Method of eliminating liquefaction in shield tunnel stratum in tunnel

A technology for shield tunneling and strata, which is applied to tunnels, tunnel linings, underground chambers, etc., can solve the problems of increased investment, difficult quality control, and large discreteness, and can solve liquefaction elimination, improve liquefaction resistance, and eliminate liquefaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

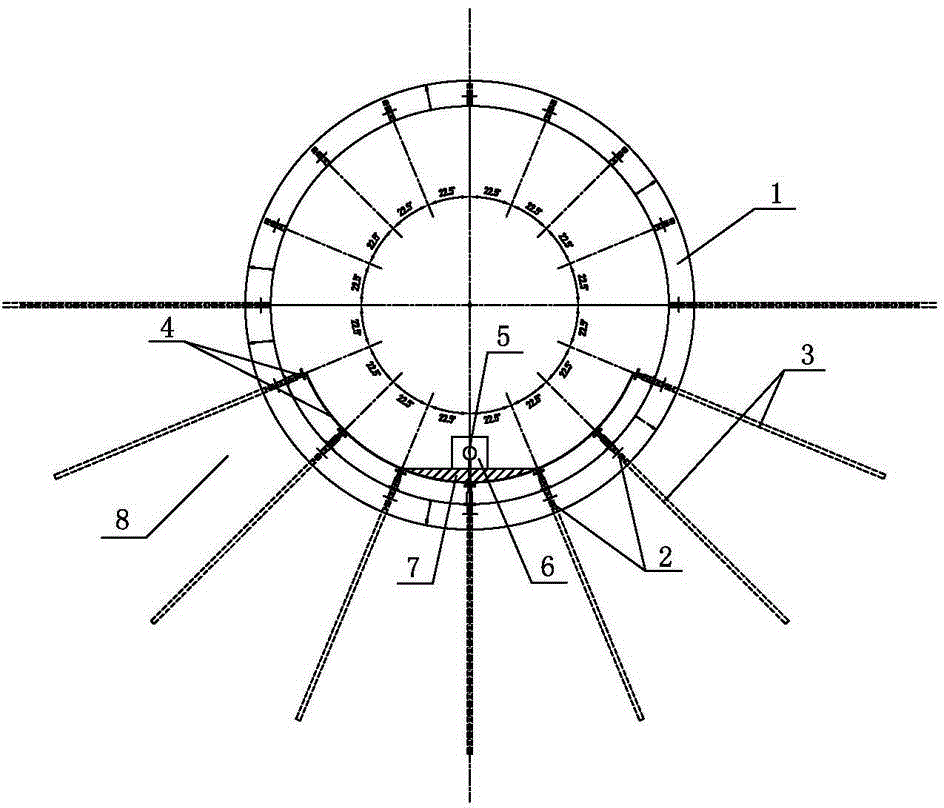

[0018] In this embodiment, in a busy city with dense buildings, it is impossible to directly implement technical measures on the ground, using the construction and structural characteristics of the shield tunnel structure, and on the premise of the assembled shield structure, through the tunnel to the shield tunnel Drainage pipes are installed in the strata around the tunnel, and vacuum (increasing the pressure difference to improve the effect) is used to pump water to promote the compaction of the liquefied soil layer, improve the anti-liquefaction ability of the stratum more evenly, and achieve the purpose of eliminating liquefaction.

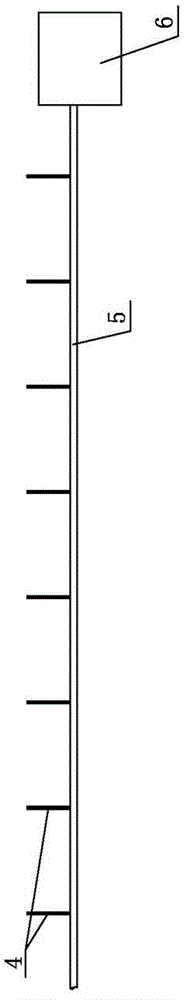

[0019] Such as figure 1 , figure 2 As shown, the method for eliminating stratum liquefaction in a shield tunnel in this embodiment includes the following steps:

[0020] S1. A group of annular linings 1 assembled from several concrete segments are spliced sequentially along the tunnel direction to form a permanent tunnel lining, and a set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com