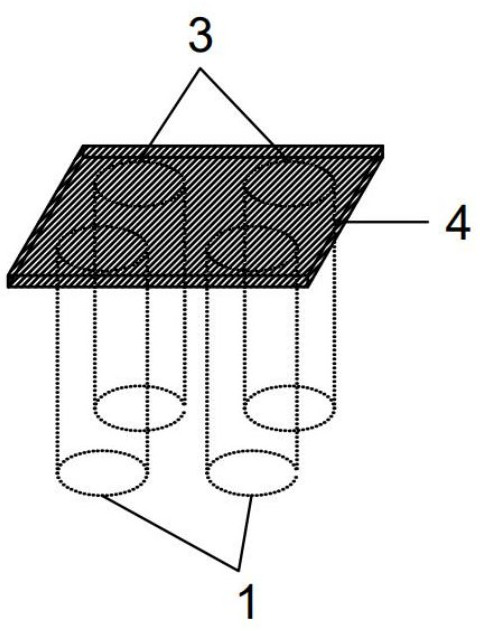

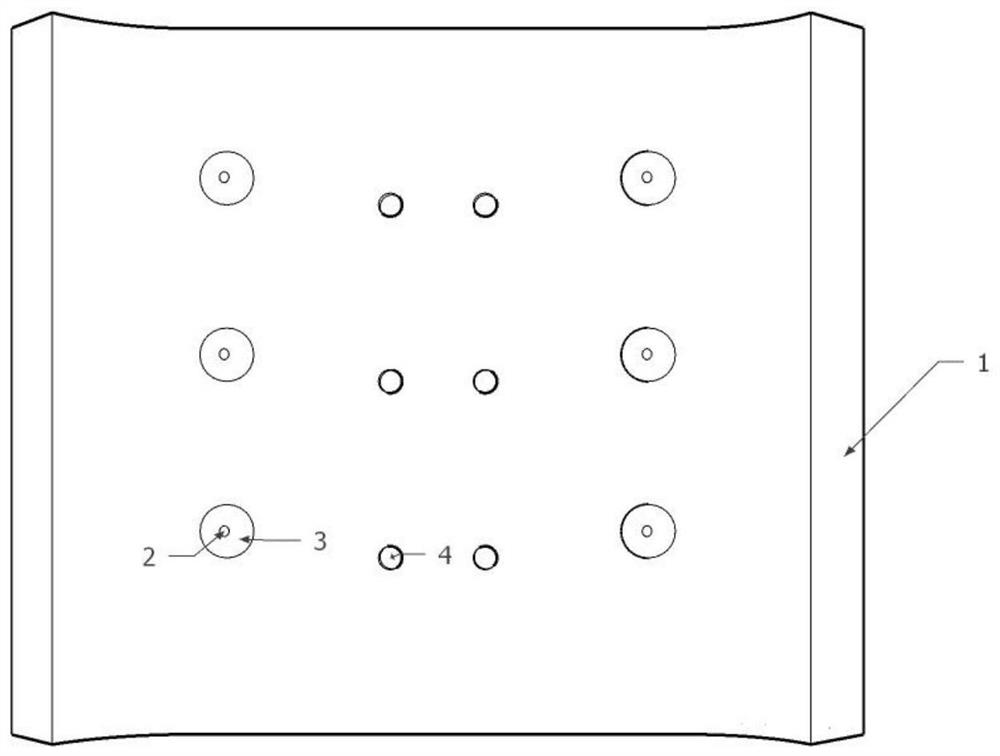

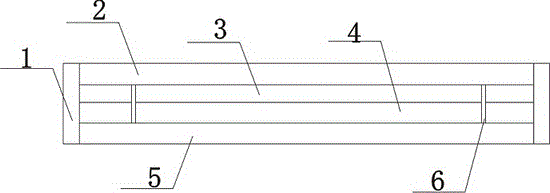

The invention relates to a microorganism slab grouting device and a microorganism slab grouting method used for reinforcing a liquefiable foundation. The device comprises a grouting panel, a pipeline switching device, an extended panel and grouting pipes. The grouting method comprises the following steps: a. vertically ramming microorganism slab grouting devices arranged in I and II forms into a to-be-reinforced stratum; b. carrying out butt joint on one ends of the first and second grouting pipes with first and second slurry passages in the microorganism slab grouting devices, connecting the other end of the first grouting pipe with a valve, a grouting pump and urease-producing microorganism bacterial liquid storage pond in sequence, and connecting the other end of the second grouting pipe with the valve, the grouting pump and a cementing solution storage pond in sequence; and c. opening the valve and the slurry injection pump to grout for the stratum, wherein the microorganism slab grouting devices are lifted uniformly during grouting, and after grouting is completed, all microorganism slab grouting devices in the field are pulled out and stand for 12h, and finally, underground water is pumped out for sewage treatment. Compared with the prior art, the microorganism slab grouting device and method can simplify the procedures, shorten the duration and eliminate the problem of size effect.

Owner:NANJING FORESTRY UNIV

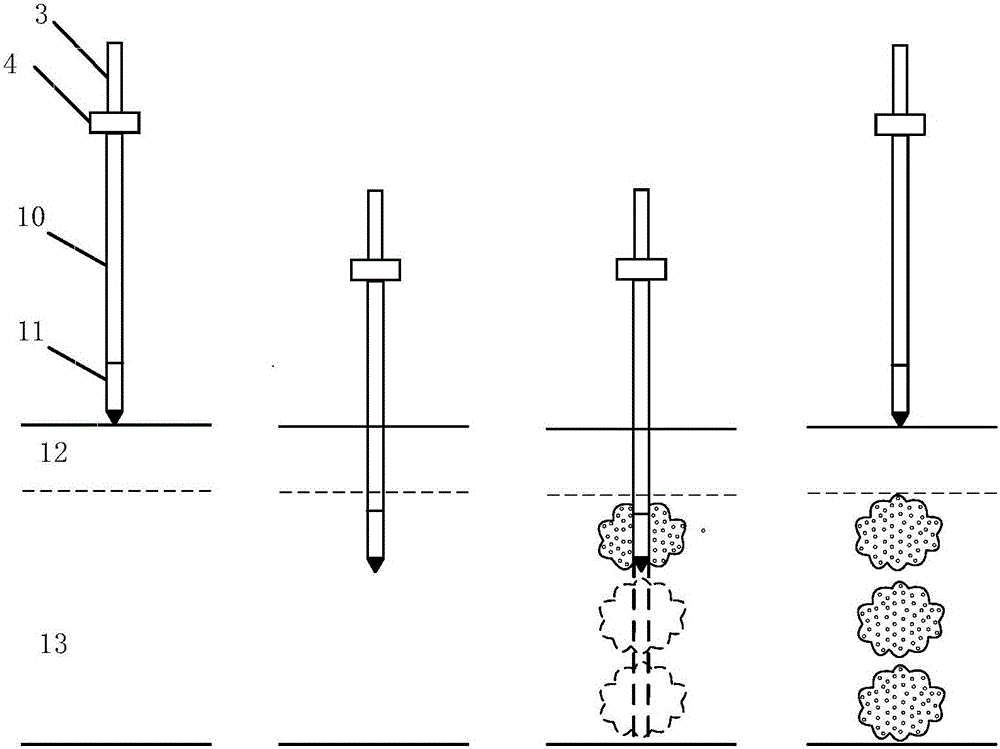

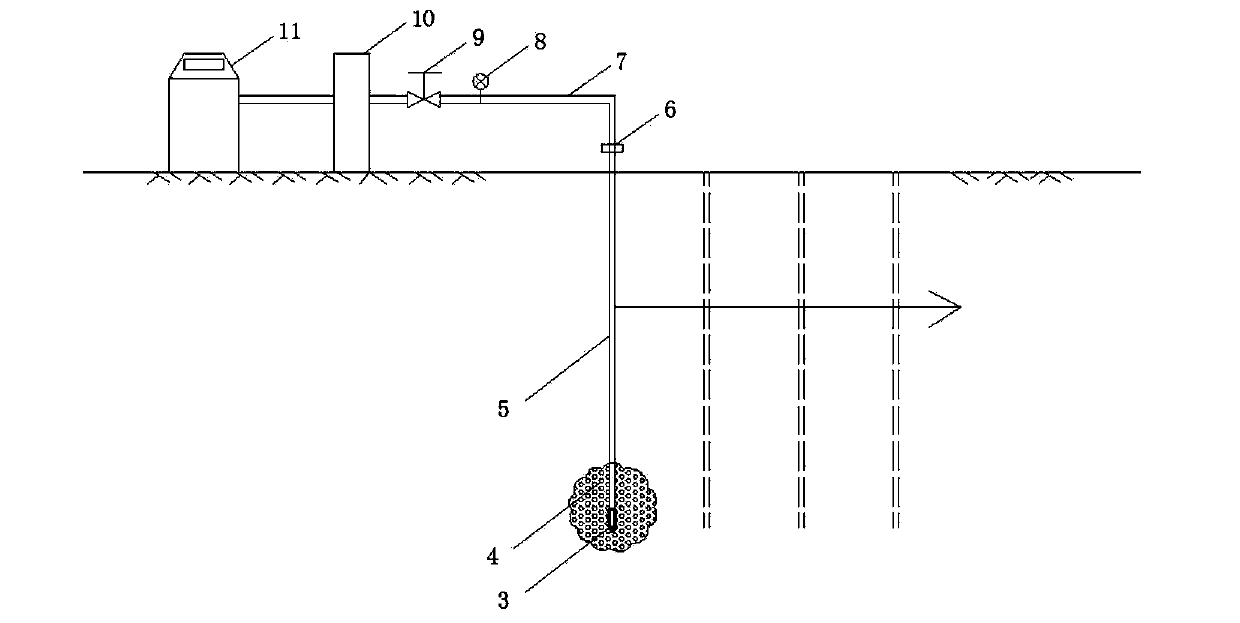

Method for treating liquefiable sandy soil foundations by aid of microbial bubble

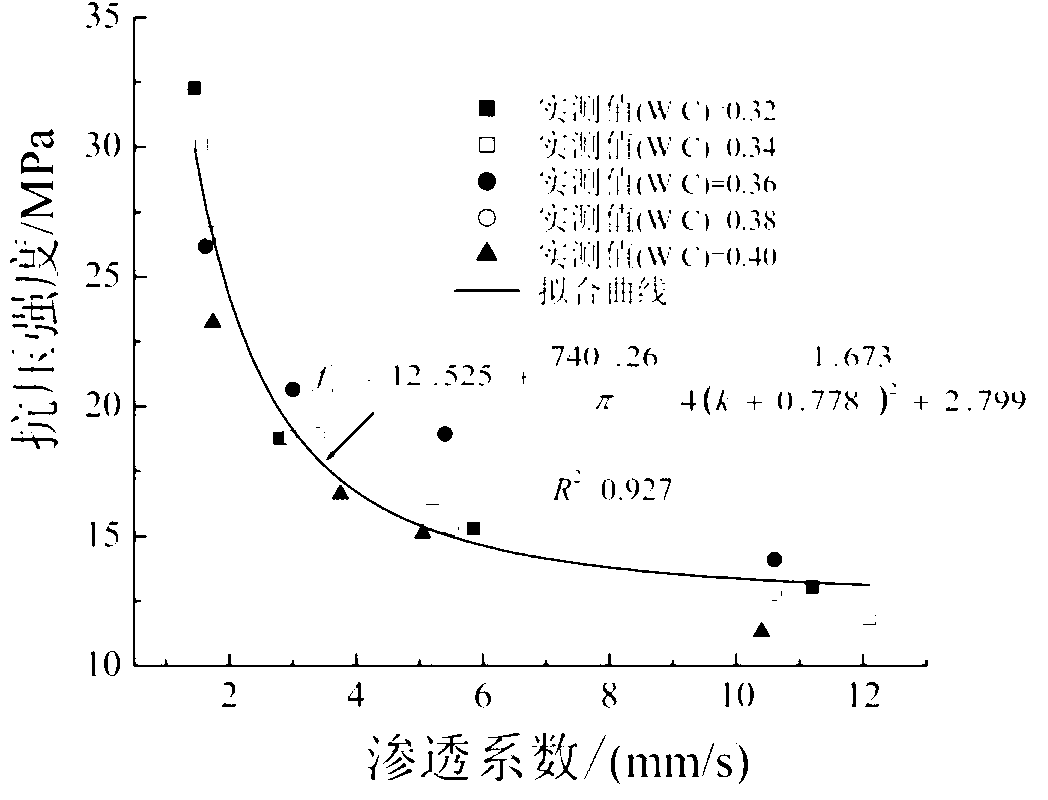

InactiveCN105862706ADesaturationImprove compression performanceSoil preservationLiquid storage tankCalcite

The invention discloses a method for treating liquefiable sandy soil foundations by using microbial bubbles, mainly targeting at liquefiable sandy soil layers, using liquid injection nozzles, hollow drill pipes, connectors, catheters, compressors, bacterial liquid storage tanks, etc. The device injects pre-enriched and cultured denitrifying bacteria liquid into the soil to replace pore water, and the bacteria perform denitrification in the pores to produce inert gases nitrogen and carbon dioxide. The nitrogen produced by biological metabolism in the pores can effectively reduce the soil saturation, increase the shear strength of the soil, and improve the soil's ability to resist liquefaction. Nitrogen dioxide produced by biological metabolism can induce the precipitation of calcium ions in the bacterial fluid to form calcite. Calcite has strong cementing properties, which can effectively improve the cohesion between soil particles, increase the shear strength, and can fill the pores of the soil, increase the compactness of the soil, and further improve its ability to resist liquefaction.

Owner:SOUTHEAST UNIV

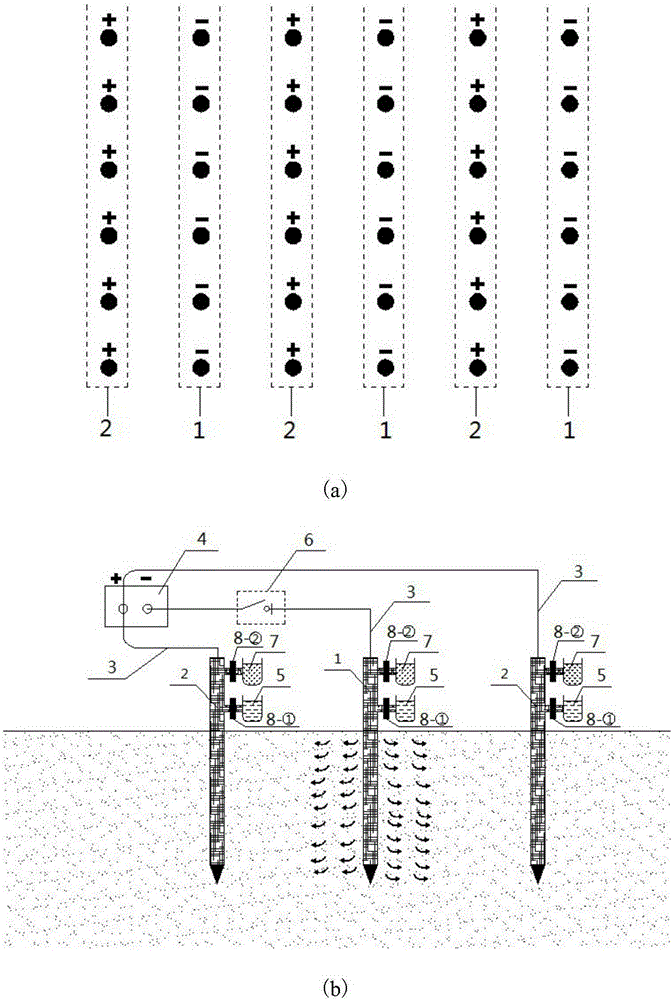

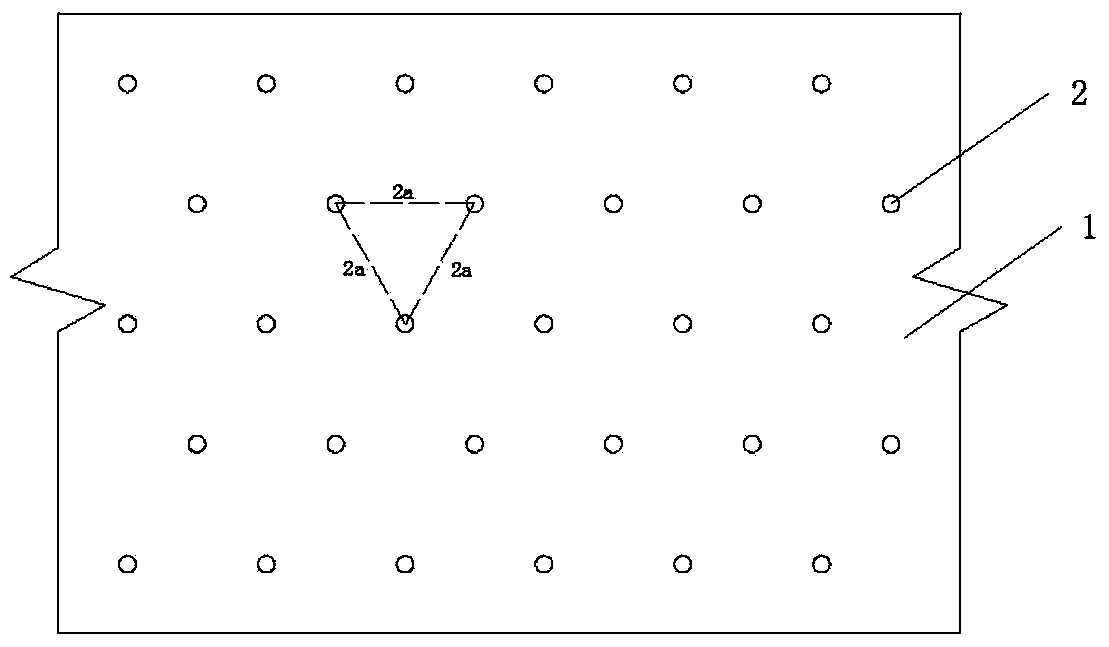

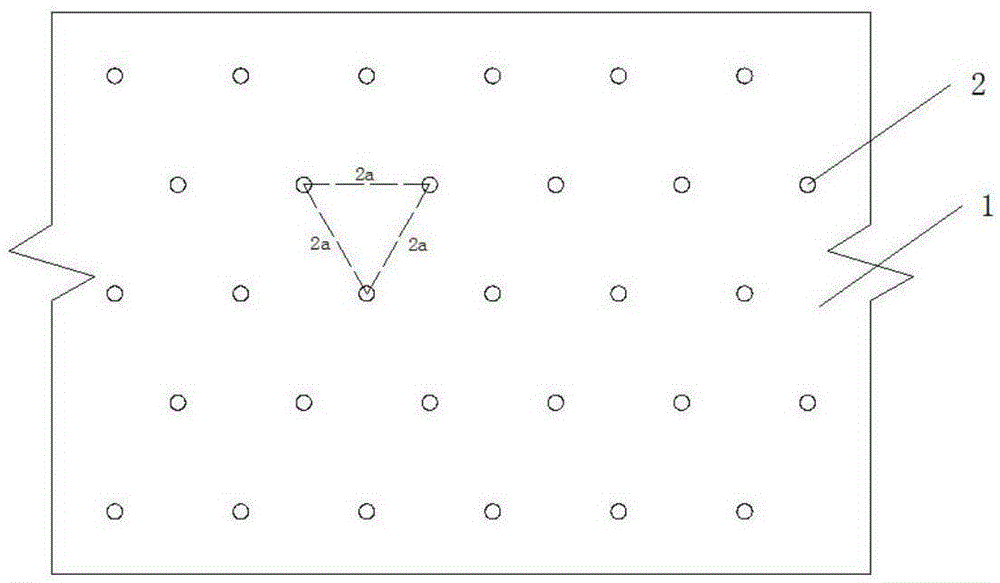

Microorganism and electric field combination reinforcing method for liquefiable foundation

