Patents

Literature

43results about How to "Improve non-uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

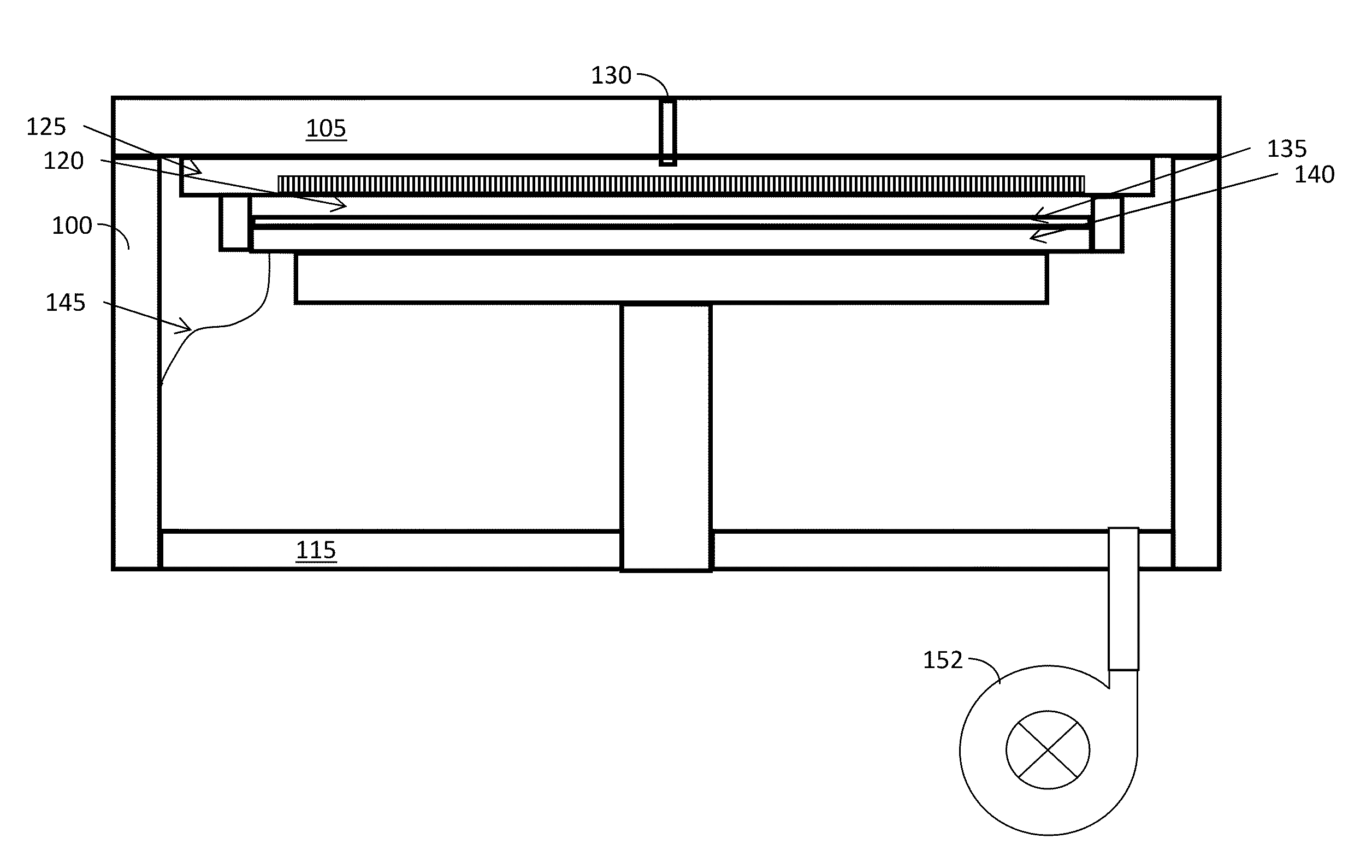

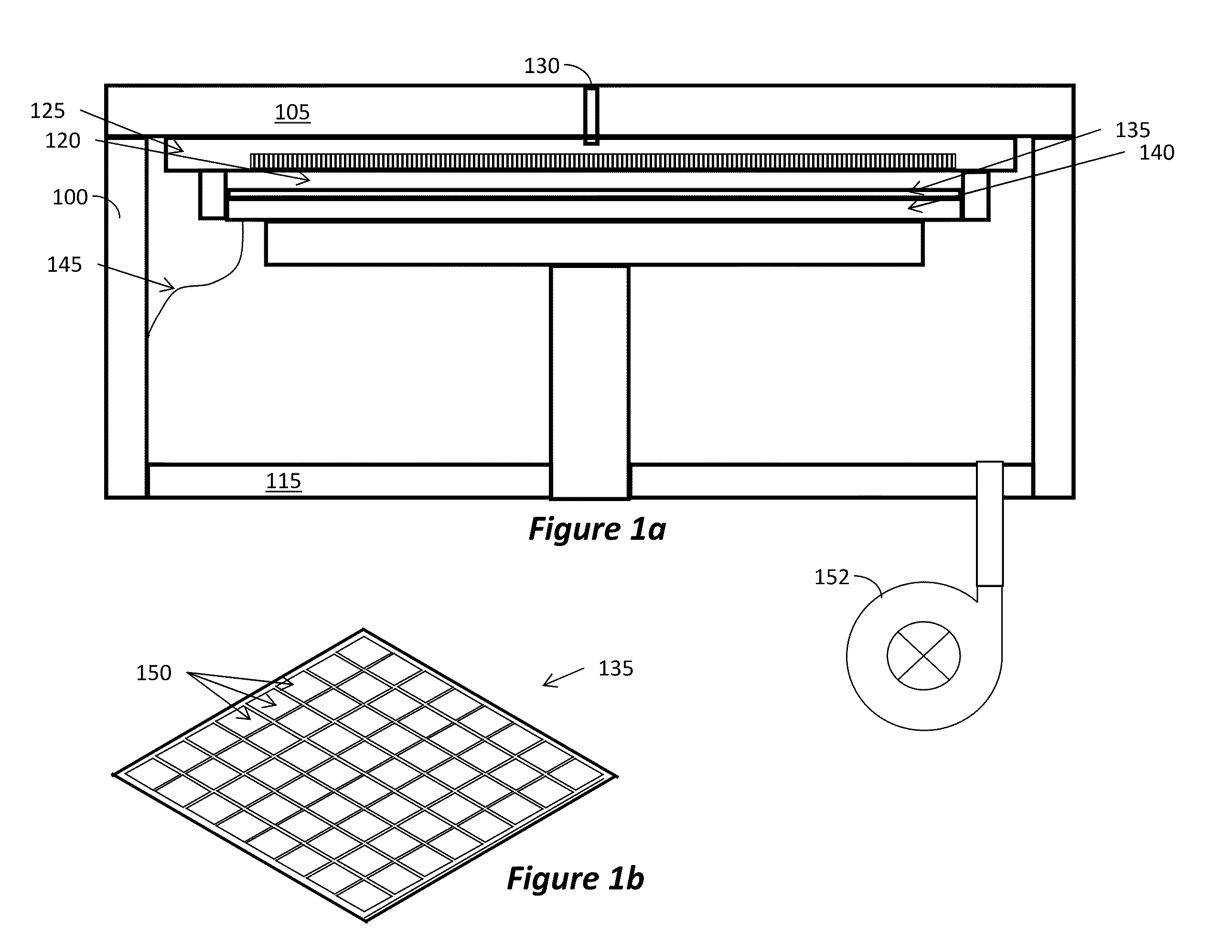

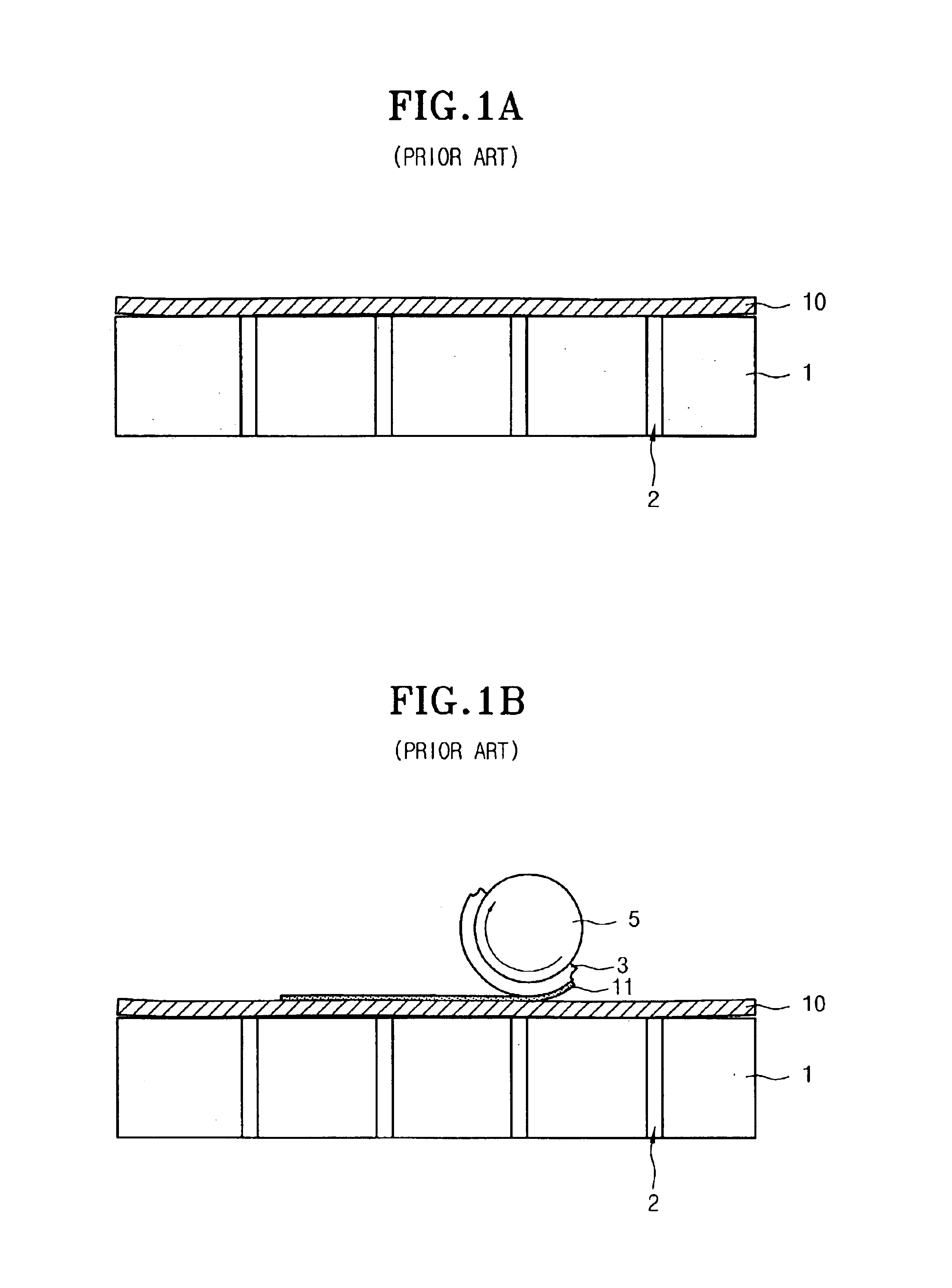

Susceptor for plasma processing chamber

InactiveUS20110315081A1Improve on susceptor designStable plasmaLiquid surface applicatorsSemiconductor/solid-state device manufacturingPlasma processingAluminium oxide

A susceptor for a plasma process apparatus, the susceptor having a graphite main body with a top surface for supporting at least one substrate, the top surface having a plasma sprayed aluminum oxide coating. A vacuum processing chamber, has a main chamber body, a showerhead provided at the ceiling of the chamber body, a pedestal provided inside the chamber body, and a susceptor coupled to the pedestal, the susceptor is made of a graphite main body having a top surface for supporting at least one substrate, the top surface having a dielectric coating such as, e.g., plasma sprayed aluminum oxide coating.

Owner:ORBOTECH LT SOLAR

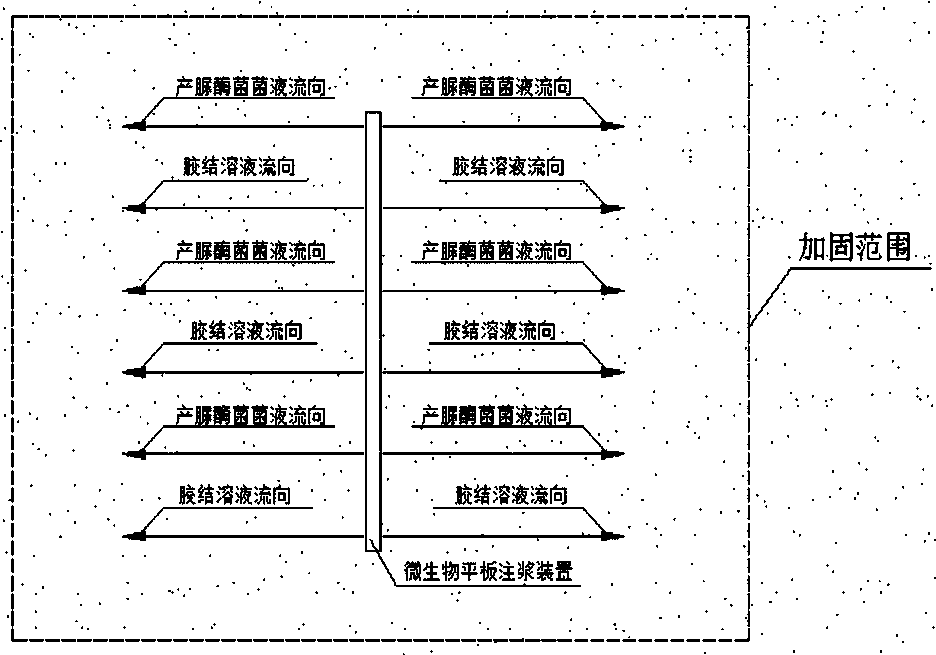

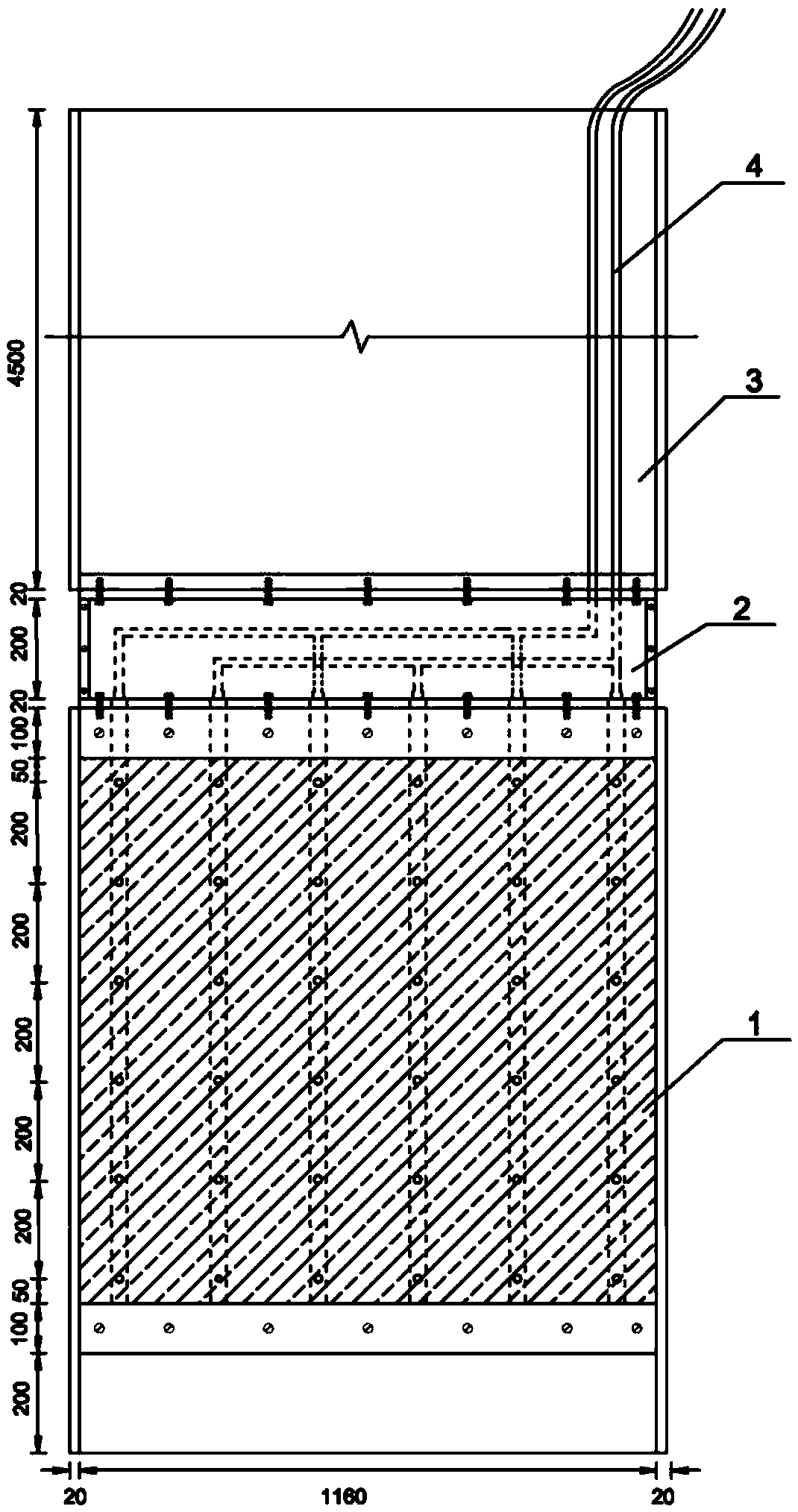

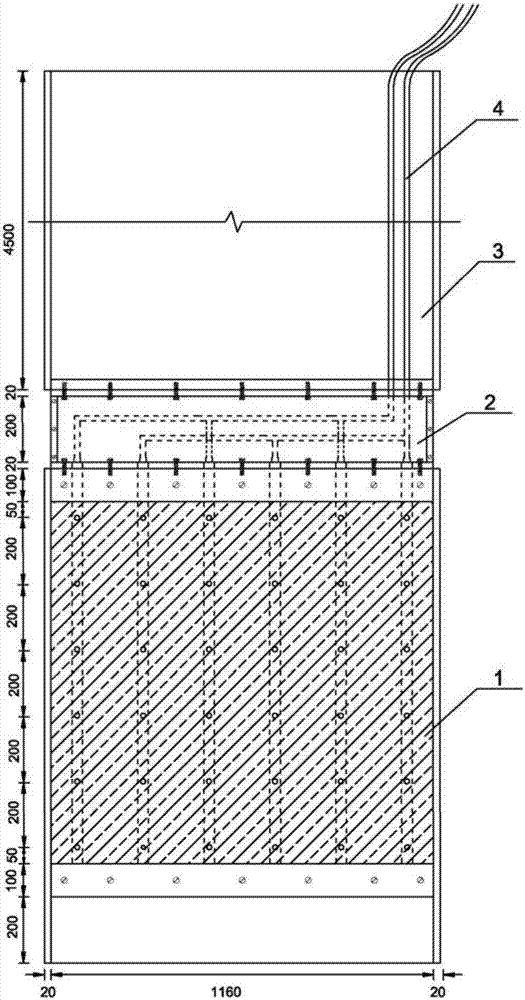

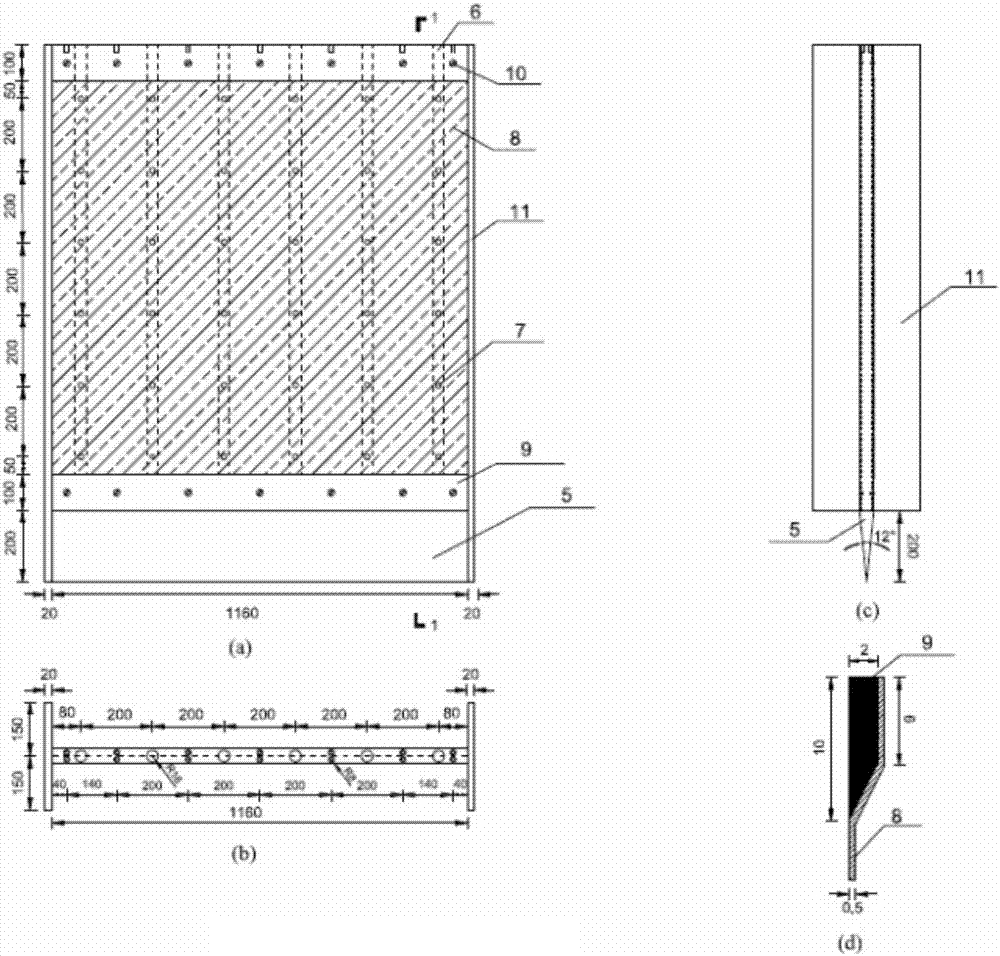

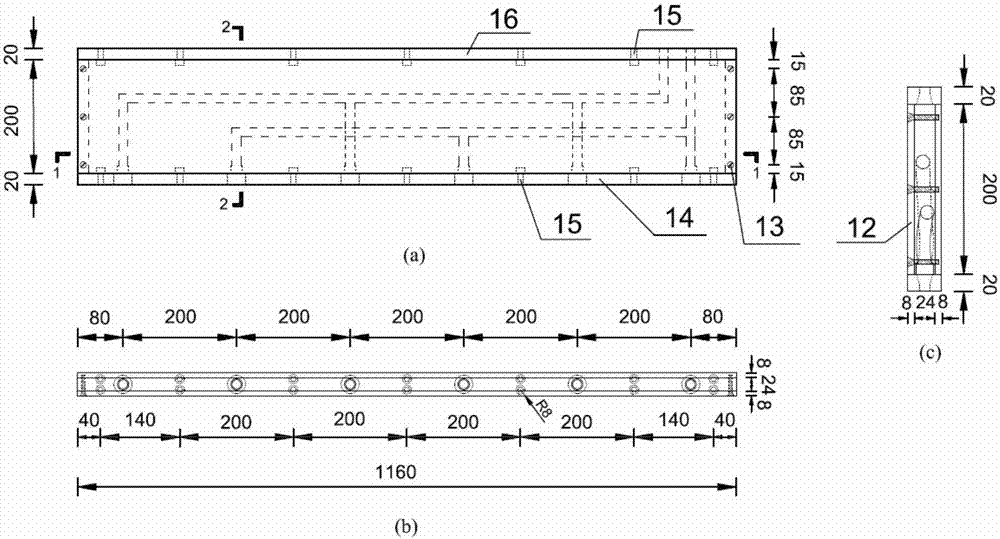

Microorganism slab grouting device and method used for reinforcing liquefiable foundation

ActiveCN105507232AAvoid cloggingGood injectabilitySoil preservationMicroorganismStructural engineering

The invention relates to a microorganism slab grouting device and a microorganism slab grouting method used for reinforcing a liquefiable foundation. The device comprises a grouting panel, a pipeline switching device, an extended panel and grouting pipes. The grouting method comprises the following steps: a. vertically ramming microorganism slab grouting devices arranged in I and II forms into a to-be-reinforced stratum; b. carrying out butt joint on one ends of the first and second grouting pipes with first and second slurry passages in the microorganism slab grouting devices, connecting the other end of the first grouting pipe with a valve, a grouting pump and urease-producing microorganism bacterial liquid storage pond in sequence, and connecting the other end of the second grouting pipe with the valve, the grouting pump and a cementing solution storage pond in sequence; and c. opening the valve and the slurry injection pump to grout for the stratum, wherein the microorganism slab grouting devices are lifted uniformly during grouting, and after grouting is completed, all microorganism slab grouting devices in the field are pulled out and stand for 12h, and finally, underground water is pumped out for sewage treatment. Compared with the prior art, the microorganism slab grouting device and method can simplify the procedures, shorten the duration and eliminate the problem of size effect.

Owner:NANJING FORESTRY UNIV

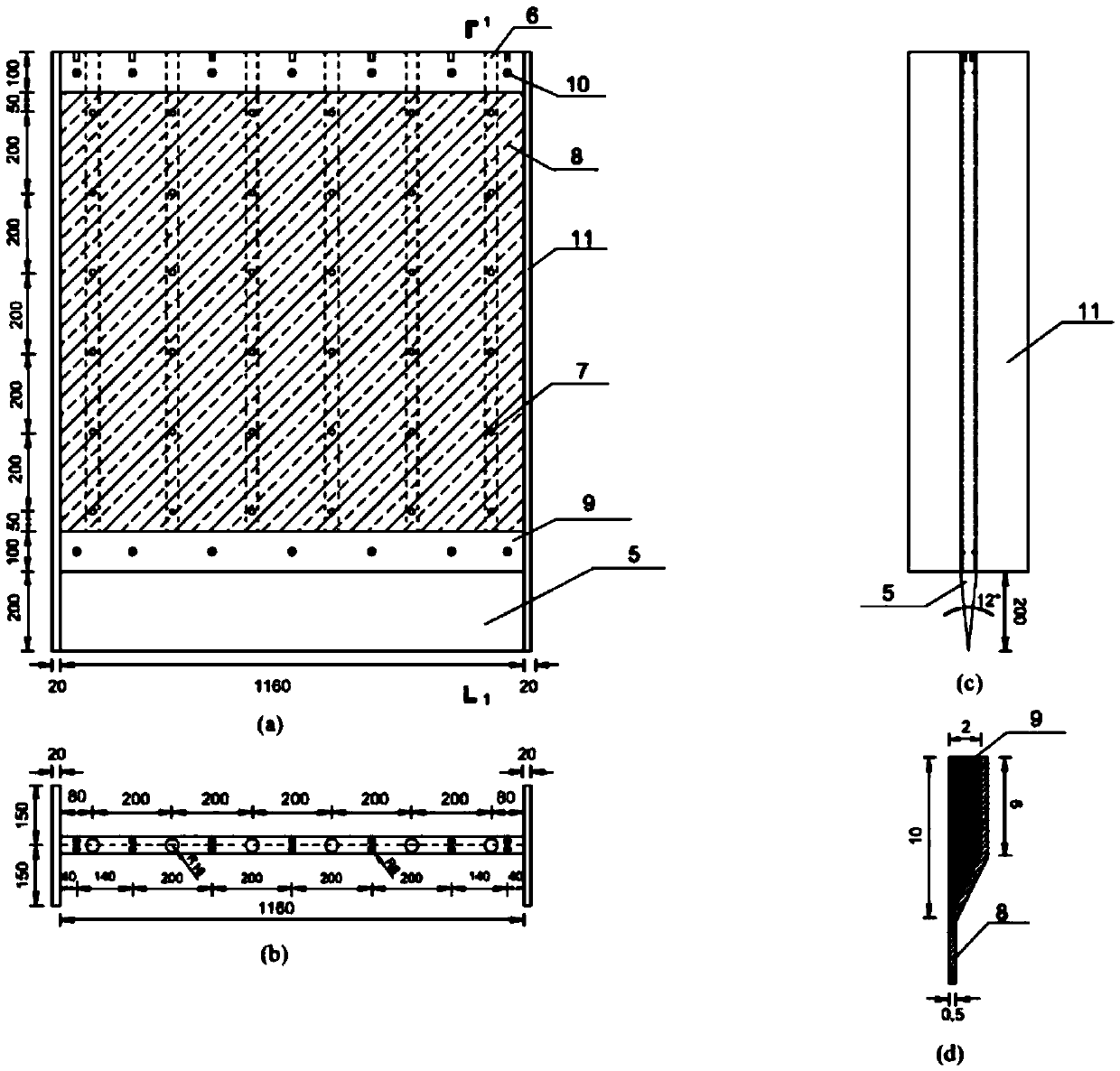

Method for calibrating thermal infrared imager pixel point

ActiveCN103076101AHigh precisionImprove non-uniformityRadiation pyrometryTemperature measurementVoltage

The invention discloses a method for calibrating a thermal infrared imager pixel point. The method comprises black-body radiation calibration and baffle temperature measurement. The mapping relation of the voltage V and temperature T of infrared imaging can be measured through the black-body radiation calibration. An n value which influences the thermal infrared imager pixel point temperature measurement accuracy is determined through deducing a baffle measured value and calculated value calculation formula for a plurality of times, and accordingly, the thermal infrared imager temperature measurement accuracy is increased. The method has the following advantages that 1, a baffle device temperature measurement method is adopted, the precision of n in a thermal infrared imaging temperature measurement formula is effectively improved, and accordingly, the thermal infrared imaging temperature measurement accuracy is improved; 2, the thermal infrared imaging temperature measurement unevenness can be effectively improved through accurately correcting each pixel of an infrared detector; 3, the baffle emissivity influence on an experiment result is not taken into consideration during the measurement experiment; and 4, the temperature influence on the experiment result is not taken into consideration during the measurement experiment.

