Patents

Literature

89results about How to "Increase backlight brightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

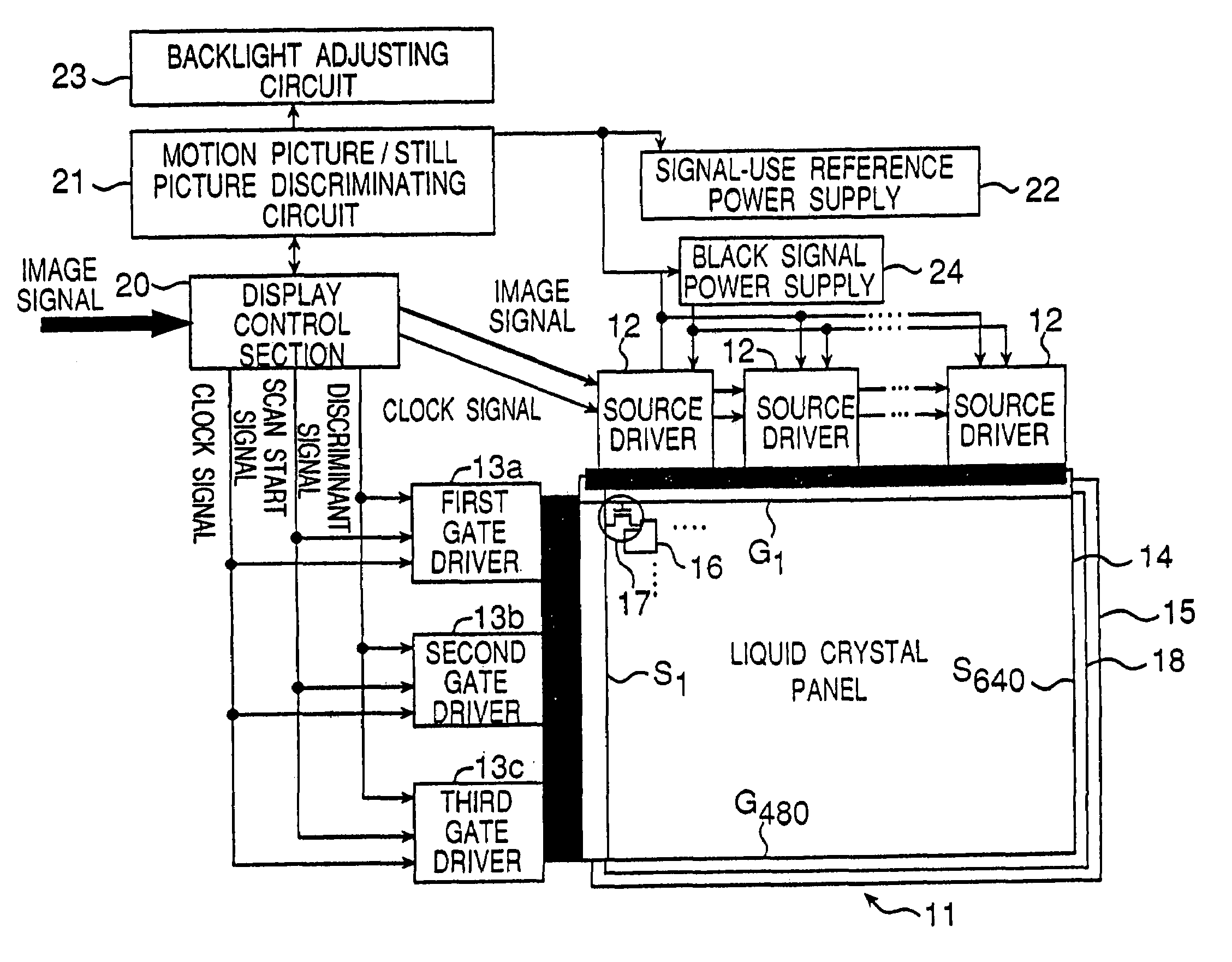

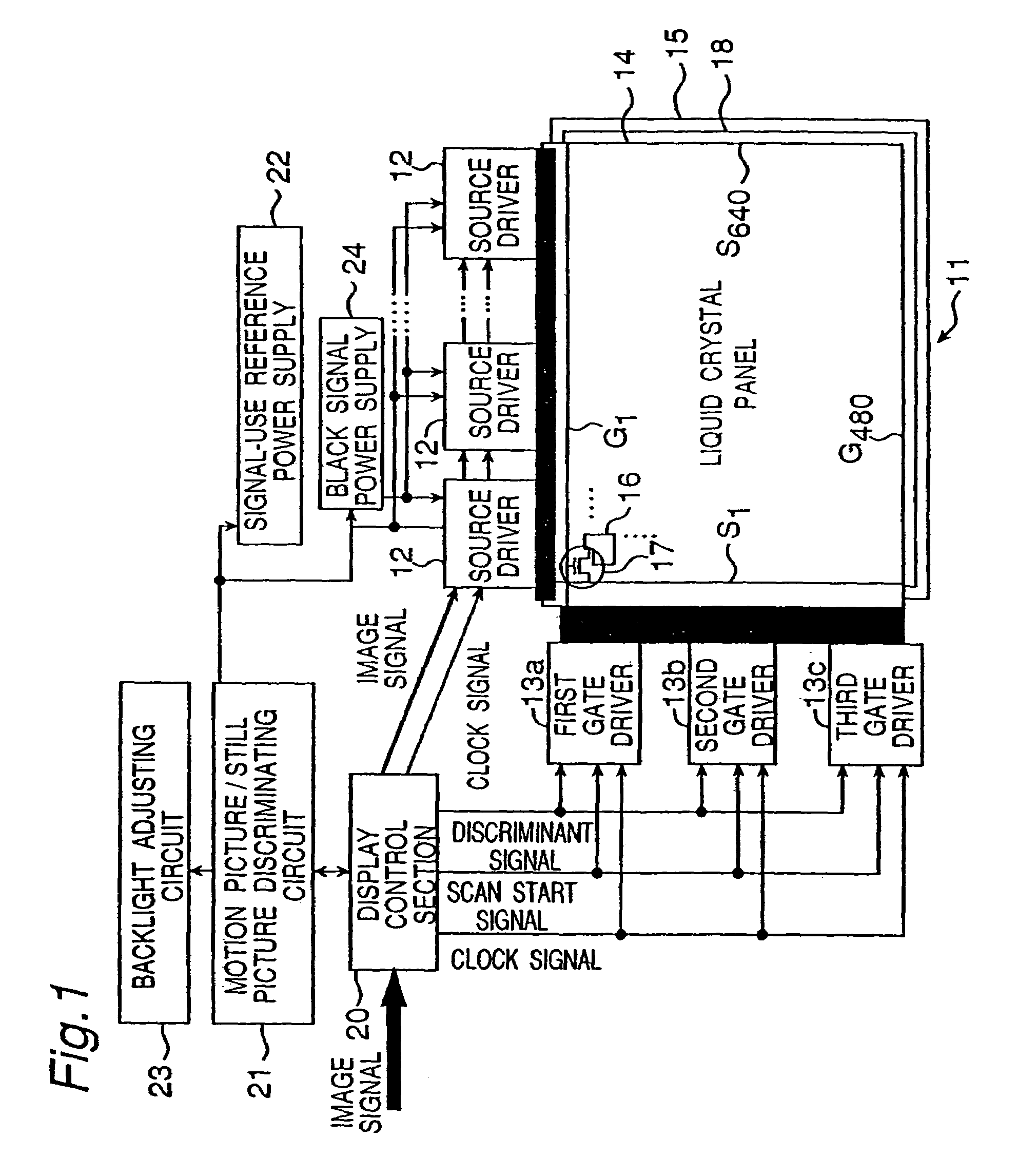

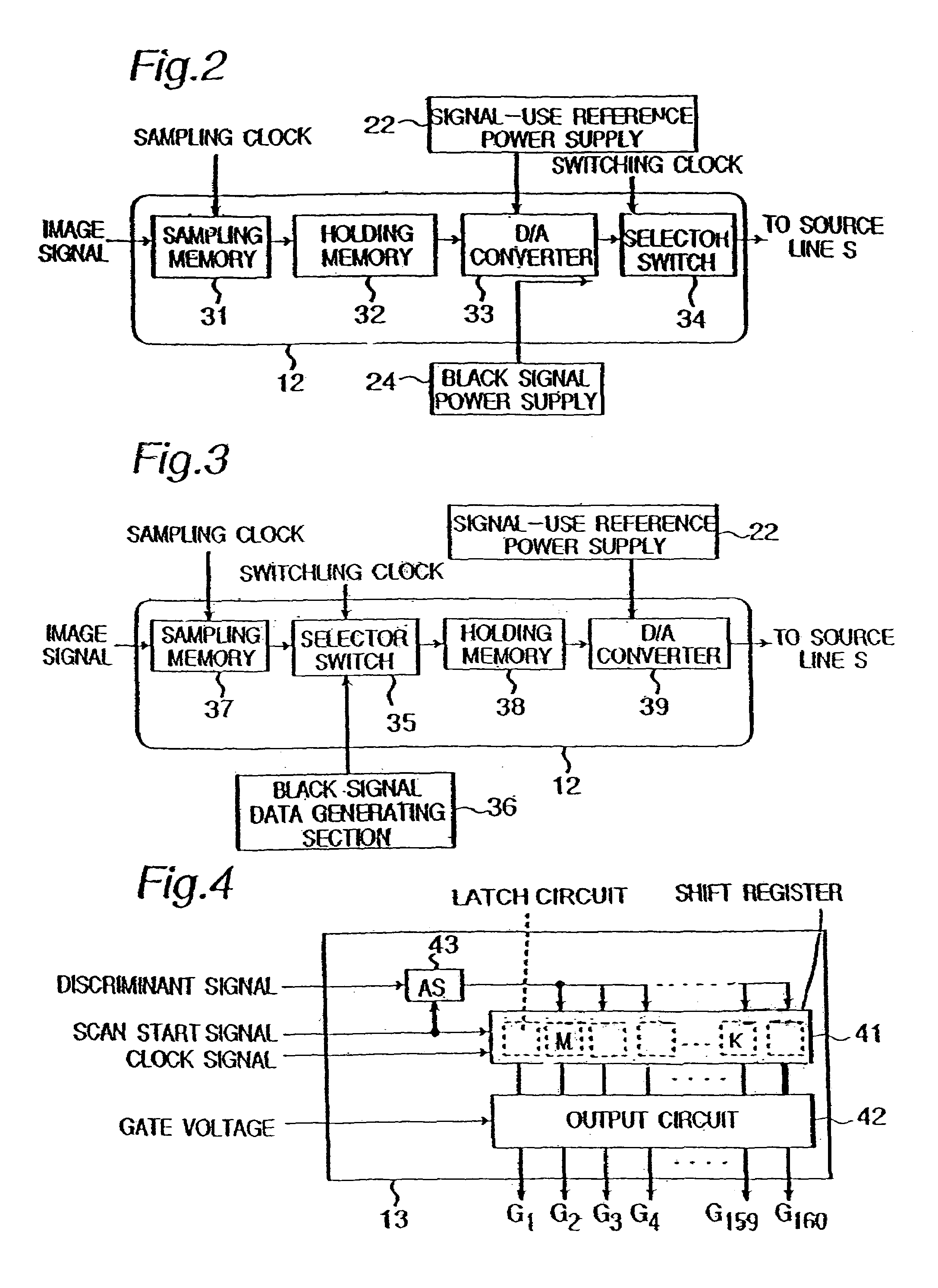

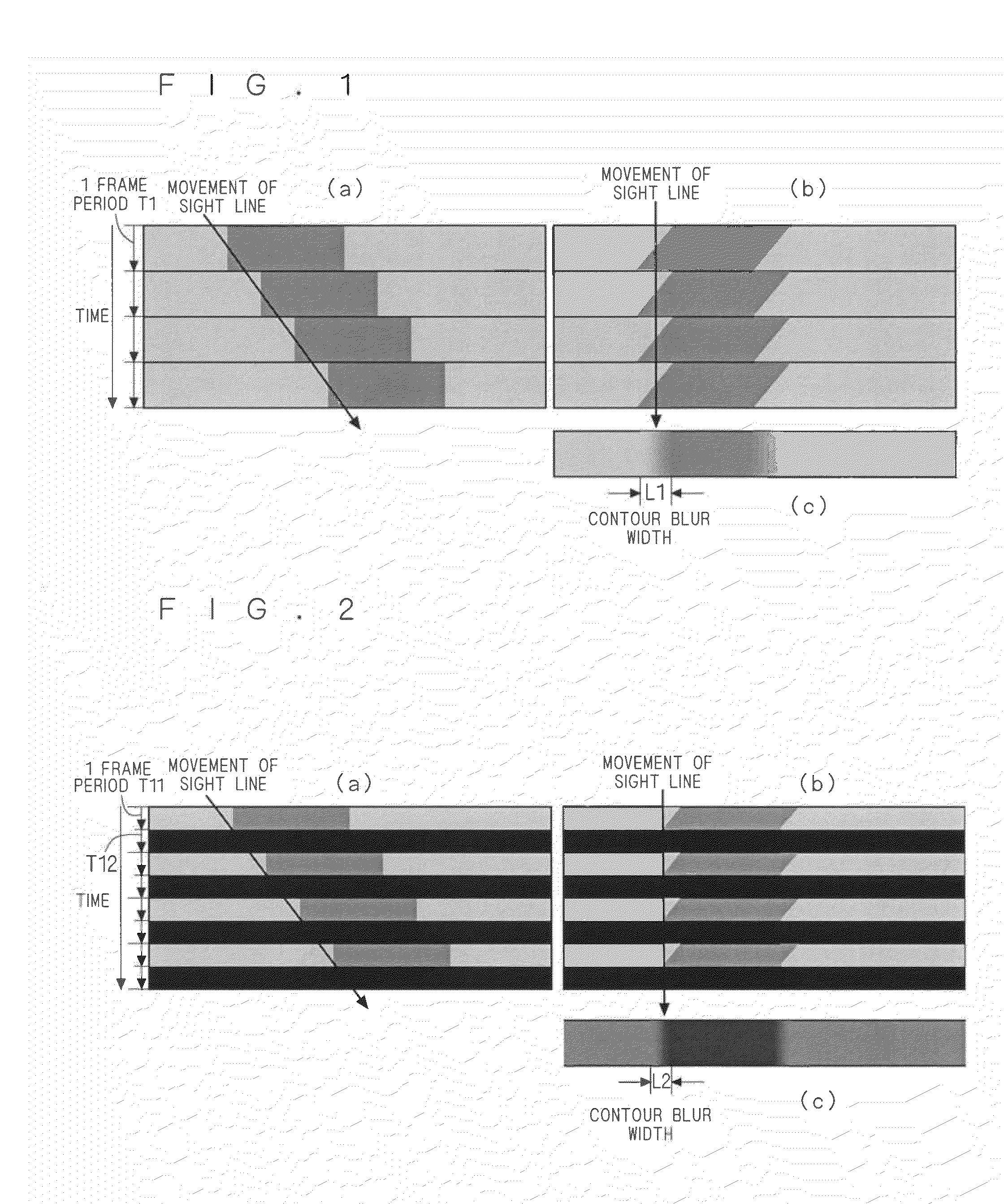

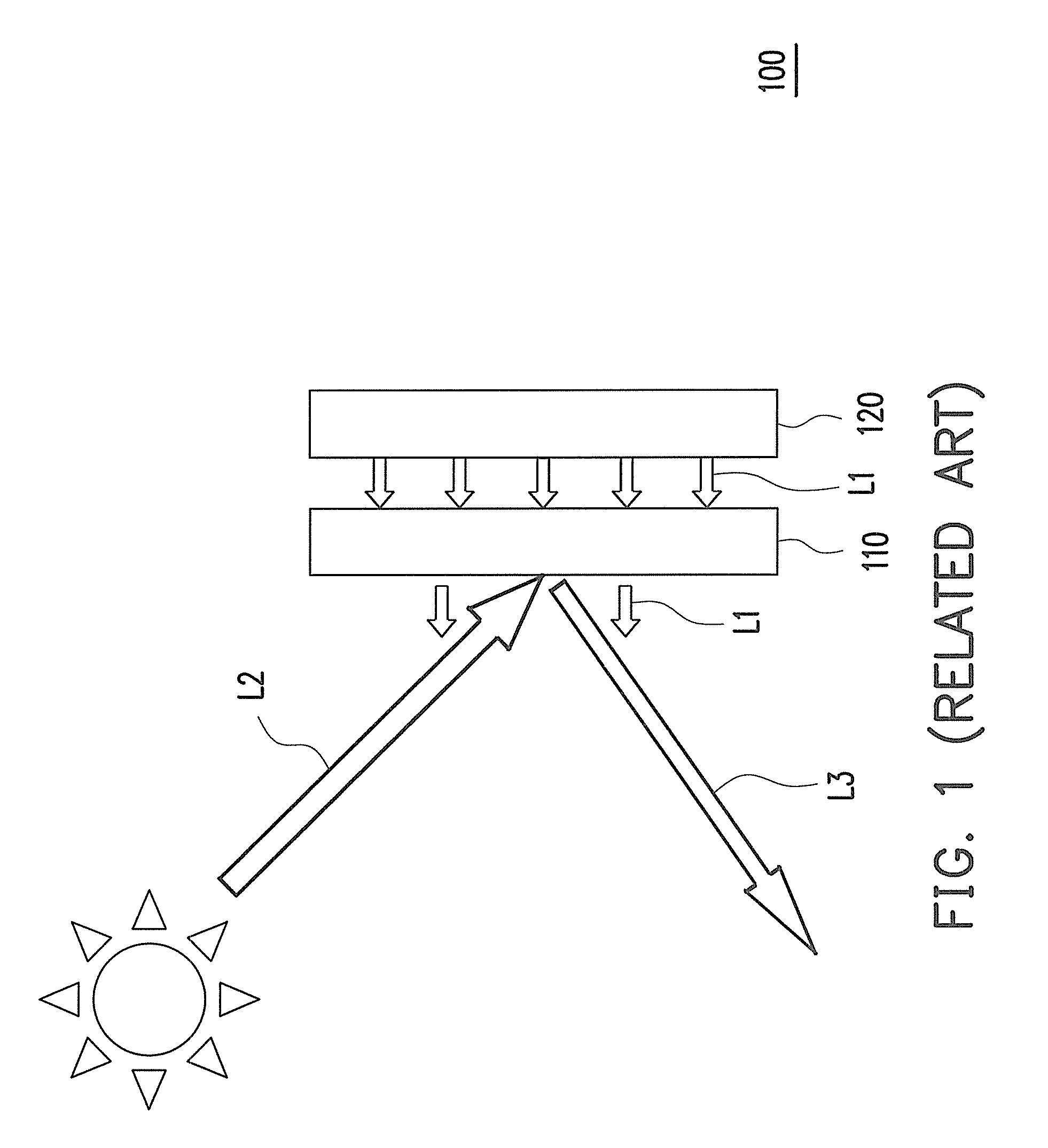

Liquid crystal display method and liquid crystal display device improving motion picture display grade

InactiveUS6937224B1Transmissivity decreaseIncrease backlight brightnessTelevision system detailsStatic indicating devicesLiquid-crystal displayData signal

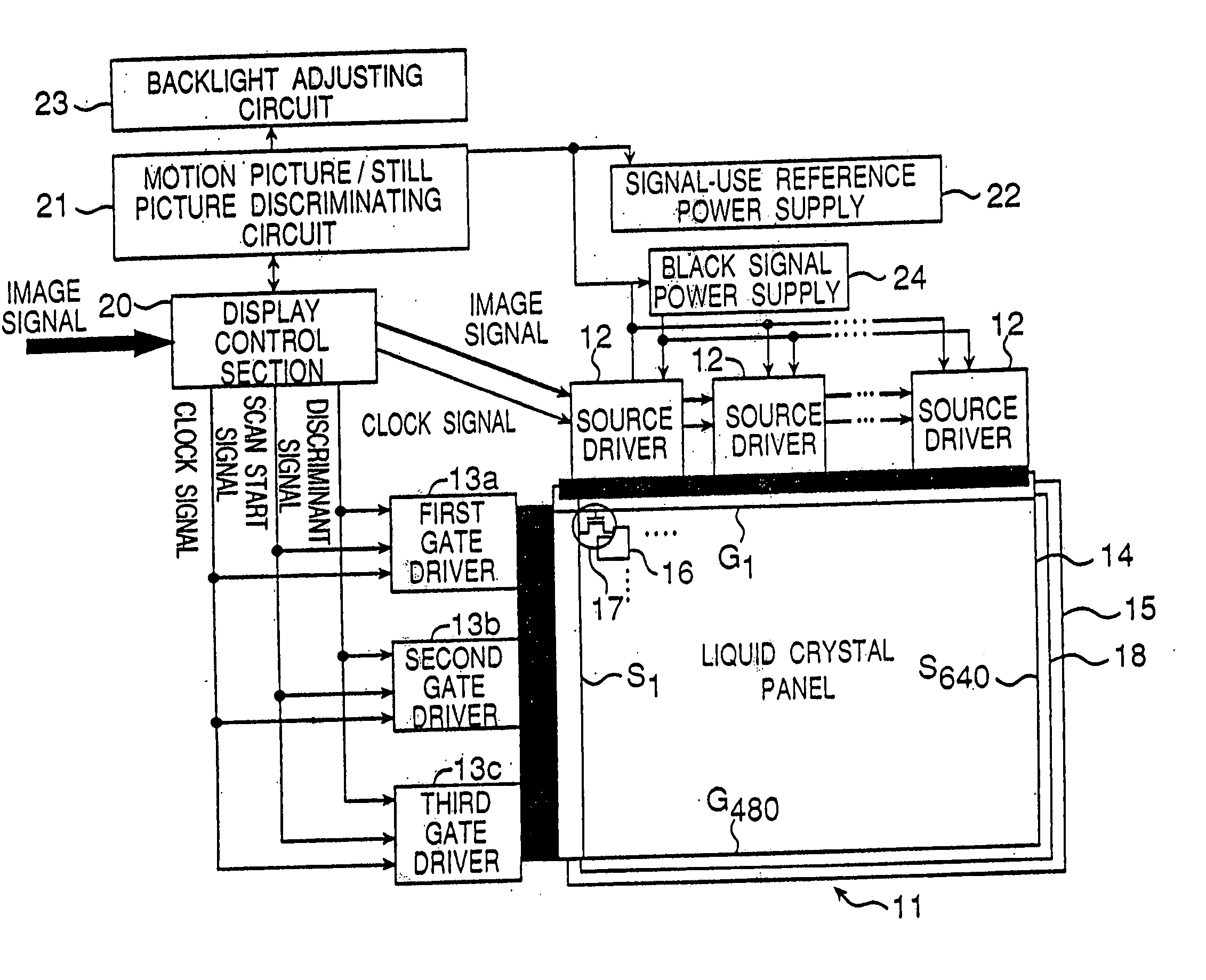

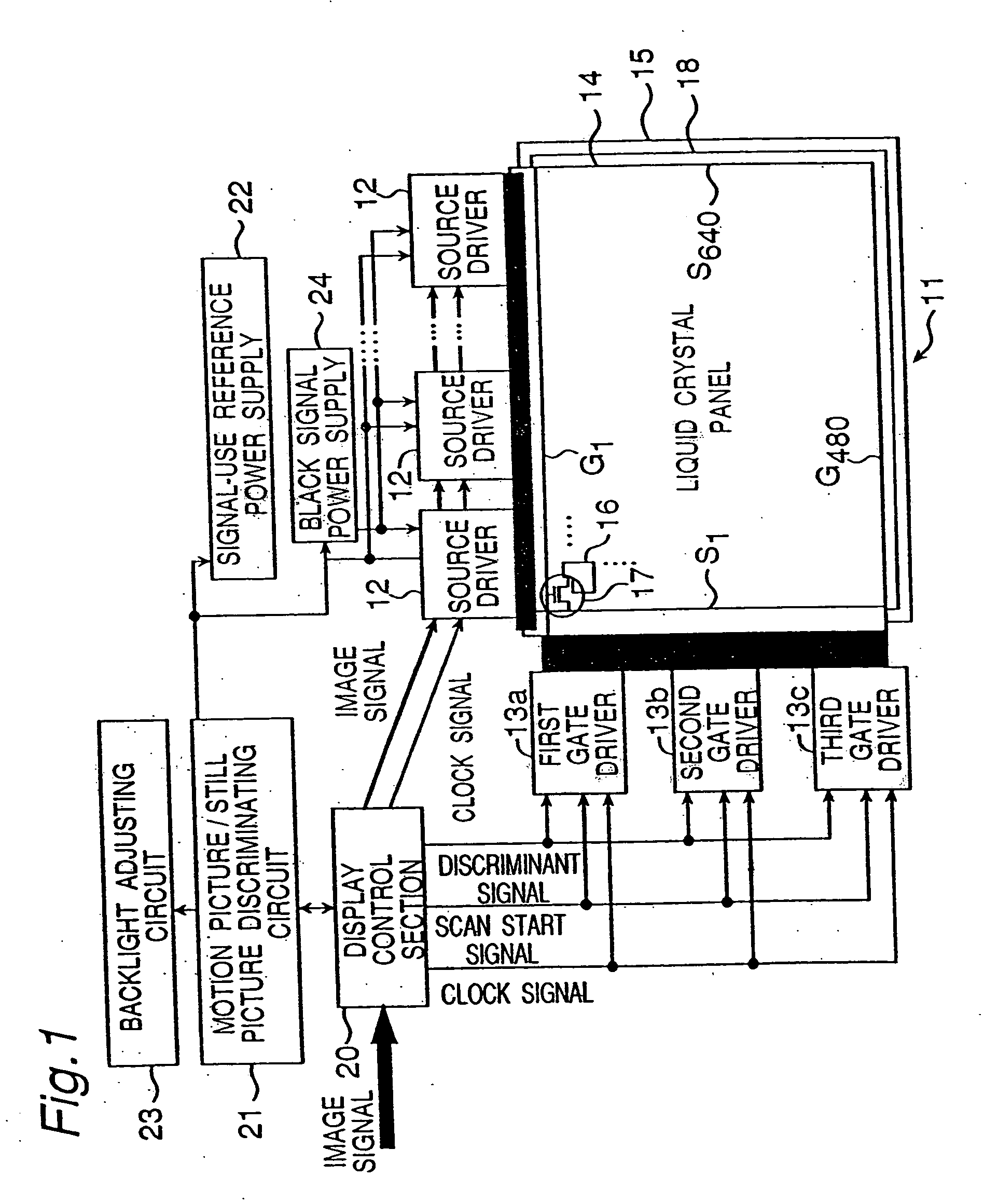

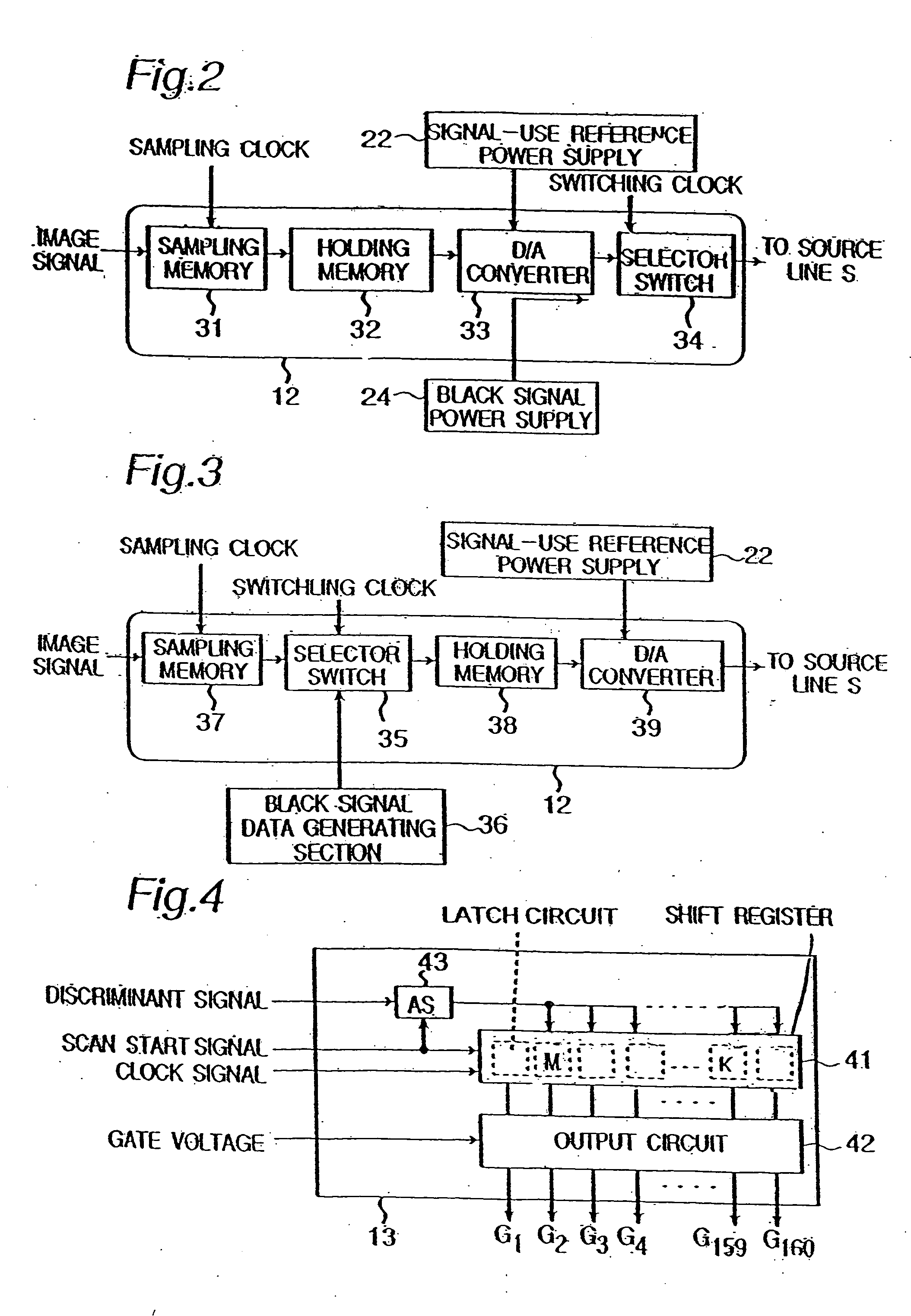

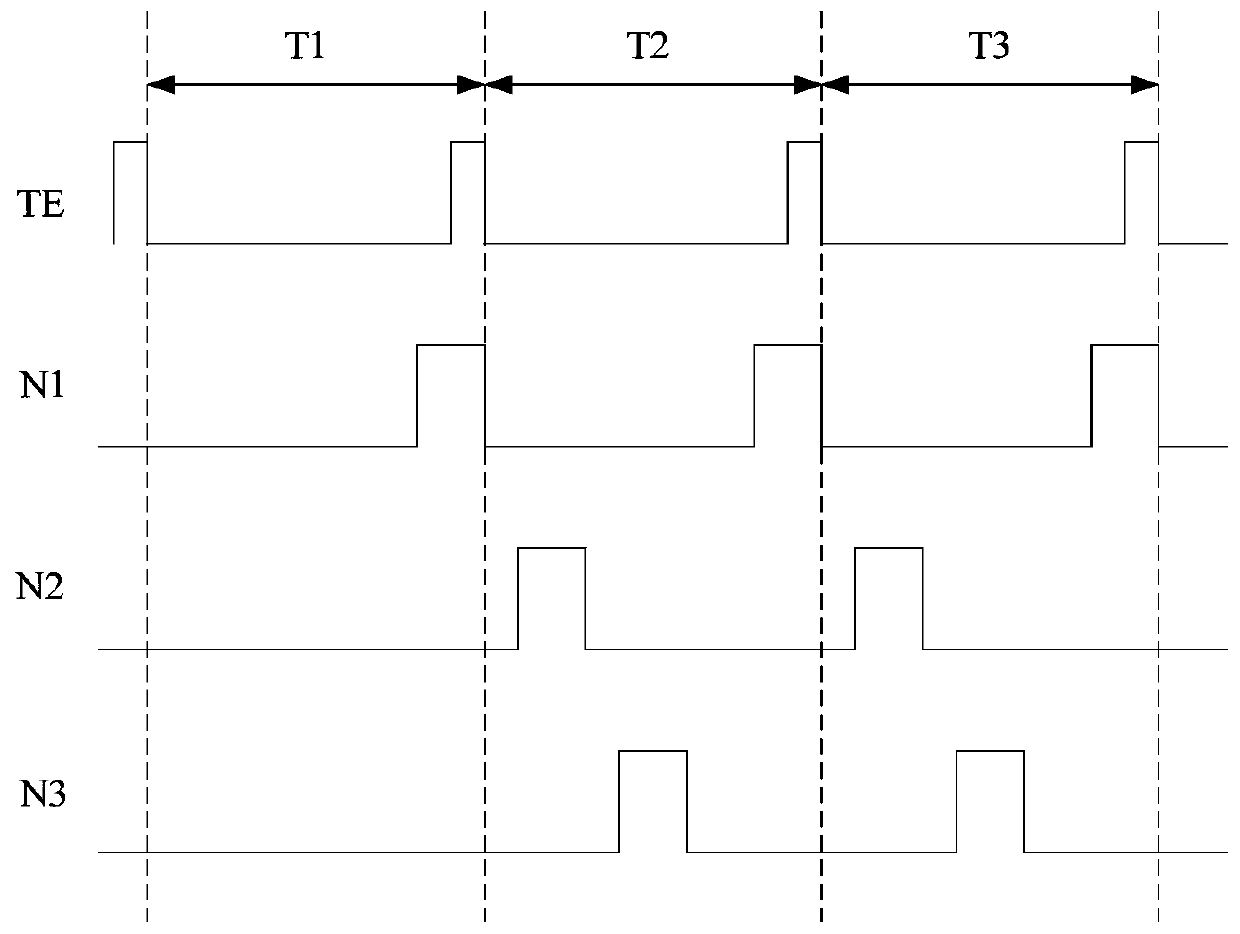

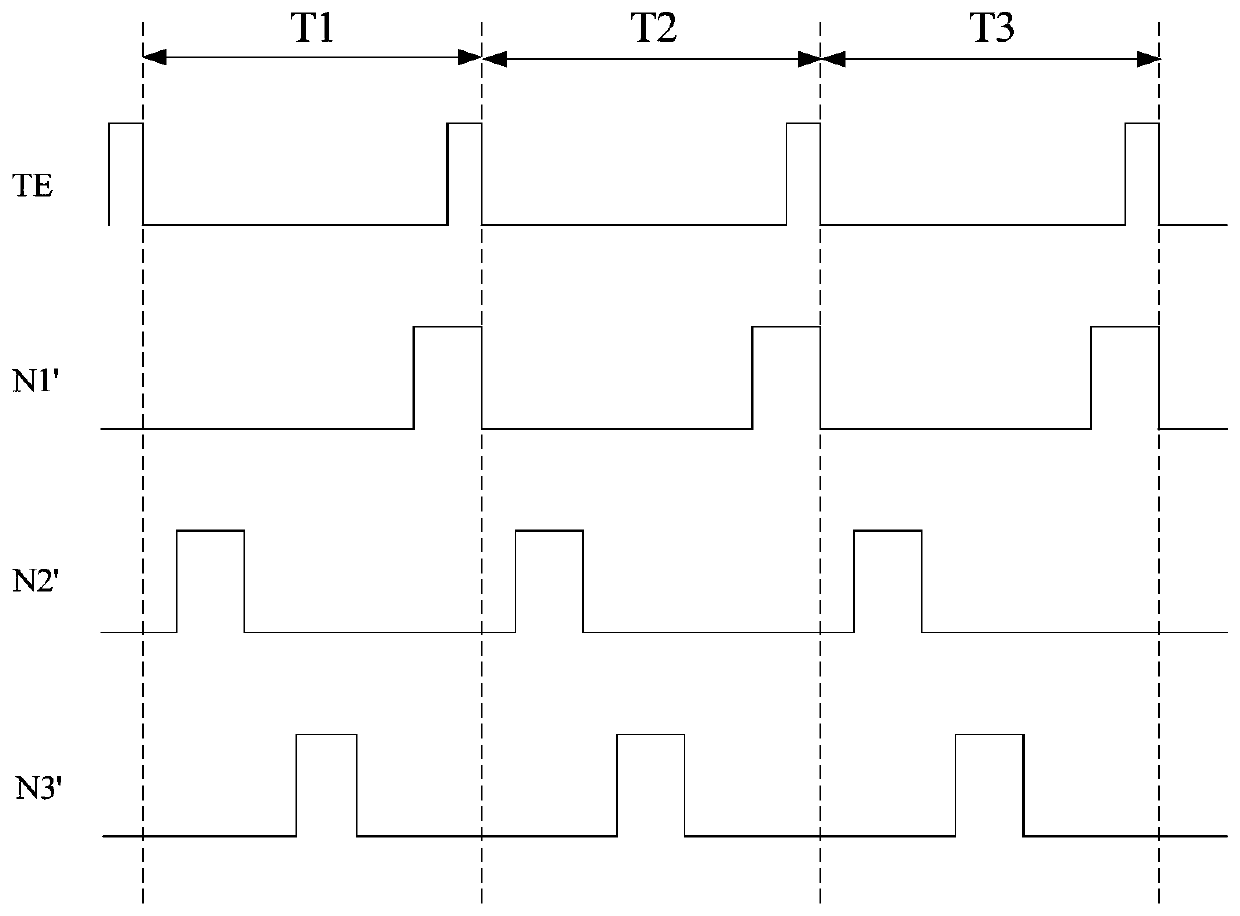

A source driver outputs a data signal and a reset (black) signal alternately to a source line. Four-hundred and eighty gate lines are divided into three groups each comprising 160 lines, and connected to gate drivers. A display control section outputs a discriminant signal, a scan start signal and a clock signal to the gate drivers, where the nth gate line is selected with the data signal outputted by the source driver, and where the (n+160)th gate line is selected with the reset signal outputted. Further, n is shifted sequentially. By writing the reset signal during the latter ⅓ of one frame like this, light leakage of pixels that are changed over from white display to black display is eliminated. Also, blurs of edge portions of a motion picture are reduced. Thus, display grade for motion pictures is enhanced with a minimum improvement.

