Anti-liquefaction treatment method for liquefiable foundation

A technology for liquefying foundations and treatment methods, which is applied in soil protection, infrastructure engineering, construction, etc. to achieve the effects of increasing the density, improving the density, and increasing the stress of the overlying stratum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with drawings and embodiments.

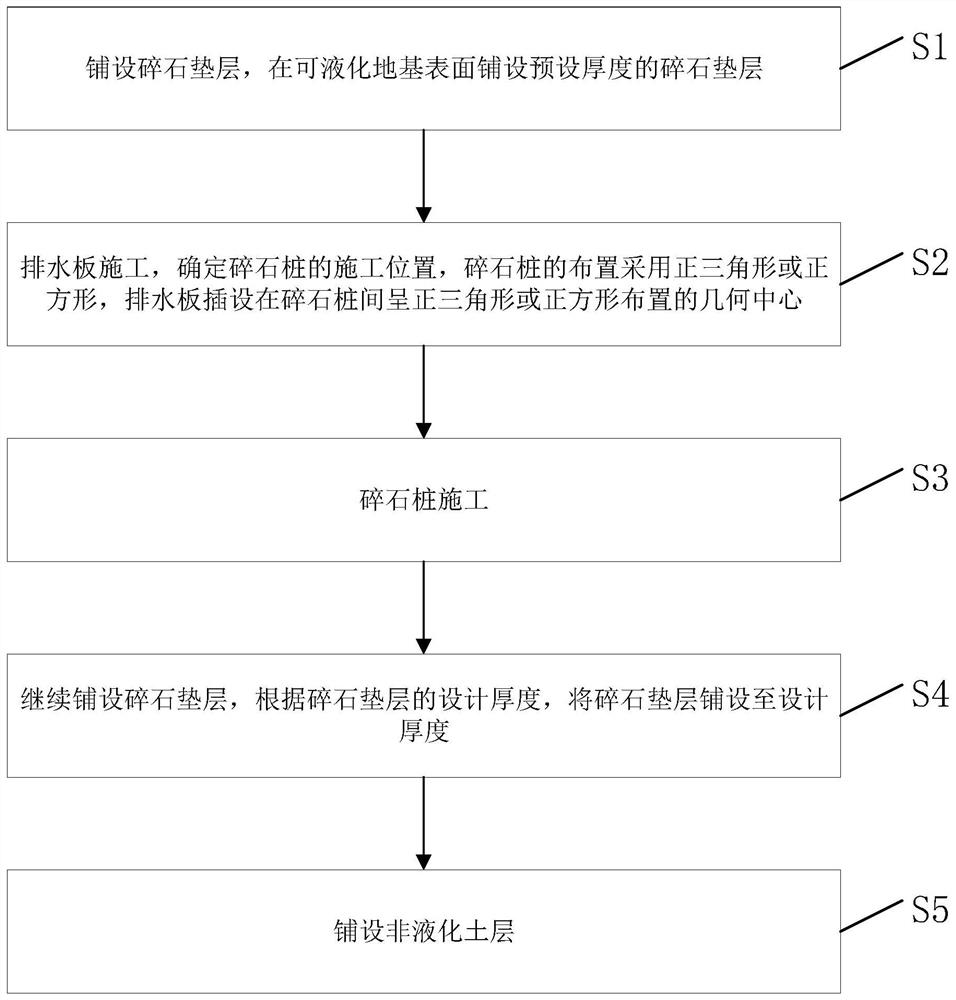

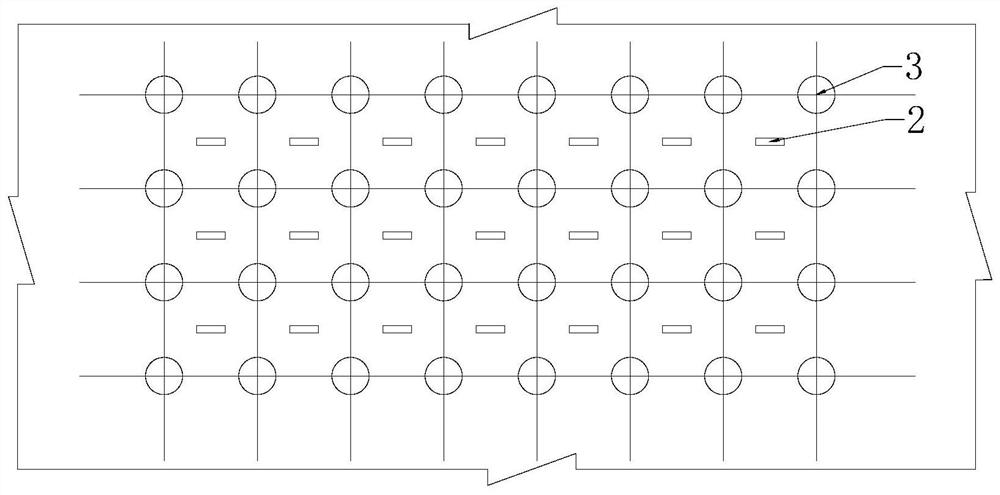

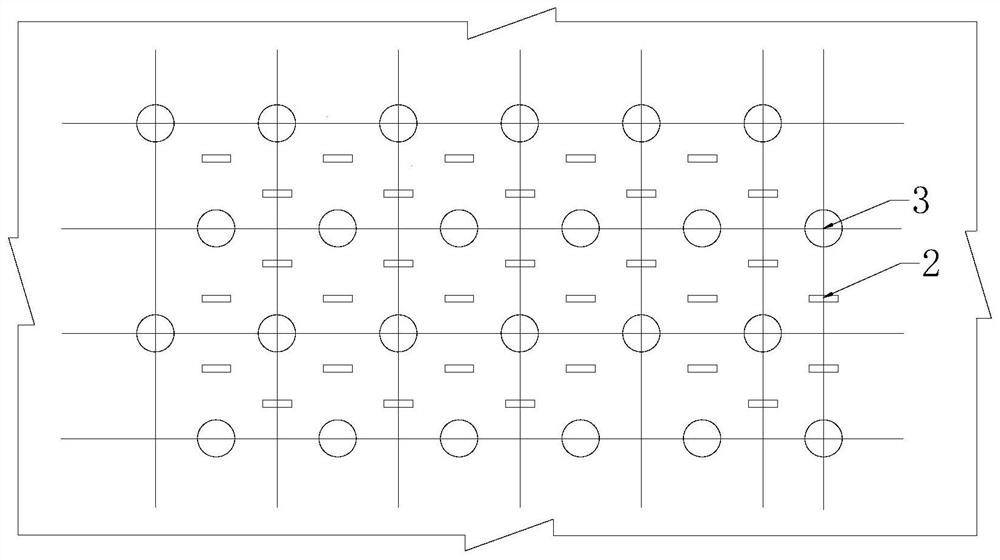

[0055] see Figure 1 to Figure 4 , figure 1 It is a flow chart of the steps of the anti-liquefaction treatment method of liquefiable foundation of the present invention, figure 2 It is a schematic plan layout diagram of an embodiment of gravel piles and drainage boards in the anti-liquefaction treatment method for liquefiable foundations of the present invention, image 3 It is a schematic plan layout diagram of another embodiment of gravel piles and drainage boards in the anti-liquefaction treatment method for liquefiable foundations of the present invention, Figure 4 It is a schematic cross-sectional view of an embodiment of a gravel pile and a drainage board in the anti-liquefaction treatment method for liquefiable foundations of the present invention. An anti-liquefaction treatment method for a liquefiable foundation, comprising the following steps:

[0056] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com