Owner:WUXI ALEADER INTELLIGENT TECH

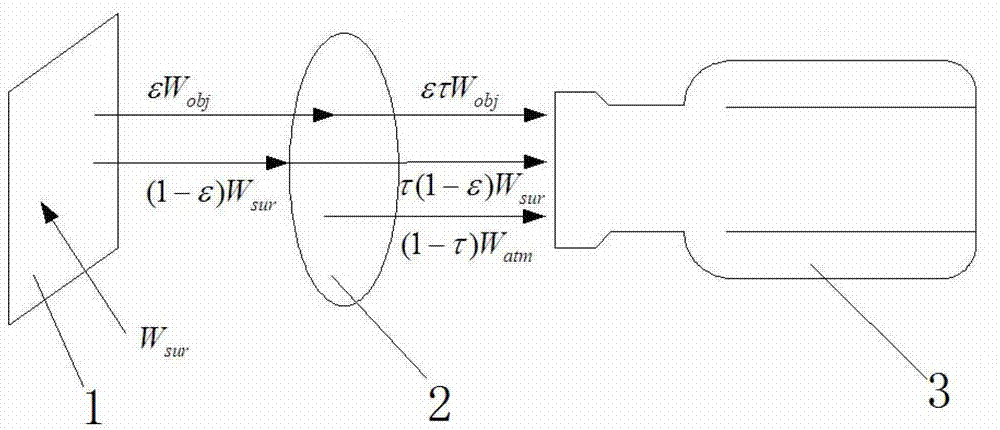

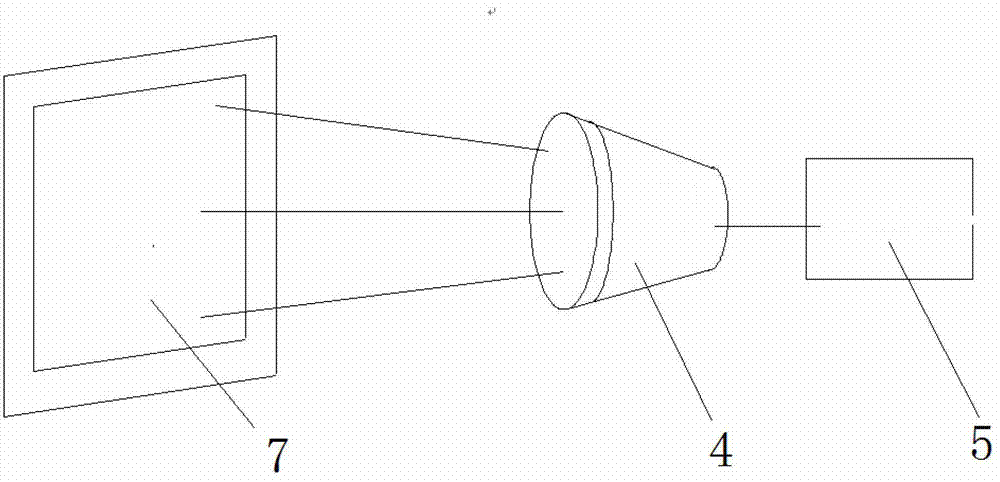

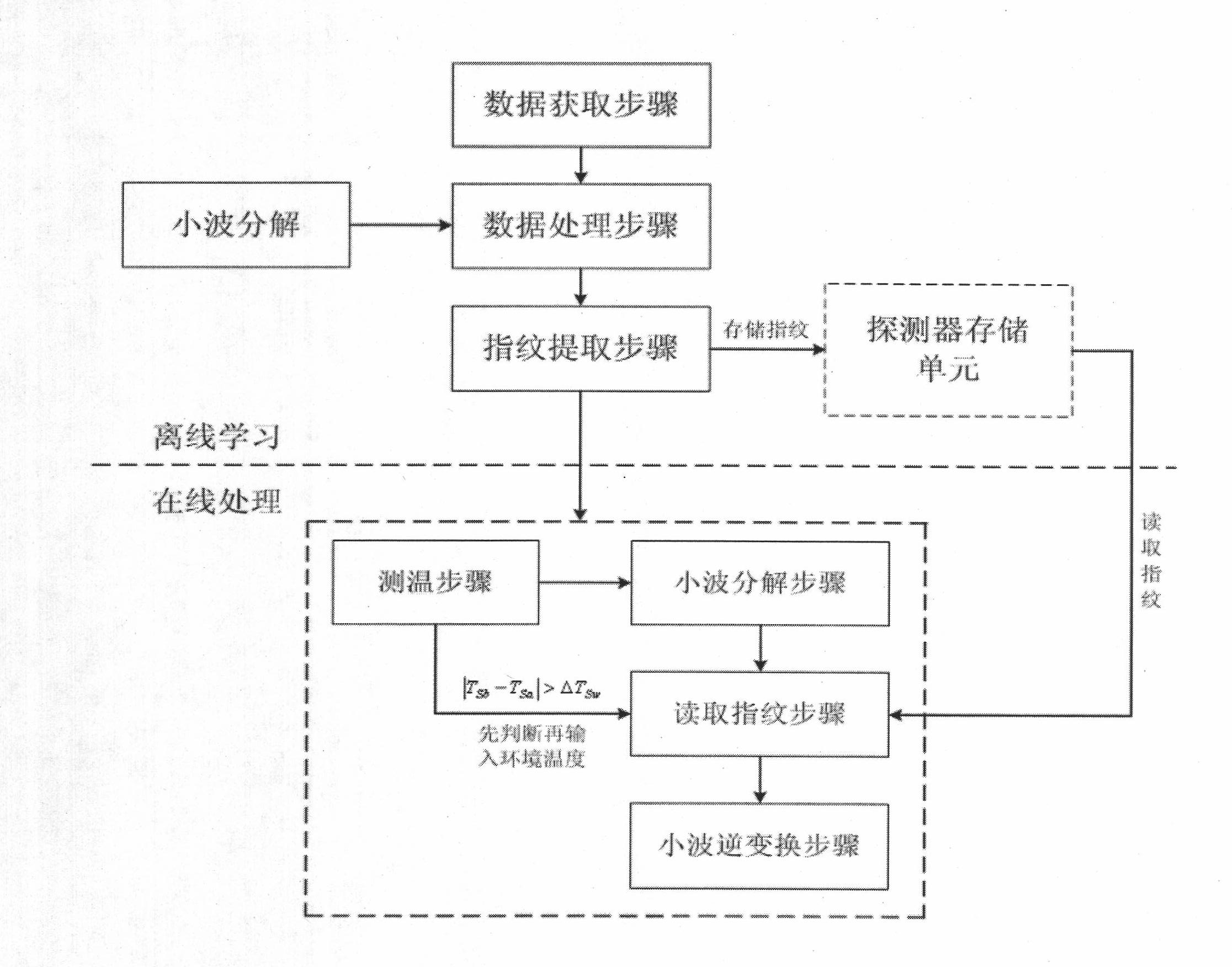

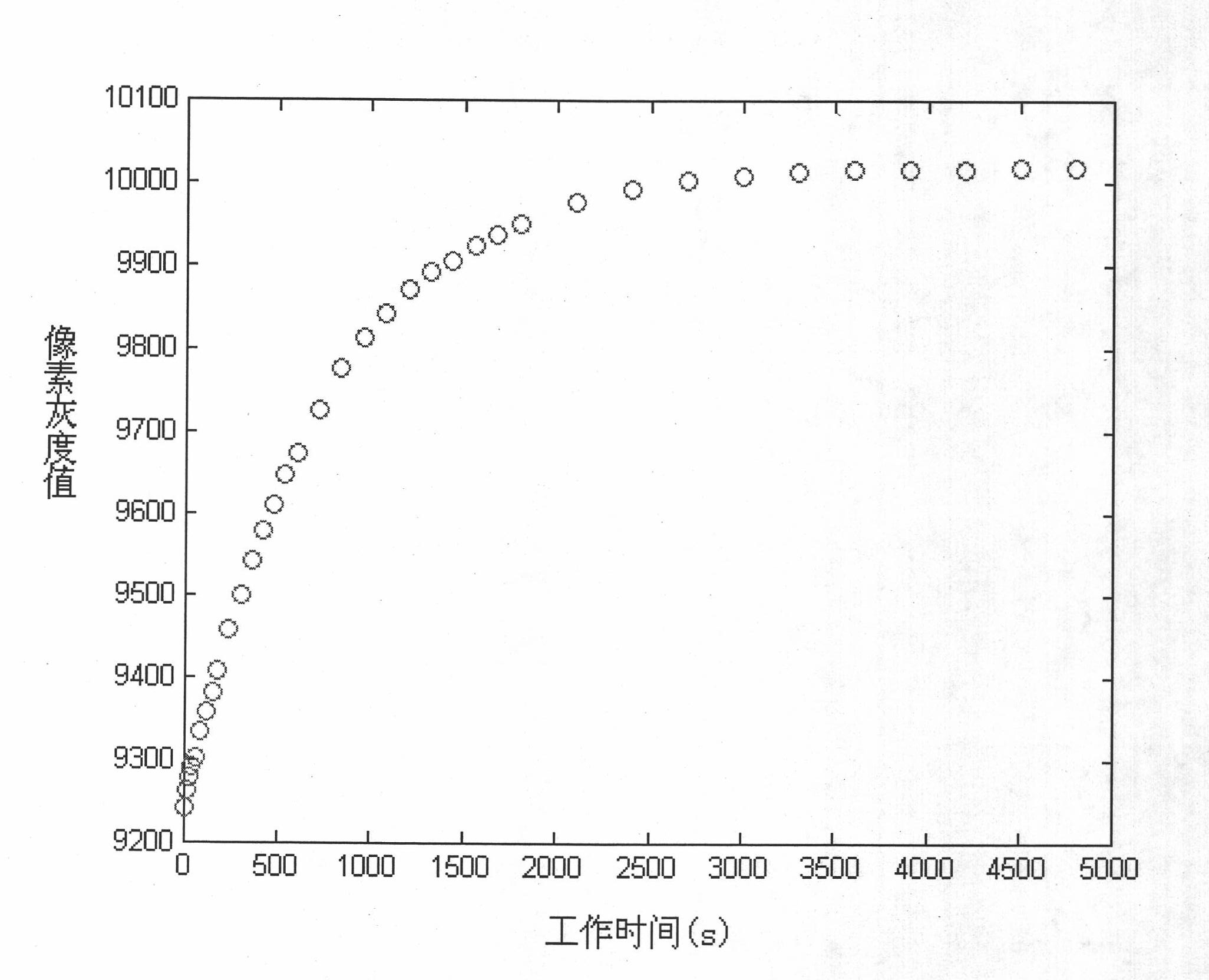

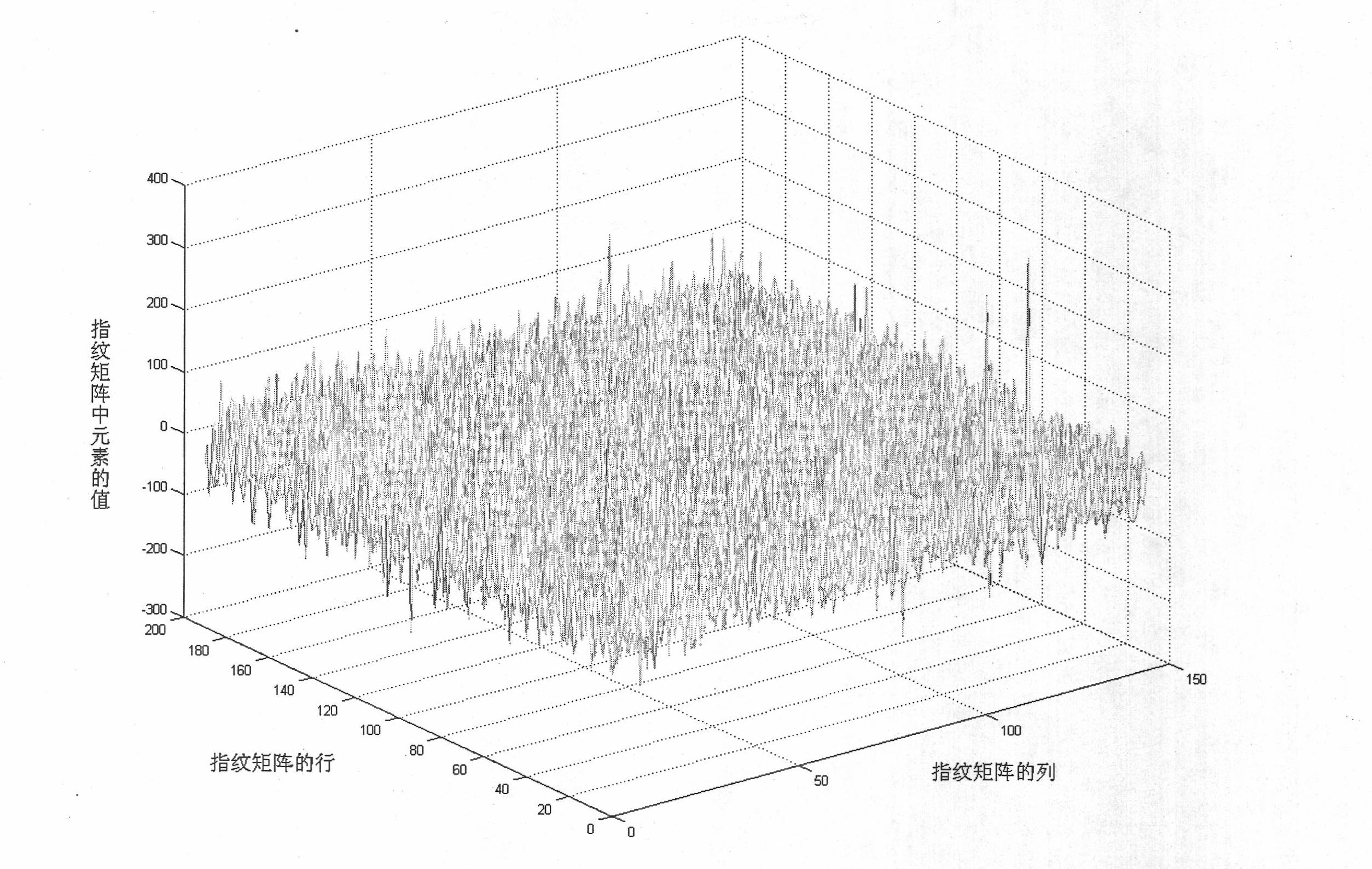

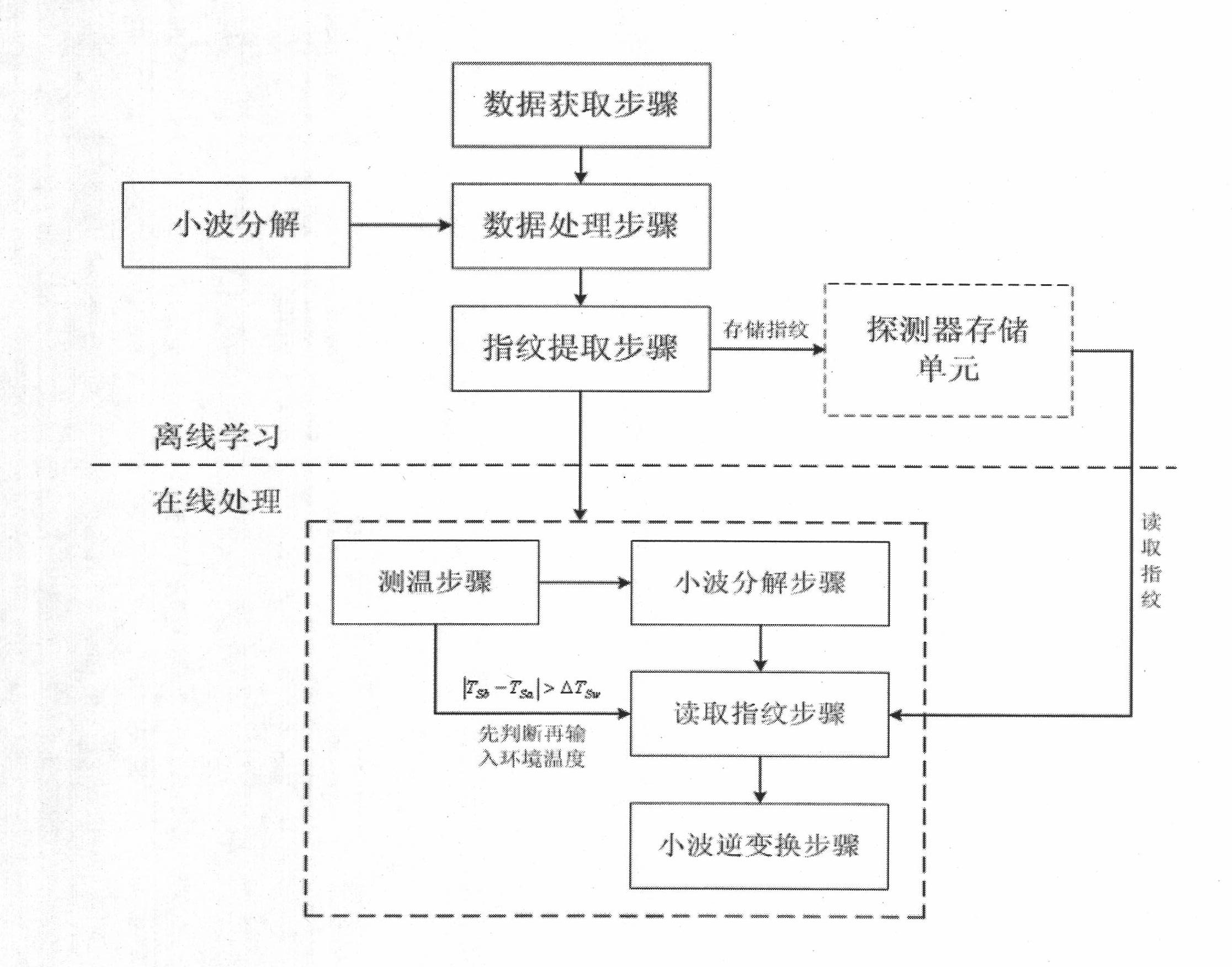

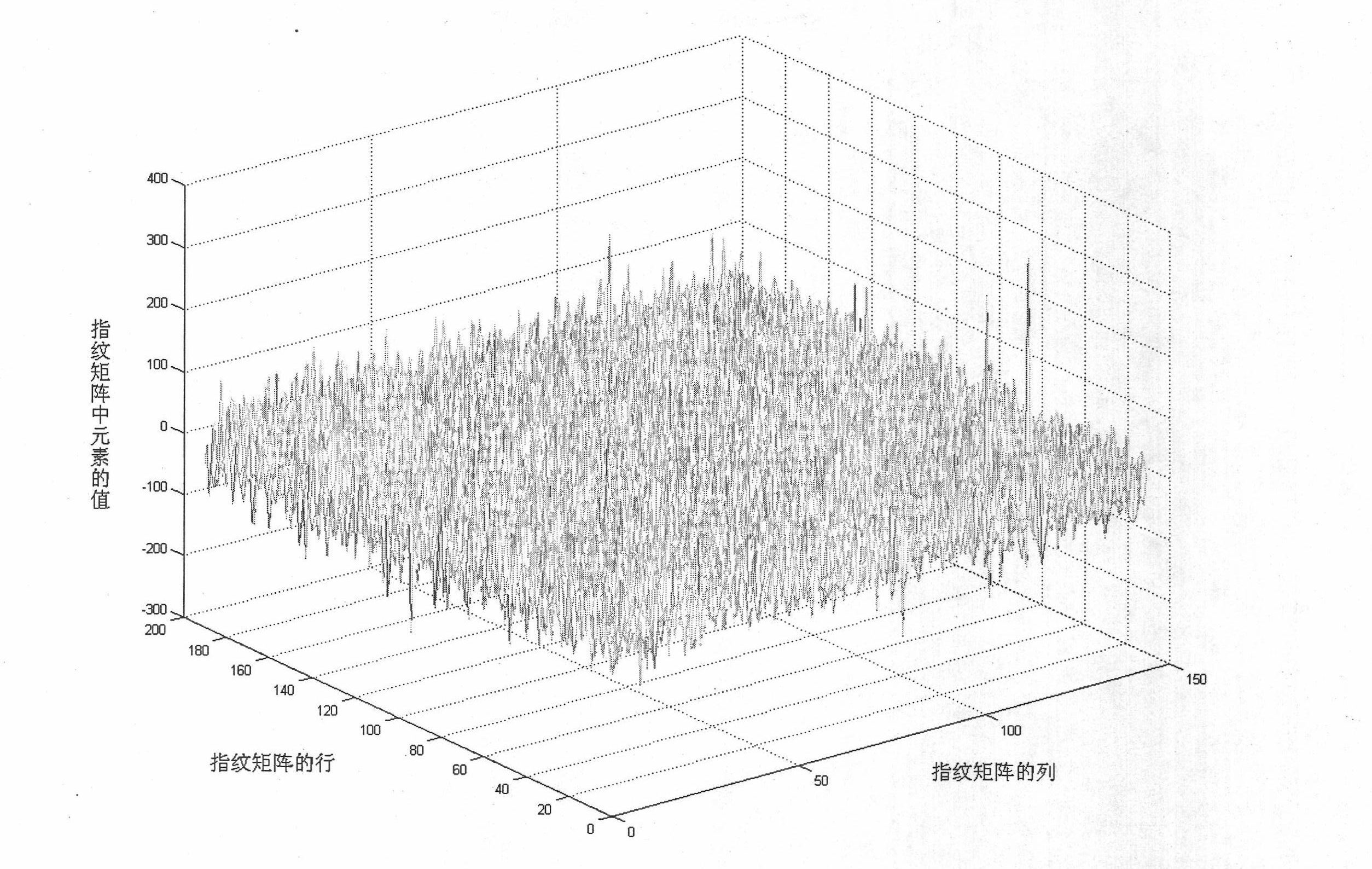

Infrared focal plane non-uniformity fingerprint extraction and image correction method

ActiveCN101776487AClear thinkingImprove non-uniformityTelevision system detailsRadiation pyrometryInfraredWavelet decomposition

The invention relates to an infrared focal plane non-uniformity fingerprint extraction and image correction method which belongs to the technical field of infrared imaging. A production process decides, each infrared focal plane is provided with a relatively stable non-uniformity mode and a rule thereof which varies with temperature, and the two are collectively called fingerprints. The invention provides the definitions of non-conformity fingerprints, analyzes the characteristics of the focal plane non-uniformity in a frequency domain by wavelet decomposition, extracts the non-uniformity fingerprints which belong to the focal plane, and then stores the fingerprints in a storage unit of a detector. When in correction, with the environment temperature as the input parameter, the method can carry out non-uniformity correction under the constraint of the fingerprints after reading the non-uniformity fingerprints at the environment temperature. Compared with convention methods, the method does not need to obtain a background frame with a uniform baffle in every time of correction and has simple correction idea, thereby simplifying the correction device and the correction process, and the image non-uniformity after correction is significantly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

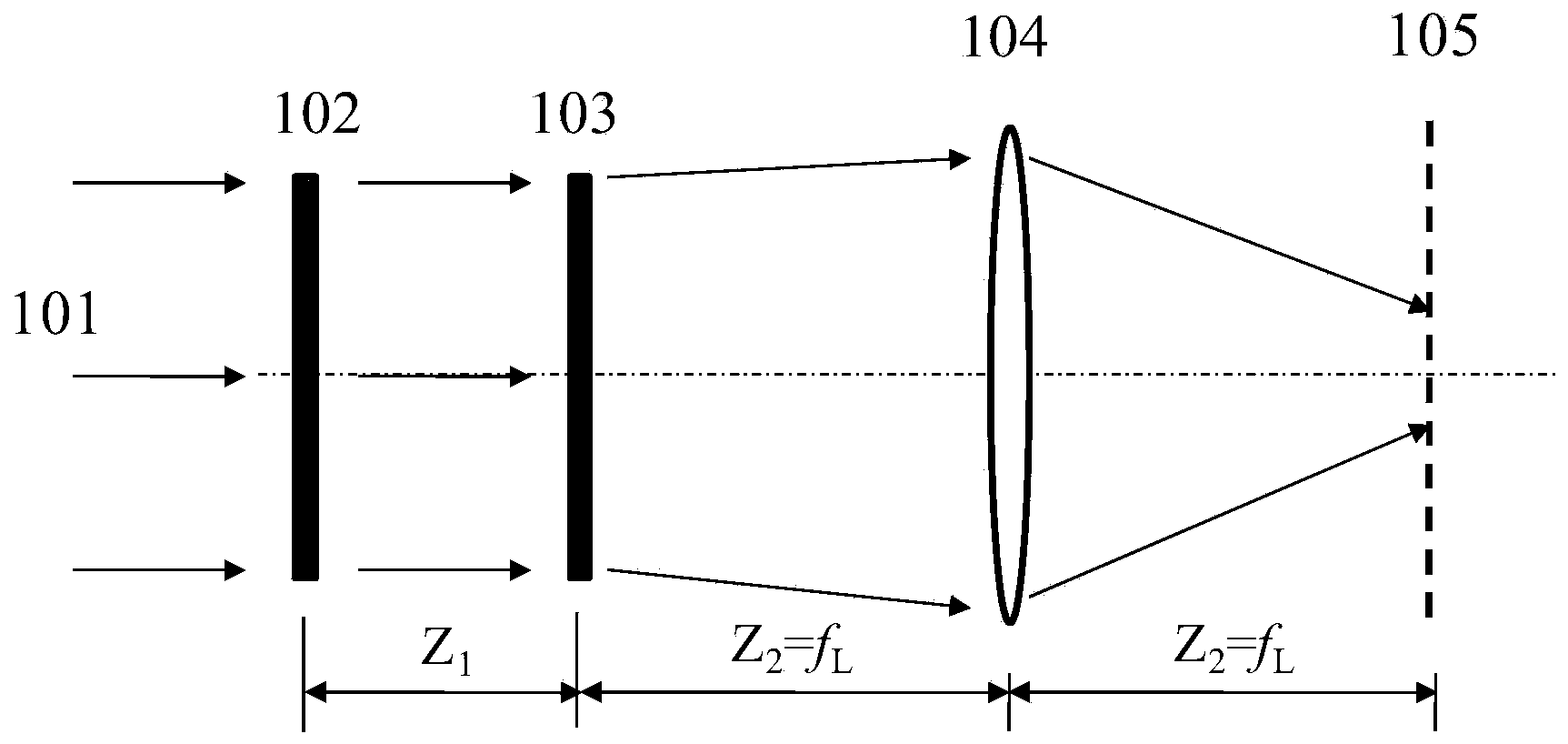

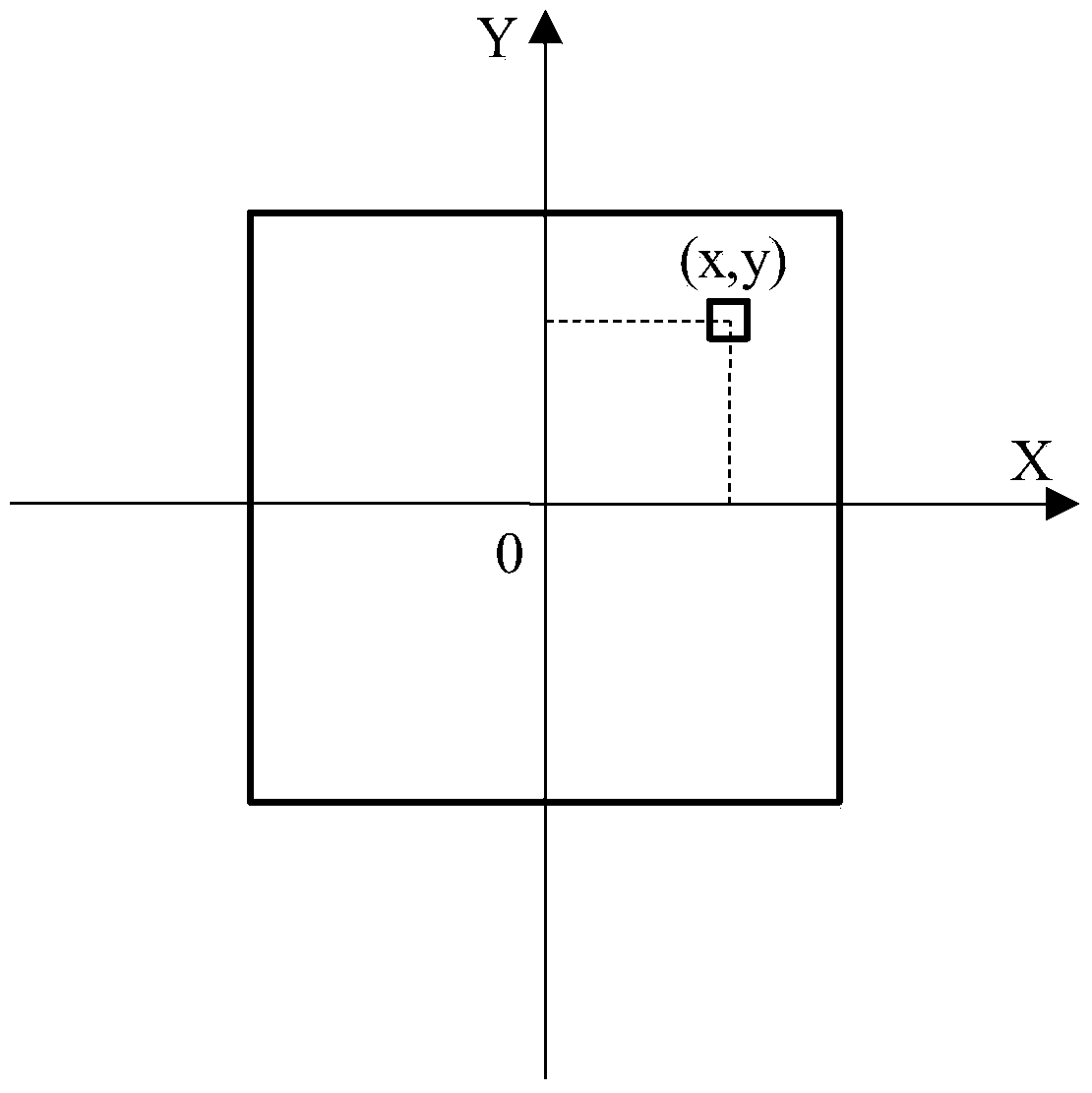

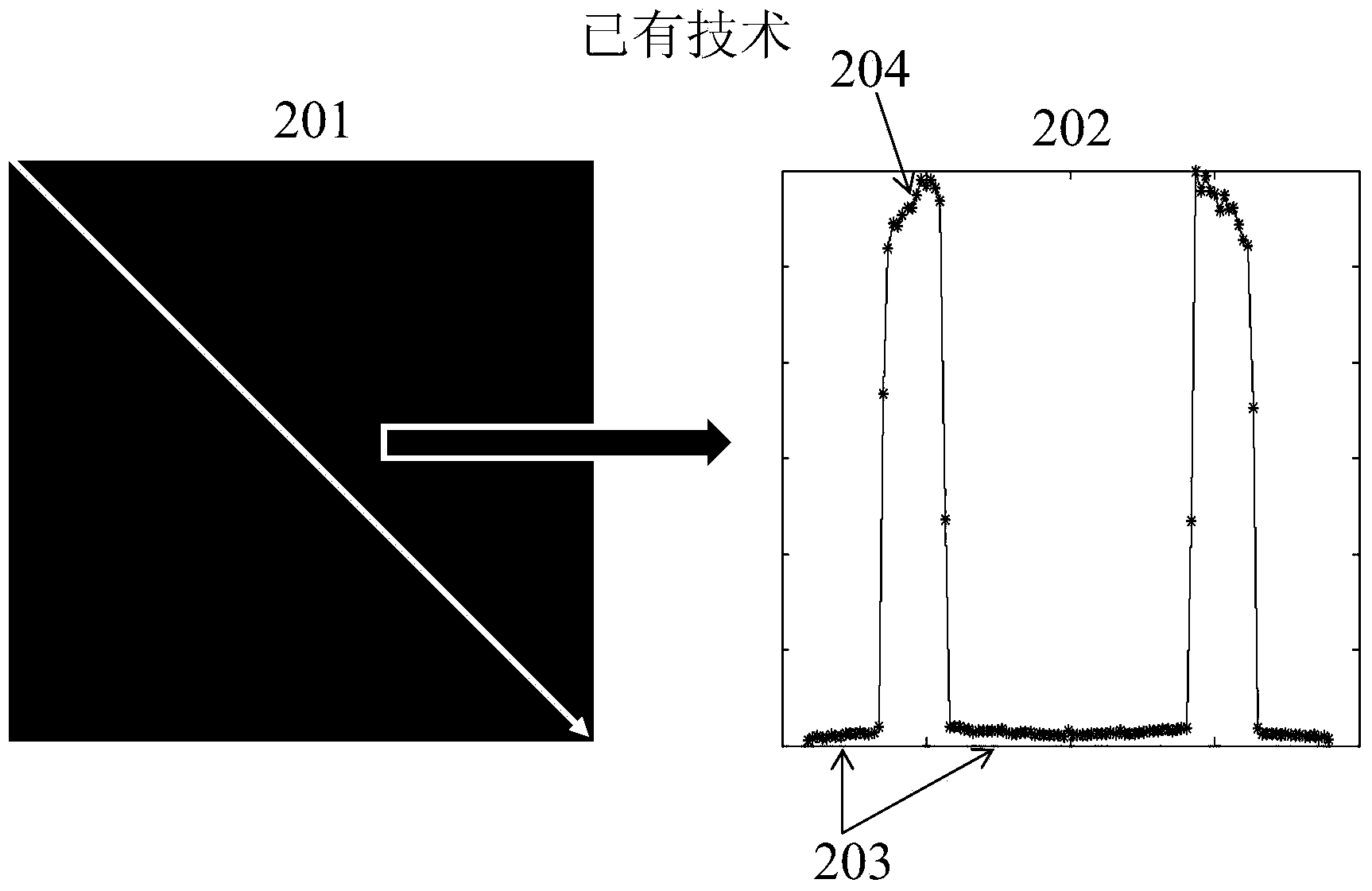

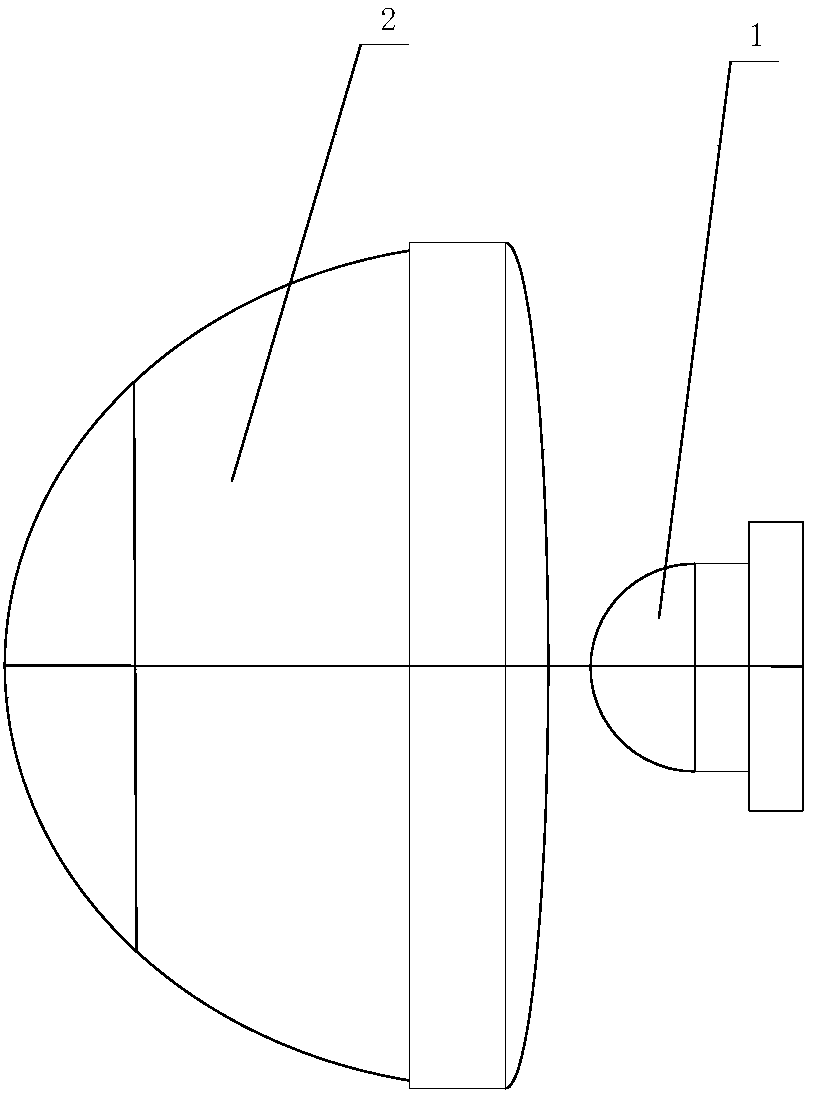

Pupil shaping unit structure of lithography machine and design method for diffraction optical element of pupil shaping unit structure