Owner:SHARP KK

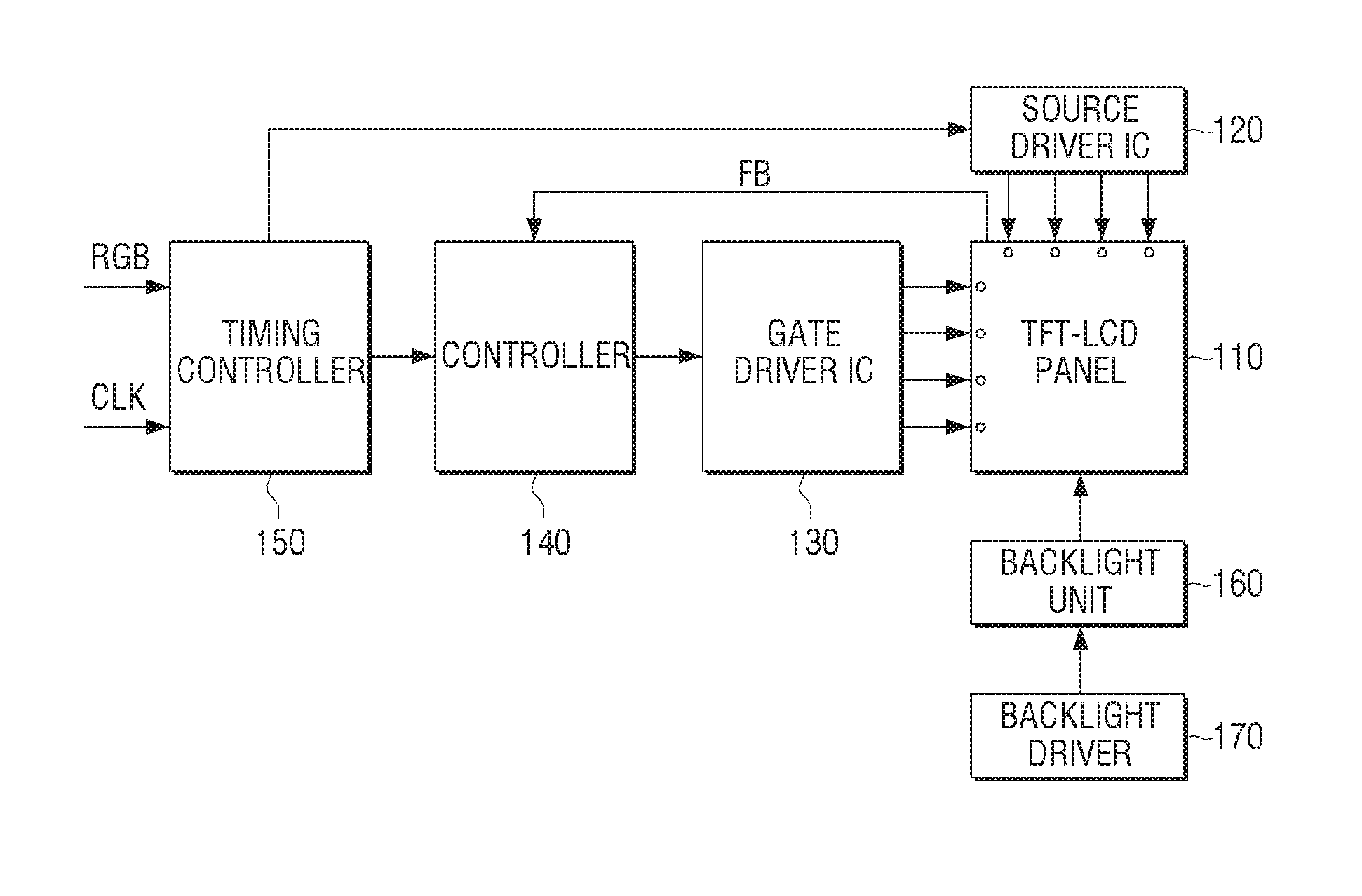

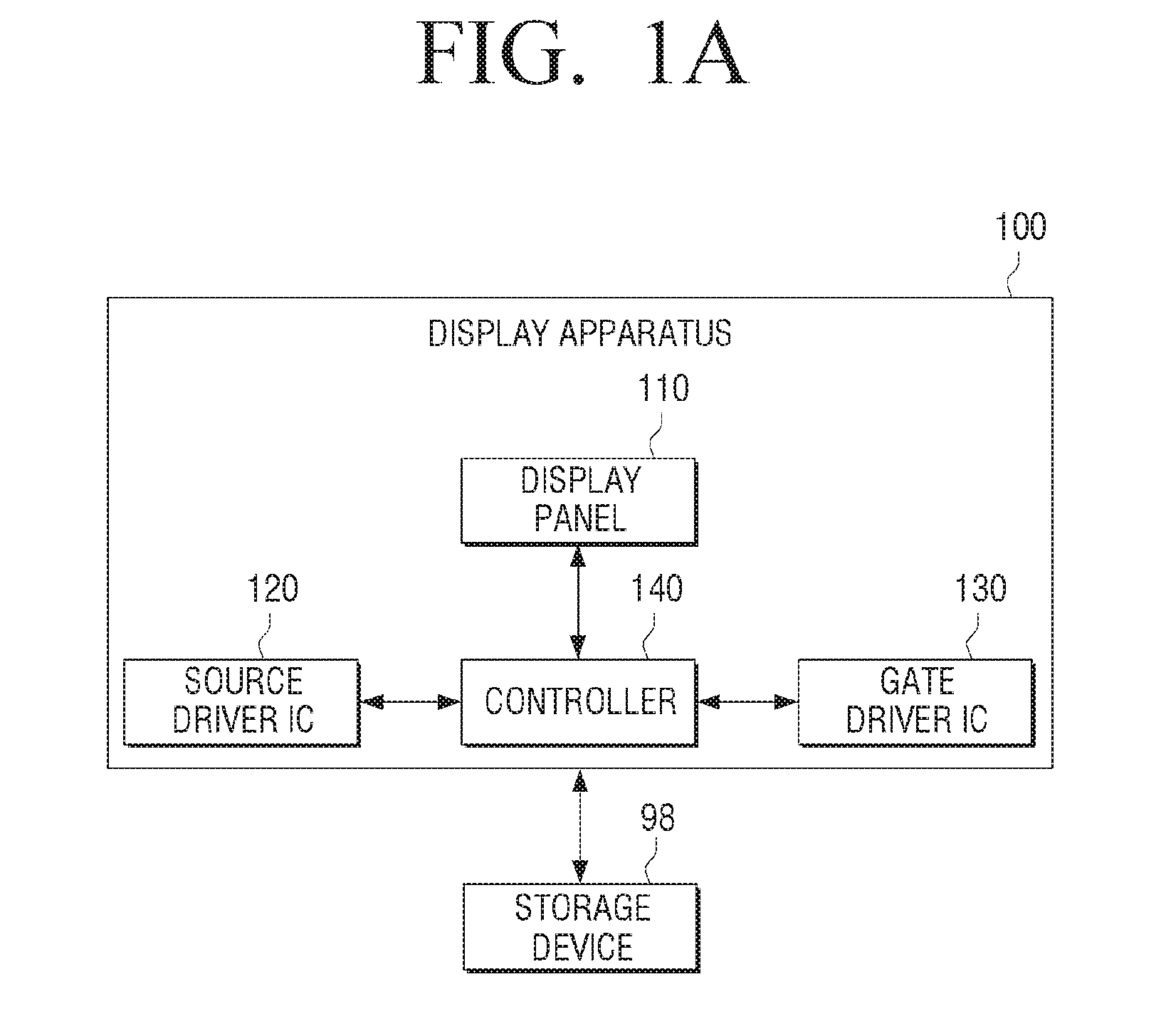

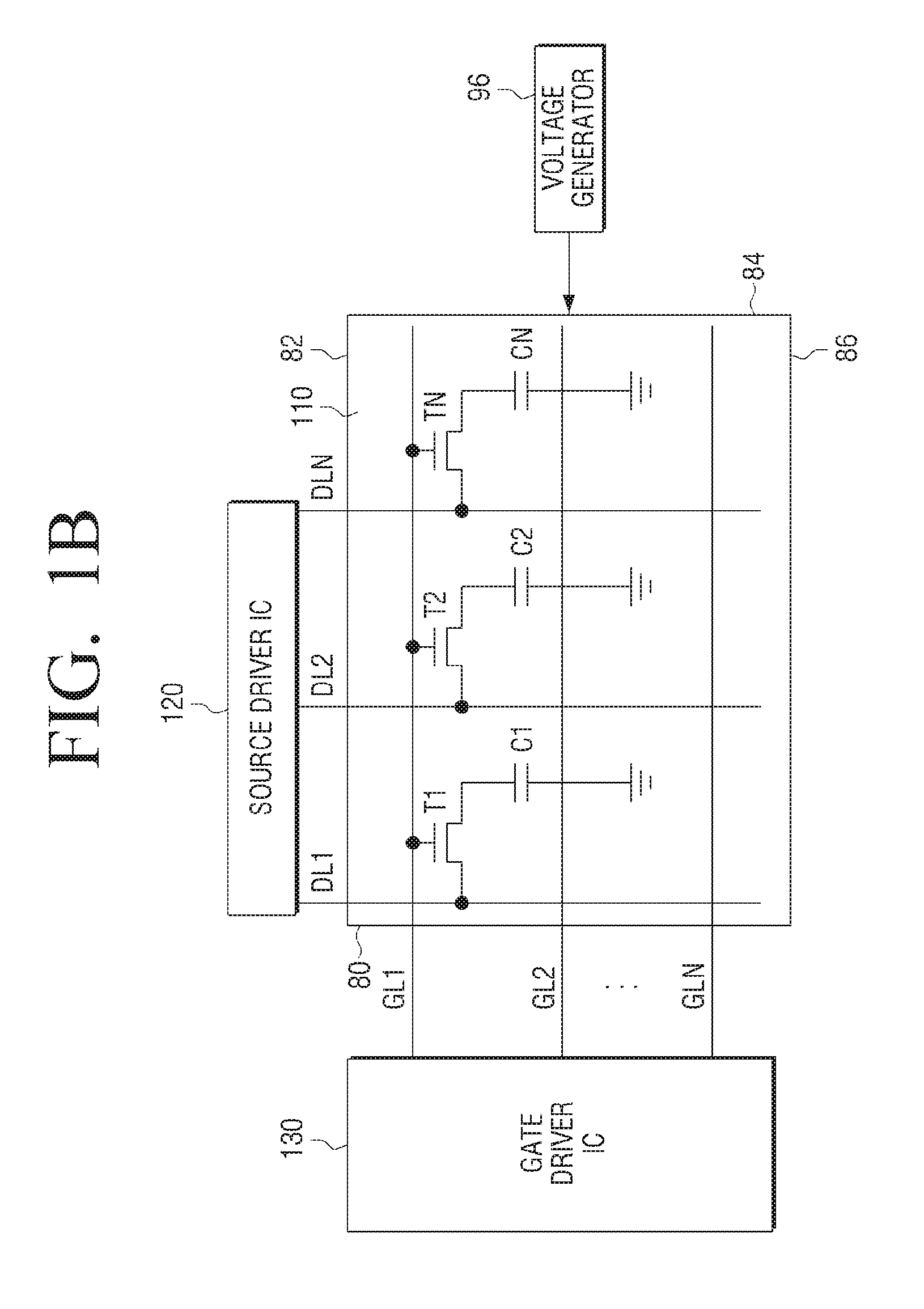

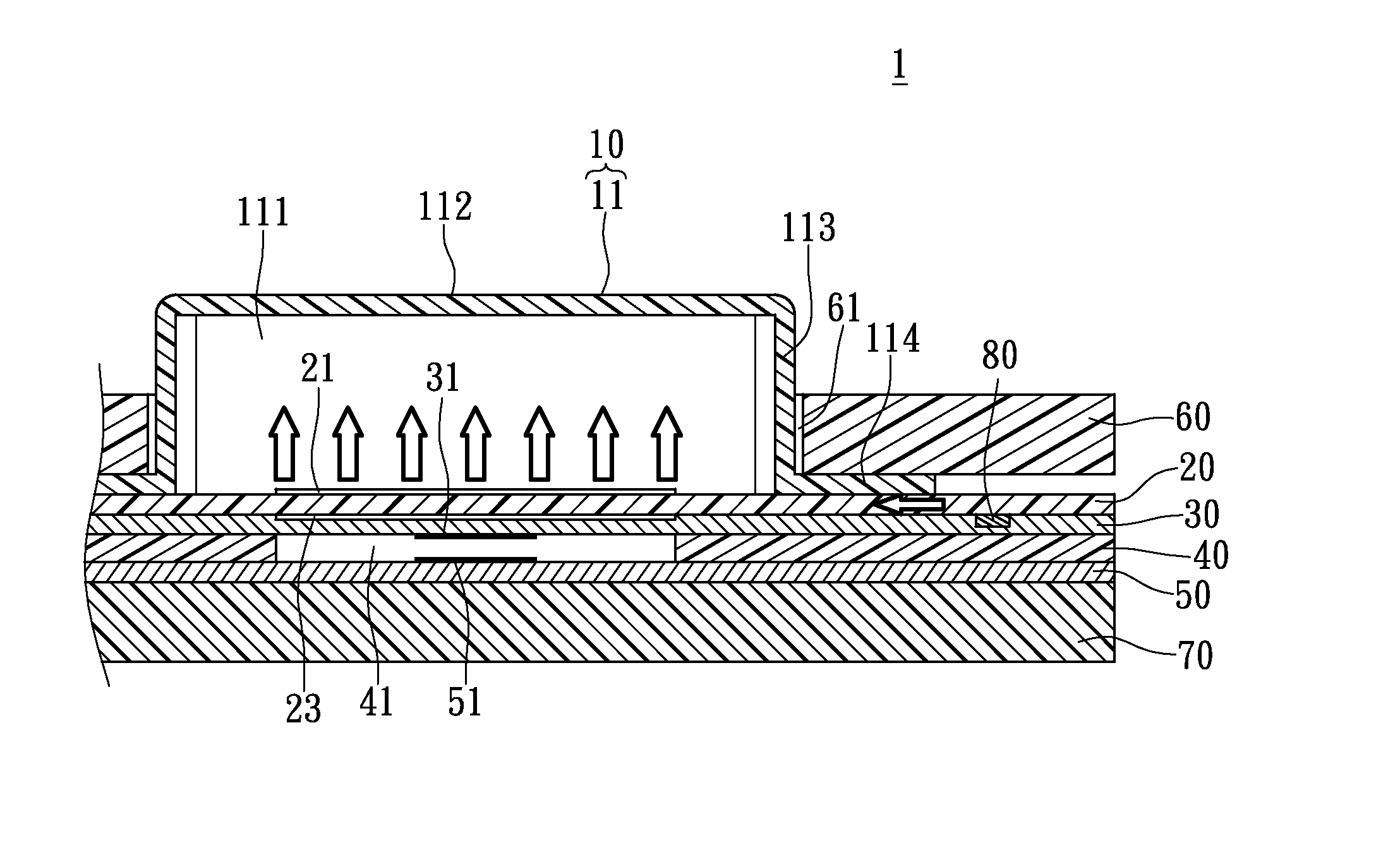

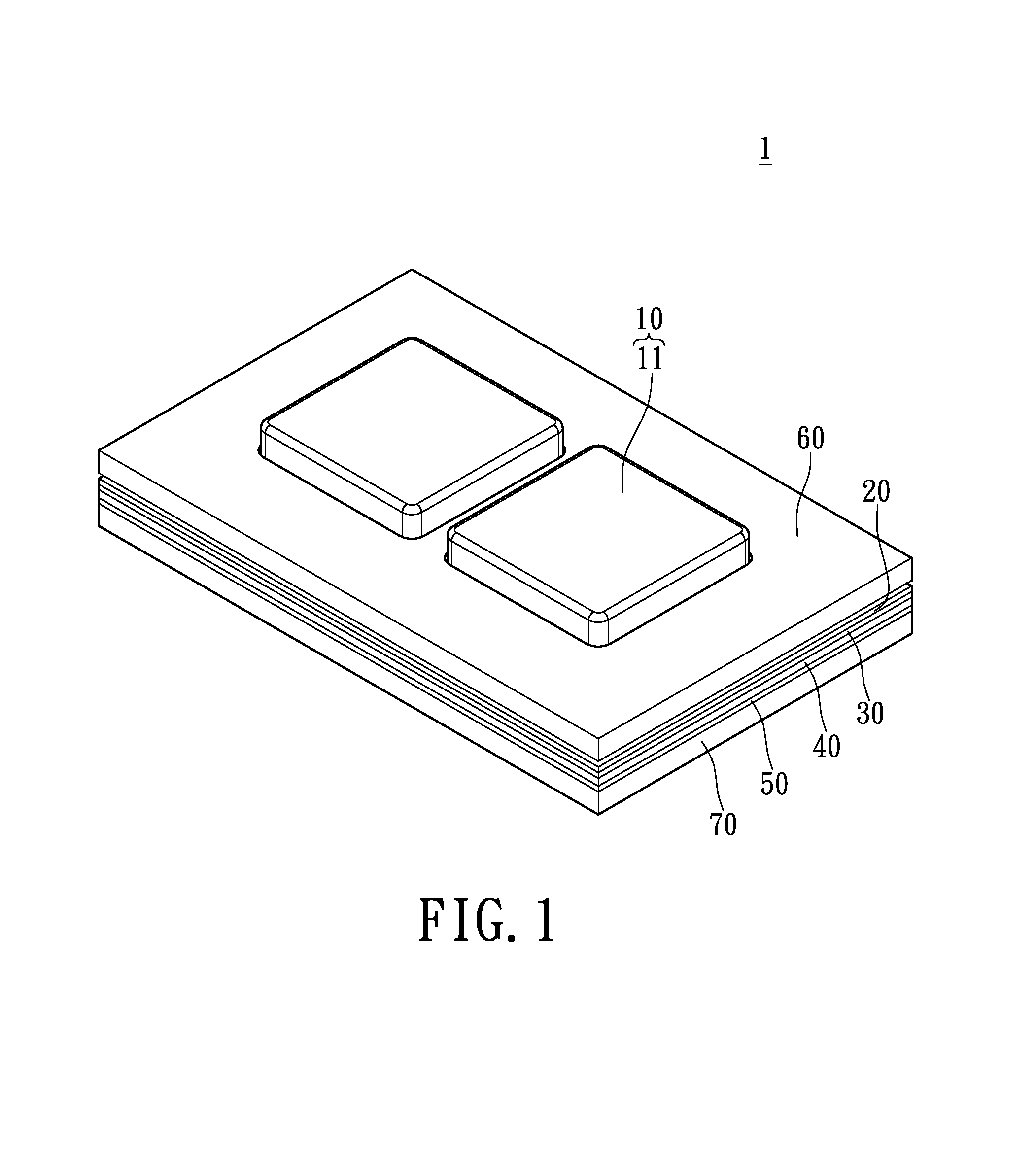

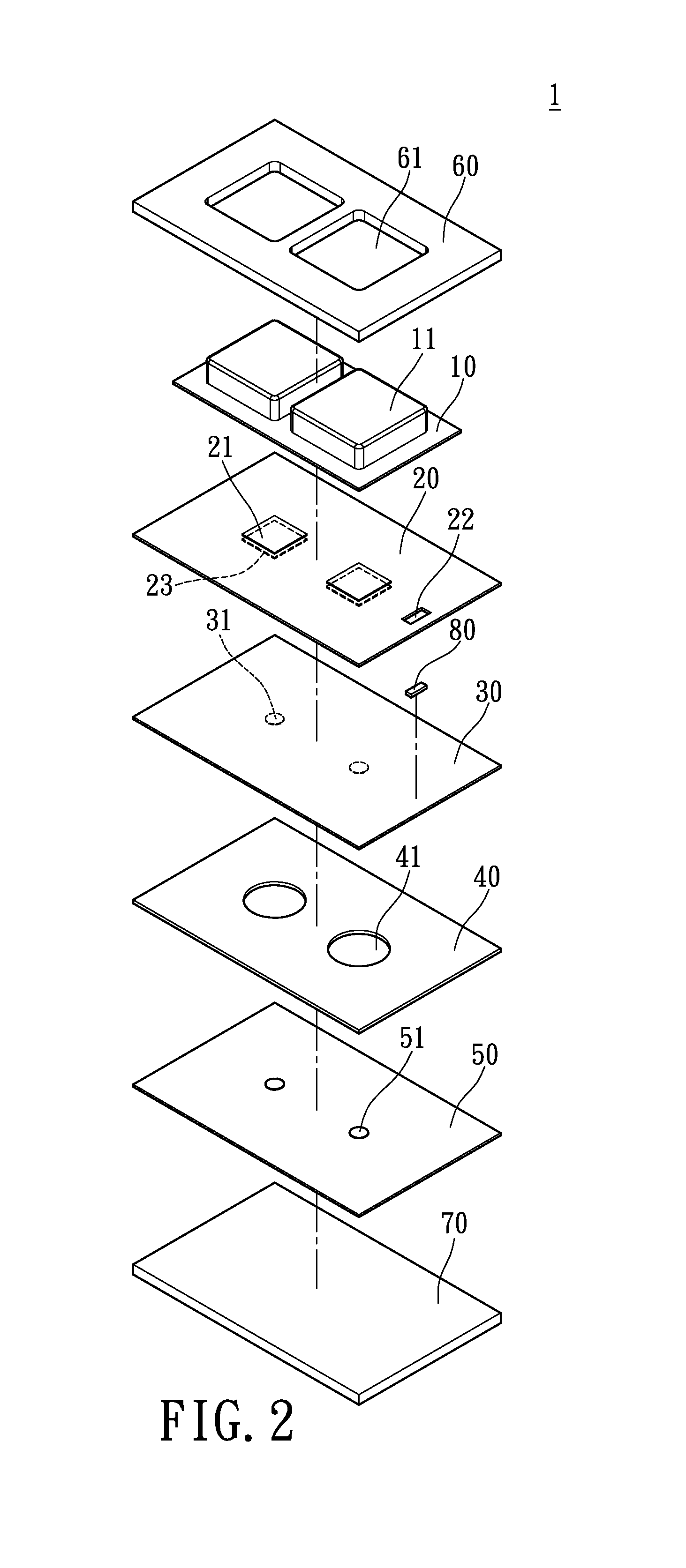

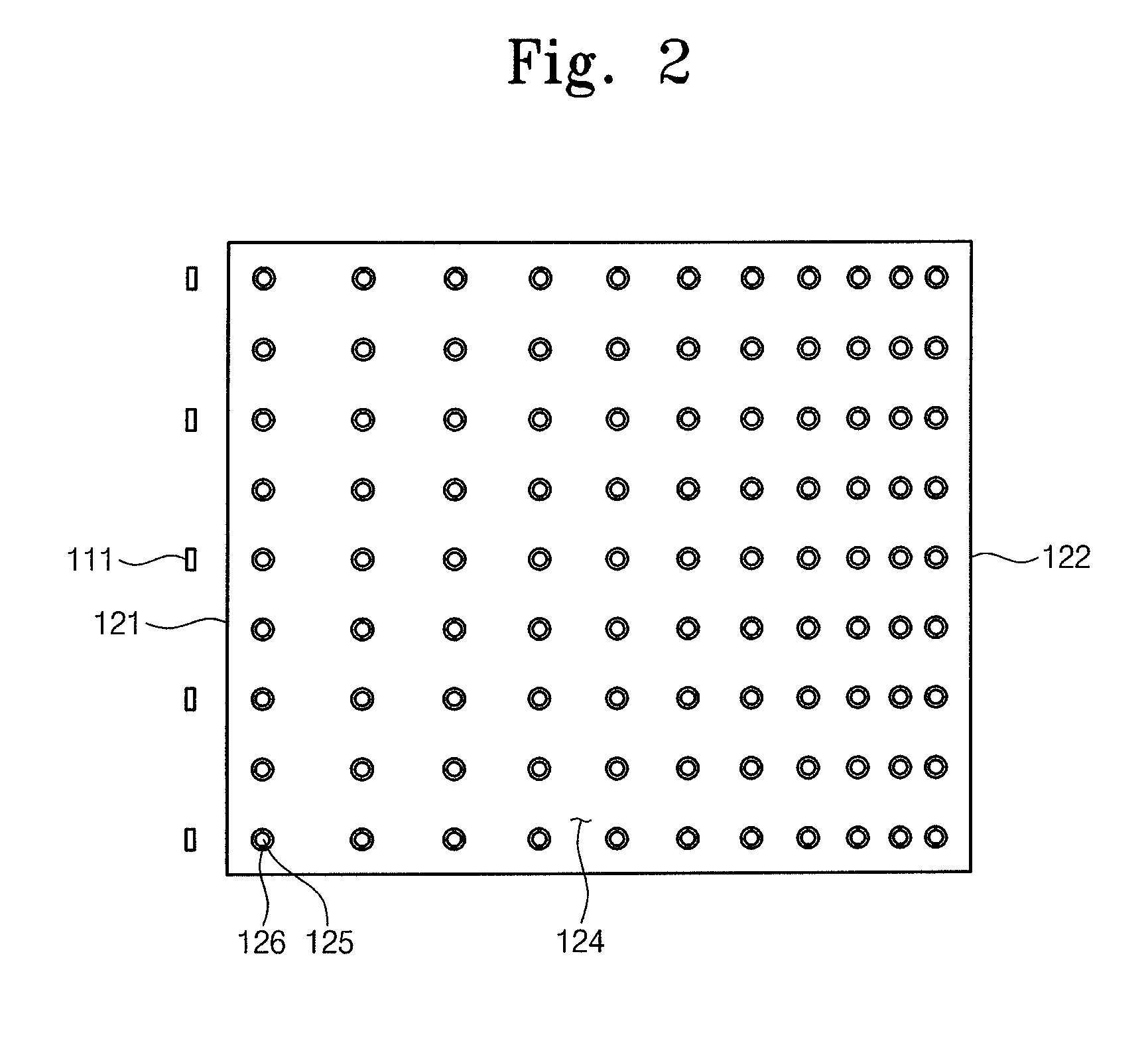

Display apparatus and method for controlling the same

ActiveUS20160365051A1Increase backlight brightnessKeep brightnessStatic indicating devicesEngineeringPixel based

A display apparatus includes a display panel including pixels arranged at an intersection of data lines and gate lines, a source driver IC configured to be disposed on one side surface of the display panel to apply a data voltage to the data lines, a gate driver IC configured to be disposed on any one of two side surfaces which are adjacent to the one side surface of the display panel to apply a gate driving voltage to the gate lines, and a controller configured to receive feedback on a gate driving voltage applied to at least one pixel, detect a distortion of the gate driving voltage applied to the pixel based on the feedback, adjust a level of the gate driving voltage applied to the gate lines to compensate for the distortion of the gate driving voltage, and apply the adjusted gate driving voltage to the gate lines.

