Mini LED backlight module and backlight source

A backlight module and backlight technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem that the color gamut range cannot meet the application requirements of high-end scenes, the ultra-thin index cannot be truly achieved, and the overall brightness of the backlight cannot be achieved. To solve high-level problems, achieve the effect of improving the uniformity of light mixing and the viewing angle of light, satisfying mass industrial production, and improving the brightness of backlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

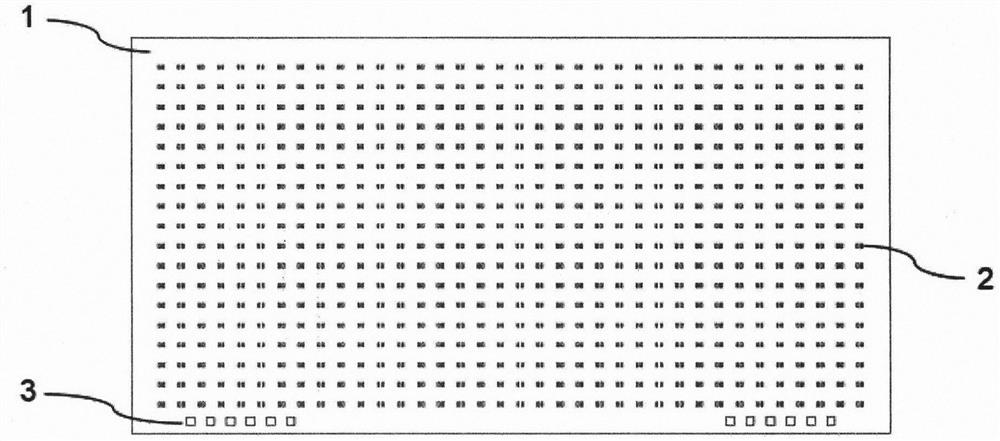

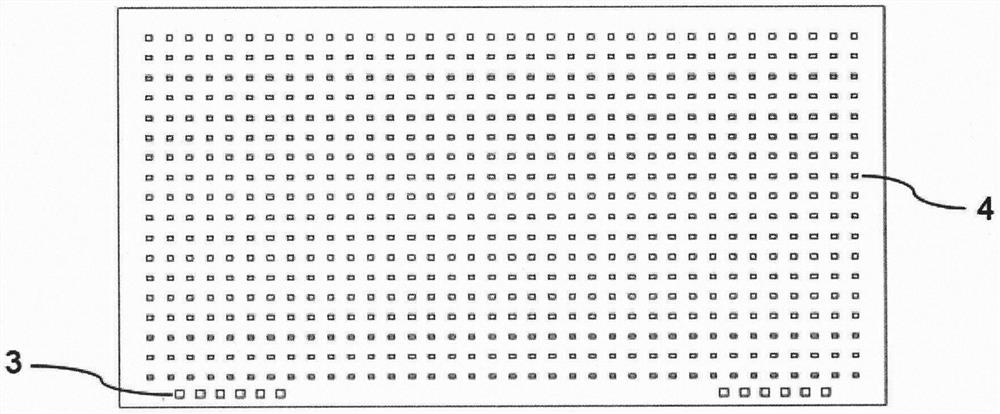

[0031] The Mini LED backlight device described in this embodiment is mainly composed of a substrate 1, a Mini LED chip 4, and an encapsulant 5. The substrate is used to carry the Mini LED chip and circuit design, such as figure 1 As shown, the substrate is provided with die-bonding pads 2 for placing LED chips. Every two groups of die-bonding pads are arranged in an array, and are respectively used to place the positive and negative poles of the same chip. Each group of adjacent pads is in the The spacing between rows or columns is ≤1.5mm. At the same time, the substrate is provided with a connection terminal 3 connected to the bonding pad. The two are connected through the metal line on the substrate. The connection terminal can individually control each bonding pad through an external drive. , the areas on the substrate except the pads and terminals are coated with white reflective material.

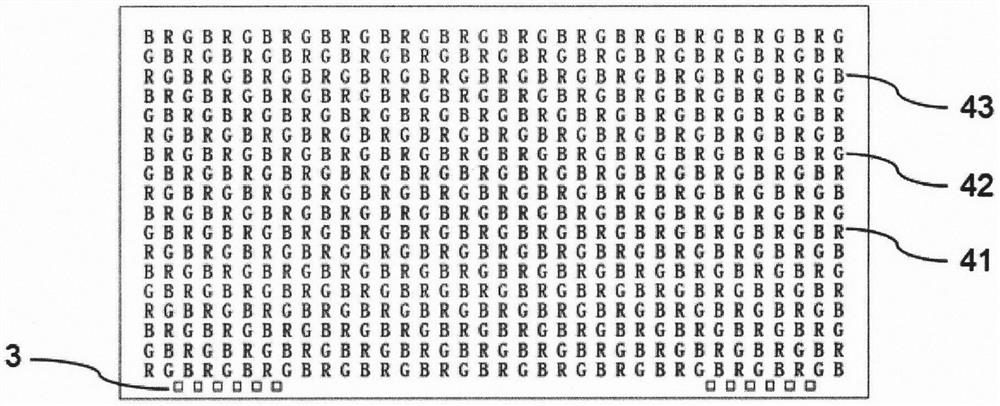

[0032] Mini LED chip 4 is divided into Mini LED red light chip 41, Mini LED green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com