An underground integrated pipe gallery structure with anti-liquefaction and anti-floating and application method thereof

A comprehensive pipe gallery and anti-liquefaction technology, which is applied to underwater structures, infrastructure engineering, buildings, etc., can solve the problems of easy liquefaction of saturated sandy soil layer, floating of comprehensive pipe gallery, economic property loss, etc. Liquefaction ability, pressure reduction, effect of preventing floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

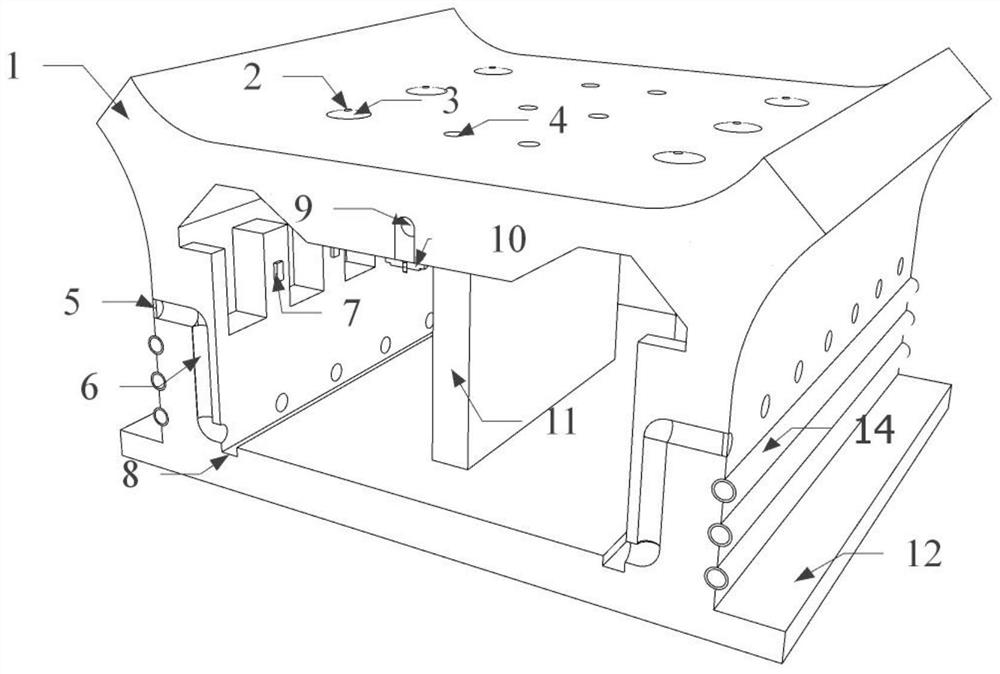

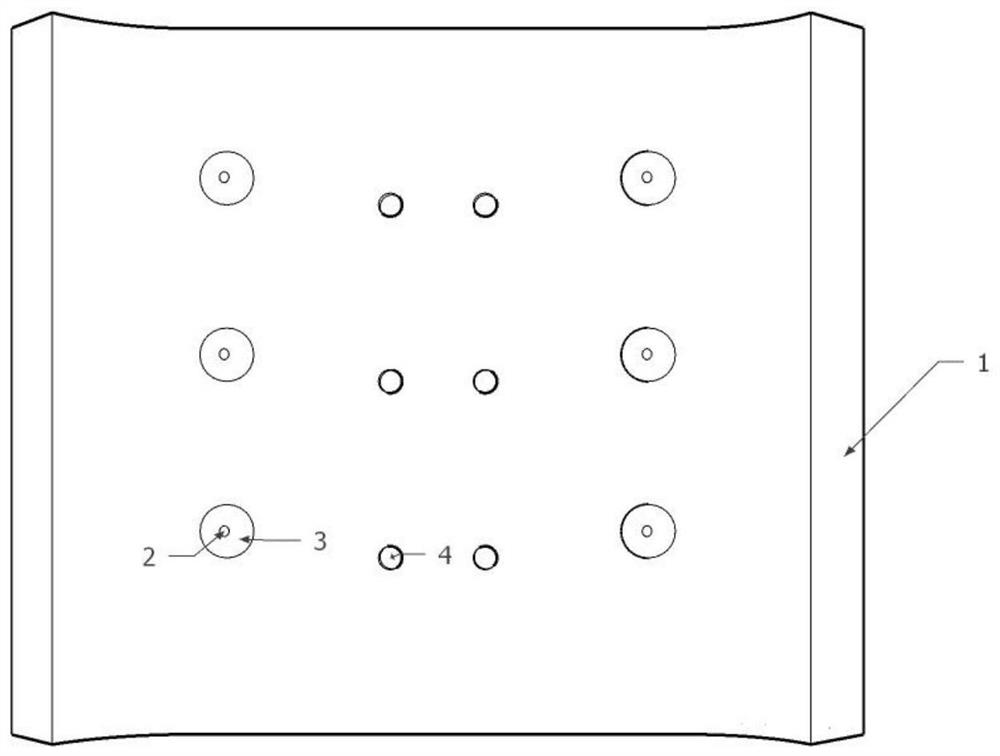

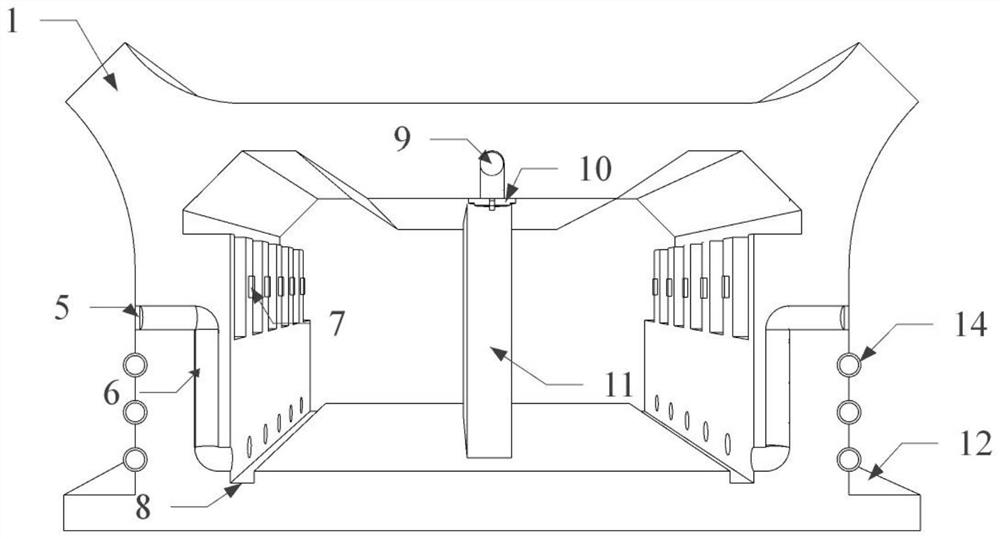

[0037] The liquefaction-resistant and anti-floating underground integrated pipe gallery structure of this embodiment, such as Figure 1-5 As shown in the figure, it includes a square tubular integrated pipe gallery body, a filter water absorption mechanism, a cooling mechanism and an air jet mechanism. The upper surface of the integrated pipe gallery body is embedded with a pore pressure sensor 2, and the filter water absorption mechanism is arranged on the side wall of the integrated pipe gallery body. It is used to remove the pore water in the surrounding soil. The cooling mechanism is arranged on the side wall of the integrated pipe gallery body to freeze the moisture in the surrounding soil into ice. The air jet mechanism is arranged on the top of the integrated pipe gallery body to spray low temperature and high pressure insoluble. water gas. The pore pressure sensor 2 is wrapped with a protective shell 3, and the interior of the integrated pipe gallery body is vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com