InactiveCN105220681AImprove resistance to liquefactionImprove unevennessSoil preservationSewage treatmentDirect current

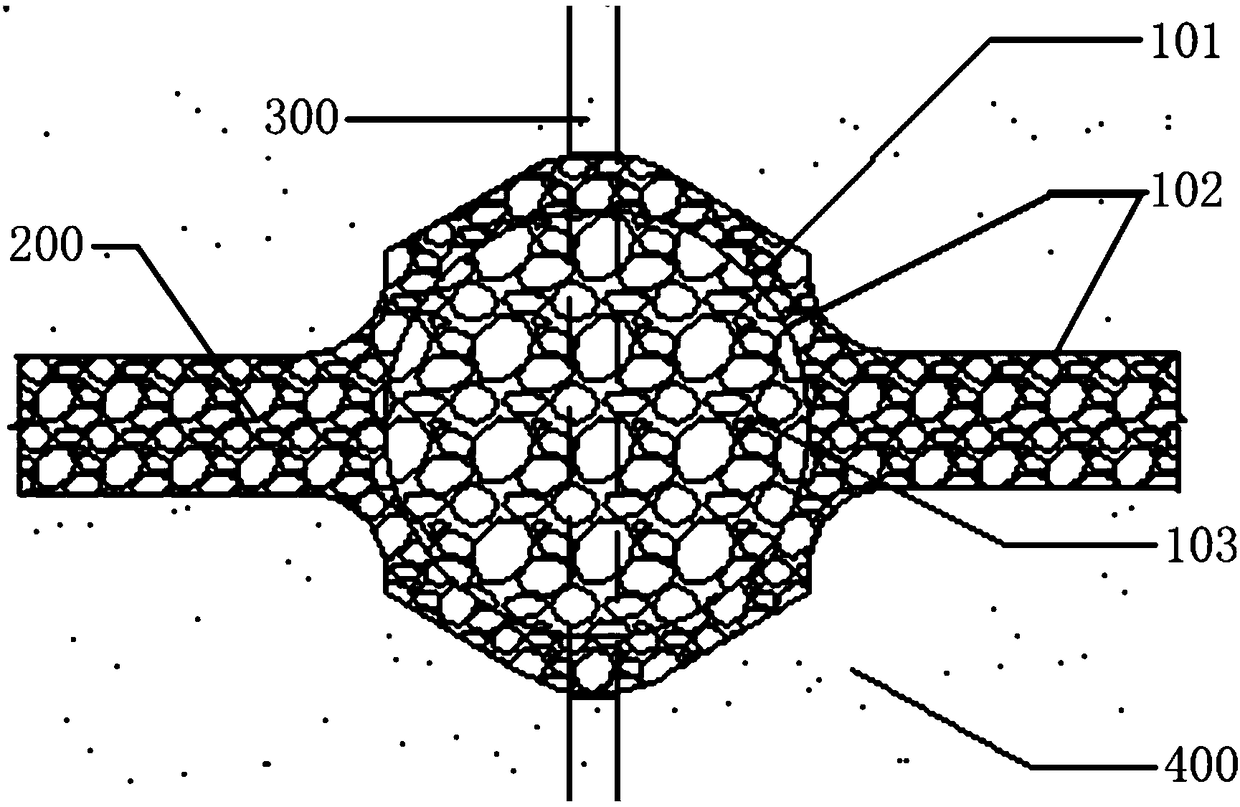

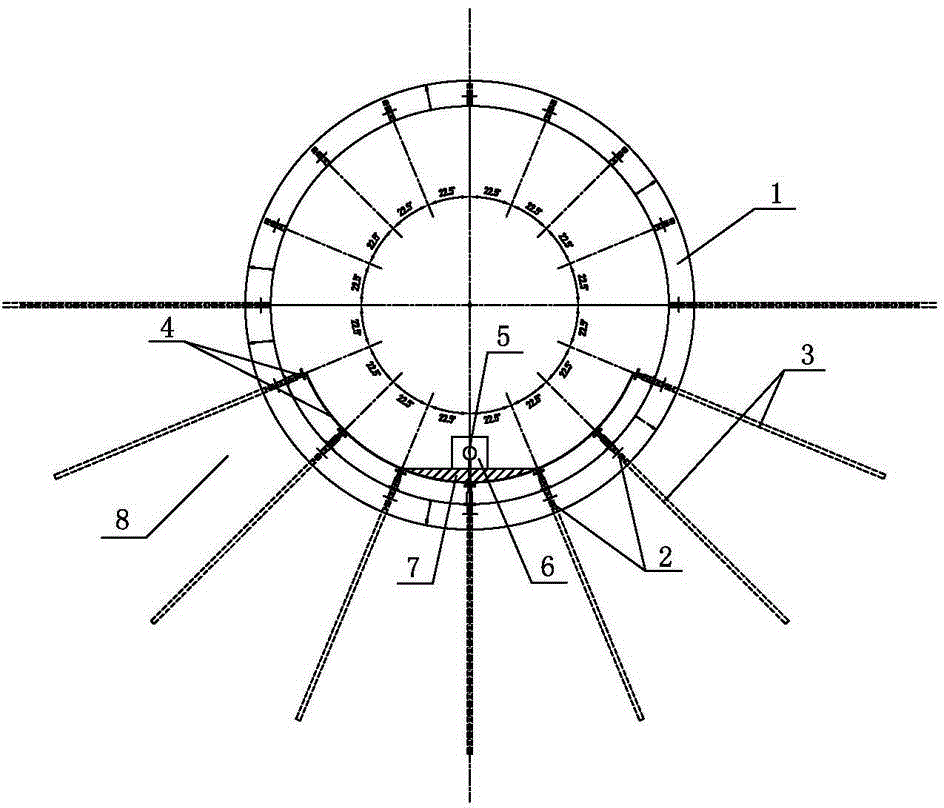

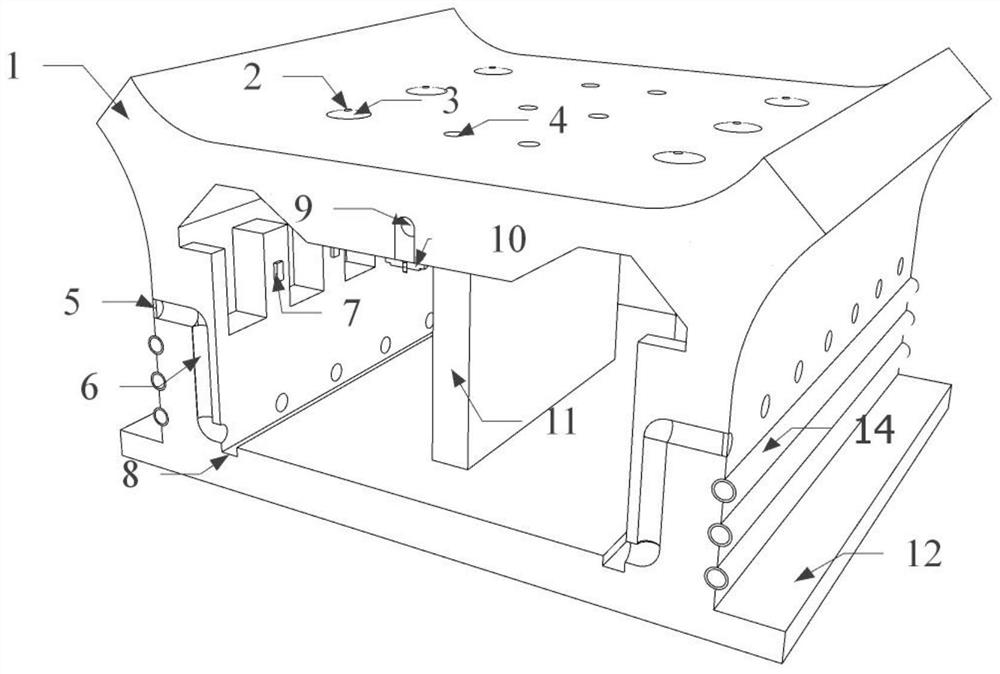

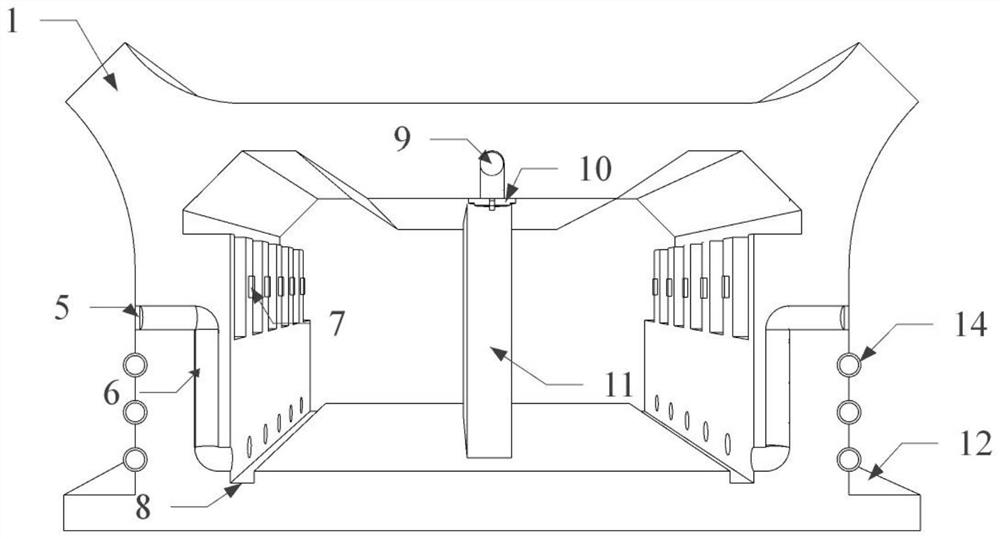

A microorganism and electric field combination reinforcing method for a liquefiable foundation comprises the following steps of a, drilling holes in the foundation to be reinforced, arranging grouting pipes a and b in rows and at intervals, and connecting the grouting pipes a with a cathode of a direct current power supply 4 into cathode grouting pipes 1 and connecting the grouting pipes b with an anode of the direct current power supply 4 into anode grouting pipes 2 through conducting wires 3; b, opening a first valve 8, and injecting a urease-producing microorganism solution 5 into the stratum through the cathode grouting pipes 1; c, when grouting begins, closing a switch 6 of the direct current power supply 4, forming a direct current electric field in a region between the cathode and anode grouting pipes, and after the action of the electric field finishes, closing the first valve 8; d, opening a second valve 8, injecting a cement solution 7 into the stratum through the cathode grouting pipes 1, closing the second valve 8, and standing for 8-12h; and e, exchanging the cathode and the anode which are connected with the grouting pipes a, repeating the steps b to d to carry out a new round of reinforcing on the foundation, pulling out all the grouting pipes after grouting is carried out on the place for required times, and pumping underground water to carry out sewage treatment.

Owner:NANJING FORESTRY UNIV

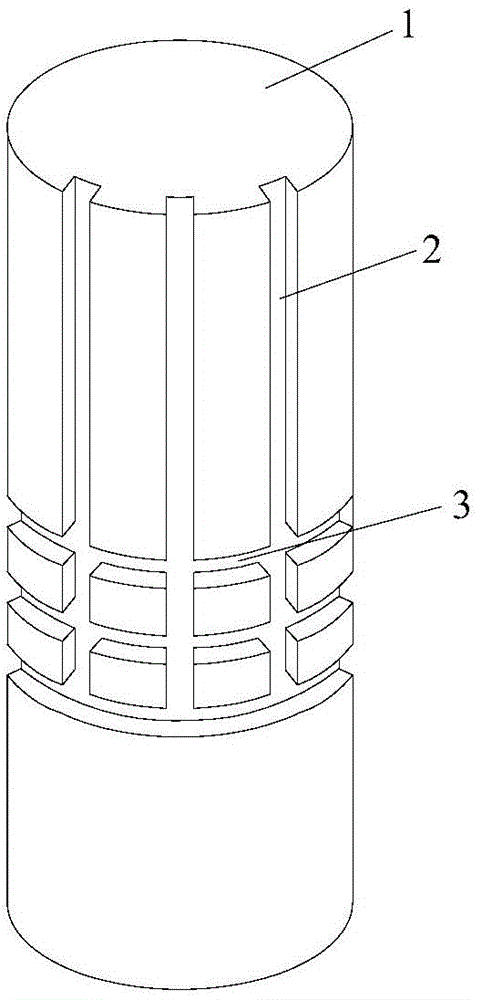

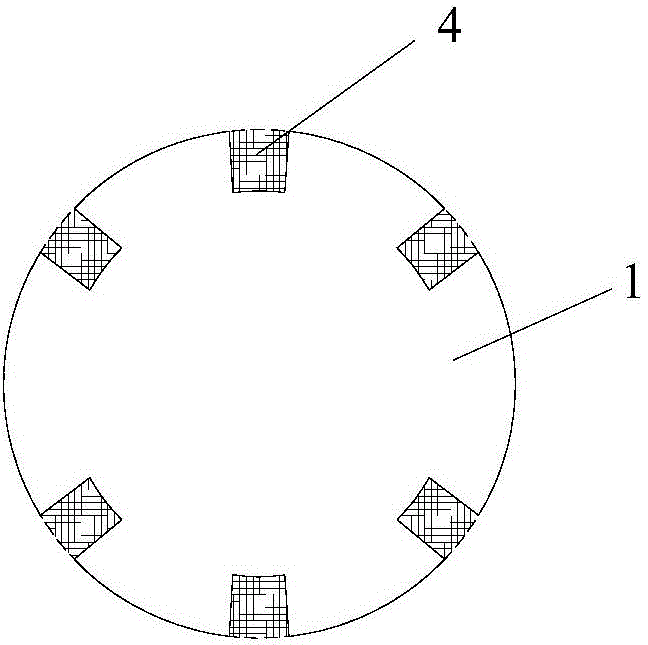

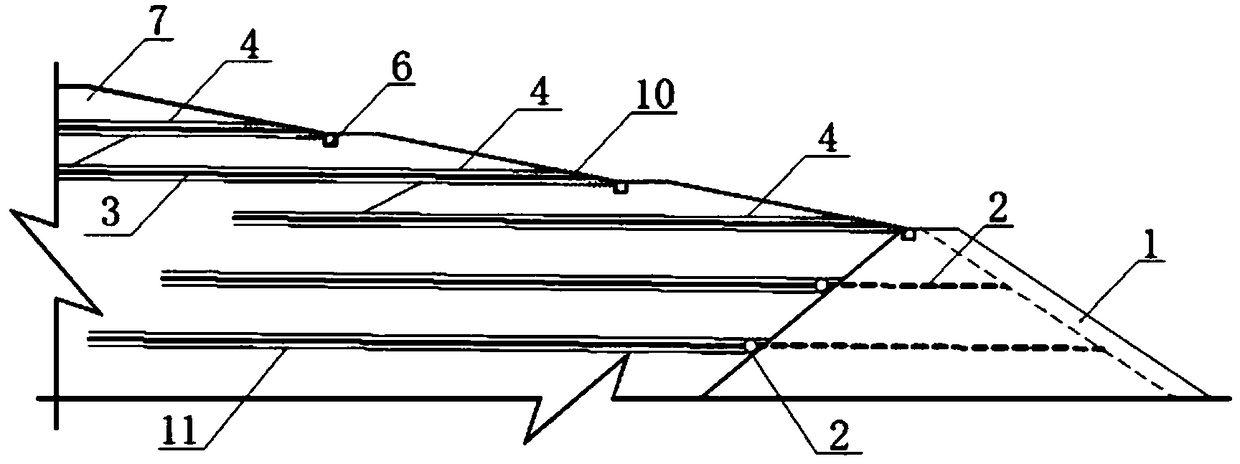

Anti-liquefaction three-dimensional drainage rigid pile and construction method thereof

InactiveCN104818711ASimple technical operationEasy to carryBulkheads/pilesSoil preservationTransverse grooveStructural engineering

The invention discloses an anti-liquefaction three-dimensional drainage rigid pile and a construction method thereof. Multiple grooves are vertically formed in the side surface of the rigid pile; vertical drainage bodies are arranged in the grooves; multiple grooves are transversely formed in the side surface of the rigid pile; transverse drainage bodies are arranged in the grooves; the depths of the vertical grooves and the vertical drainage bodies can reach the bottom of a liquefied soil layer; and the transverse grooves and the transverse drainage bodies are arranged on a pile body in a range of the liquefied soil layer. The vertical drainage bodies and the transverse drainage bodies are fixed in the grooves; and layers of steel wire meshes cover the surfaces of the drainage bodies.

Owner:CHONGQING UNIV

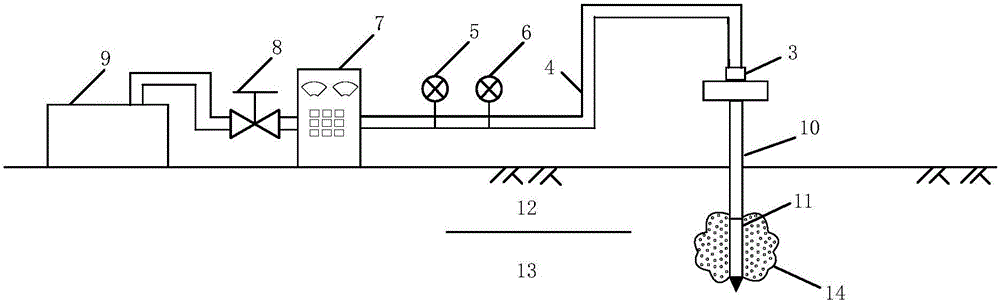

Liquefiable foundation device for micro-nano bubble processing and operation method

ActiveCN103993594AImprove resistance to liquefactionIncreased shear strengthSoil preservationMicro nanoSoil science

The invention discloses a liquefiable foundation device for micro-nano bubble processing and an operation method. In terms of a liquefiable sand layer in a foundation, a mixture of micro-nano bubbles and water is injected through a micro-nano gas-liquid mixture generator, a compressor, an air guide pipe, a hollow drilling pipe, a gas sprayer and the like, the micro-nano bubbles can stay in soil for a long time, the saturation is reduced, shearing strength of the soil is enhanced, and accordingly liquefaction resistance of the liquefiable sand layer is remarkably improved. When the liquefiable sand layer bears a vibration load, gas left in the soil can serve as a buffering agent and effectively buffer the tendency that pore water pressure rises, and accordingly the liquefaction resistance of the foundation is improved.

