In-hole treatment method for shield tunnel in liquefiable stratum

A technology of shield tunnel and treatment method, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of tunnel collapse, reduced restraint effect, endangering the safety of structures, etc., to shorten the construction period and improve the liquefaction resistance. , The effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

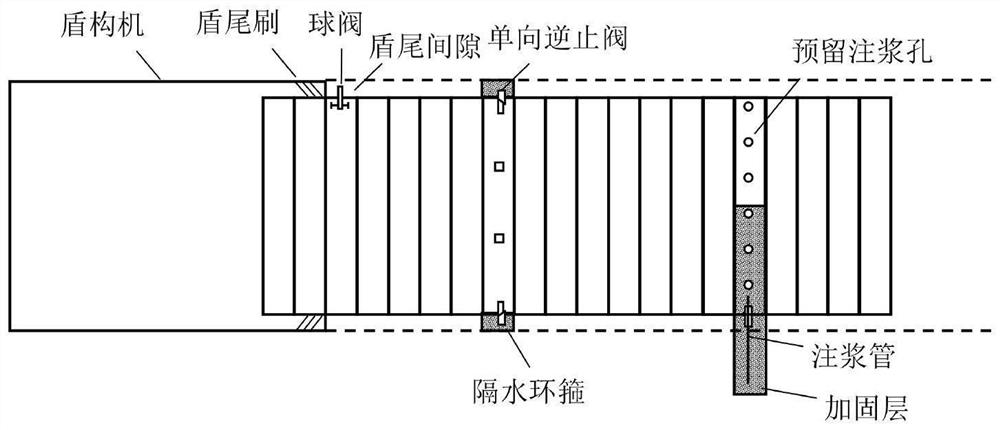

[0034] Specific implementation mode 1: This implementation mode records a treatment method in a liquefiable stratum shield tunnel, and the method is specifically:

[0035] Step 1: Synchronous grouting to replace pore water;

[0036] Step 2: Secondary grouting to cut off pore water;

[0037] Step 3: Anti-liquefaction treatment in the cave.

specific Embodiment approach 2

[0038] Embodiment 2: In the method for treating the inside of a liquefiable stratum shield tunnel described in Embodiment 1, in step 1, the specific operation of synchronous grouting to replace pore water is as follows:

[0039] The groundwater in the liquefiable formation is rich and has a large permeability coefficient. When the shield tail gap is formed, the precipitated pore water fills up rapidly, which makes grouting difficult, and the grout is diluted by pore water after entering the formation, and the performance of the grout is greatly affected, so grouting cannot be guaranteed fill effect.

