Patents

Literature

228 results about "Tunneling direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

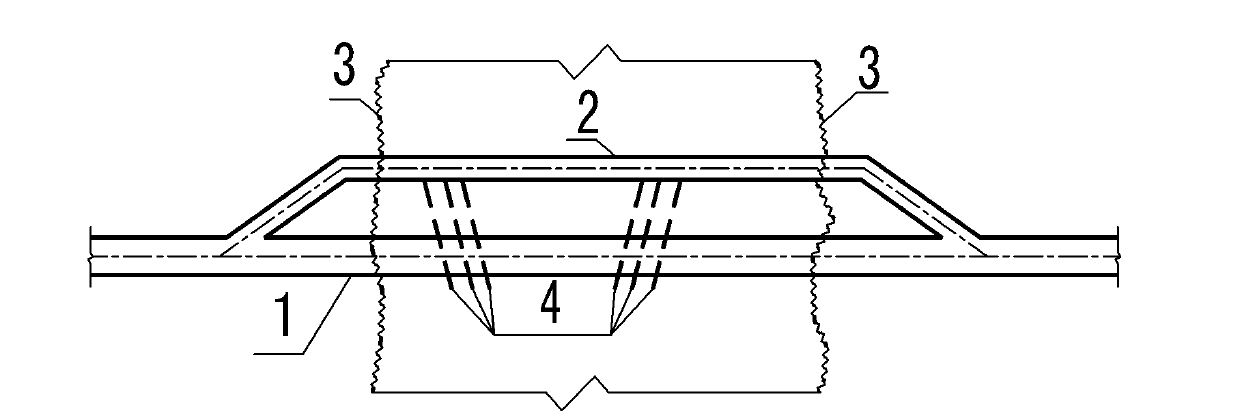

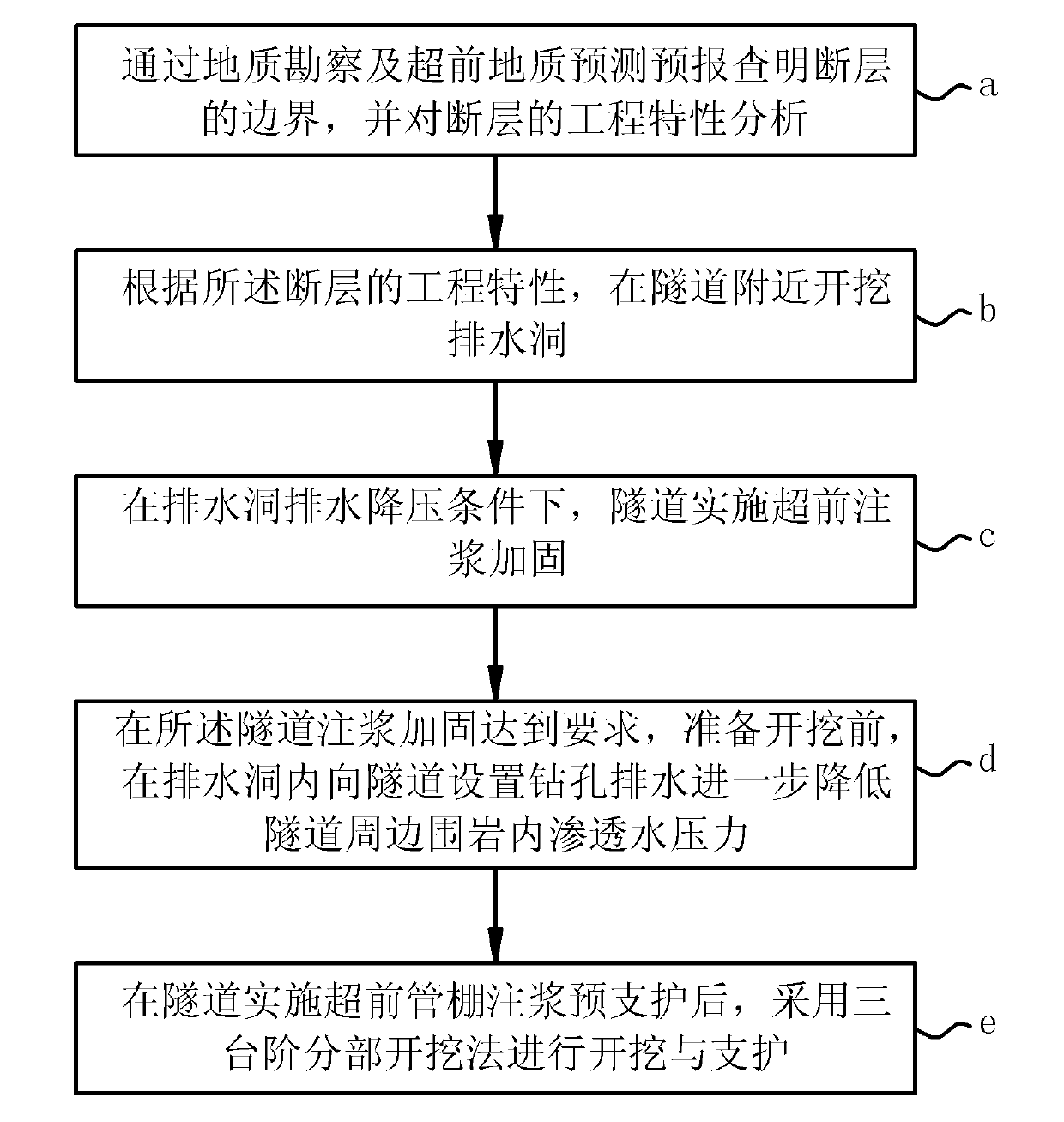

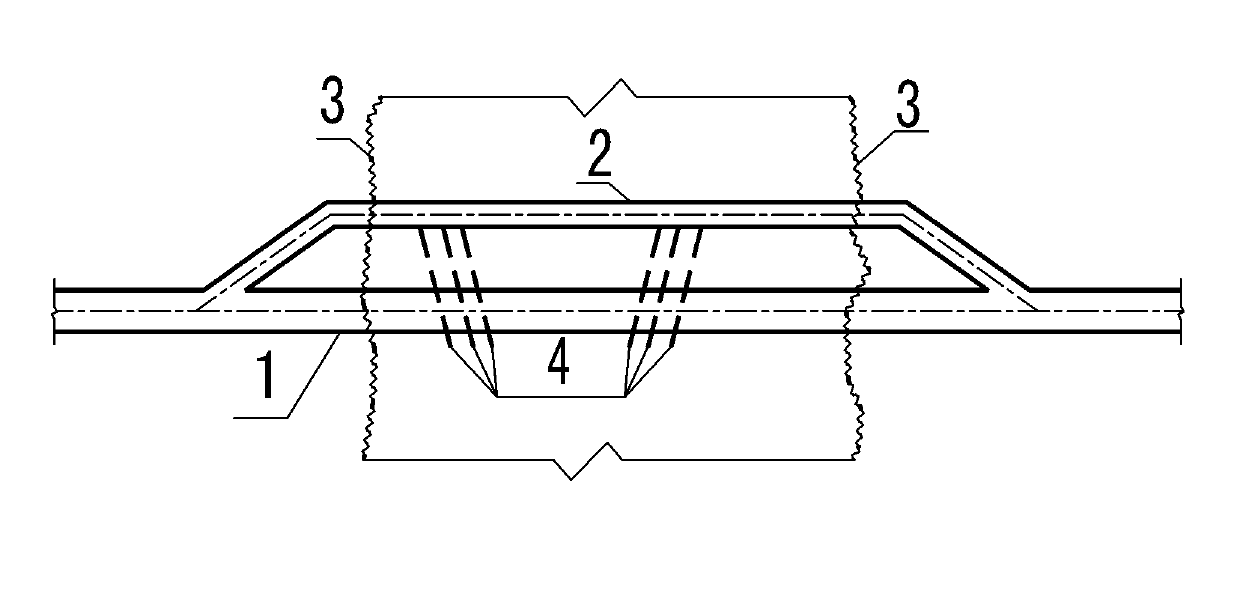

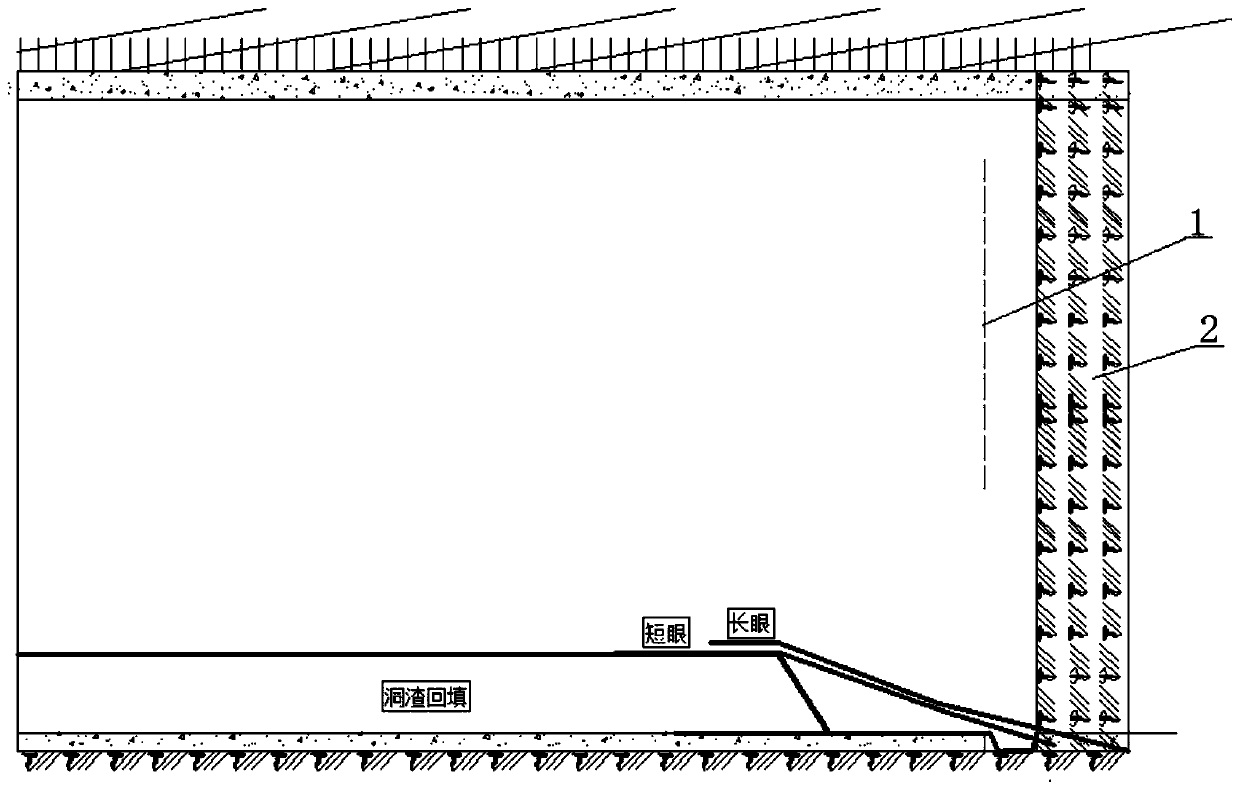

Fault processing method of high pressure water enrichment area

InactiveCN101922302AReduce water pressureAvoid water inrushUnderground chambersDrainagePore water pressureHigh pressure water

The invention relates to a fault processing method of a high pressure water enrichment area, comprising the following steps of: a. ascertaining the boundary of a tunnel passing through a fault through geological exploration and advance geological prediction, and judging the inflow direction of the fault; b. excavating a drainage hole at the inflow side of the fault next to the tunnel according to the inflow direction of the fault; c. carrying out advanced grouting pre-strengthening per cycle on a tunnel working face under the condition that the drainage hole drains and depressurizes; d. drilling towards the tunnel direction in the drainage hole before excavation and after the grouting pre-strengthening per cycle