A kind of LED backlight driving method, LED backlight driving circuit and liquid crystal display device

A technology for a backlight driving circuit and a liquid crystal display device, which is applied to lighting devices, electroluminescent light sources, light sources, etc., can solve problems such as loss, backlight brightness decline, and decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

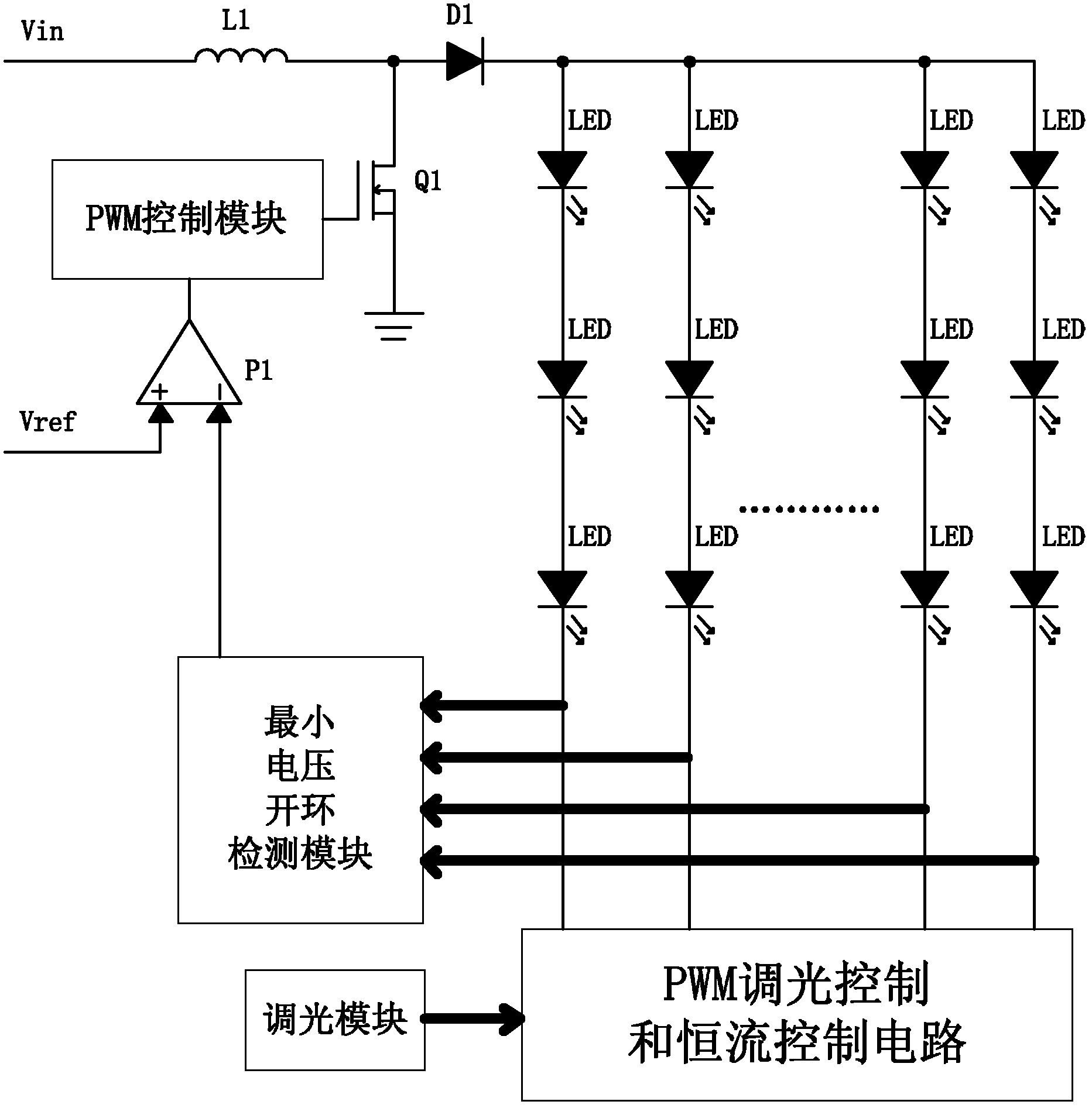

[0030] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

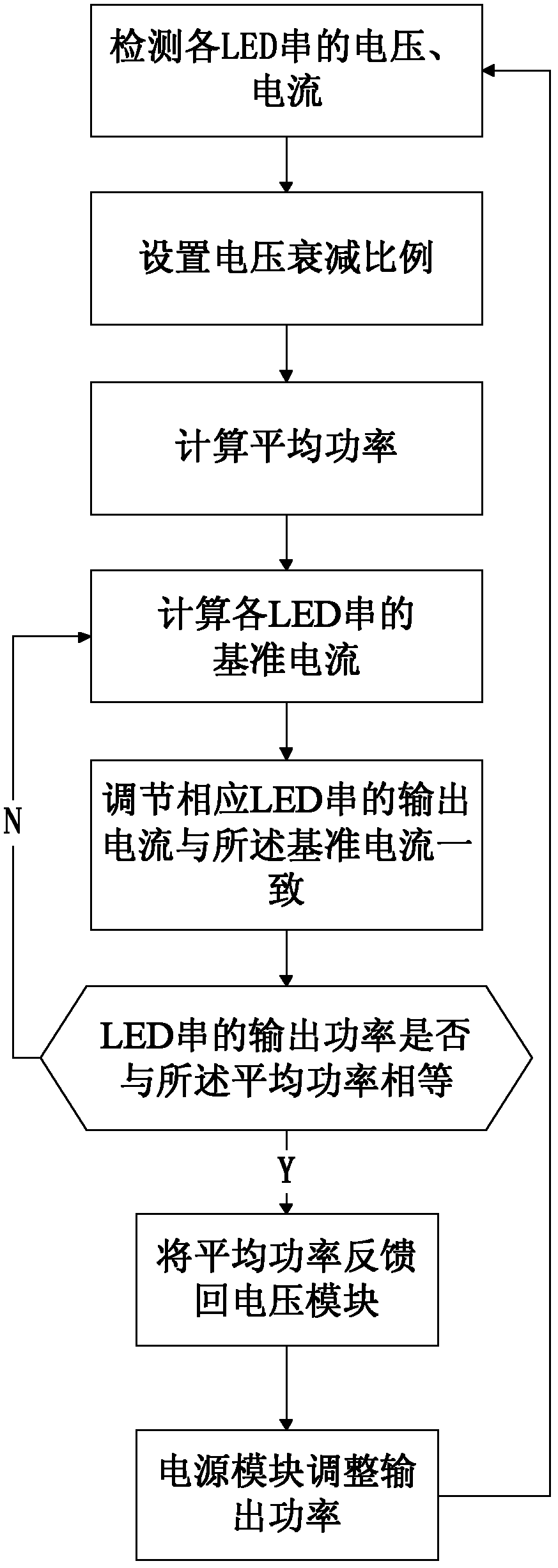

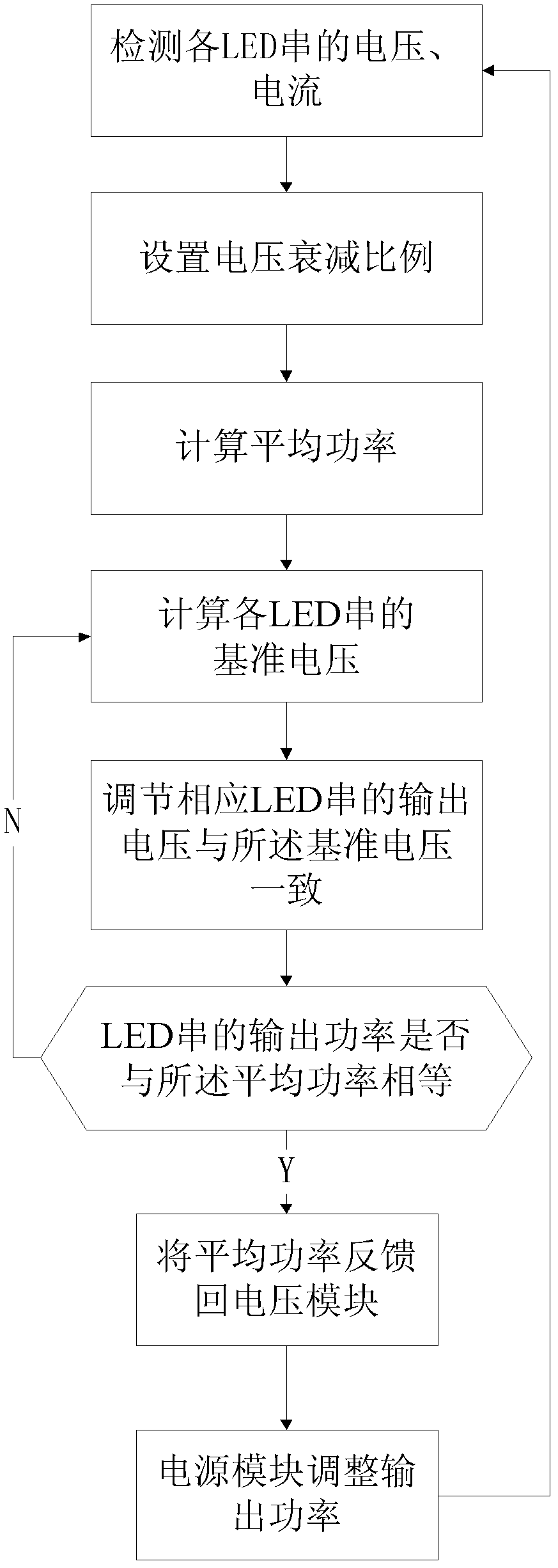

[0031] The inventive principle of the LED backlight driving method of the present invention is: by simultaneously detecting the cross-voltage and current of the Lightbar, setting the voltage attenuation ratio, and feeding back the product of the voltage Vf and the current If of the LED string, that is, Vf*If, if Vf is small , If will be large, and if If is large, Vf will also become large, and finally it will be compromised, so that the smaller Vf will move closer to the larger Vf; vice versa, the larger Vf will move closer to the smaller Vf. Finally, the voltage across the LED is very close. This can reduce the voltage applied to the current balance caused by the difference in the cross-voltage Vf.

[0032] When the temperature rises, the brightness of the backlight will decrease, and the Vf of the LED will decrease, and the If will increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com