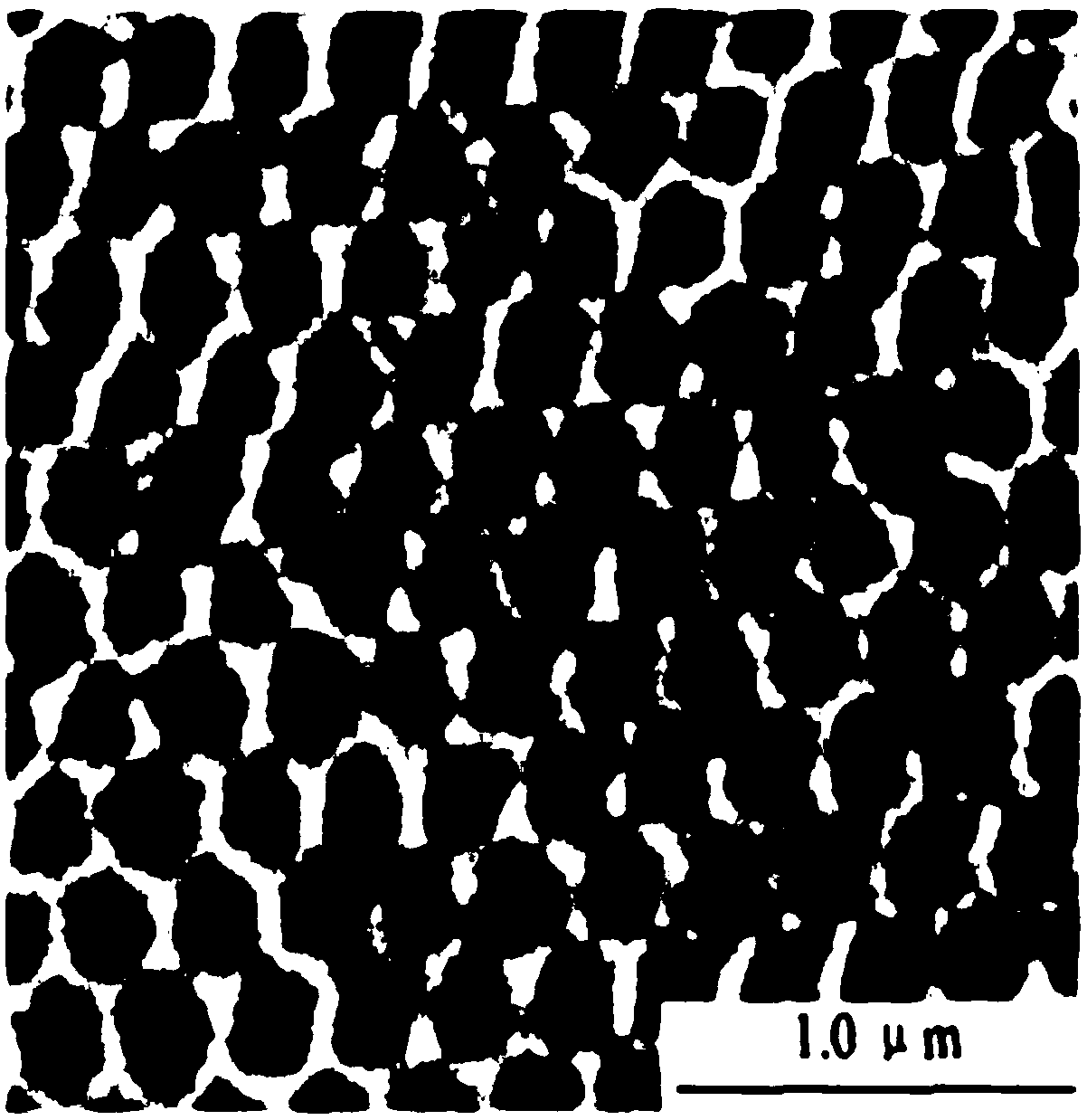

CMP polishing layer based on porous cerium oxide and preparation method thereof

A technology of cerium oxide and polishing layer, which is applied in the field of CMP polishing layer based on porous cerium oxide and its preparation, can solve the problems of inability to form hollow small holes, easy damage of polymer microspheres, wide range of size distribution, etc., and achieve improvement Grinding and polishing efficiency, good machinability, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Place the mold in an oven to preheat to 50°C, place 5000g of polyurethane prepolymer in a vacuum oven and preheat to 50°C in a vacuum state, then add 70g of porous cerium oxide filler to the polyurethane prepolymer, at 20r Stir and mix at a speed of 1 / min to obtain a mixed prepolymer.

[0032]Transfer the above mixed prepolymer to the first tank, and carry out heat preservation, stirring, and circulation treatment. The temperature inside the first tank is 50°C, and the stirring speed is 20r / min; at the same time, the mixed prepolymer is in the first tank Circulate in the pipeline between the injection machine head and the temperature in the circulation pipeline is the same as the temperature inside the first tank.

[0033] Add MOCA to the second tank and perform melting treatment at a temperature of 60°C. After the MOCA in the second tank is completely melted, start the cycle from the second tank to the pouring head, and the second tank and The piping between the depos...

Embodiment 2

[0036] Place the mold in an oven to preheat to 150°C, place 5000g of polyurethane prepolymer in a vacuum oven and preheat to 50°C under vacuum, then add 220g of porous cerium oxide filler to the polyurethane prepolymer, and heat it at 120r Stir and mix at a speed of 1 / min to obtain a mixed prepolymer.

[0037] Transfer the above mixed prepolymer to the first tank, and carry out heat preservation, stirring, and circulation treatment. The temperature inside the first tank is 150°C, and the stirring speed is 120r / min; at the same time, the mixed prepolymer is in the first tank Circulate in the pipeline between the injection machine head and the temperature in the circulation pipeline is the same as the temperature inside the first tank.

[0038] Add DMTDA into the second tank and carry out melting treatment at a temperature of 150°C. After the DMTDA in the second tank is completely melted, start the cycle from the second tank to the pouring head, and the second tank and The pipi...

Embodiment 3

[0041] Place the mold in an oven to preheat to 200°C, place 5000g of polyurethane prepolymer in a vacuum oven and preheat to 50°C under vacuum, then add 300g of porous cerium oxide filler to the polyurethane prepolymer, and heat it at 300r Stir and mix at a speed of 1 / min to obtain a mixed prepolymer.

[0042] Transfer the above mixed prepolymer to the first tank, and carry out heat preservation, stirring, and circulation treatment. The temperature inside the first tank is 200°C, and the stirring speed is 150r / min; at the same time, the mixed prepolymer is in the first tank Circulate in the pipeline between the injection machine head and the temperature in the circulation pipeline is the same as the temperature inside the first tank.

[0043] Add the cross-linking agent into the second tank and carry out melting treatment at a temperature of 200°C. After the cross-linking agent in the second tank is completely melted, start the cycle from the second tank to the pouring head, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com