Infrared focal plane non-uniformity fingerprint extraction and image correction method

An infrared focal plane and non-uniformity technology, applied in the field of infrared imaging, can solve the problems of inconvenient hardware implementation, cumbersome calibration process, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

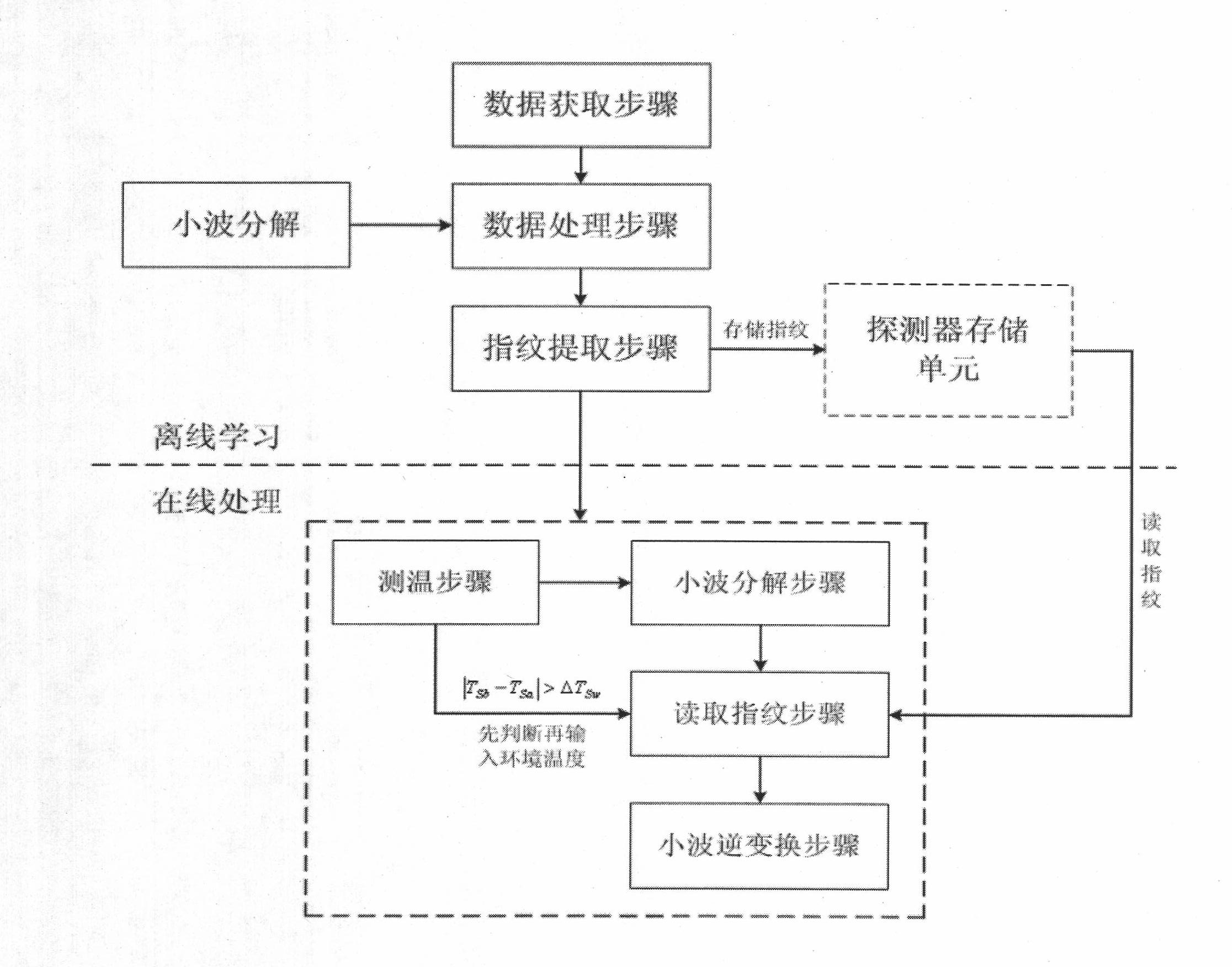

[0078] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the actual specification of the infrared focal plane array used is R×C=288×384.