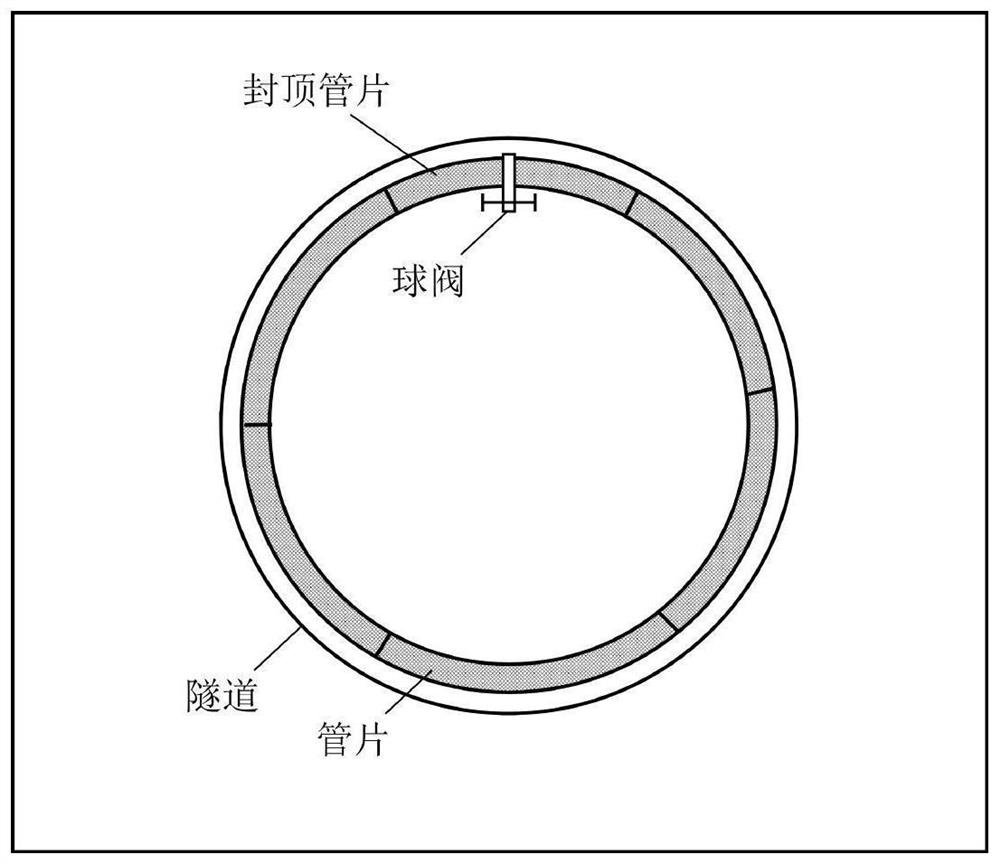

[0040] Before the start of excavation of each ring shield, ball valves are installed in the reserved grouting holes of the capping block segment at the top of the third last ring of the shield tail (that is, the first ring out of the shield tail), and the reserved grouting holes are opened through steel brazing or electric drills , close the ball valve in time, and when the excav...

specific Embodiment approach 3

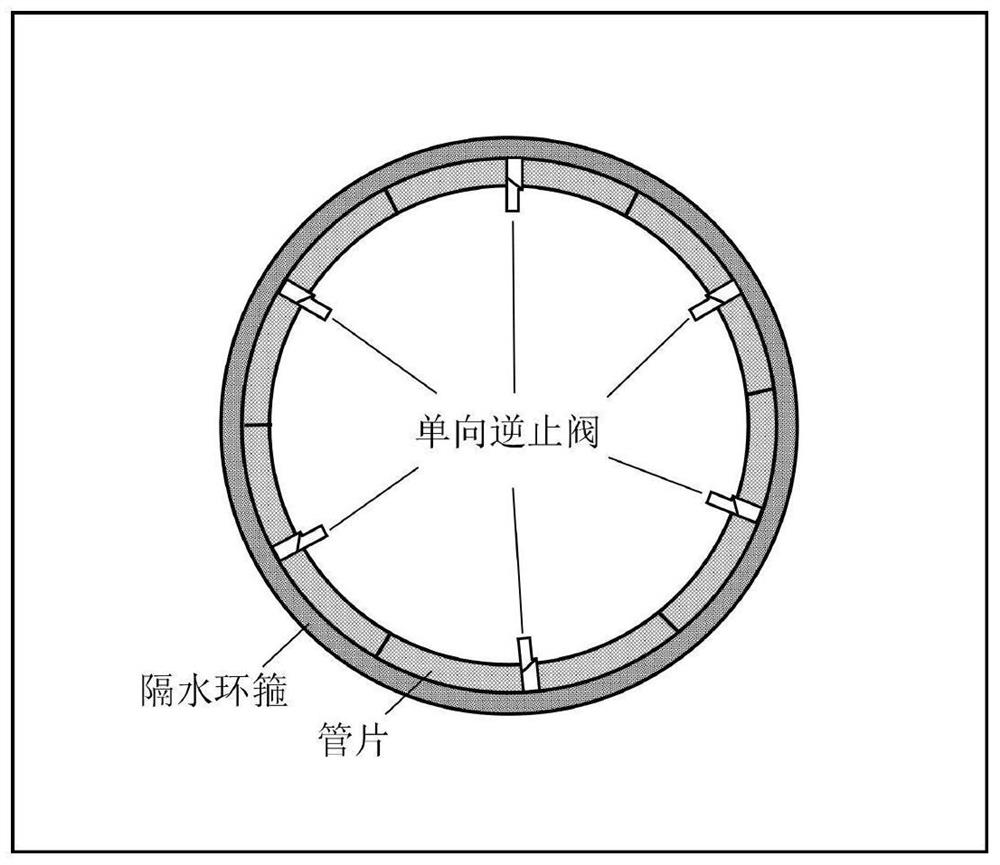

[0041] Specific implementation mode three: the treatment method in a liquefiable stratum shield tunnel described in specific implementation mode 1 or 2, in step 2, the specific operation of the secondary grouting to cut off pore water is as follows:

[0042] The formation of the water-proof hoop requires secondary grouting in the pre-embedded grouting holes of the 6 segments of the ring, from bottom to top, left and right alternately symmetrical grouting; after selecting the grouting hole position, put on the grouting unidirectional After the check valve, use an electric hammer to drill through the concrete protective layer of the hole, connect the tee, the cement slurry pipe and the water glass slurry pipe. When injecting double slurry, first inject the pure cement slurry for 1 minute, and then open the water glass valve. 1:1 mixed injection, the concentration of water glass itself should be increased from the initial 35°Be' to 40°Be' when the final hole is completed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com