of the tunnel meets requirements, increasing the drainage ability by using the drilled hole, and further reducing the seepage water pressure in a surrounding rock at the periphery of the tunnel; and e. tunneling from the tunnel working face. Through arranging the drainage hole, the invention reduces the seepage water pressure near the tunnel, effectively avoids the occurrence of the phenomenon of water burst, mud gushing (stones) of fault broken rocks under the action of high pressure water in the construction process and improves the safety and the reliability of tunnel construction and operation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Construction method for tool changing under pressure in shield of water-rich silty soil and silty sand stratum under station tracks of railways

ActiveCN102758635AGuaranteed operational safetyOvercoming the risk of collapseTunnelsSoil scienceEarth surface

The invention discloses a construction method for tool changing under pressure in a shield of the water-rich silty soil and silty sand stratum under station tracks of railways. The construction method comprises the following steps of: carrying out reinforcement on a soil body at a tool changing position by adopting a high-pressure rotary jet pile; inspecting whether holes exist on the ground surface in the soil reinforcing area, and adjusting the tunneling posture and the tunneling direction of a shield machine; after reinforcing soil enters a cutting port of the shield machine, reducing the pressure of a soil warehouse, and adjusting construction parameters; injecting bentonite into the soil warehouse of the shield; determining an air pressure value, and determining a tool-changing air pressure value in the soil warehouse according to the obtained water-soil pressure value; and finally, clearing the warehouse, and reducing the pressure; and workers enter to change a tool, and after tool changing, the shield machine restores the tunneling working state. The construction method disclosed by the invention has the advantages that the risk that water-rich soft soil is easy to flow to cause collapse when the tool is changed under pressure in tunnel shield construction of the water-rich silty soil and silty sand stratum is overcome, and the operation safety of upper railways is ensured.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