Owner:SAMSUNG ELECTRONICS CO LTD

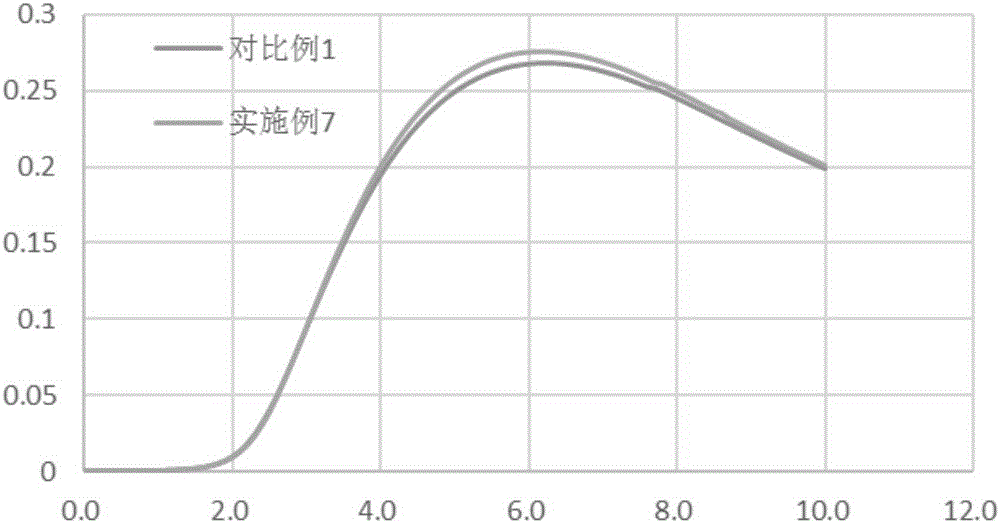

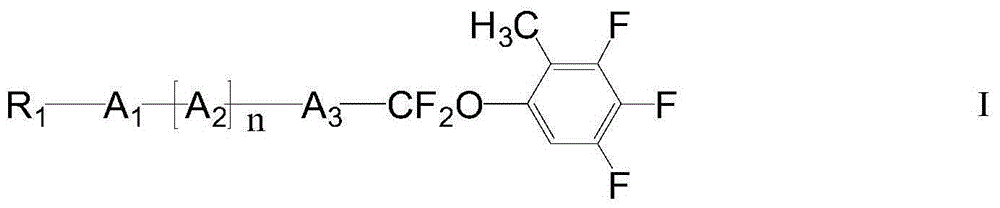

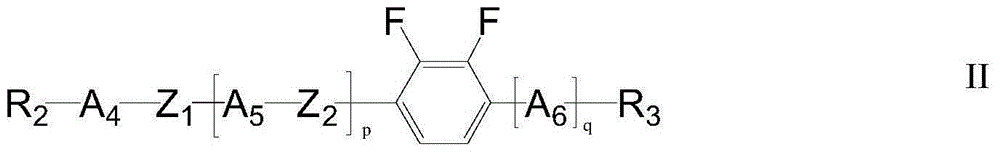

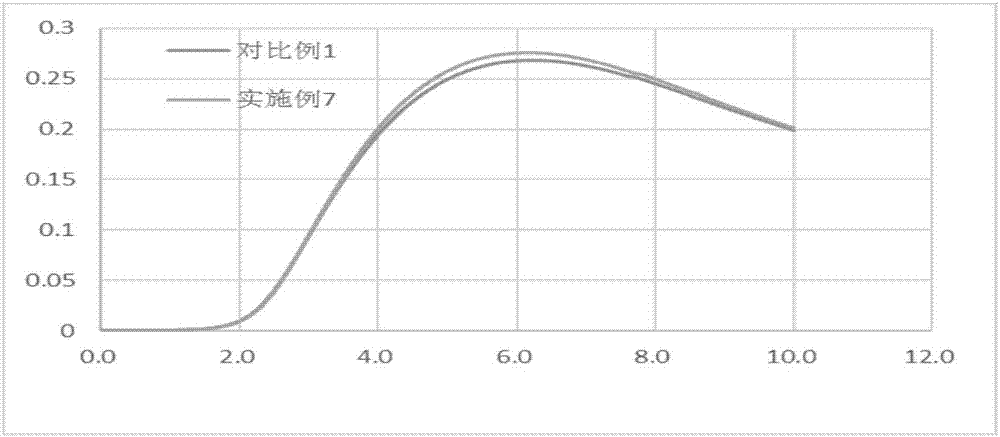

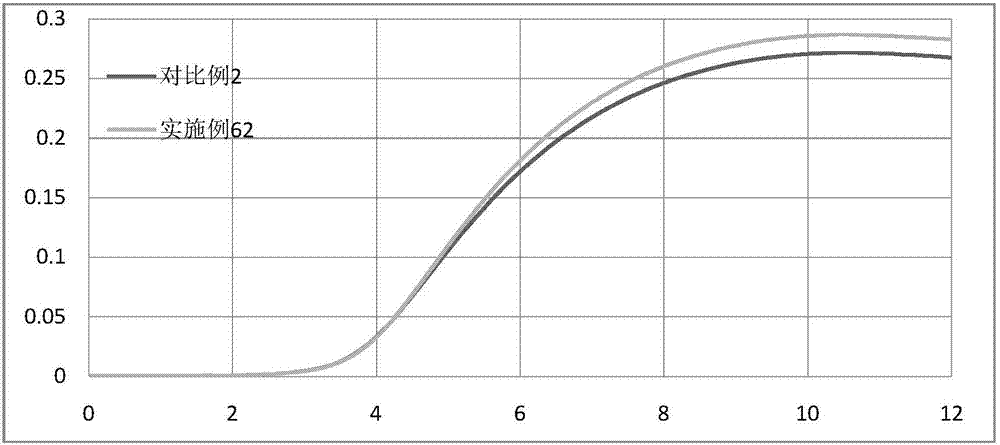

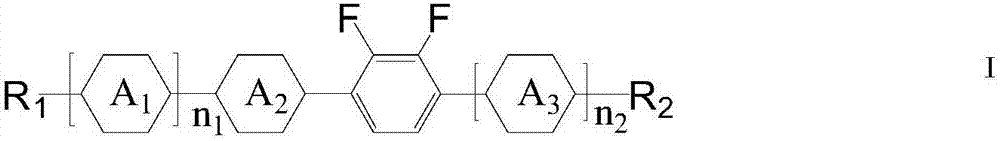

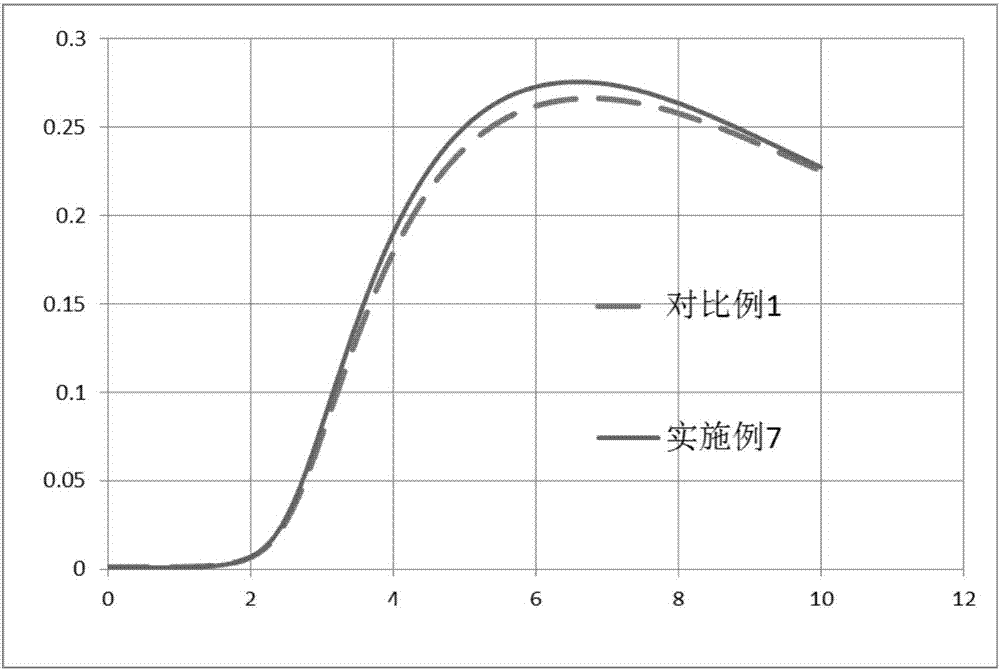

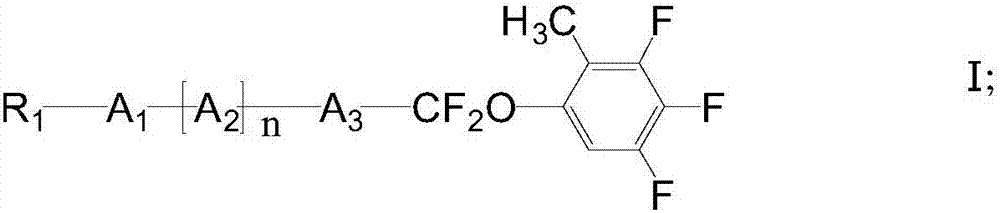

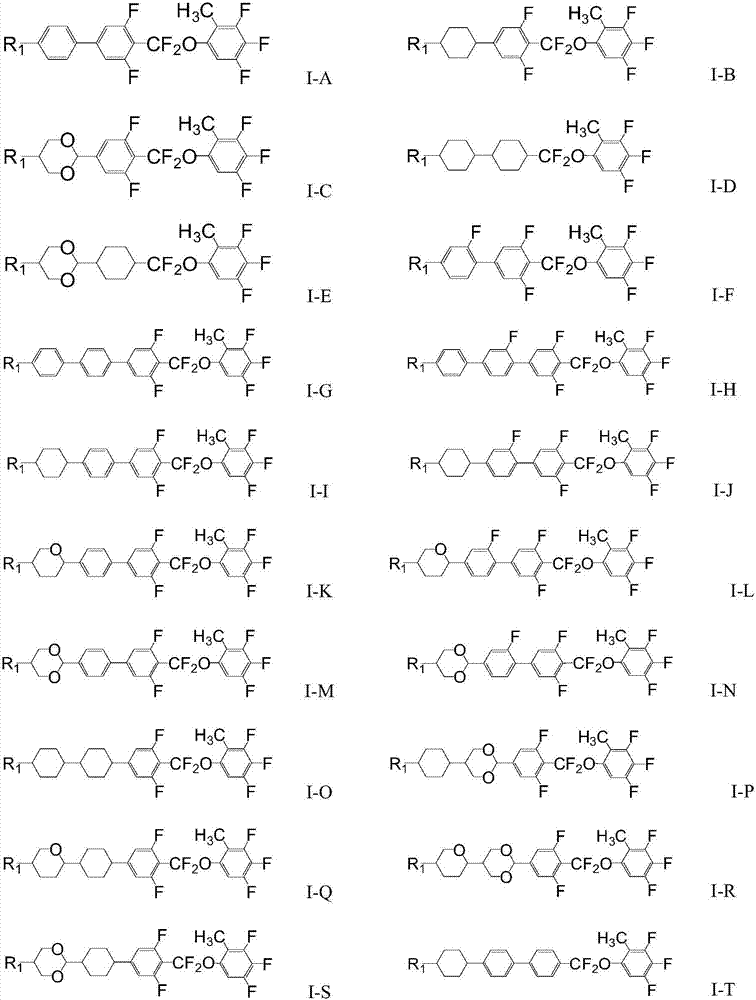

Liquid crystal composition with high transmittance, and application thereof

ActiveCN106554783AIncrease polarityGood miscibilityLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a liquid crystal composition with high transmittance. The liquid crystal composition contains at least one or more of compounds represented by general formula I shown in the description and at least one of compounds represented by formula II shown in the description. The liquid crystal composition has the characteristics of low viscosity, high resistivity, good low temperature intersolubility, fast response speed and excellent transmittance, and can be used in fast response liquid crystal display with multiple display modes. FFS and IPS are most mainstream display modes at present, but the problem of low transmittance of the FFS and the IPS is a key problem to be solved. A result of experiments shows that the liquid crystal composition with large dielectric strength has high transmittance, so the brightness is improved without increasing the electric energy consumption. The liquid crystal composition provided by the invention has large dielectric strength, and effectively improves the transmittance of liquid crystal displays, and especially the displays in the FFS and IPS display modes.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Liquid crystal display method and liquid crystal display device improving motion picture display grade

InactiveUS20050237294A1Transmissivity decreaseIncrease backlight brightnessTelevision system detailsStatic indicating devicesLiquid-crystal displayData signal

A source driver outputs a data signal and a reset (black) signal alternately to a source line. Four-hundred and eighty gate lines are divided into three groups each comprising 160 lines, and connected to gate drivers. A display control section outputs a discriminant signal, a scan start signal and a clock signal to the gate drivers, where the nth gate line is selected with the data signal outputted by the source driver, and where the (n+160)th gate line is selected with the reset signal outputted. Further, n is shifted sequentially. By writing the reset signal during the latter ⅓ of one frame like this, light leakage of pixels that are changed over from white display to black display is eliminated. Also, blurs of edge portions of a motion picture are reduced. Thus, display grade for motion pictures is enhanced with a minimum improvement.