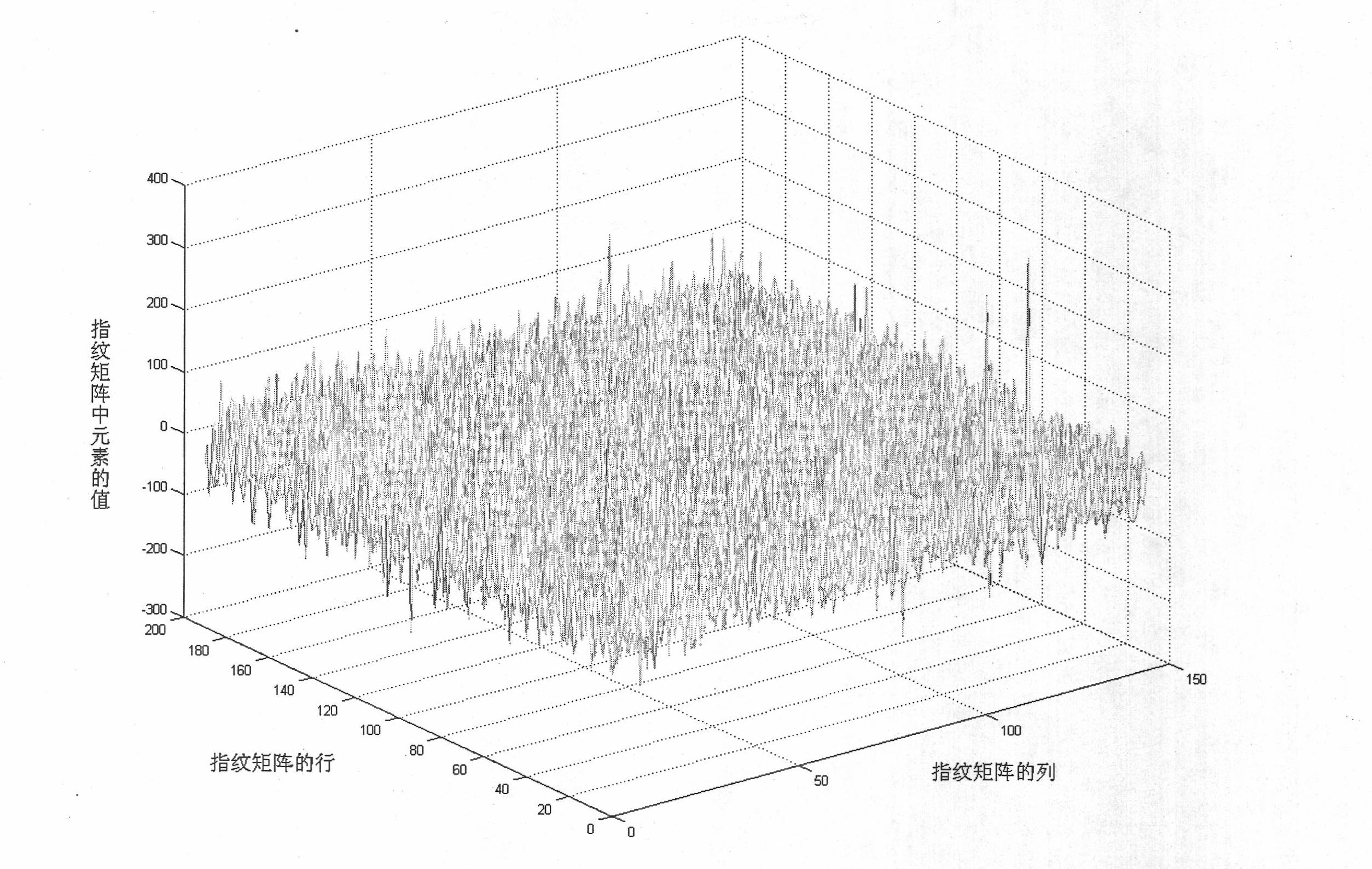

[0079] (1) Fingerprint extraction and storage step: Utilize described infrared focal plane nonuniformity fingerprint extraction method to extract the nonuniformity fingerprint of detector infrared focal plane,

[0080] (1.1) The data acquisition step of described non-uniformity fingerprint extraction method:

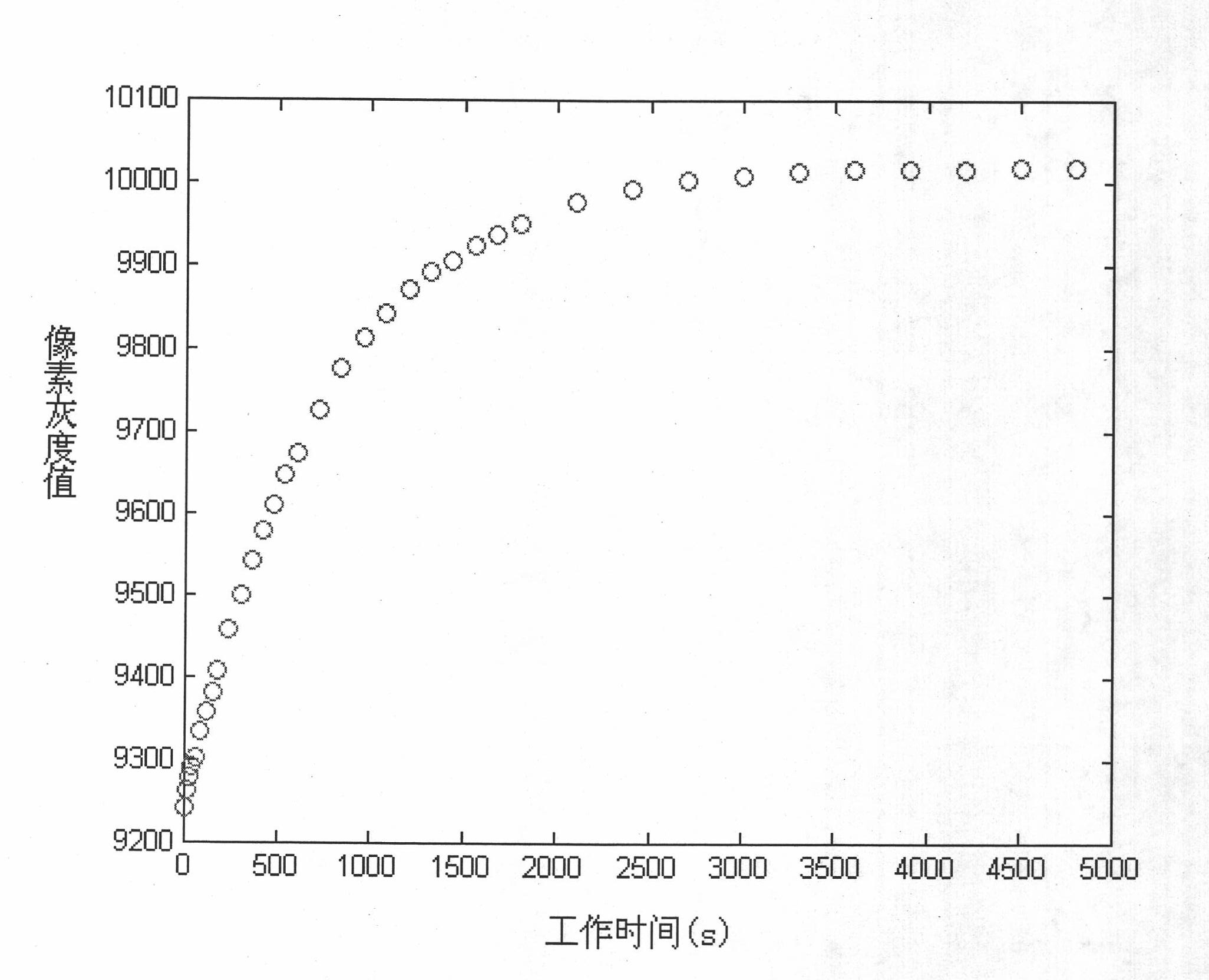

[0081] First let the surface source blackbody temperature T b constant at 40 degrees;

[0082] Secondly, make the focal plane work at an ambient temperature of T SL = In the incubator at -40°C, a total of FrmNumber = 36 frames of black body images were collected from the start of the detector until the work was stable for a period of time;

[0083] Then let the ambient temperature increase by ΔT S = 10 degrees, so that the focal plane works at ΔT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com