Owner:SOUTHEAST UNIV

Stirring pile-permeable concrete pile compound foundation and treatment method thereof

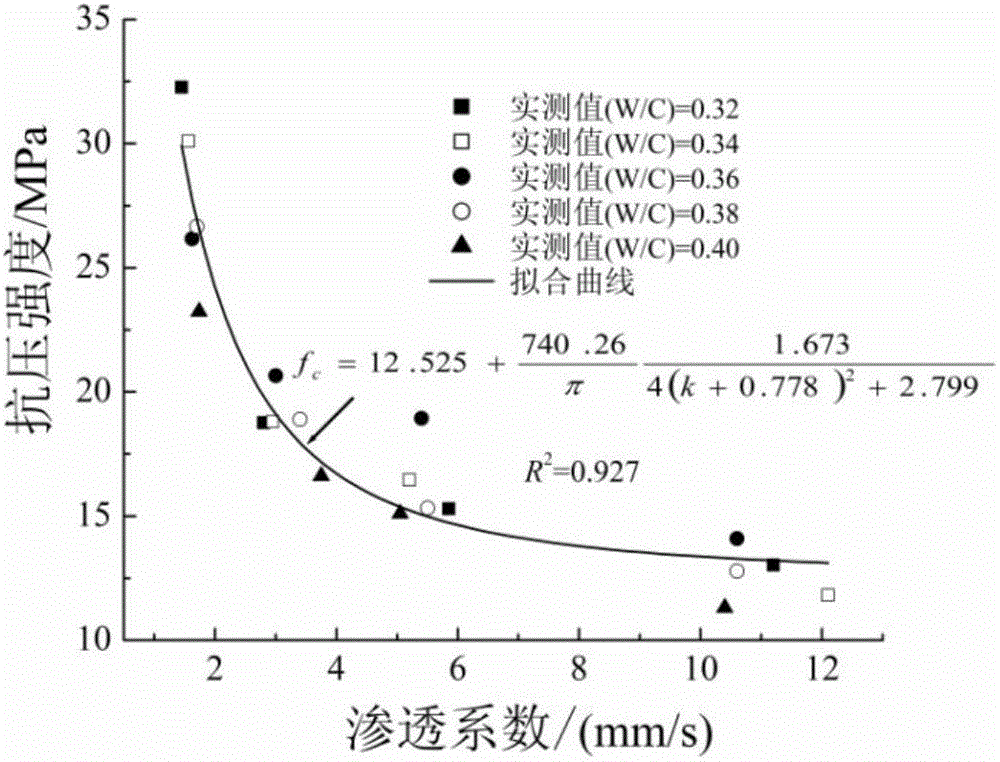

ActiveCN102839647AImprove carrying capacityGood water permeabilityBulkheads/pilesSoil preservationCrushed stoneCushion

The invention discloses a stirring pile-permeable concrete pile compound foundation, which comprises a plurality of rows of stirring piles and permeable concrete piles, wherein the stirring piles and the permeable concrete piles are arranged in a row spacing way; and a gravel cushion layer is paved on the surface of the foundation on the upper parts of the stirring piles and the permeable concrete piles. The invention discloses a method for treating the foundation simultaneously. The compound foundation has high bearing capability and high permeability, post-construction settlement can be effectively reduced, and the liquefaction resistance of the foundation can be improved. Meanwhile, under the action of drainage consolidation, the compound foundation can be used for eliminating engineering diseases caused by stirring pile construction.

Owner:SHANDONG UNIV

Seepage eliminating system for lowering tailing pond dam body seepage line by using mining barren rocks and construction method thereof

InactiveCN108265685ASpeed up seepageImprove resistance to liquefactionSoil drainageFoundation engineeringEngineeringTailings dam

The invention provides a seepage eliminating system for lowering a tailing pond dam body seepage line by using mining barren rocks and a construction method thereof. The seepage eliminating system comprises barren rock columns arranged in a dam body along a dam central axis, transverse seepage eliminating blind grooves arranged on a tailing sand deposition surface in the dam body along the dam central axis, and longitudinal seepage eliminating pipes arranged in the dam body perpendicular to the dam central axis. The barren rocks without economical value are used for producing the barrel rock columns to cooperate with the transverse seepage eliminating blind grooves and the longitudinal seepage eliminating pipes to form the seepage eliminating system capable of realizing self-flowing. The mining barren rocks are excellent in seepage performance, so that the seepage speed of seepage water in a tailing dam can be accelerated, the liquefication resistance of the tailing dam is improved, and the liquefication area of the dam body is reduced; the seepage eliminating system is low in cost, convenient to construct and popularize and higher in commercial value; and meanwhile, through limitations of specification parameters and arrangement modes of the barren rock columns, the drainage solidification of tailing sand can be accelerated, and the stability of a tailing pond can be improved.

Owner:NANHUA UNIV

Method of eliminating liquefaction in shield tunnel stratum in tunnel

ActiveCN103953367ASolving Liquefaction Elimination ProblemsImprove resistance to liquefactionUnderground chambersTunnel liningWater tableEngineering

The invention relates to a method of eliminating liquefaction in a shield tunnel stratum in a tunnel and aims to provide the method of eliminating liquefaction in the shield tunnel stratum in the tunnel to solve the problem of stratum liquefaction under the condition of densely covered building structures. The technical scheme of the invention is that a group of annular linings formed by assembling concrete segments are sequentially spliced into permanent linings of a tunnel along the tunnel direction, and a group of pumping holes are evenly arranged on horizontal center lines on two sides of each annular lining and the part below along the radial direction; a water pipe is arranged on each pumping hole by using the casing process, one end of each water pipe penetrates through the annular linings to extend into the liquefied stratum, multiple drainage holes are formed in the surface of each water pipe, and a filtering membrane wraps each water pipe; a rubber branched pipe is communicated with the other end of each water pipe to be connected with a vacuum pump to realize a header pipe for pumping; the vacuum pump is started, thus vacuum is formed within the liquefied stratum surrounding the annular linings, and a given vacuum 80 kPa is maintained until the underground water level within the double tunnel diameter depth range up and down left and right outside the tunnel is decreased by 7-10m; the pipe grouting is maintained to fill the drainage holes.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

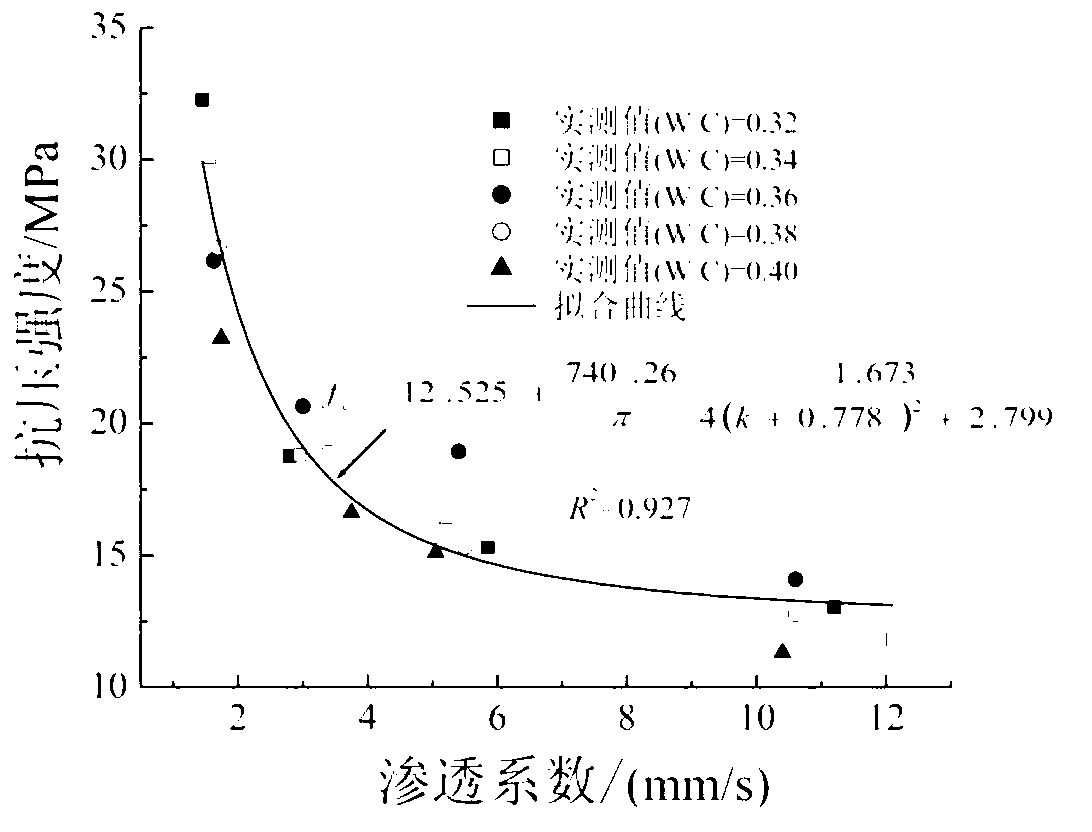

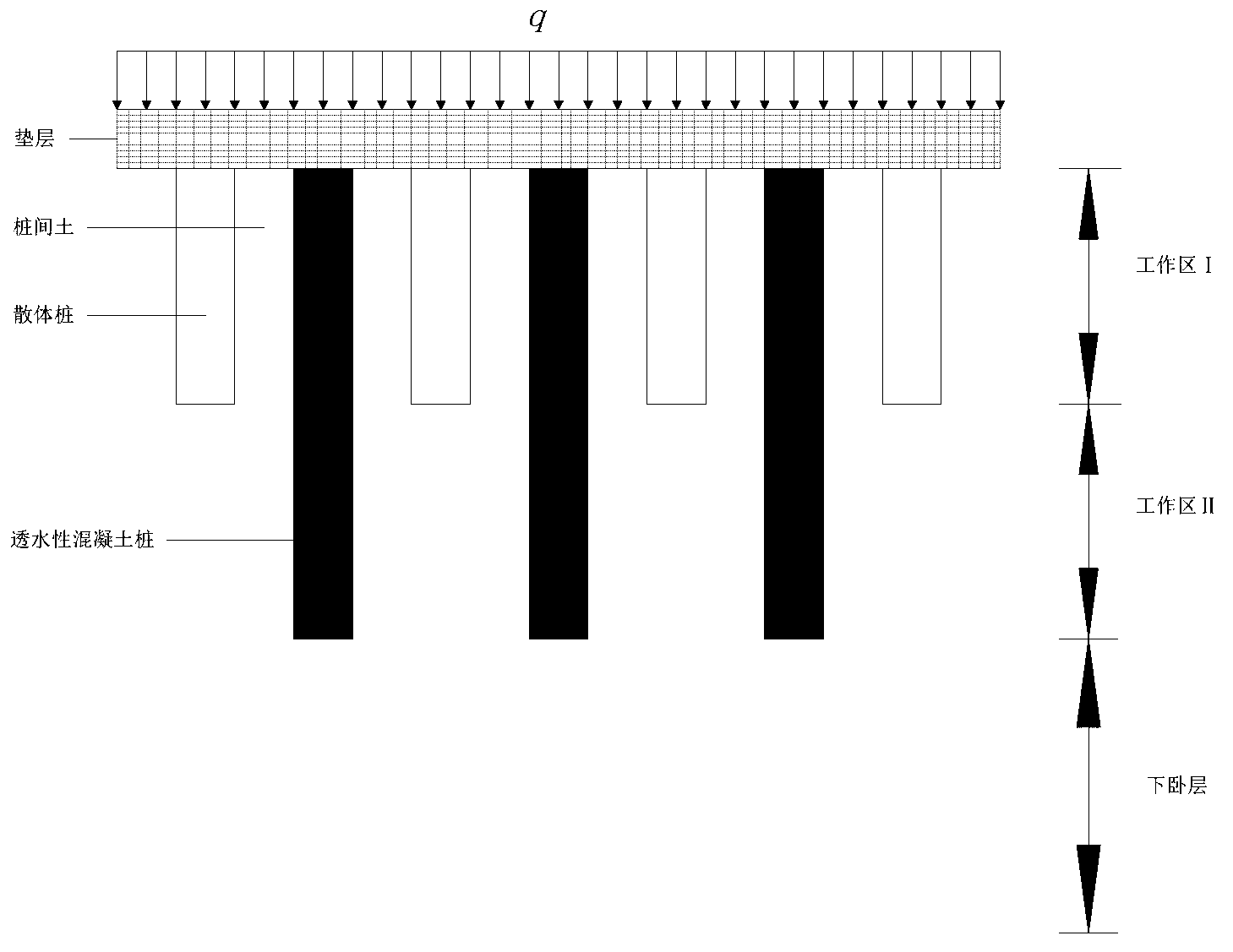

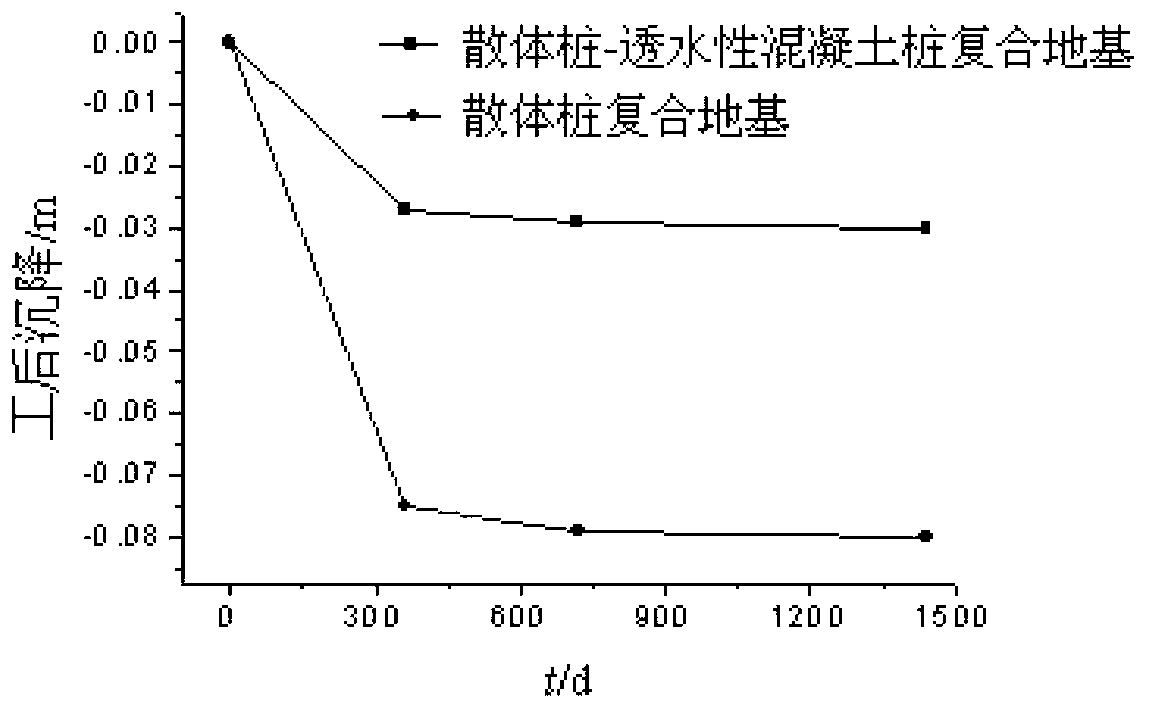

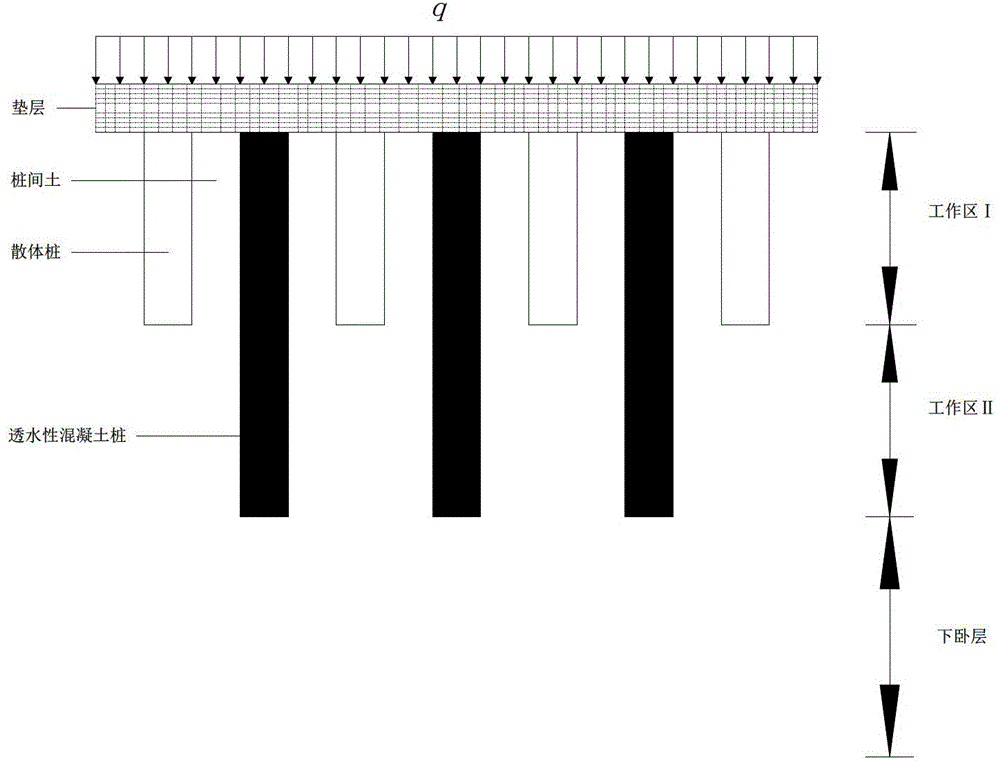

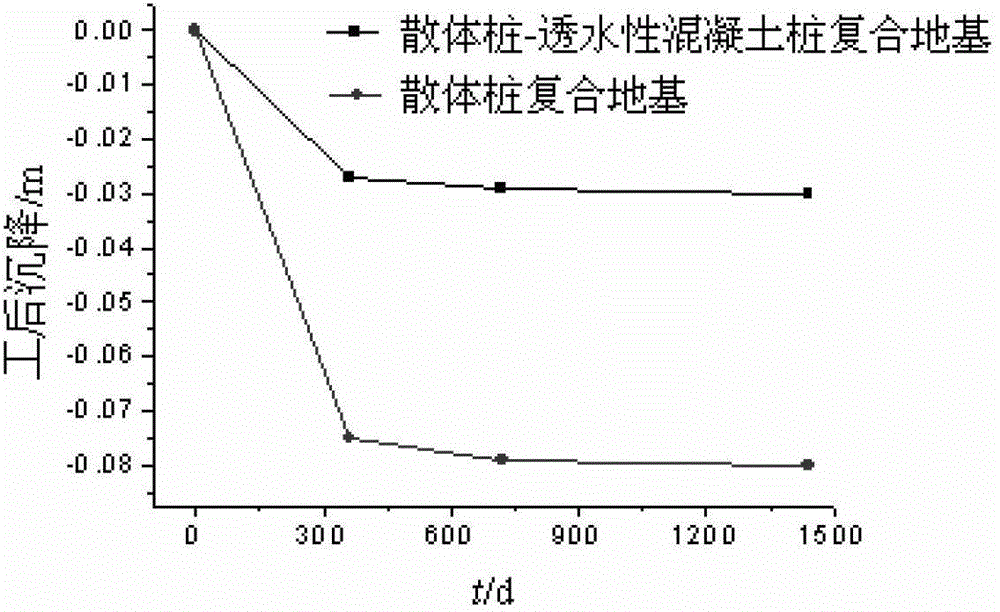

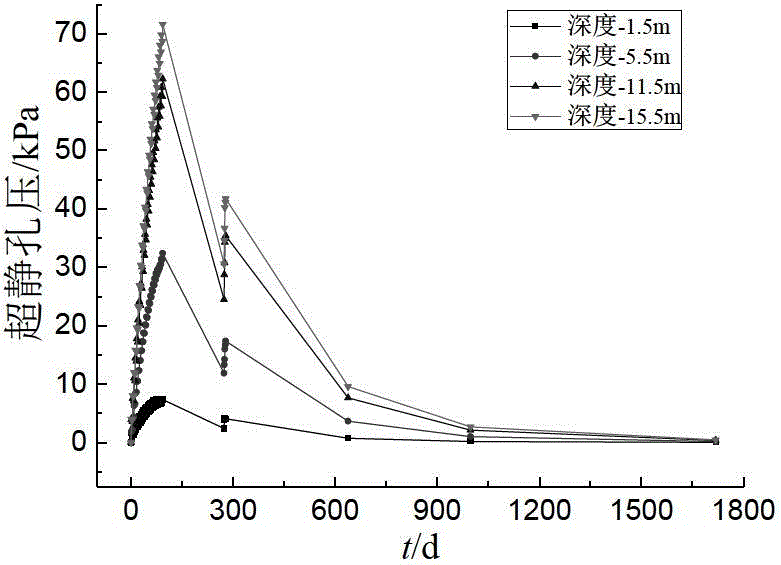

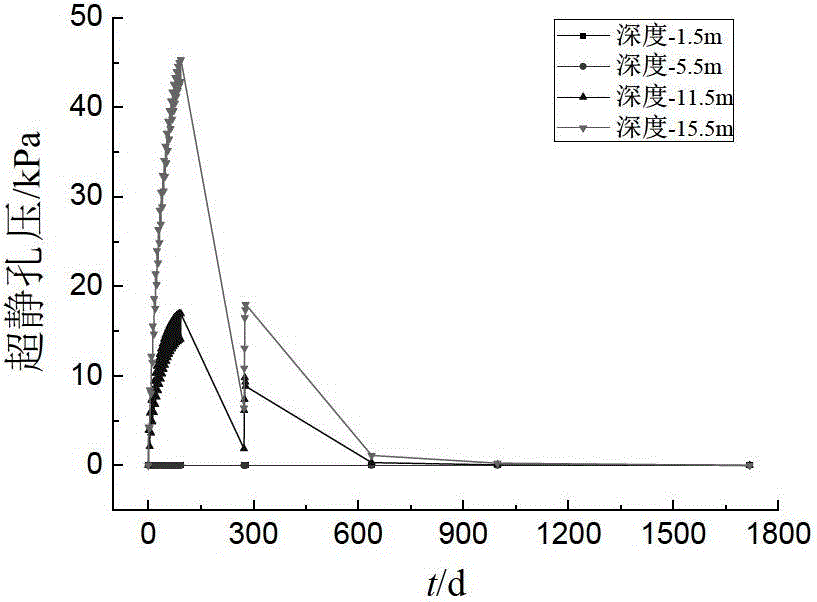

Discrete pile-water permeability concrete pile novel binary composite foundation and treatment method of composite foundation

ActiveCN102839683AGood water permeabilityStrong rigidityBulkheads/pilesSoil preservationLiquefaction resistancePore water pressure

The invention discloses a discrete pile-water permeability concrete pile novel binary composite foundation, which comprises concrete piles and water permeability concrete piles, wherein the concrete piles and the water permeability concrete piles are alternately arranged in rows, and the foundation surfaces of the upper parts of the concrete piles and the water permeability concrete piles are provided with broken stone hardcores. The invention also discloses a treatment method of the composite foundation. The composite foundation belongs to a binary foundation treatment mode integrating high bearing performance and high water discharge performance, the post-construction settlement of the foundation can be reduced, and in addition, the liquefaction resistance capability of the foundation can be effectively improved. In addition, during the concrete pile construction, hyperstatic pore water pressure can be generated in the foundation, the ground surface doming (cohesive soil layers) and the pile settlement (sandy soil layers) can be caused, and the occurrence of engineering harm can be prevented through reducing hyperstatic pore water pressure during the concrete pile construction via the arrangement of the water permeability concrete piles.