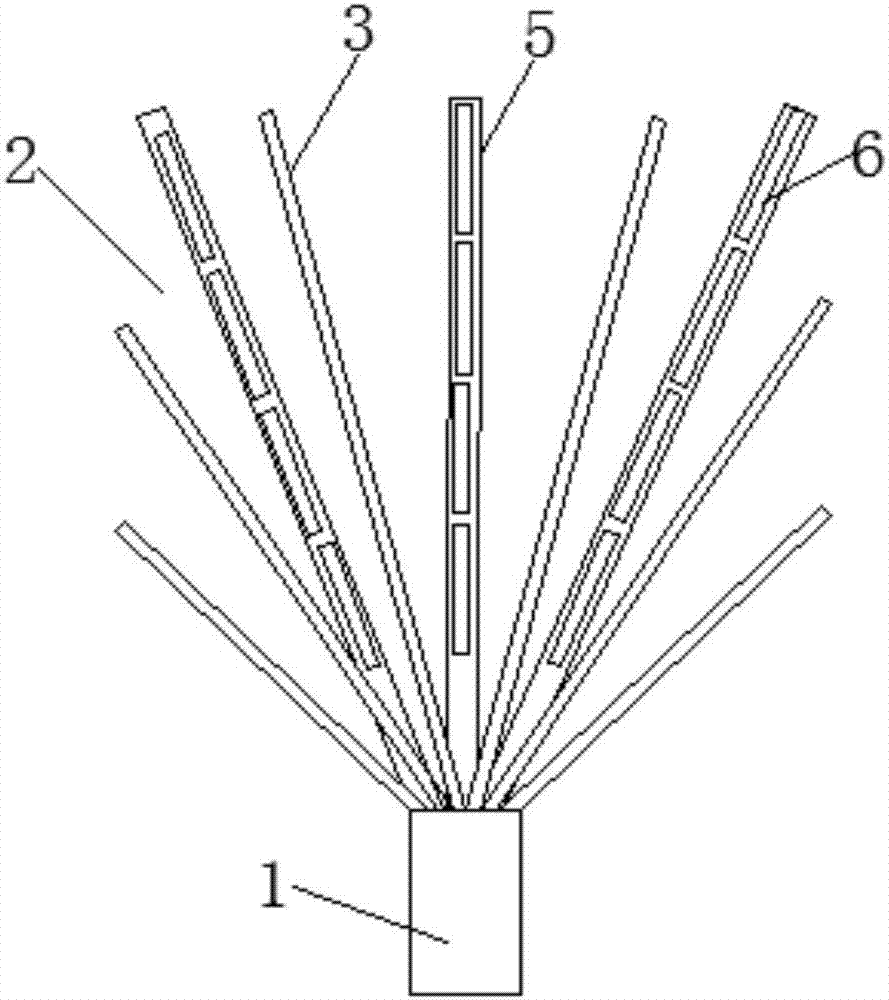

High-efficiency tunneling gas control method for high outburst mine coal roadway

The invention discloses a high-efficiency tunneling gas control method for a high outburst mine coal roadway, which comprises the following steps: before the working surface of the outburst mine coal roadway is used for tunneling, respectively forming a drill site at two sides of the coal roadway, perforating overlong deep holes from each drill site along the tunneling direction of the coal roadway, and carrying out grouting treatment so that gas in the grouting range along the tunneling direction of the coal roadway is relatively isolated from the surrounding environment, thereby forming a relatively closed roadway tunneling space, eliminating the potential safety hazard of outburst in the roadway tunneling process, and overcoming the original defect that as the time for pumping and discharging the gas is too long, the whole tunneling efficiency is very low; meanwhile, the method of the invention realizes high-efficiency tunneling in the premise of safety and has simple operation of construction processes; and the method is suitable for being popularized and utilized under various conditions of occurrence of high outburst coal seams.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