ActiveCN103676498AMultiple Design FreedomHigh diffraction efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusUnit structureDiscretization

The invention discloses a pupil shaping unit structure of a lithography machine and a design method for a diffraction optical element of the pupil shaping unit structure. The pupil shaping unit structure comprises a cascade diffraction optical element and a varifocal collimating lens group, wherein the cascade diffraction optical element comprises a first diffraction optical element and a second diffraction optical element; the light transmittance surfaces of the two diffraction optical elements are perpendicular to the optical axis of a lighting system; the two diffraction optical elements are pure phase elements. The design method for the cascade diffraction optical element comprises the following steps of calculating a period of a phase unit; enabling a light beam to be incident, determining the light intensity distribution of the required optical beam and performing discretization processing; entitling initial phase matrixes of the first diffraction optical element and the second diffraction optical element; performing quantification processing through an iteration algorithm to obtain quantified phase matrixes of the first diffraction optical element and the second diffraction optical element; evaluating a design result.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

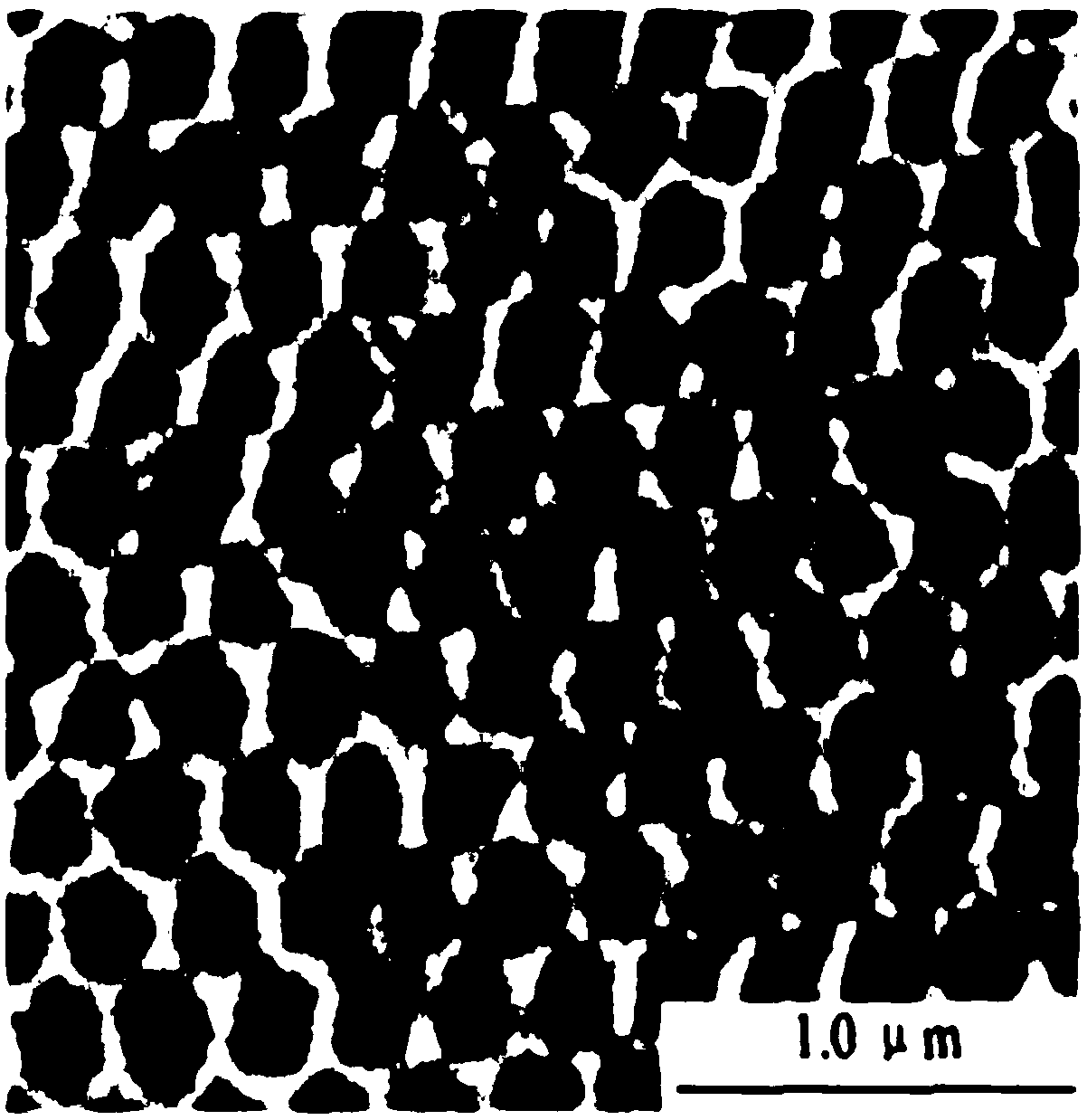

Porous materials

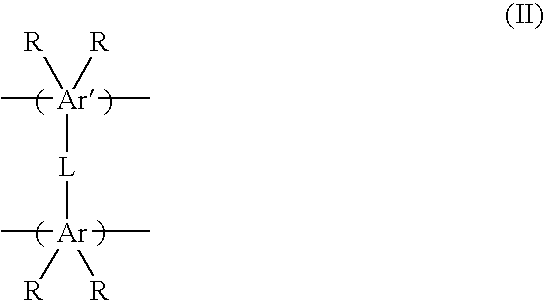

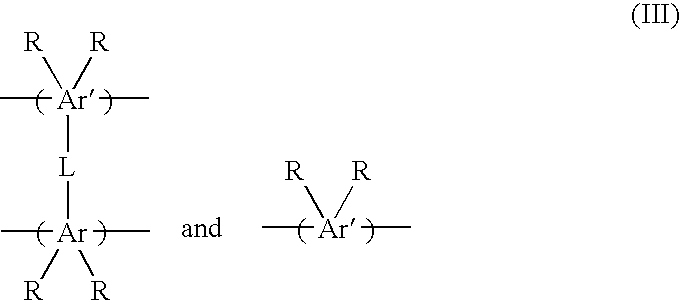

InactiveUS6998148B1Improve non-uniformityIncrease in sizeSemiconductor/solid-state device detailsSolid-state devicesElectronic componentMaterials science

Porous thermoset dielectric materials having low dielectric constants useful in electronic component manufacture are provided along with methods of preparing the porous thermoset dielectric materials. Also provided are methods of forming integrated circuits containing such porous thermoset dielectric material.

Owner:SHIPLEY CO LLC

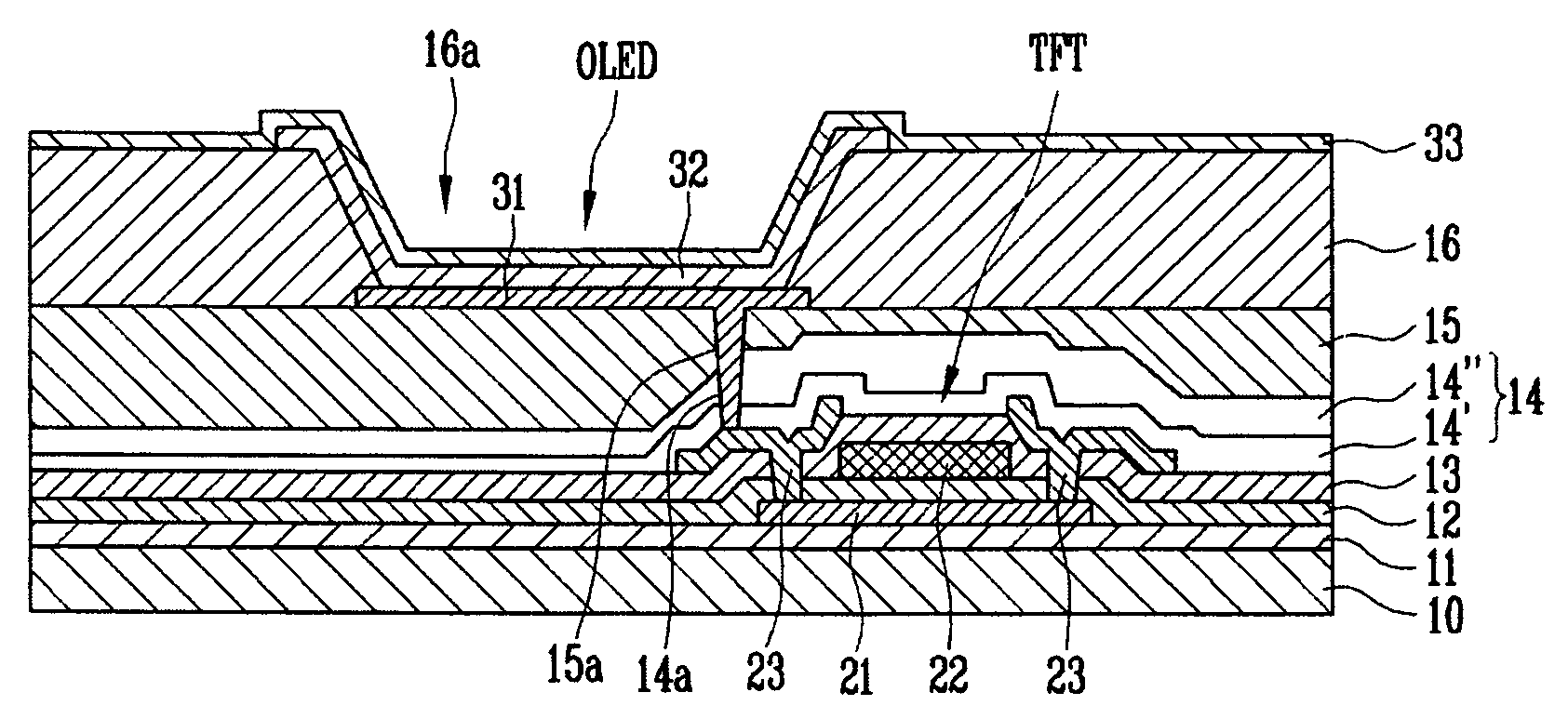

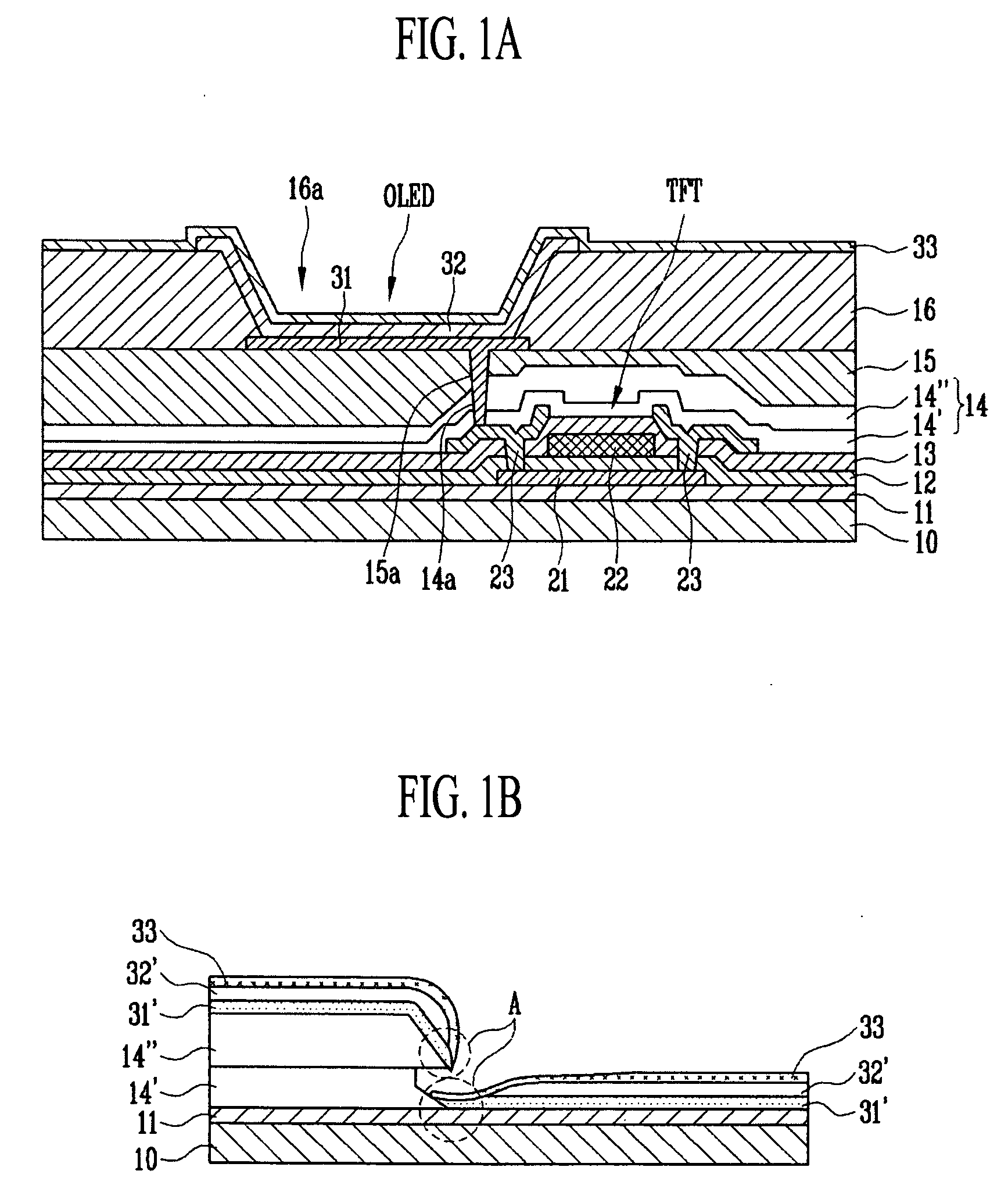

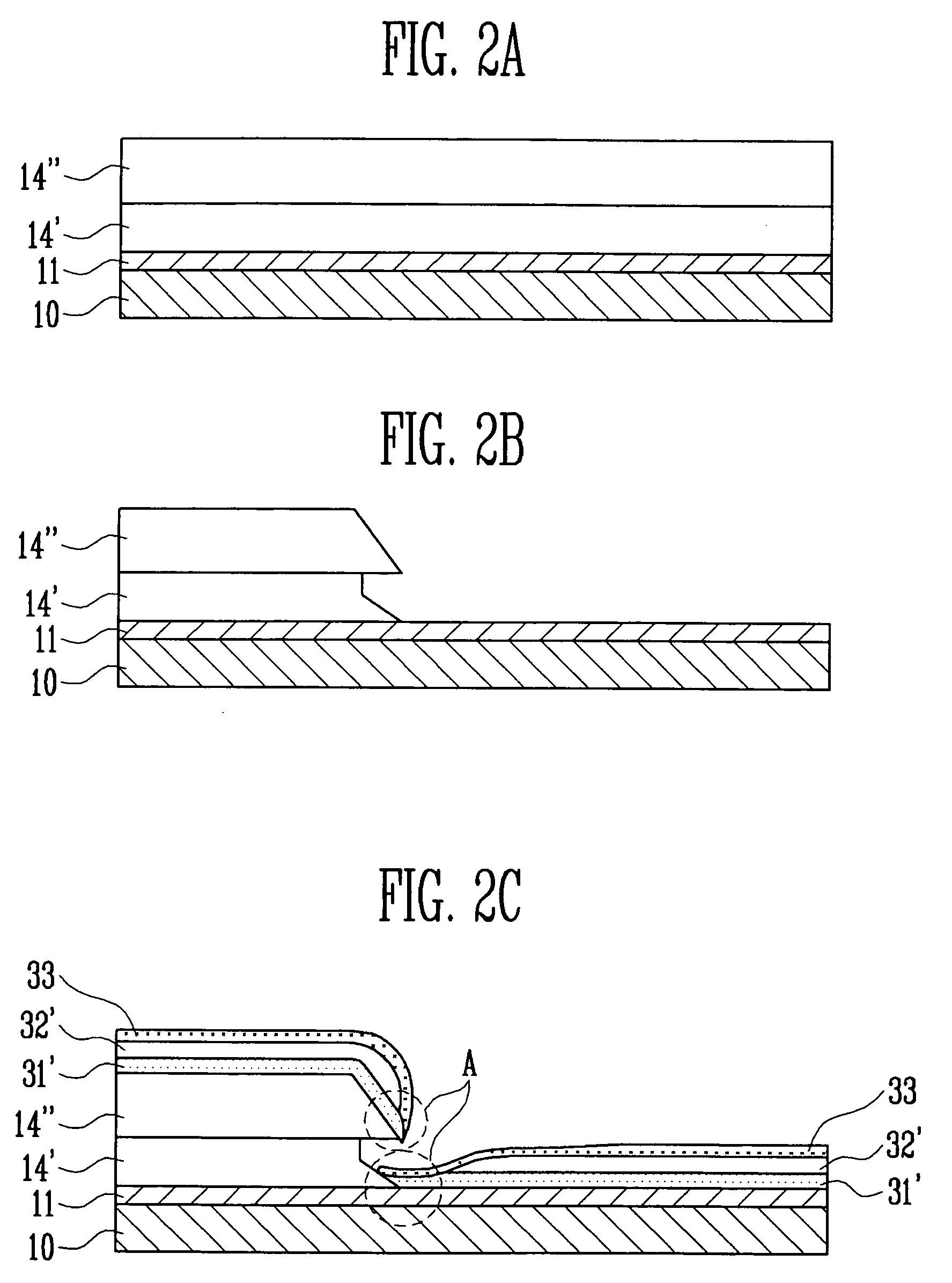

Organic light emitting display and its method of fabrication

ActiveUS20090309493A1Lower resistanceImprove non uniformityDischarge tube luminescnet screensLamp detailsAuxiliary electrodeOptoelectronics

An organic light emitting display is divided into a light emitting region and a non-light emitting region, the non-light emitting region of the organic light emitting display including: a first substrate; a first passivation layer and a second passivation layer sequentially arranged on the first substrate and having a step in an undercut shape; and an auxiliary electrode layer, an El common layer, and a second layer sequentially arranged throughout the non-light emitting region including the first and second passivation layers, the auxiliary electrode layer being shorted to the second layer in the step at the slope of the second passivation layer or shorted to the first passivation layer in the undercut shape arranged under the second passivation layer.

Owner:SAMSUNG DISPLAY CO LTD

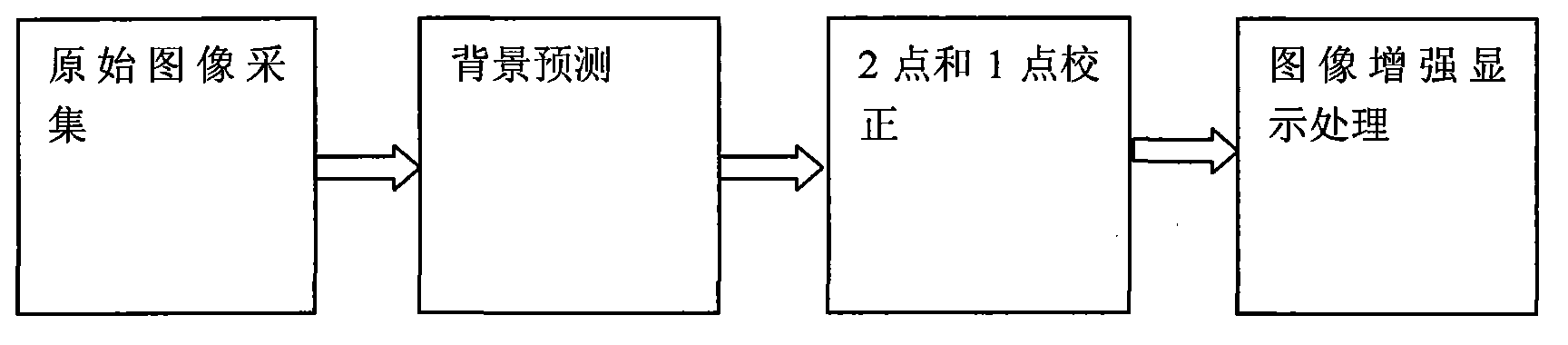

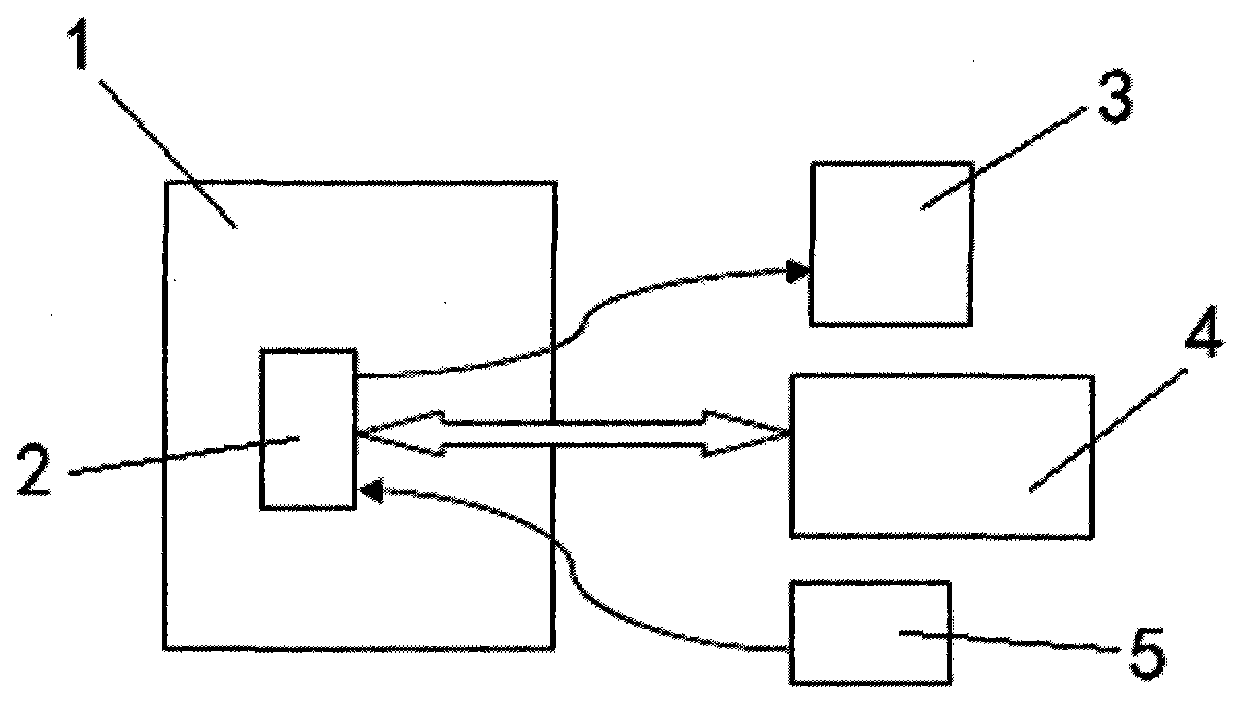

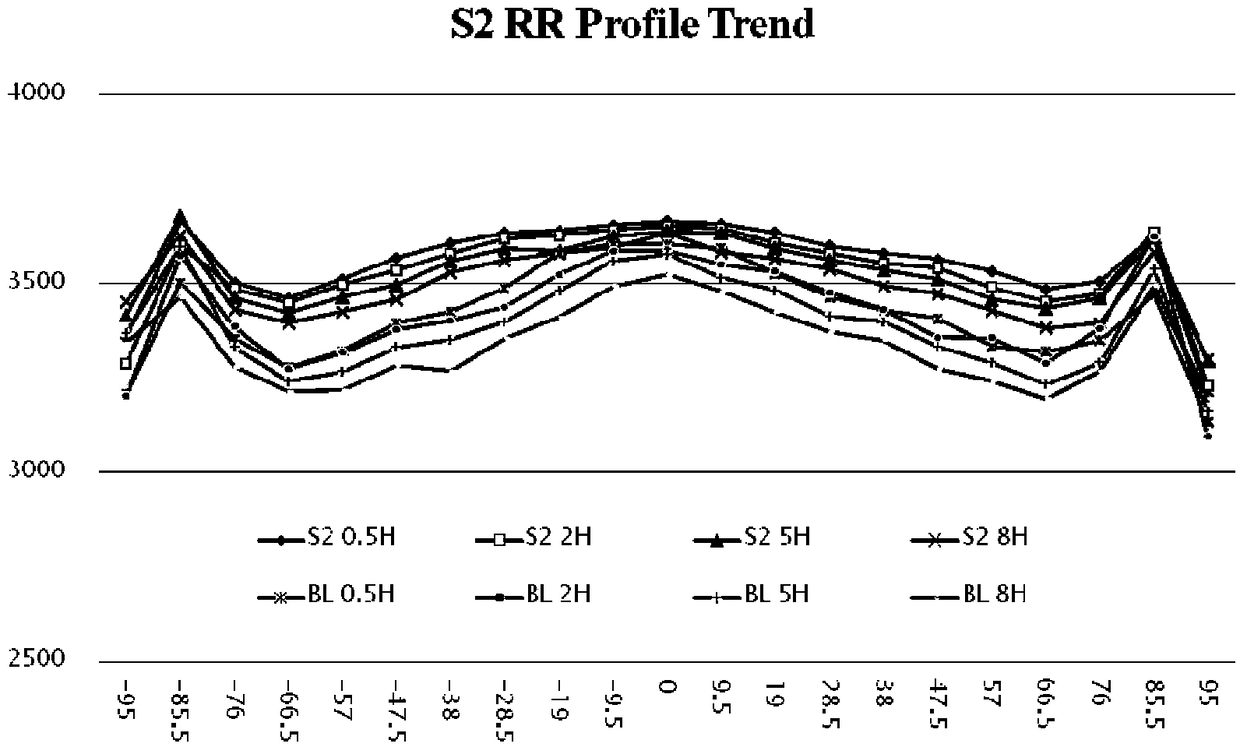

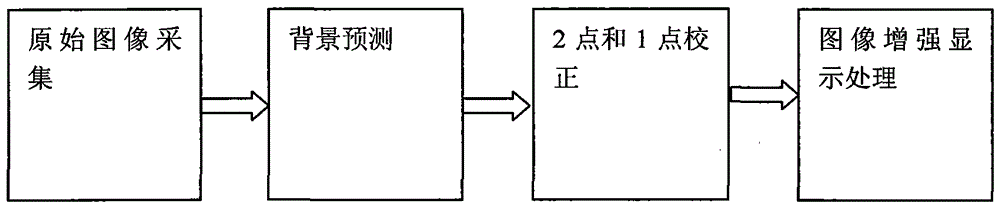

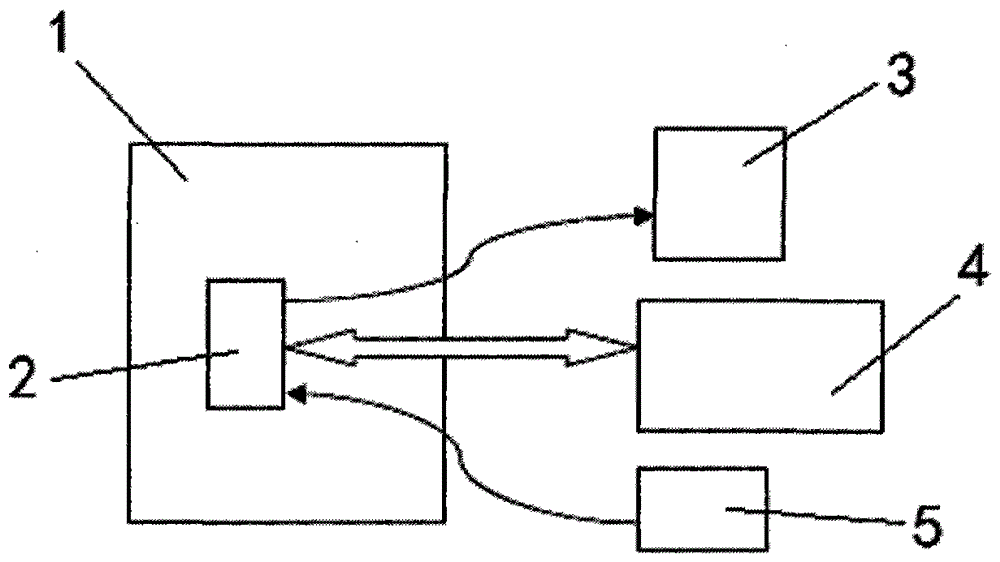

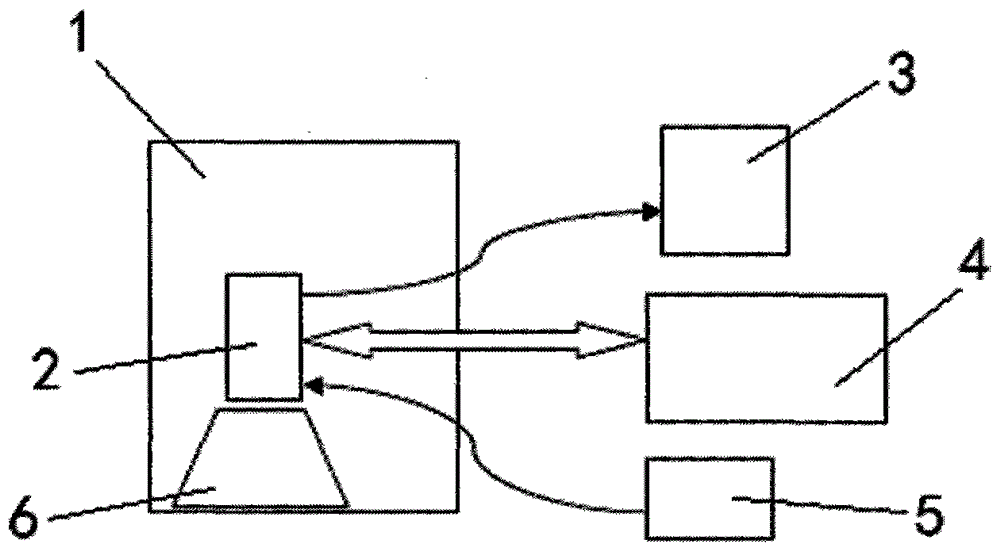

Zero shutter thermal infrared imager based on voice operated exchange (VOX) detector and use method thereof

InactiveCN103162843AEliminate residual errorsImprove non-uniformityPyrometry using electric radation detectorsThermodynamicsSystems design

The invention relates to a zero shutter thermal infrared imager based on a voice operated exchange (VOX) detector. The zero shutter thermal infrared imager based on the VOX detector comprises a high-low temperature chamber and a machine core, wherein a monitor, a computer and a power source are respectively connected with the machine core. The use method of the thermal infrared imager includes the following steps: collecting original images; forecasting a background; revising a point 2 and a point 1; and performing image enhancement display processing. Compared with a usual shutter revision method, the zero shutter thermal infrared imager based on the VOX detector and the use method thereof can effectively reduce the size and the power consumption of an infrared machine core, are unlike a conventional method in which a shutter needs to be used to obtain uniform images at every time of revision, and use the original images as background images to revise, and therefore system design is simplified greatly, the size and the power consumption are reduced, and simultaneously due to zero shutter design, the problems of uneven images caused by heat emitting of the shutter and the like are avoided.

