Pupil shaping unit structure of lithography machine and design method for diffraction optical element of pupil shaping unit structure

A diffractive optical element and shaping unit technology, applied in the field of lithography machine, can solve the problems of light field collapse, affecting the non-uniformity of the illumination pupil, and unable to apply the illumination system of the deep ultraviolet lithography machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereto.

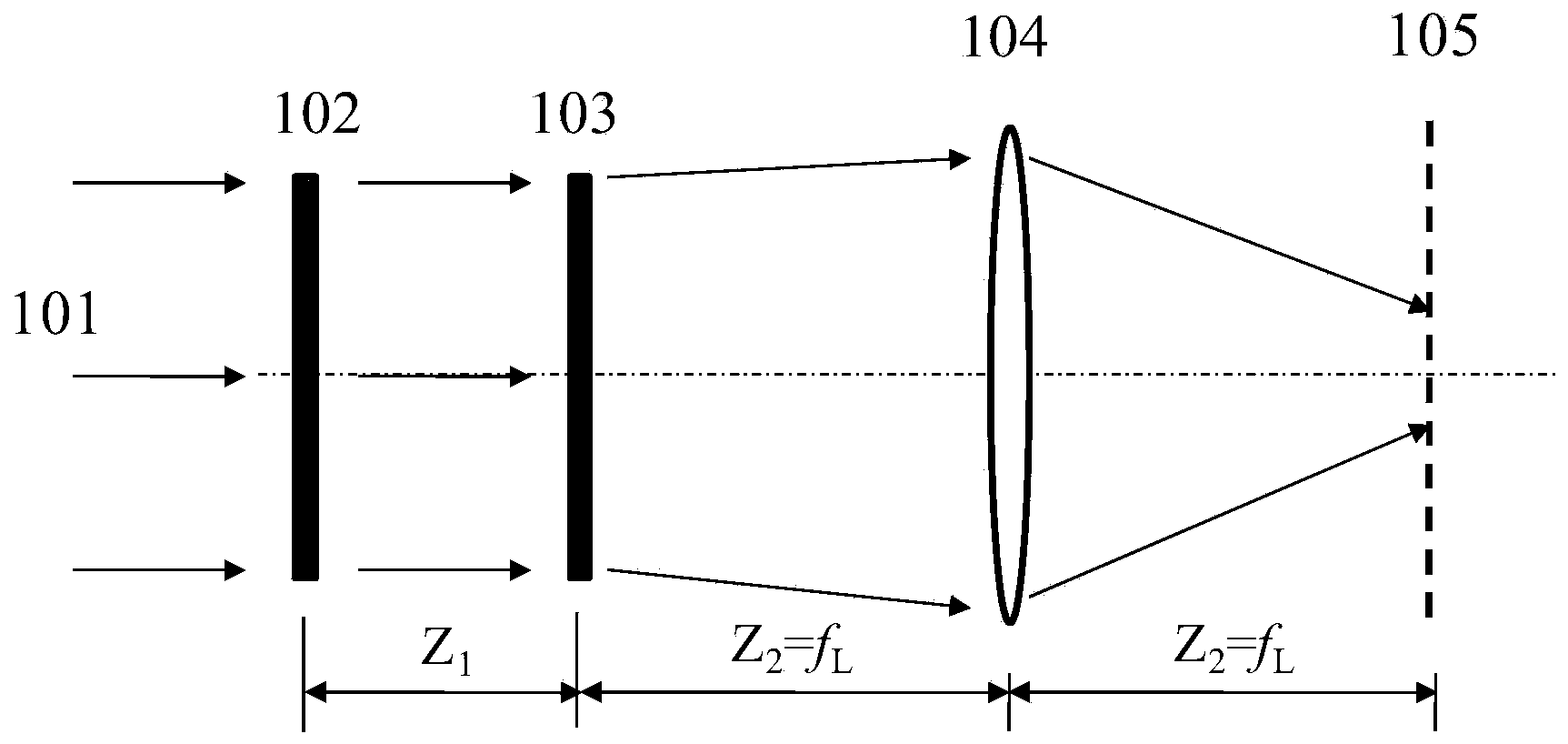

[0057] see first figure 1 , figure 1 It is a schematic diagram of the optical path structure of the pupil shaping unit of the lithography machine of the present invention, which is used to generate the required pupil surface light intensity distribution in the ultraviolet lithography machine. Depend on figure 1 It can be seen that the pupil shaping unit includes a first diffractive optical element 102 , a second diffractive optical element 103 , and a zoom collimator lens group 104 . After the incident light beam 101 passes through the first diffractive optical element 102 and the second diffractive optical element 103 whose light-passing surface is set to be perpendicular to the optical axis of the illumination system, it is irradiated on the zoom collimating lens group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com