Owner:MIYACHI KOICHI

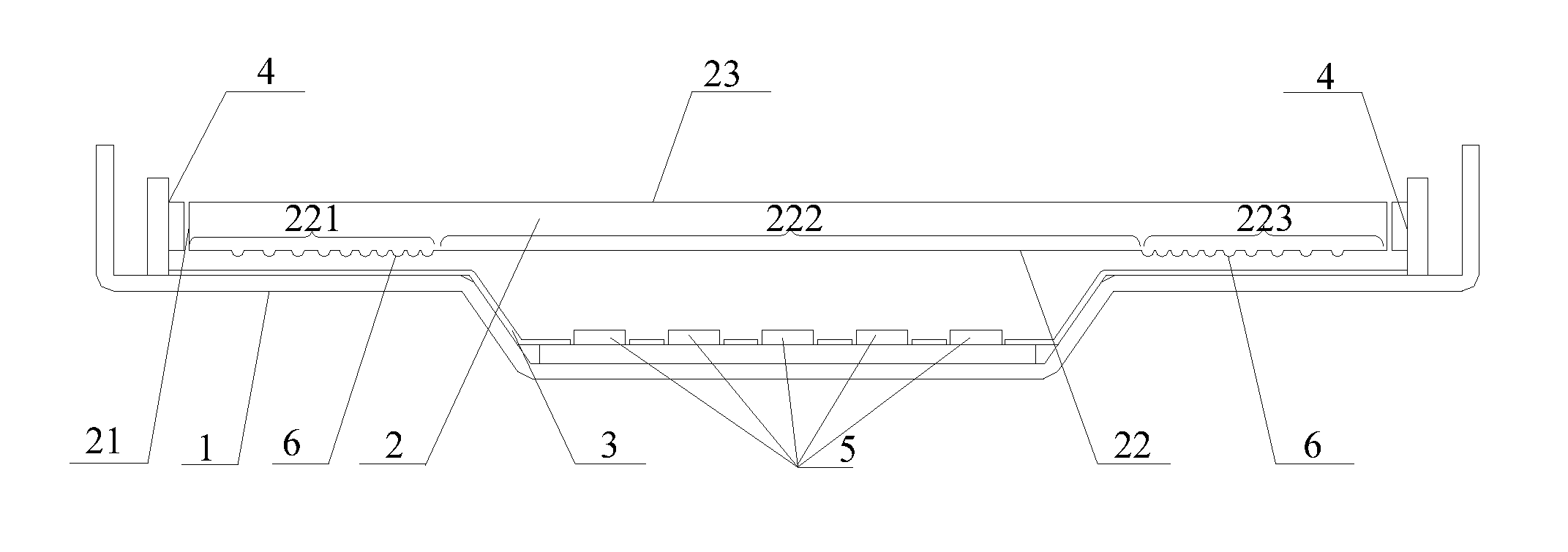

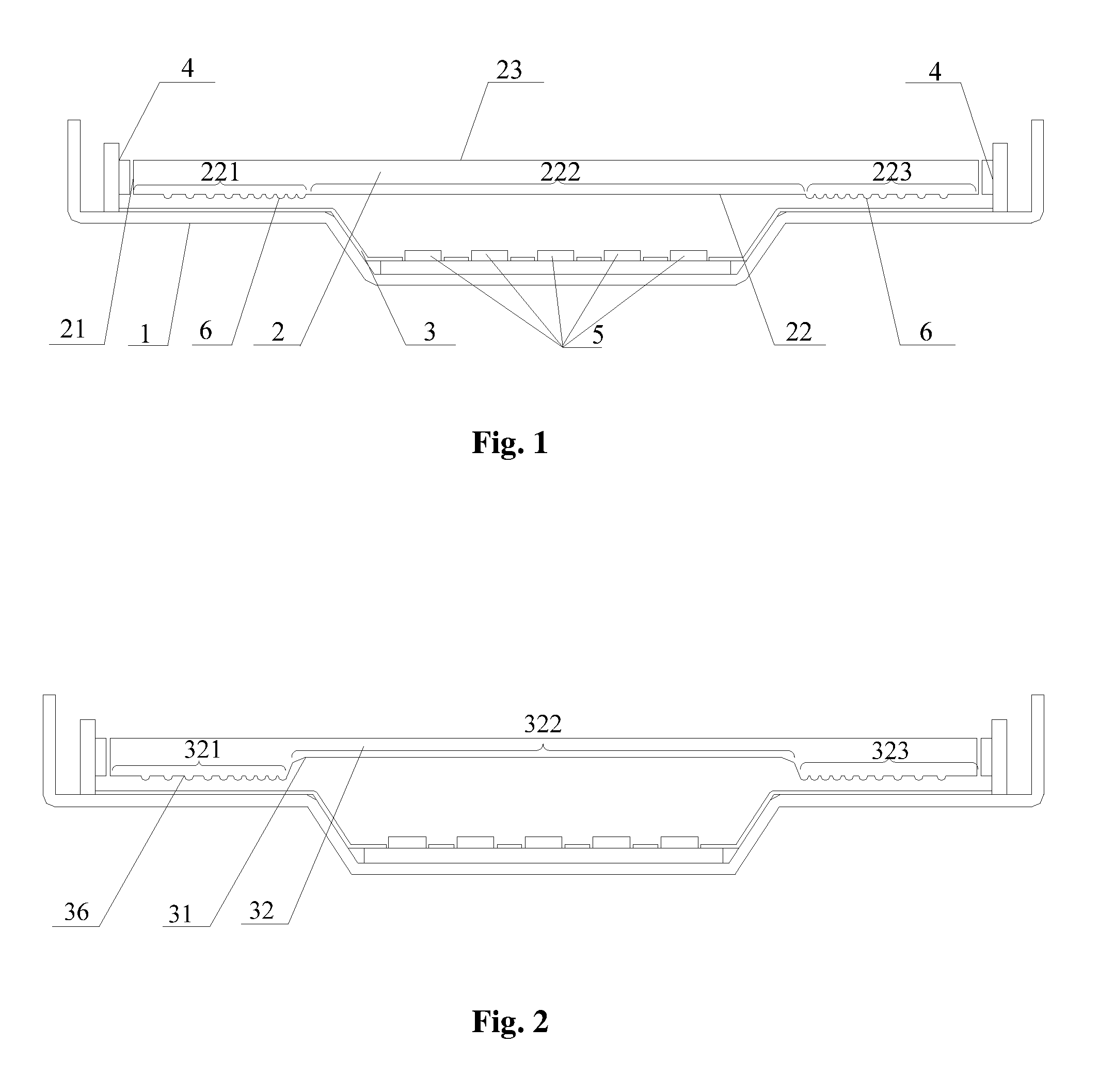

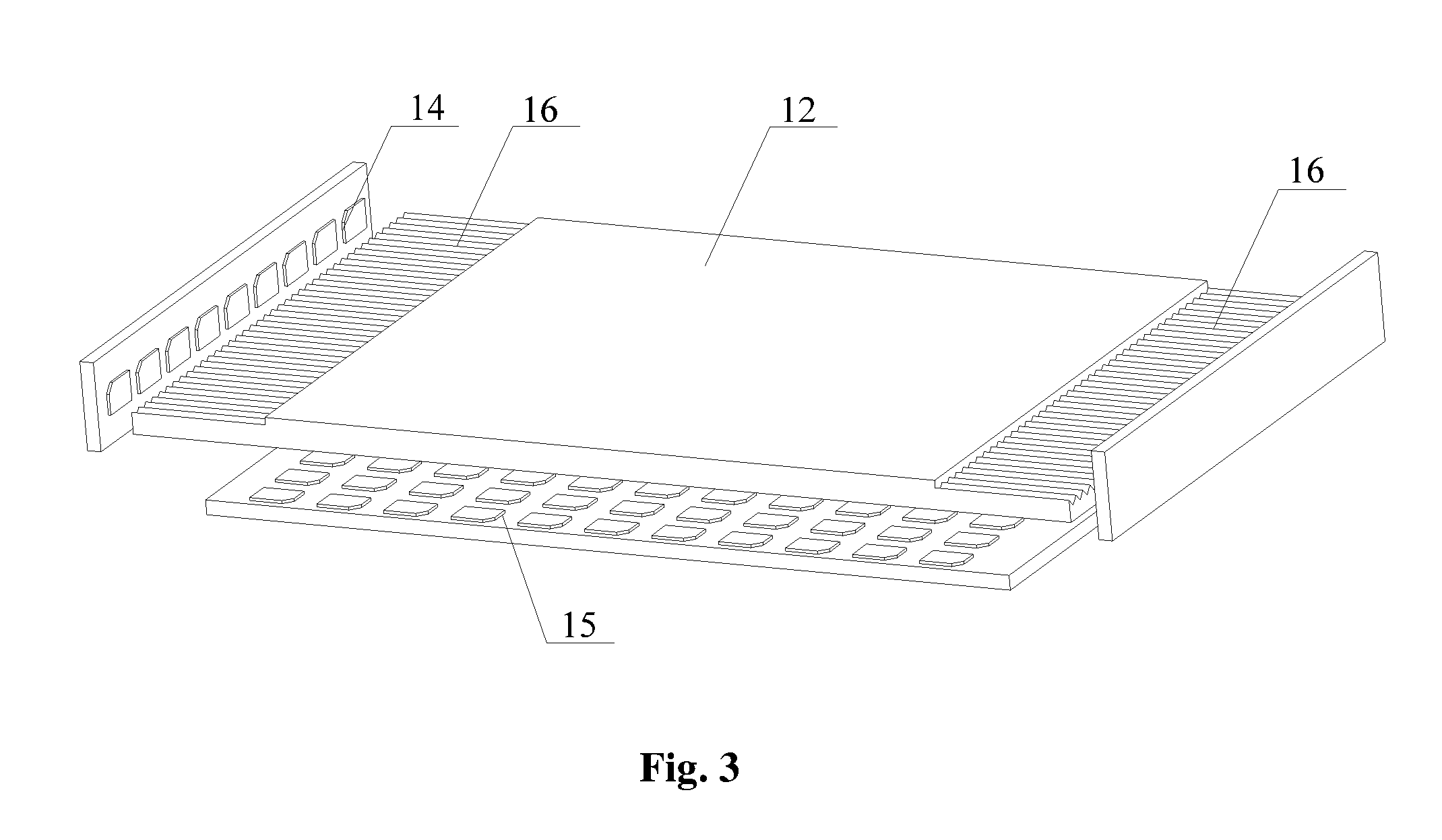

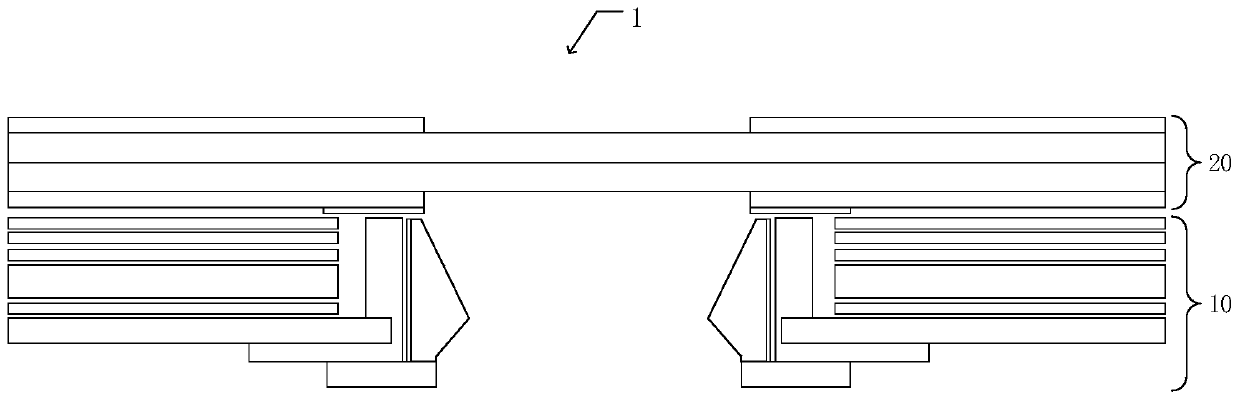

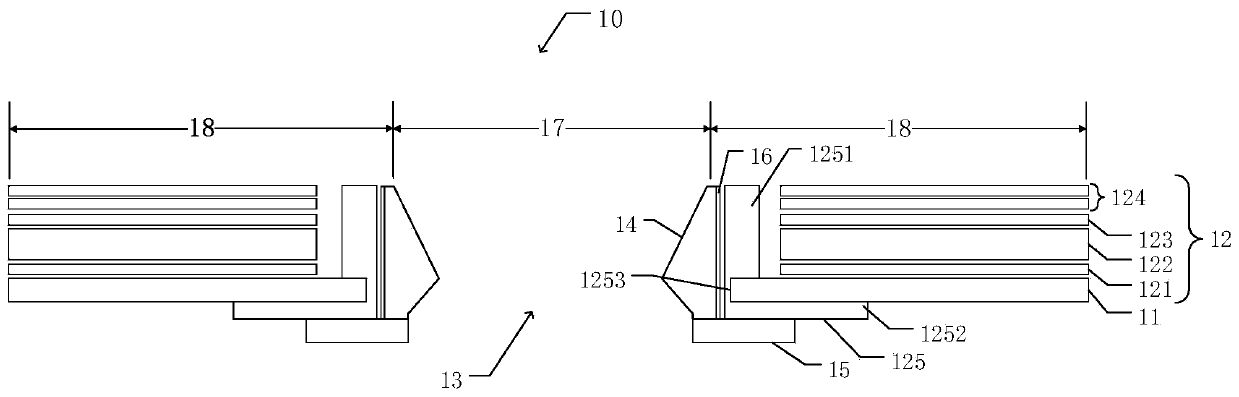

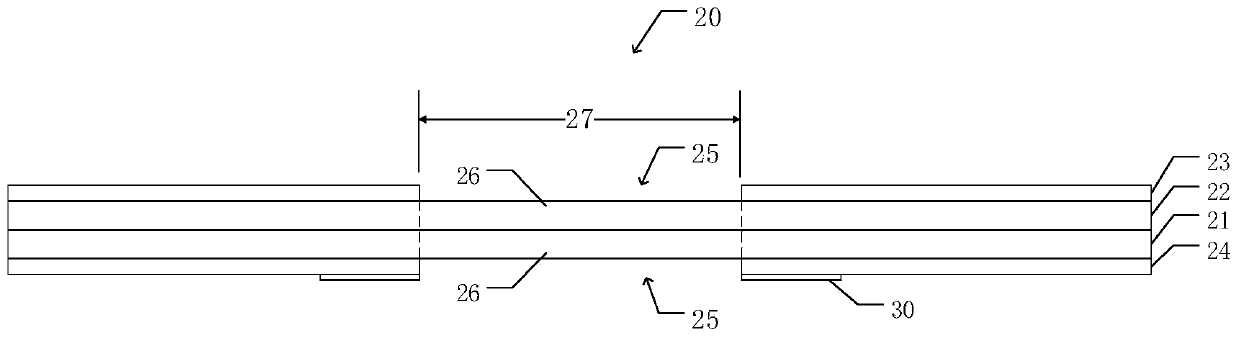

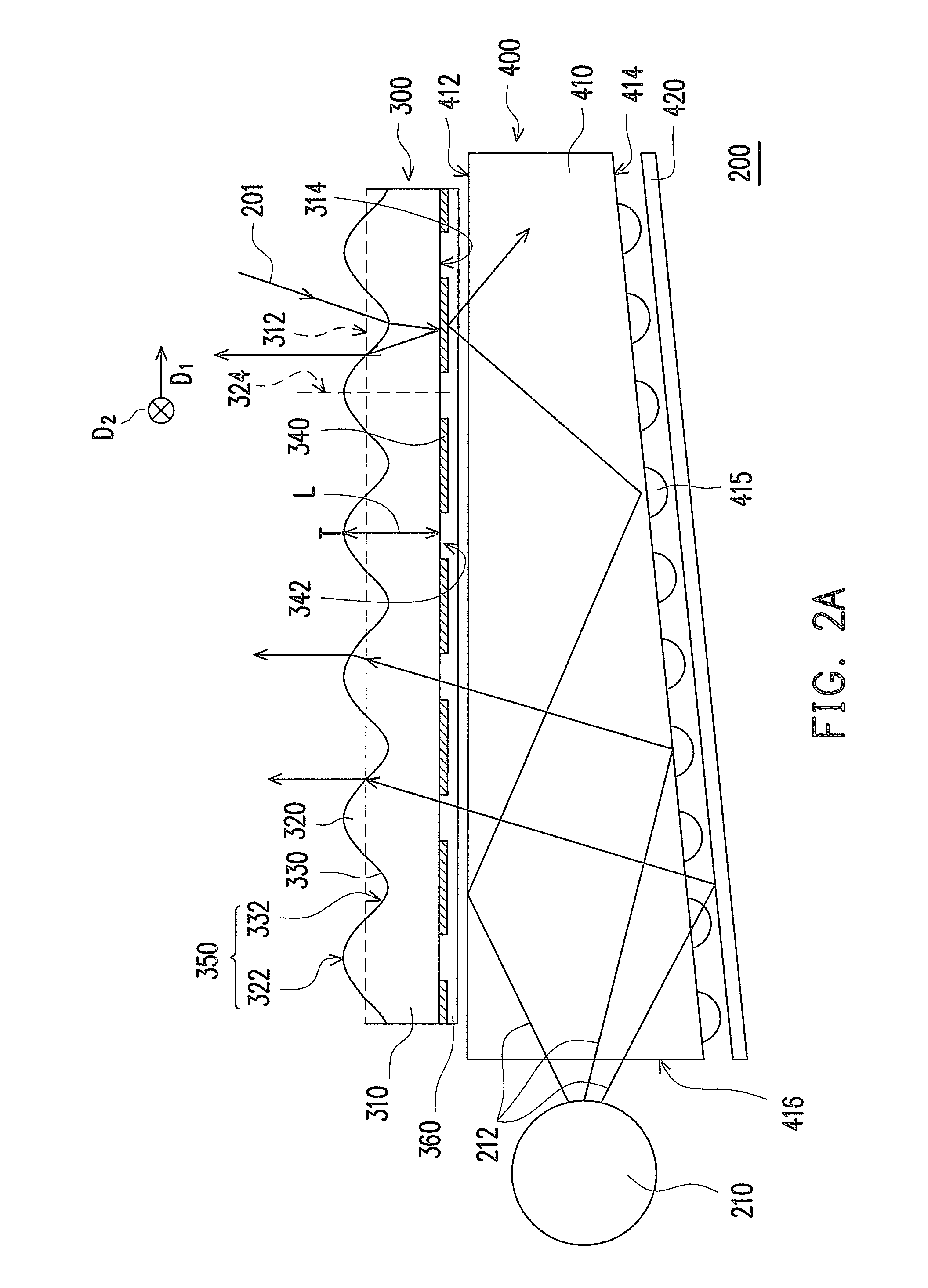

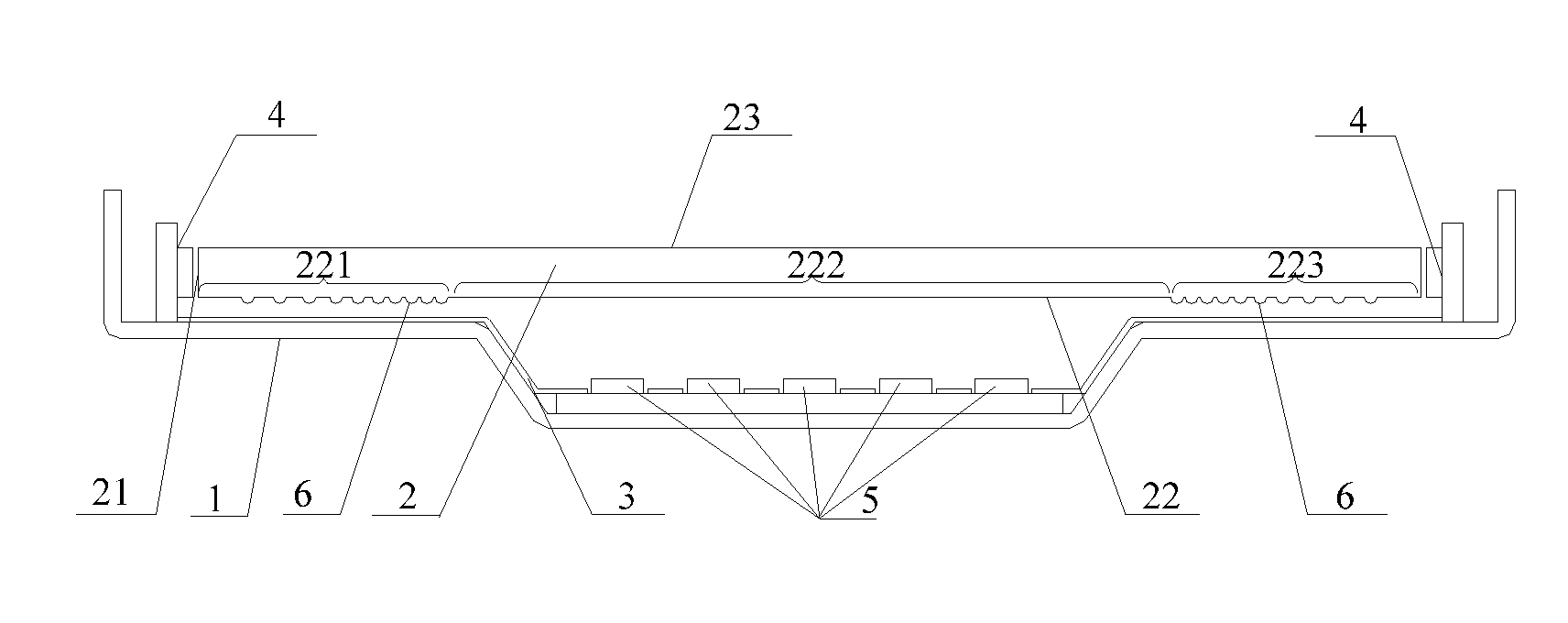

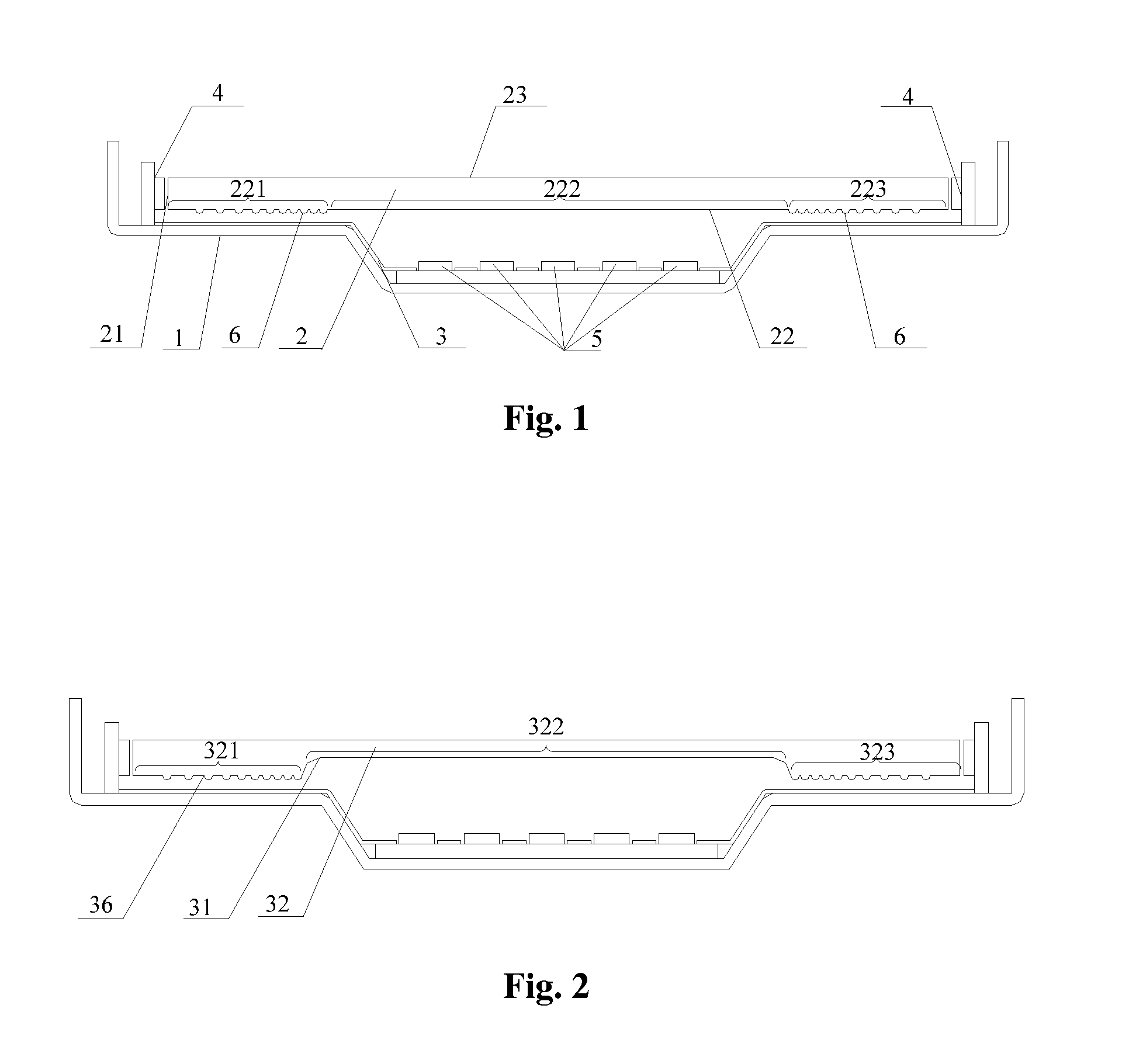

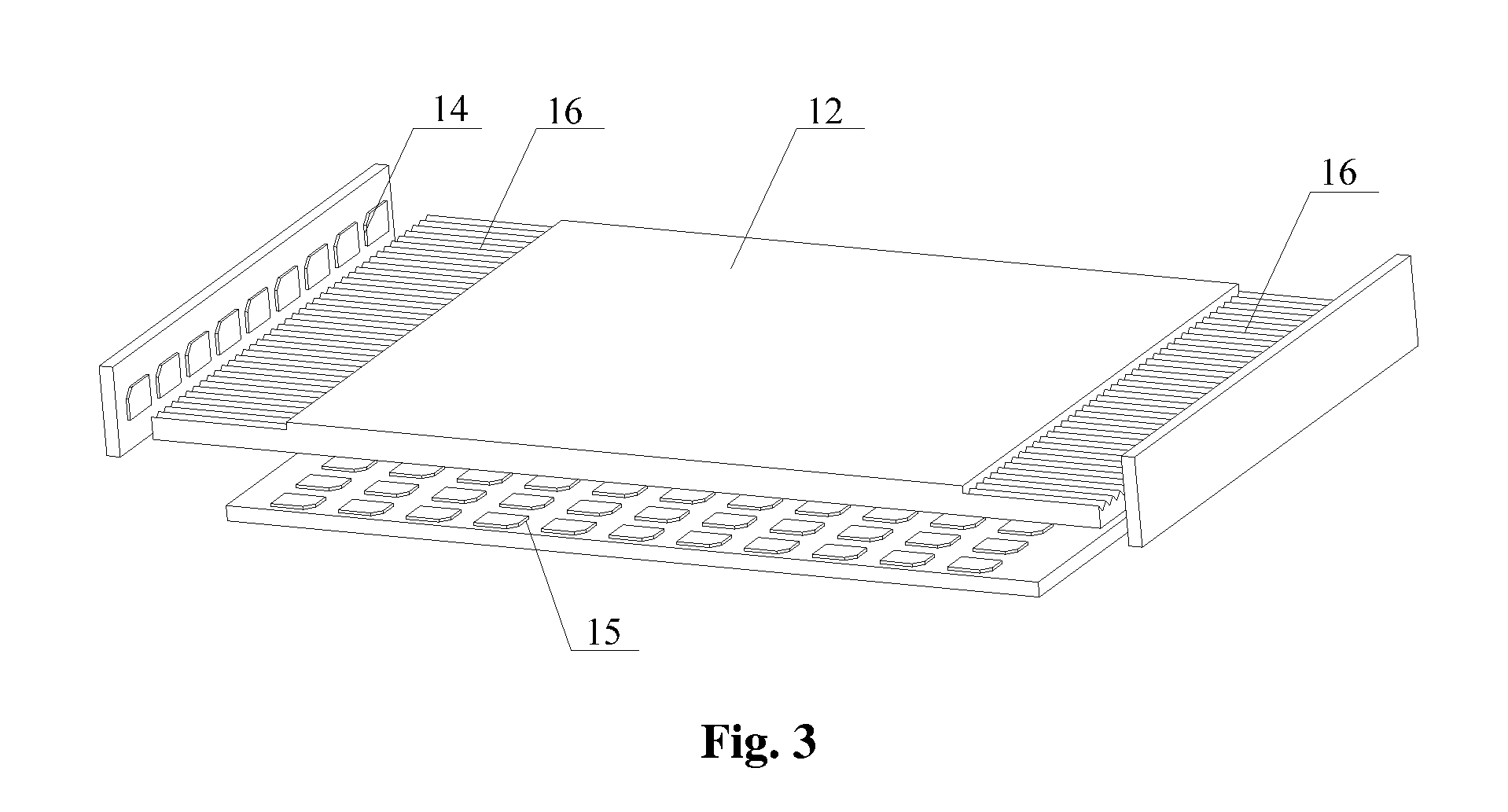

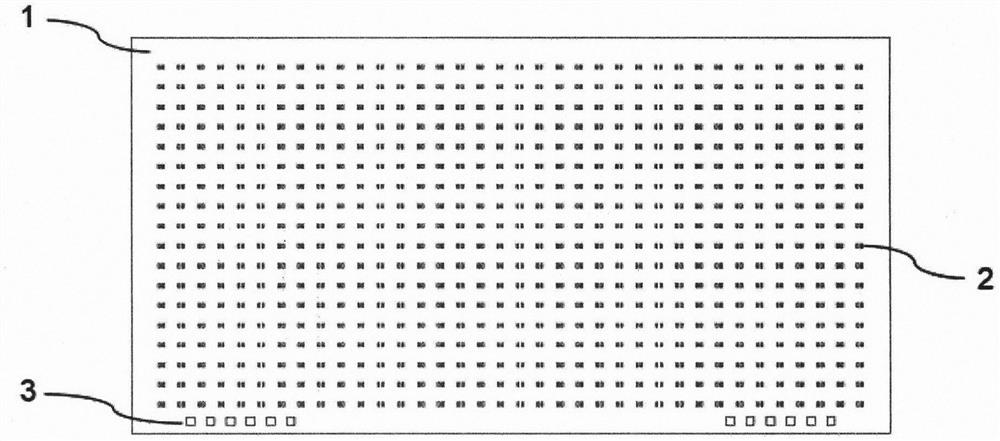

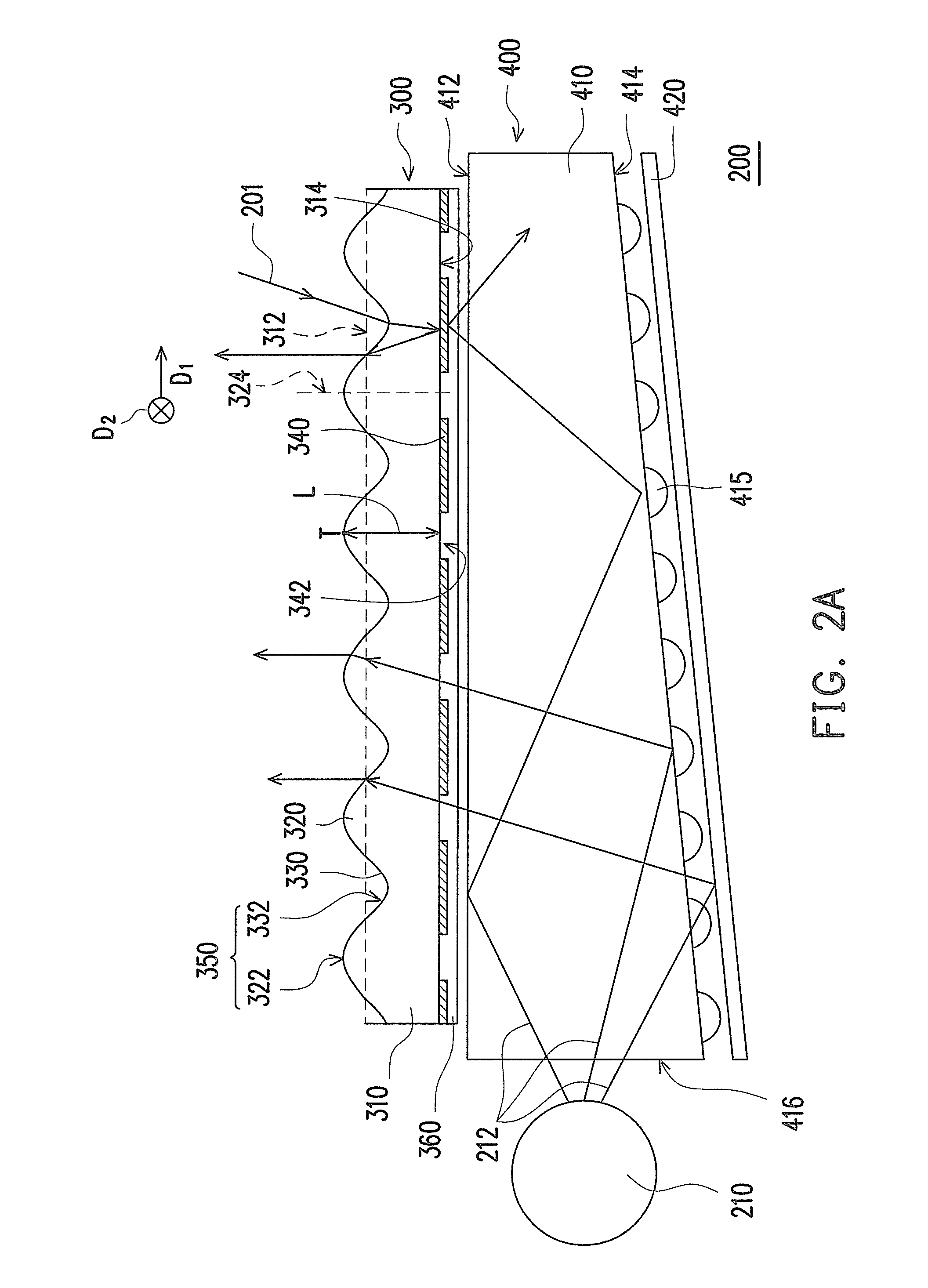

Backlight module and LCD comprising the same

ActiveUS20130094242A1Improve adjustmentReduce power consumptionOptical light guidesIlluminated signsExit surfaceScattered light

A backlight module comprises a backplate having a baseplate and side plates, a direct-lit LED array, edge-lit LED arrays and a light guide panel. The light guide panel is located above the baseplate. The direct-lit LED array is disposed between the baseplate and the light guide panel. The edge-lit LED arrays are disposed at two sides of the light guide panel and facing light incident surfaces thereof respectively. Light scattering structures for scattering light rays are disposed on a light exiting surface or on a bottom surface of the light guide panel. With the LED arrays and the light scattering structures, the light guide panel is divided into three backlight regions. Displaying of the backlight module is controlled region by region by the light scattering structures and the LED drive circuit to improve the brightness of the backlight module and reduce the power consumption of the liquid crystal module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

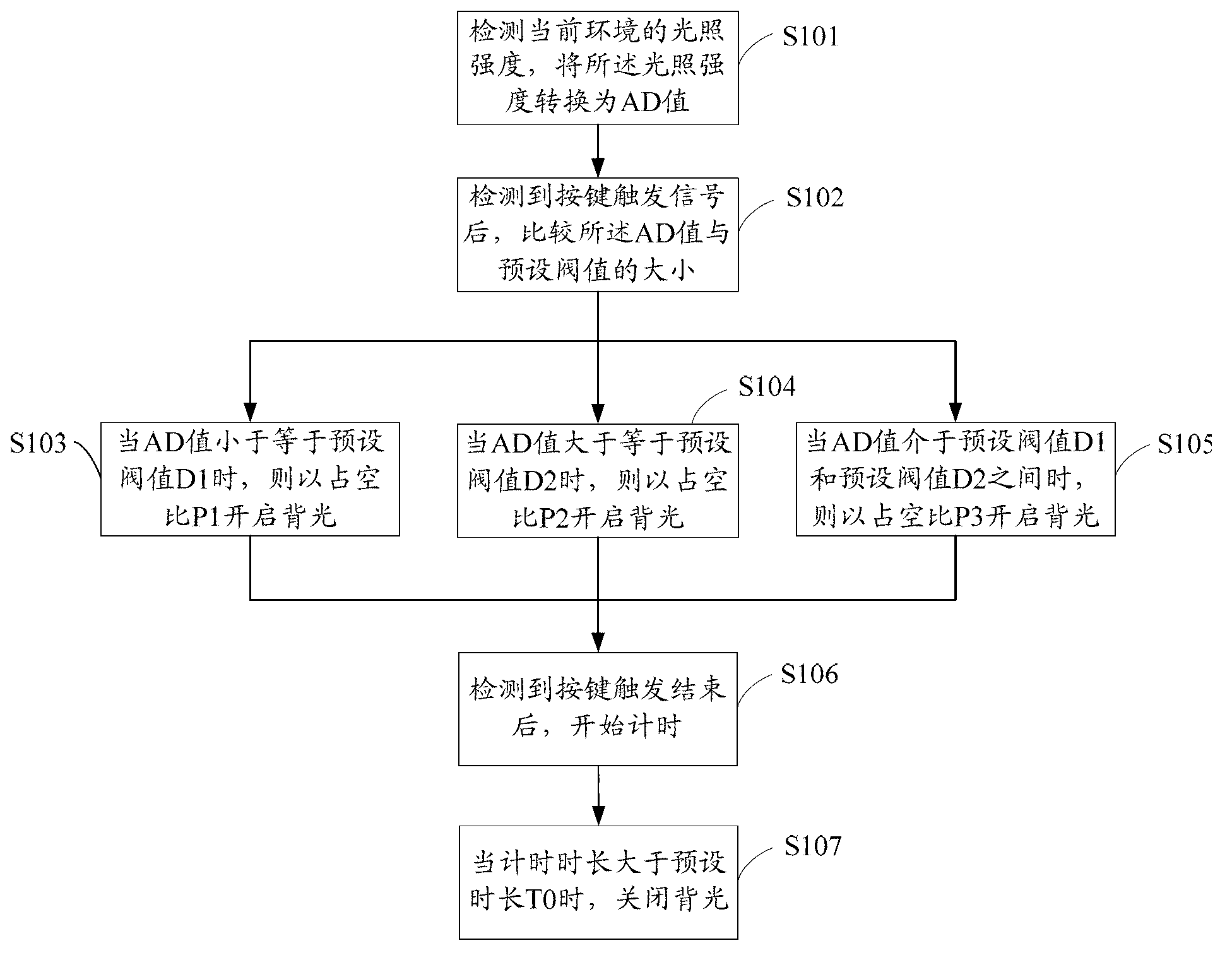

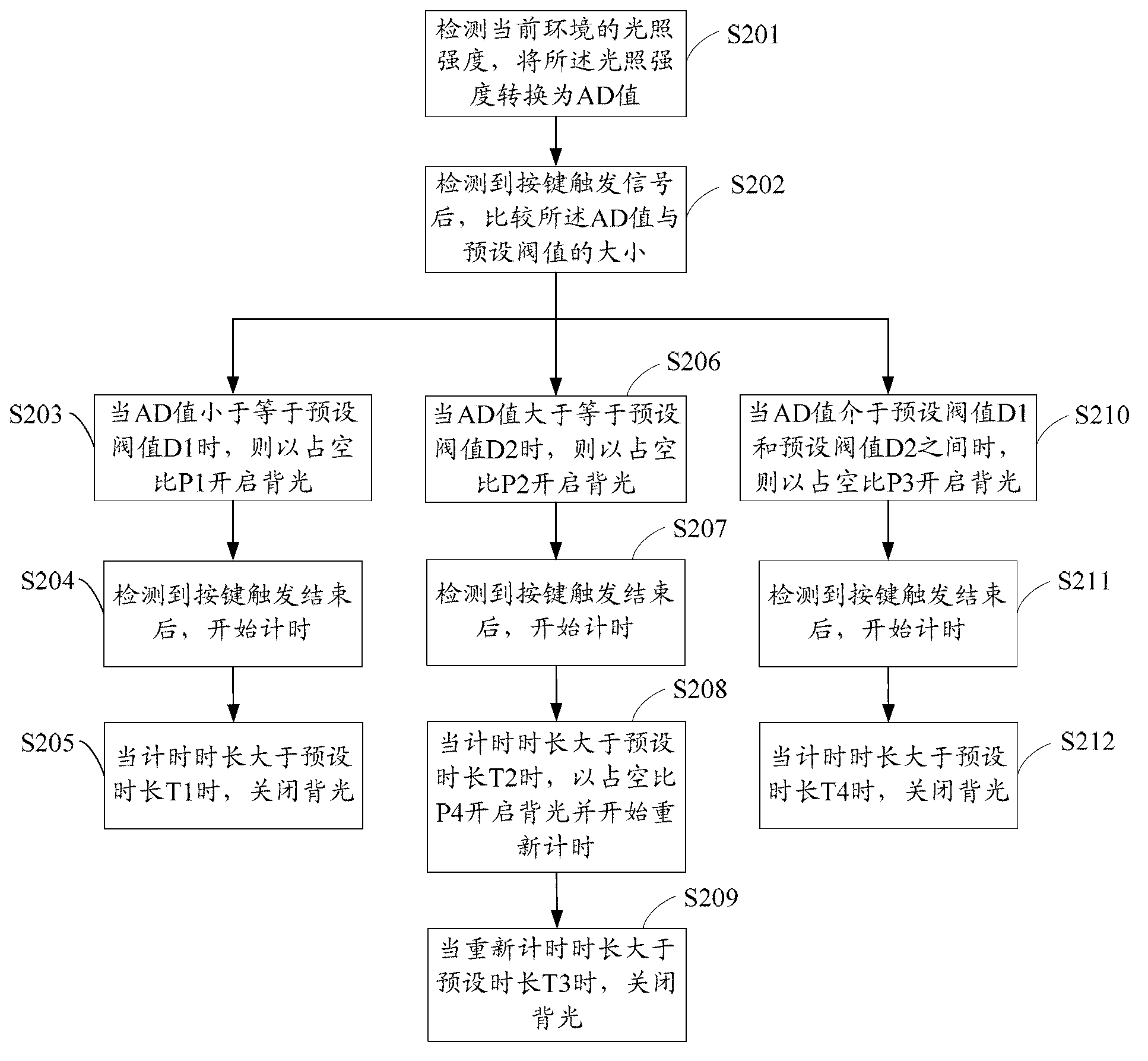

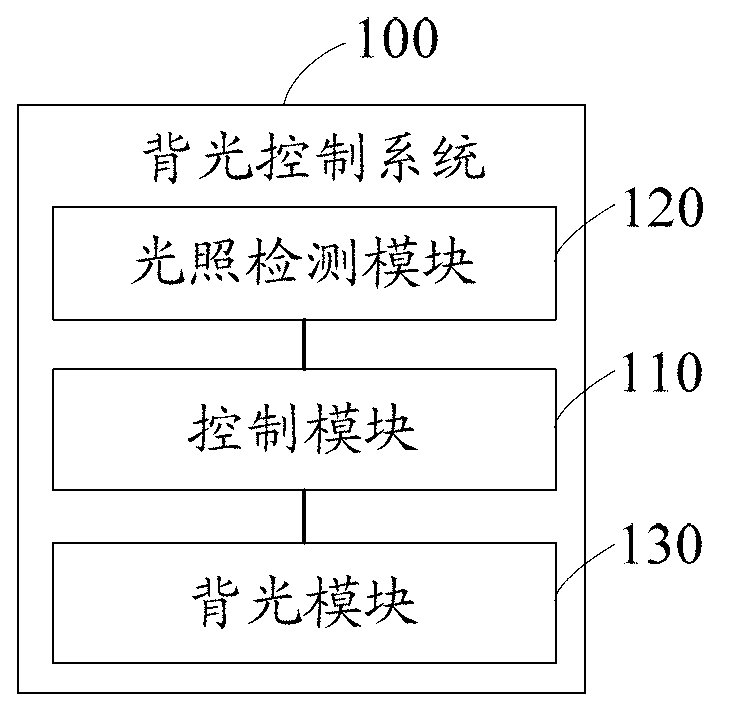

Remote control, and backlight control method and backlight control system thereof

InactiveCN103179748AReduce power consumptionReduce consumptionElectric light circuit arrangementEnergy saving control techniquesElectric energyElectricity

The invention discloses a remote control, and a backlight control method and a backlight control system thereof. The backlight control method includes steps: detecting illumination intensity of current environment, and converting the illumination intensity into an AD (administrative distance) value; after a button triggering signal is detected, comparing the AD value with a preset threshold valve, and turning on backlight with corresponding duty ratio according to comparison results; and after the backlight is turned on with the corresponding duty ratio for a preset time period, turning off the backlight. Control on backlight brightness according to the illumination intensity of the current environment is realized, the backlight brightness is lowered when the illumination intensity of the current environment is high, and the backlight brightness is increased when the illumination intensity of the current environment is low, so that electricity consumption is effectively lowered, and more humanization and intelligentization are realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

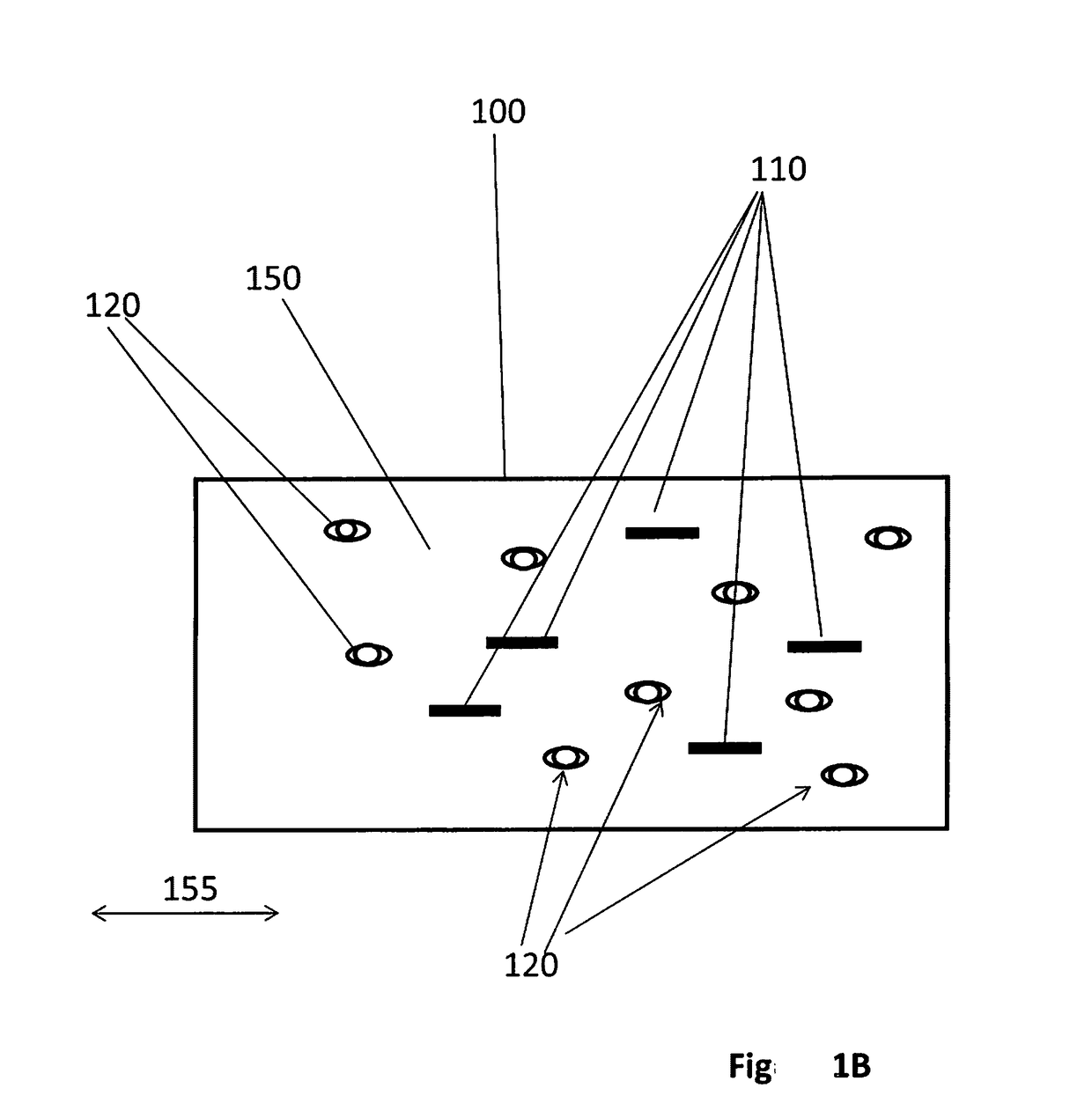

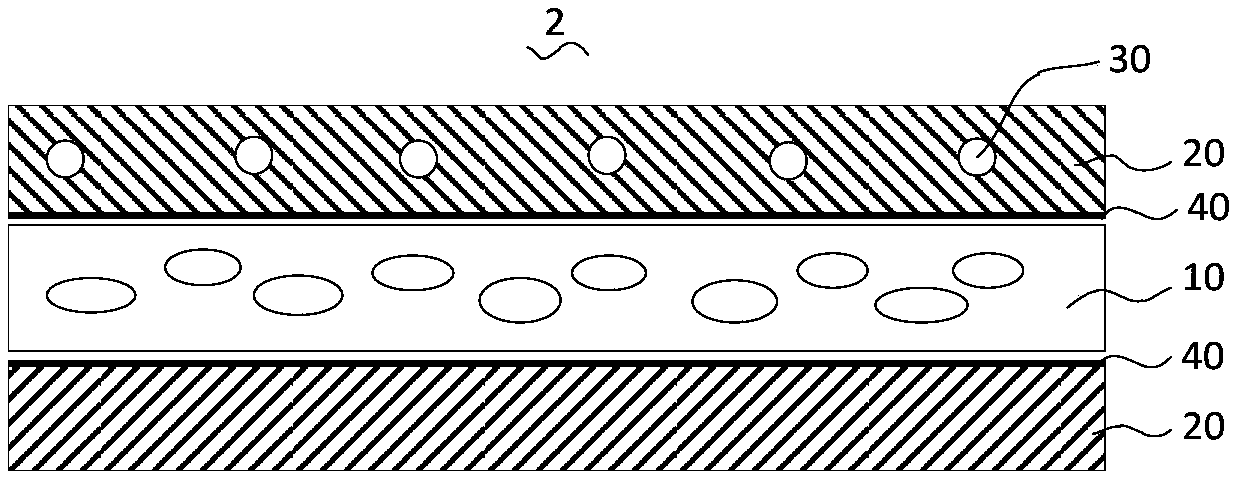

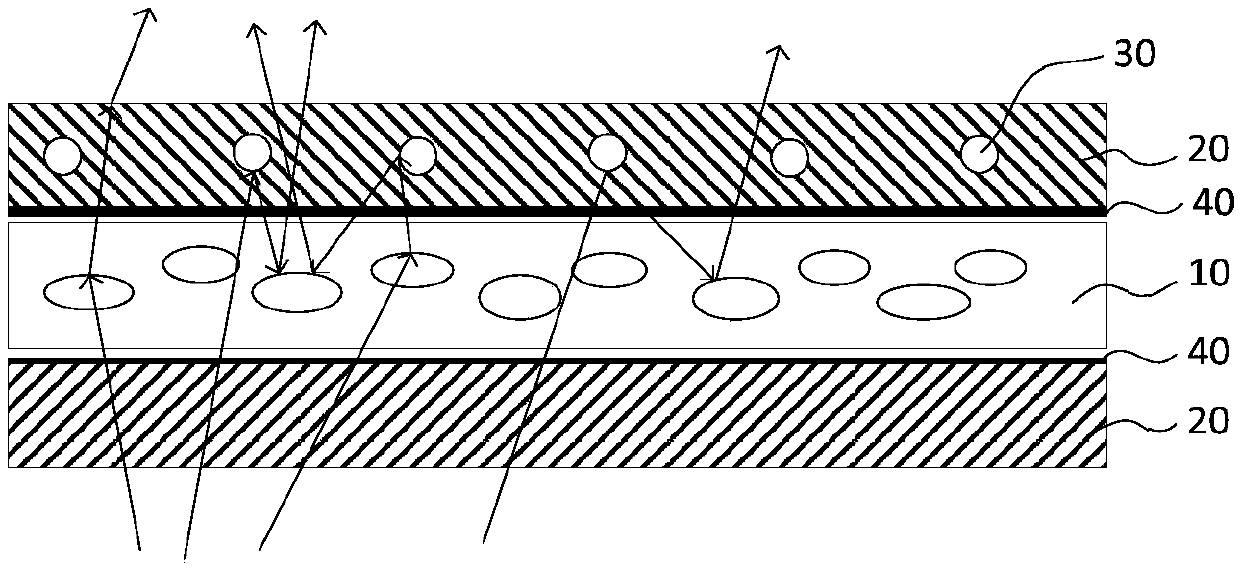

Emitting film with improved light-out coupling

ActiveUS20170153007A1Improve efficiencyReduce power consumptionDiffusing elementsLight guides with fluorescent dopantsWavelength rangeLight scattering

The present invention provides an optically active structure and the use thereof in a backlight unit. The optically active structure comprises a plurality of optically active particles configured to emit light of one or more predetermined wavelength range in response to pumping energy, and a plurality of light scattering elements. The plurality of light scattering elements comprises optically transparent void regions, such as void regions surrounding filler particles.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