Owner:北京红源盛达光电技术有限公司

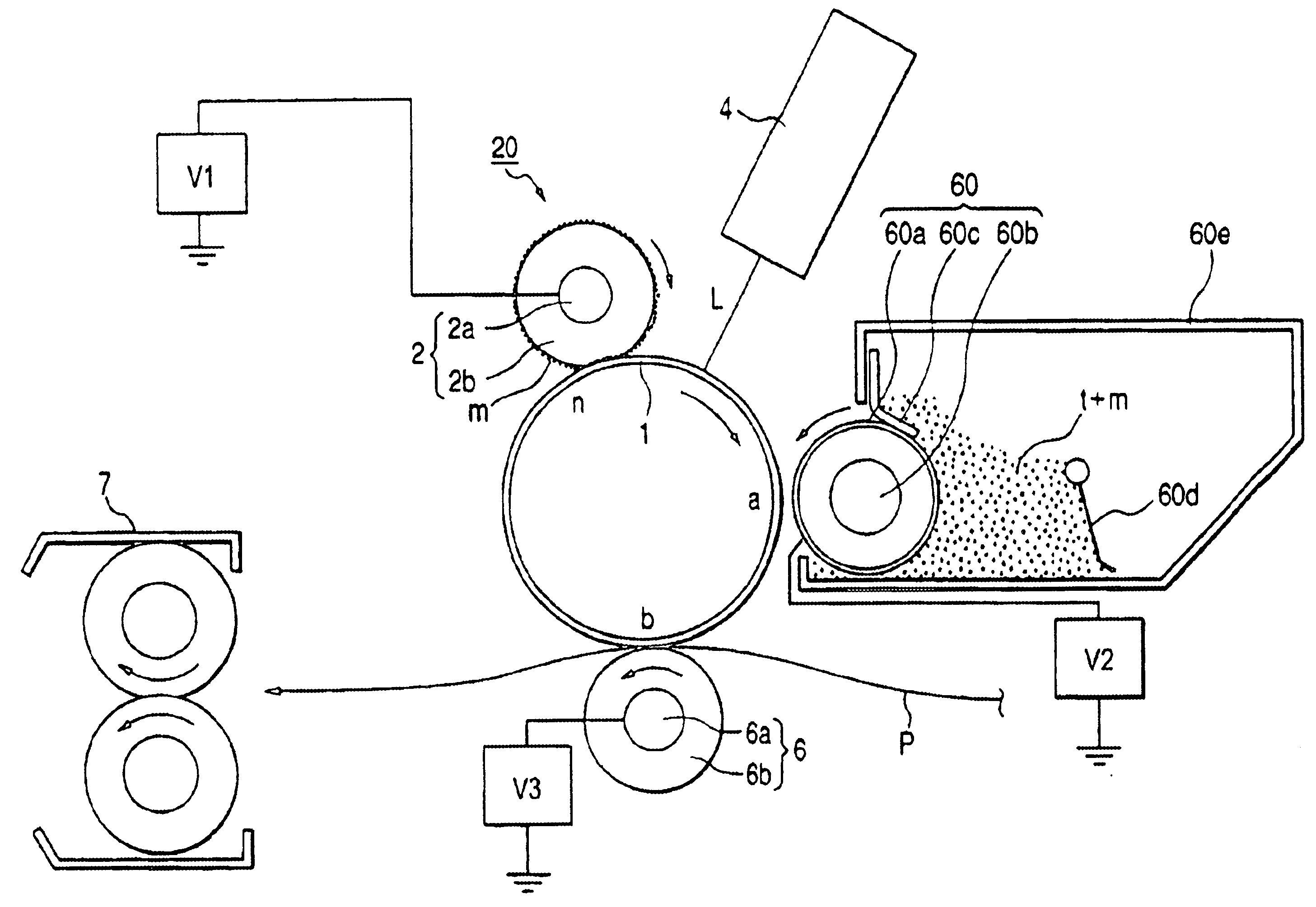

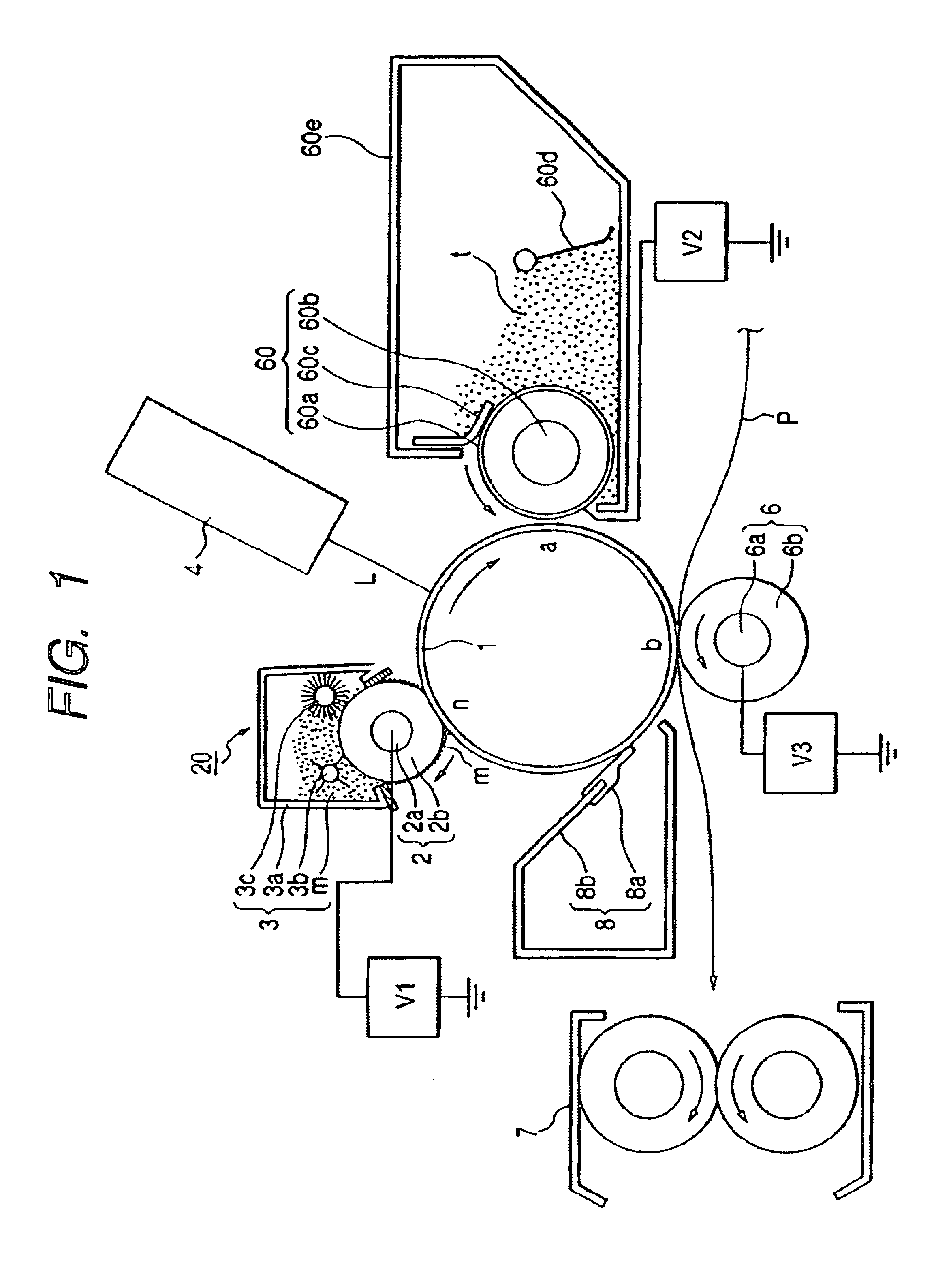

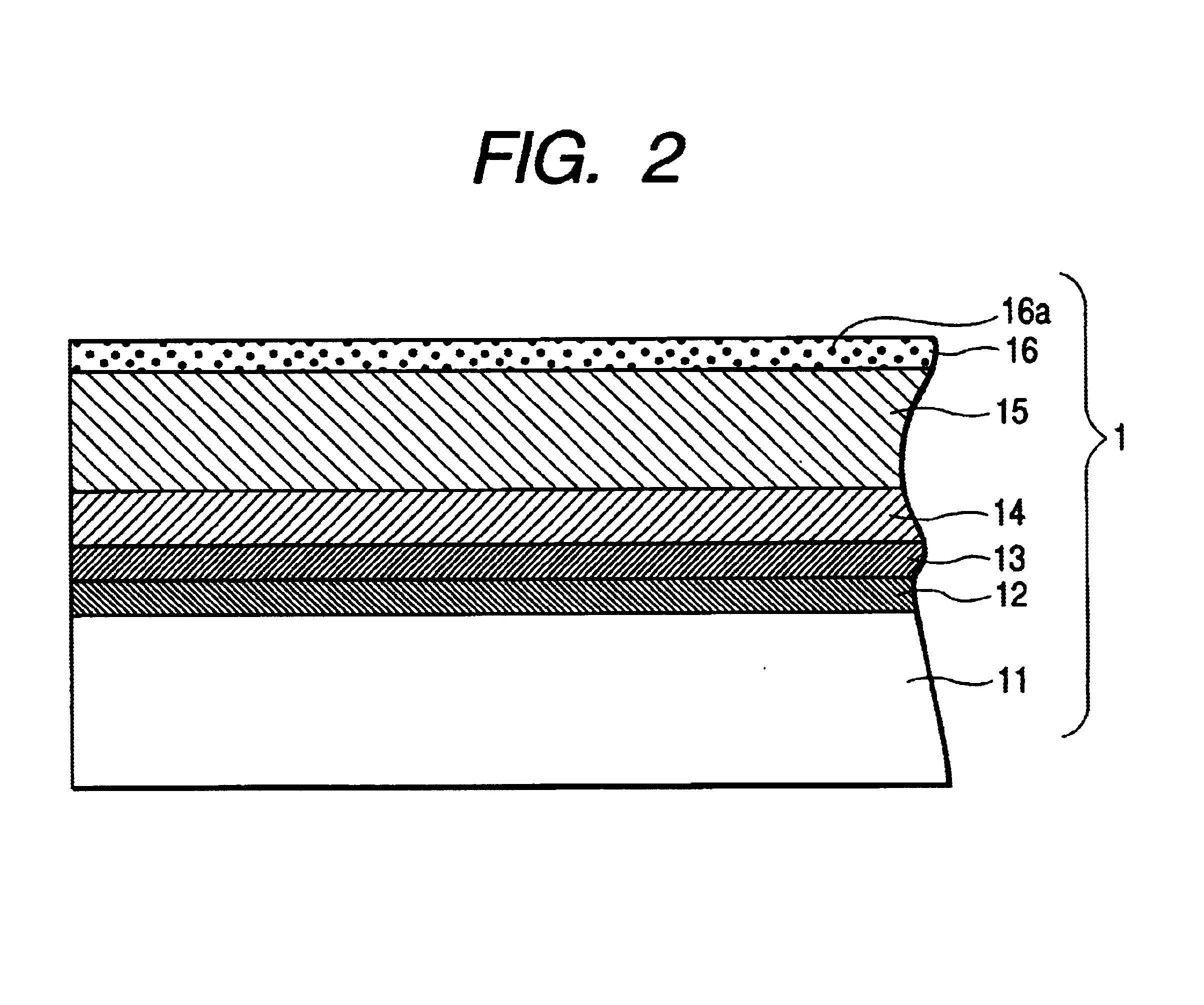

Charging member and image forming apparatus provided with the same

InactiveUS6847796B2Improve non uniformityIncreased non-uniformityElectrographic process apparatusCorona dischargeElectrically conductiveColor tone

A charging member for charging a member to be charged and an image forming apparatus provided with the same have electrically conductive particles and an electrically conductive particle bearing member having elasticity and bearing the electrically conductive particles thereon, and the degree of cohesion of the electrically conductive particles is 0.1 to 85%. Thereby, the non-uniformity of a halftone image peculiar to particle charging can be improved.

Owner:CANON KK

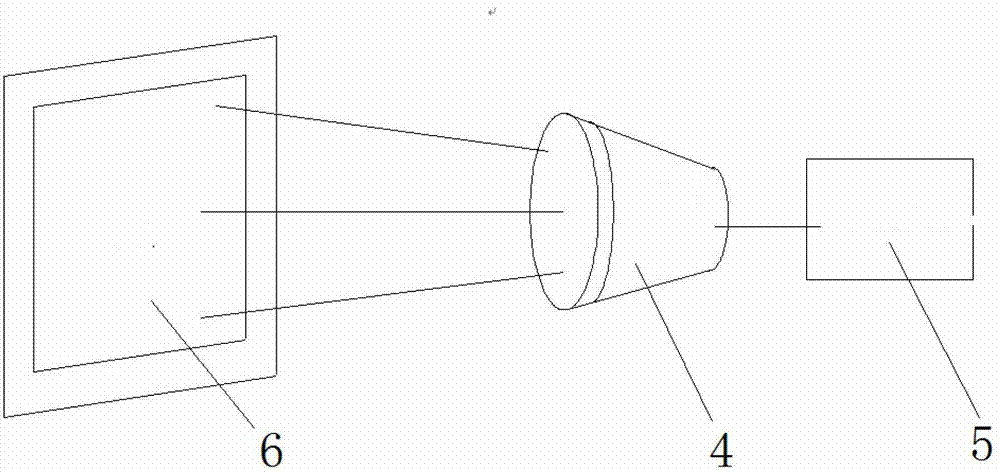

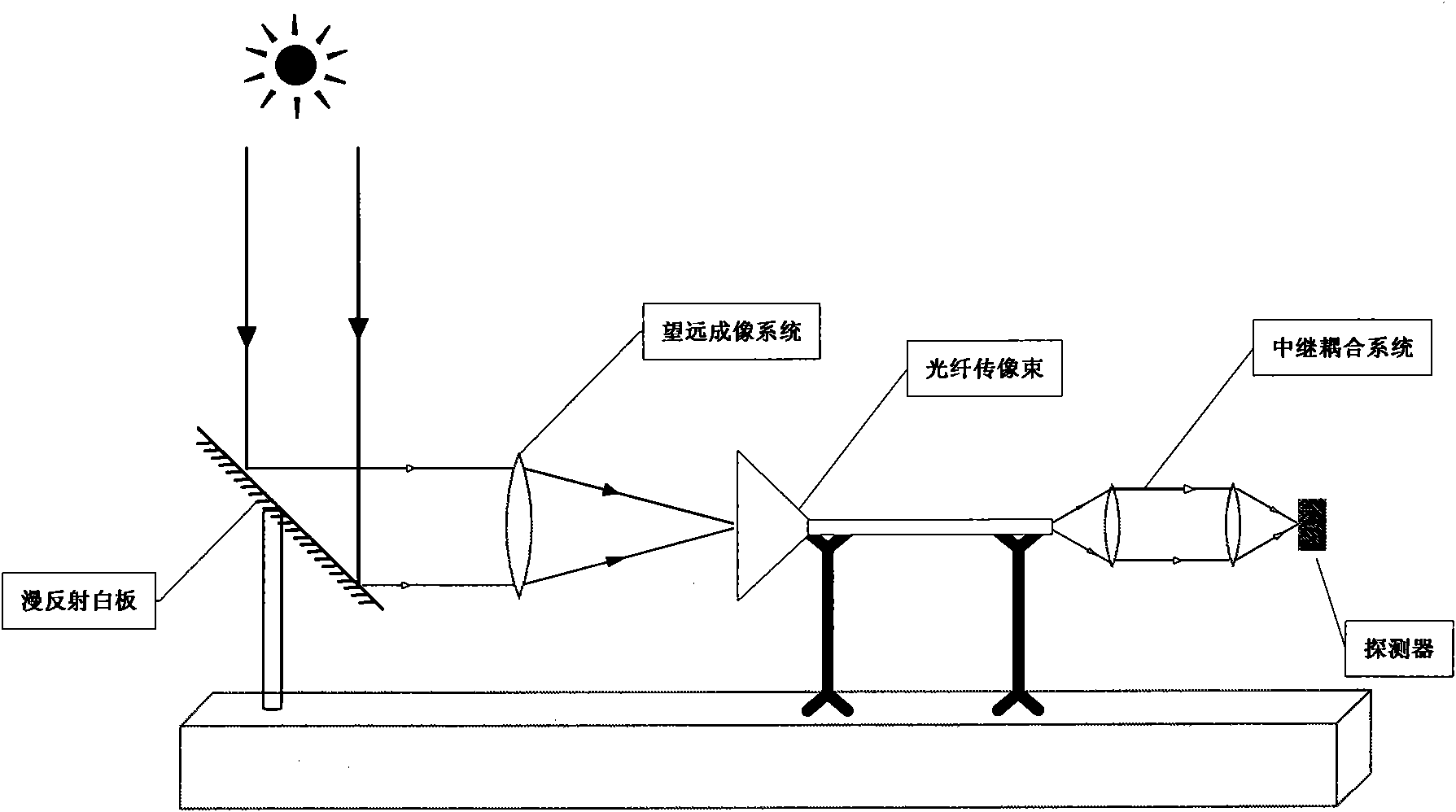

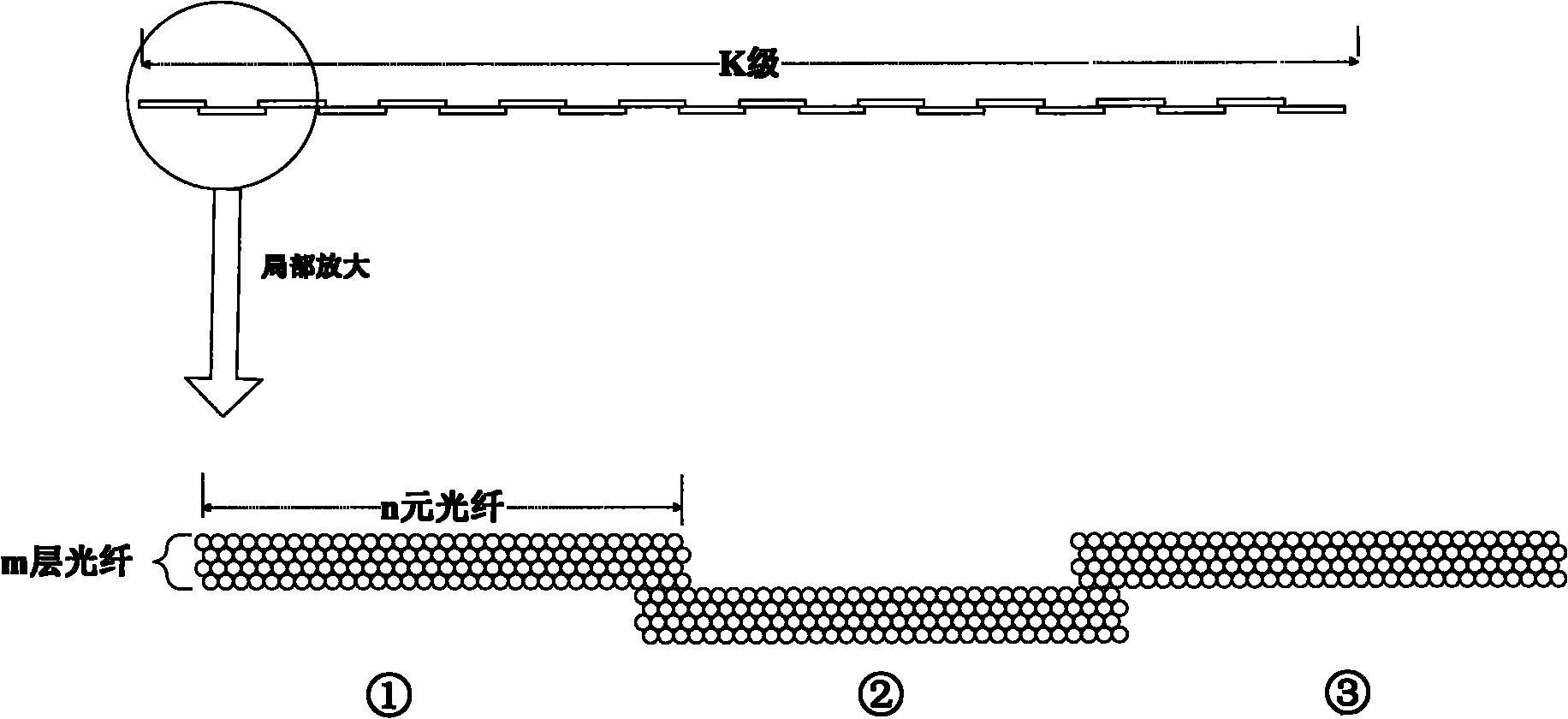

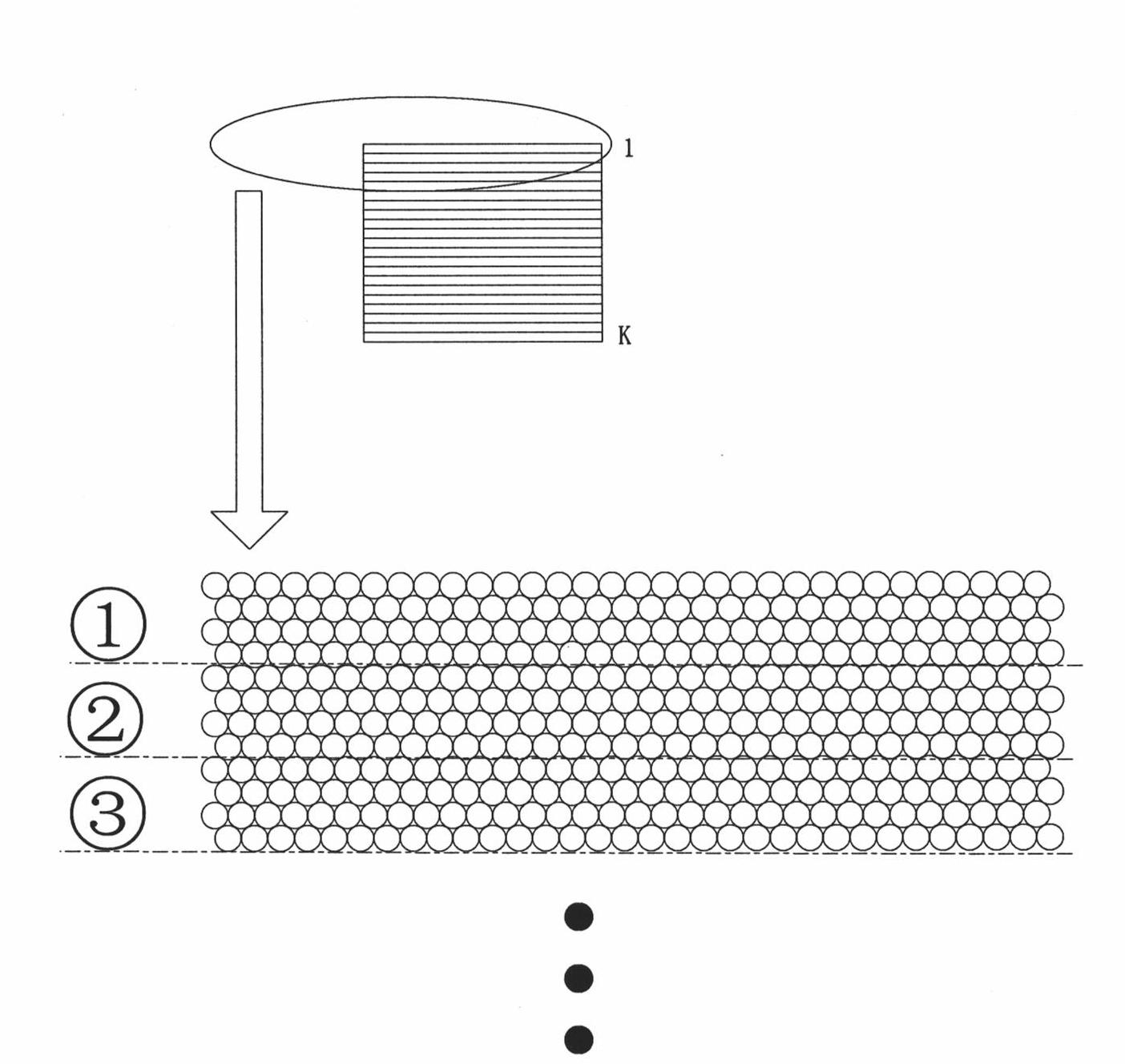

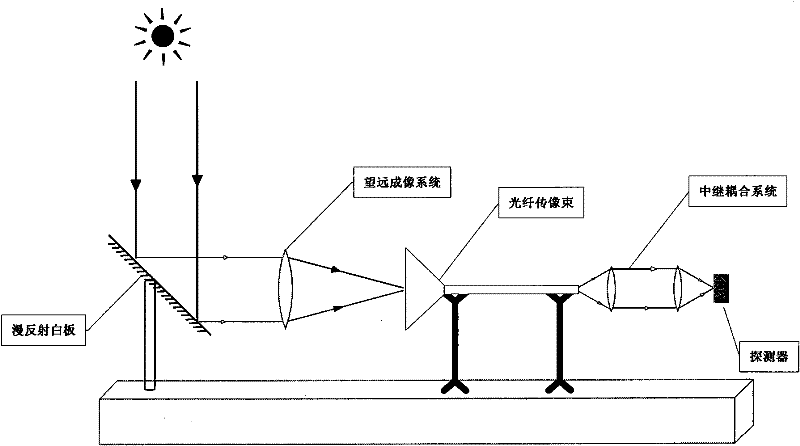

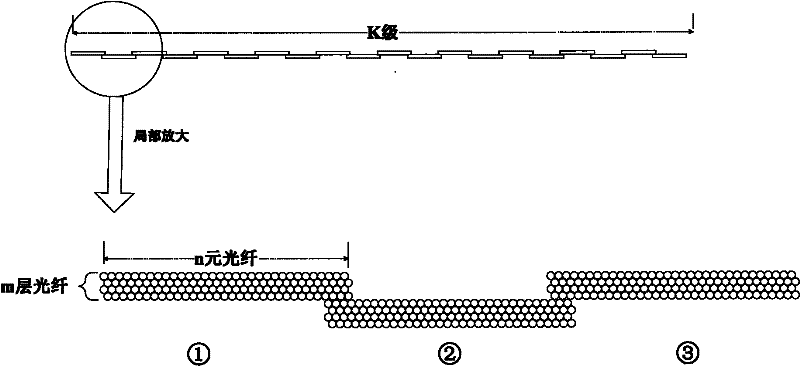

Method for correcting heterogeneities in optical beam image transmission system

InactiveCN101833755AImprove non-uniformityPositive non-uniformityImage enhancementBundled fibre light guideImaging analysisLine array

The invention discloses a method for correcting heterogeneities in a line-face conversion type optical beam image transmission system. The method is used for correcting in a photoelectrical system of an ultra-long line array detector for acquiring line-face conversion type optical beams by adopting a multi-section type graded one point method. After the method is used, the heterogeneities of images are obviously improved, thereby laying foundation for subsequent image analysis.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

