Backlight module and LCD comprising the same

a backlight module and liquid crystal display technology, applied in the field of backlight modules and liquid crystal display (lcd), can solve the problems of invariable power consumption of conventional liquid crystal modules using backlight during operation, inability to adjust the brightness of backlight, so as to reduce the power consumption of liquid crystal modules and improve the effect of adjusting the backlight region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]It shall be understood that, the embodiments described herein are only intended to illustrate but not to limit the present disclosure.

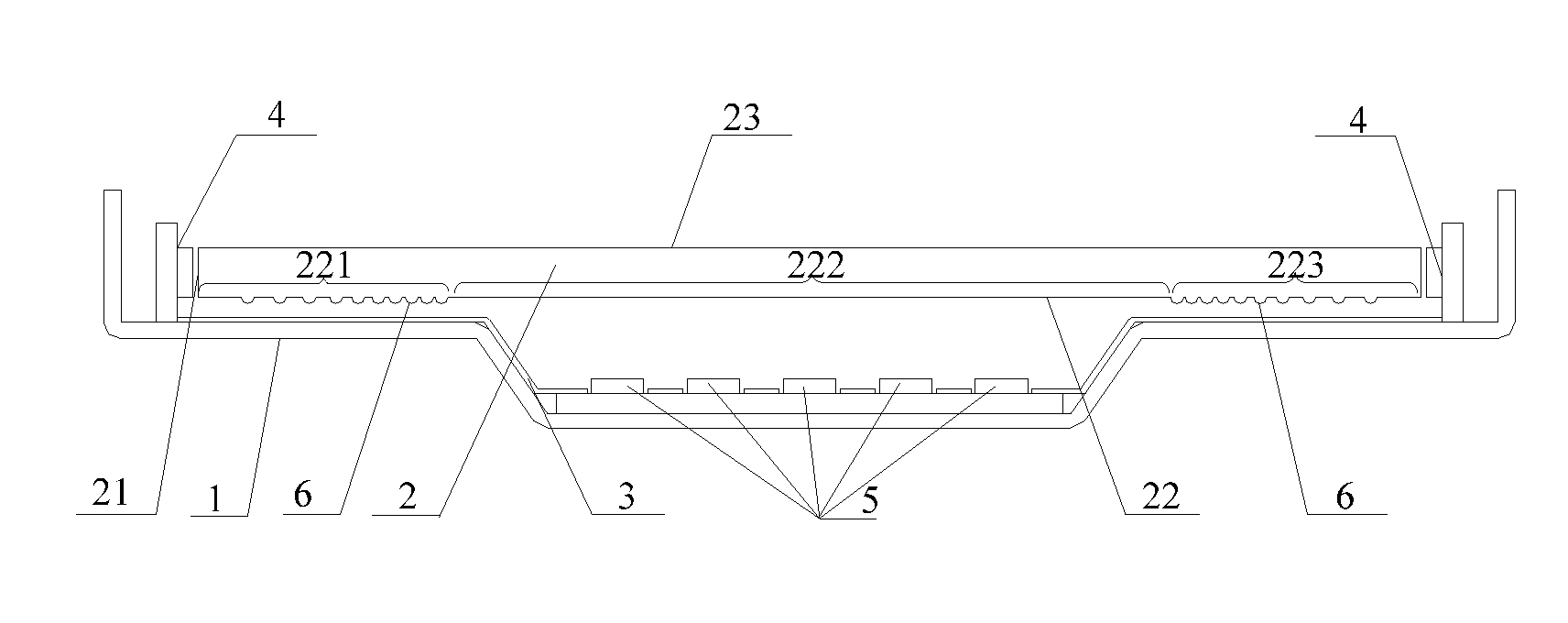

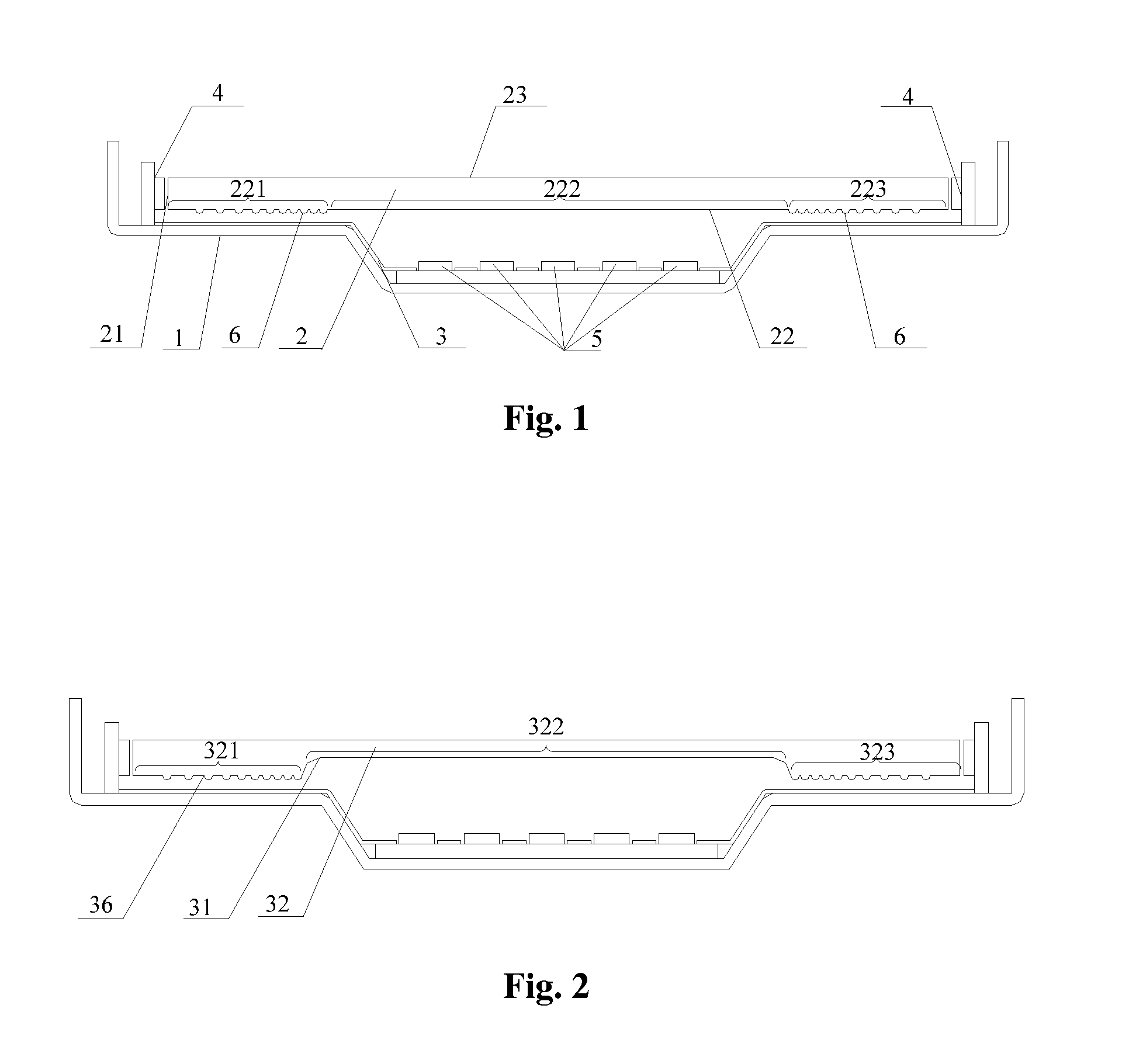

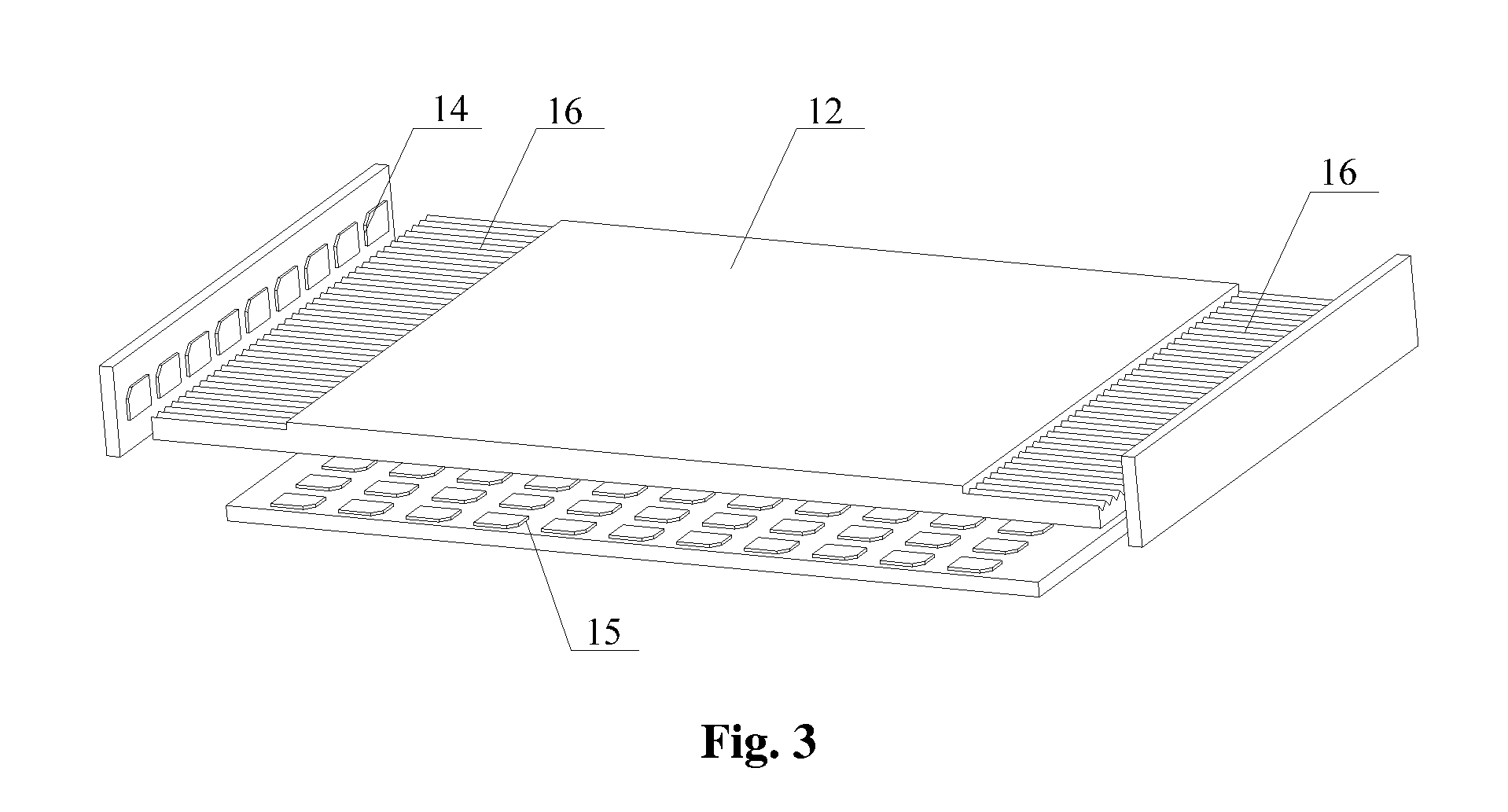

[0028]Embodiments of the present disclosure mainly adopt the following solution: the direct-lit design and the edge-lit design are used in combination in the backlight module, and a number of light scattering structures for scattering light rays are disposed on a light exiting surface or a bottom surface of the light guide panel at both ends of the light guide panel to divide the light guide panel into three 10 backlight regions. Regions illuminated by the backlight from the edge-lit LED arrays are controlled by the light scattering structures on the light guide panel while a region illuminated by the backlight from the direct-lit LED array is controlled by the LED drive circuit. In this way, the effect of adjusting the brightness of the backlight of the backlight module region by region is improved and the power consumption of the liquid crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com