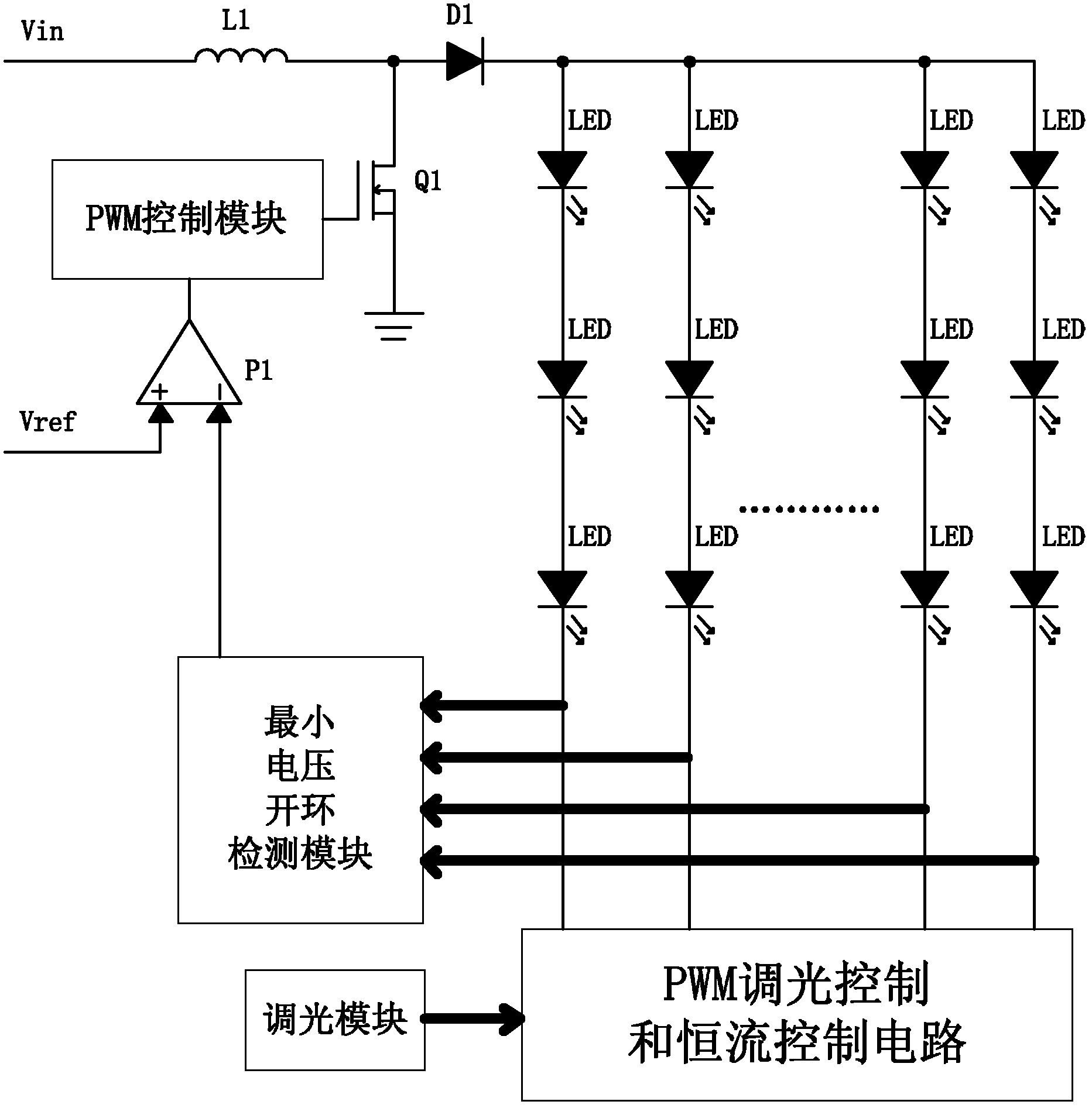

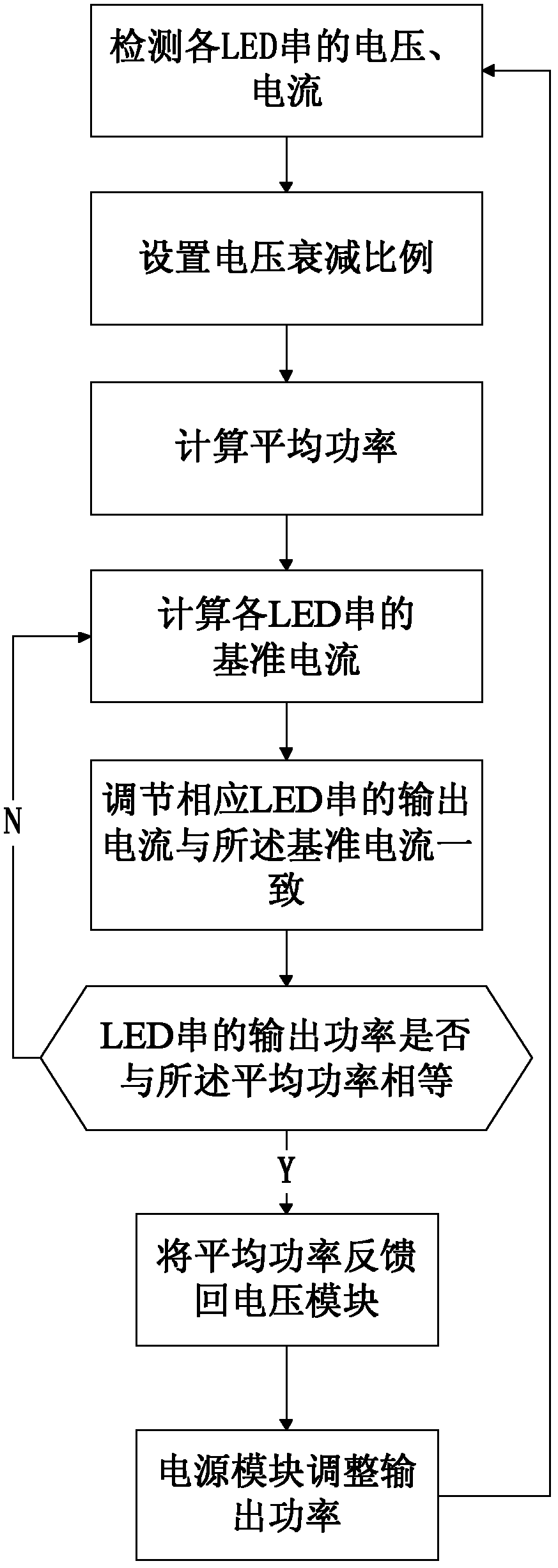

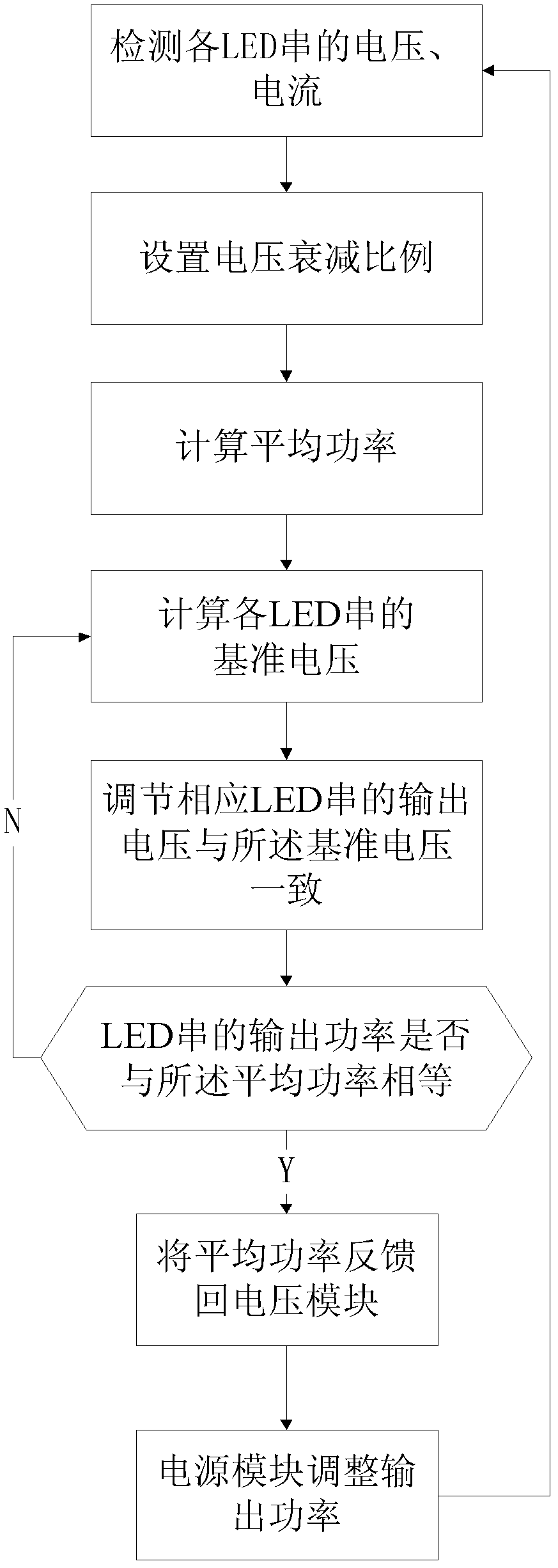

A kind of LED backlight driving method, LED backlight driving circuit and liquid crystal display device

InactiveCN102280089AReduce lossReduce the temperatureElectrical apparatusStatic indicating devicesLiquid-crystal displayEngineering

Disclosed are an LED backlight driving method, an LED backlight driving circuit, and a liquid crystal display device. The LED backlight driving method comprises the following steps: detecting the voltage and current of each LED string, calculating the power of each LED string, determining a reference power; and adjusting for each LED string the output power thereof until same equals the reference power. The constant power control scheme employed in the present invention, on the one hand, supplements a reduction in brightness of the LED due to heating, while on the other hand, by adjusting automatically the voltage and current of a light guide plate, thus allowing for reduced current for high crossover voltage, and for increased voltage for low crossover voltage, reduces the wearing and temperature of a constant current control circuit due to different crossover voltages.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

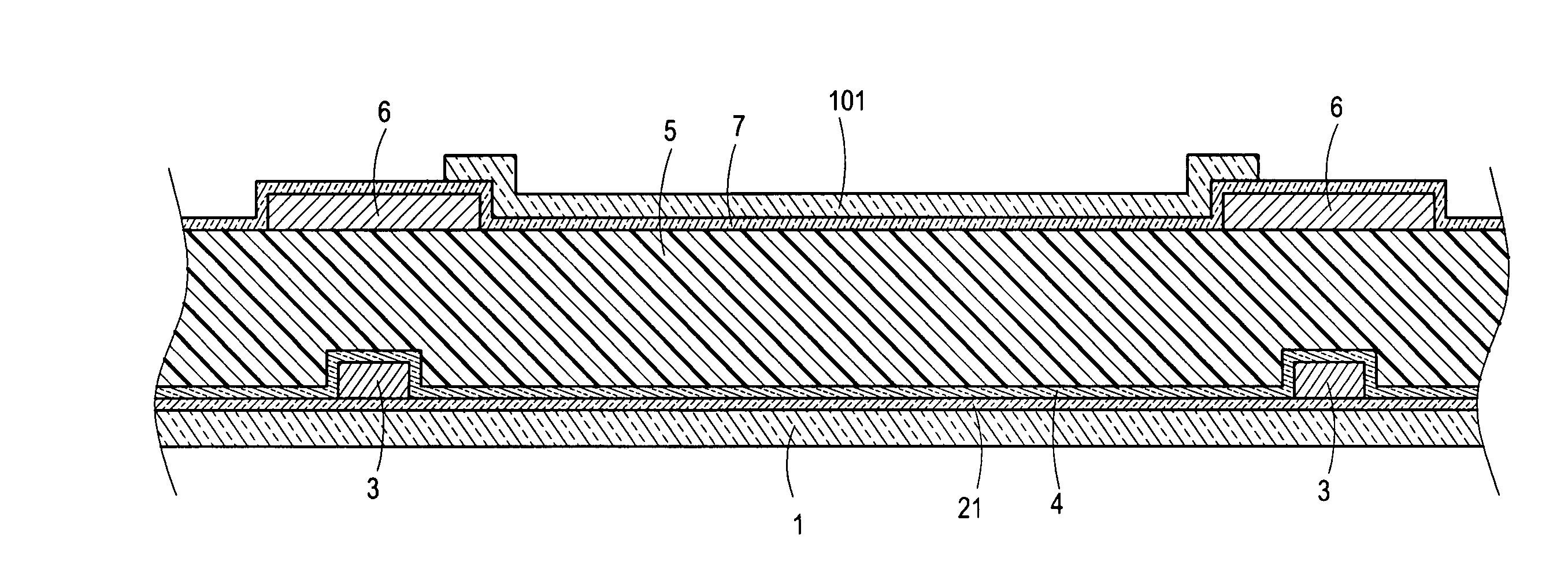

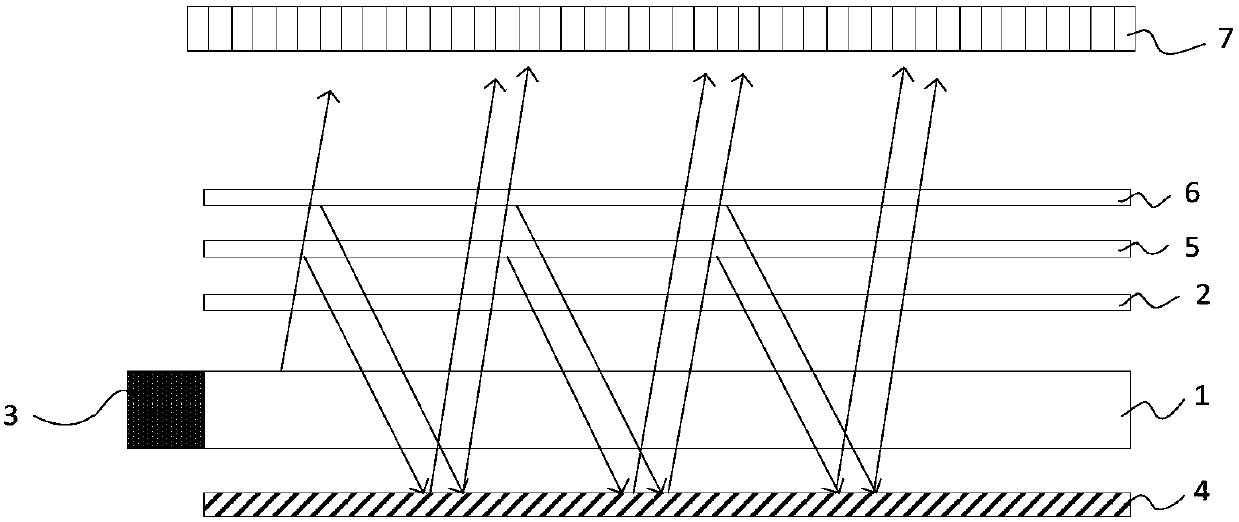

Backlight module and display device

InactiveCN110515237AReduce light lossIncrease backlight brightnessNon-linear opticsDisplay deviceLight control

The invention provides a backlight module and a display device. The backlight module comprises a substrate, an optical film structure layer, a through hole and a light control structure. Wherein the optical film structure layer is arranged on the substrate, the through hole penetrates through the substrate and the optical film structure layer, and the light control structure is arranged in the through hole.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Positive and negative mixed liquid crystal combination and application thereof

ActiveCN107189791ANegative dielectric anisotropyLow rotational viscosity propertiesLiquid crystal compositionsNon-linear opticsSolubilityDielectric

The invention relates to the field of liquid crystal materials, in particular to a positive and negative mixed liquid crystal combination and application thereof. The combination at least comprises a compound represented by a general formula I and at least comprises a compound represented by a general formula II. The liquid crystal combination has the characteristics of low viscosity, high resistivity, good low-temperature solubility, high response speed and excellent transmittance and can be used for fast response liquid crystal display of various display modes. At present, FFS and IPS become the most mainstream display modes, but the problem of low transmittance of FFS and IPS becomes a key problem to be solved; through experiments, it is found that the liquid crystal combination with large vertical dielectrics has high transmittance, and therefore the effect of improving brightness without increasing electric energy consumption can be achieved. The liquid crystal combination has the large vertical dielectrics, so that the transmittance characteristic of a liquid crystal display can be effectively improved, especially in displays of FFS and IPS display modes. The formulas are shown in the description.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

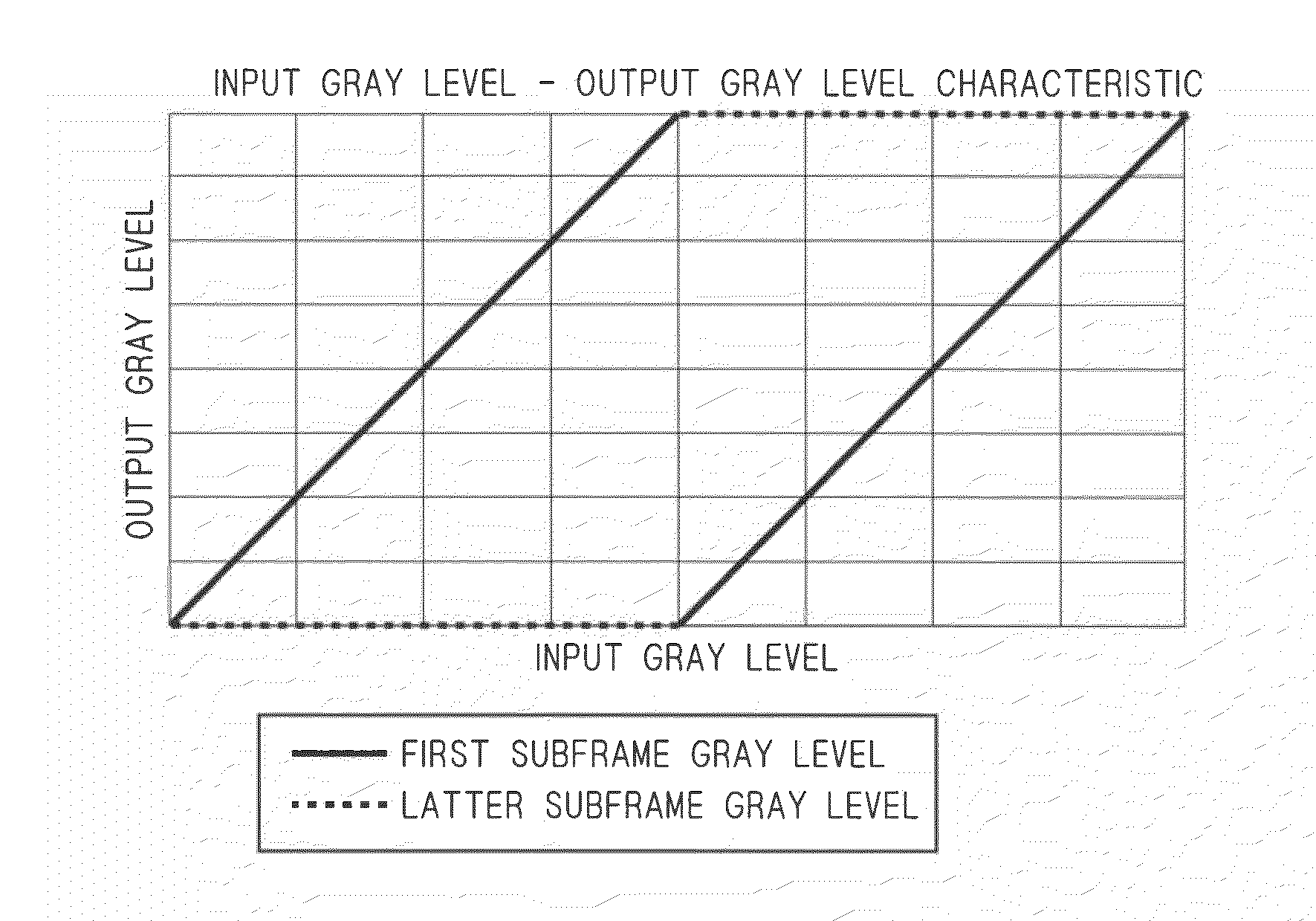

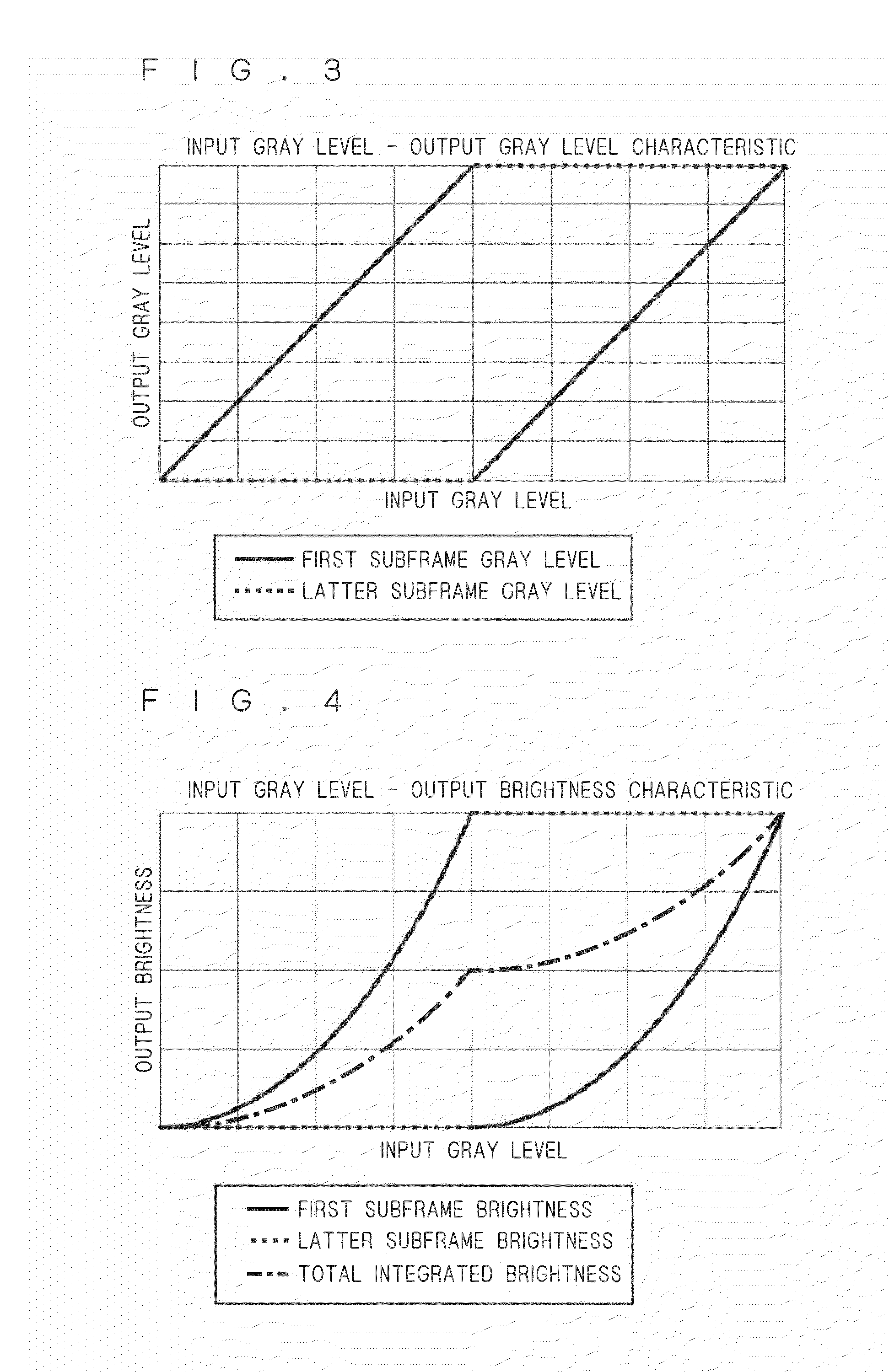

Liquid crystal display

ActiveUS20090267881A1Solve imaging blurIncrease brightnessCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayTheoretical computer science

A data converter divides input data into first subframe data and latter subframe data, and the latter subframe data is given to a data serial-parallel converter and serial-parallel converted. The first subframe data is given to a line memory group, and given to an overdrive operation circuit after a given delay. The latter subframe data converted into parallel data is given to a line memory group, and given to a data parallel-serial converter after a given delay, where it is parallel-serial converted, and then it becomes output data after the first subframe data outputted from the overdrive operation circuit.

Owner:TRIVALE TECH

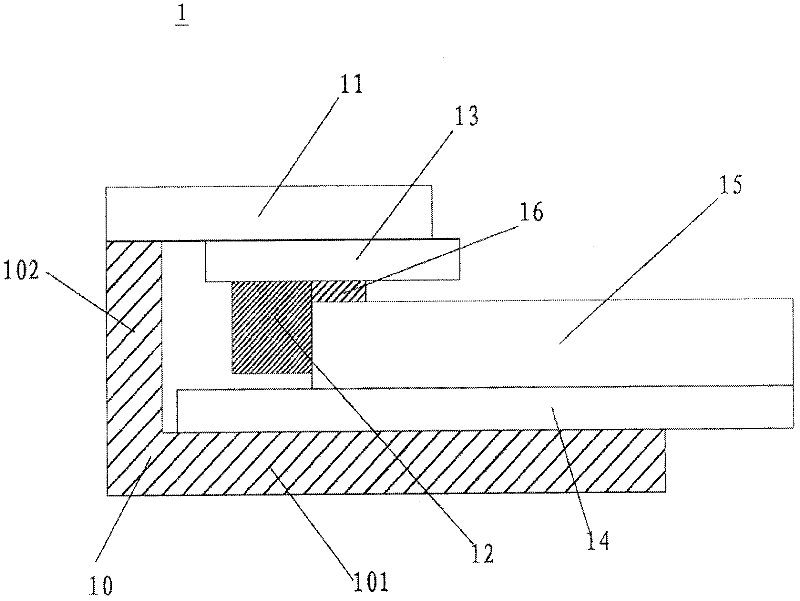

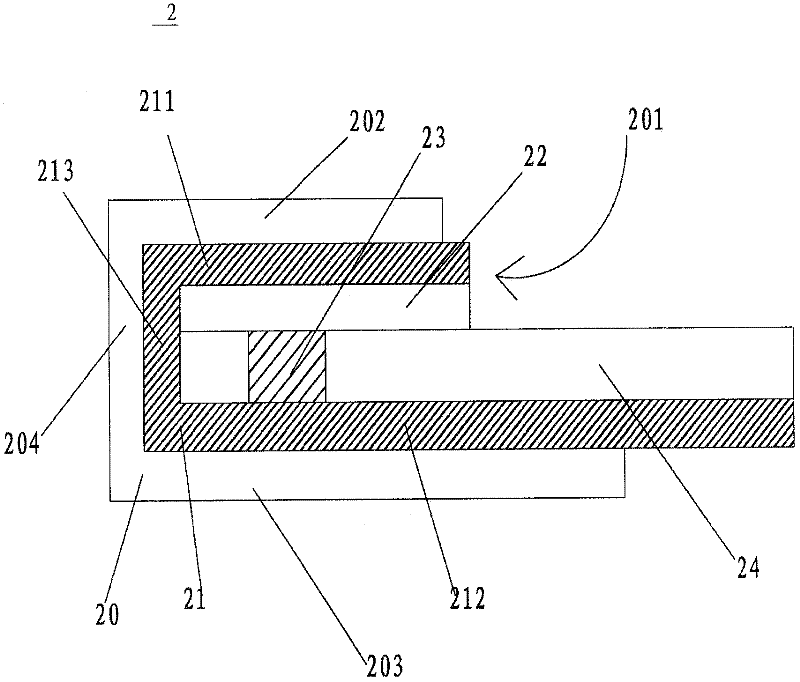

Resilient pressing member structure

InactiveUS20140042005A1Display clearIncrease backlight brightnessEmergency actuatorsOperation facilitationLight guideEngineering

The instant disclosure is a resilient pressing member structure having a pressing unit disposed on top of a translucent insulated layer, an upper cover, a light-emitting unit, two conductive layers and a spacer. The pressing unit includes a plurality of pressing members while the cover is formed with a cavity filled with a fluid to achieve the effect of pressure dispersion. A light guiding structure and a light reflecting structure are disposed on the topside and the backside of the insulated layer, respectively. The insulated layer is formed by at least one light unit opening which extends through the insulated layer. The light-emitting unit is hosted inside the light unit opening. Light from the light-emitting unit penetrates the insulated layer and reaches the pressing member. Then the guiding structure directs light while the reflecting structure reflects light towards the pressing member, thus illuminates the pressing member.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

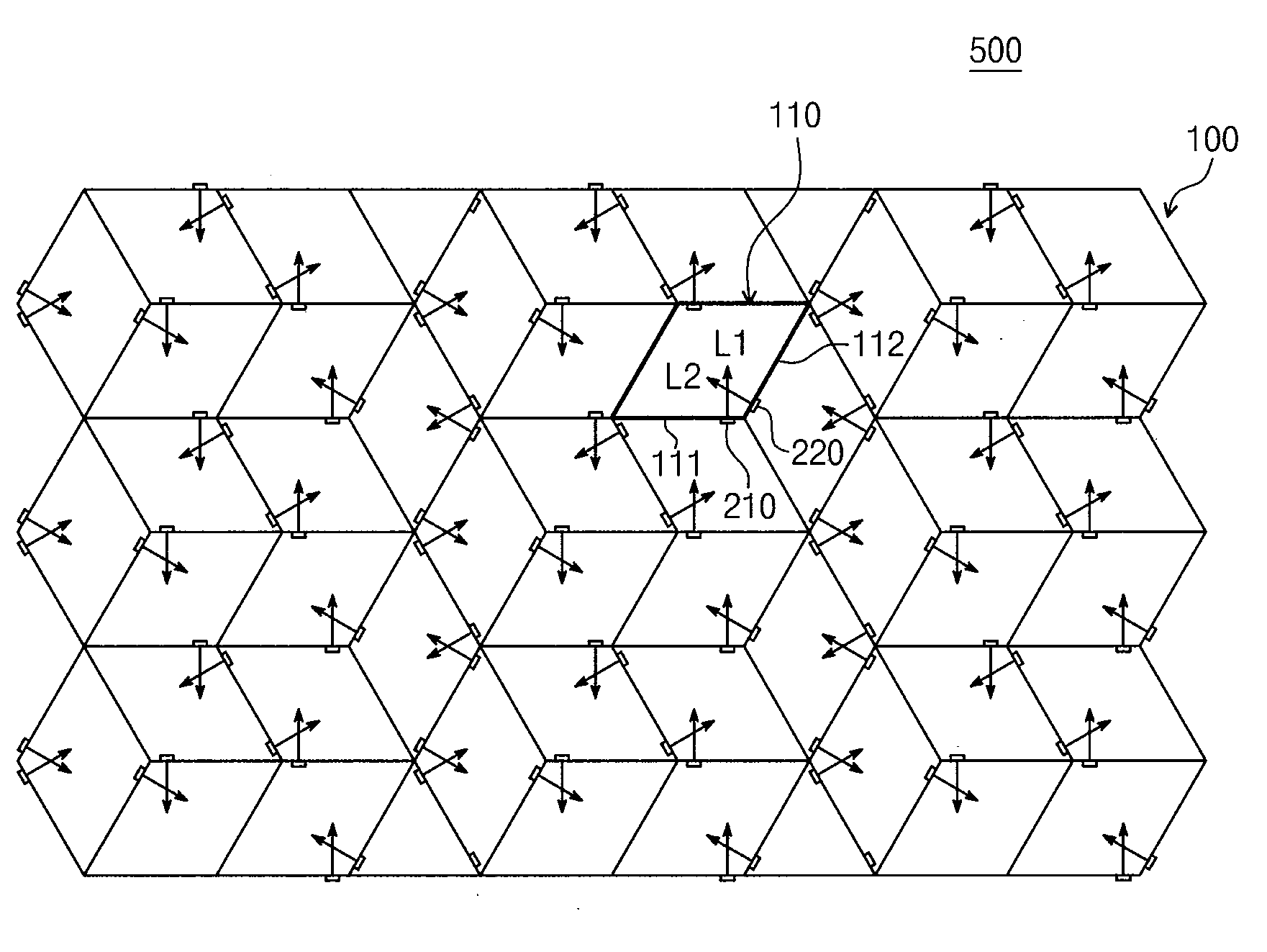

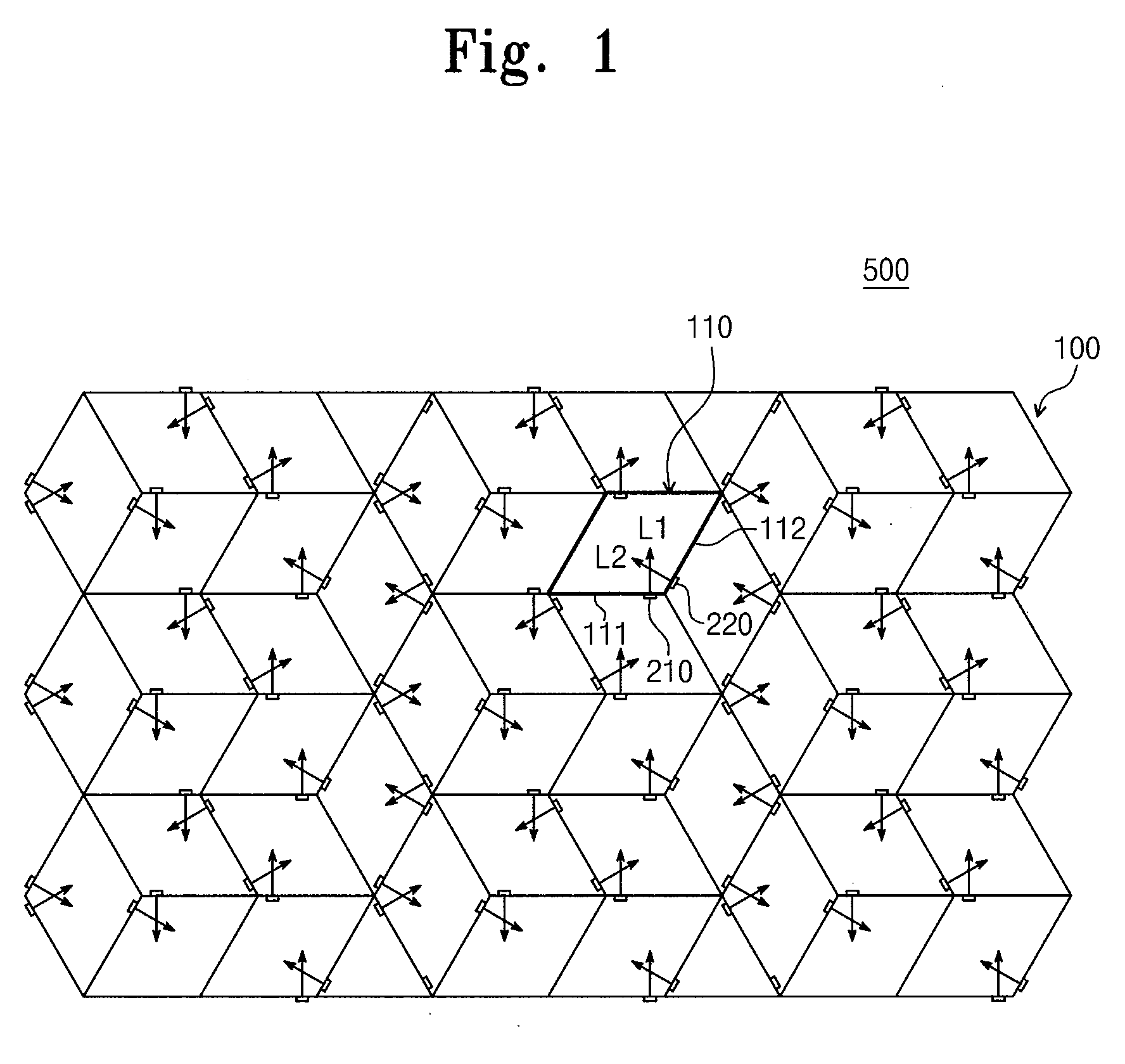

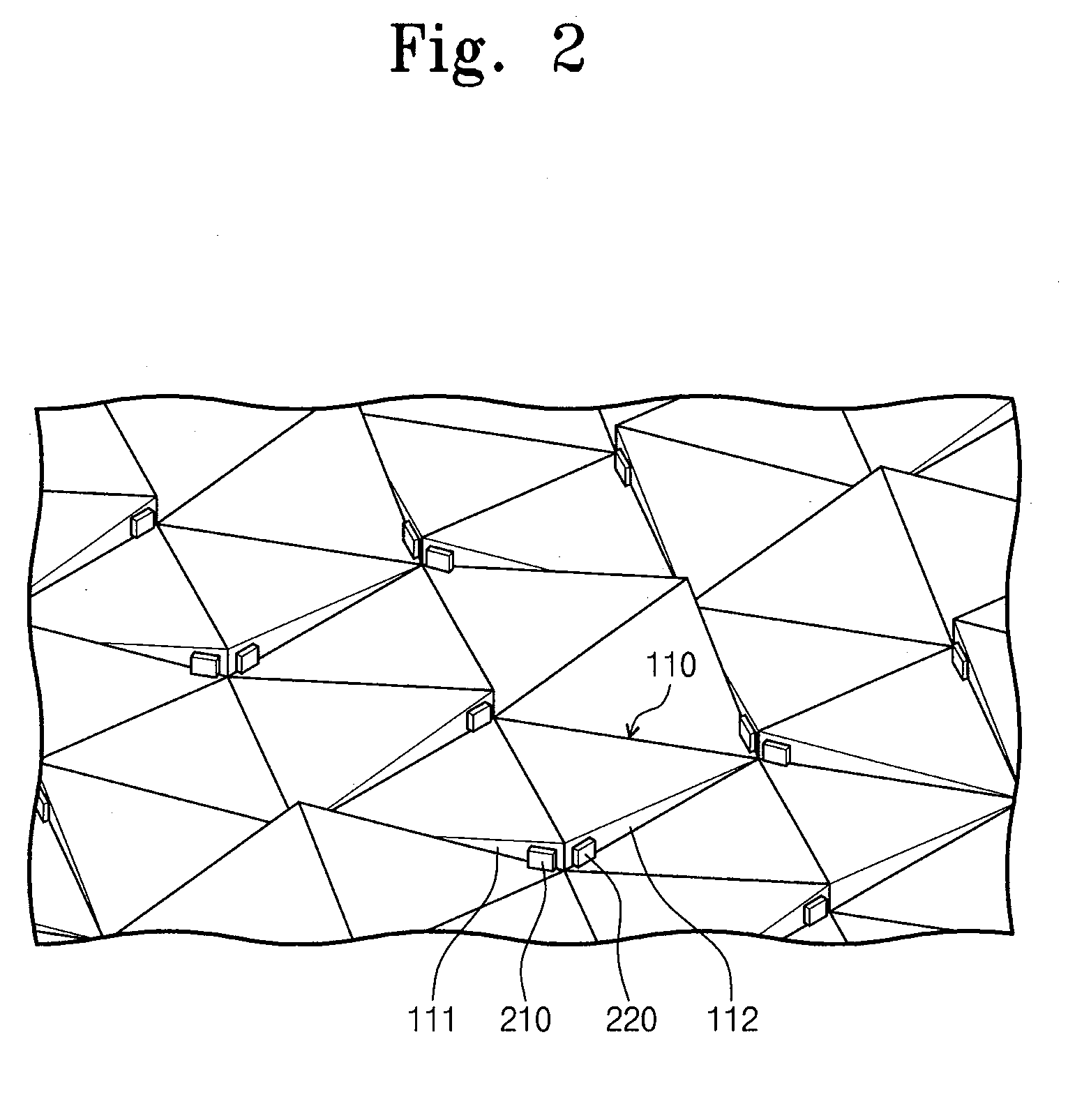

Light guide plate and backlight assembly having the same

InactiveUS20090310336A1Increase brightnessReduce thicknessMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