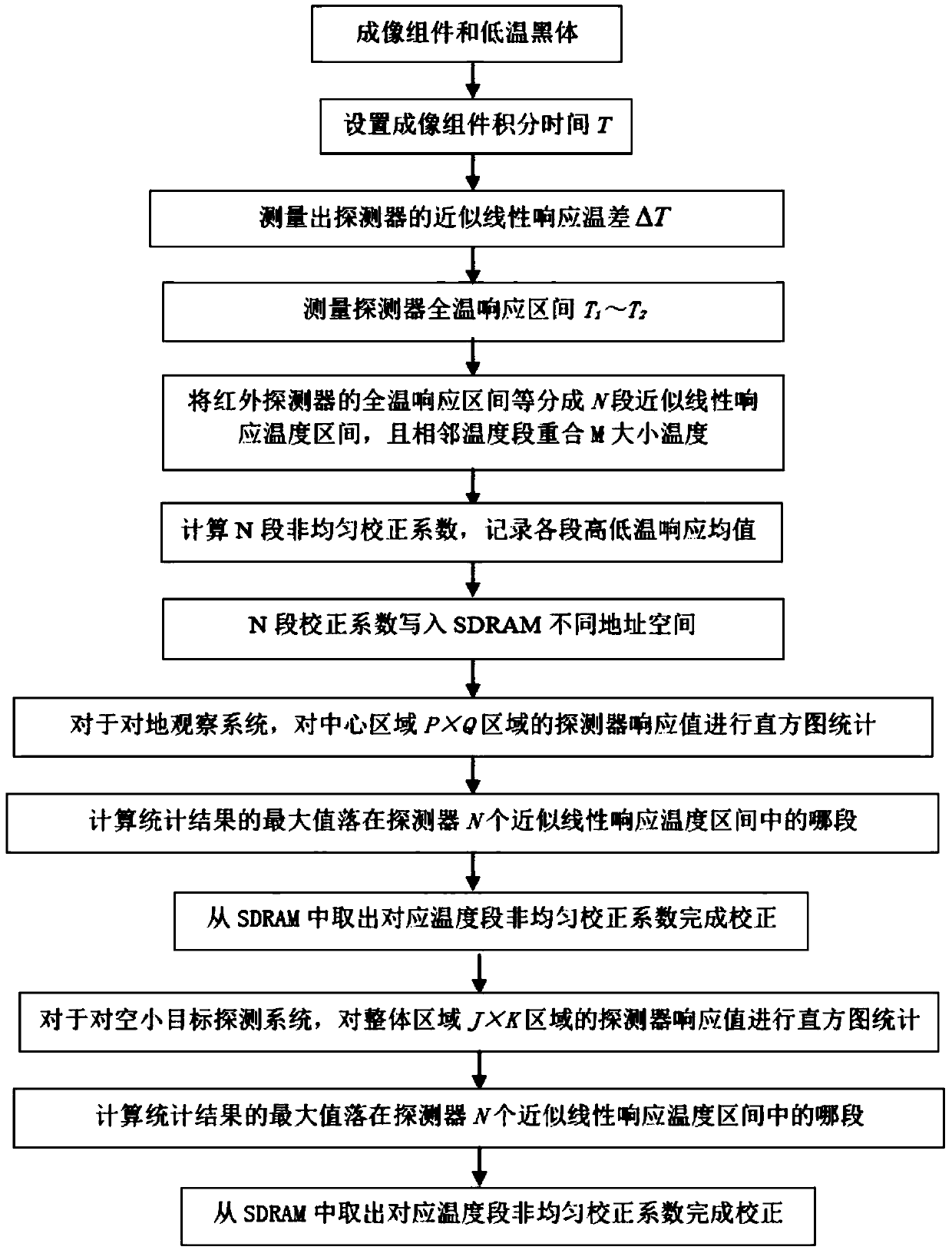

Method and apparatus for eliminating nonuniformity of infrared detector in full-temperature response scope

ActiveCN105371964AImprove non-uniformityRealize seamless switching in real timePyrometry using electric radation detectorsTemperature responseImaging quality

The invention relates to a method and apparatus for eliminating nonuniformity of an infrared detector in a full-temperature response scope. The method comprises the following steps: first of all, calculating a non-uniform correction coefficient corresponding to the detector; and then, according to the corresponding non-uniform correction coefficient, carrying out non-uniform correction on the detector. According to the invention, through performing multistage non-uniform correction on the infrared detector, by use of a real-time seamless switching technology between non-uniform correction coefficients at stages, the nonuniformity of the detector in the full-temperature response scope is effectively improved, while the system imaging quality and the detection performance are improved, the operation complexity of the system is not changed, and the engineering practicality and the application flexibility are also quite good. The method can be applied to various infrared imaging systems and detection systems.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

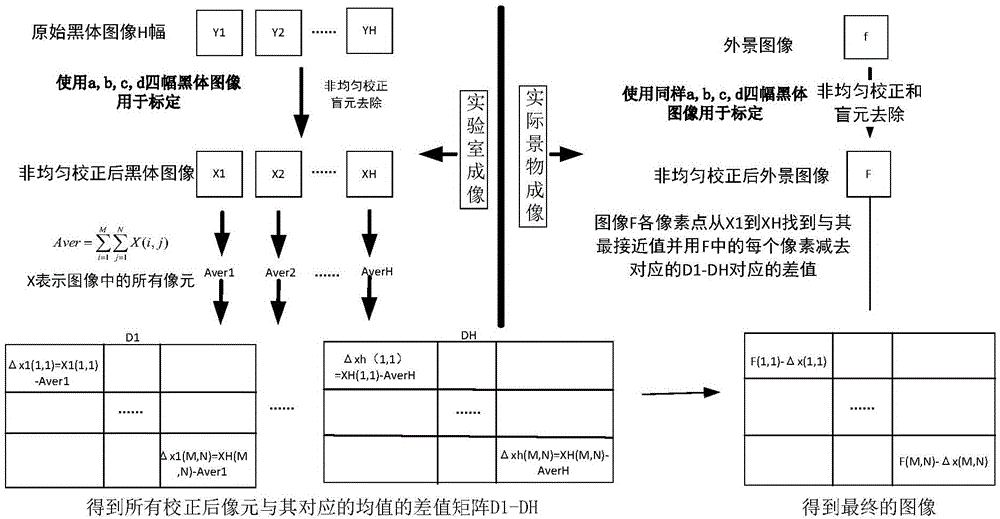

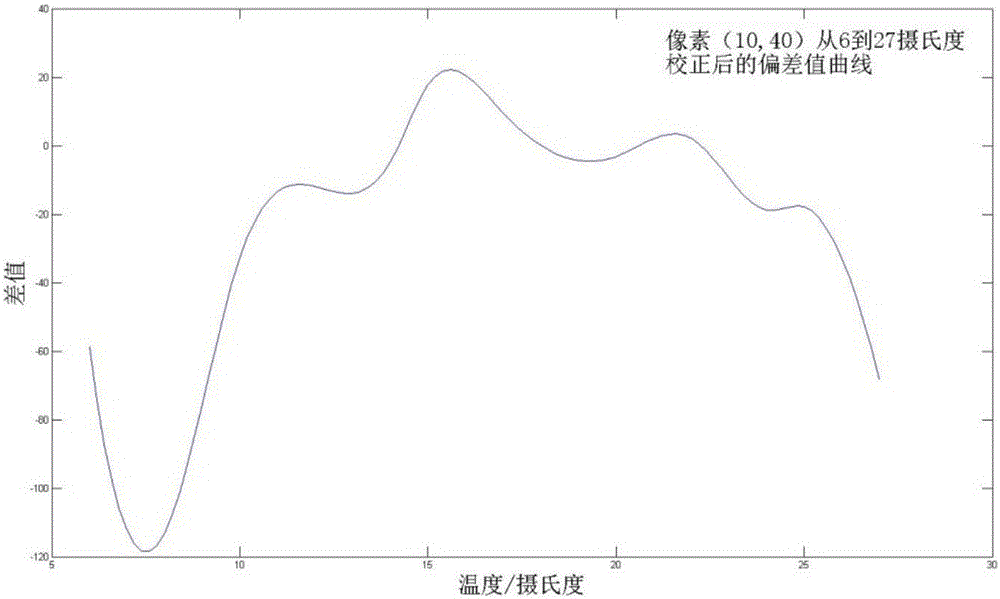

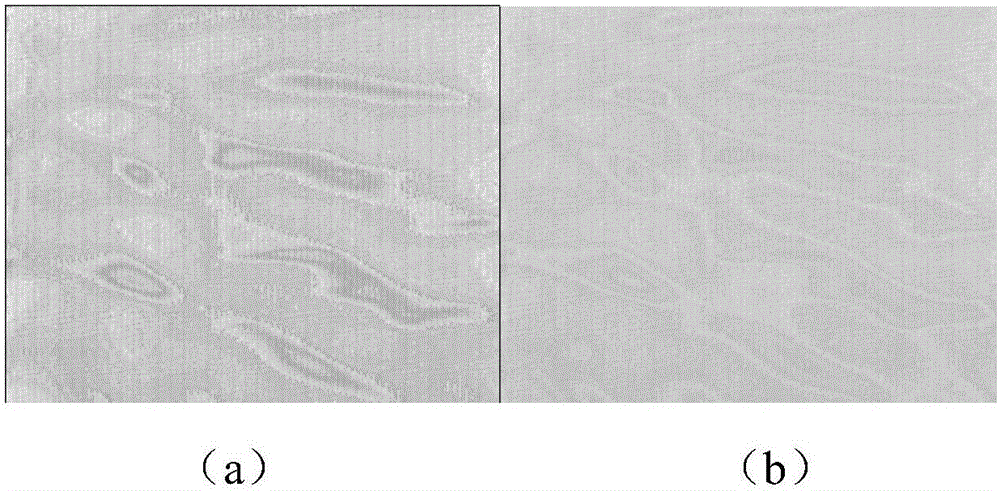

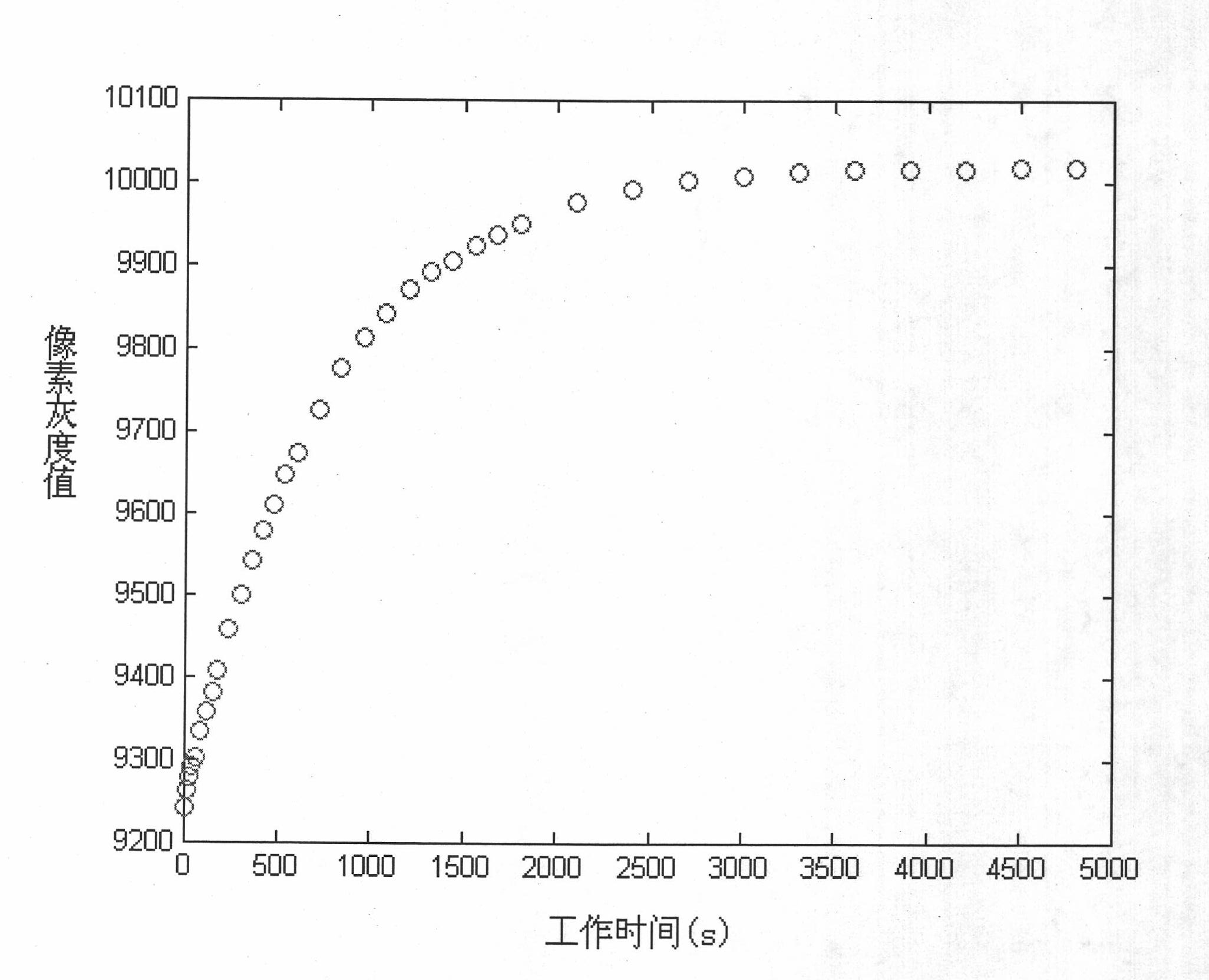

Residual heterogeneous noise elimination method for aiming at thermal infrared image after heterogeneous correction

ActiveCN105869129AReduce spatial noiseReduce non-uniformity noiseImage enhancementImage analysisPattern recognitionArray data structure

The invention discloses a residual heterogeneous noise elimination method for aiming at thermal infrared image after heterogeneous correction. The method comprises the following steps of 1), imaging a black body by means of an infrared imaging system at different temperature for obtaining an infrared image; 2), performing heterogeneous correction on the obtained black body image; 3), calculating a pixel mean value of the black body image after correction; 4), subtracting the pixel mean value from each pixel value in the black body image after correction and storing results; 5), photographing an outdoor scene image and performing heterogeneous correction; and 6), comparing the image pixel value after correction with the image mean values at different temperatures for finding out a subtraction number array which corresponds with a nearest value, and subtracting the value of the corresponding position in the array from the pixel value for obtaining a new image. According to the residual heterogeneous noise elimination method, defects in a traditional infrared image noise elimination method are settled, and furthermore the residual heterogeneous noise is more effectively and more accurately eliminated. According to the residual heterogeneous noise elimination method, the residual heterogeneous noise in the infrared image can be effectively eliminated without original information loss of the image, and furthermore a high-quality restored image is obtained.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

