A microbial flat grouting device and method for strengthening liquefiable foundations

A grouting device and liquefied foundation technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of difficult control of the reinforcement range and uneven strength of the reinforcement body, so as to improve the overall anti-liquefaction ability and eliminate the size effect problem, the effect of improving non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

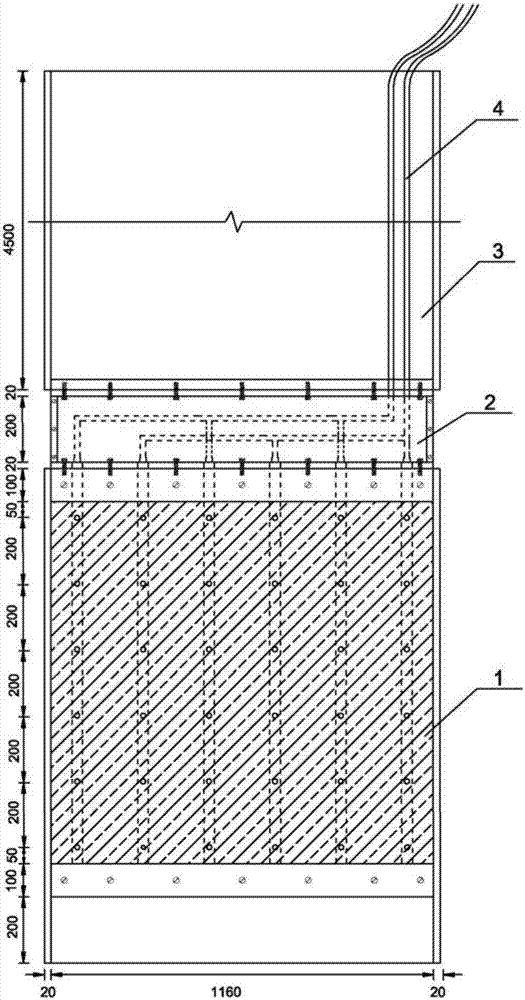

[0030] The plane size of a construction site: 72m in length and 60m in width, the content of soil particles with a particle size greater than 0.25mm in the site is 78.3%, which exceeds 50% of the total weight. According to the standard of solid body classification, the foundation soil of this site belongs to liquefiable medium sand, and it is necessary to take anti-liquefaction treatment measures to strengthen the foundation of the site. The thickness of the foundation soil layer to be reinforced is 4.3m~4.9m. figure 1 -6 and this engineering case further illustrate the present invention.