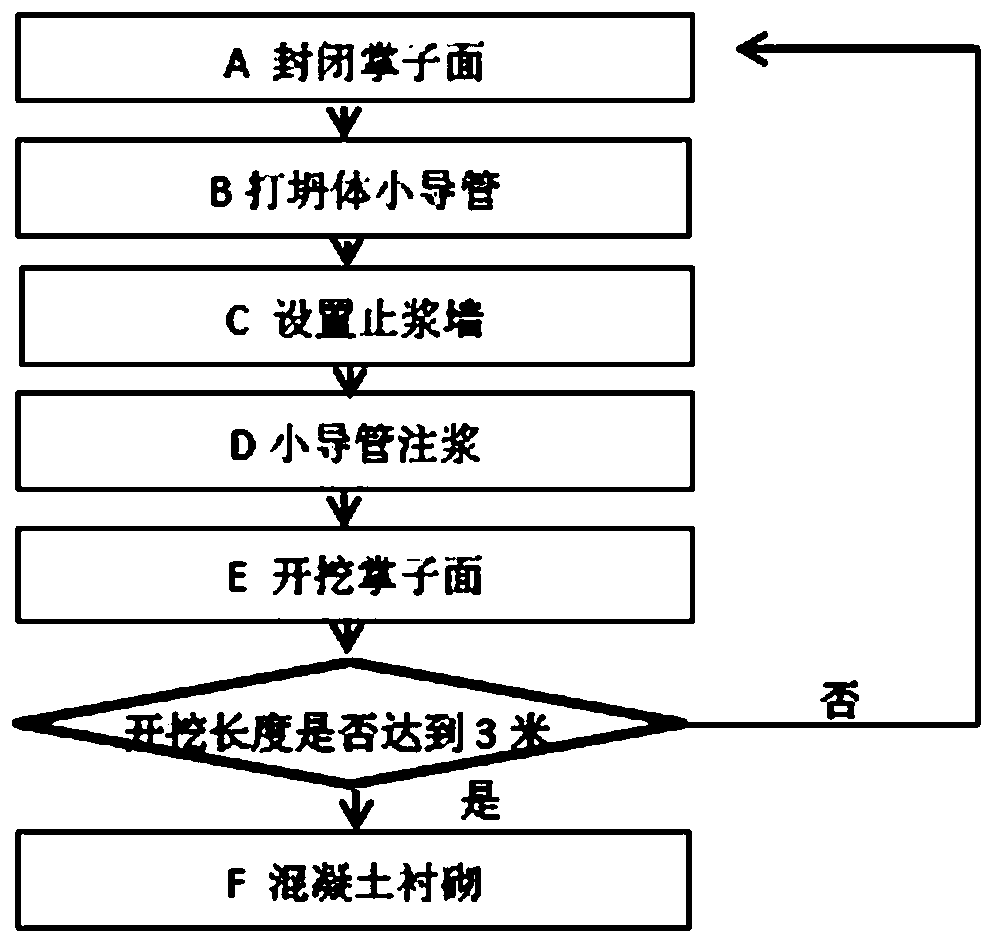

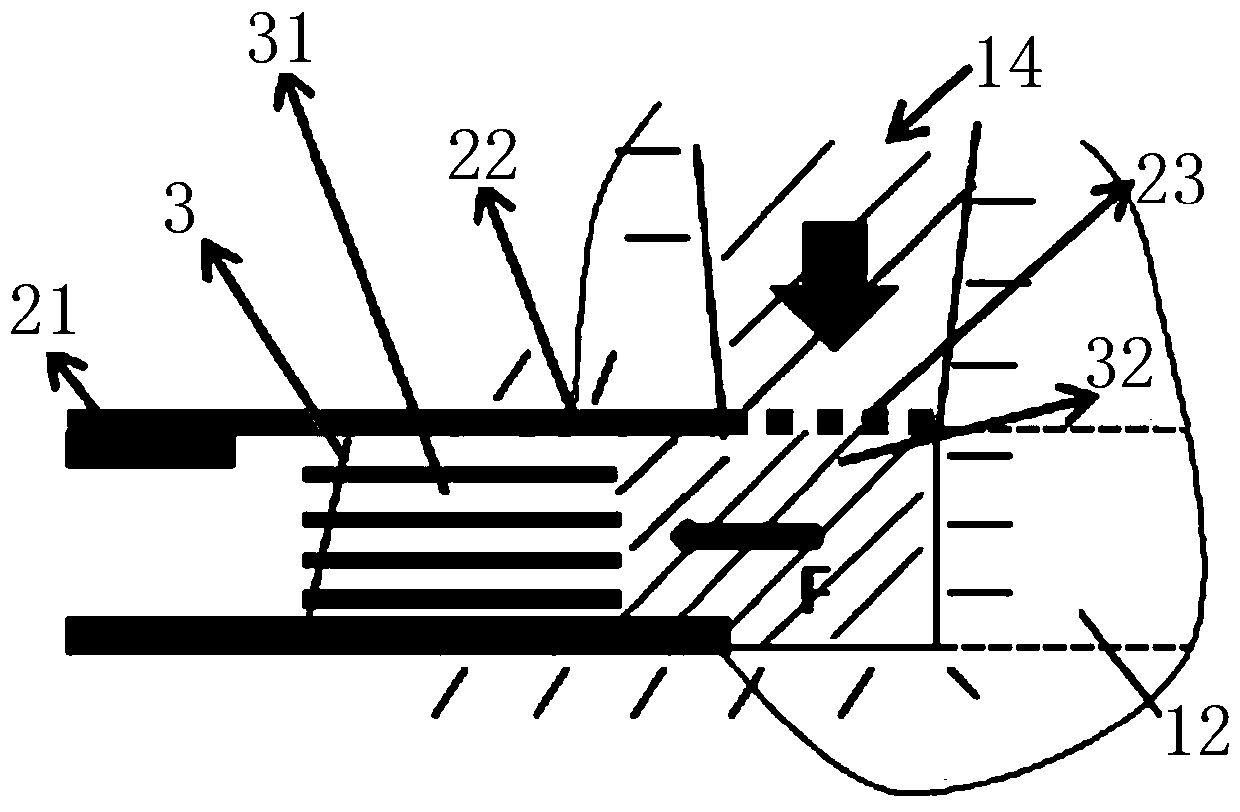

Construction method used after tunnel integral type collapse

ActiveCN107165652AStable supportAvoid the disadvantages of inoperabilityUnderground chambersTunnel liningStructural engineeringImpact area