Owner:SHANDONG UNIV

Coal ash soil composite material for highway subgrade and preparation method thereof

The invention relates to a fly ash and soil composite material used in highway roadbed and is characterized in that the material consists of fly ash, soil and polypropylene fiber; the technique is simple and reliable to ensure that the fly ash and soil composite material has good frost resistance property; the unconfined compressive strength of the fly ash and soil which is doped with the polypropylene fiber is 1.26 to 1.74 times higher than the unconfined compressive strength of pure fly ash and soil. According to the characteristics of roadbed freezing injury mechanism and structural style in seasonal frozen areas, the fly ash and soil composite material of the invention adopts novel materials which have the advantages of good resistance to freezing and thawing, high strength, low cost and environmental protection as the roadbed filler, which not only has theoretical guidance meaning, but also has direct practical meaning for solving engineering problems.

Owner:JILIN UNIV

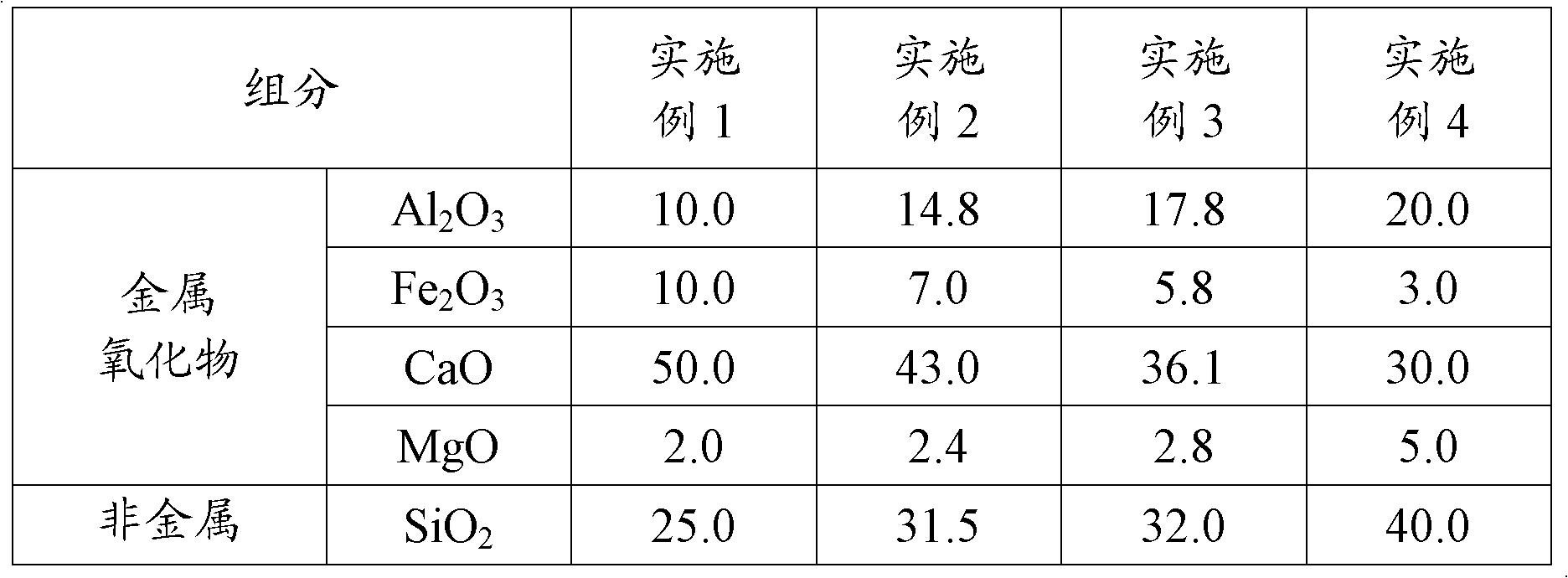

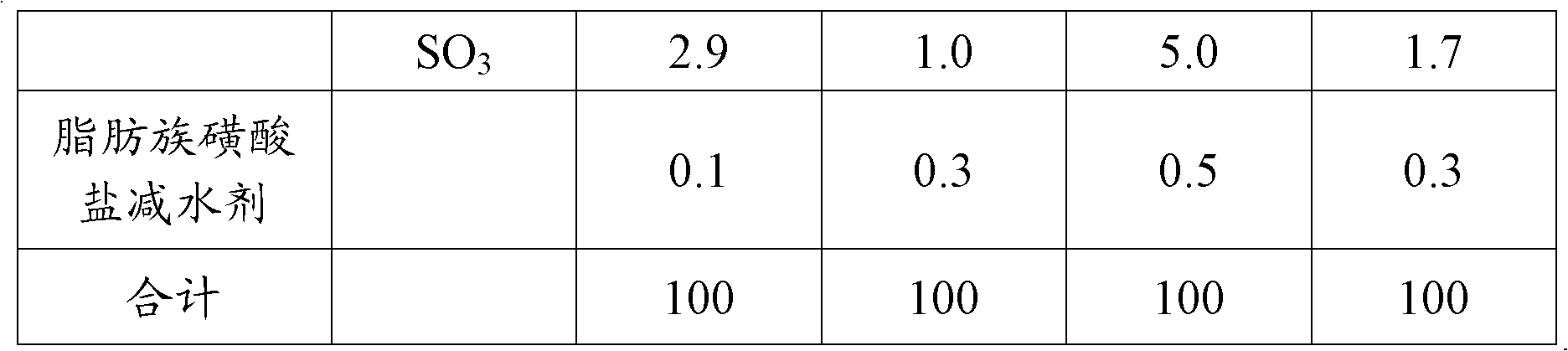

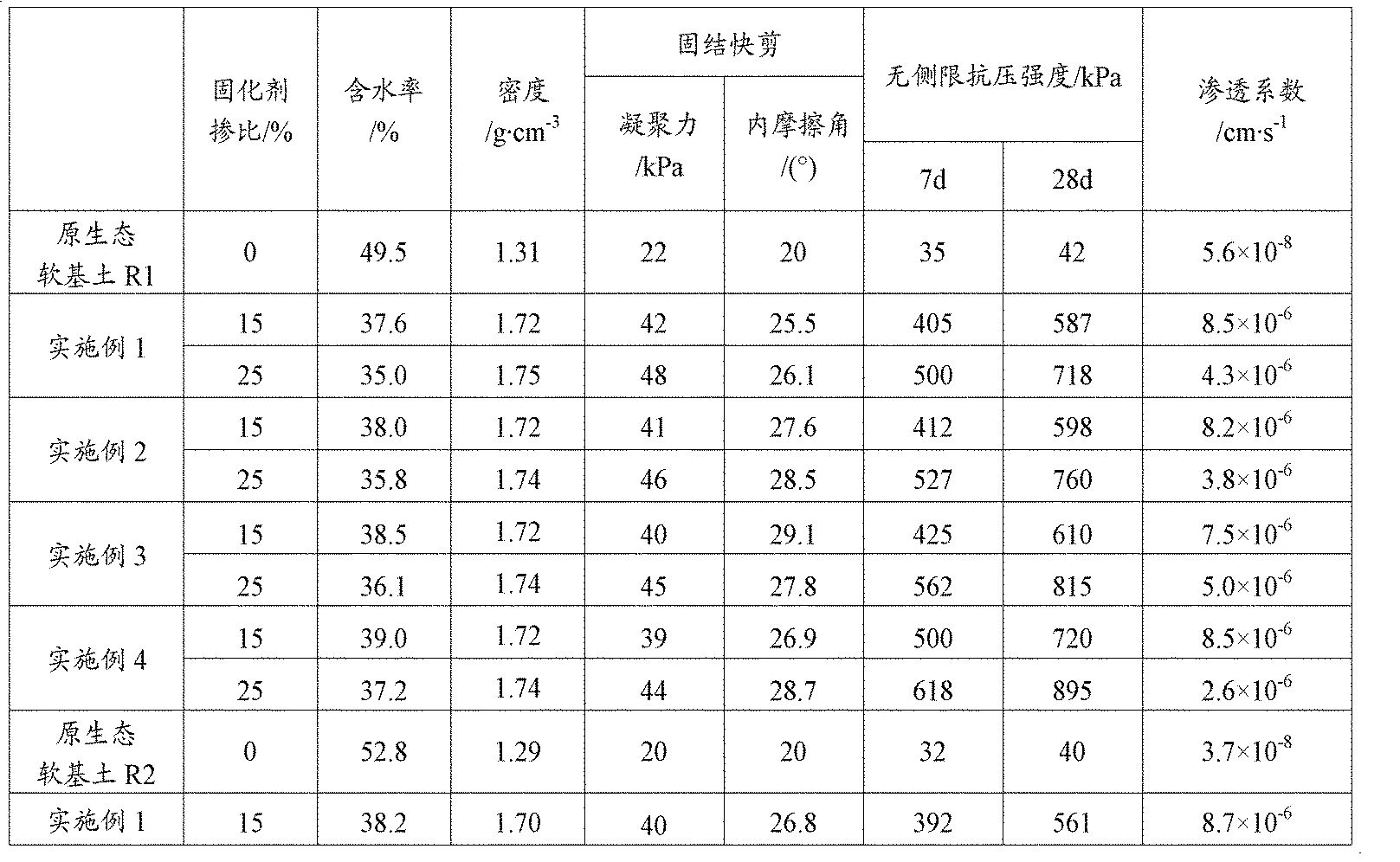

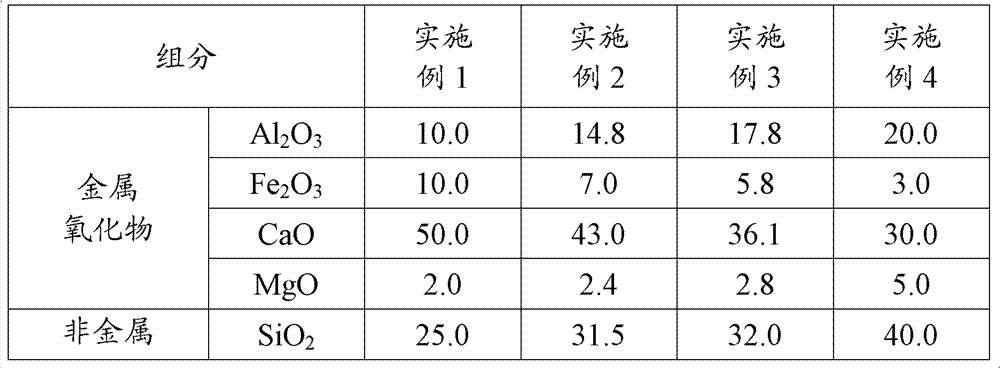

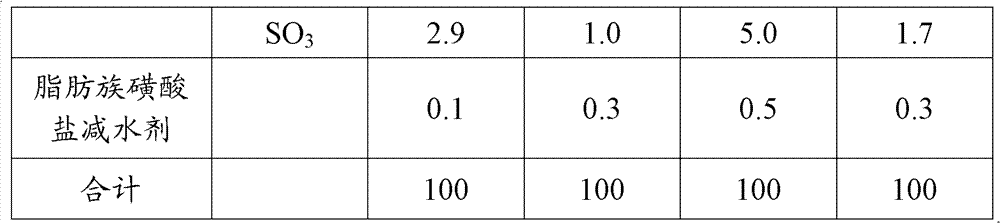

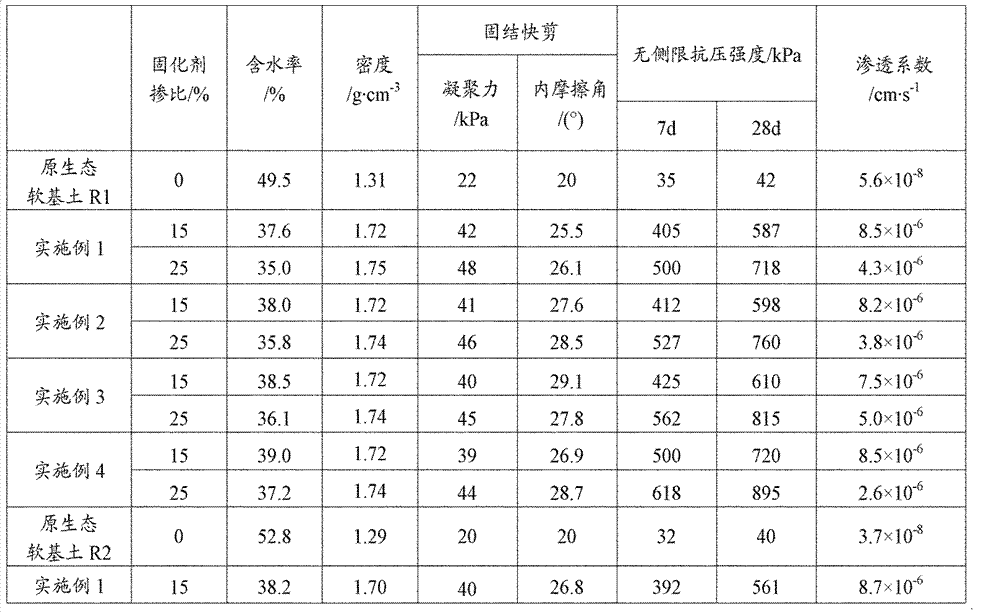

Curing agent for treating deep soft foundation soil layer and preparation method thereof

InactiveCN102134494AImproved unconfined compressive strengthGood deformabilityBuilding constructionsOrganic fertilisersSulfonateFirming agent

The invention relates to a curing agent for treating a deep soft foundation soil layer and a preparation method thereof. The curing agent consists of metal oxides with activity of Al2O3, Fe2O3, CaO and MgO, nonmetal oxides with activity of SiO2 and SO3, and an acyclic sulfonate water-reducer. The preparation method for the curing agent comprises the following steps of: drying the metal oxides andthe nonmetal oxides in a dryer, and heating at the temperature of between 750 and 850DEG C for 3 to 4 hours; grinding into granules that the residue of a 80 mu m square sifter is not more than 4.0 percent by using a ball mill; and adding the acyclic sulfonate water-reducer and uniformly stirring to obtain the curing agent for treating the deep soft foundation soil layer. The curing agent can makethe unconfined compressive strength, deformation, permeability, liquefaction resistance and other properties of the treated soft foundation soil body obviously improved.

