Embankment reinforcing system for liquefiable site reinforced gravel pile composite foundation and reinforcing method

A technology for composite foundations and liquefaction sites, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as the lack of liquefiable sand foundations, achieve improved stability and anti-liquefaction ability, strong anti-liquefaction ability, and overall good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

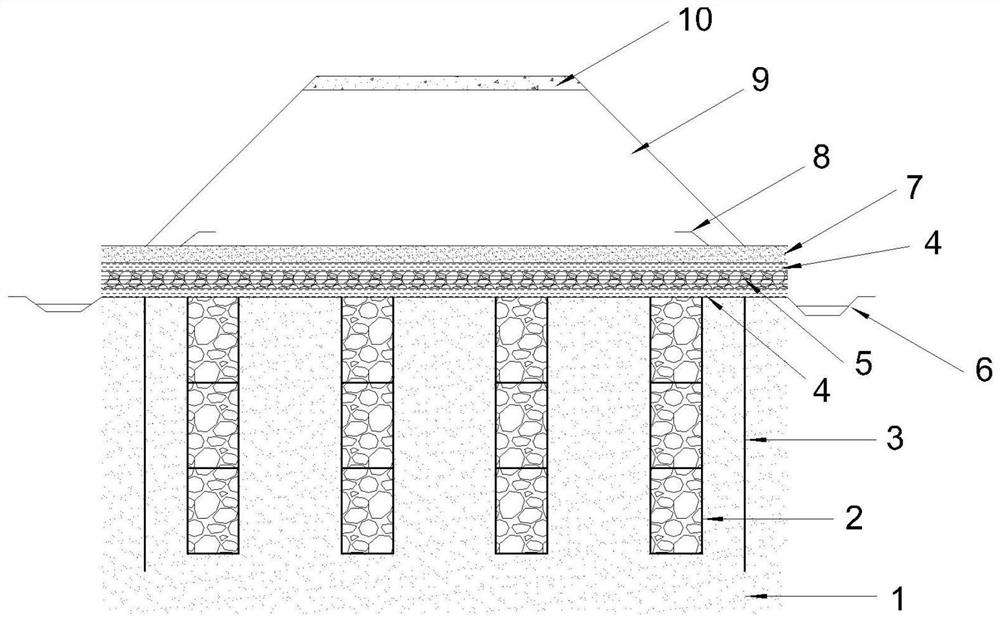

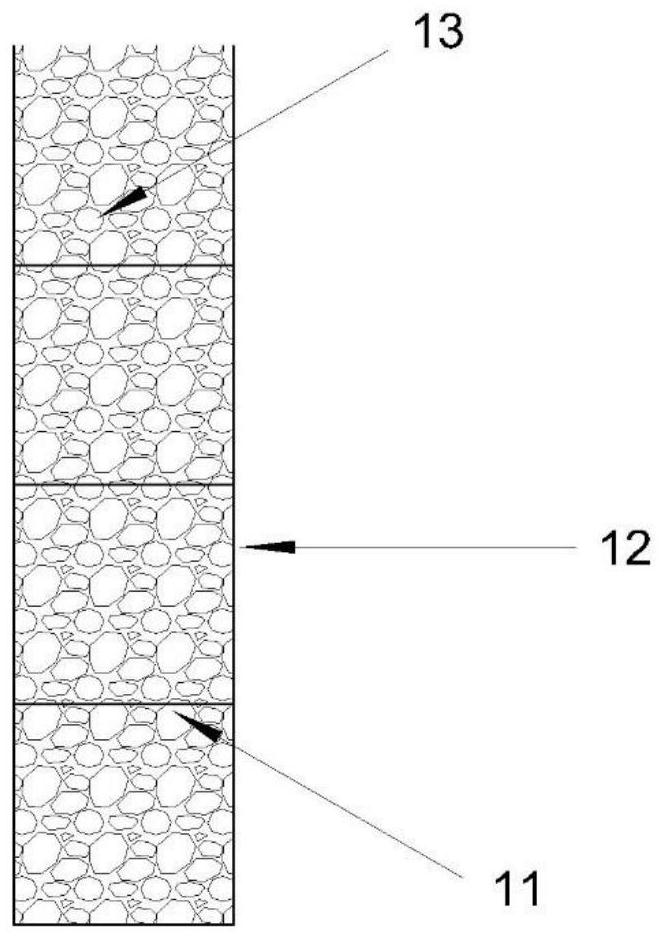

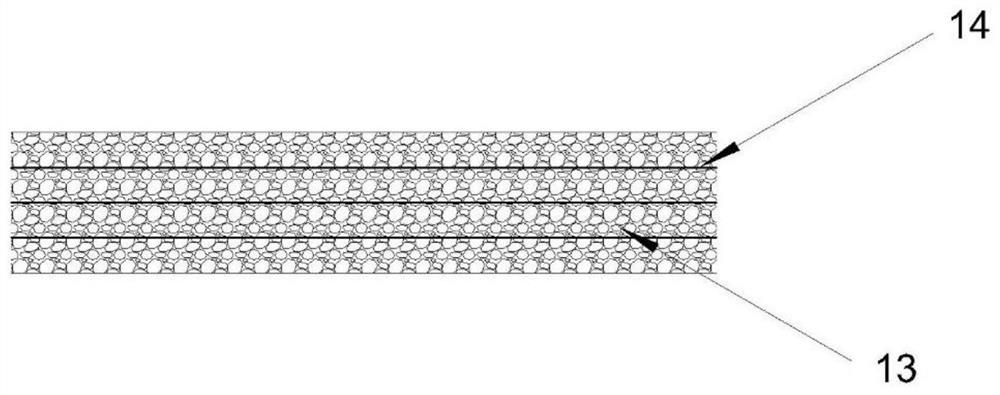

[0051] Such as Figure 1 ~ 4 As shown, a liquefied field plus damper pile composite ground base path embankment reinforcement system, including two-way plug-in gravel pile 2, plate pile wall 3, geotextile pad layer 4, geogr grid plus crush pad layer 5, Drainage 6, sand mat 7, embankment filling layer 9 and asphalt concrete surface layer 10. Among them, the two-way plug-in gravel pile 2, the geotextile pad layer 4, the geogr grid plus crushed pad layer 5, the geotextile pad layer 4, the sand pad layer 7 and the embankment filling layer 9 are sequentially arranged from below; The two-dimensional plug-gravel pile 2 is arranged on both sides of the plate pile wall 3. On both sides of the reinforced crumb pad, the drainage groove 6 is arranged, and a liquefied ventricular reinforcement system is formed.

[0052] The diameter of the two-way plug-gravel pile 2 is 0.8m, the length is 5m, the pile spacing is 4m and is a square distribution; the U-shaped steel plate pile 15 used by the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com