Owner:DATANG LINZHOU THERMAL POWER CO LTD

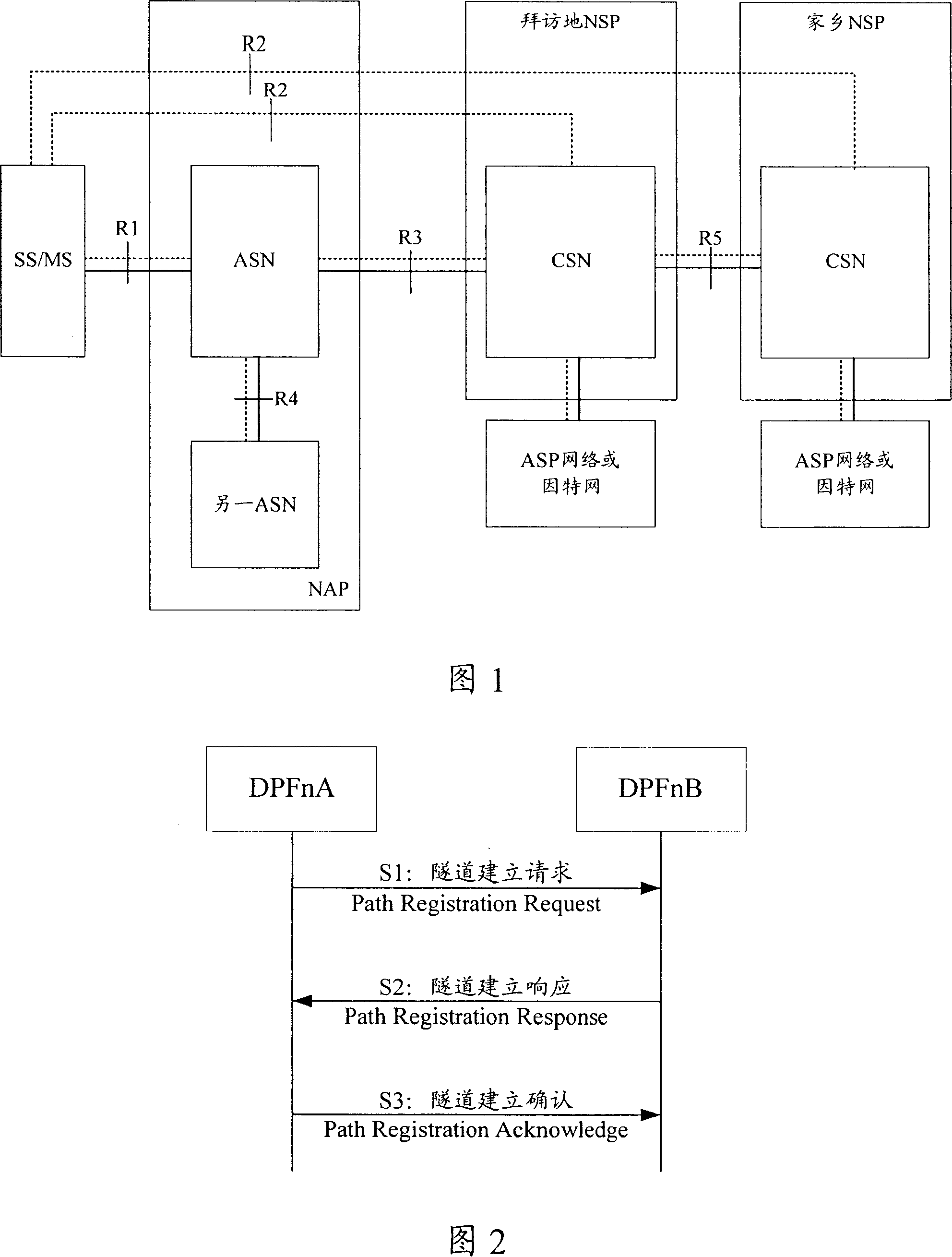