In a light guide plate and a backlight assembly having the same, the light guide plate includes a plurality of light guide cells. Each light guide cell has at least one incident surface that receives light from an outside light source. The incident surfaces of the light guide cells are arranged in non-parallel planes. A light source unit includes at least one light source adjacent to the incident surface of each light guide cell. Thus, brightness of the backlight assembly is improved and thickness of the backlight assembly is reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

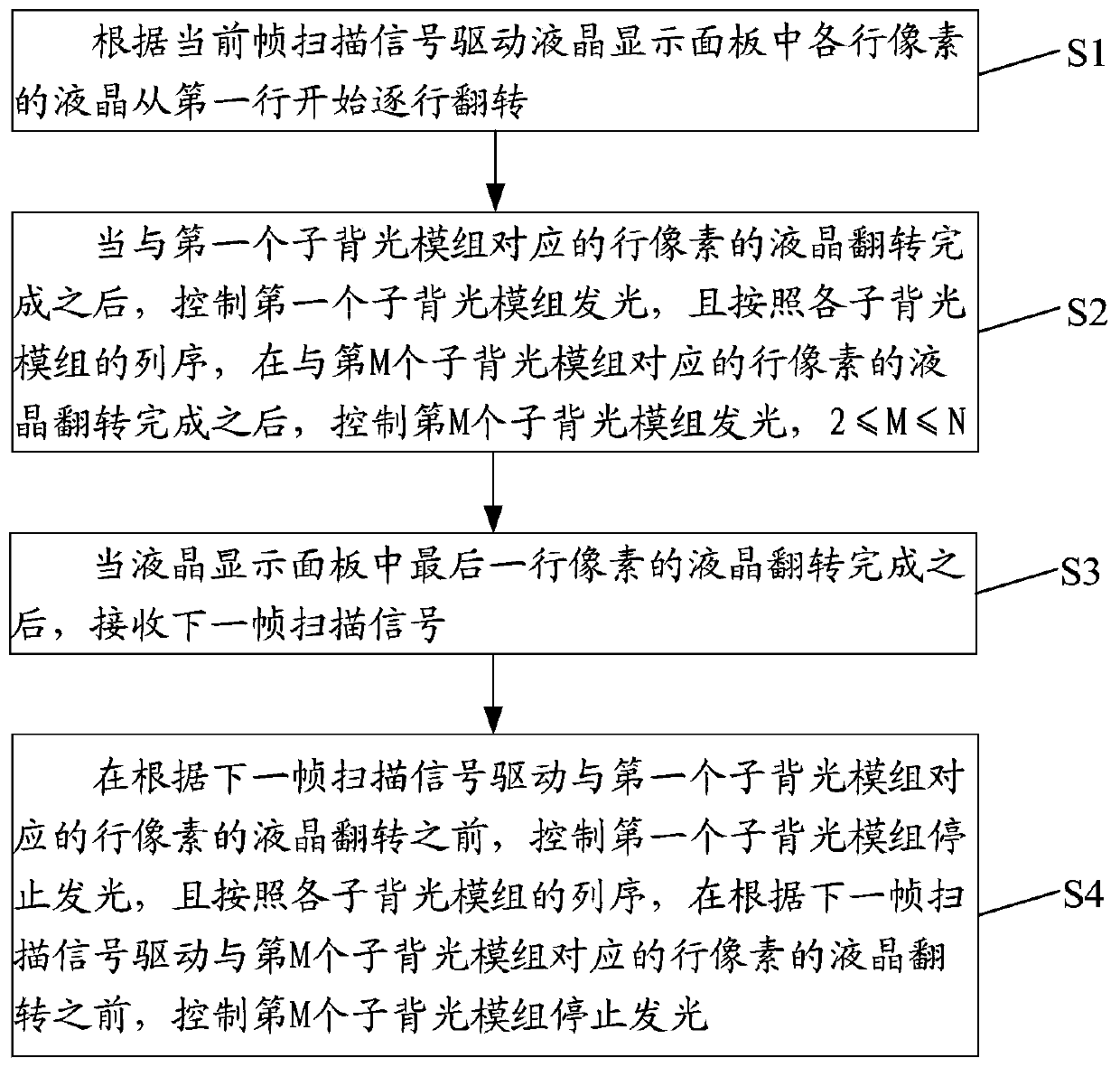

Backlight driving method and device and display device

InactiveCN109741712AShorten the lengthIncrease refresh rateStatic indicating devicesLiquid-crystal displayLiquid crystal

The embodiment of the invention discloses a backlight driving method and device, relates to the technical field of display, and is used for improving the refresh frequency and backlight brightness ofa display device. The backlight driving method comprises the following steps: driving liquid crystals of each row of pixels in a liquid crystal display panel to turn over line by line from a first rowaccording to a current frame scanning signal; After the liquid crystals of the row pixels corresponding to the first sub-backlight module are turned over, controlling the first sub-backlight module to emit light, and according to the column sequence of all the sub-backlight modules, after the liquid crystals of the row pixels corresponding to the Mth sub-backlight module are turned over, controlling the Mth sub-backlight module to emit light; When the liquid crystal of the last row of pixels in the liquid crystal display panel is overturned, receiving a next frame of scanning signal; And controlling the corresponding sub-backlight modules to stop emitting light one by one before driving the liquid crystals of the row pixels corresponding to the sub-backlight modules to turn over in sequence according to the next frame of scanning signal. The backlight driving method and device provided by the embodiment of the invention are used for the liquid crystal display panel.

Owner:BOE TECH GRP CO LTD +1

Backlight assembly and method of manufacturing light guide plate therefor

ActiveUS8277105B2Reduce in quantityIncrease brightnessOptical articlesOptical light guidesLight guidePrism

A backlight assembly and a manufacturing method of light guide plate of the backlight assembly is provided. The light guide plate includes an incident surface to which light is incident, an exiting surface from which the light exits, and a reflection surface facing the exiting surface. The light guide plate includes recesses provided on the reflection surface recessed toward the exiting surface to scatter the light. Each of the recesses has a depth-to-width ratio of about 0.2 to about 0.33. Two prism sheets are disposed on the light guide plate. Light exits from the light guide plate at an angle of about 25 degrees to about 30 degrees.

Owner:SAMSUNG DISPLAY CO LTD

Method for controlling dynamic backlight of LED of liquid crystal display based on dynamic threshold

ActiveCN102903340AQuality improvementSmall distortionStatic indicating devicesLiquid-crystal displayImaging quality

The invention provides a method for controlling dynamic backlight of an LED (Light-Emitting Diode) of a liquid crystal display based on a dynamic threshold, comprising the following steps of: firstly, obtaining a threshold T which maximizes the interclass variance between the background and a target by a threshold dichotomization method; calculating the backlight brightness change coefficient of each region; putting the backlight brightness change coefficient K (m, n) in a formula BL (m, n)=average (m, n)+K (m, n)*(max(m, n)-average (m, n)), thereby obtaining the backlight brightness of each region. The method is characterized in that the algorithm dynamically increases the backlight brightness according to the proportion of image details on the basis of the average image brightness, the proportion of the image details is obtained by the Otsu method, the algorithm is simple, and the image quality of the liquid crystal display is improved while the power consumption is reduced.

Owner:中航华东光电有限公司

Positive and negative mixed liquid crystal combination and application thereof

ActiveCN107189792AIncrease consumptionReduce consumptionLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

The invention provides a positive and negative mixed liquid crystal combination. The liquid crystal combination has large vertical dielectrics, so that the transmittance characteristic of a liquid crystal display can be effectively improved; a first-class compound is added in the liquid crystal combination to increasing parallel dielectrics of the liquid crystal combination, a second-class compound with negative dielectric anisotropy is added to increasing the vertical dielectrics of the combination, a third-class compound is further utilized to reduce the rotational viscosity of the liquid crystal combination, and therefore the liquid crystal combination with quick response and high transmittance is achieved. The liquid crystal combination is suitable for TN, IPS, FFS type liquid crystal displays, and especially suitable for the IPS and FFS type liquid crystal displays.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Pixel structure of a thin film transistor liquid crystal display

InactiveUS20080227242A1Increase the aperture ratioImprove pixel qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay contrastData signal

A pixel structure of a thin film transistor liquid crystal display employs a design of three metal layers and includes an organic insulating layer between a data signal line and a common electrode for reducing a parasitic capacitance, while a passivation layer included between the common electrode and a pixel electrode acts as a storage capacitor required for the pixels, so as to achieve a high aperture ratio, and the common electrode can act as a shielding bar for enhancing the display contrast.

Owner:WINTEK CORP

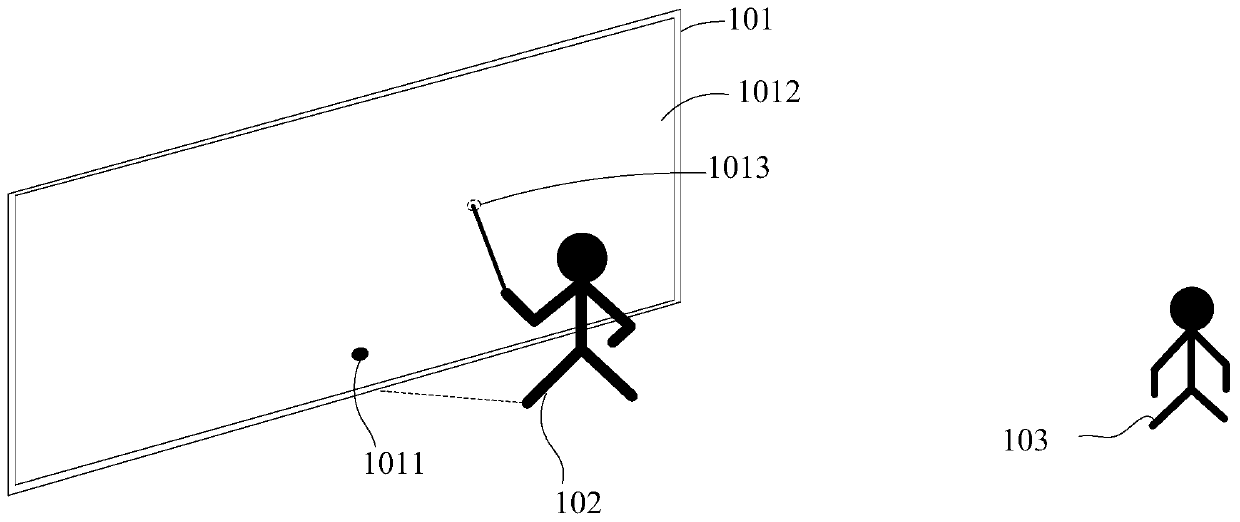

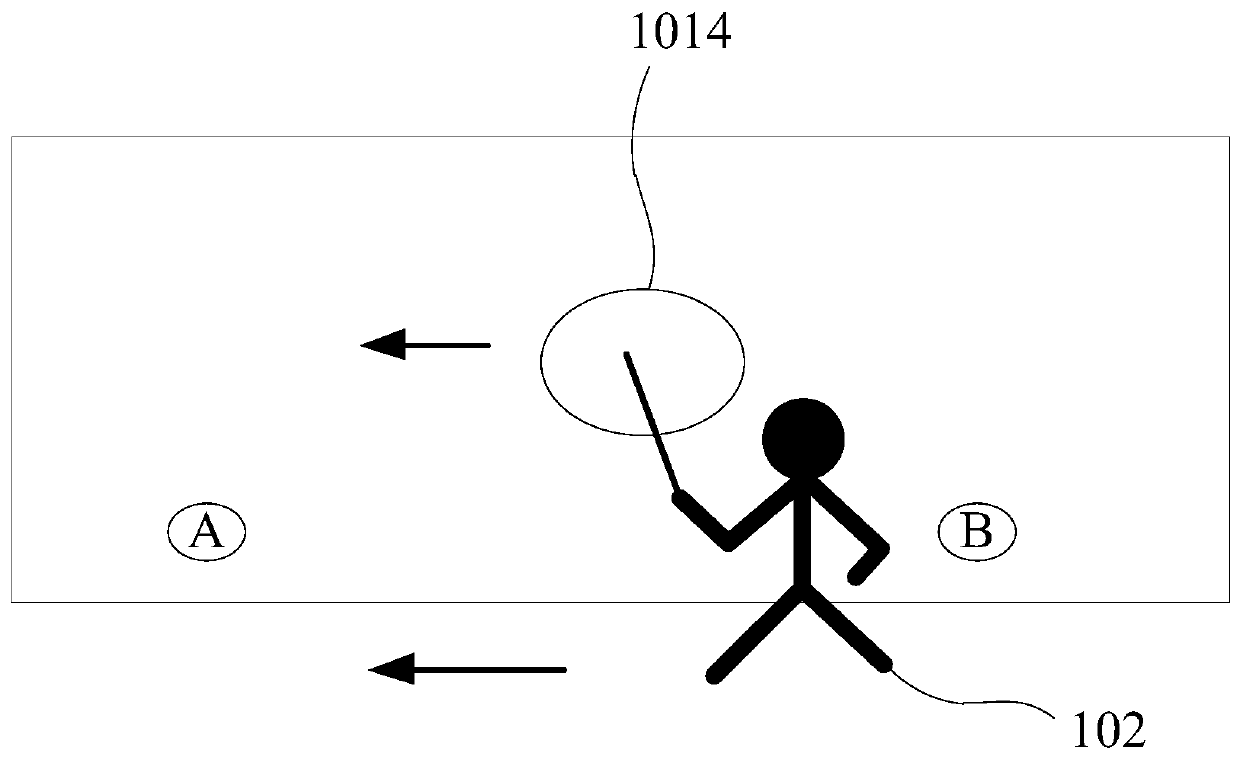

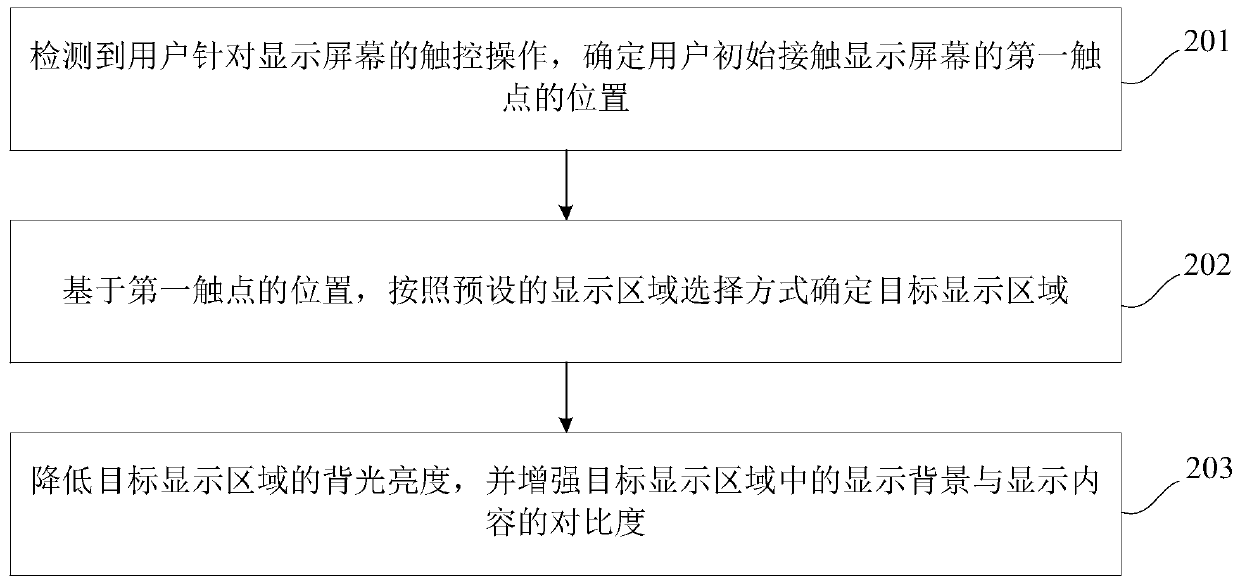

Display adjustment method and device, electronic equipment and storage medium

InactiveCN111414114AReduce irritationProtect eyesightInput/output processes for data processingEngineeringComputer hardware

The invention discloses a display adjustment method and device, electronic equipment and a storage medium, relates to the technical field of display control, and is used for ensuring that a farther user can clearly see contents displayed in a target display area while protecting the eyesight of the user. The method comprises: detecting a touch operation of the user for a display screen, and determining the position of a first contact initially contacted with the display screen by the user; determining a target display area according to a preset display area selection mode based on the positionof the first contact; and adjusting and reducing the backlight brightness of the target display area, and enhancing the contrast between the display background in the target display area and the handwriting of the display content user for the display screen.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

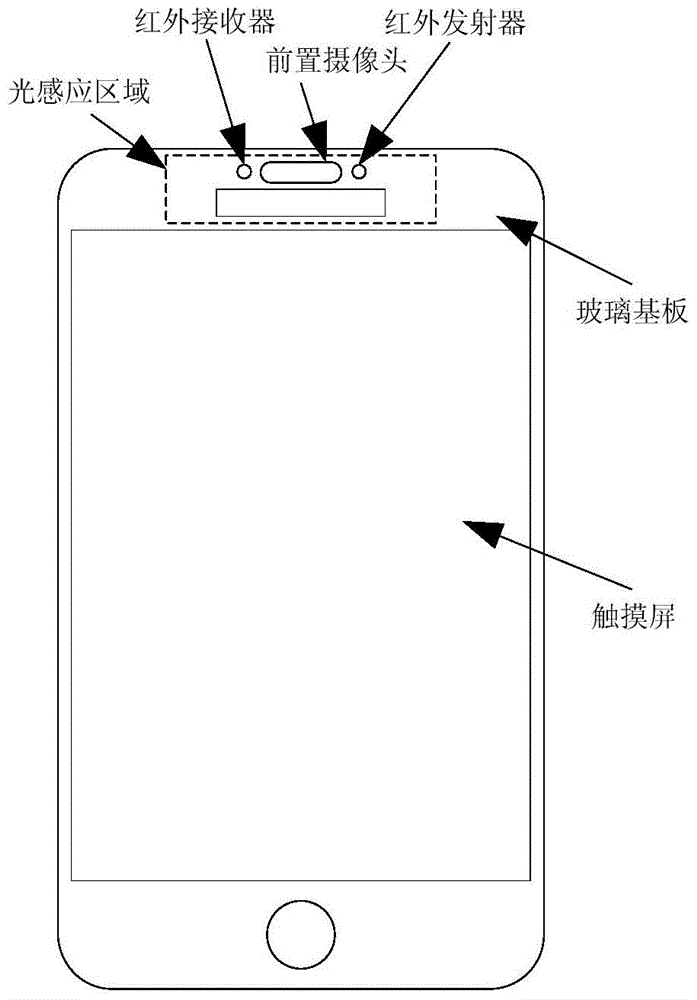

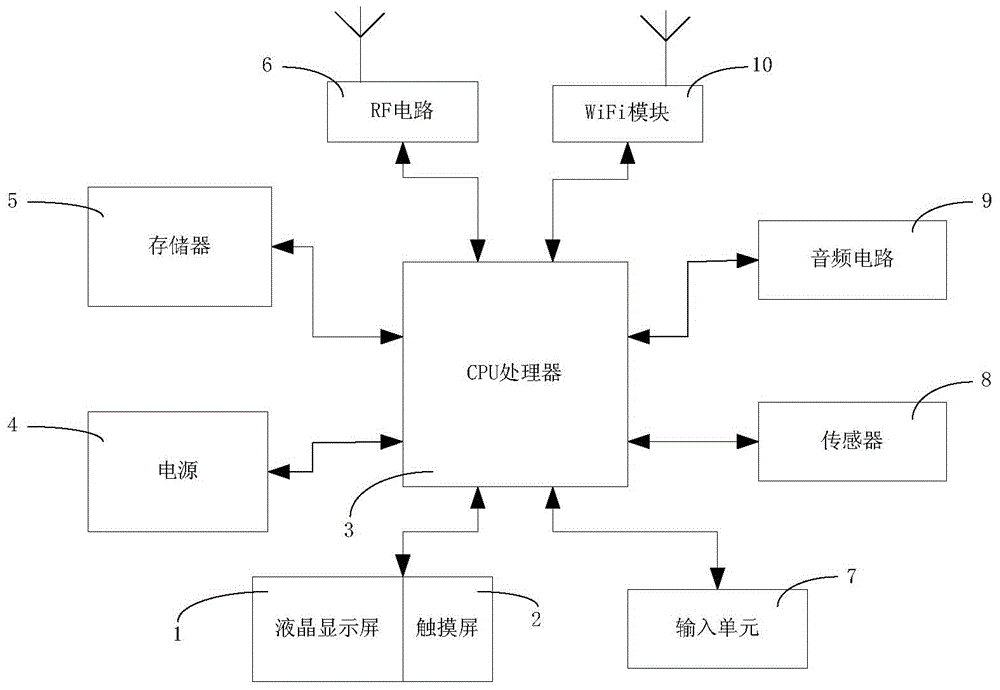

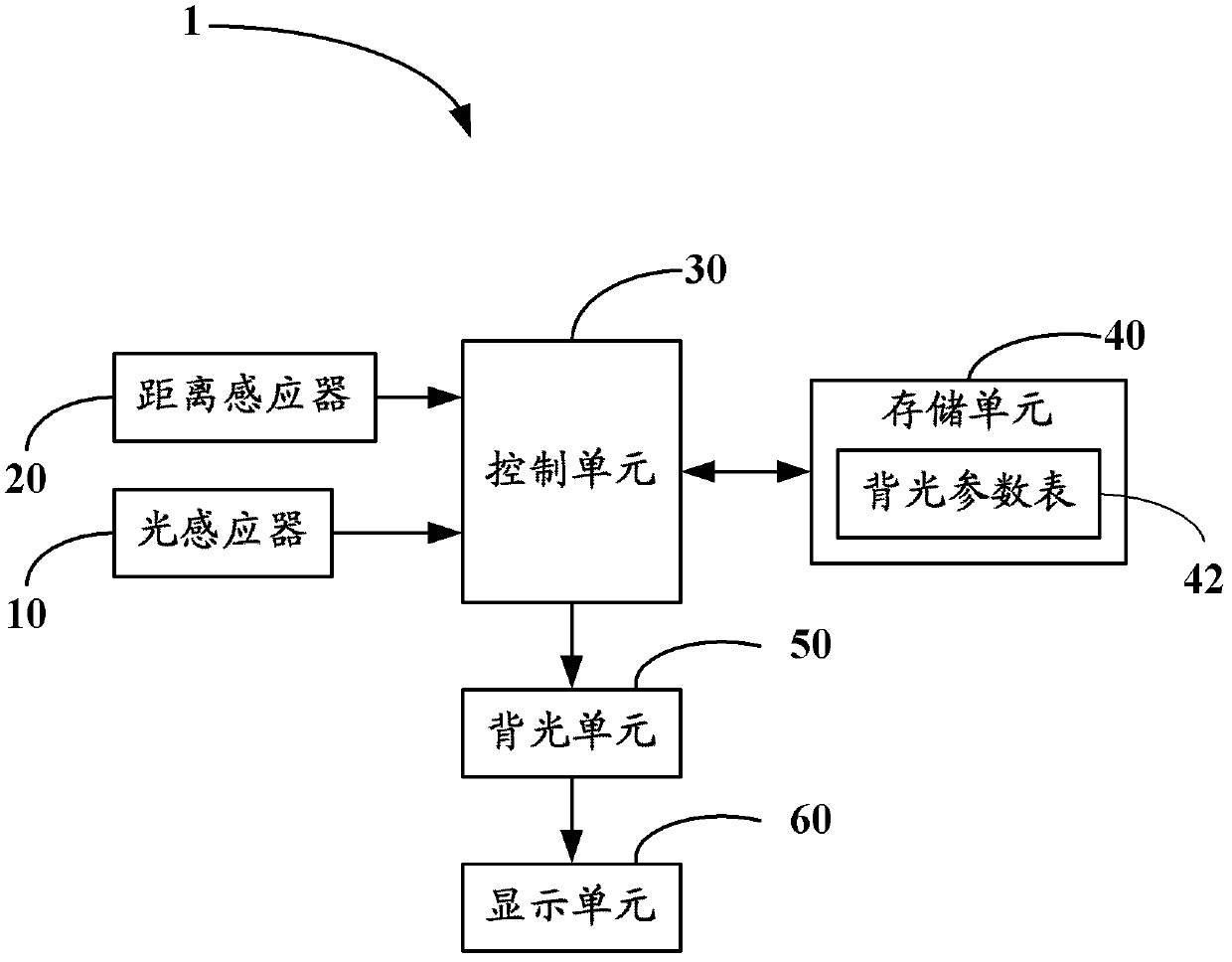

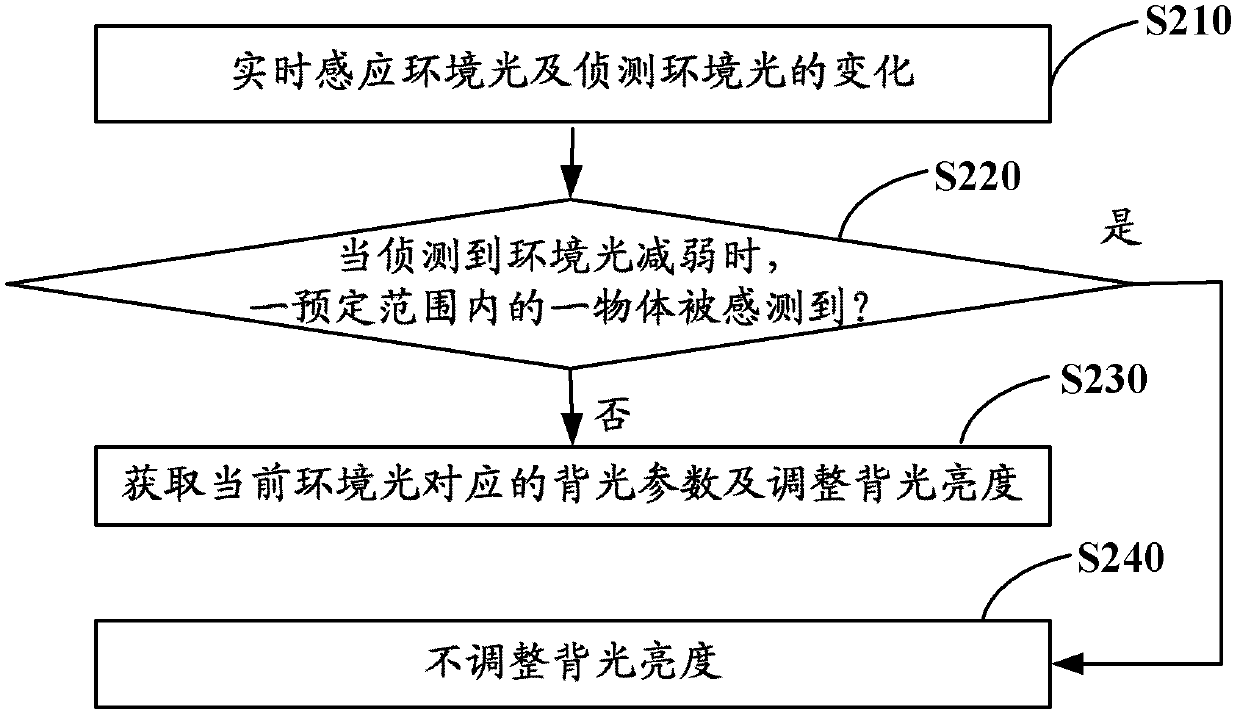

Mobile terminal of touch screen based on embedded sensor

InactiveCN105677110AIncrease backlight brightnessReduce brightnessInput/output processes for data processingExternal connectionLiquid-crystal display

The invention discloses a mobile terminal of a touch screen based on an embedded sensor. A display device is a liquid crystal display. The touch screen is fixed to a mobile terminal casing and covers the liquid crystal display, a plurality of layers of waveguide tubes are inscribed in a glass substrate of the touch screen to form a plurality of sensors having different functions. The sensors comprise an optical sensor and a temperature sensor, or the waveguide tubes inscribed in the glass substrate are provided with a plurality of small light-leaking holes, and the mobile terminal is certificated through a pattern composed of the small holes. Due to the fact that the external connection mode of the mobile terminal of the touch screen based on the embedded sensor is changed, a built-in mode is adopted, the size of a device and the number of parts are greatly reduced, users experience true portability, and user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

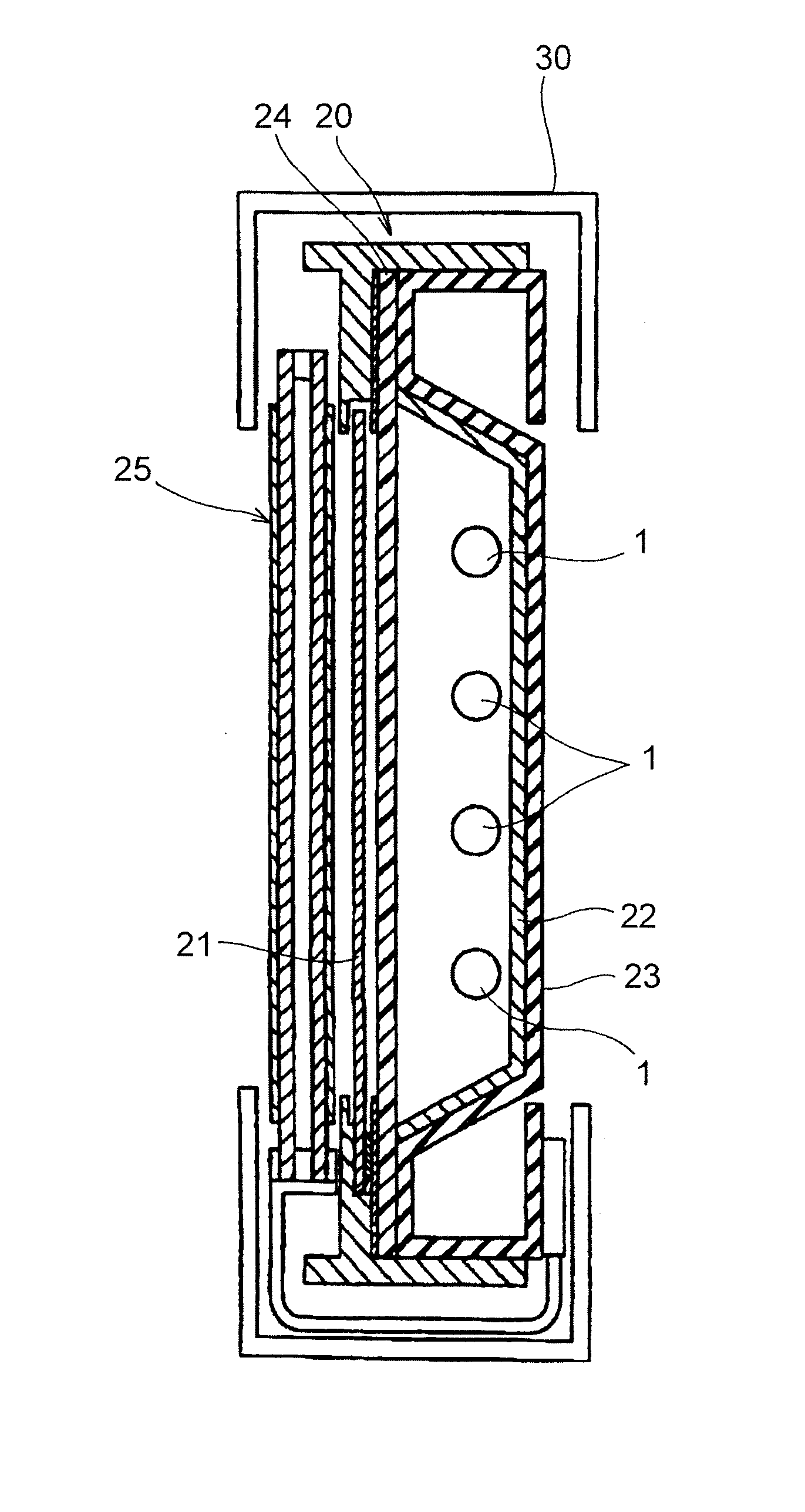

External Electrode Flourescent Lamp, Lighting Device, And Display Device

InactiveUS20080012498A1Save componentEasy to assembleSolid cathode detailsGas discharge lamp detailsDisplay deviceEngineering

An external electrode fluorescent lamp has external electrodes at opposite ends. The portions provided with the external electrodes are bent so that their axes are orthogonal to the axis of a light emitting sections. A conventional external electrode fluorescent lamp is not bent in its portions provided with external electrodes. Since the external electrodes of the external electrodes fluorescent lamps serve concurrently as holding sections for the fluorescent lamps the axial length is made greater than the outer diameter so as to provide sufficient strength. The width of the frame section of the fluorescent lamp of the invention when mounted on a backlight unit is smaller than the width of the frame section of conventional fluorescent lamp. Therefore, the effective light emitting area of the backlight unit can be enlarged.

