PVD drainage system and method thereof

A technology of drainage system and drainage department, which is applied in the direction of construction, infrastructure engineering, soil protection, etc., can solve the problems of slow seepage speed, fast seepage time, slow pore pressure dissipation, etc., to increase the degree of consolidation and speed up seepage Speed, the effect of solving well resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

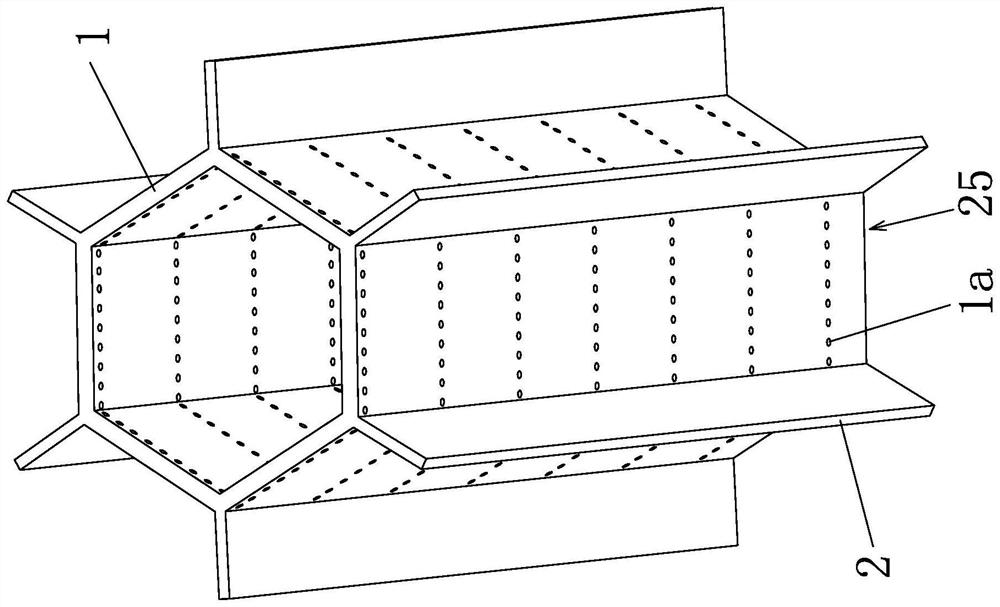

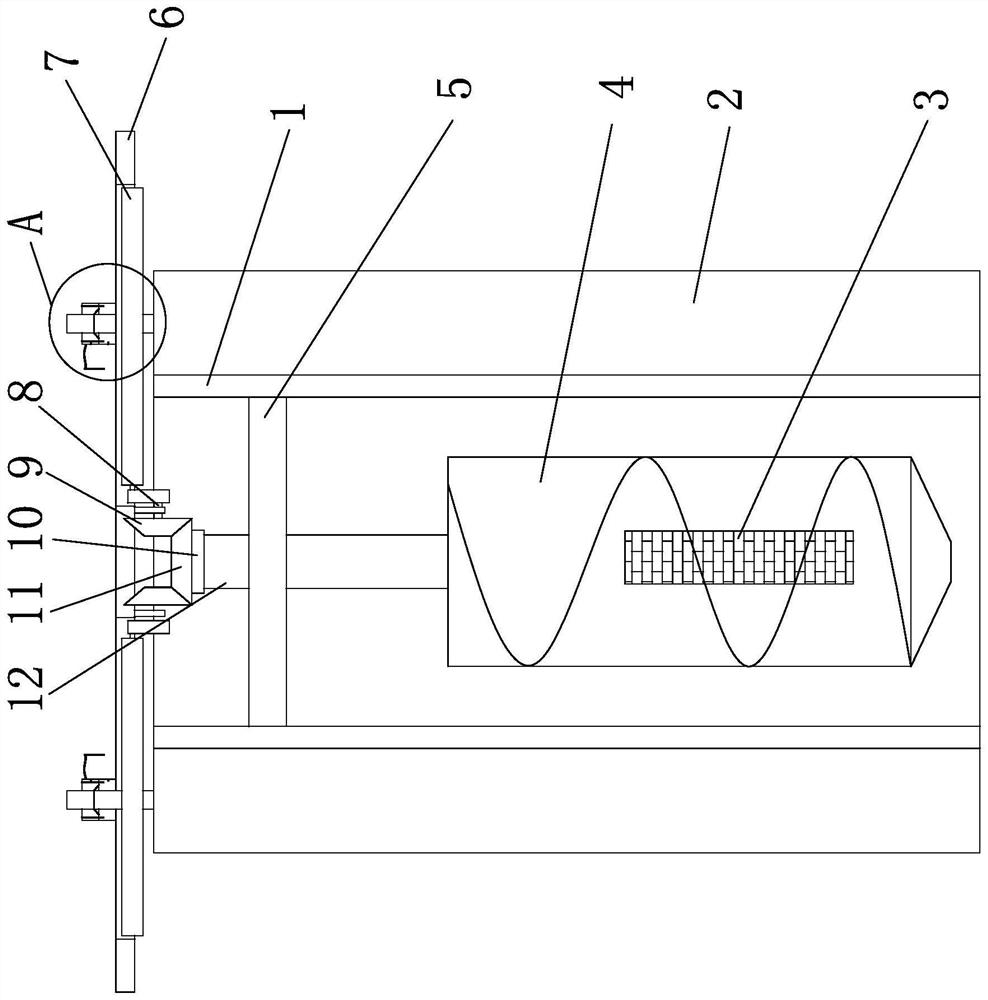

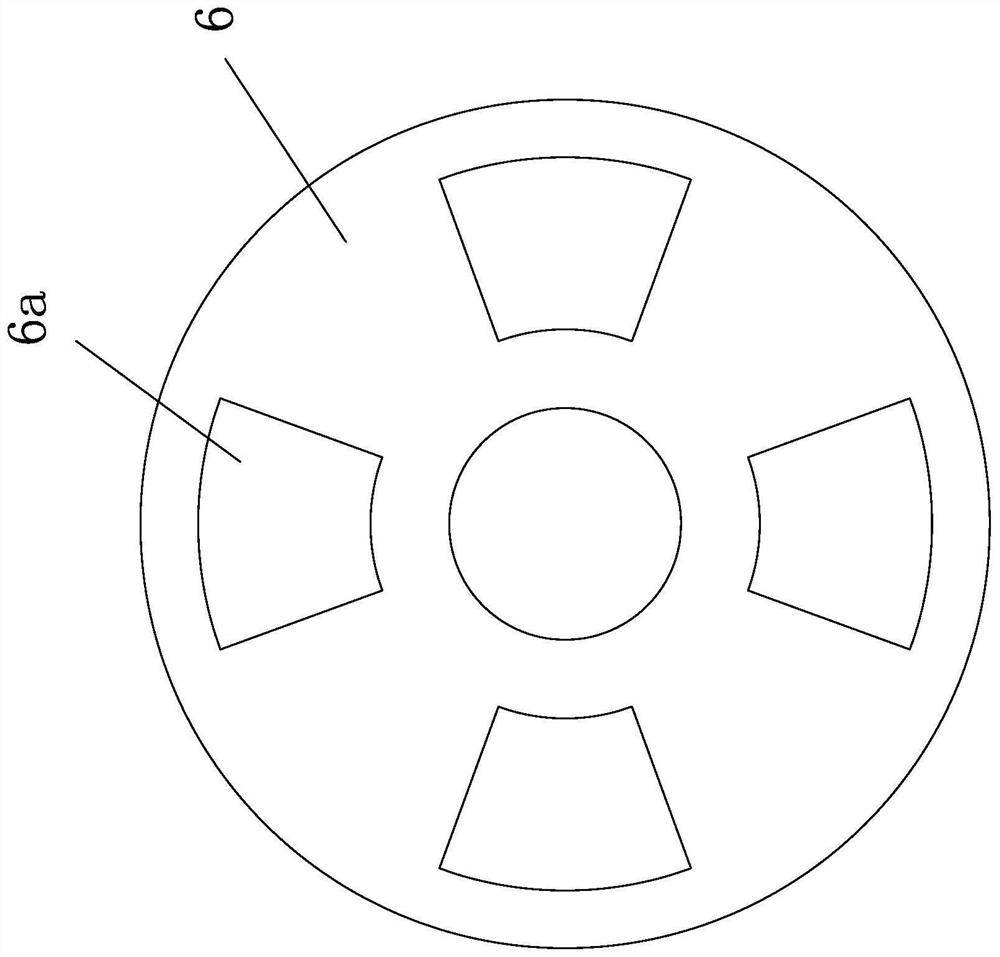

[0024] like Figure 1-Figure 6 As shown, the PVD drainage system and method thereof, the PVD drainage system includes a polygonal cylinder 1, the outside of the cylinder 1 has a number of drainage strips 2 uniformly distributed along its length direction, and the drainage strips 2 are evenly distributed, adjacent two A drainage part 25 is formed between the two drainage strips 2, and a plurality of auxiliary through holes 1a are also arranged on the cylinder body 1. The small mouth end of 1a is located on the inner side of the cylinder body 1, and a reinforcing bracket 5 is installed on the inner side of the cylinder body 1, and a linkage shaft 12 is vertically rotated on the reinforcement bracket 5, and the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com