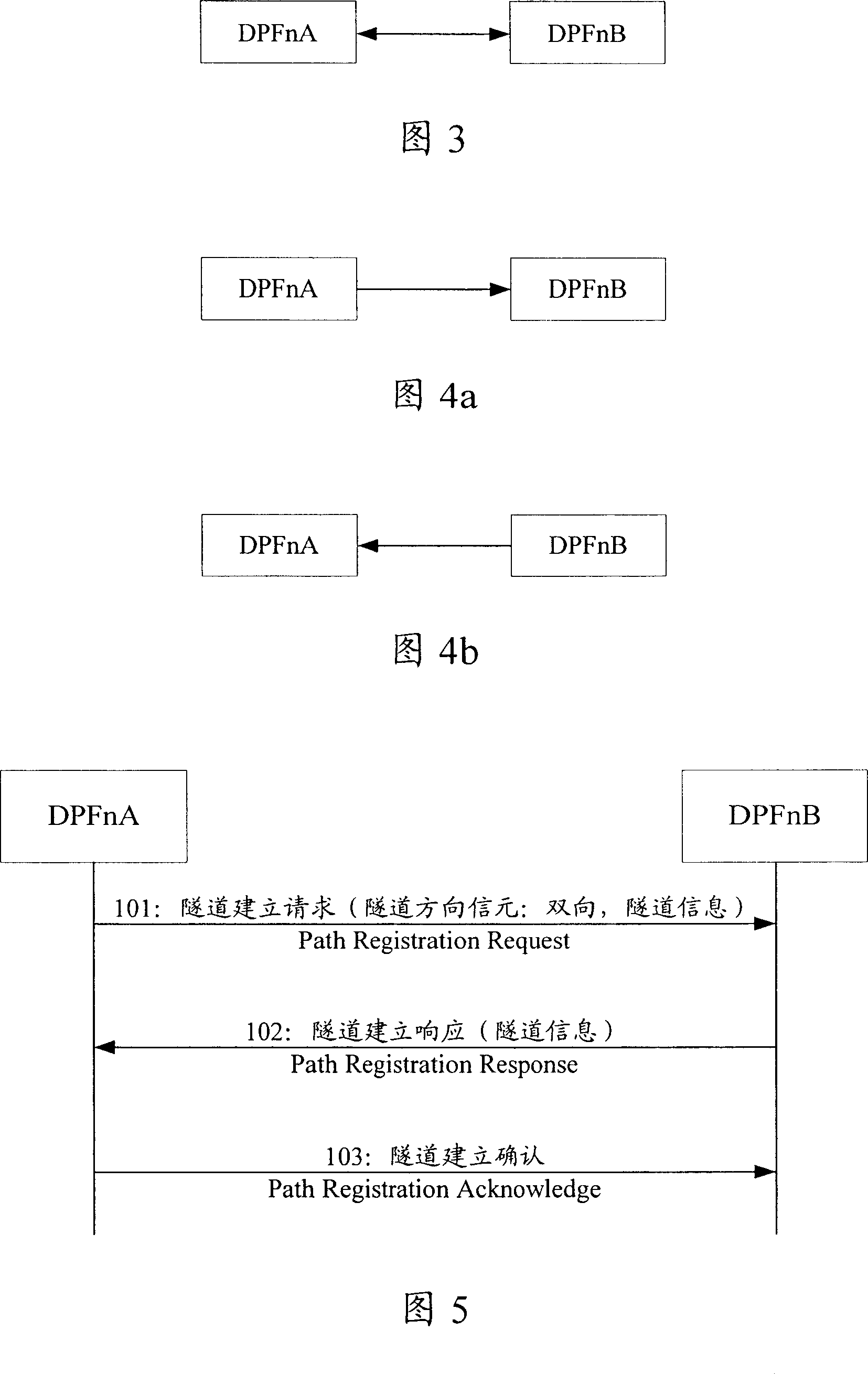