Owner:SHARP KK

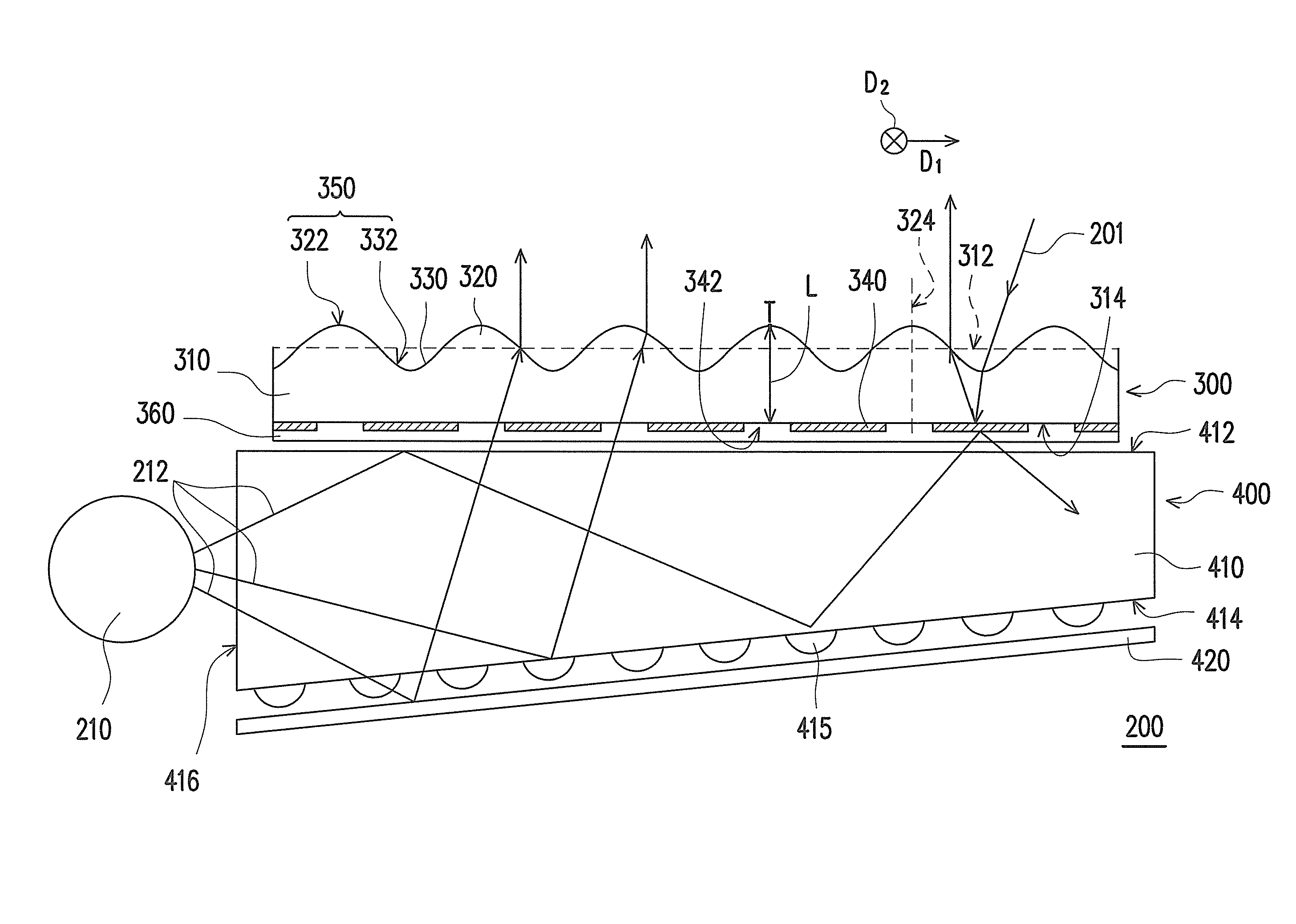

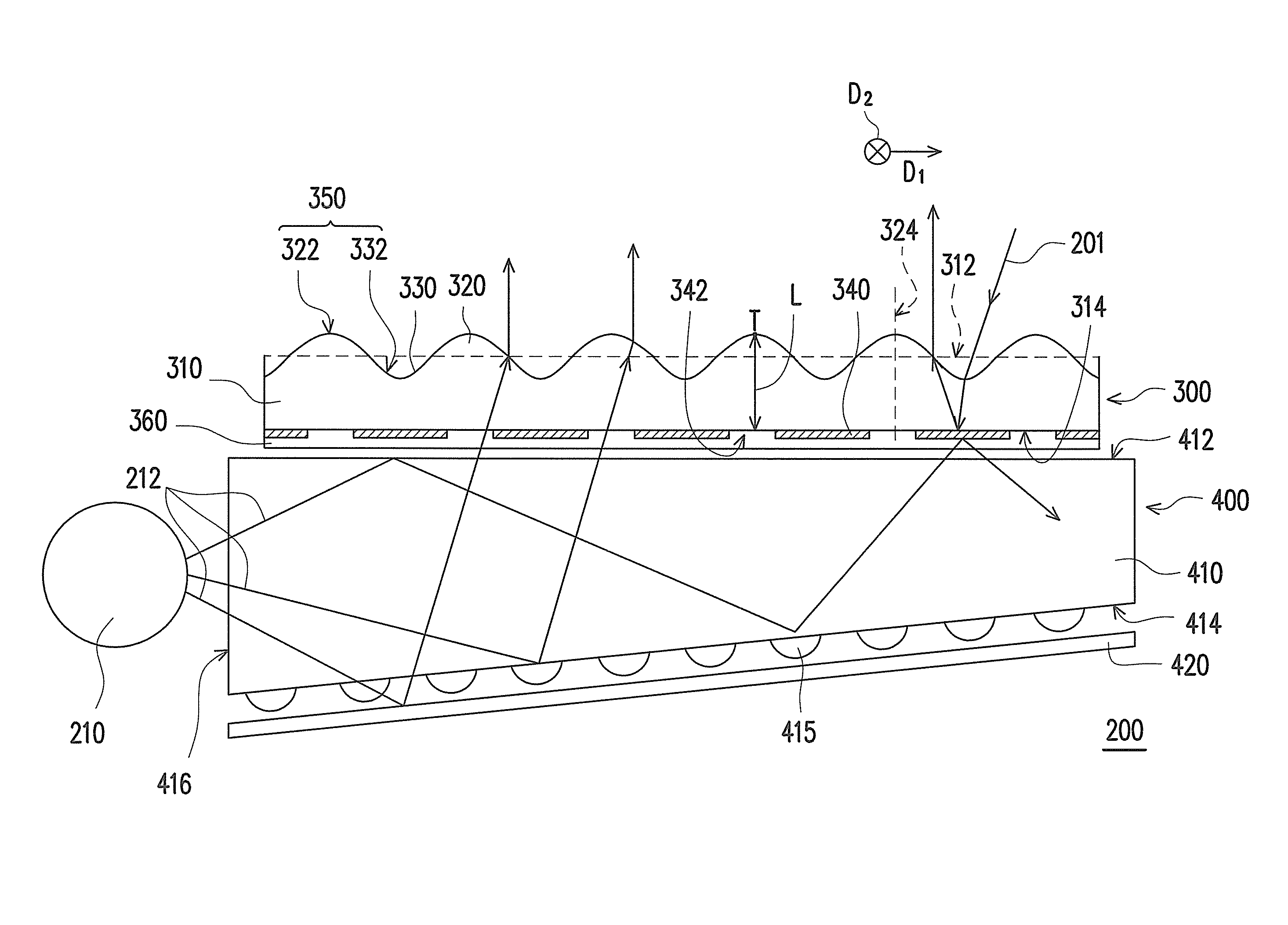

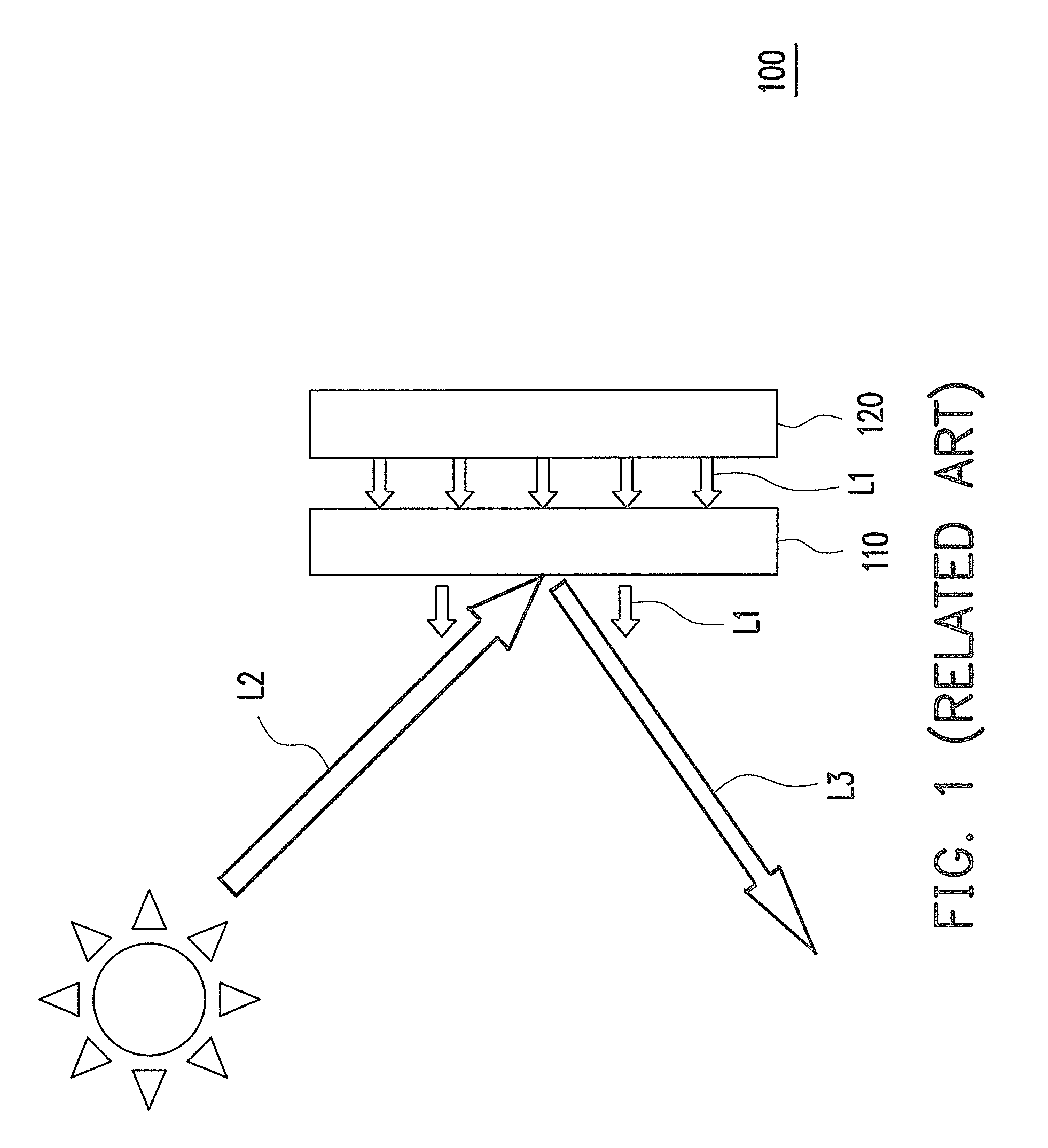

Brightness enhancement film and backlight module

InactiveUS20110141718A1Efficient use ofOptical brightness enhancement effectIlluminated signsNon-linear opticsOptical axisConvex side

A brightness enhancement film including a light transmissive substrate, convex lens portions, concave lens portions, and a reflective layer is provided. The light transmissive substrate has a first surface and a second surface opposite to the first surface. The convex lens portions are disposed on the first surface. Each of the convex lens portions has a curved convex surface facing away from the light transmissive substrate. The concave lens portions are disposed on the first surface. The convex lens portions and the concave lens portions are alternately arranged. Each of the concave lens portions has a curved concave surface facing away from the light transmissive substrate. A wavy continuous curve surface is formed by the curved convex surfaces and the curved concave surfaces. The reflective layer is disposed on the second surface and has light passing openings respectively on the optical axes of the convex lens portions.

Owner:CORETRONIC

Backlight module, quantum dot diaphragm and manufacturing method thereof

InactiveCN107688255AImprove photoluminescence utilizationIncrease backlight brightnessNon-linear opticsPhotoluminescenceQuantum dot

The invention discloses a quantum dot diaphragm which comprises a quantum dot layer, an upper protective layer and a lower protective layer. The quantum dot layer is clamped between the upper and lower protective layers; the upper protective layer is internally provided with a micro-hole structure with bubbles. The inventionfurther discloses a manufacturing method of the quantum dot diaphragm anda backlight module. Bubbles are formed inside one protective layer of the quantum dot layer, light enters the bubbles insidethe protective layer from the quantum dot layer, total reflection can happen, and then the light enters the quantum dot layer again, so that the photoluminescence utilization rate of the quantum dot layer is increased, the backlight brightness is improved, and the phenomenonthat the color of backlight is blue is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

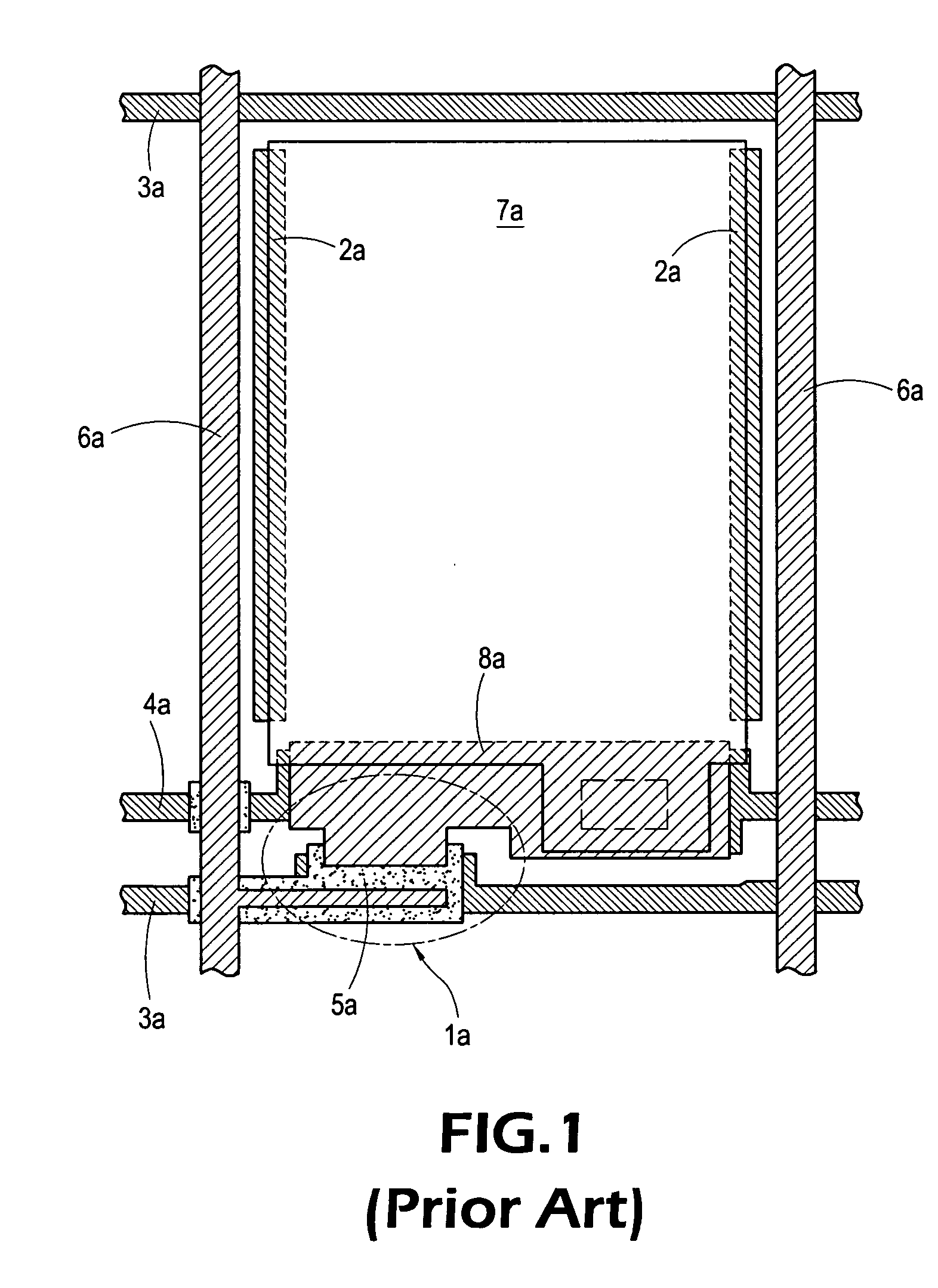

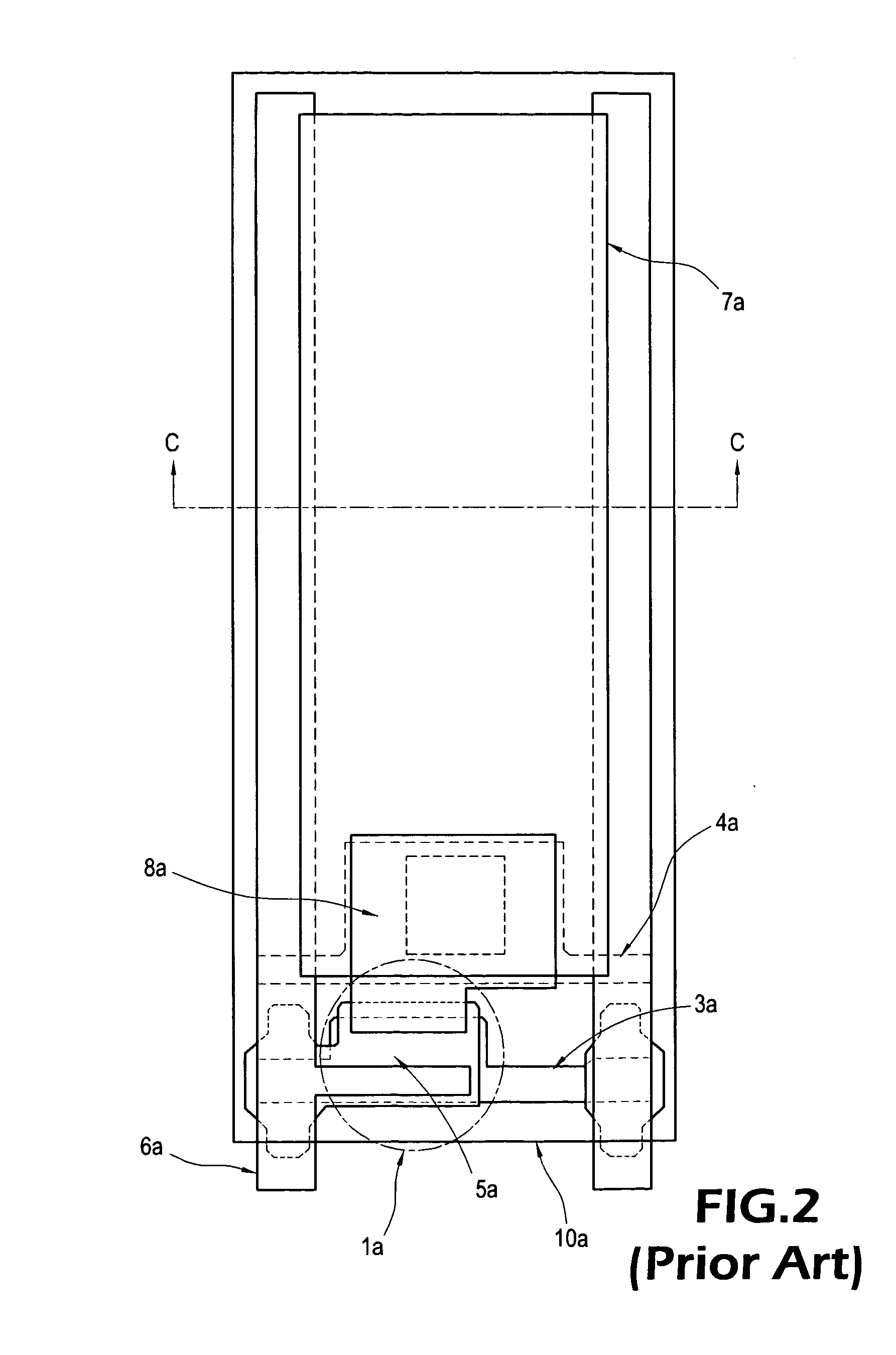

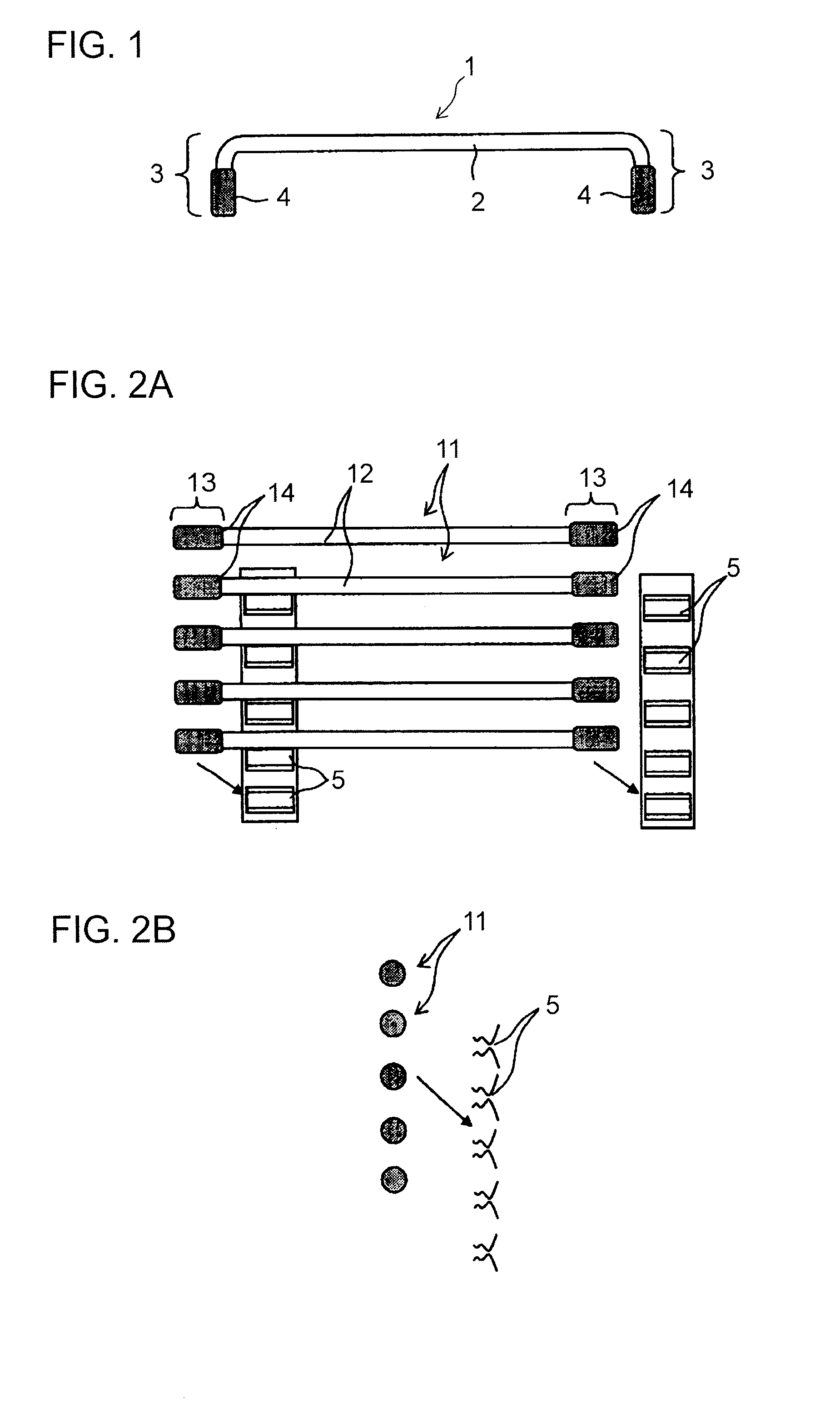

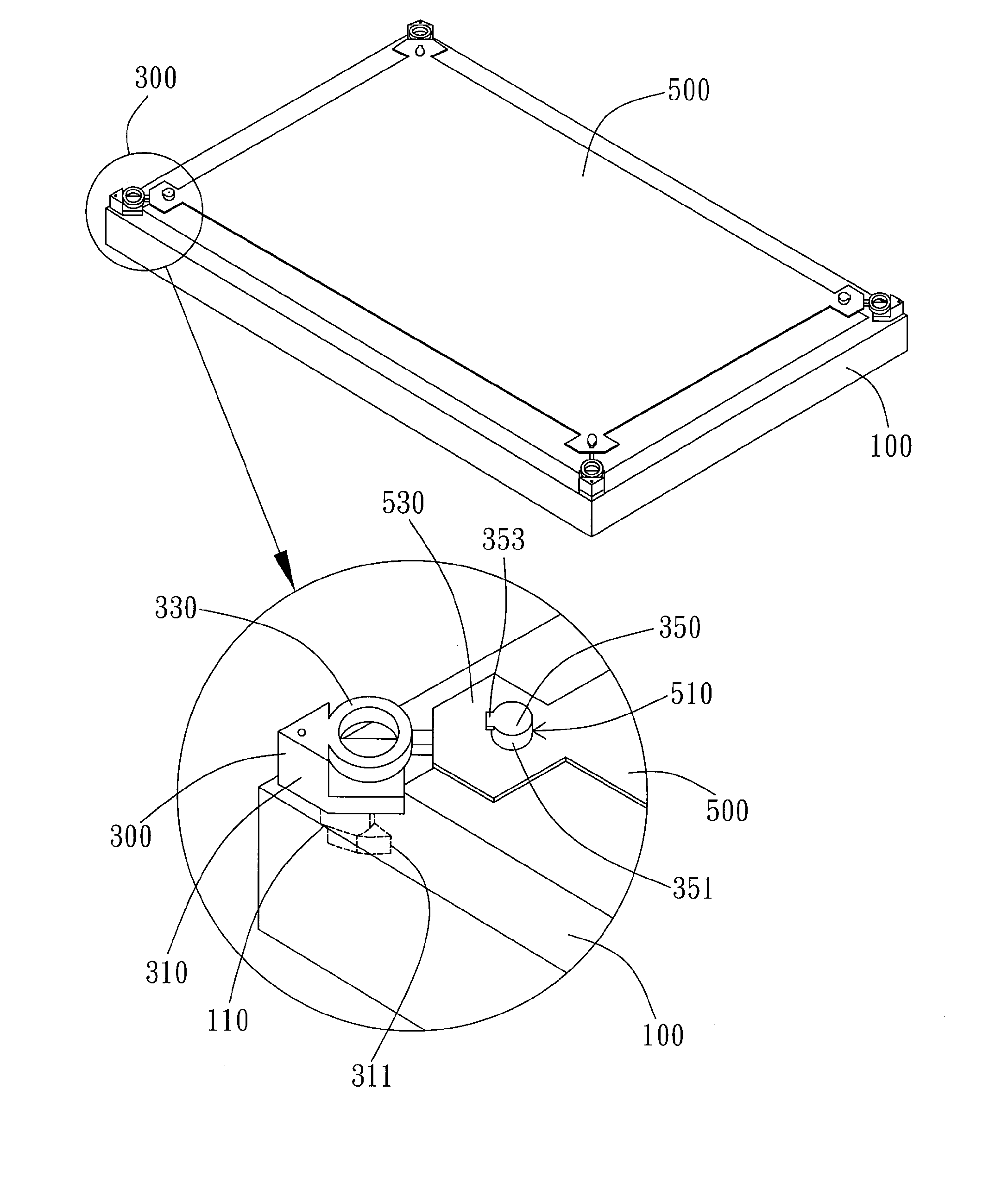

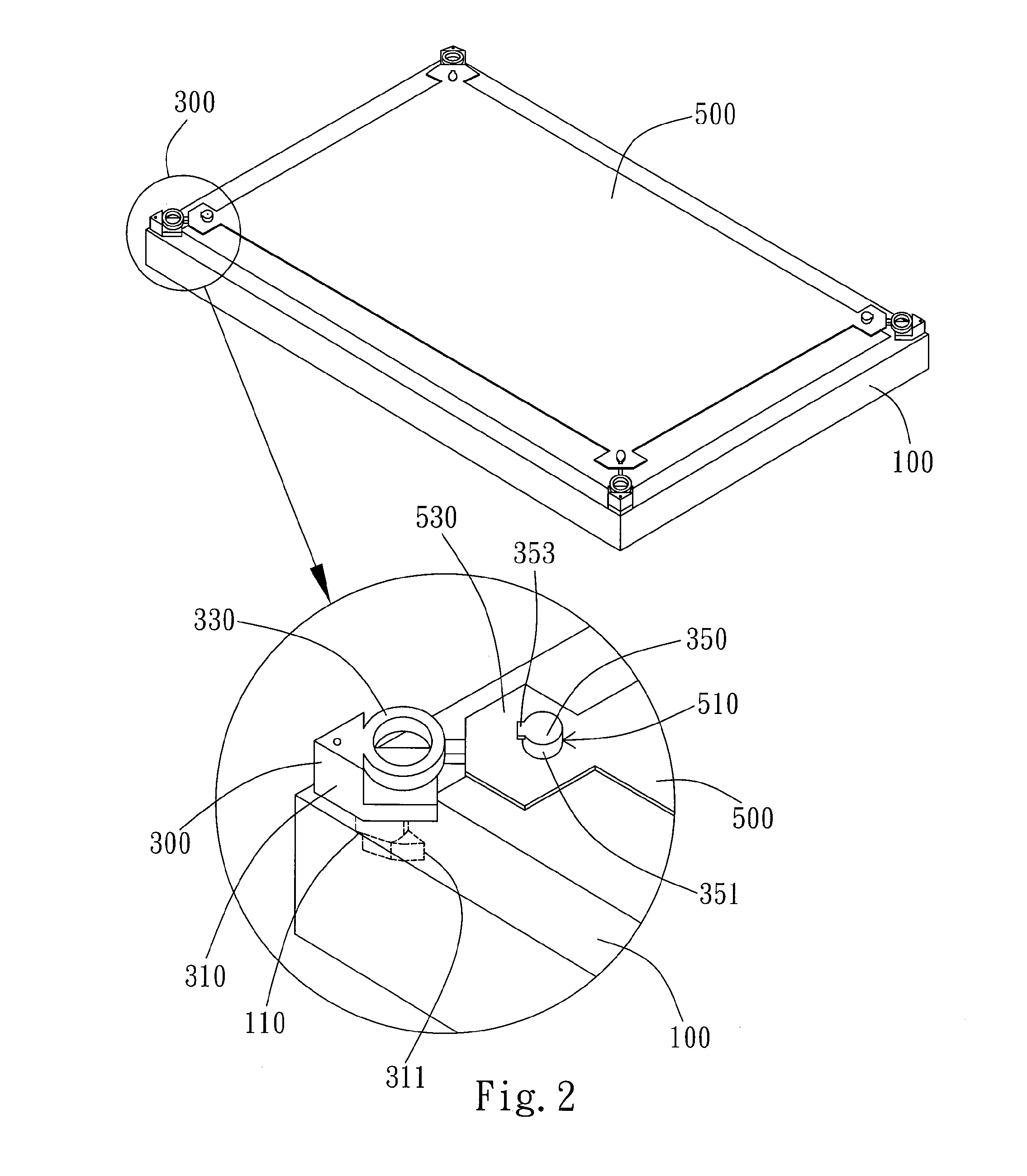

Film-Carrying System and a Film-Carrying Device Used Therein

ActiveUS20080158471A1Reduce the possibilitySufficient supporting forceSnap fastenersCandle holdersLinear displacementAngular displacement

A film-carrying system and a film-carrying device used therein are provided. The film-carrying system includes a support base, a film-carrying device and a film. The film-carrying device includes a support connection part, an elastic part, and a film connection part. The support connection part is coupled to the support base while the film connection part is coupled to the film. The elastic part has a free end and a fixed end; the free end connects to the film connection part, and the fixed end connects to the support connection part. The elastic deformation of the elastic part provides the film connection part with a degree of freedom in linear displacement, and the film connection part also has a degree of freedom in angular displacement corresponding to the support connection part.

