Blank holders for stamping tools for body linings of motor vehicles

A technology for stamping tools and car bodies, applied in the field of stamping of sheet metal parts, can solve the problems of variable thickness, wrinkles and cracks, and achieve the effect of reducing size and achieving simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

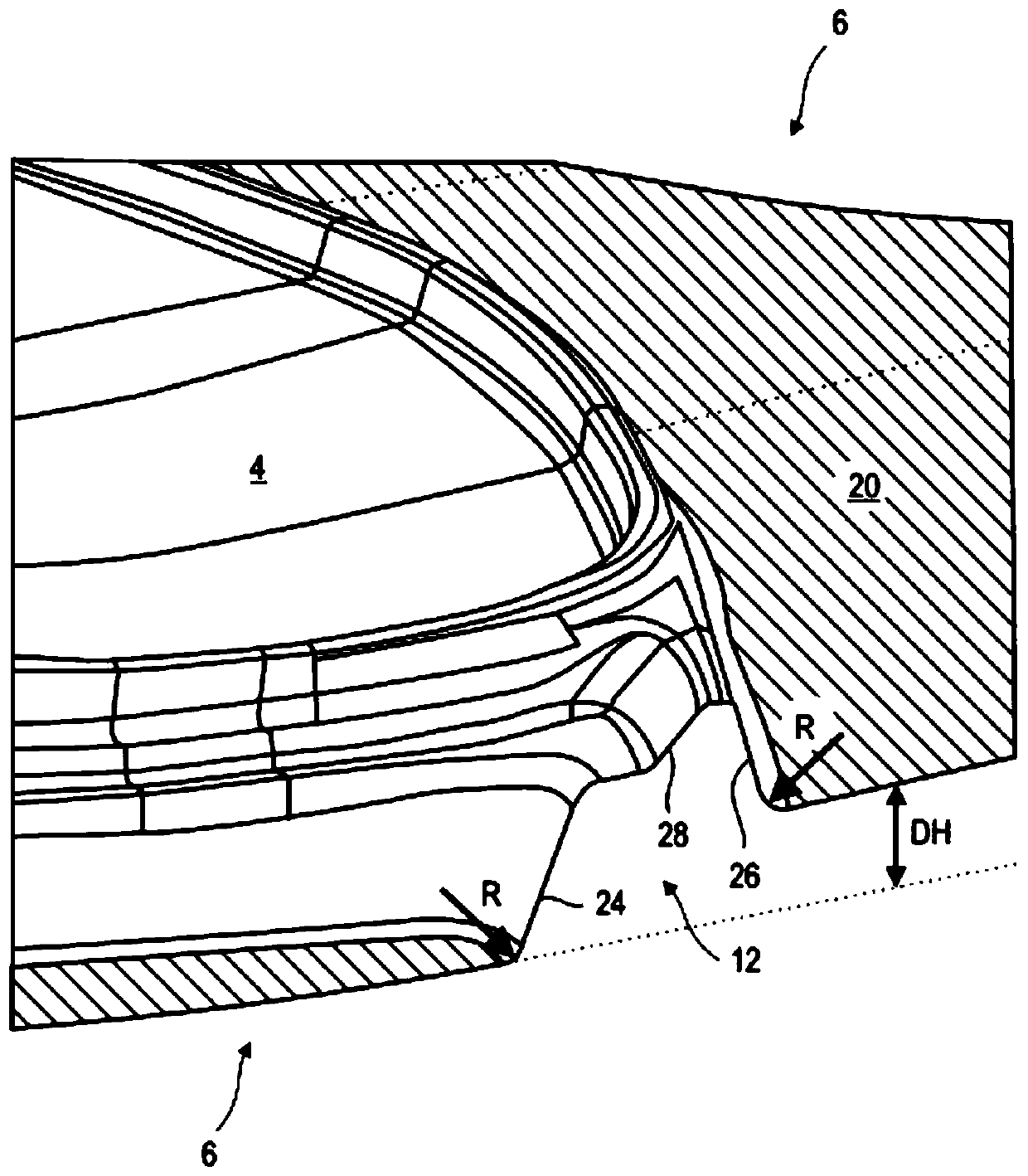

[0038] In the present invention, the direction of punching corresponds to the direction of opening and closing of the punching tool allowing sheet metal working operations. The horizontal direction is perpendicular to the direction of punching.