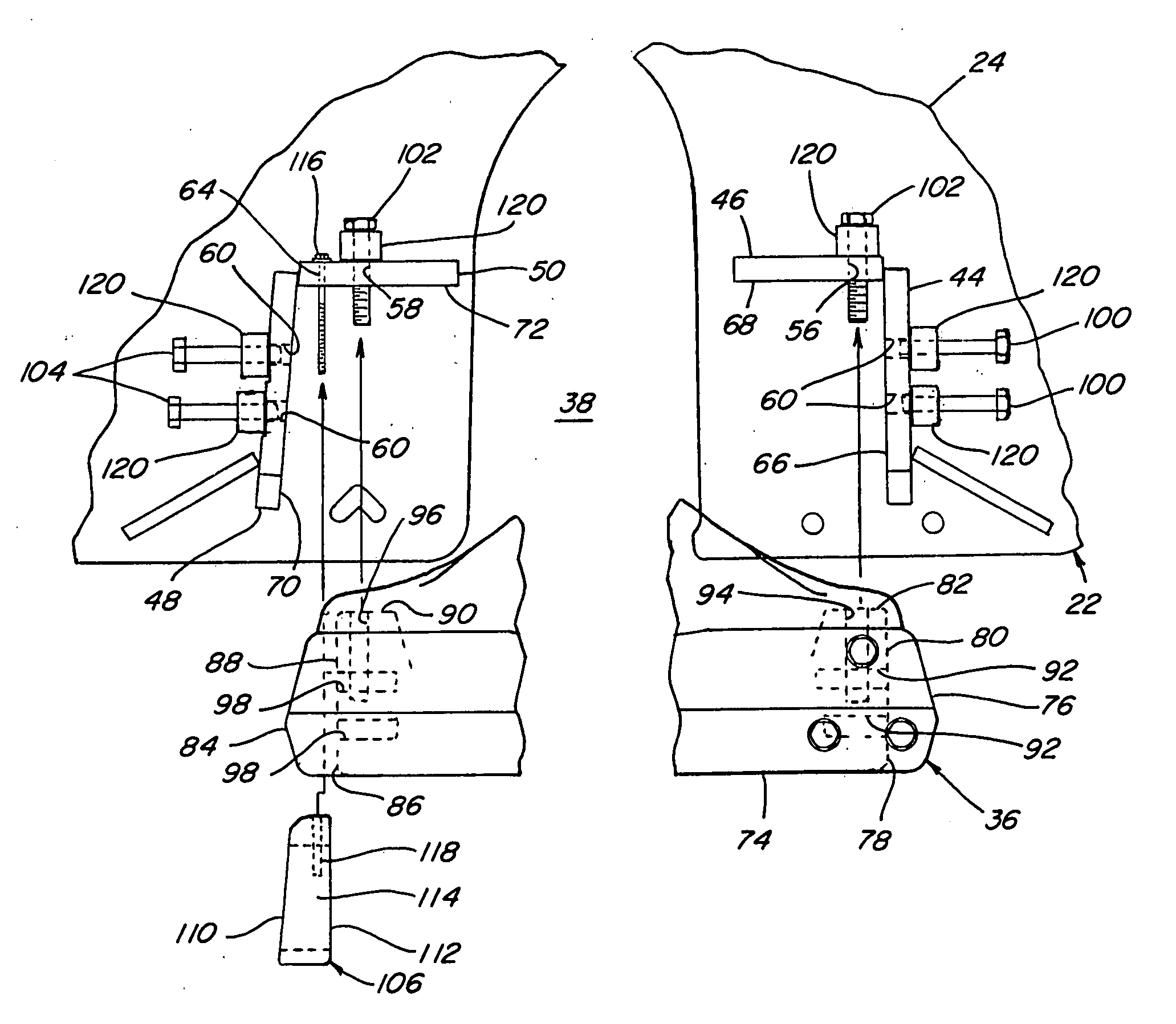

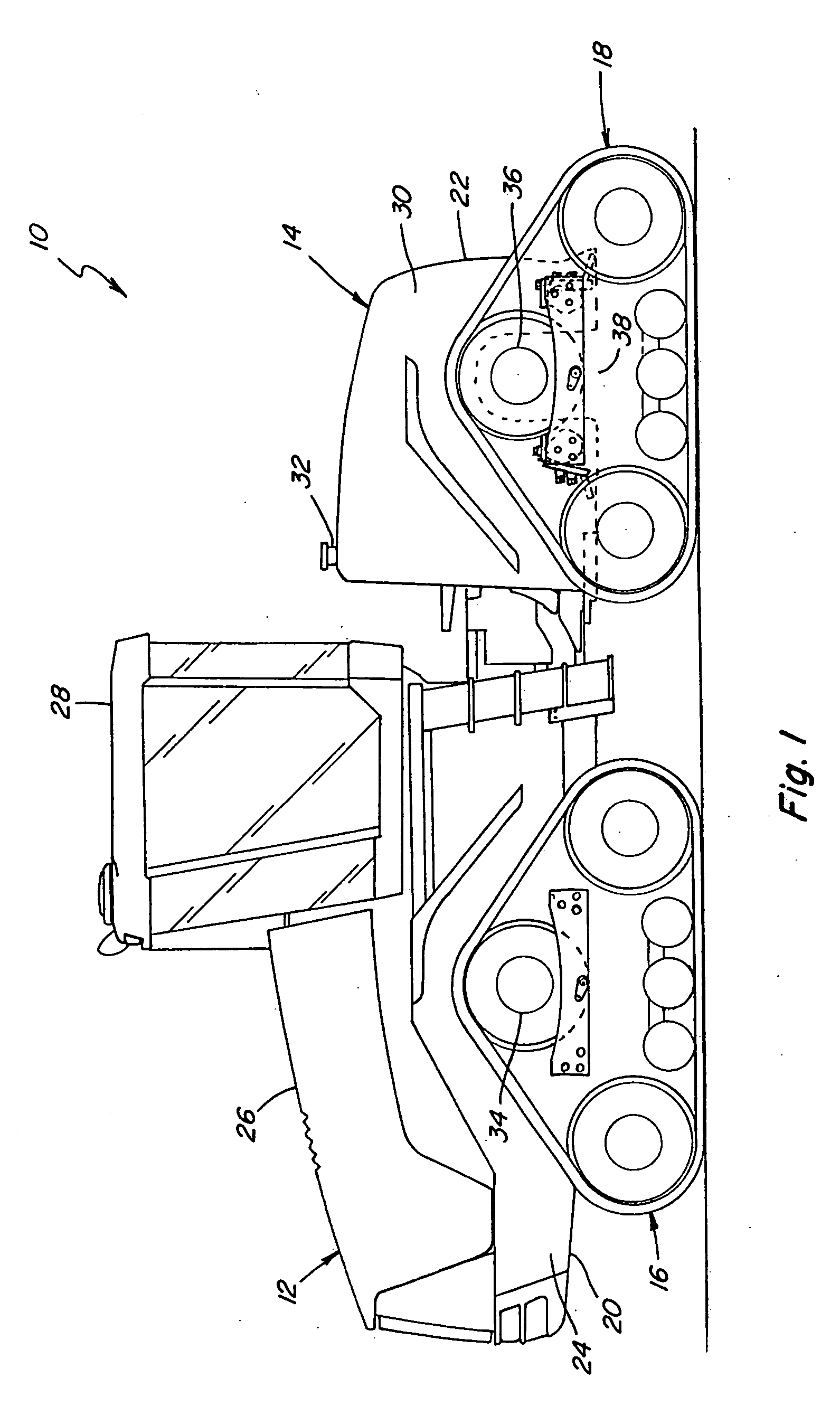

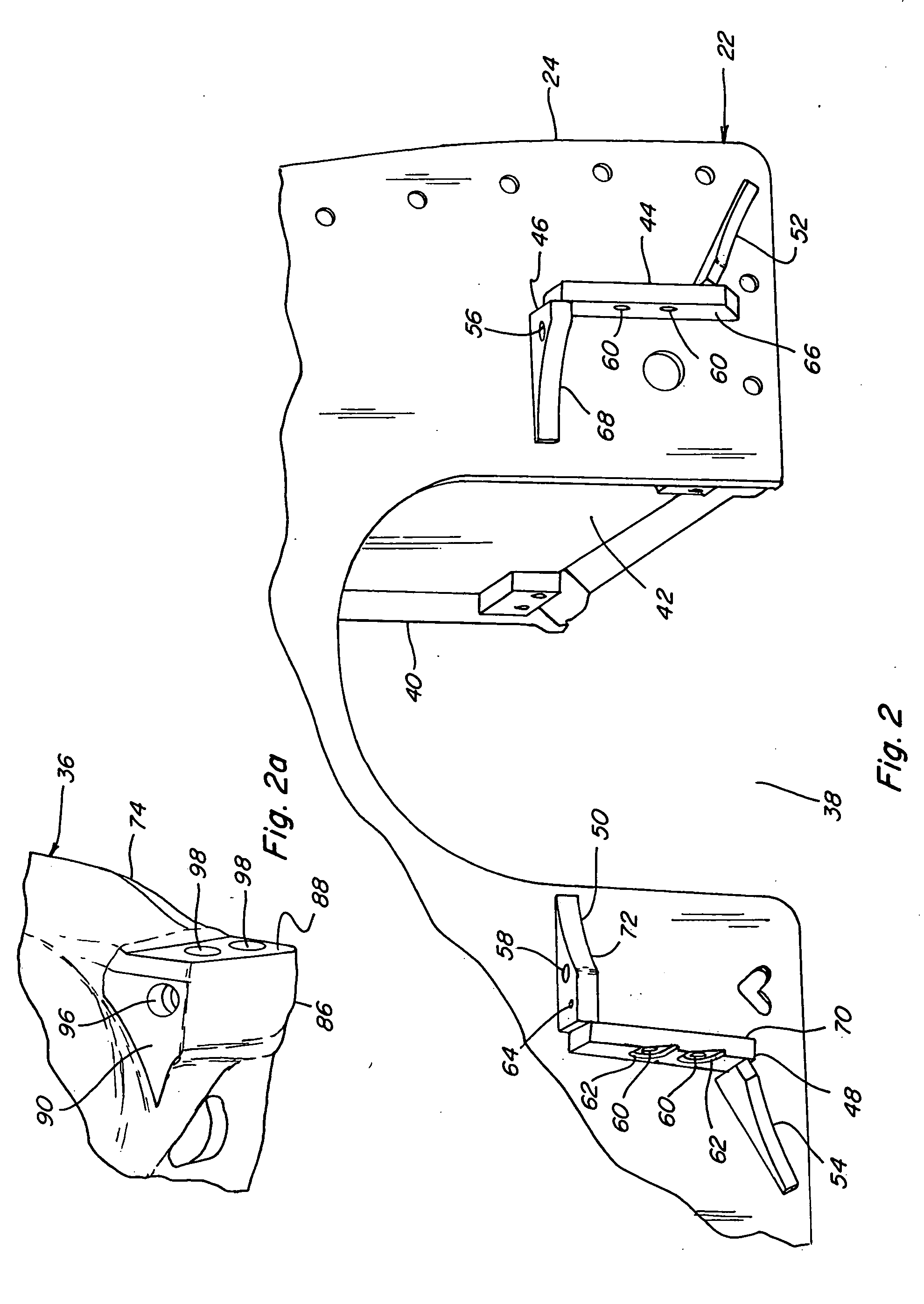

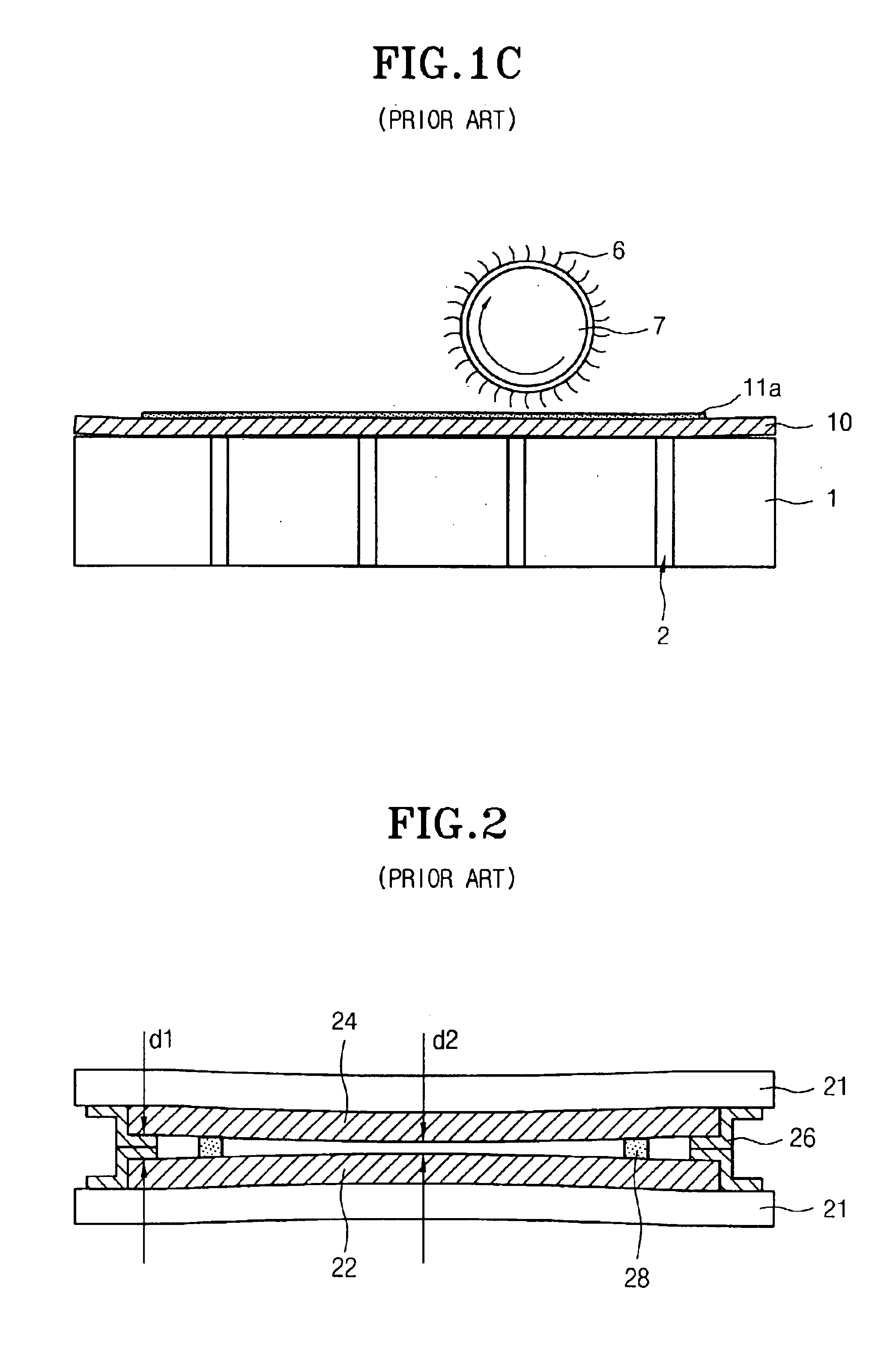

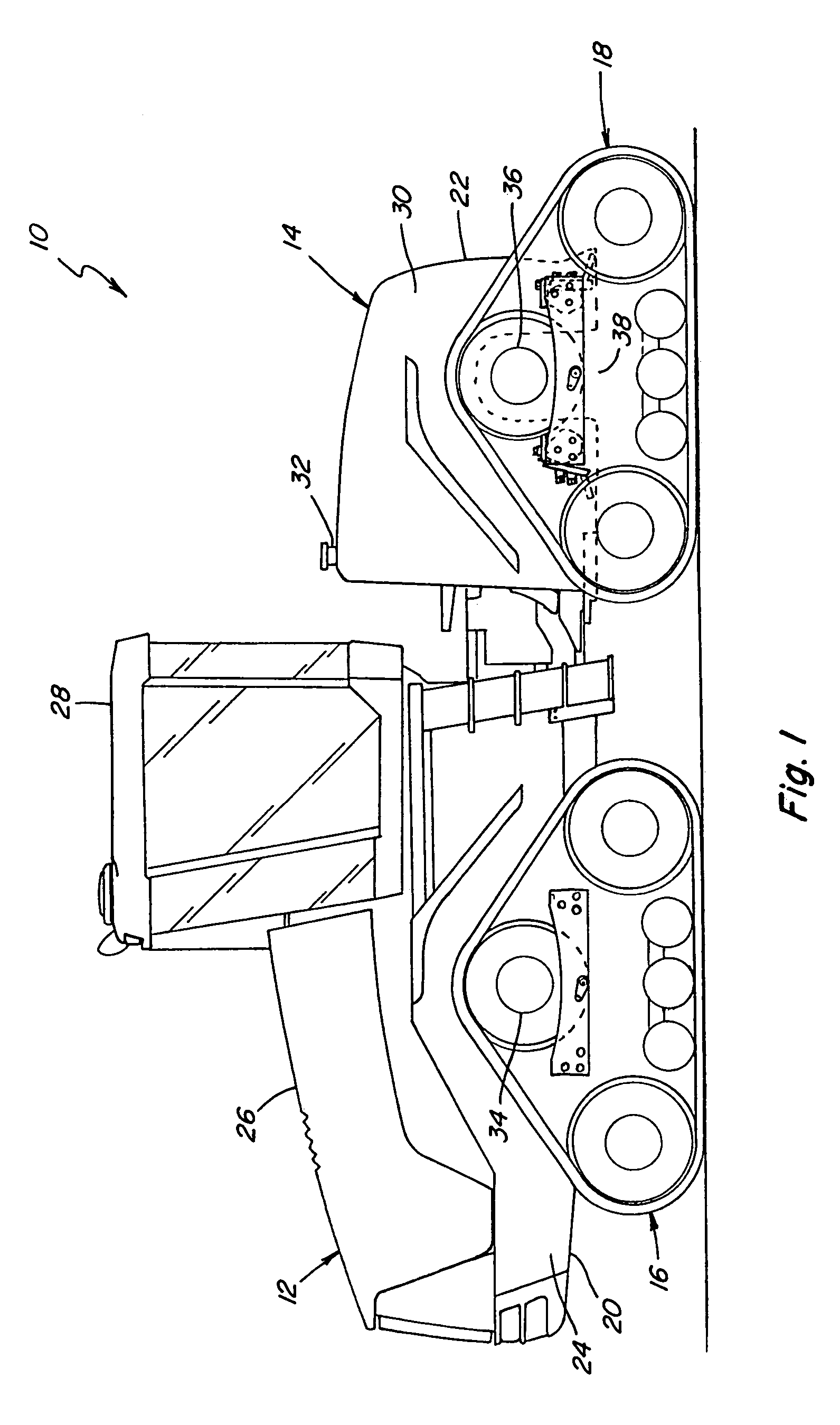

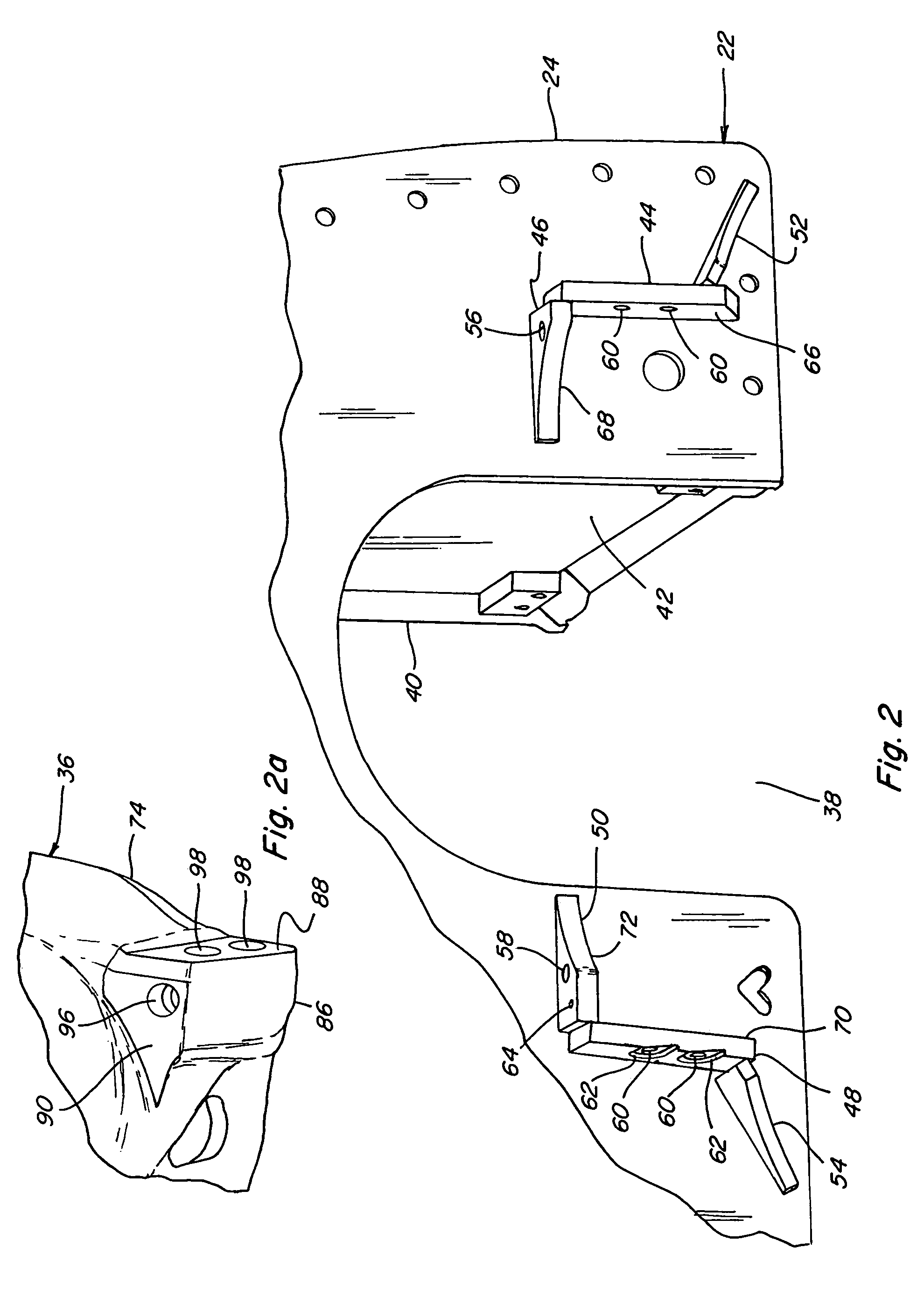

Apparatus and method for reducing shear loading on elements connecting an axle and a chassis of a vehicle

ActiveUS20060138739A1Reduce and straighten out of warpageReduce and straighten out of and distortionMechanical machines/dredgersVehicle body-frame connectionsEngineeringShear force

An apparatus and method for mounting or assembling an axle or axle housing and a chassis of a vehicle, which improves fit-up between a chassis and axle and reduces shear loads exerted against connectors such as bolts or the like connecting the axle and chassis. The chassis and axle are connected and fixed in relation one to the other in the desired position by the connectors. Wedge surfaces are located on the chassis and on the axle in opposing relation at a predetermined angle and define a space therebetween. A tapered block or wedge member is positionable in the space between the wedge surfaces. An adjusting member is adjustable for applying forces against the wedge surfaces to urge the wedge surfaces apart, for reducing at least some of any shear forces acting against the connectors connecting the axle and chassis.

Owner:BLUE LEAF I P INC

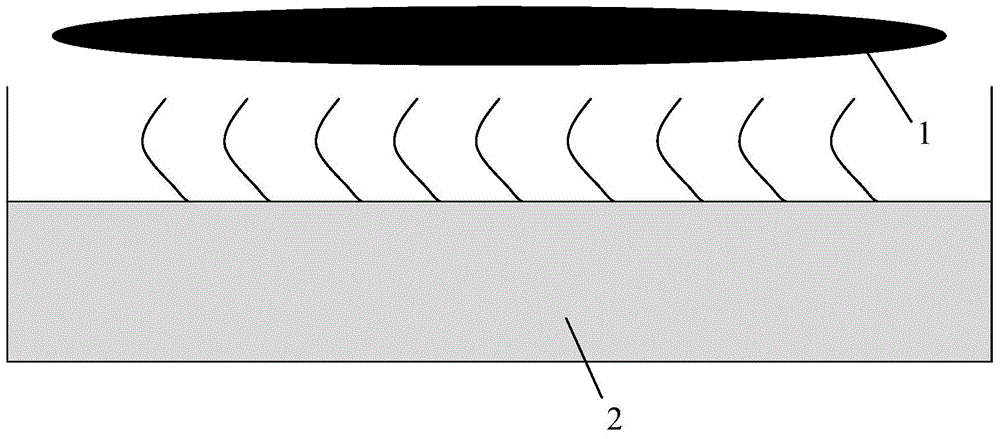

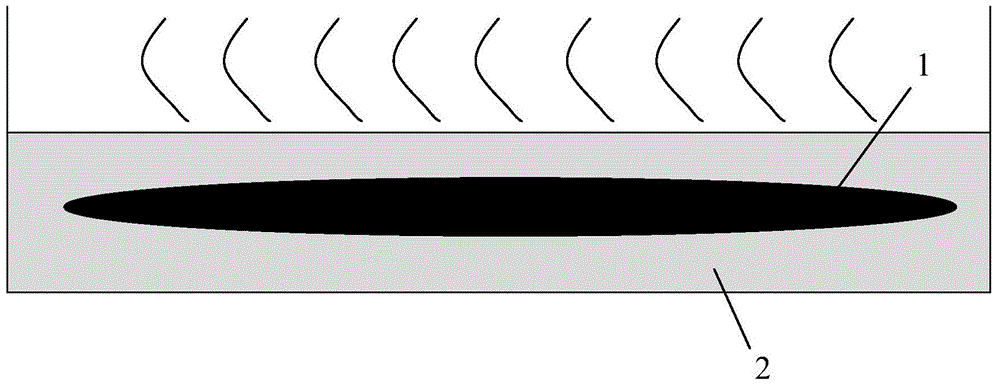

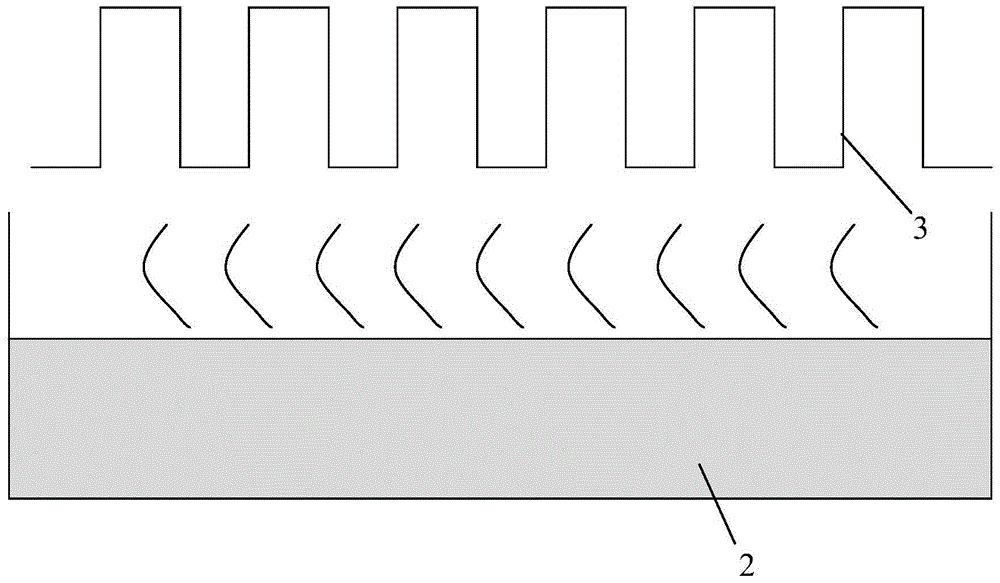

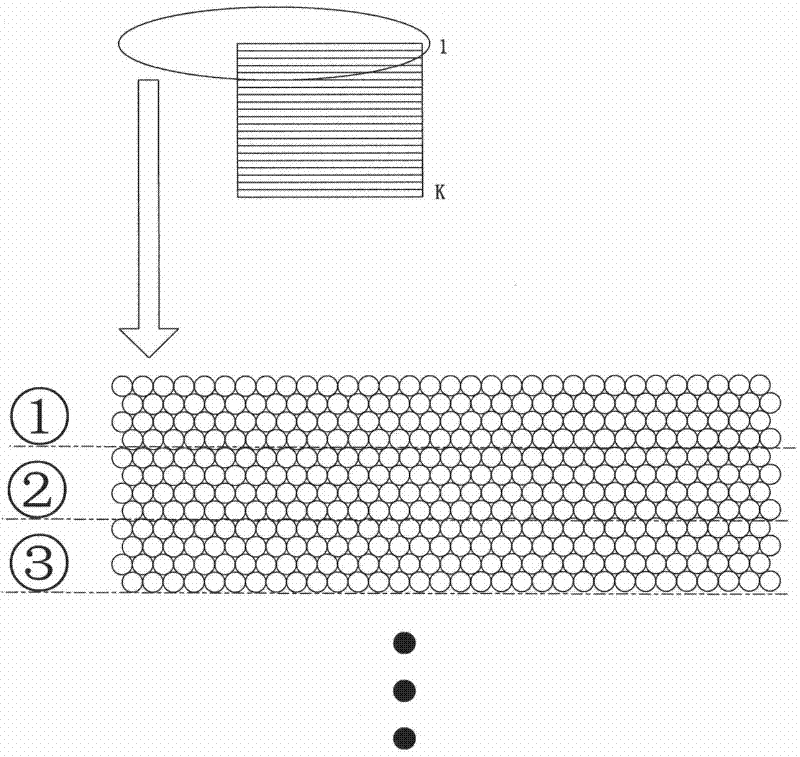

Surface texturing method of solar battery and of great-wall solar battery substrate

ActiveCN104701407AImprove non-uniformityReduce light reflectivityPolycrystalline material growthAfter-treatment detailsEtchingChemical reaction

A solar battery surface texturing processing method comprises the following steps: a, providing a silicon wafer (1) and an etching agent (2); b, placing the silicon wafer in a reaction chamber in which the etching agent is placed or above the etching agent to perform chemical vapor etching, or immersing the silicon wafer in the etching agent to perform liquid phase etching; and c, repeating step b at least once. In this texturing processing method, better heterogeneity can be formed, and therefore a good porous layer can be obtained for a silicon wafer in another crystal orientation, thereby obtaining a lower luminous reflectance.

Owner:骆志炯

CMP polishing layer based on porous cerium oxide and preparation method thereof

ActiveCN109015341AImprove polishing efficiencyExcellent machinabilityOther chemical processesAbrasion apparatusCross-linkMixed materials

The invention relates to the field of CMP polishing pad machining and manufacturing, in particular to a CMP polishing layer based on porous cerium oxide and a preparation method thereof. The CMP polishing layer based on the porous cerium oxide is obtained by mixing and curing raw materials of a polyurethane prepolymer, a cross-linking agent and the porous cerium oxide; and the preparation method comprises the steps of preheating the polyurethane prepolymer in a vacuum state first, and then adding a porous cerium oxide packing to the polyurethane prepolymer, and sufficiently stirring and mixingthe porous cerium oxide packing and the polyurethane prepolymer to obtain a mixed prepolymer; transferring the mixed prepolymer into a first tank body and carrying out heat preservation, stirring andcycling treatment on the mixed prepolymer; adding the cross-linking agent to a second tank body to be melted; correcting injection weight ratio of the first tank body and the second tank body and then mixing materials in the first tank body and the second tank body at a high speed; injecting the mixed materials into a mold; curing the mold; and vulcanizing materials in the mold to obtain the polishing layer. The CMP polishing layer based on the porous cerium oxide has the advantages of higher polishing efficiency, more stable wear resistance, more stable flowing property and more stable cutting property.

Owner:HUBEI DINGHUI MICROELECTRONICS MATERIALS CO LTD

A kind of shutterless thermal imaging camera based on vox detector and its application method

InactiveCN103162843BImprove non-uniformityAvoid non-uniformityPyrometry using electric radation detectorsSystems designThermodynamics

The invention relates to a zero shutter thermal infrared imager based on a voice operated exchange (VOX) detector. The zero shutter thermal infrared imager based on the VOX detector comprises a high-low temperature chamber and a machine core, wherein a monitor, a computer and a power source are respectively connected with the machine core. The use method of the thermal infrared imager includes the following steps: collecting original images; forecasting a background; revising a point 2 and a point 1; and performing image enhancement display processing. Compared with a usual shutter revision method, the zero shutter thermal infrared imager based on the VOX detector and the use method thereof can effectively reduce the size and the power consumption of an infrared machine core, are unlike a conventional method in which a shutter needs to be used to obtain uniform images at every time of revision, and use the original images as background images to revise, and therefore system design is simplified greatly, the size and the power consumption are reduced, and simultaneously due to zero shutter design, the problems of uneven images caused by heat emitting of the shutter and the like are avoided.

Owner:北京红源盛达光电技术有限公司

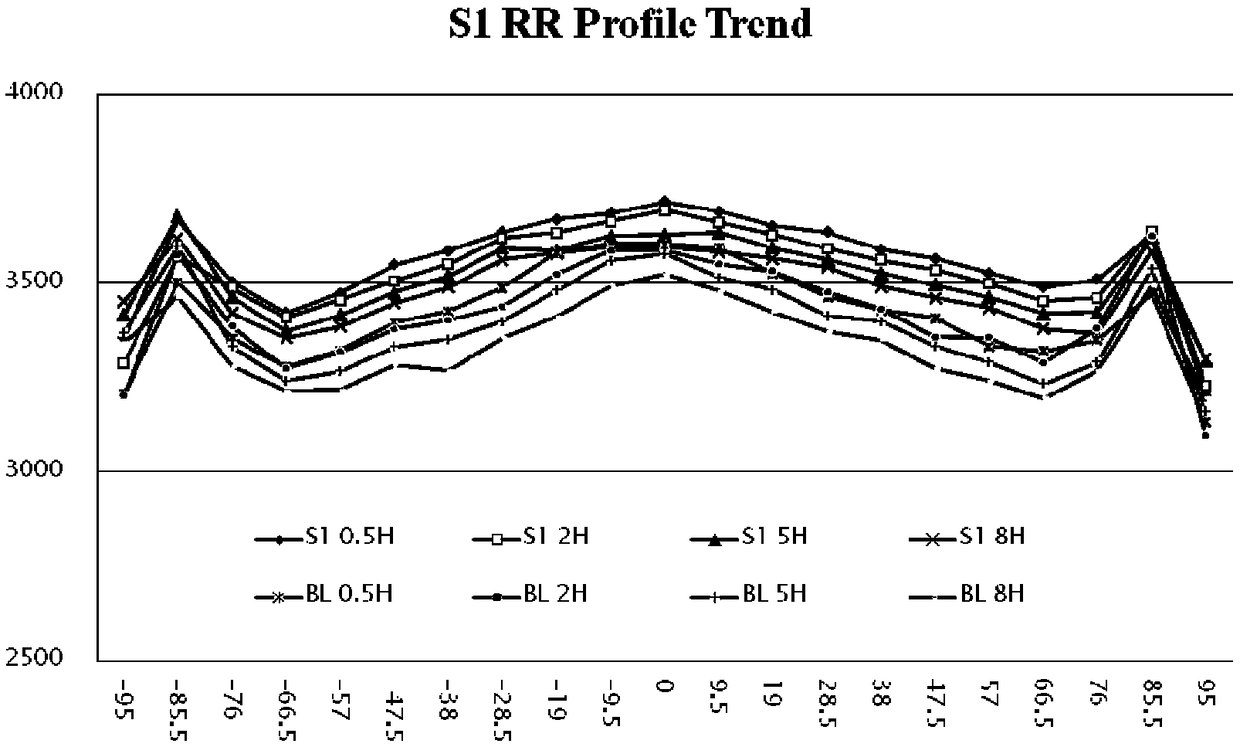

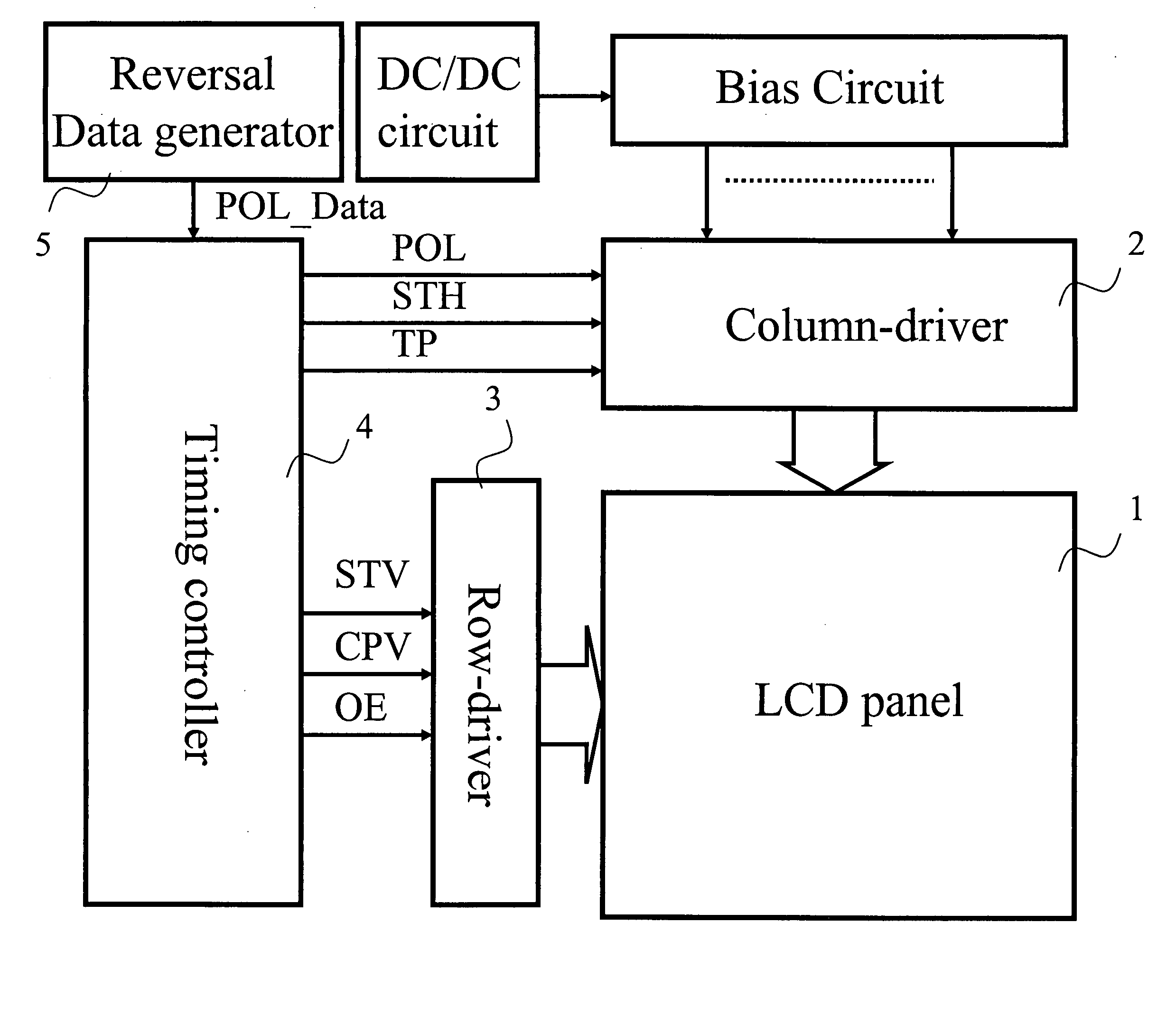

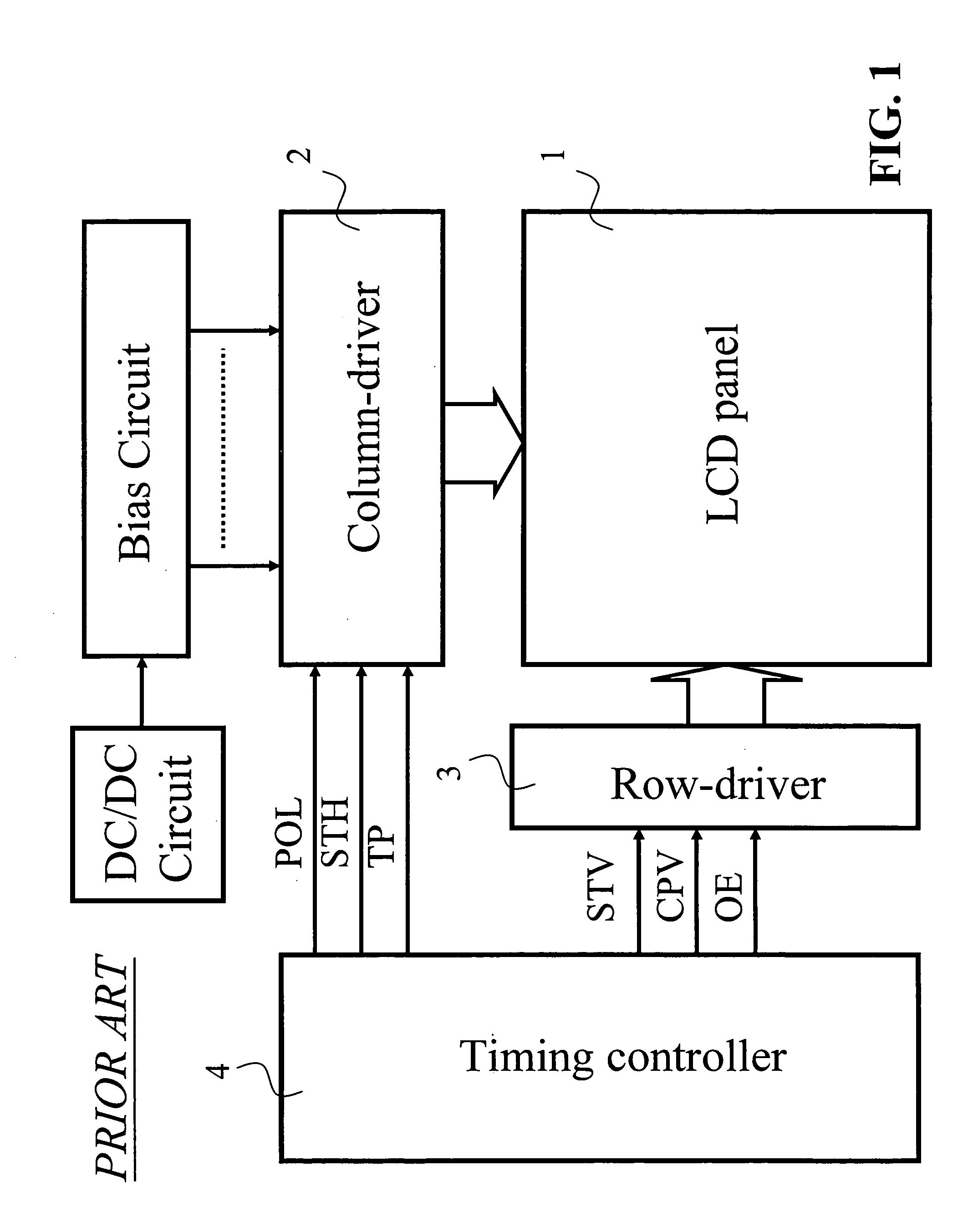

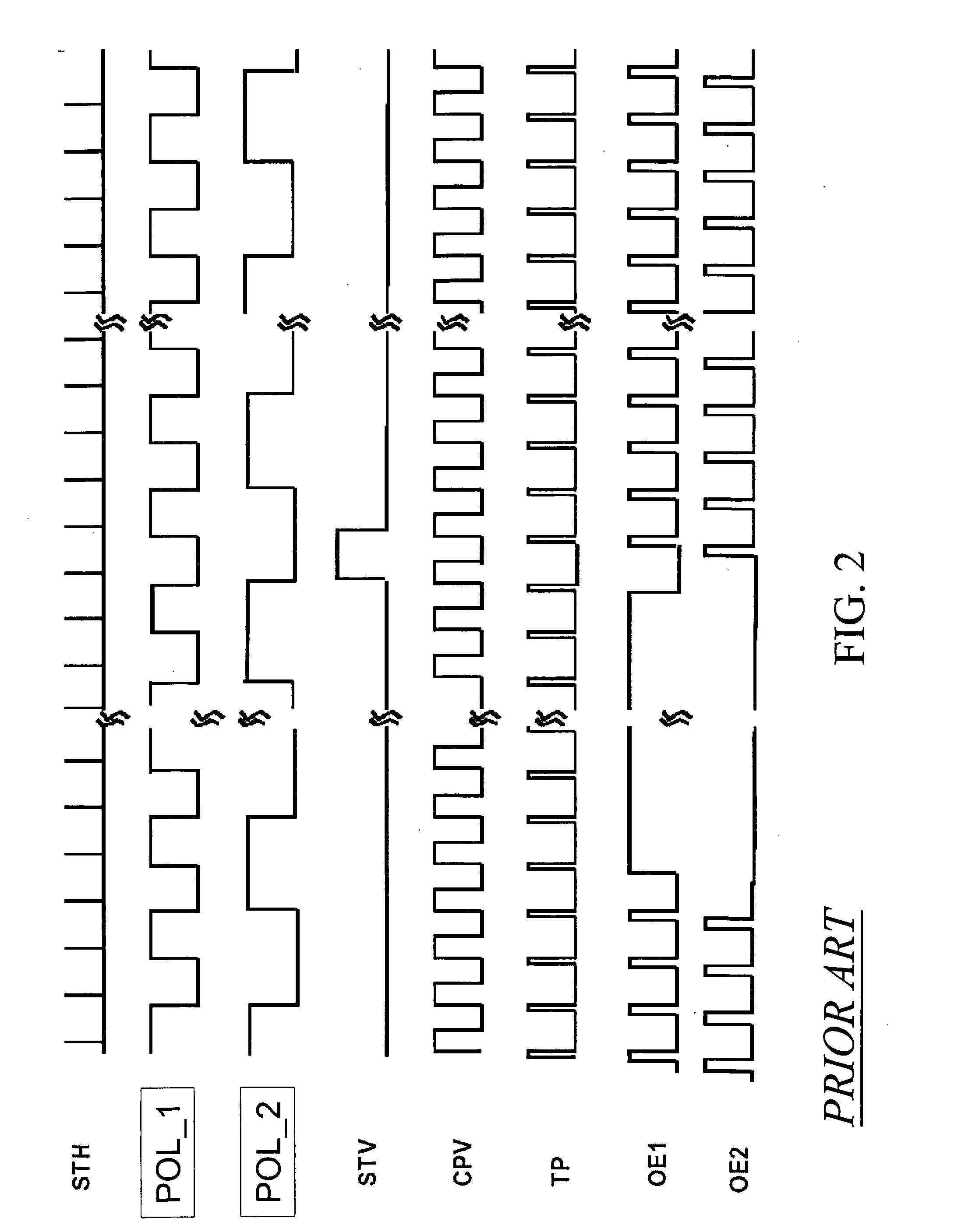

LCD module and control method

InactiveUS20070120804A1Improve flickeringImprove non-uniformityStatic indicating devicesLiquid-crystal displayData signal

A TFT liquid crystal display (LCD) module comprising a timing controller and a reversal data generator is disclosed. The timing controller provides a plurality of signals to the column-driver and row-driver of LCD panel. The reversal data generator outputs a reversal data signal to the timing controller, which in turn outputs a non-periodic reversal signal to the column-driver. The generation of reversal data signal by the reversal data generator is independent of the timing of the timing controller, or the reversal data signal is a non-periodic signal and the non-periodic reversal signal will change its state within a specific time range posterior to the column start signal.