Owner:HUBEI COMM PLANNING & DESIGN INST CO LTD

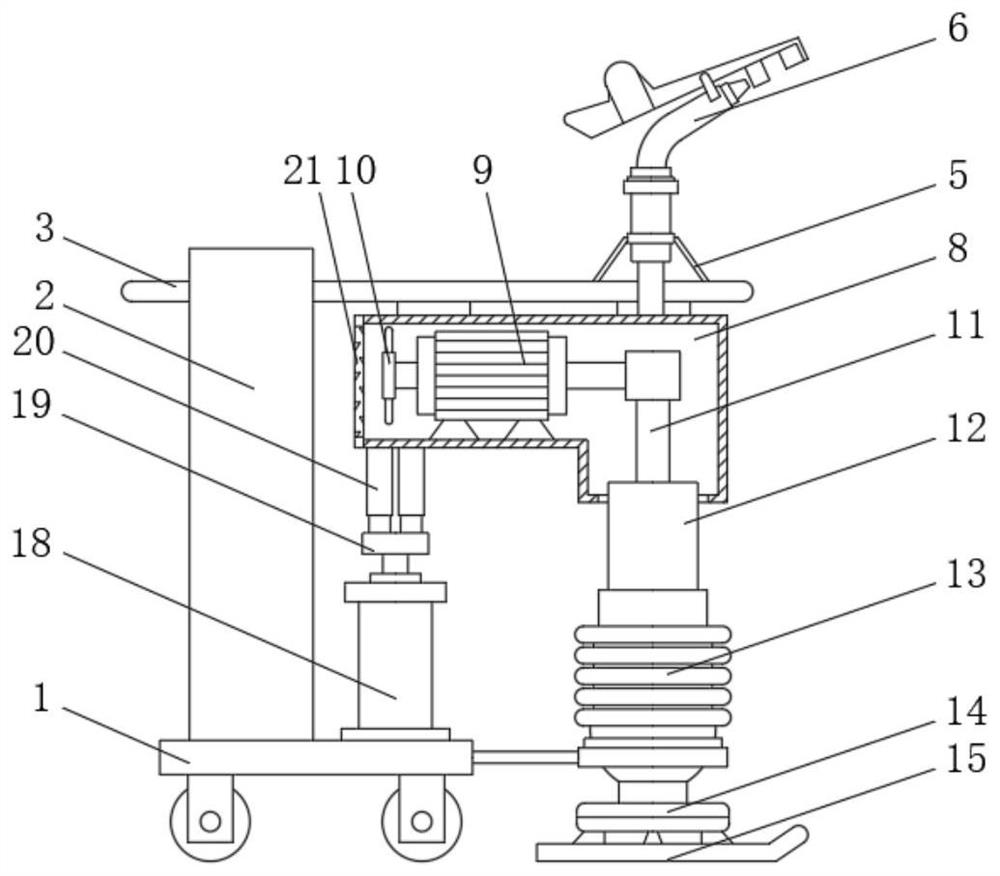

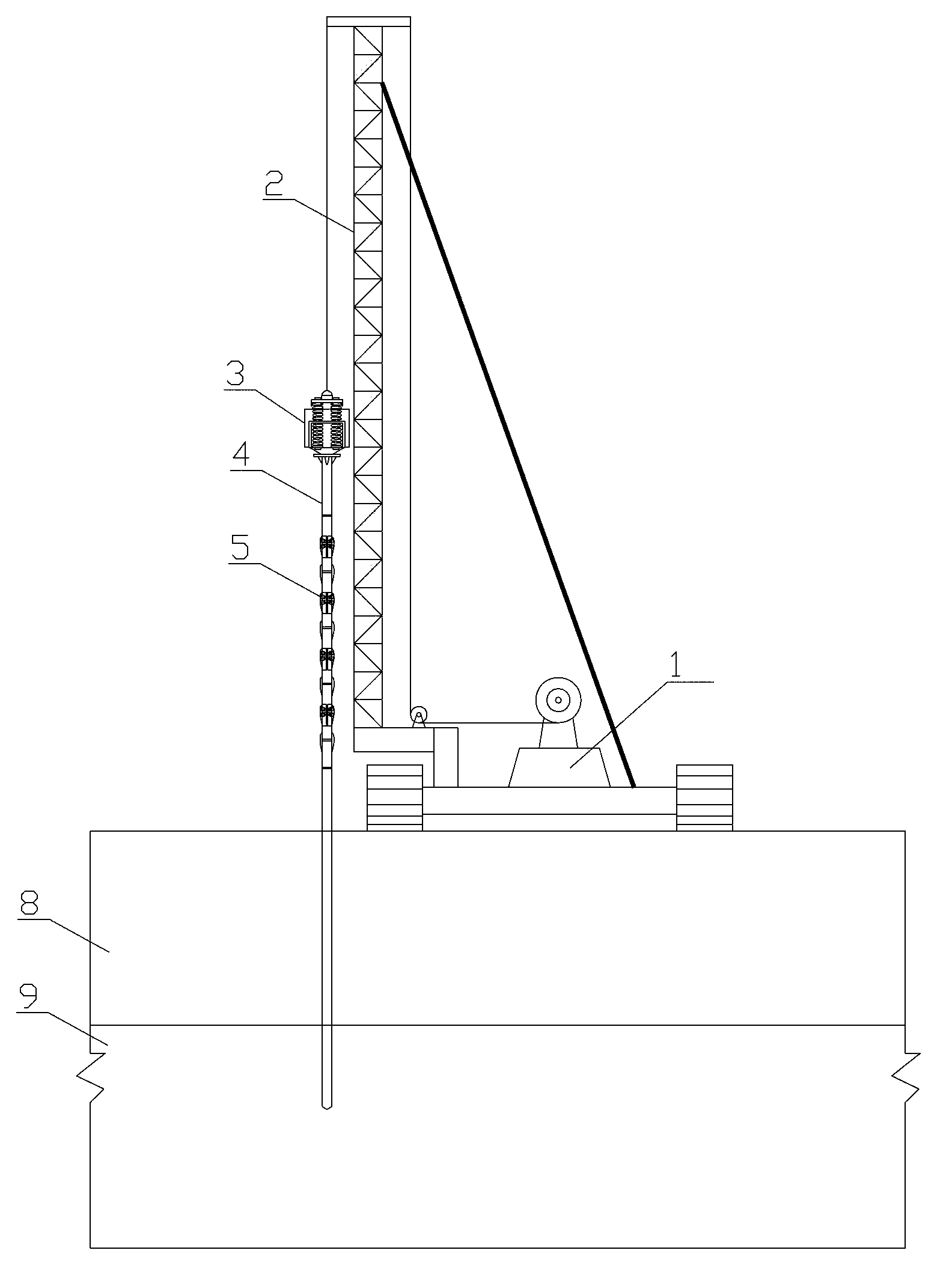

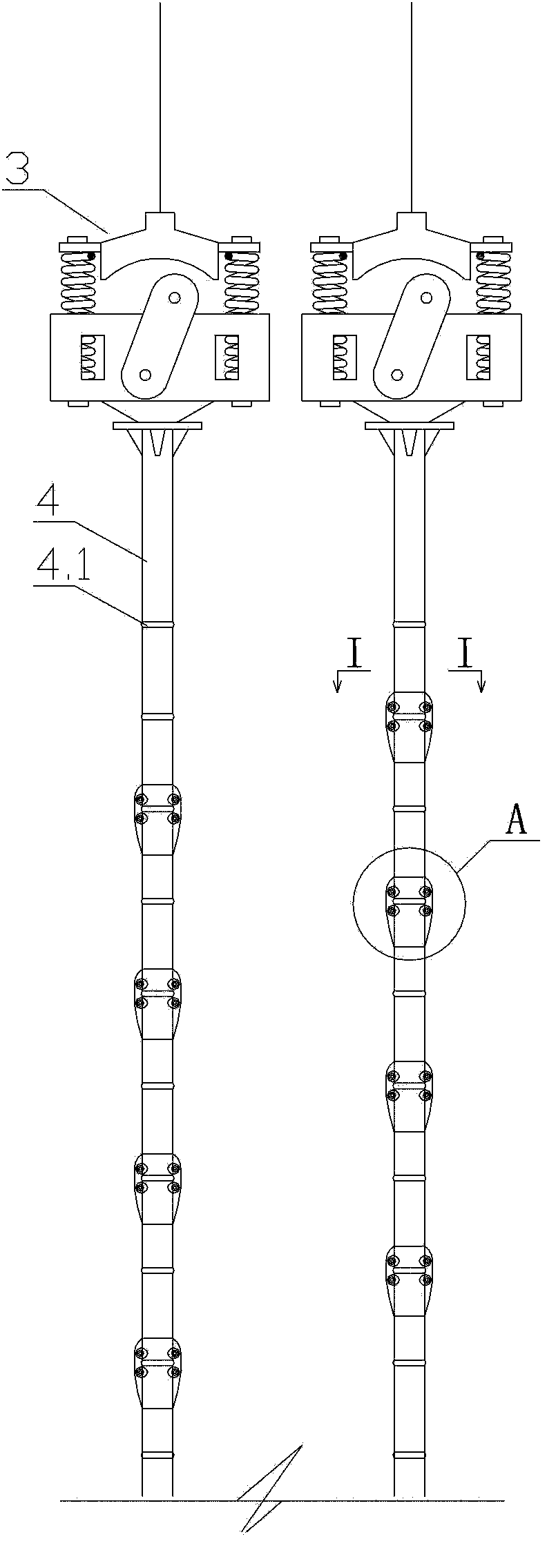

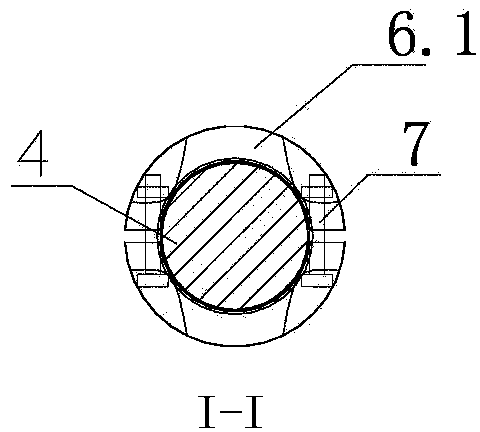

Plate plug method capable of realizing vibratory compaction

ActiveCN102966089AAchieving vibration compactionImprove compactnessSoil preservationDouble tubeWater discharge

The invention discloses a plate plug method capable of realizing vibratory compaction. The plate plug method comprises the following steps of: a, staking out in survey; b, reconstructing the tube wall structure of a pile tube; c, penetrating a water discharge plate through the tube and arranging a shoe; d, plugging the pile tube downwardly to a design depth; e, pulling the pile tube upwardly and cutting the water discharge plate; f, cleaning and refilling a pile hole of the water discharge plate; and g, moving to a next position. According to the plate plug method, vibratory compaction of a fine sand and silty-fine sand layer can be realized while a plate plug operation process is finished by reconstructing the tube wall structure of the pile tube and rationally arranging the construction parameters such as diameter of the pile tube, frequency of a vibrator, vibration excitation force and vibration retention time based on a crawler type double-tube vibration plate plug machine, so that the compaction degree is greatly improved, and the anti-liquefaction capacity is enhanced; and the method has the obvious advantages of convenience in construction, short working period, low manufacturing cost and the like.

Owner:CCCC FOURTH HARBOR ENG INST +3

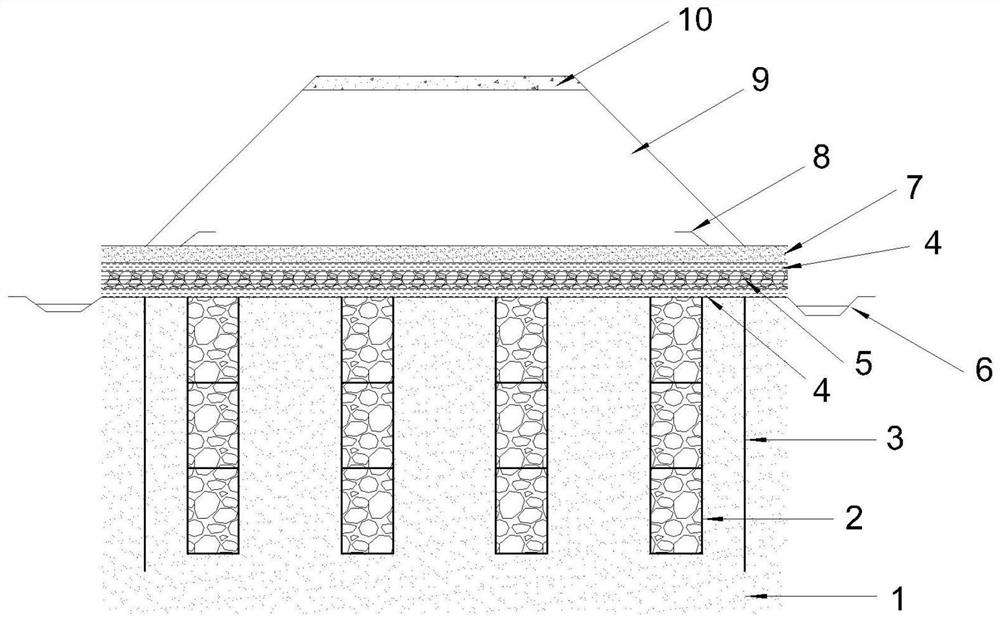

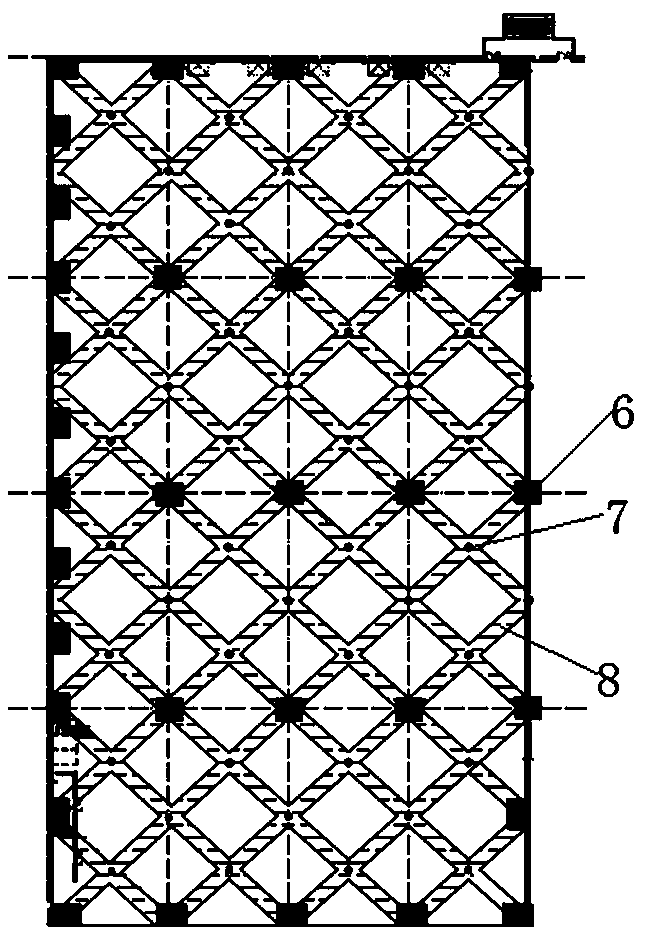

Embankment reinforcing system for liquefiable site reinforced gravel pile composite foundation and reinforcing method

InactiveCN112921946AImprove stabilityImprove resistance to liquefactionBulkheads/pilesSoil preservationSoil scienceCrushed stone

The invention belongs to the field of foundation reinforcing engineering, and relates to an embankment reinforcing system for liquefiable site reinforced gravel pile composite foundation and a reinforcing method. The reinforcing system involves two-way reinforced gravel piles, a sheet pile wall, a geotextile cushion layer, a geogrid reinforced gravel cushion layer, a horizontal drainage channel, drainage ditches, a sand cushion layer, an embankment filling layer and an asphalt concrete surface layer, wherein the reinforced gravel piles are constructed through a vibroflotation method and are arranged in a square shape to form a vertical drainage channel, the geotextile cushion layer, the geogrid reinforced gravel cushion layer and a second geotextile cushion layer are sequentially laid on the upper portions of the two-way reinforced gravel piles to jointly form the horizontal drainage channel, the drainage ditches are formed in the two sides of the horizontal drainage channel, the sand cushion layer is arranged at the top of the horizontal drainage channel, and finally, the embankment filling layer is built on the top surface of the sand cushion layer. The embankment reinforcing system for the liquefiable site reinforced gravel pile composite foundation and the reinforcing method are easy and convenient to construct, short in construction period, low in cost, higher in bearing capacity and liquefying resistance, the embankment reinforcing system for the liquefiable site reinforced gravel pile composite foundation and the reinforcing method which are economical and efficient are provided.