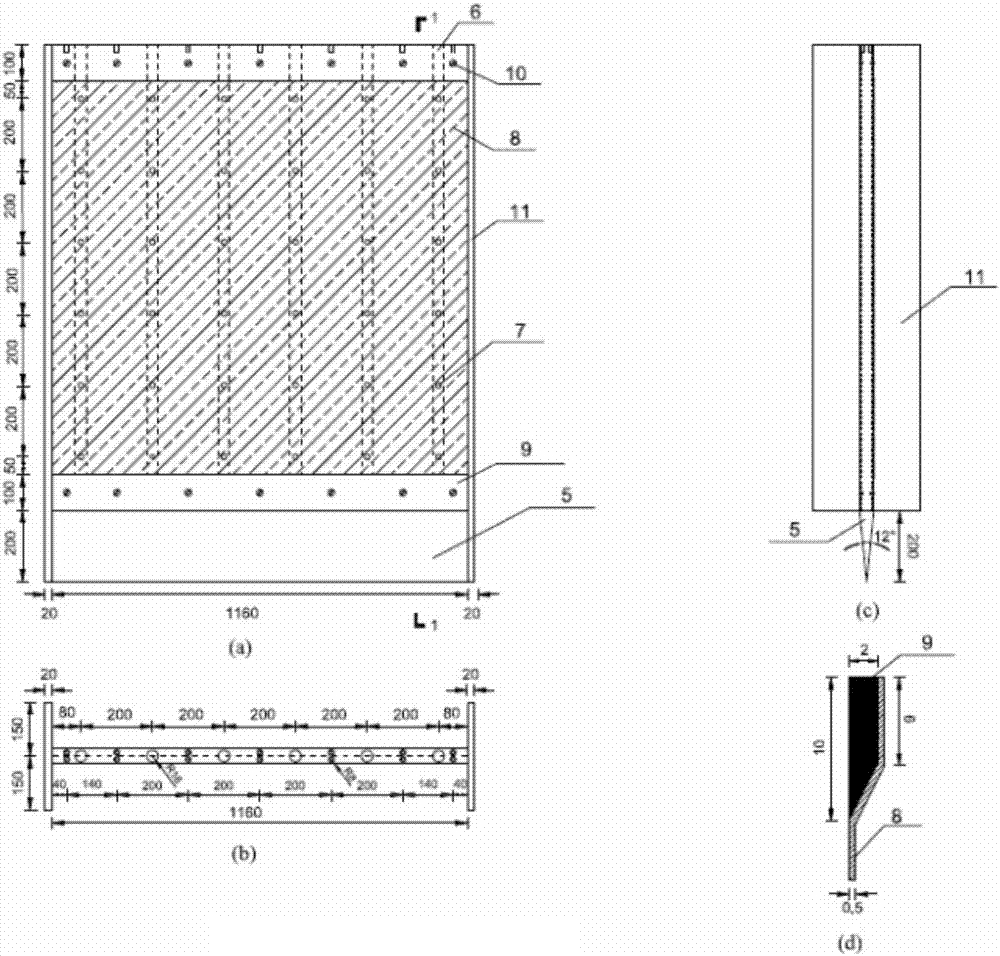

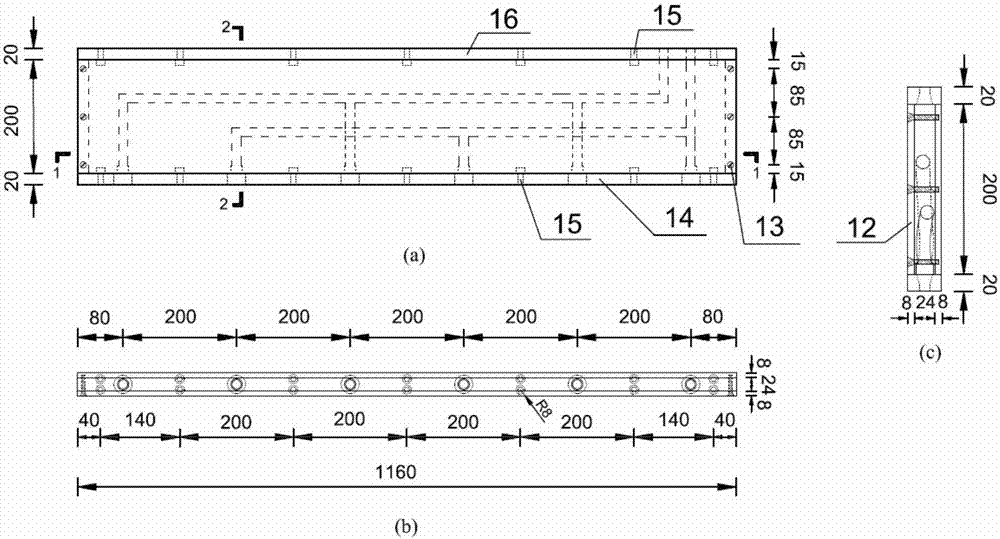

[0031]The microbial flat plate grouting device proposed by the present invention is composed of a stainless steel grouting plate 1, a pipeline transfer device 2, an extension plate 3 and a grouting pipe 4. The surface of the device is in the Evenly apply lubricating grease to the depth of the soil to facilitate the device to be pulled out from the soil layer after the grouting is completed;...

Embodiment 2

[0038] In this example, the present invention is used to strengthen the silt foundation with a plane size of 60m in length and 60m in width, and the thickness of the foundation soil layer to be reinforced is 4.1m~4.4m, combined below figure 1 -6 and this engineering case further illustrate the present invention.

[0039] The microbial flat plate grouting device proposed by the present invention is composed of a stainless steel grouting plate 1, a pipeline transfer device 2, an extension plate 3 and a grouting pipe 4. The surface of the device is in the Evenly apply lubricating grease to the depth of the soil to facilitate the device to be pulled out from the soil layer after the grouting is completed; the grouting plate 1 is 1160mm long, 40mm thick, and 1500mm high. The front end of the grouting plate 1 is processed into a 12° edge angle 5 to facilitate To break the soil, a Ф32mm slurry channel 6 is drilled along the height direction at the part above the blade angle 5, and a ...

Embodiment 3

[0046] The plane size of a construction site is 120m in length and 96m in width. The content of soil particles with a particle size greater than 0.1mm in the site is 80.2%, which exceeds 75% of the total weight. According to the standard of solid body classification, the foundation soil of this site belongs to liquefiable fine sand, and anti-liquefaction treatment measures need to be taken to strengthen the site foundation. The thickness of the foundation soil layer to be reinforced is 4.8m~5.3m. Combine below figure 1 -6 and this engineering case further illustrate the present invention.

[0047] The microbial flat plate grouting device proposed by the present invention is composed of a stainless steel grouting plate 1, a pipeline transfer device 2, an extension plate 3 and a grouting pipe 4. The surface of the device is in the Evenly apply lubricating grease to the depth of the soil to facilitate the device to be pulled out from the soil layer after the grouting is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com