Owner:HUNG JIMI

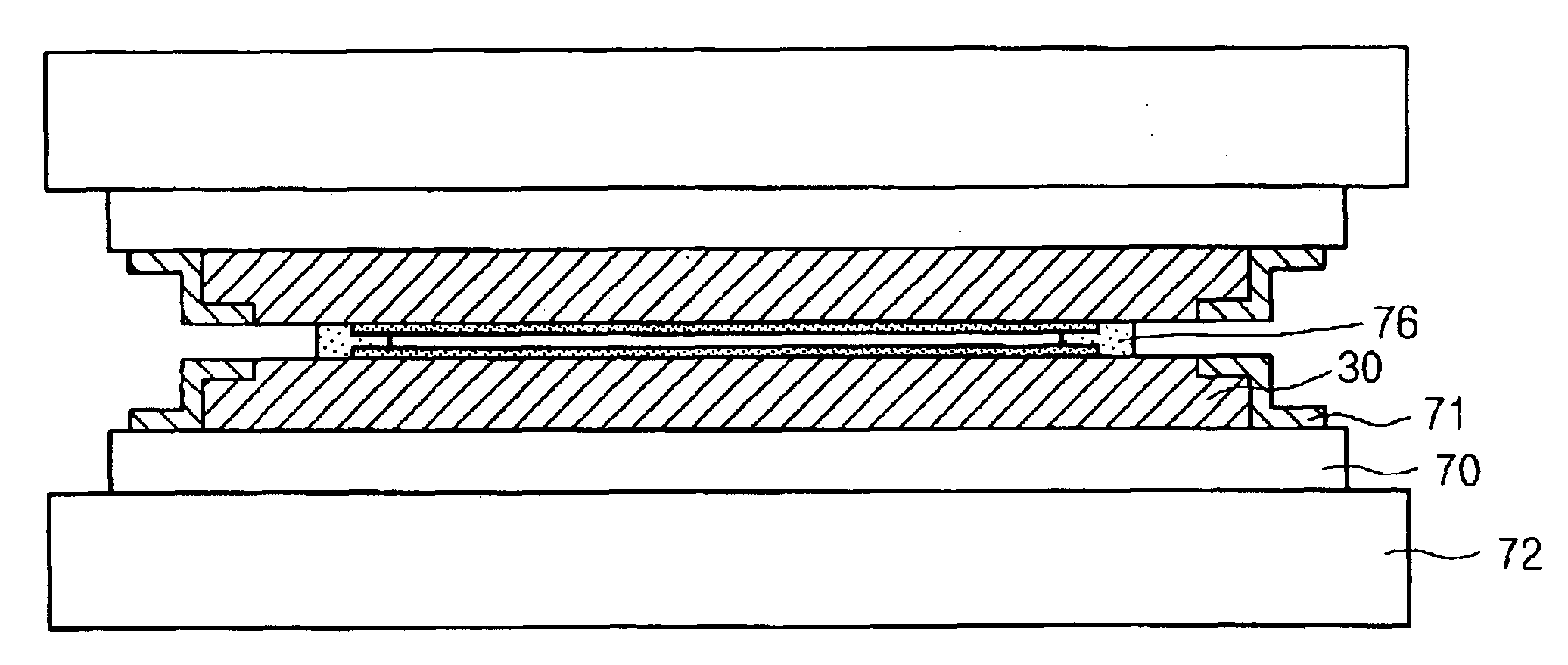

Liquid crystal display device with plastic substrate

ActiveUS6853434B2Improve non uniformityNon-uniform coatingNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display device with plastic substrates is disclosed, which comprises: a subsidiary substrate, upper and lower plastic substrates including edge grooves and being fixed on the subsidiary substrate by heat resistant tapes and being joined with liquid crystals sealed there-between, and alignment layers formed on the surfaces which face one another of the upper and lower plastic substrates.

Owner:BOE HYDIS TECH

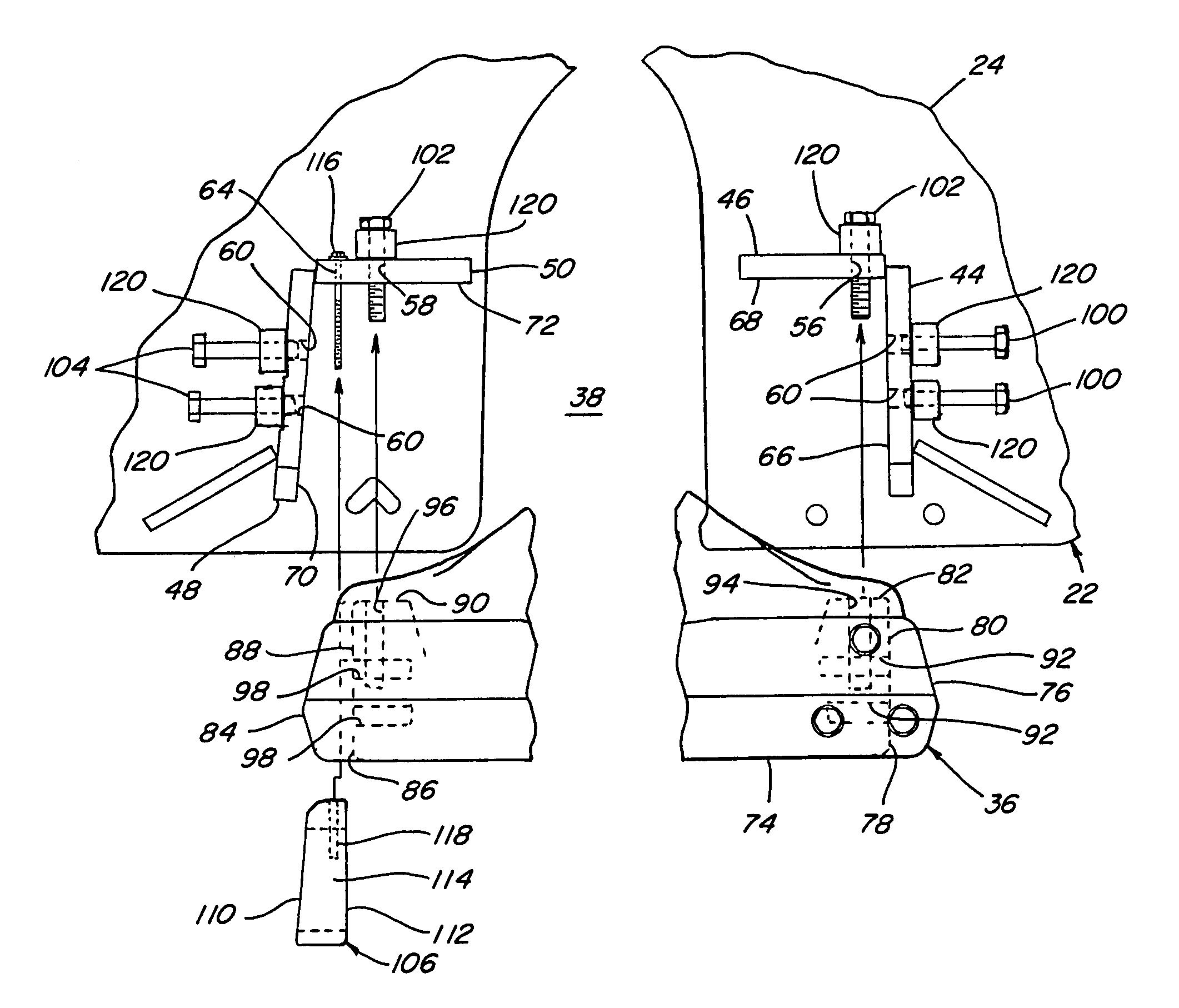

Apparatus and method for reducing shear loading on elements connecting an axle and a chassis of a vehicle

ActiveUS7383914B2Reduce and straighten out of warpageReduce and straighten out of and distortionUnderstructuresEndless track vehiclesForce equilibriumAbutment

Referring more particularly to FIG. 4, the present invention red ices such shear loading on the bolts, by utilizing a wedge member or a tapered block 106, inserted and wedged into a space 108 between wedge surfaces 70 and 88, and having oppositely facing outer surfaces 110 and 112 thereby placed into abutment with those surfaces, respectively, so as to exert a fore and aft directed force against those surface, denoted by arrows C, effectively acting to push those surfaces apart and counteracting the shear loads B. Such forces will also act in opposition to and reduce tensile loads acting on bolts 100. Tapered block 106 has at least one passage 114 therethrough (FIG. 3) for the passage of bolts 104 therethrough, to allow insertion of those bolts into threaded holes 98 and tightening those bolts to exert compressive forces against tapered block 106, denoted by arrows D, for holding that block in position. This may also be sufficient to apply a tensile load bolts 100, which are preferably at least generally longitudinally aligned therewith as shown. As a result, a force equilibrium condition can be achieved, which can significantly and predictably reduce and control shear forces acting against the bolts or other connectors for connecting axle housing 74 to the side plates 24 of chassis 22.

Owner:BLUE LEAF I P INC

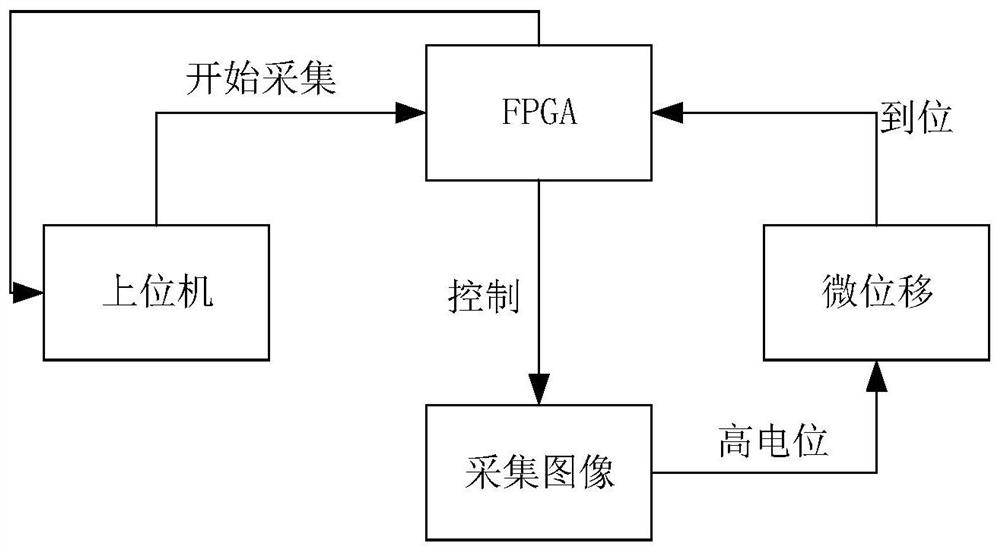

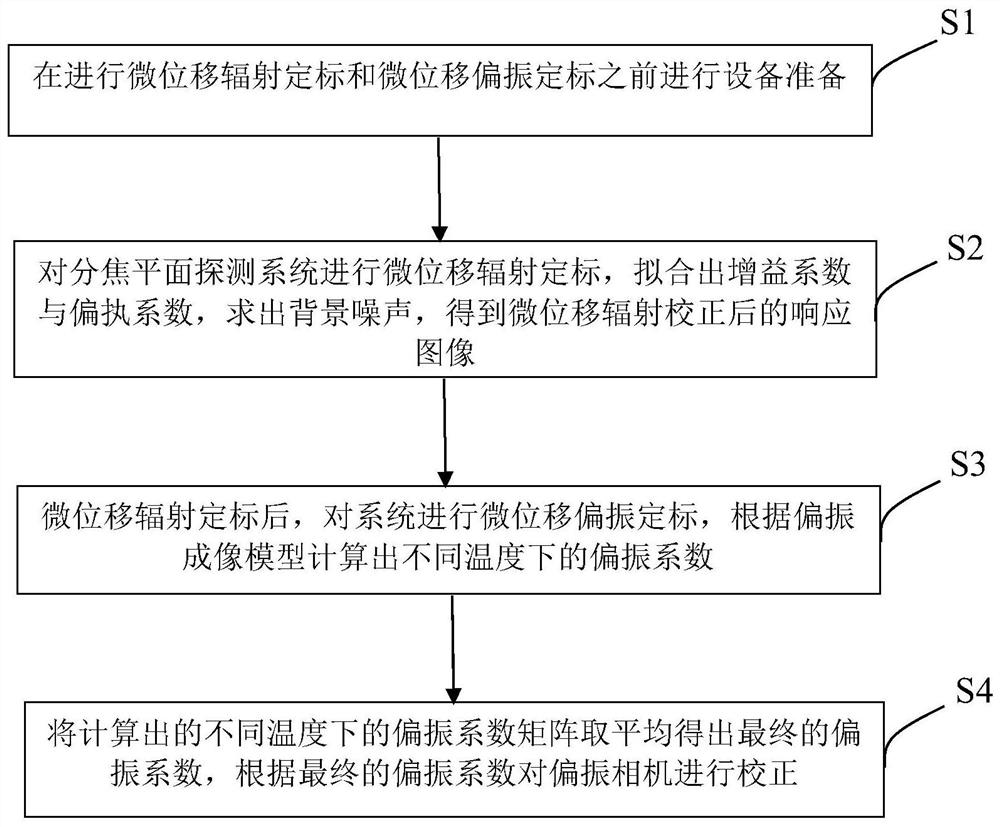

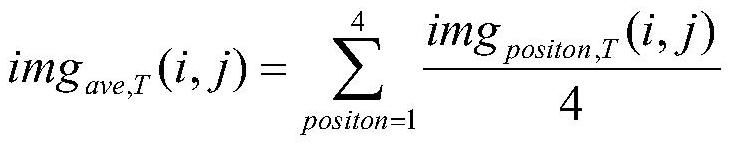

Focal plane polarization detection system calibration method

PendingCN113970374AHigh precisionReduce spatial noiseLight polarisation measurementSpatial noiseGain coefficient

The invention provides an infrared focal plane polarization detection system calibration method. The method comprises the following steps: preparing equipment before micro-displacement radiation calibration and micro-displacement polarization calibration; carrying out micro-displacement radiation calibration on the focal plane detection system, fitting a gain coefficient and a bias coefficient, solving background noise, and obtaining a response image after micro-displacement radiation correction; after micro-displacement radiation calibration, carrying out micro-displacement polarization calibration on the system, and calculating polarization coefficients at different temperatures according to a polarization imaging model; and averaging the calculated polarization coefficient matrixes at different temperatures to obtain a final polarization coefficient, and correcting the polarization camera according to the final polarization coefficient. According to the invention, the spatial noise of the camera can be reduced, and the non-uniformity of the polarization camera can be corrected.

Owner:上海济物光电技术有限公司

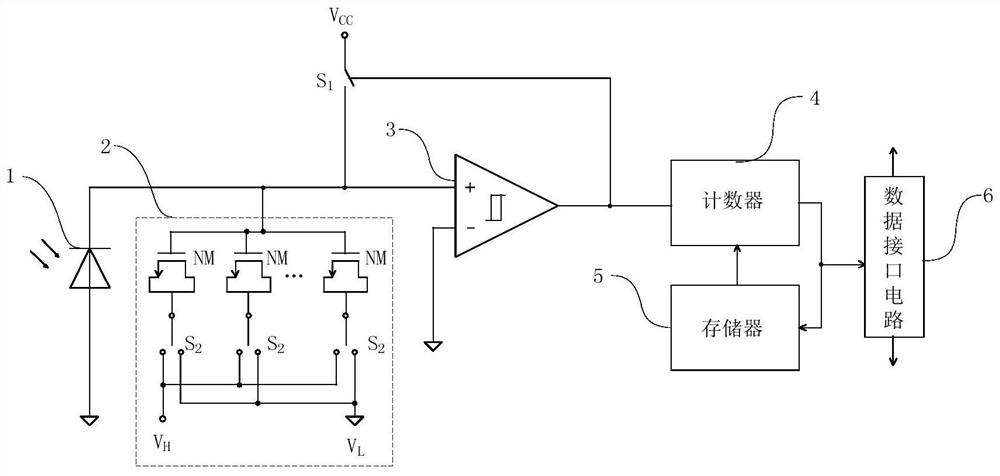

Focal plane digitization pixel gain fine tuning circuit

ActiveCN112468746AImprove non-uniformityDecrease the adjustment stepTelevision system detailsColor television detailsCapacitancePhotovoltaic detectors

The invention discloses a focal plane digitization pixel gain fine tuning circuit, which comprises a photoelectric detector, a capacitance adjusting circuit, a comparator, a counter and a memory. Thephotoelectric detector is used for detecting an optical signal and outputting a current signal, and the capacitance adjusting circuit is used for adjusting the magnitude of an integrating capacitor connected to the fine tuning circuit. The comparator is used for receiving a current signal transmitted by the photoelectric detector and outputting an oscillation signal according to the current signal, the counter is used for counting the oscillation signal and storing the oscillation signal in the memory, and fine adjustment of the size of the integrating capacitor is realized through the capacitance adjusting circuit. Therefore, gain adjustment of pixels of the reading circuit during digital-to-analog conversion is realized, and imaging non-uniformity is improved.

Owner:NO 24 RES INST OF CETC

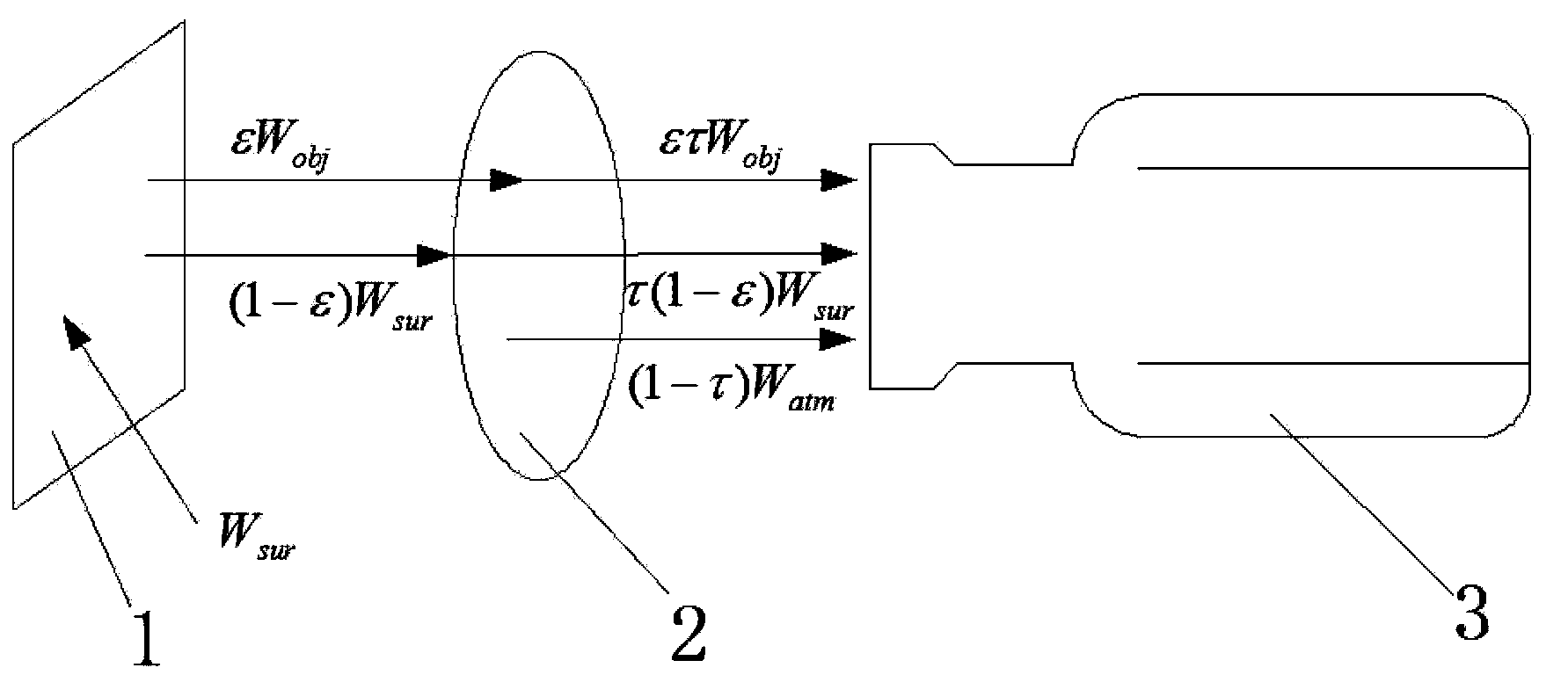

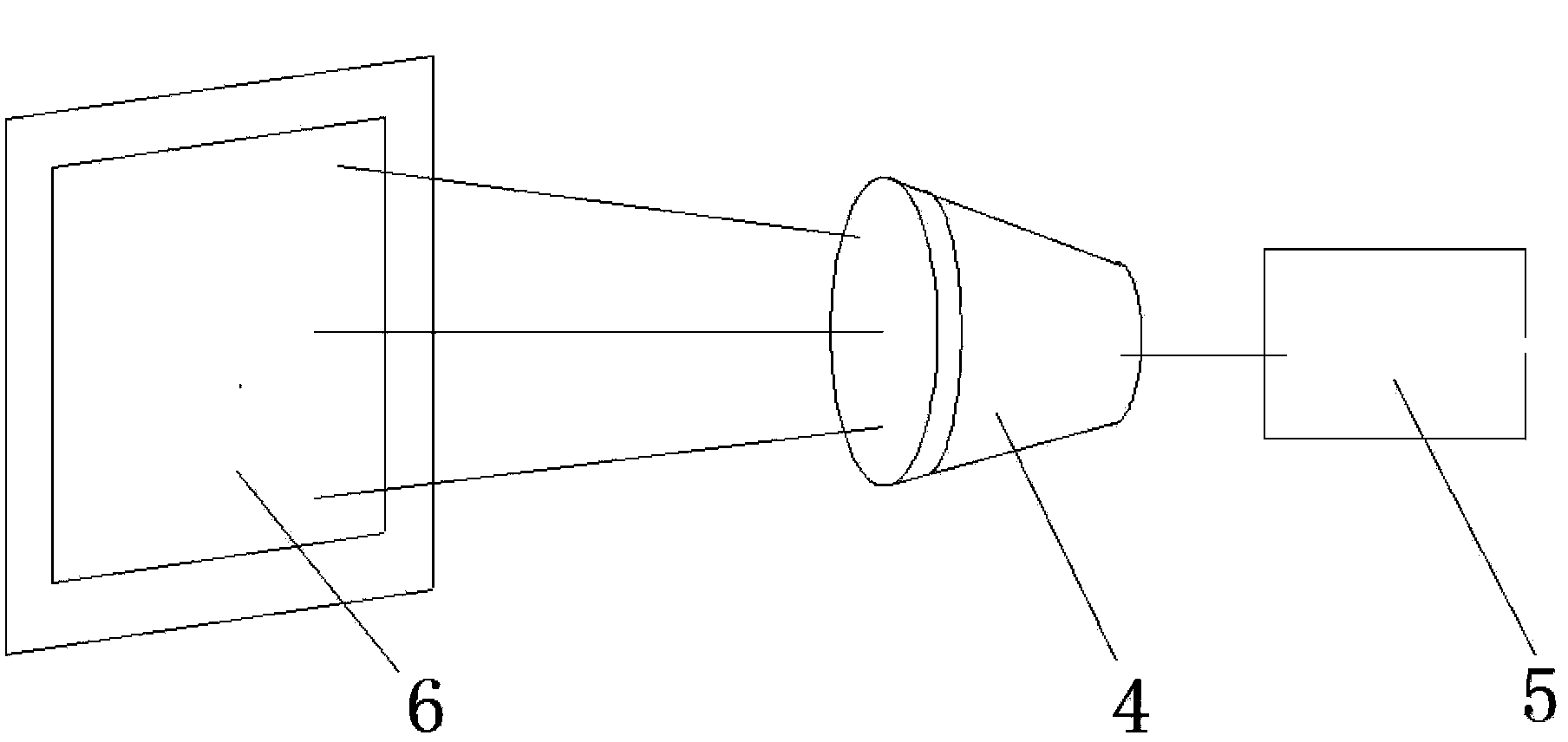

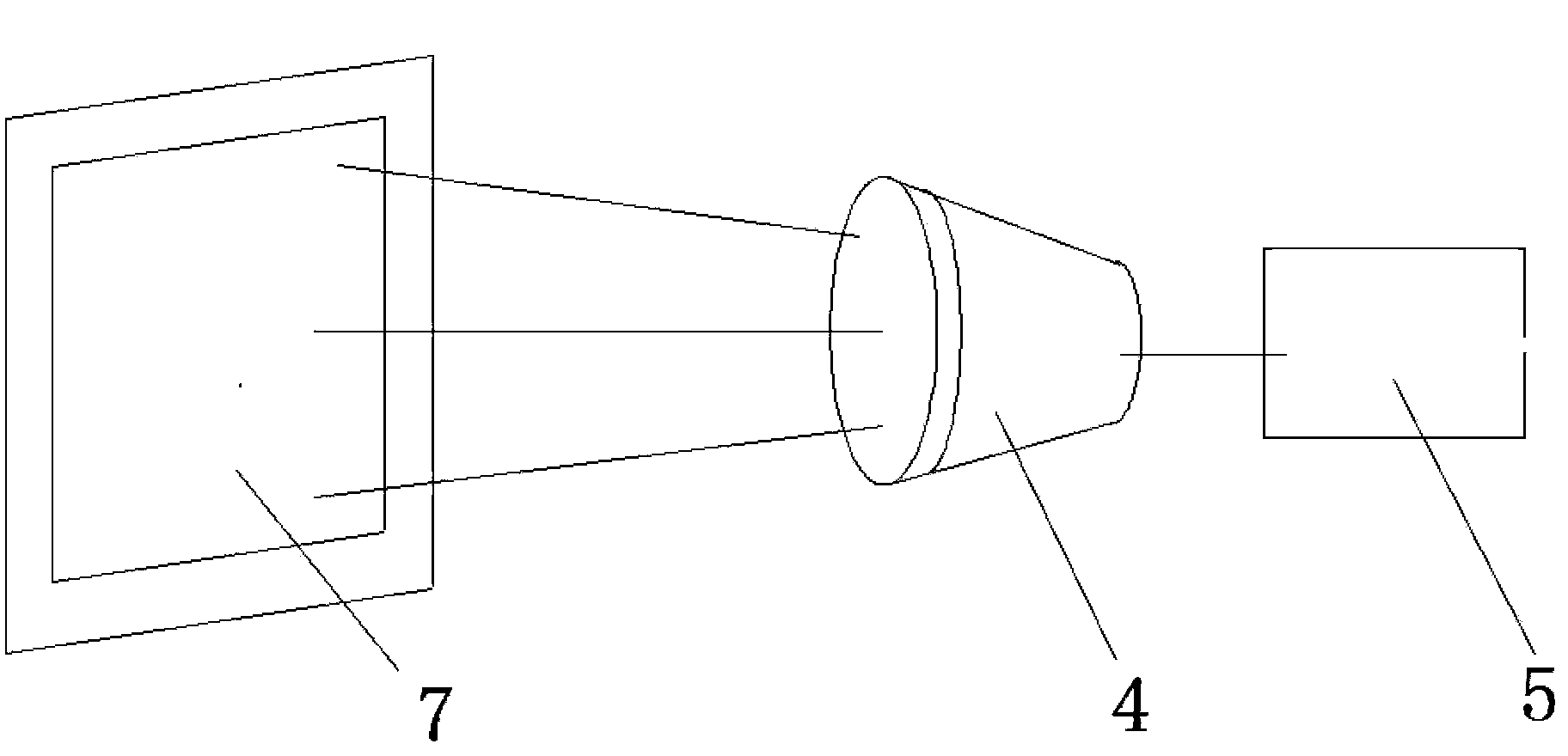

Method for calibrating thermal infrared imager pixel point

ActiveCN103076101BHigh precisionImprove non-uniformityRadiation pyrometryEmissivityBlack-body radiation

The invention discloses a method for calibrating a thermal infrared imager pixel point. The method comprises black-body radiation calibration and baffle temperature measurement. The mapping relation of the voltage V and temperature T of infrared imaging can be measured through the black-body radiation calibration. An n value which influences the thermal infrared imager pixel point temperature measurement accuracy is determined through deducing a baffle measured value and calculated value calculation formula for a plurality of times, and accordingly, the thermal infrared imager temperature measurement accuracy is increased. The method has the following advantages that 1, a baffle device temperature measurement method is adopted, the precision of n in a thermal infrared imaging temperature measurement formula is effectively improved, and accordingly, the thermal infrared imaging temperature measurement accuracy is improved; 2, the thermal infrared imaging temperature measurement unevenness can be effectively improved through accurately correcting each pixel of an infrared detector; 3, the baffle emissivity influence on an experiment result is not taken into consideration during the measurement experiment; and 4, the temperature influence on the experiment result is not taken into consideration during the measurement experiment.