Owner:WUHAN UNIV

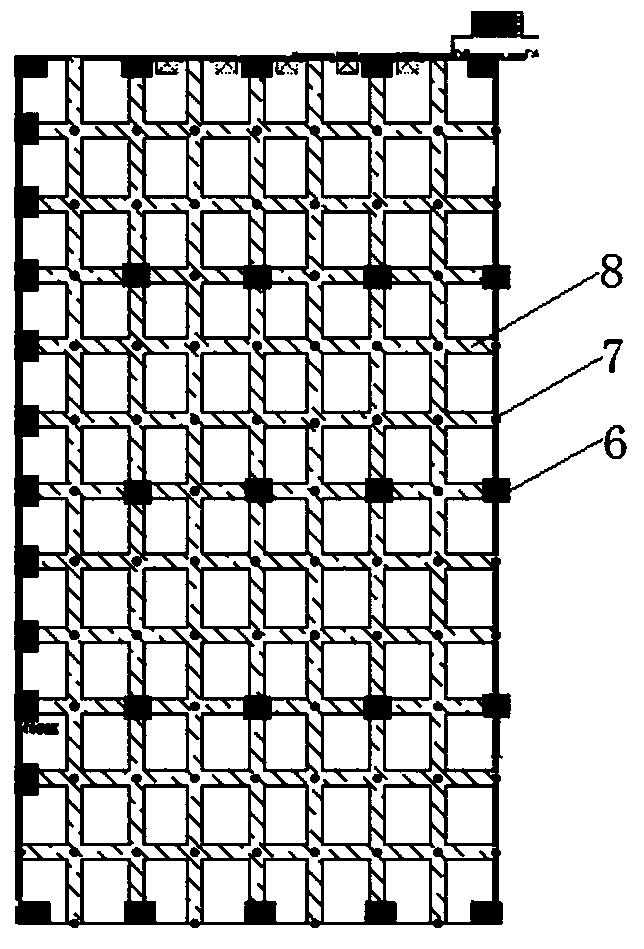

Anti-liquefaction treatment method for liquefiable foundation

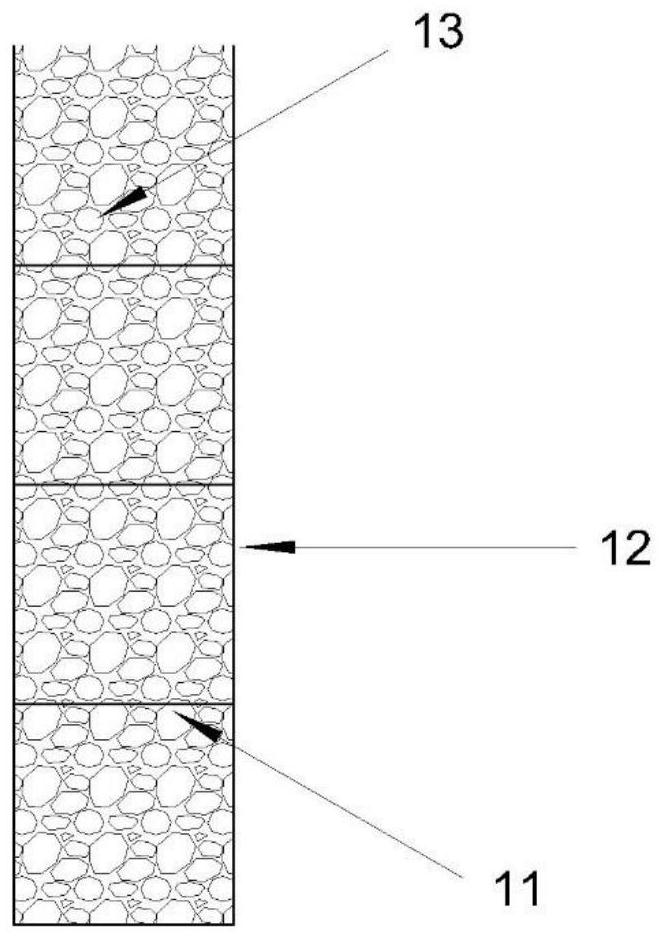

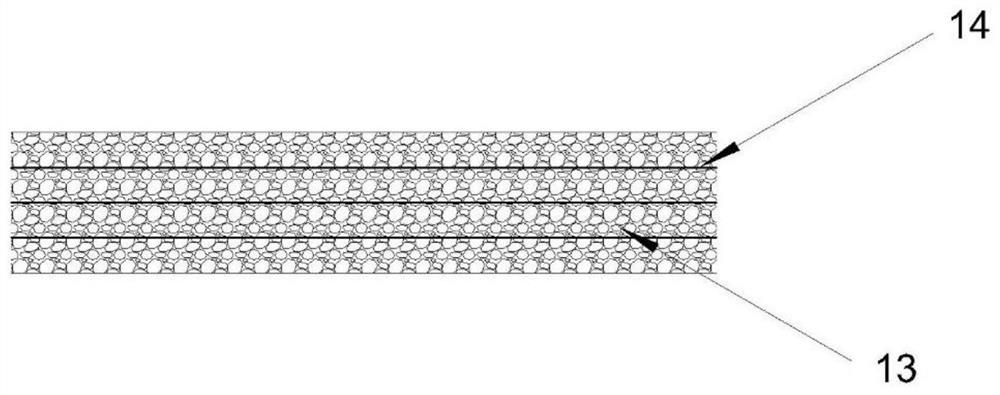

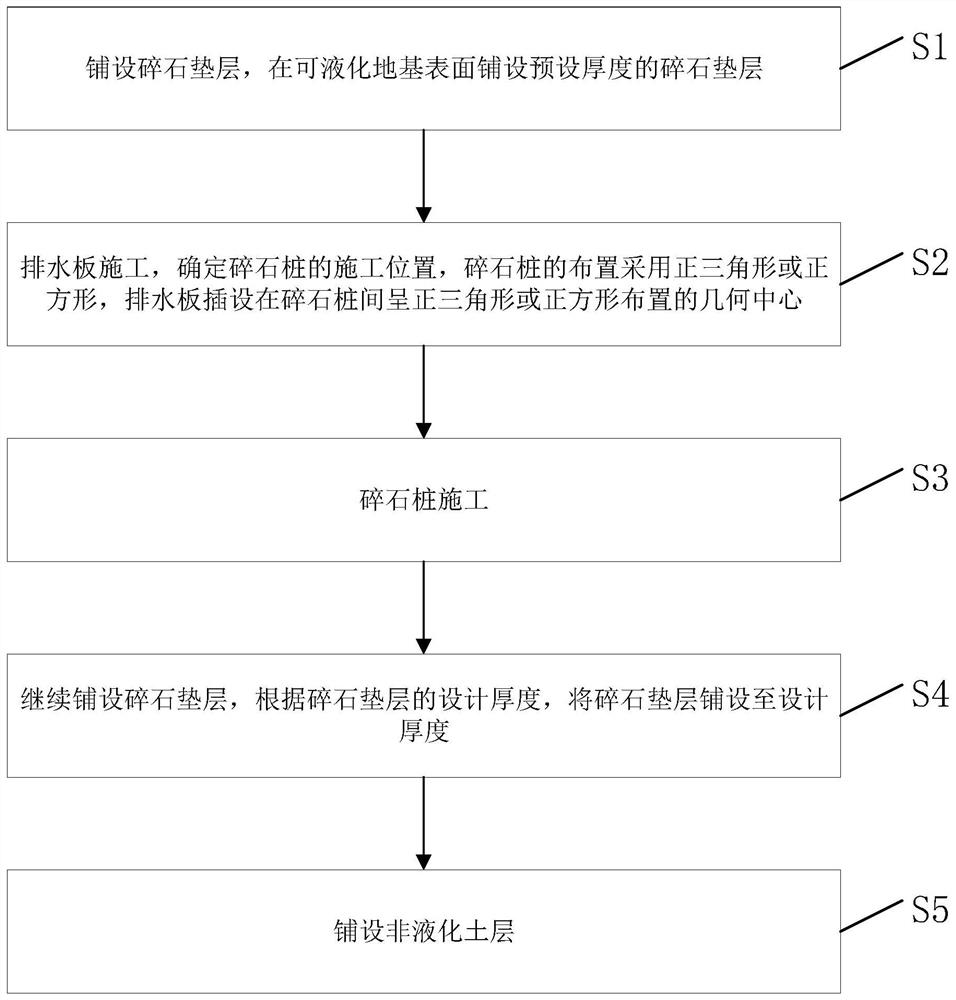

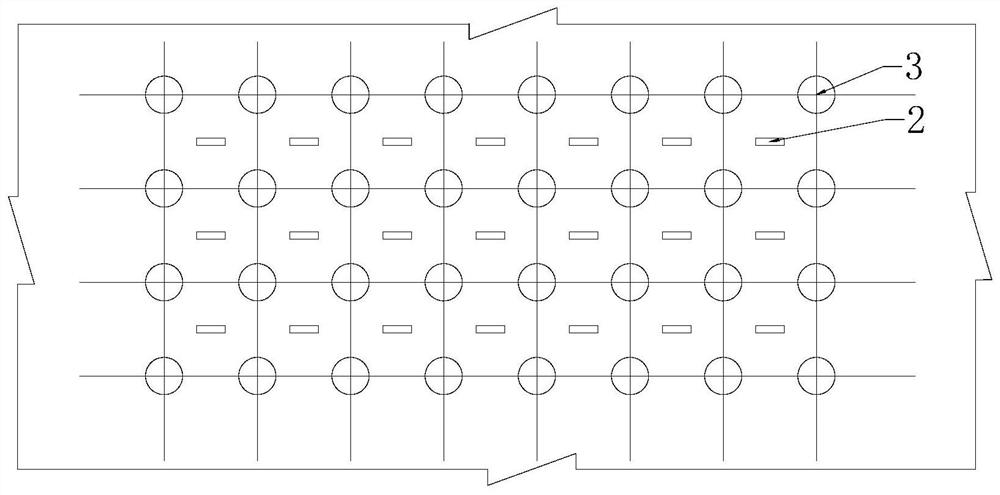

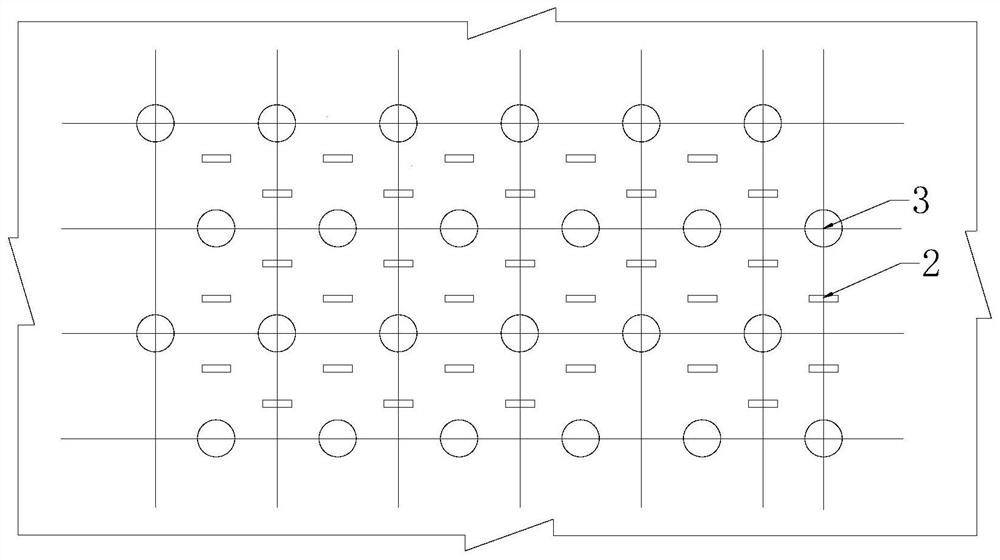

ActiveCN112030934ADecreased resistance to liquefaction and drainageReduce pore water pressureSoil preservationCrushed stoneSquare Shape

The invention provides an anti-liquefaction treatment method for a liquefiable foundation. The anti-liquefaction treatment method comprises the following steps that a broken stone hardcore is laid, and specifically the broken stone hardcore with the preset thickness is laid on the surface of the liquefiable foundation; drainage plate construction is conducted, wherein the construction positions ofgravel piles are determined, the gravel piles are arranged in a regular triangle or square shape, and drainage plates are inserted into the geometric centers of the gravel piles arranged in the regular triangle or square shape; gravel pile construction is carried out; the broken stone hardcore is continuously laid, and the broken stone hardcore is laid to the designed thickness according to the designed thickness of the broken stone hardcore; and a non-liquefied soil layer is laid. The anti-liquefaction treatment method aims to overcome the defects of an existing anti-liquefaction treatment method for the liquefiable foundation.

Owner:CCCC FOURTH HARBOR ENG CO LTD

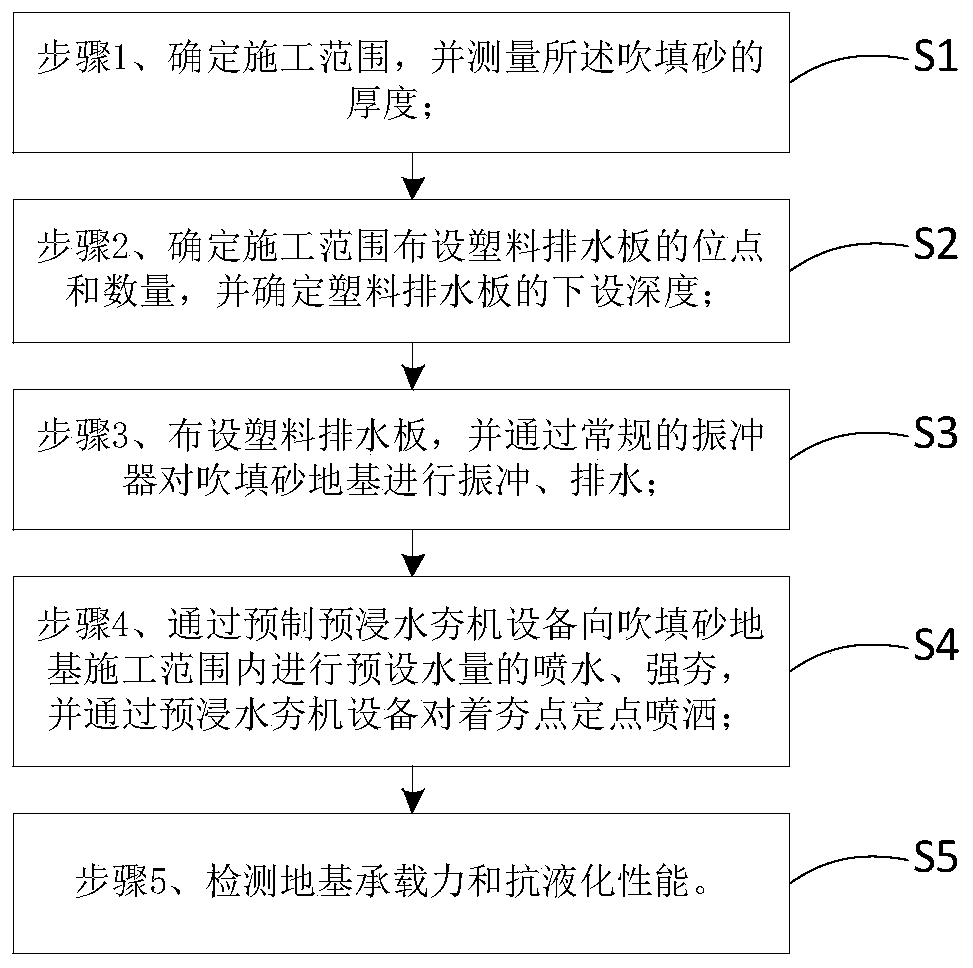

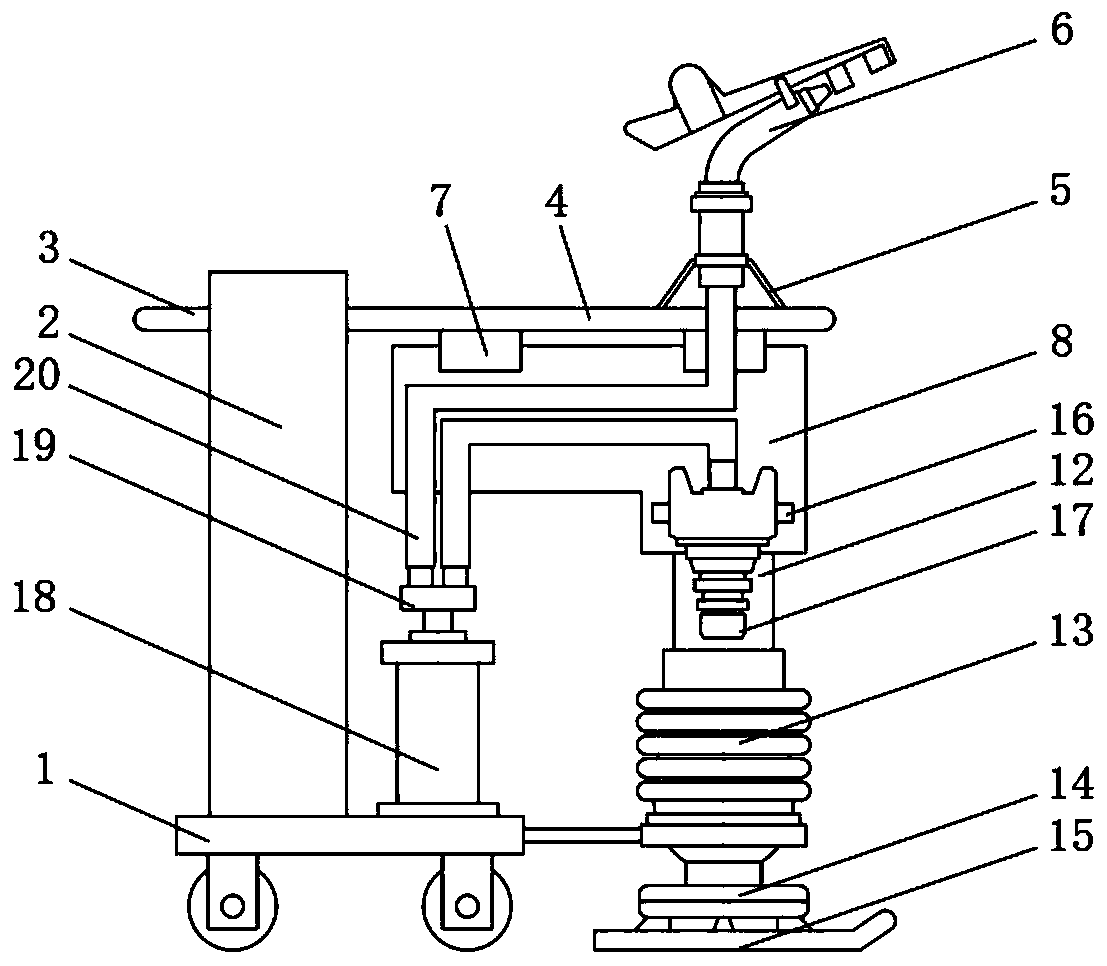

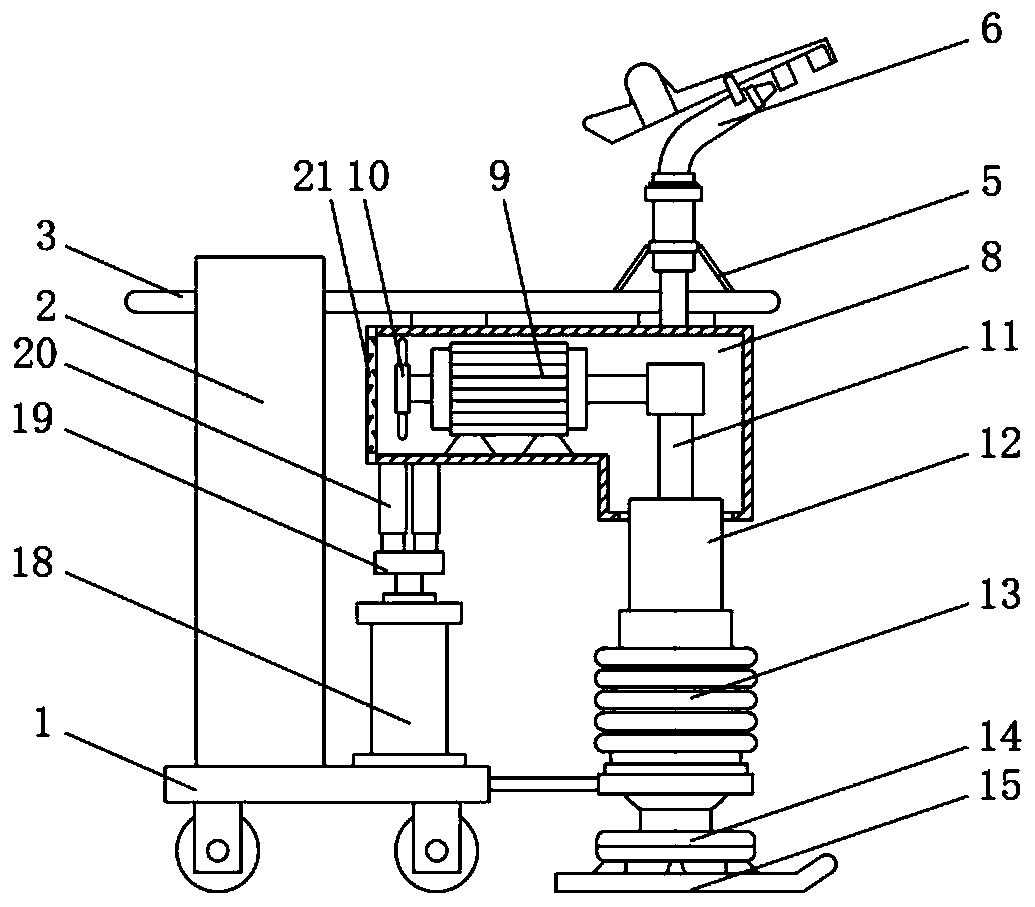

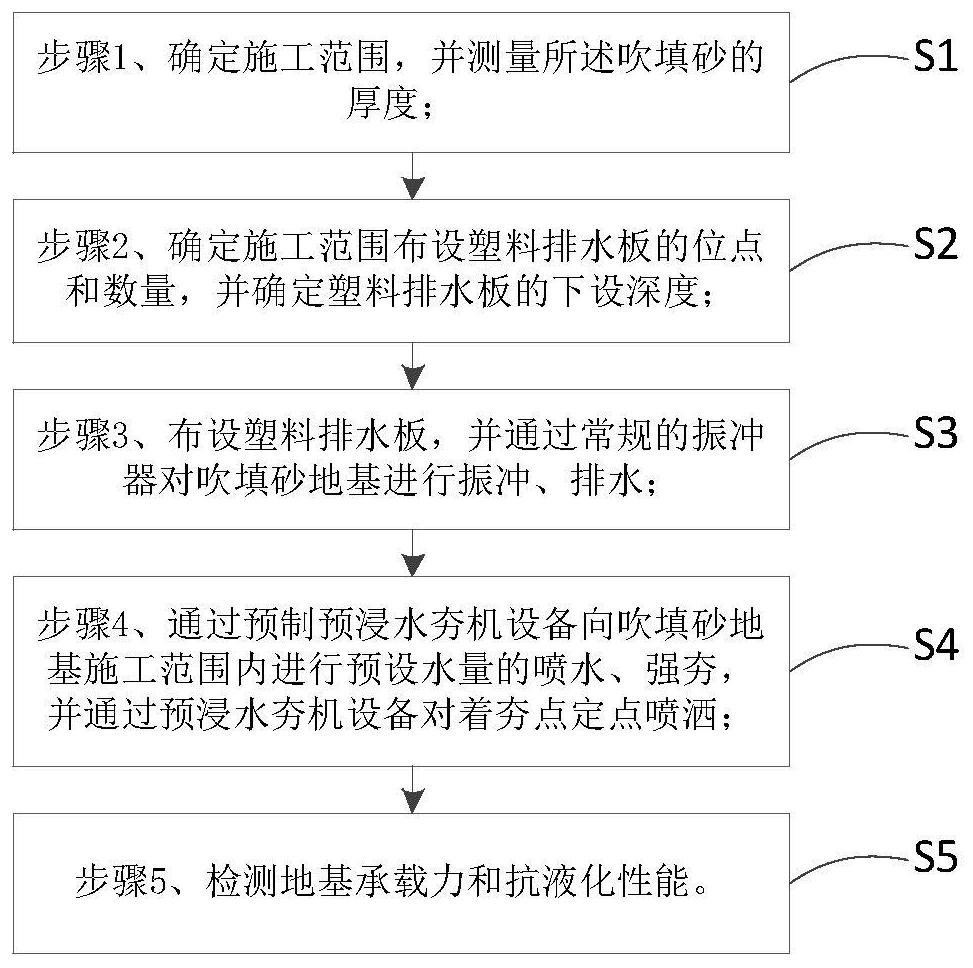

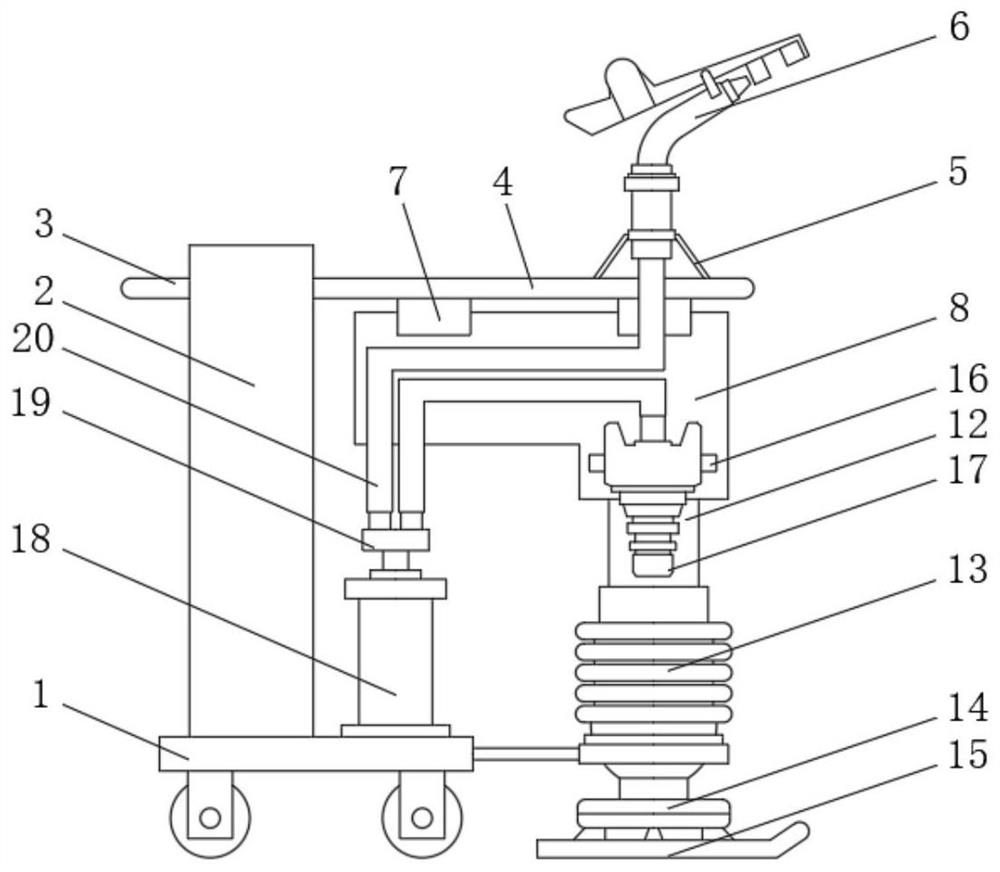

Construction method of engineering foundation pre-soaking dynamic consolidation

ActiveCN110130310AImprove bearing capacityImprove resistance to liquefactionSoil preservationSurface layerWater content

