High-precision free-form surface lens based on light-emitting diode light distribution curve

A technology of light emitting diodes and curved lenses, applied in optics, nonlinear optics, components of lighting devices, etc., can solve the problems of small distance between LCD screen and LED light source, difficult to design light modulation of a single lens, etc., to improve backlight brightness, The effect of improving the utilization rate of light energy and improving the non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0015] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

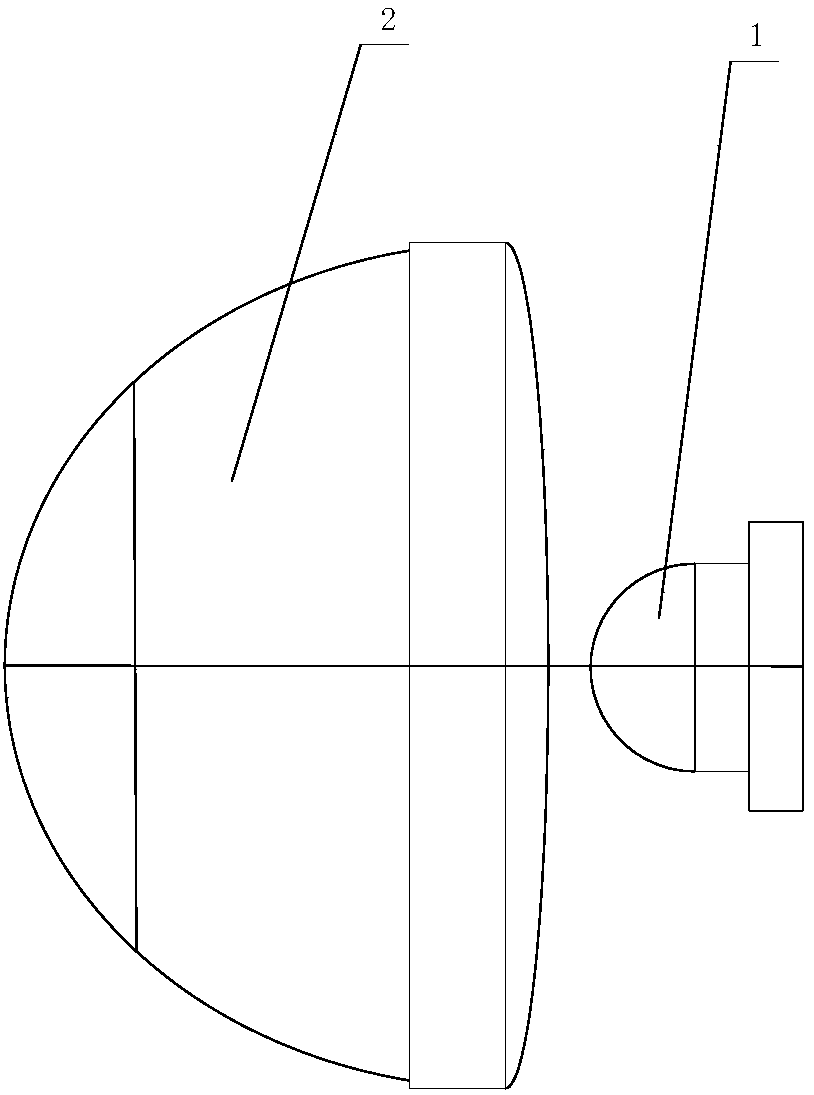

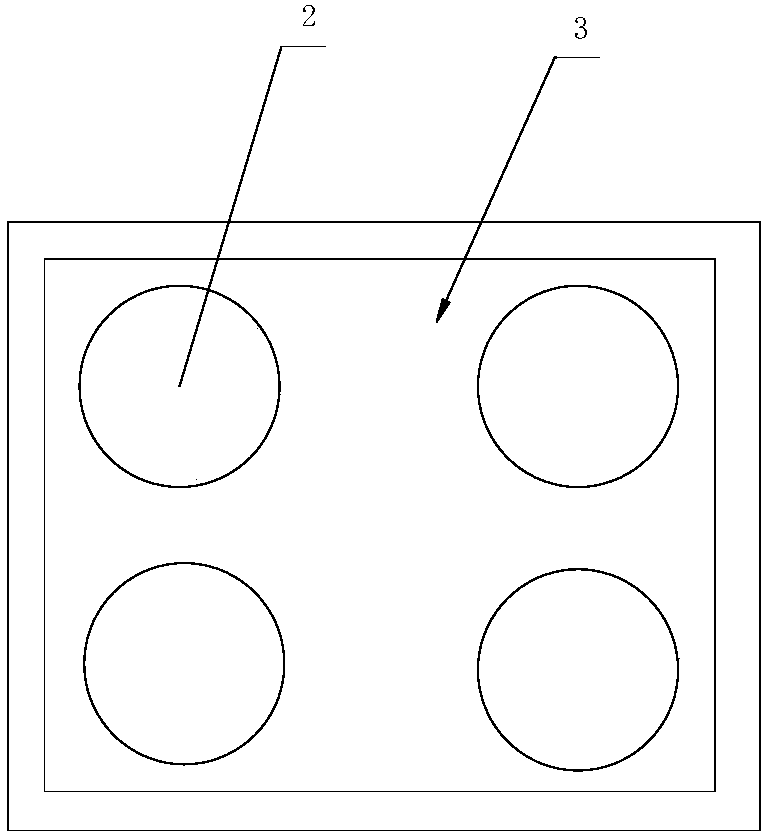

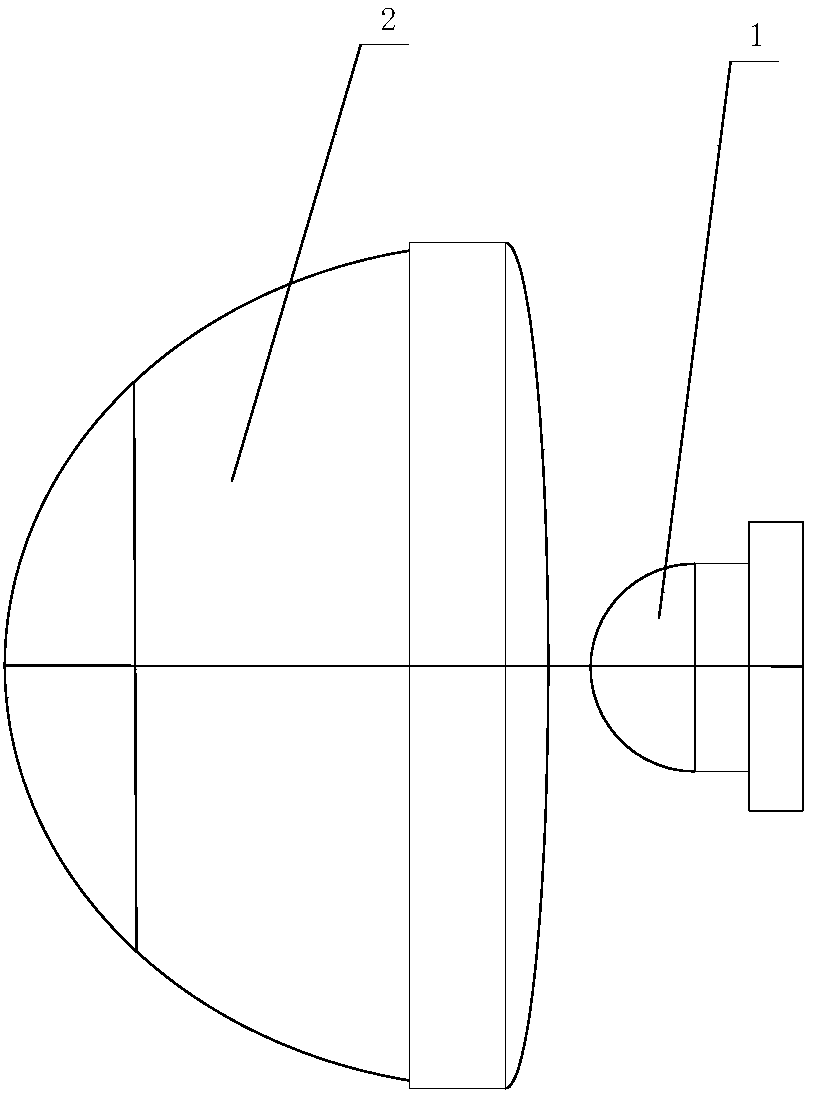

[0016] Such as figure 1 As shown, the present invention provides a high-precision free-form surface lens based on the light distribution curve of a light-emitting diode, including: a light-emitting diode 1 and a plurality of double free-form surface lenses 2 with different radii; the double free-form surface lens 2 becomes a rectangular lens after cutting It can also form a rectangul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com