Owner:WUXI ALEADER INTELLIGENT TECH

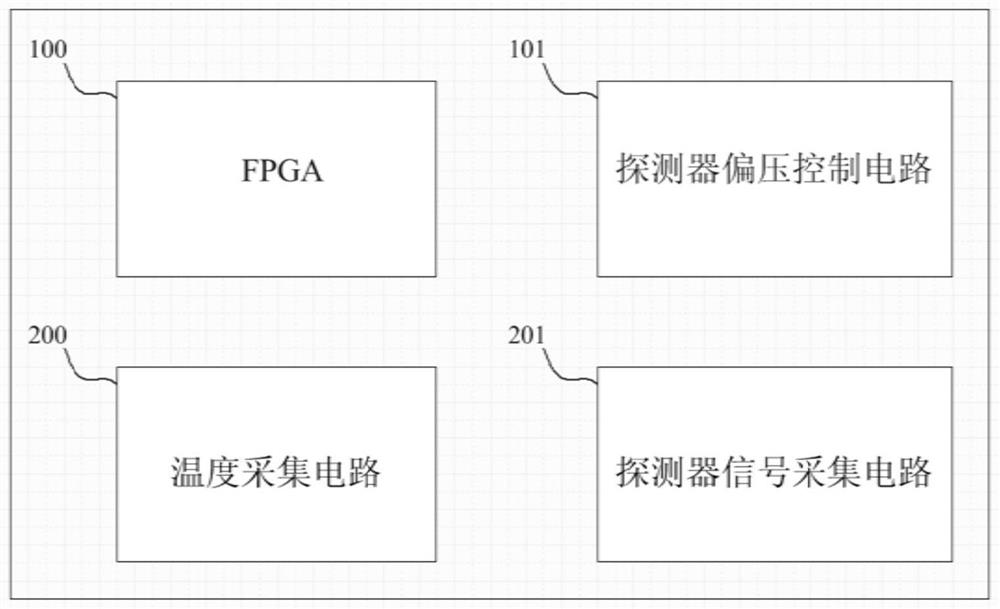

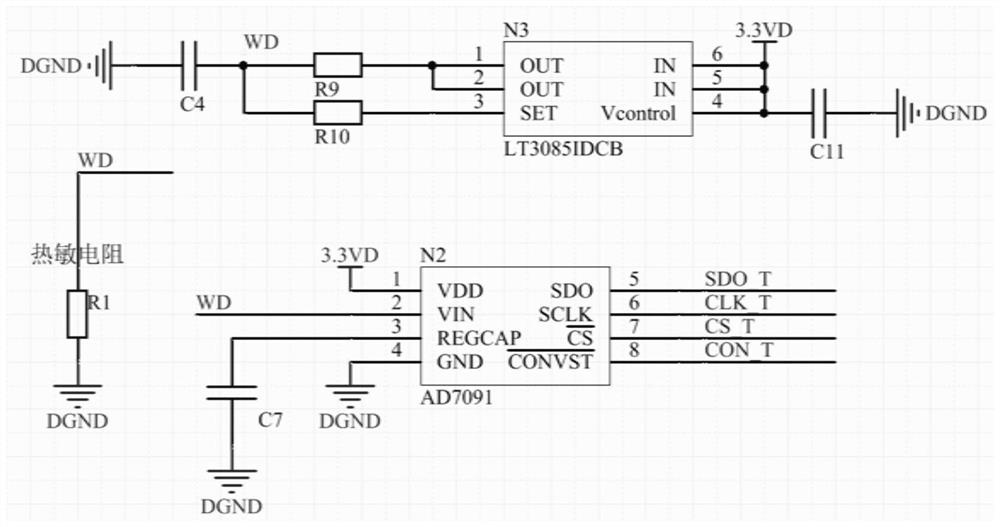

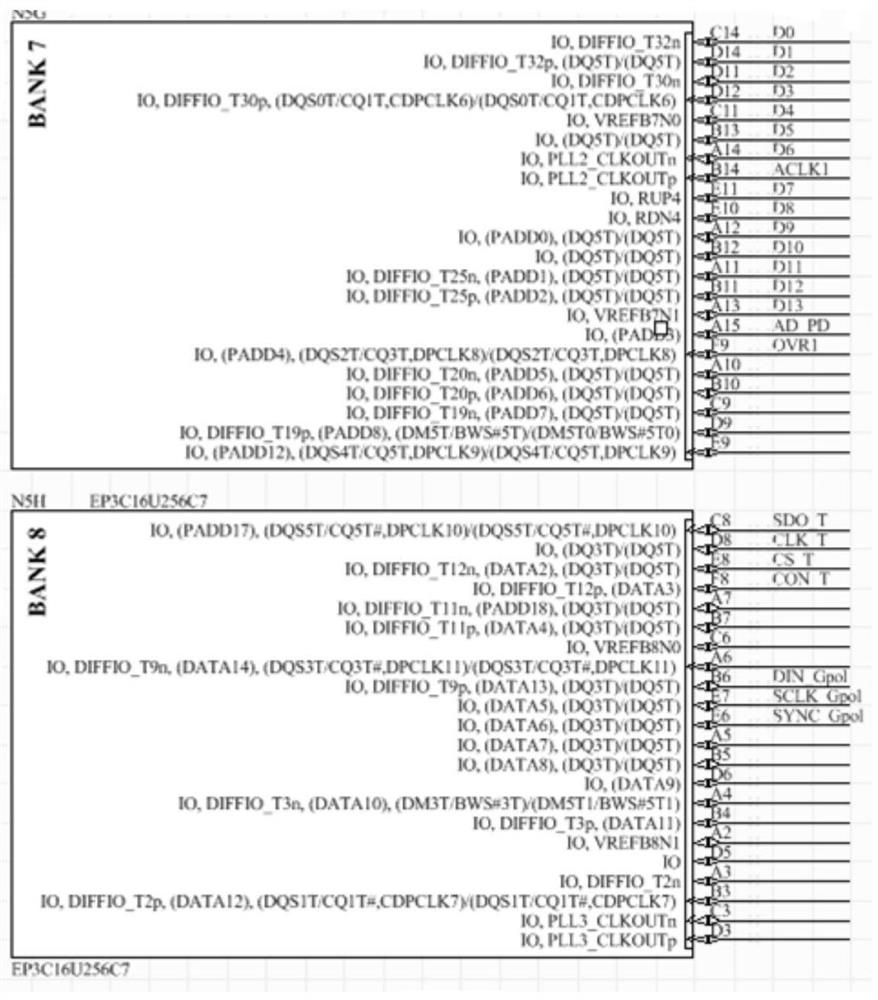

Signal quality stable output circuit of infrared detector

InactiveCN112050951AStable image signal outputAchieve isolationTelevision system detailsColor television detailsSignal qualitySoftware engineering

The invention discloses a signal quality stable output circuit of an infrared detector. The signal quality stable output circuit comprises a main processor FPGA, a temperature acquisition circuit, a detector bias control circuit and a detector signal acquisition circuit; the temperature acquisition circuit acquires the working environment temperature of the infrared detector, digitalizes the temperature and sends the digitalized temperature to the main processor FPGA; the main processor FPGA updates a detector bias voltage working instruction according to the temperature acquired by the temperature acquisition circuit and sends the detector bias voltage working instruction to the detector bias voltage control circuit; the detector bias control circuit updates the working voltage VR and Vgpol of the infrared detector according to a detector bias working instruction. The detector signal acquisition circuit corrects an output analog image signal according to the working voltage VR and Vgpol of the infrared detector, digitizes the analog image signal and sends the digitized analog image signal to the main processor FPGA. Acquisition of the environment temperature is completed through the temperature acquisition circuit, the acquired temperature is used as guidance, prior information is read, the detector bias voltage is configured through the detector bias voltage control circuit,bias voltage real-time configuration is achieved, and image signal output is stabilized.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Infrared focal plane non-uniformity fingerprint extraction and image correction method

ActiveCN101776487BClear thinkingImprove non-uniformityTelevision system detailsRadiation pyrometryInfraredWavelet decomposition

The invention relates to an infrared focal plane non-uniformity fingerprint extraction and image correction method which belongs to the technical field of infrared imaging. A production process decides, each infrared focal plane is provided with a relatively stable non-uniformity mode and a rule thereof which varies with temperature, and the two are collectively called fingerprints. The inventionprovides the definitions of non-conformity fingerprints, analyzes the characteristics of the focal plane non-uniformity in a frequency domain by wavelet decomposition, extracts the non-uniformity fingerprints which belong to the focal plane, and then stores the fingerprints in a storage unit of a detector. When in correction, with the environment temperature as the input parameter, the method cancarry out non-uniformity correction under the constraint of the fingerprints after reading the non-uniformity fingerprints at the environment temperature. Compared with convention methods, the methoddoes not need to obtain a background frame with a uniform baffle in every time of correction and has simple correction idea, thereby simplifying the correction device and the correction process, and the image non-uniformity after correction is significantly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

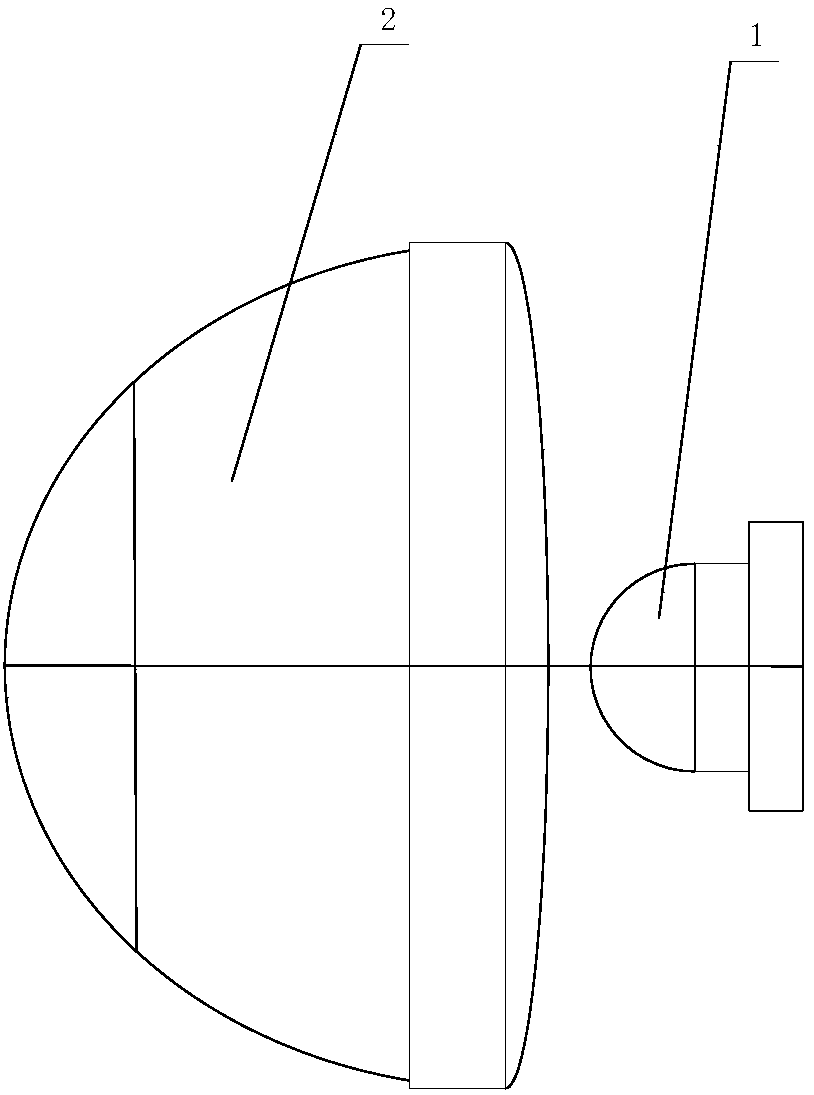

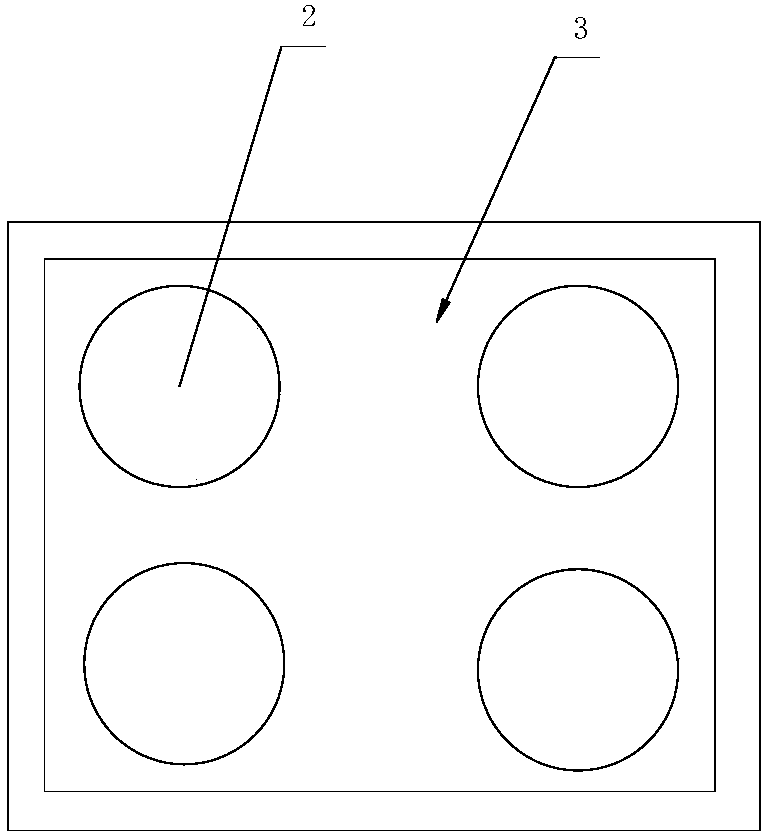

High-precision free-form surface lens based on light-emitting diode light distribution curve

InactiveCN109838759AImprove light energy utilizationMeet the use requirementsNon-linear opticsRefractorsFree formLight energy

The invention relates to a high-precision free-form surface lens based on a light-emitting diode light distribution curve. The high-precision free-form surface lens comprises a light-emitting diode and a plurality of double-free-form surface lenses with different radiuses; the double-free-form surface lenses are cut into rectangular lens and can form rectangular light spots and are spliced into alens array by using a rectangular lens; the matrix backlight surface is 10 mm x 13. 4 mm, the matrix is a 2 x 2 matrix, the size of the single rectangular lens is 5.05 mm x 6.7mm. Compared with a traditional backlight structure adopting a two-layer diffusion film, the light energy utilization rate of the backlight after the lens array and the two layers of diffusion films are adopted is improved,the backlight brightness is improved and the heterogeneity is improved, the half-brightness visual angle is reduced from 37 degrees to 19 degrees; the lens and the array provided are used for collimating light rays emitted by the LED light sources, so that a uniform rectangular light spot with high brightness is easily formed, and the use requirement of the head is met.

Owner:成都中源红科技有限公司

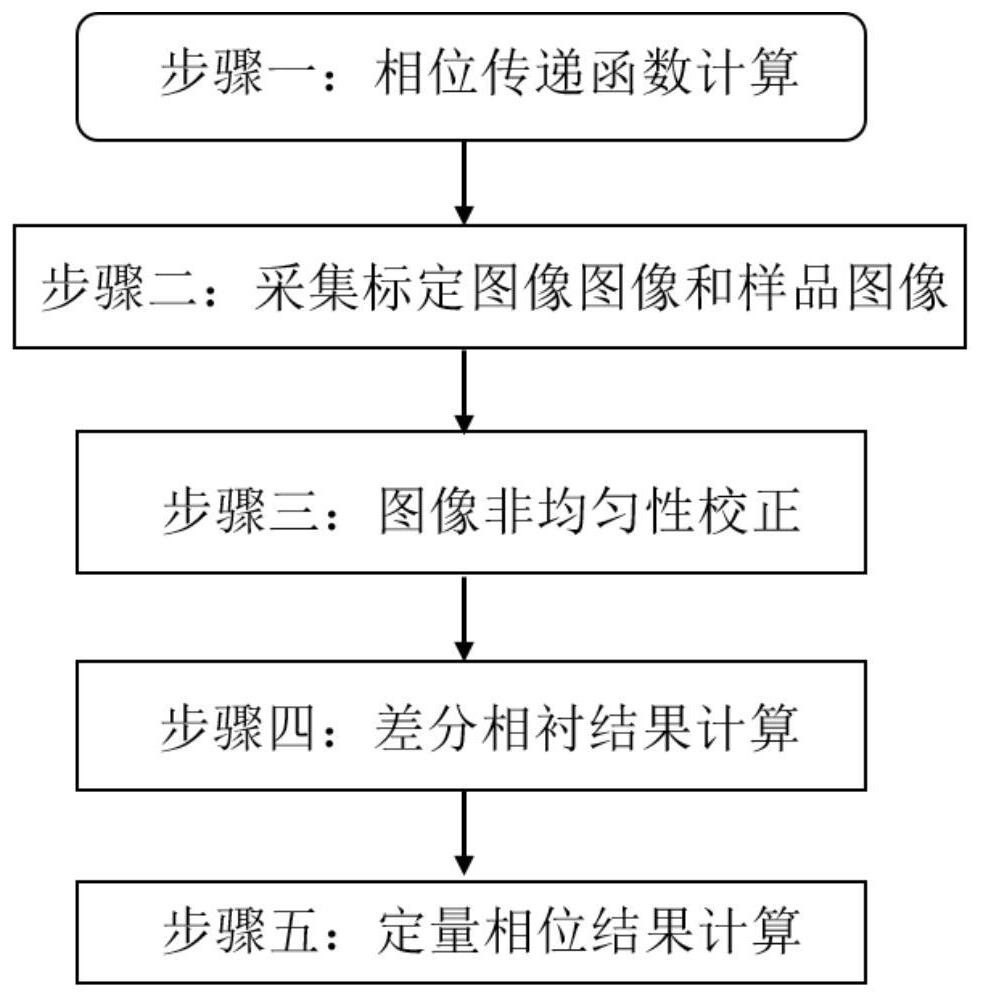

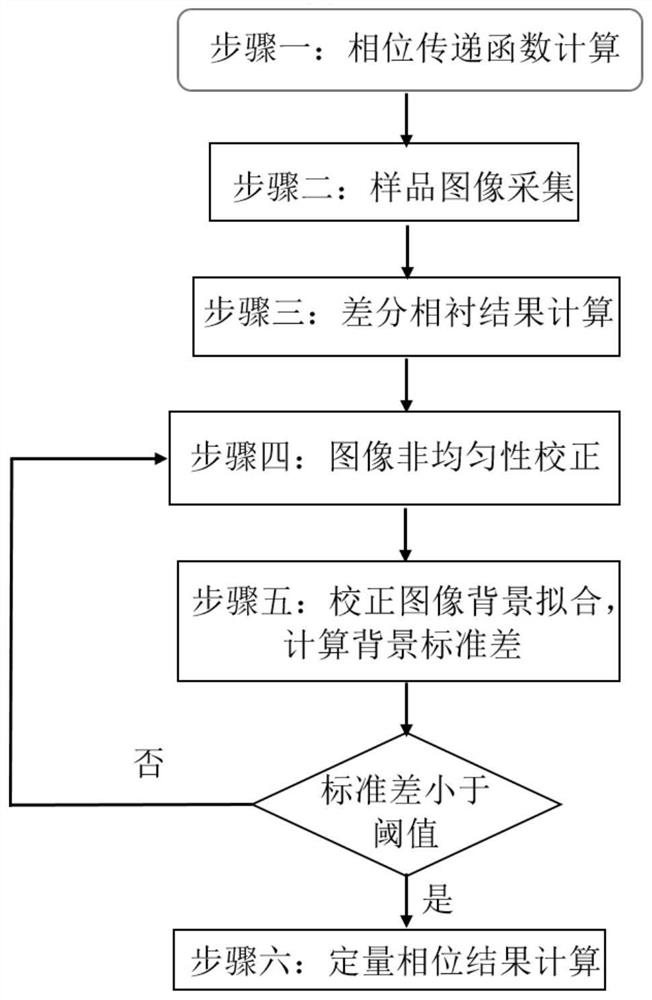

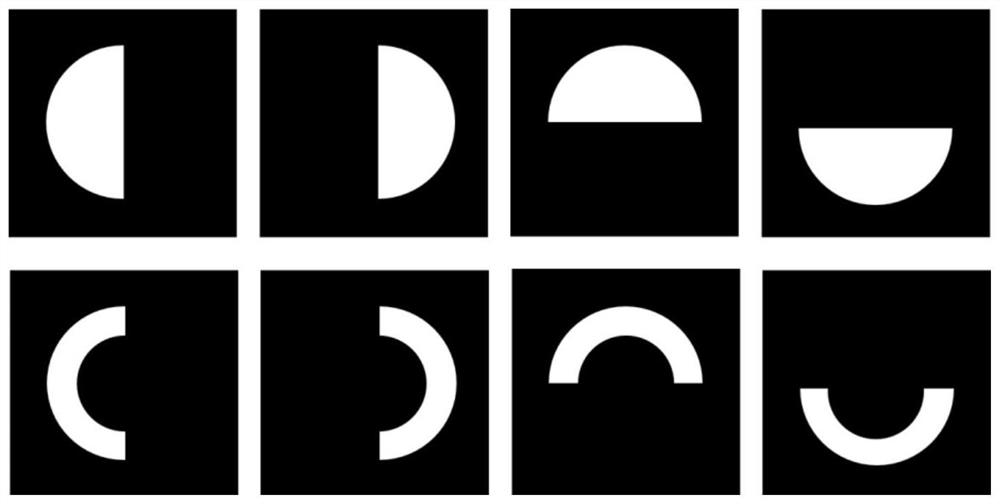

Correction and Compensation Method of Background Nonuniformity in Differential Phase Contrast Microscopy

ActiveCN108537842BImprove non-uniformityGood non-uniformity correctionImage enhancementImage analysisMicro imagingImaging quality

The invention discloses a correction and compensation method for background non-uniformity in differential phase-contrast microscopic imaging. The background pre-calibration or self-adaptive background fitting method is adopted. In the background image, the non-uniformity of the image is eliminated by subtraction or division in subsequent calculations. In differential phase contrast imaging, the inhomogeneity of the image is distributed linearly in the direction of illumination. Based on this, the adaptive background fitting method adopts three kinds of fitted background images, which are eliminated by subtraction or division in subsequent calculations. Image non-uniformity. The present invention solves the problem of uneven brightness and darkness of images that exist when a differential phase-contrast imaging system collects images, and improves imaging quality and phase resolution accuracy on the basis of ensuring the imaging speed of the differential phase-contrast imaging microscope system.

Owner:NANJING UNIV OF SCI & TECH

A kind of injection method of solid retarded acid

ActiveCN111364964BSave construction water horsepowerReduce construction riskFluid removalDrilling compositionAcetic acidGlycolic acid

The invention relates to a method for injecting a solid retarded acid, which includes: (1) uniformly mixing a solid acidic substance and a natural polymer according to a mass ratio of 0.2-1.2:1 to produce particles with a particle size of 20-70 mesh, and releasing In the coating pan, sprinkle zinc acetate powder, the coating pan rotates at a speed of 100-300 rpm, and at the same time irradiates with infrared light. After rotating for 10-30 minutes, spray the concentration of 92-98% with a spray gun Glycolic acid aqueous solution, stop after spraying for 60-90 minutes, and continue to rotate for 30-60 minutes to obtain solid retarded acid; (2) inject non-reactive liquid and solid retarded acid into the sand mixer, and the solid retarded acid The mass to volume ratio of the non-reactive liquid is 10‑80:100. After the sand mixer is mixed evenly, it is injected into the formation with a fracturing truck. When the solid retarded acid is delivered to the design position, stop the pump, remove the pipeline, and wait After 3‑6 hours, open the well and blow out. The invention has good resistance-reducing performance, is easy to discharge back, reduces construction cost, is beneficial to environmental protection, and has broad market application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

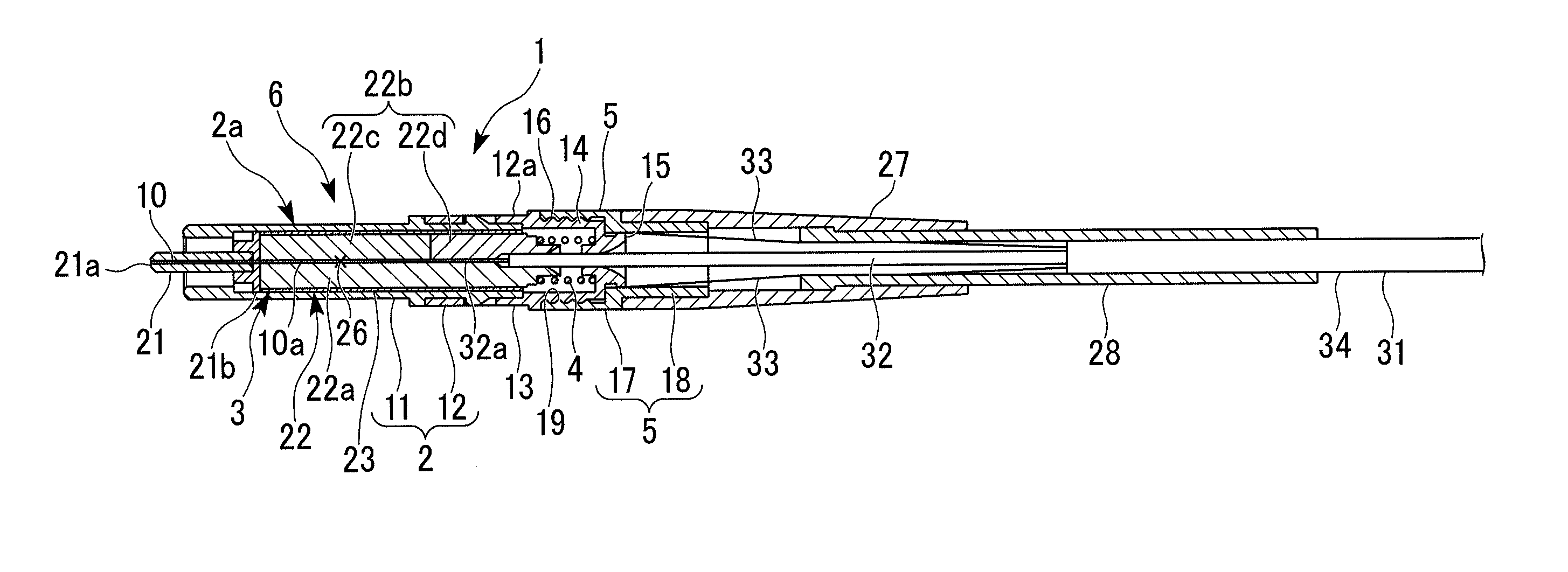

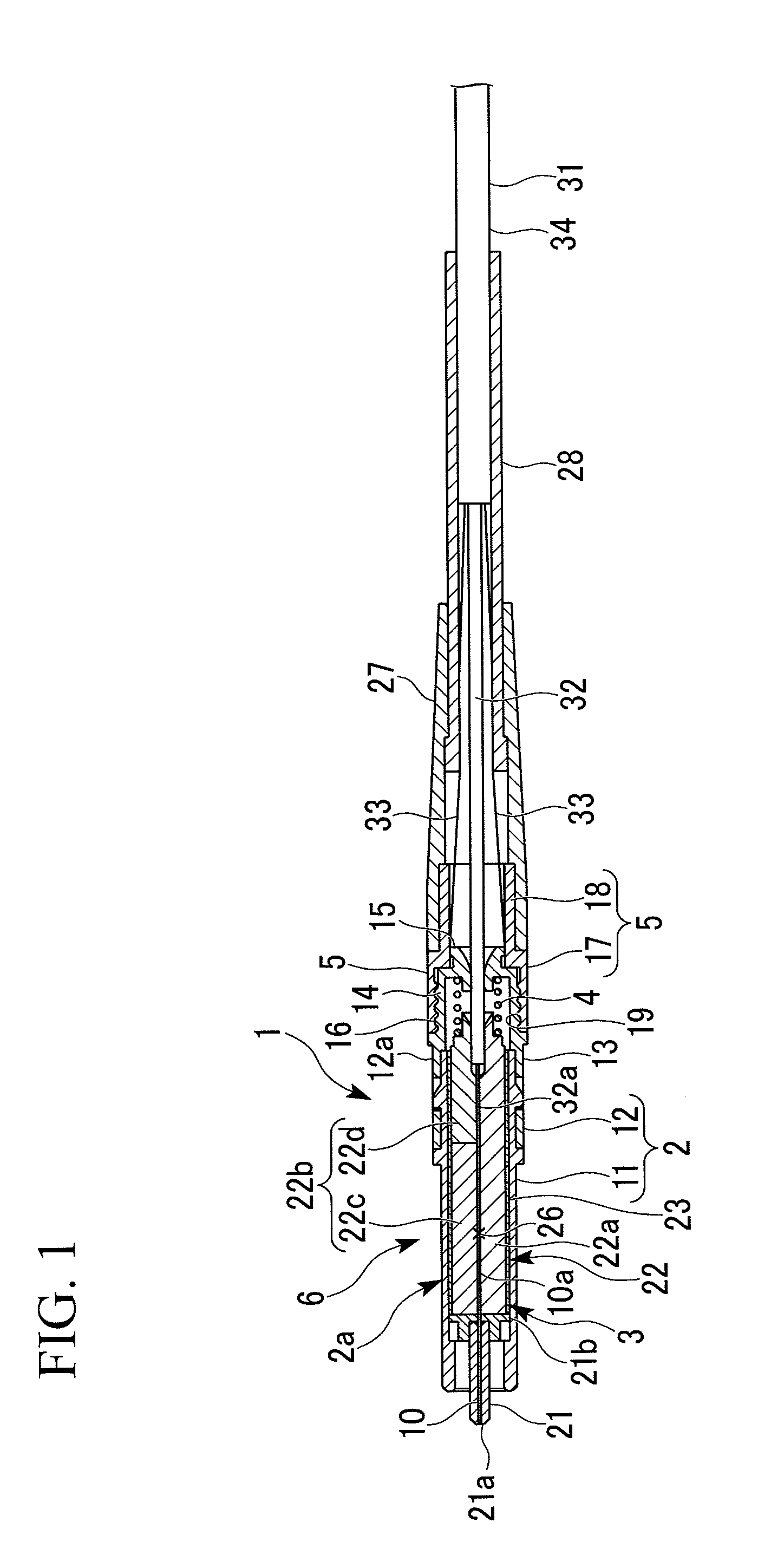

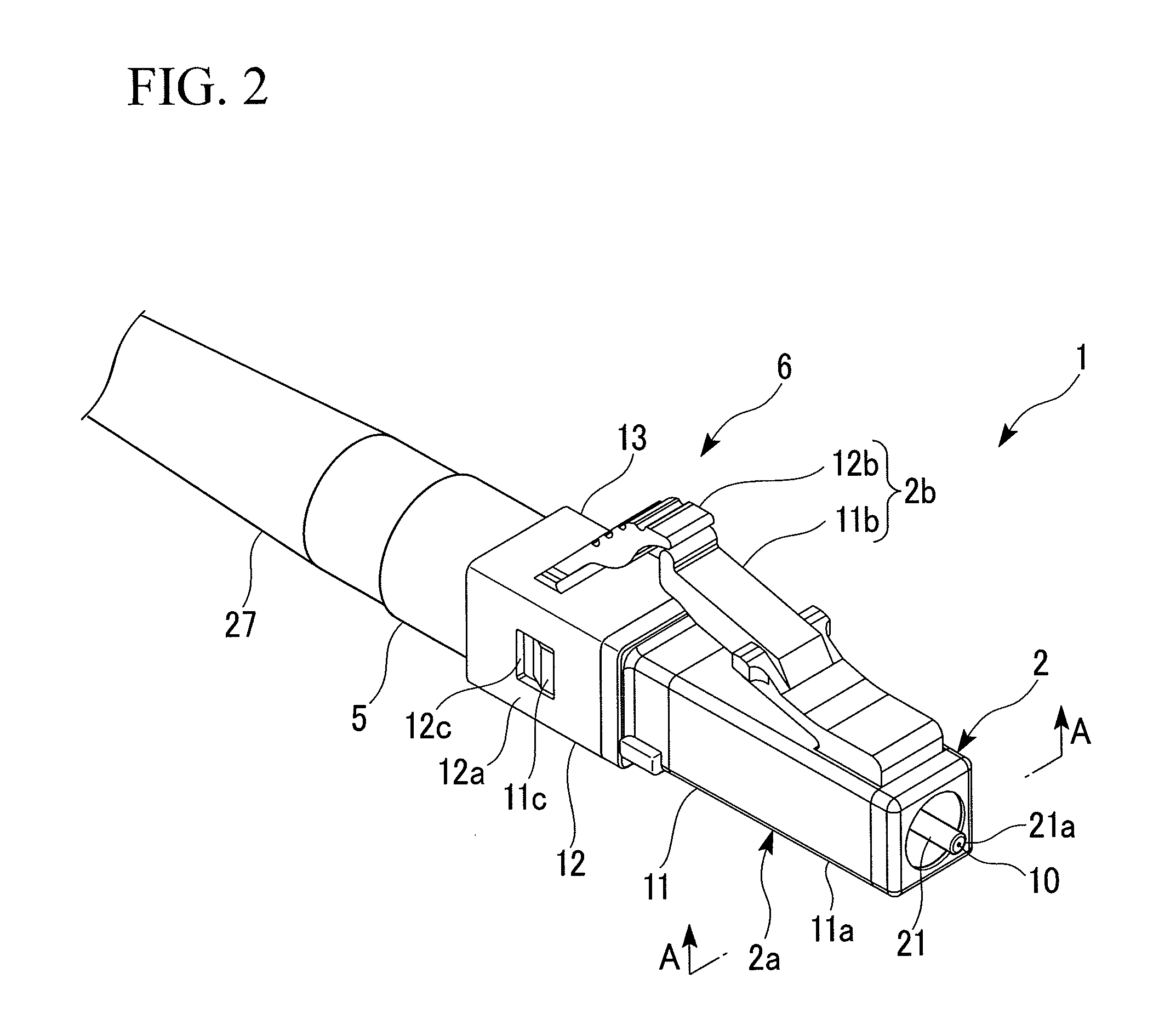

Optical connector and method of assembling optical connector

ActiveUS20110293224A1Improve non uniformityHigh strengthCoupling light guidesMetal working apparatusBiomedical engineeringOptical fiber cable

An optical connector that is assembled at the terminal of an optical fiber cable that integrates an optical fiber and a tension-resisting member extending in the longitudinal direction of the optical fiber, the optical connector including: a connector body having a stationary portion at the rear end thereof, the stationary portion having a threaded portion formed on the outer periphery surface, and a fixing cap that is screwed onto the threaded portion of the stationary portion, wherein the fixing cap fixes the tension-resisting member that has been drawn out from the optical fiber cable terminal by sandwiching the tension-resisting member between the fixing cap and the connector body when the fixing cap is screwed onto the stationary portion.

Owner:THE FUJIKURA CABLE WORKS LTD

A microbial flat grouting device and method for strengthening liquefiable foundations

Owner:NANJING FORESTRY UNIV

Method for correcting heterogeneities in optical beam image transmission system

InactiveCN101833755BImprove non-uniformityPositive non-uniformityImage enhancementBundled fibre light guideImaging analysisLine array

The invention discloses a method for correcting heterogeneities in a line-face conversion type optical beam image transmission system. The method is used for correcting in a photoelectrical system of an ultra-long line array detector for acquiring line-face conversion type optical beams by adopting a multi-section type graded one point method. After the method is used, the heterogeneities of images are obviously improved, thereby laying foundation for subsequent image analysis.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com