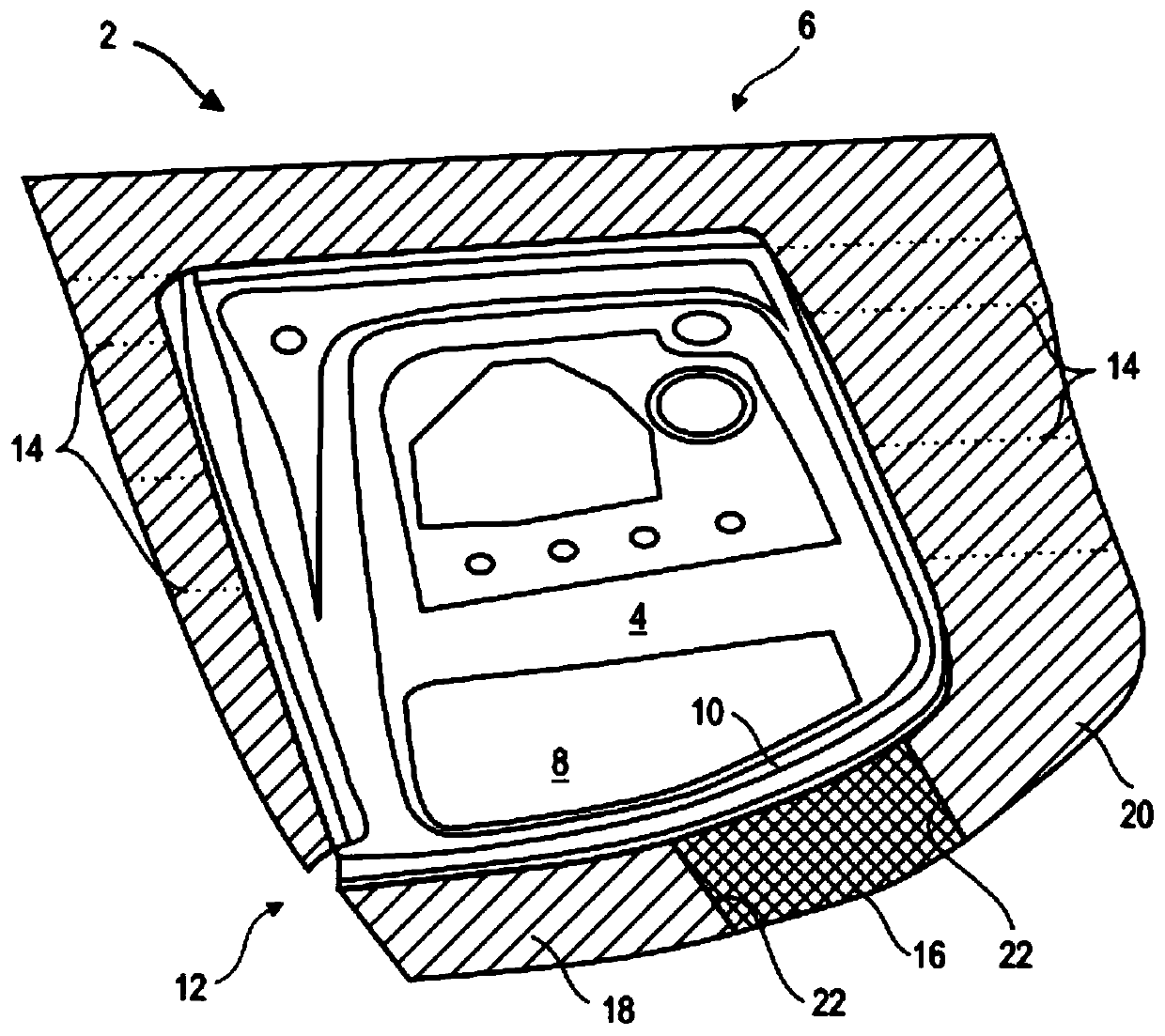

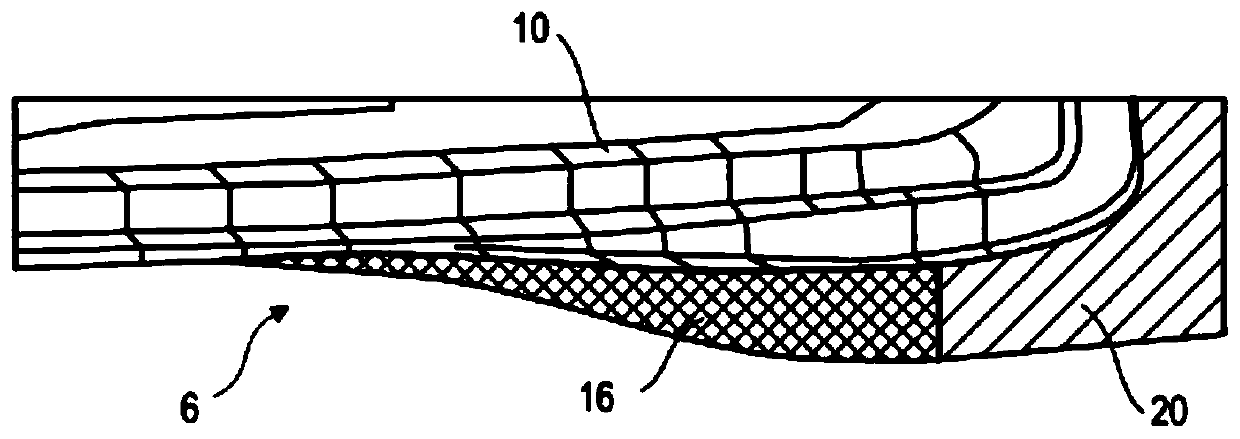

[0039] figure 1 is an isometric view of a stamping tool 2. figure 1 The binder ring and the punch 4 surrounded by the binder ring are shown. The punch is shown by its fastening surface 6 . Tool 2 also includes a female die, not shown for reasons of clarity. The female die is known to have a cavity into which the male die 4 is inserted to form a sheet metal blank (not shown). The punch 4 (shown by its working surface) is complementary to the cavity, their surfaces abutting. The die and / or punch 4 and / or the blankholder are rigid, possibly metallic.

[0040] The punch 4 generally has a quadrangular, trapezoidal shape. It allows to realize the lining of the left rear door of a motor vehicle. This opening forms a belly-shaped wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com