The invention provides a construction method of engineering foundation pre-soaking dynamic consolidation. The construction method includes the following steps that 1, the construction range is determined, and the thickness of blow filling sand is measured; 2, sites and the number of laid plastic drainage plates in the construction range are determined, and the arranged depth of the plastic drainage plates is determined; 3, the plastic drainage plates are laid, and a blow filling sand foundation is subjected to vibroflotation and drainage through a conventional vibroflot; 4, water with the preset water yield is sprayed into the construction range of the blow filling sand foundation by prefabricated pre-soaking ramming equipment so as to maintain the preset water content of the blow fillingsand foundation, then dynamic consolidation is carried out by the pre-soaking ramming equipment, and fixed point spraying of ramming points is carried out by the pre-soaking ramming equipment in the process of dynamic consolidation so as to ensure no dust; and 5, the foundation bearing capacity and liquefaction resistance performance are detected. According to the construction method of engineering foundation pre-soaking dynamic consolidation, the problems that the quality of dynamic consolidation and subsequent vibration rolling construction is affected and the environment is polluted due tothe fact that a surface layer is difficult to be compacted in the treatment process of the existing blow filling sand foundation are effectively solved.

Owner:江苏筑港建设集团有限公司

A method for treating liquefied foundation by blasting drainage

ActiveCN104988900BAccelerated dissipationAccelerated settlementSoil preservationPore water pressureEngineering

The invention discloses a method for treating a liquefied foundation through explosion and drainage. The method comprises the following steps: arranging a plurality of vertical drainage boards penetrating through a soil layer which is liable to be liquefied at intervals in a liquefied foundation region to be treated; burying explosives in the soil layer which is liable to be liquefied; igniting the explosives, and rearranging the soil structure in the liquefied foundation by utilizing the impact force generated by the explosives; squeezing water out, and discharging the water from the drainage boards. The method disclosed by the invention has the advantages that 1) the method provides vertical drainage channels, the instantaneous impact force generated by explosion can accelerate the dispersion of pore water pressure, so that the water in the foundation is discharged, and the purposes of realizing quick dense sedimentation and eliminating liquefaction are achieved; 2) the construction speed is greatly increased, and the construction period is shortened; compared with the method for treating the liquefied foundation through pile foundations, the method disclosed by the invention is low in cost, simple to operate, and good in liquefaction resisting effect; 3) the application range is extensive, and the method is applicable for general liquefied foundations.

Owner:SHANGHAI SHEN YUAN GEOTECHN

Binary Composite Foundation of Discrete Pile-Permeable Concrete Pile and Its Treatment Method

ActiveCN102839683BGood water permeabilityStrong rigidityBulkheads/pilesSoil preservationWater dischargePore water pressure

Owner:SHANDONG UNIV

A construction method of pre-soaked water dynamic compaction method for engineering foundation

ActiveCN110130310BImprove bearing capacityImprove resistance to liquefactionSoil preservationWater volumeArchitectural engineering

The invention provides a construction method of a pre-impregnated water dynamic compaction method for engineering foundations, comprising the following steps: step 1, determining the construction scope, and measuring the thickness of the sand filling; step 2, determining the location of the construction scope for laying a plastic drainage board and quantity, and determine the depth of the plastic drainage board; Step 3, lay out the plastic drainage board, and vibrate and drain the sand-filled foundation through a conventional vibrator; Spray water with a preset amount of water within the construction scope of the sand-filled foundation to maintain the preset moisture content, and then perform dynamic compaction through the pre-impregnated water compactor equipment. Spray on the ramming point at a fixed point to ensure no dust; Step 5, check the bearing capacity and liquefaction resistance of the foundation. The invention effectively solves the problems that the surface layer of the existing blowing and filling sand foundation is difficult to be compacted during the treatment process, which affects the construction quality of dynamic compaction and subsequent vibratory rolling, and pollutes the environment.

Owner:江苏筑港建设集团有限公司

A microbial flat grouting device and method for strengthening liquefiable foundations

Owner:NANJING FORESTRY UNIV

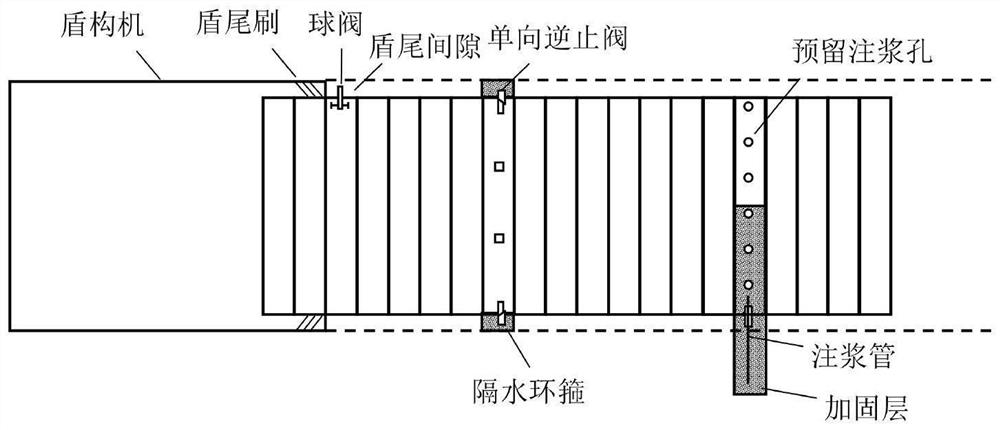

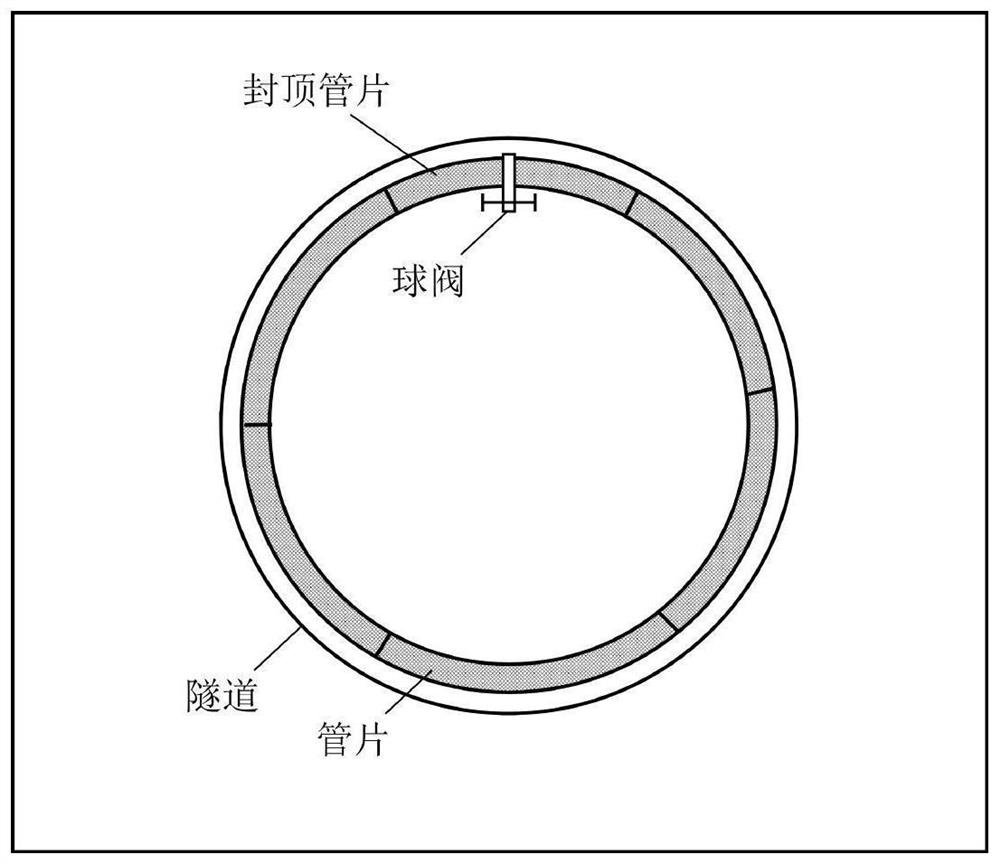

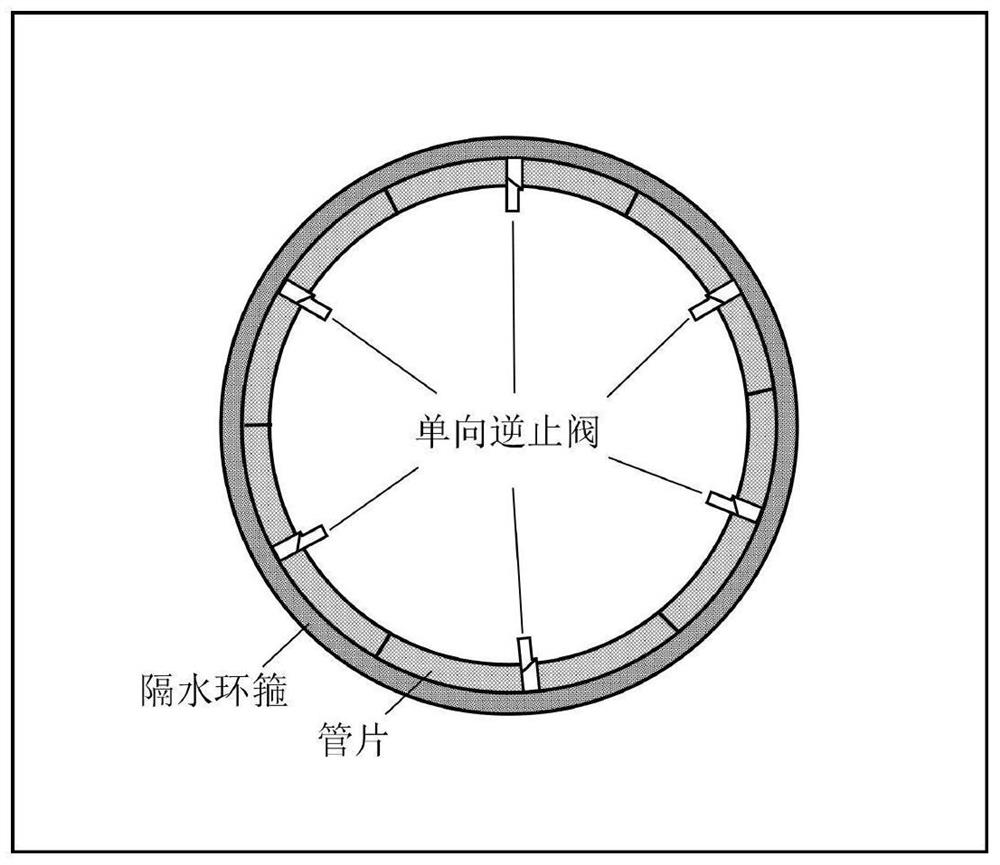

In-hole treatment method for shield tunnel in liquefiable stratum

PendingCN113503177AImprove resistance to liquefactionReduce project costUnderground chambersTunnel liningSoil scienceGeotechnical engineering

The invention discloses an in-hole treatment method for a shield tunnel in a liquefiable stratum, and belongs to the technical field of tunnel shield construction. The invention aims to solve the shield construction risk of the liquefiable stratum. The method comprises the following steps of synchronously grouting and replacing pore water; cutting off pore water through secondary grouting; and carrying out in-hole anti-liquefaction treatment. While the shield tail gap of the liquefiable stratum is prevented from being formed, separated-out pore water is used for diluting slurry, and the grouting filling effect is guaranteed; pore water is prevented from flowing and gathering along a formed tunnel, and synchronous grouting slurry which is not initially set is limited to longitudinally flow due to the gradient of the tunnel; and the anti-liquefaction capability of the shield tunnel is improved, the construction cost is reduced, and the construction period is shortened. Compared with a traditional method for conducting full-section reinforcement treatment on a liquefied soil layer from the ground through cement-soil mixing piles and high-pressure jet grouting piles, targeted local stratum treatment can be conducted under the condition that the ground does not meet the construction condition.

Owner:CHINA RAILWAY NO 17 BUREAU GRP +1

A micro-nano bubble treatment device and operation method for liquefiable foundation

ActiveCN103993594BImprove resistance to liquefactionIncreased shear strengthSoil preservationMicro nanoPore water pressure

The invention discloses a liquefiable foundation device for micro-nano bubble processing and an operation method. In terms of a liquefiable sand layer in a foundation, a mixture of micro-nano bubbles and water is injected through a micro-nano gas-liquid mixture generator, a compressor, an air guide pipe, a hollow drilling pipe, a gas sprayer and the like, the micro-nano bubbles can stay in soil for a long time, the saturation is reduced, shearing strength of the soil is enhanced, and accordingly liquefaction resistance of the liquefiable sand layer is remarkably improved. When the liquefiable sand layer bears a vibration load, gas left in the soil can serve as a buffering agent and effectively buffer the tendency that pore water pressure rises, and accordingly the liquefaction resistance of the foundation is improved.

Owner:SOUTHEAST UNIV

Inverted filter material water permeable pile composite foundation and water permeable rate measuring device and method thereof

PendingCN112525801AGood physical propertiesIncreased shear strengthPermeability/surface area analysisBulkheads/pilesSoil sciencePre stress

The invention discloses an inverted filter material water permeable pile composite foundation and a water permeable rate measuring device and method thereof. The composite foundation comprises recycled concrete water permeable piles, prestressed concrete piles, geotextile wrapping the recycled concrete water permeable piles and a mattress layer laid at the tops of the water permeable piles. The measuring device comprises a sleeve, an inner support arranged in the sleeve, a pervious concrete test piece arranged on the inner support and geotextile wrapping a water permeable concrete test piece.Waste concrete is recycled to be made into recycled concrete, the recycled concrete is combined with the geotextile, resources are saved, meanwhile, the foundation has good water permeability, water can be drained to the maximum extent, sandy soil is reserved, piping and quicksand caused by hydraulic power are prevented, the bearing capacity of the foundation is improved, and sedimentation of a building is reduced; the corresponding water permeable rate testing device is simple in structure, the testing method is convenient to use, and the water permeable performance of the water permeable concrete and the impermeability of a concrete test block can be rapidly detected.

Owner:NANCHANG UNIV

An underground integrated pipe gallery structure with anti-liquefaction and anti-floating and application method thereof

ActiveCN113833015BPrevent floatingIncrease weightArtificial islandsProtective foundationSoil sciencePipe

The invention relates to a liquefaction-resistant and anti-floating underground integrated pipe gallery structure and an application method thereof, belonging to the technical field of integrated pipe gallery. The anti-liquefaction and anti-floating underground integrated pipe gallery structure includes a square tubular integrated pipe gallery body, a filter water absorption mechanism, a cooling mechanism and an air jet mechanism. The upper surface of the integrated pipe gallery body is embedded with a pore pressure sensor, and the filter water absorption mechanism is arranged in the integrated pipe gallery. On the side wall of the pipe gallery body, the cooling mechanism is arranged on the side wall of the integrated pipe gallery body, and the air jet mechanism is arranged on the top of the integrated pipe gallery body. In the liquefaction-resistant and anti-floating underground integrated pipe gallery structure of the present invention, the pore pressure sensor can quickly detect the change of the water content of the surrounding soil during an earthquake. It can reduce the water content of the soil and consolidate the surrounding sand, reducing the conditions for the liquefaction of the soil, thereby preventing the floating of the integrated pipe gallery.