Owner:AU OPTRONICS CORP

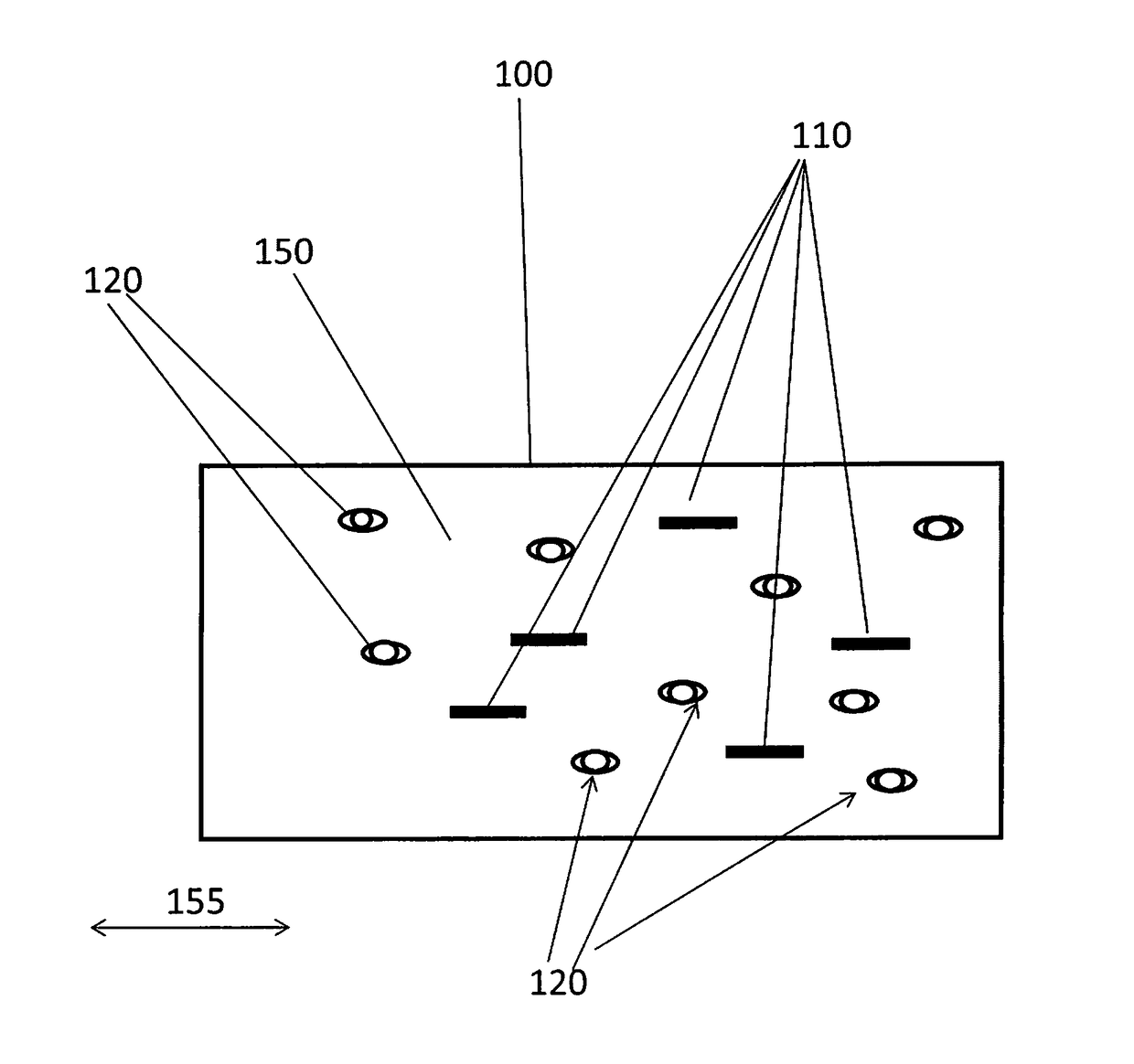

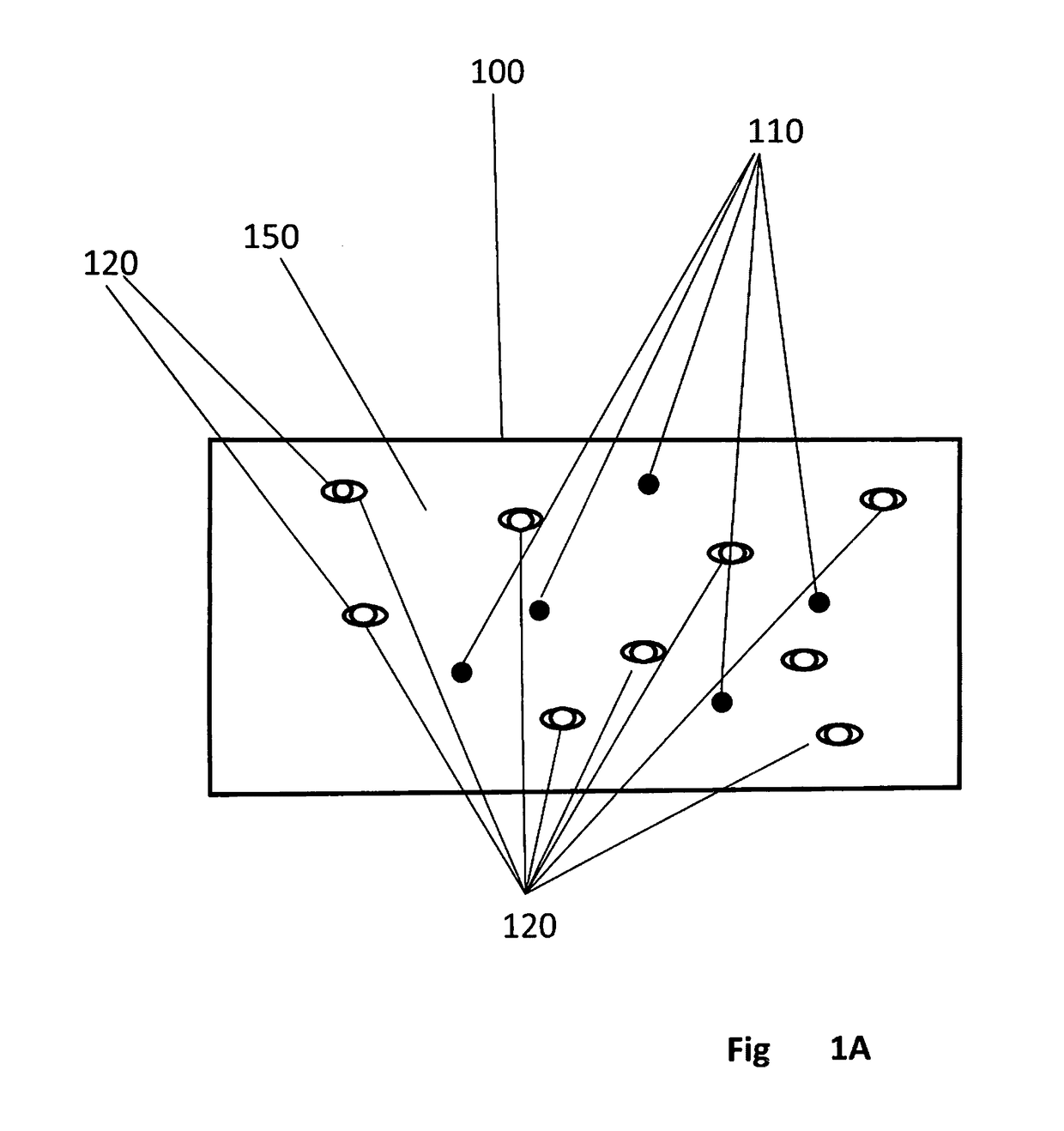

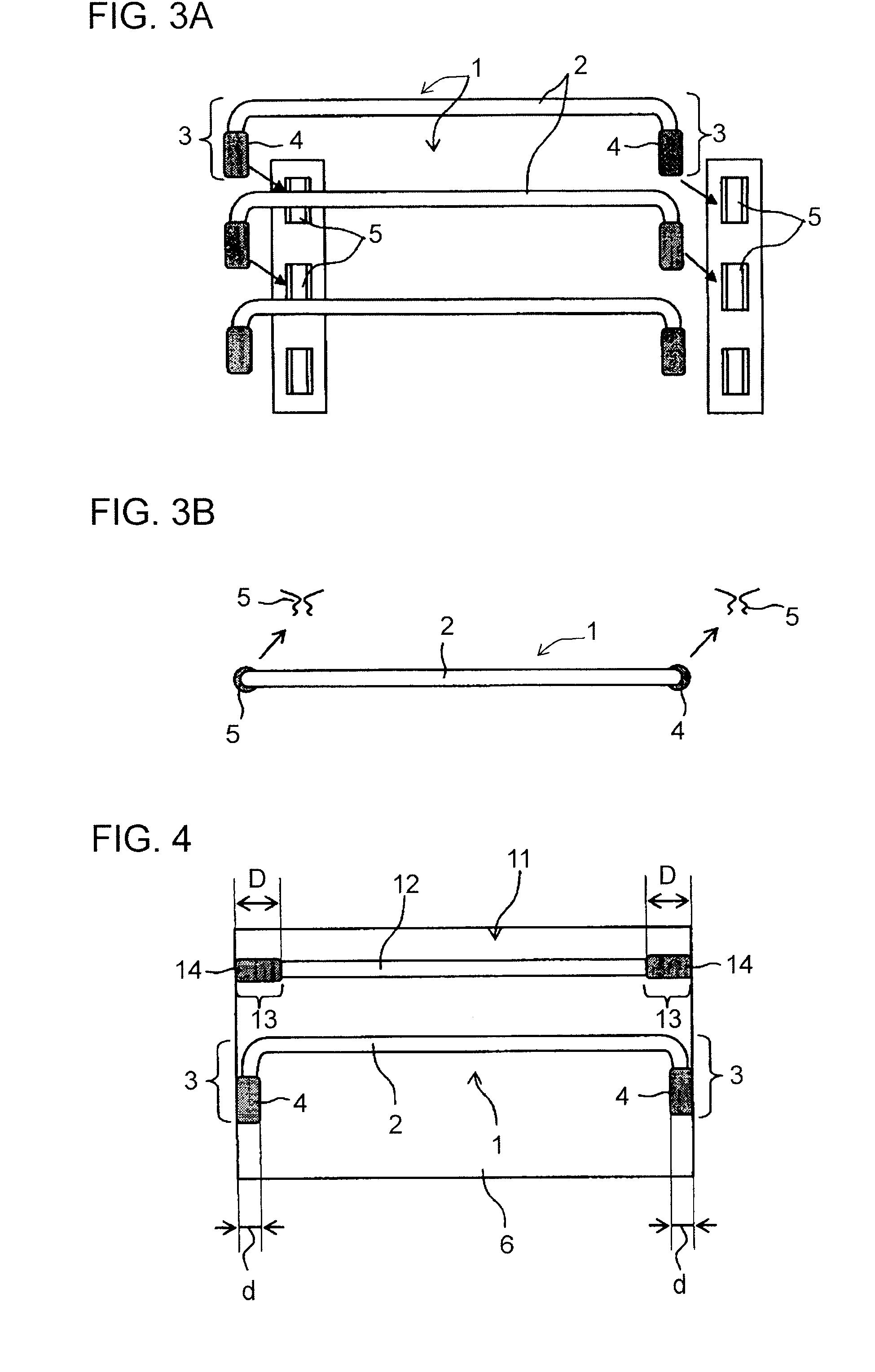

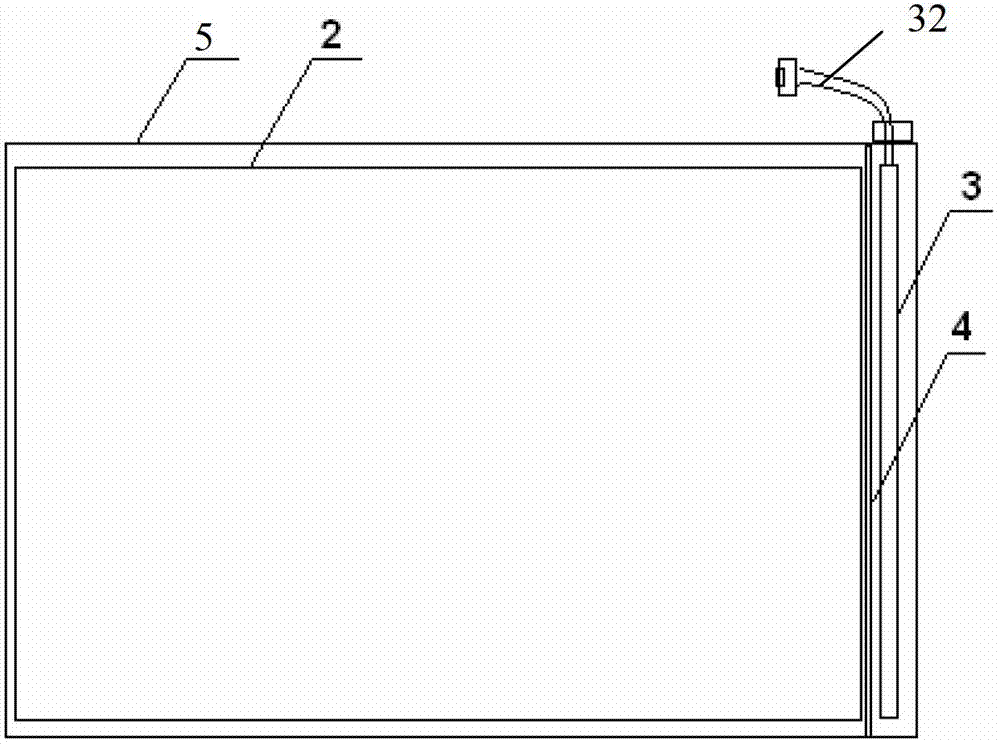

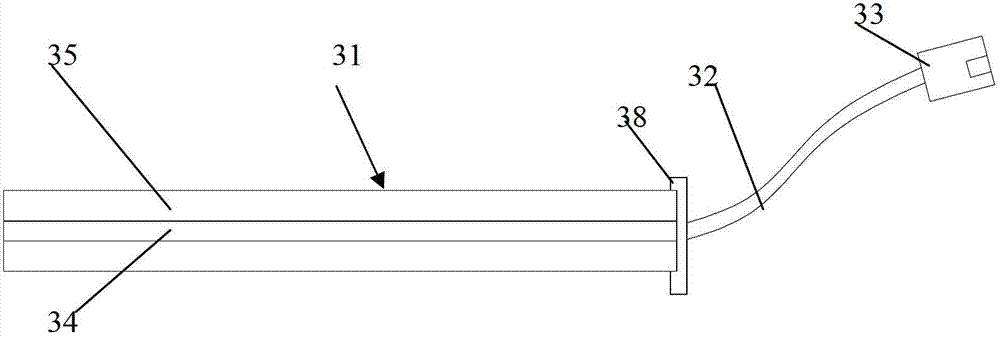

Backlight module and LCD comprising the same

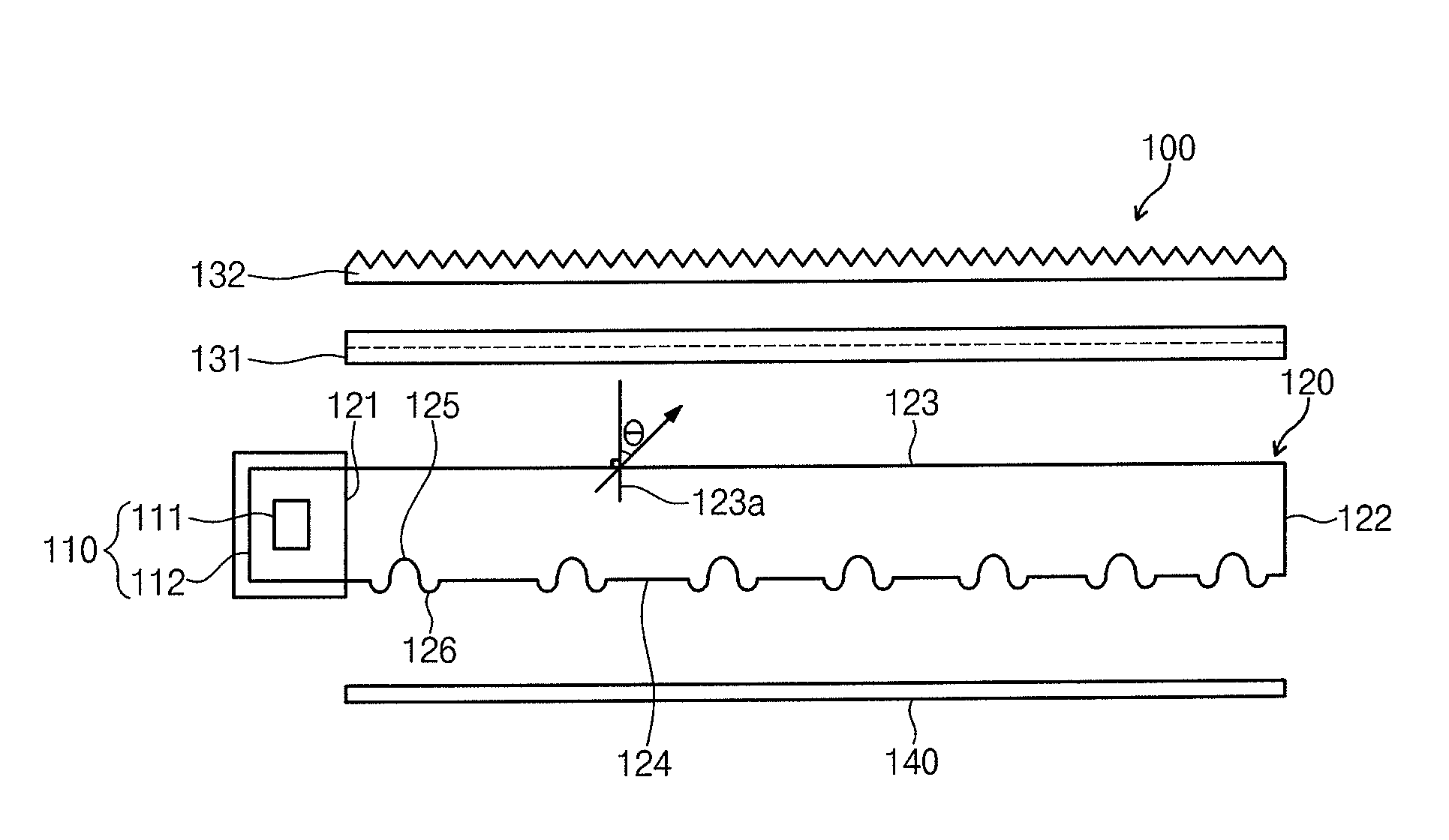

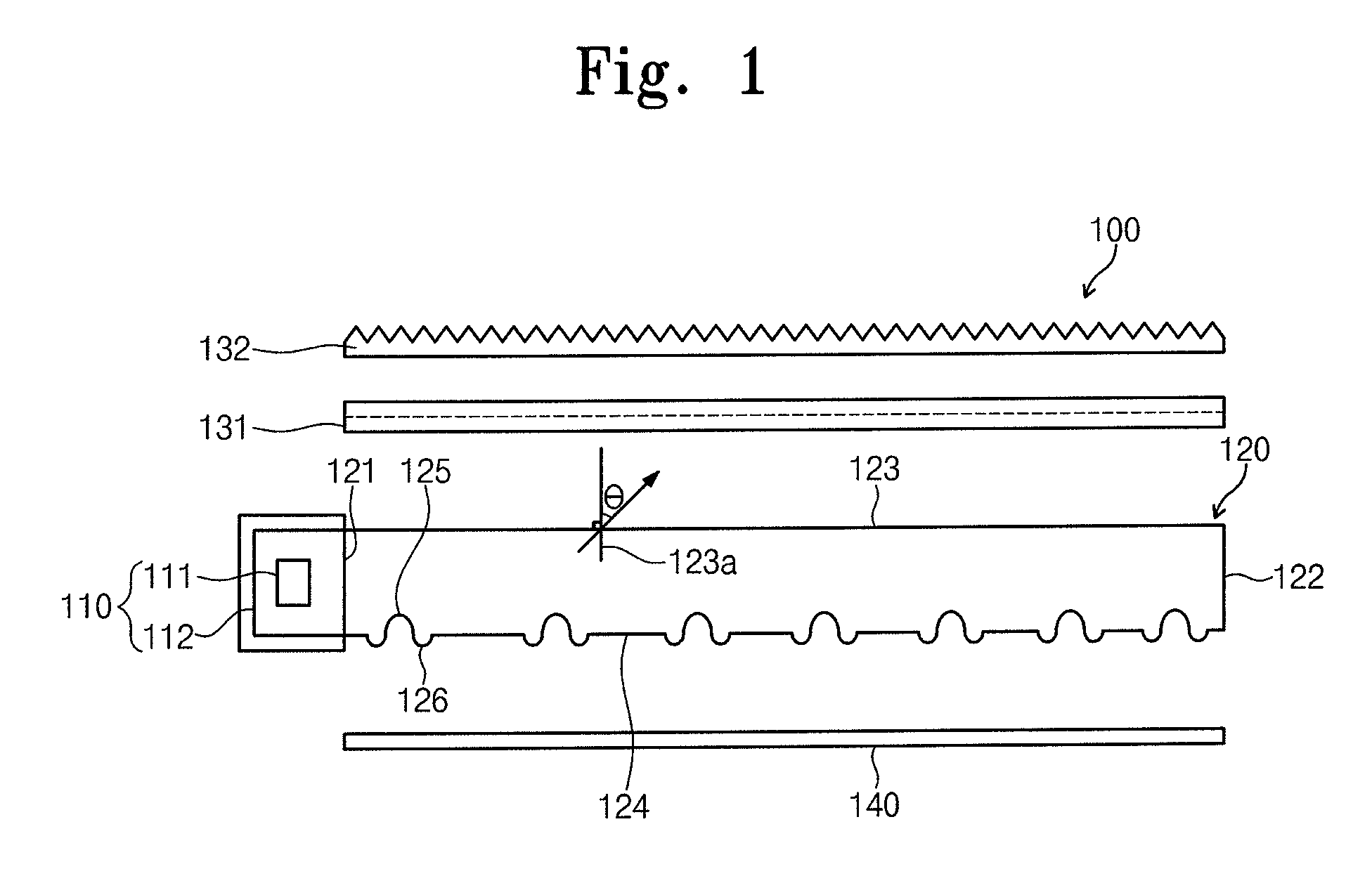

ActiveUS20140036530A1Reduce power consumptionGood effectMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A backlight module comprises a backplate having a baseplate and side plates, a direct-lit LED array, edge-lit LED arrays and a light guide panel. The light guide panel is located above the baseplate. The direct-lit LED array is disposed between the baseplate and the light guide panel. The edge-lit LED arrays are disposed at two sides of the light guide panel and facing light incident surfaces thereof respectively. Light scattering structures for scattering light rays are disposed on a light exiting surface or on a bottom surface of the light guide panels. With the LED arrays and the light scattering structures, the light guide panel is divided into three backlight regions. Displaying of the backlight module is controlled region by region by the light scattering structures and the LED drive circuit to improve the brightness of the backlight module and reduce the power consumption of the liquid crystal module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display device

InactiveCN102768434AWill not affect the environmentLow costPoint-like light sourceLight fasteningsEngineeringLED lamp

The invention discloses a liquid crystal display device, which comprises a liquid crystal display panel, a backlight module and an outer frame, wherein the liquid crystal display panel and the backlight module are accommodated in the outer frame; the backlight module comprises a rubber frame, a light guide plate and a light source which is arranged on a light entering side of the light guide plate; a light-transmitting sealing plate for separating the light guide plate from the light source is fixedly arranged between the light guide plate from the light source; the light source is detachably and fixedly connected with the rubber frame or the outer frame; and the light source is electrically connected with an energy supply device in a pluggable mode. The light guide plate is separated from a light-emitting diode (LED) light bar through the light-transmitting sealing plate with high transmittance, so that the environment of the light guide plate is not influenced by the action of the LED light bar; the fixing mode of the LED light bar is changed into a mode of fixedly fastening the LED light bar in a withdrawing way, and an airtight device is arranged at an outlet of the withdrawing LED light bar. When the normal service life of the LED light bar is reached, the backlight brightness and a normal using effect can be achieved by only replacing the light bar instead of the whole liquid crystal display device, and the user cost is greatly reduced.

Owner:TIANJIN SAMSUNG ELECTRONICS CO LTD +1

Electronic device and method for adjusting backlight brightness

InactiveCN102890915AIncrease backlight brightnessEasy to adjustStatic indicating devicesBrightness perceptionComputer science

Owner:FU TAI HUA IND SHENZHEN +1

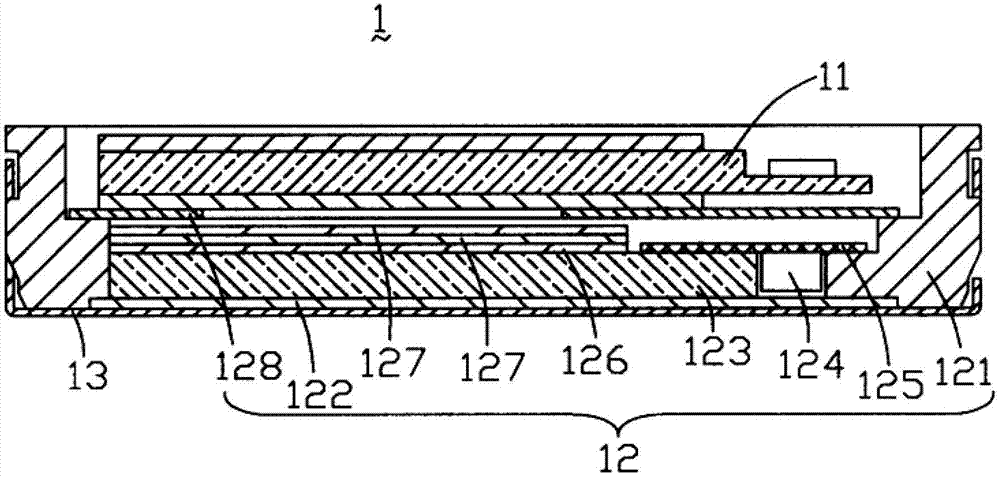

Backlight mould and manufacturing method thereof

InactiveCN102506343AEasy to assembleImprove backlight brightness and optical qualityLight fasteningsFixed installationEngineeringLight guide

The invention provides a backlight mould which comprises an outer frame, a reflector, a circuit board, a backlight source and a light guide plate, wherein the outer frame is provided with a containing space one side of which is provided with an opening, the reflector is arranged in the containing space of the outer frame, and the upper and lower walls of the reflector are respectively fitted on the upper and lower walls of the outer frame; the circuit board is pasted on the lower surface of the upper wall of the reflector, and the backlight source is fixed on the lower surface of the circuit board and is fitted with the lower wall of the reflector; and the light guide plate is fitted on the backlight source and clamped between the circuit board and the lower wall of the reflector. The invention also provides a manufacturing method of the backlight mould; the manufacturing method comprises the following steps: providing the circuit board with the backlight source, pasting the circuit board on the reflector, overturning the circuit board pasting the reflector, and forming buckling; providing the outer frame, providing the containing space one side of which is provided with the opening, pushing the reflector in the containing space of the outer frame; providing the light guide plate to push the reflector to the interior of the outer frame; and adopting the backlight source and the light guide plate which can be closely connected, and promoting backlight brightness and optical quality.

Owner:AU OPTRONICS CORP

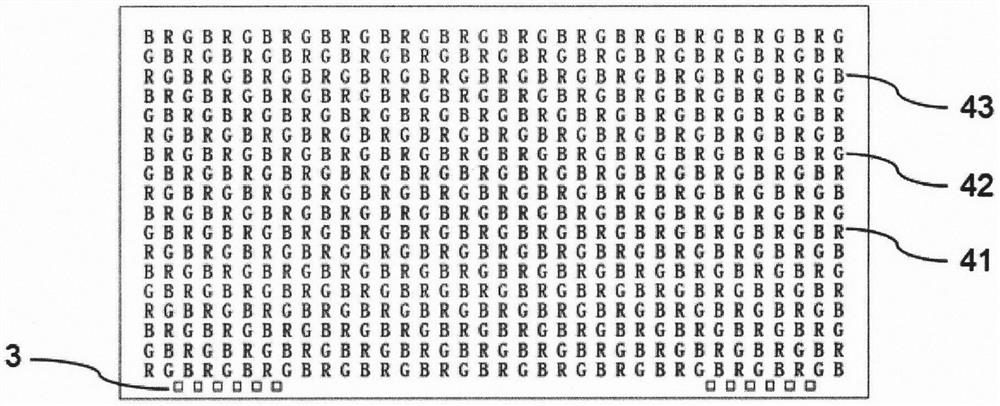

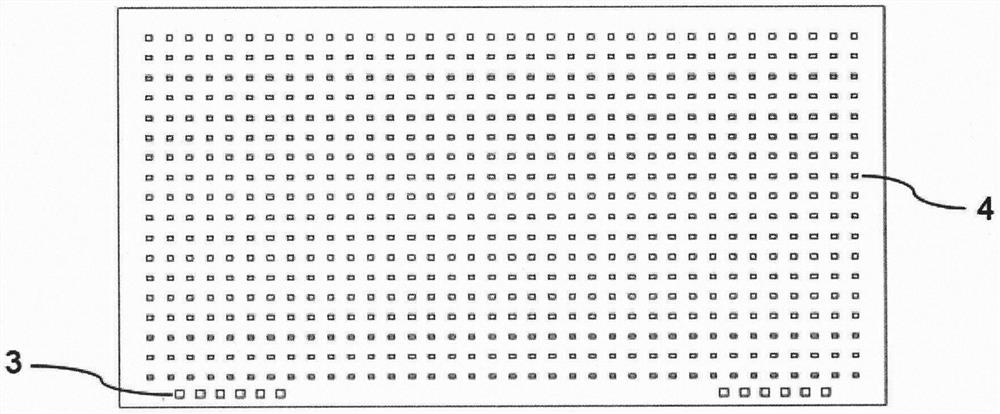

Mini LED backlight module and backlight source

PendingCN112599512AIncrease color gamut rangeIncrease backlight brightnessSolid-state devicesNon-linear opticsHigh contrastHemt circuits

The invention discloses a Mini LED backlight module and a backlight source. The Mini LED backlight module comprises a substrate, a Mini LED light-emitting unit and packaging colloid. ,A solid crystalbonding pad, a metal circuit and a wiring terminal are distributed on the substrate, the metal circuit connects the solid crystal bonding pad to the wiring terminal and is communicated with a drivingcircuit, the light-emitting unit comprises a Mini LED red light chip, a Mini LED green light chip and a Mini LED blue light chip, the three chips are distributed on the substrate in an array interaction mode, each chip can be independently driven through the substrate circuit, and spherical packaging is carried out on the light-emitting unit in a dispensing mode or a printing mode. The red chip, the green chip and the blue chip are adopted as backlight, the color gamut range and brightness of the backlight source can be greatly improved; through interactive distribution and spherical packagingof the three chips, the light color of the backlight can be more uniform after the light rays are mixed, a diffusion plate is not needed, the backlight thickness can be greatly reduced, and partitionlight control can be conducted on the backlight through the independent driving design of the chips, so that the performances of wide color gamut, miniaturization, high brightness and high contrast are realized.

Owner:NANJING UNIV OF TECH

Brightness enhancement film and backlight module

InactiveUS8360619B2Efficient use ofEnhancement effect is goodGlobesIlluminated signsOptical axisOptoelectronics

A brightness enhancement film including a light transmissive substrate, convex lens portions, concave lens portions, and a reflective layer is provided. The light transmissive substrate has a first surface and a second surface opposite to the first surface. The convex lens portions are disposed on the first surface. Each of the convex lens portions has a curved convex surface facing away from the light transmissive substrate. The concave lens portions are disposed on the first surface. The convex lens portions and the concave lens portions are alternately arranged. Each of the concave lens portions has a curved concave surface facing away from the light transmissive substrate. A wavy continuous curve surface is formed by the curved convex surfaces and the curved concave surfaces. The reflective layer is disposed on the second surface and has light passing openings respectively on the optical axes of the convex lens portions.

Owner:CORETRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com