Seepage eliminating system for lowering tailing pond dam body seepage line by using mining barren rocks and construction method thereof

A technology for mining waste rocks and tailings ponds, applied in the field of seepage drainage systems, can solve the problems of large vertical sandbag wells, frequent fluctuations in the soaking line, and endangering the safety of the dam body, so as to be beneficial to environmental protection and improve the ability to resist liquefaction , The effect of accelerating drainage consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

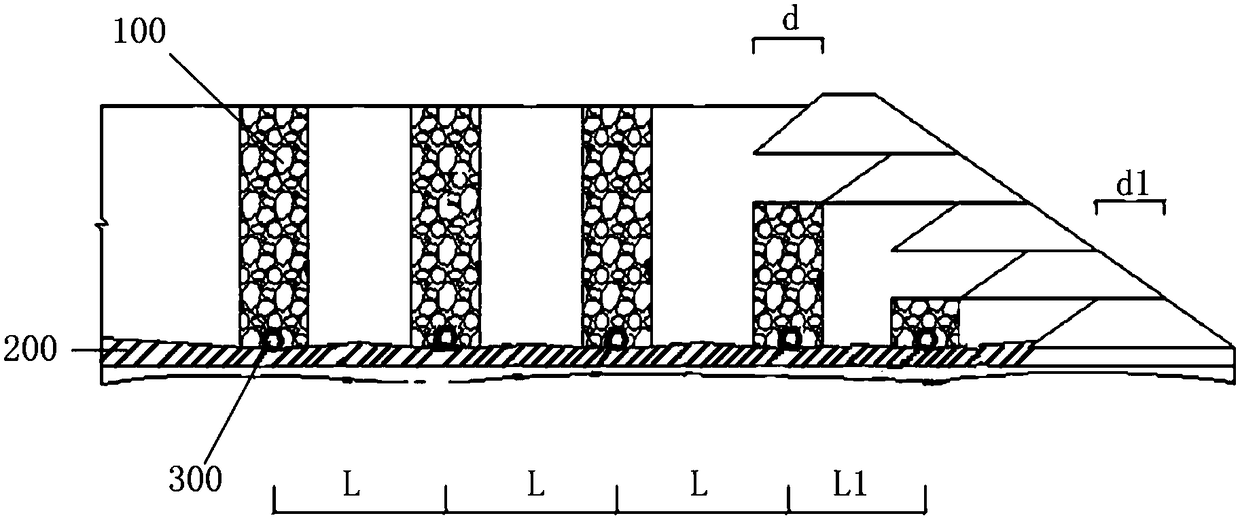

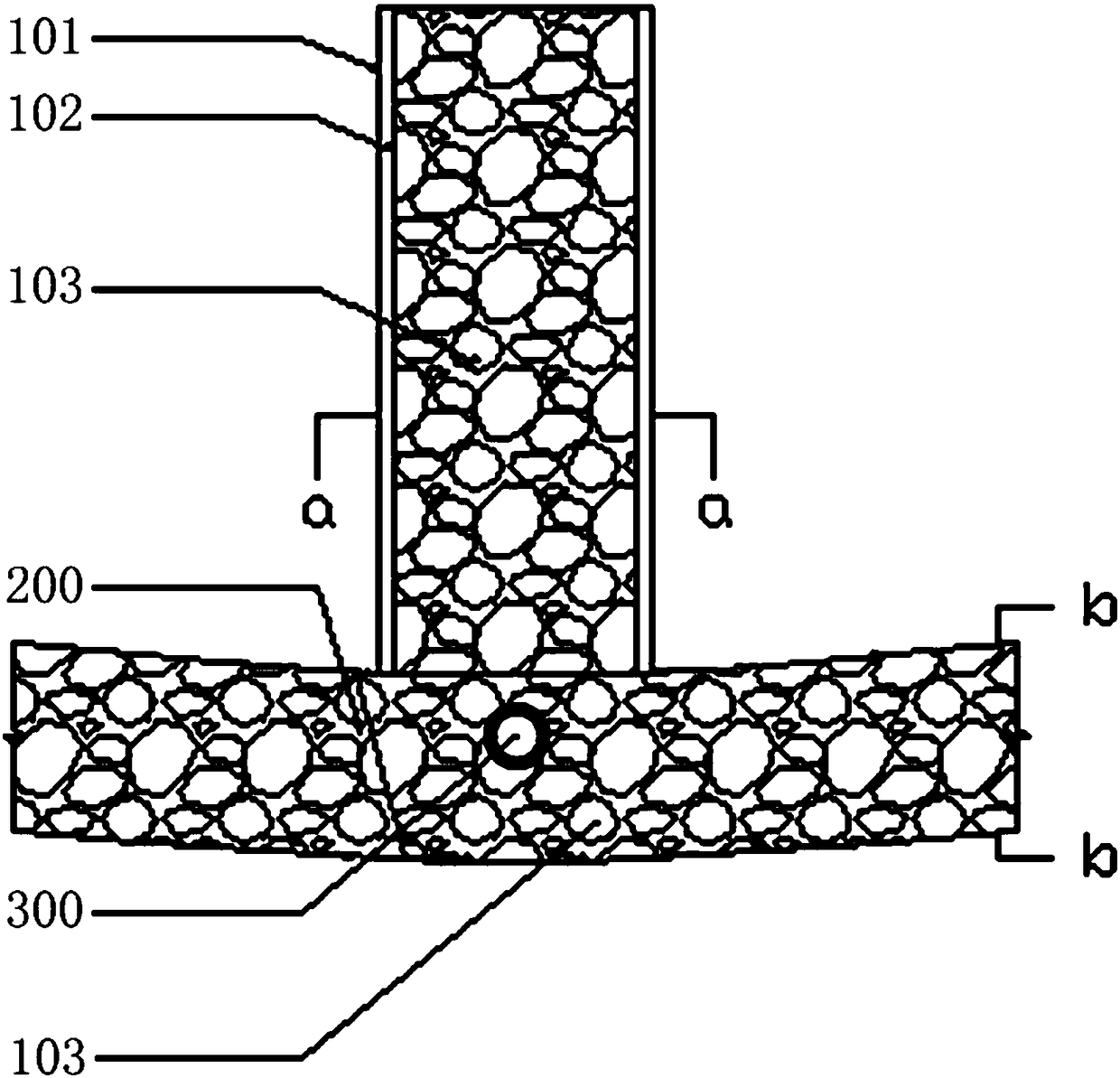

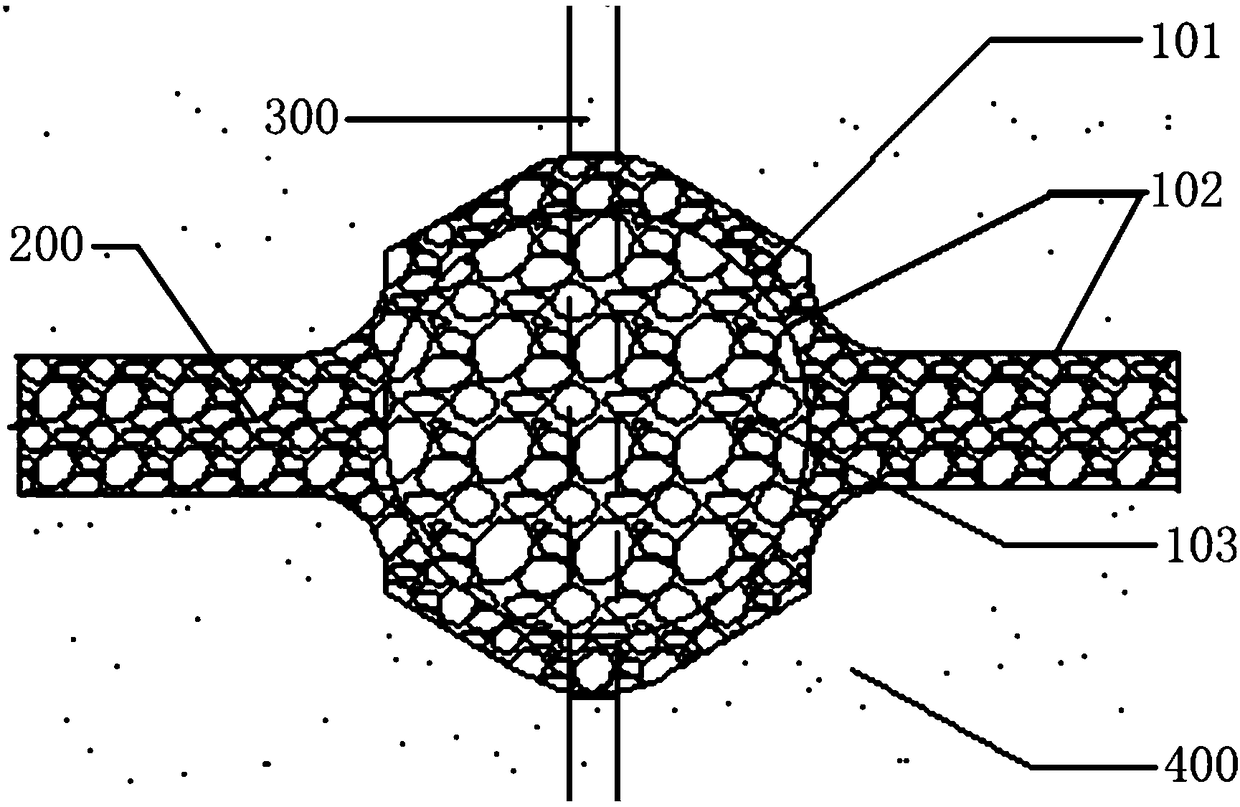

[0047] Such as figure 1 As shown, a seepage drainage system that uses mining waste rocks to reduce the wetting line of the dam body of the tailings pond provided by Embodiment 1 of the present invention includes: a waste rock column 100 arranged inside the dam body along the direction of the central axis of the dam; The horizontal seepage drainage blind ditch 200 arranged on the tailing sand deposition beach inside the dam body and the vertical seepage drainage pipe 300 arranged inside the dam body perpendicular to the direction of the central axis of the dam; Both are connected with the bottom of the waste stone column 100; the vertical seepage drainage pipe 300 is vertically intersected with the horizontal seepage drainage blind ditch 200; figure 2 As shown), the diameter d of the waste rock column is greater than or equal to the width d1 of the initial dam crest of the tailings pond, and the height of the waste rock column is not lower than the highest water level in the d...

Embodiment 2

[0053] Figure 5 It shows the steps of a seepage drainage construction method using mining waste rocks to reduce the wetting line of the tailings pond dam body provided by Embodiment 2 of the present invention, including: Step S1: According to the geological survey report and the foundation design data of the tailings pond, obtain Tailings dam basic information;

[0054] Wherein, the tailings dam basic information includes at least the width of the initial dam crest of the tailings pond, the direction of the central axis of the dam, the highest water level in the dam, and the height of the tailings dam;

[0055] Step S2: use mining waste rocks in the dam body to build waste stone pillars along the central axis of the dam;

[0056] Among them, the waste rock column includes skeleton, geotextile and mining waste rock arranged from outside to inside, the diameter of the waste rock column is greater than or equal to the width of the initial dam crest of the tailings pond, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com