Owner:NANJING TECH UNIV

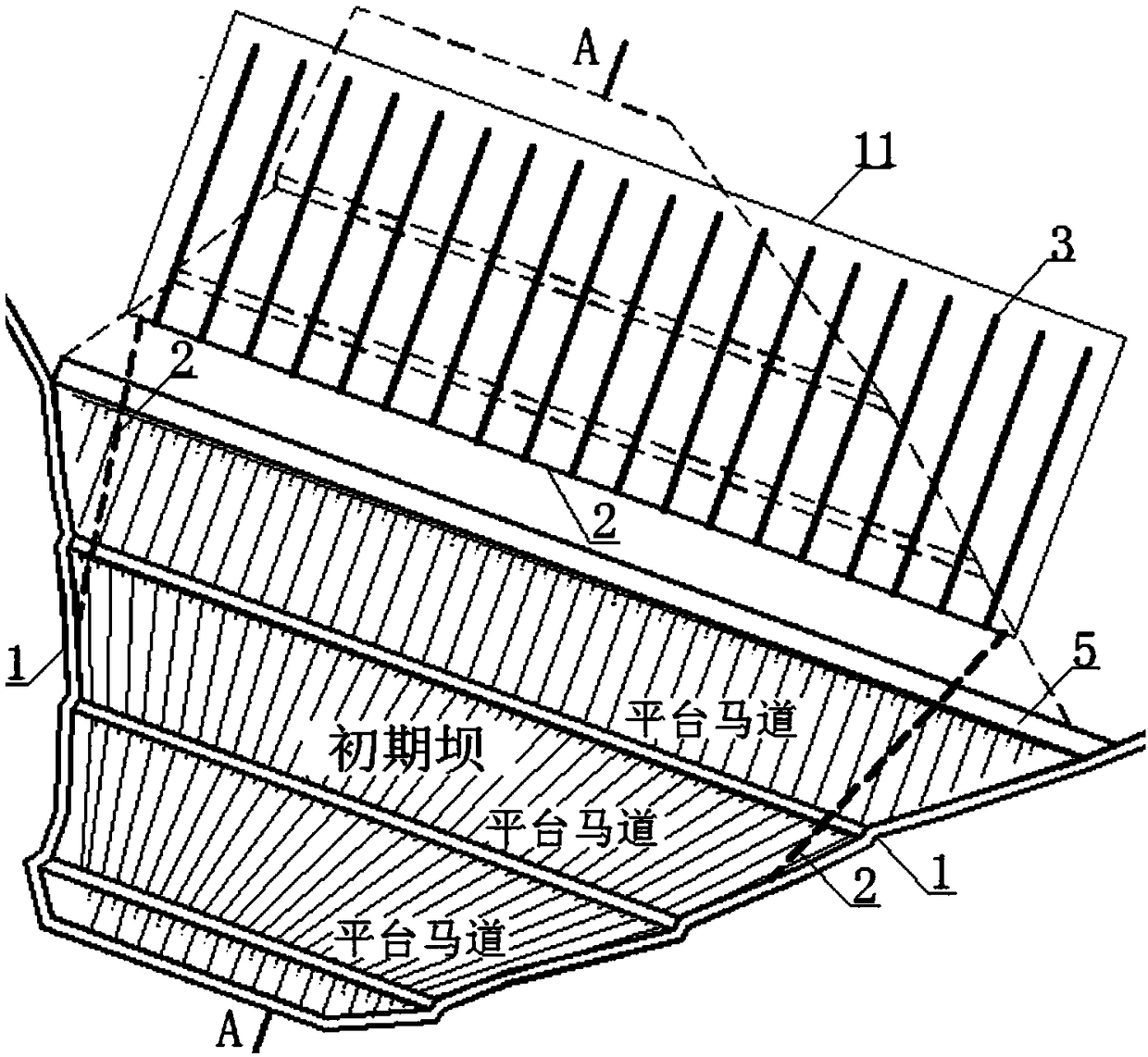

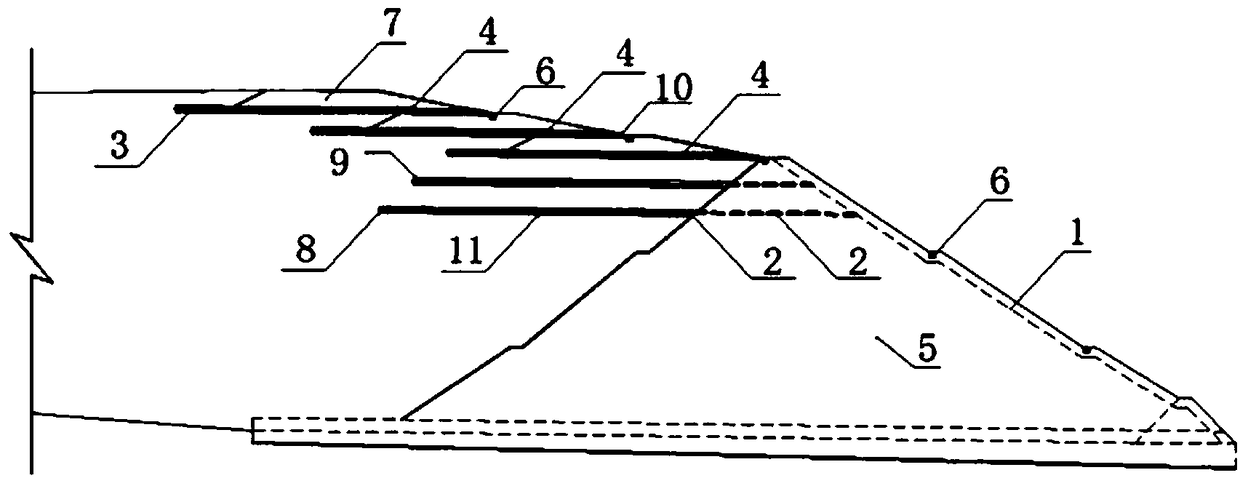

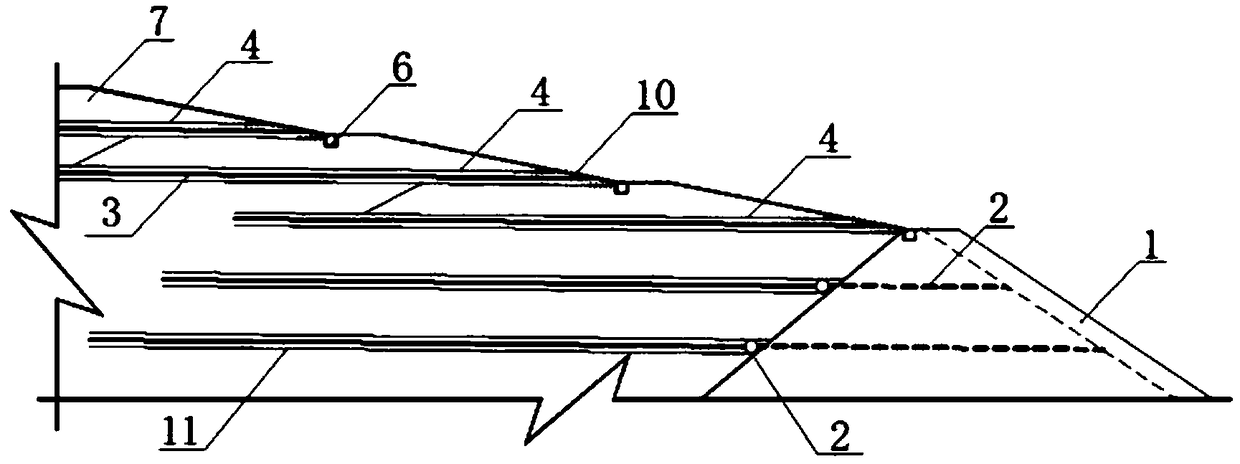

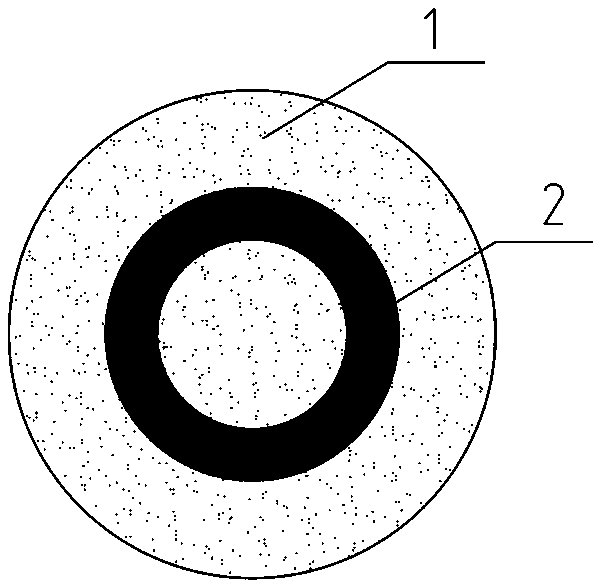

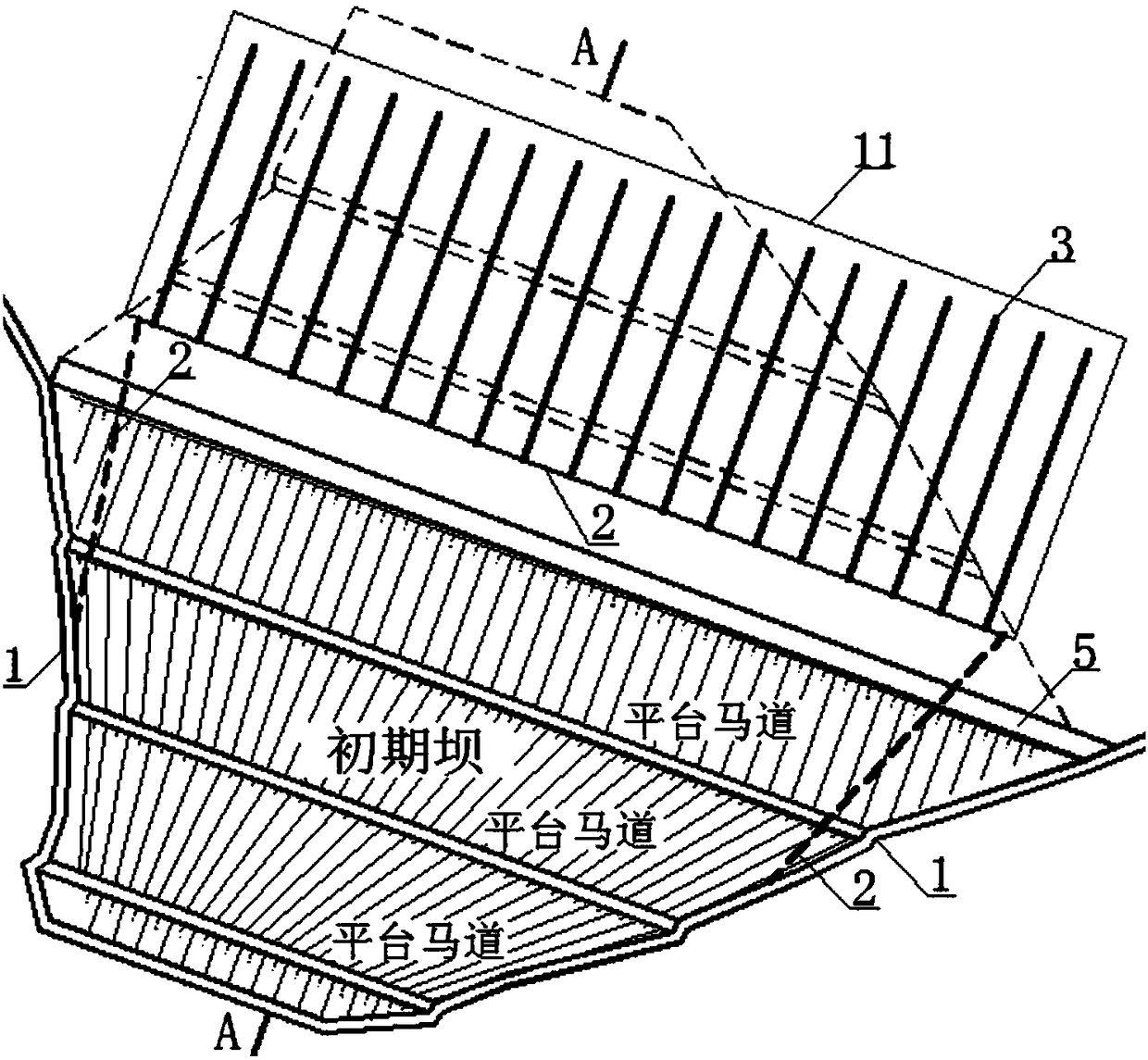

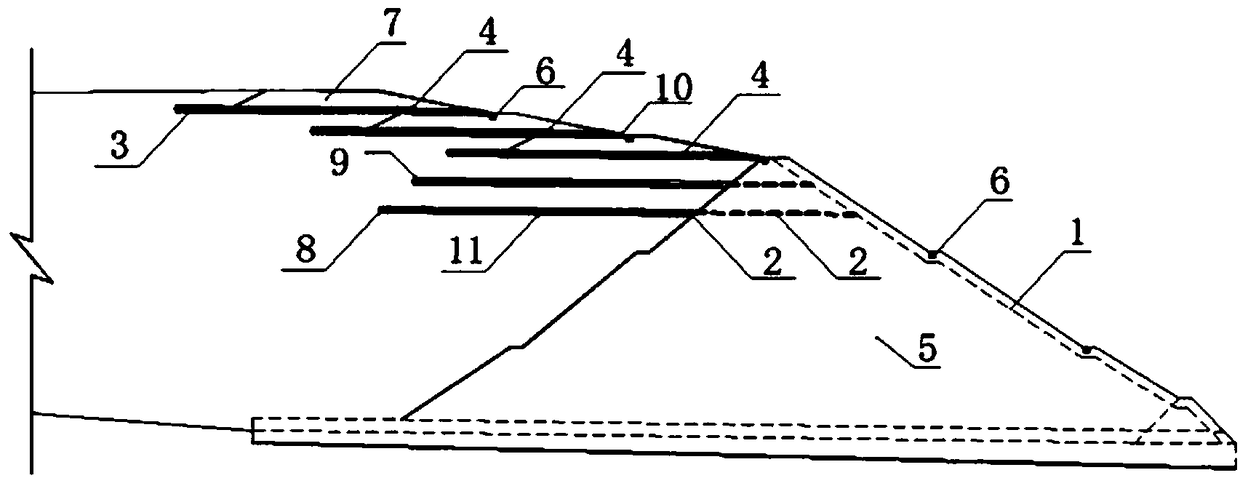

Method of damming ultra-fine grain and upstream method tailings to prevent earthquake liquefaction instability and damage

ActiveCN106759174BLower Wetting LineAccelerated consolidationDamsClimate change adaptationTailings damInstability

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

Foundation leveling system for controlling settlement of storage terrace and construction method thereof

PendingCN110593246AReduce uneven settlementGood sinking effectSoil preservationBearing capacityBuilding construction

The invention relates to the technical field of foundation treatment and foundation reinforcement, in particular to a foundation leveling system for controlling settlement of a storage terrace and a construction method thereof. The system is characterized in that the system comprises a plurality of structural pile foundations, a plurality of leveling pile foundations, flexible foundation separation belts and horizontal reinforcement bodies, wherein the structural pile foundations and the leveling pile foundations are uniformly arrayed, the flexible foundation separation belts correspondingly connect the structural pile foundations and the leveling pile foundations one by one and divide a foundation into a plurality of chambers, and the horizontal reinforcement bodies are arranged at the upper part of the flexible foundation separation belt and support a structural layer of the storage terrace. The foundation leveling system for controlling settlement of the storage terrace and the construction method thereof have the advantages that the foundation leveling system is suitable for large-area ground load, especially terrace settlement control of buildings such as factories, workshopsand warehouses, and have the advantages of short construction period, controllable construction quality, low engineering cost, good anti-seismic effect, high bearing capacity, small uneven settlementand the like.

Owner:SHANGHAI SHEN YUAN GEOTECHN

A method for preventing earthquake liquefaction instability of ultra-fine tailings piled upstream tailings dam

ActiveCN106702983BLower Wetting LineImprove the stability of the dam bodyDamsSoil drainageTailings damInstability

The invention discloses a method for preventing earthquake liquefaction instability of an ultrafine tailing heaping upstream method tailing dam. An initial dam (5) and a dam abutment flood stop ditch (1) are built according to a design scheme; embedment depths of a first earthquake liquefaction resisting medium-coarse sand drainage / seepage layer and a second earthquake liquefaction resisting medium-coarse sand drainage / seepage layer are determined according to the region seismic fortification intensity; the first and second earthquake liquefaction resisting medium-coarse sand drainage / seepage layers both consist of medium-coarse sand drainage / seepage layers (11), and a row of groove hole drainage / seepage pipes (3) paved in the medium-coarse sand drainage / seepage layers (11); the groove hole drainage / seepage pipes (3) are communicated with drainage communicating pipes (2) through three-way pipes (12); and the outer ends of the drainage communicating pipes (2) are connected with the dam abutment flood stop ditch (1). The method improves the earthquake liquefaction resistance and the stability of the ultrafine tailing heaping dam, prevents the earthquake liquefaction instability damage, and in particular, is suitable for the ultrafine tailing heaping upstream method tailing dam in high-intensity earthquake region.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

Stirring pile-permeable concrete pile compound foundation and treatment method thereof

ActiveCN102839647BImprove carrying capacityGood water permeabilityBulkheads/pilesSoil preservationCrushed stoneEngineering

The invention discloses a stirring pile-permeable concrete pile compound foundation, which comprises a plurality of rows of stirring piles and permeable concrete piles, wherein the stirring piles and the permeable concrete piles are arranged in a row spacing way; and a gravel cushion layer is paved on the surface of the foundation on the upper parts of the stirring piles and the permeable concrete piles. The invention discloses a method for treating the foundation simultaneously. The compound foundation has high bearing capability and high permeability, post-construction settlement can be effectively reduced, and the liquefaction resistance of the foundation can be improved. Meanwhile, under the action of drainage consolidation, the compound foundation can be used for eliminating engineering diseases caused by stirring pile construction.

Owner:SHANDONG UNIV

Liquefiable sandy soil structure

InactiveCN104947705AImprove carrying capacityGood water permeabilitySoil preservationCrushed stoneRebar

The invention discloses a liquefiable sandy soil structure. The liquefiable sandy soil structure comprises a liquefiable sandy soil layer. The lower surface of the liquefiable sandy soil layer is provided with a concrete gravel layer. The thickness of the concrete gravel layer is smaller than that of the liquefiable sandy soil layer. Non-woven cloth is laid between the liquefiable sandy soil layer and the concrete gravel layer. The lower surface of the concrete gravel layer is provided with an anti-seep gravel layer. The anti-seep gravel layer is connected with the concrete gravel layer through steel pipe piles. The steel pipe piles are fixed to the anti-seep gravel layer and the concrete gravel layer. The lower surface of the anti-seep gravel layer is provided with a broken stone hardcore. Reinforcing rods are embedded between the broken stone hardcore and the anti-seep gravel layer. The liquefiable sandy soil structure further comprises vibro-replacement stone columns. The liquefiable sandy soil structure has very high bearing capacity, very high permeable capacity, capable of effectively reducing sedimentation generated after construction as well as improving the liquefying resistance capacity of a foundation and capable of playing a role in water drainage better so that next construction process can be better conducted, and construction efficiency is improved greatly.

Owner:CHENGDU XUNDE SCI & TECH

Curing agent for treating deep soft foundation soil layer and preparation method thereof

InactiveCN102134494BImproved unconfined compressive strengthGood deformabilityBuilding constructionsOrganic fertilisersSulfonateFirming agent

The invention relates to a curing agent for treating a deep soft foundation soil layer and a preparation method thereof. The curing agent consists of metal oxides with activity of Al2O3, Fe2O3, CaO and MgO, nonmetal oxides with activity of SiO2 and SO3, and an acyclic sulfonate water-reducer. The preparation method for the curing agent comprises the following steps of: drying the metal oxides and the nonmetal oxides in a dryer, and heating at the temperature of between 750 and 850DEG C for 3 to 4 hours; grinding into granules that the residue of a 80 mu m square sifter is not more than 4.0 percent by using a ball mill; and adding the acyclic sulfonate water-reducer and uniformly stirring to obtain the curing agent for treating the deep soft foundation soil layer. The curing agent can make the unconfined compressive strength, deformation, permeability, liquefaction resistance and other properties of the treated soft foundation soil body obviously improved.

Owner:HUBEI COMM PLANNING & DESIGN INST CO LTD

Plate plug method capable of realizing vibratory compaction

ActiveCN102966089BAchieving vibration compactionImprove compactnessSoil preservationDouble tubeWater discharge

The invention discloses a plate plug method capable of realizing vibratory compaction. The plate plug method comprises the following steps of: a, staking out in survey; b, reconstructing the tube wall structure of a pile tube; c, penetrating a water discharge plate through the tube and arranging a shoe; d, plugging the pile tube downwardly to a design depth; e, pulling the pile tube upwardly and cutting the water discharge plate; f, cleaning and refilling a pile hole of the water discharge plate; and g, moving to a next position. According to the plate plug method, vibratory compaction of a fine sand and silty-fine sand layer can be realized while a plate plug operation process is finished by reconstructing the tube wall structure of the pile tube and rationally arranging the construction parameters such as diameter of the pile tube, frequency of a vibrator, vibration excitation force and vibration retention time based on a crawler type double-tube vibration plate plug machine, so that the compaction degree is greatly improved, and the anti-liquefaction capacity is enhanced; and the method has the obvious advantages of convenience in construction, short working period, low manufacturing cost and the like.

Owner:CCCC FOURTH HARBOR ENG INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com