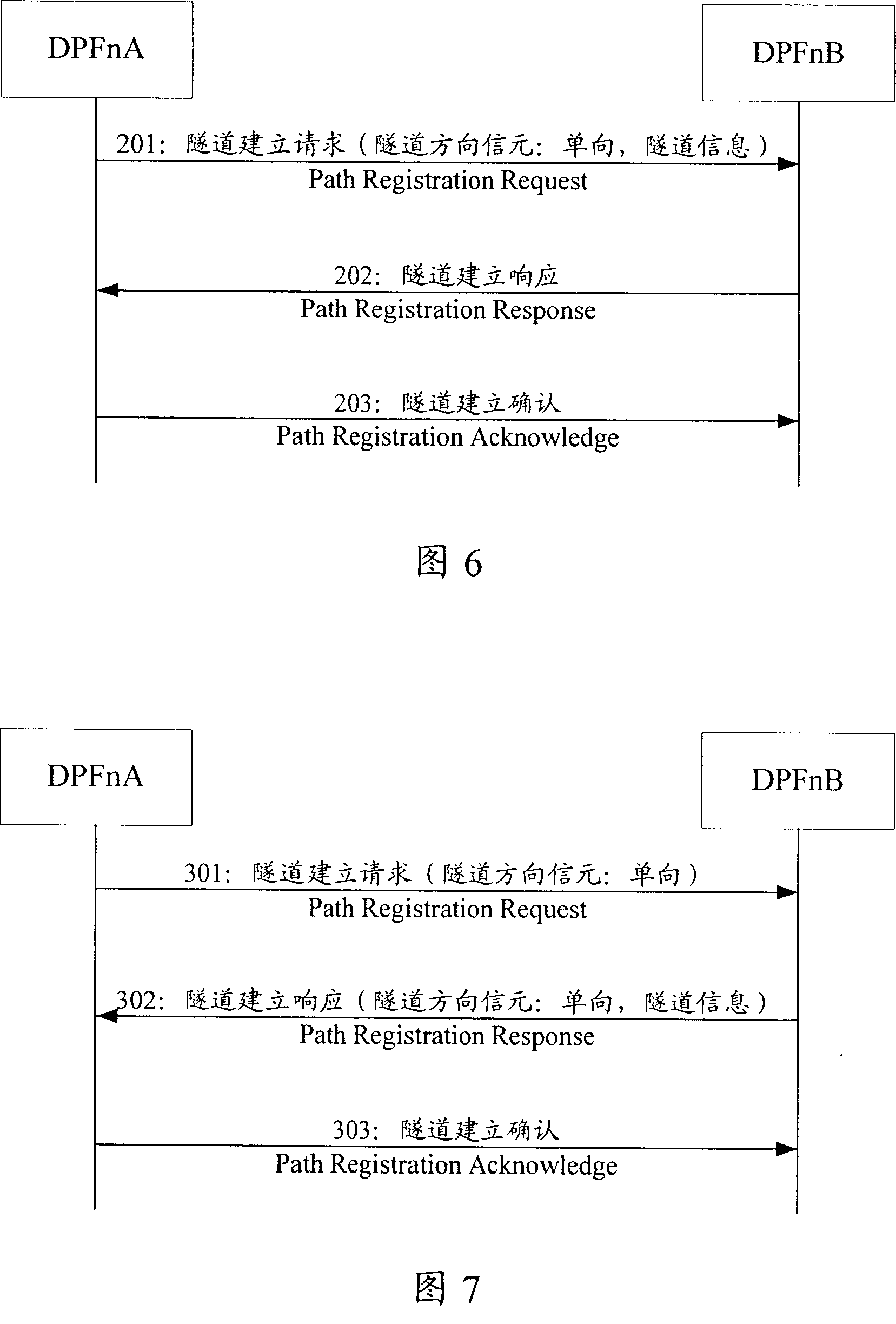

Method for setting data tunnel

InactiveCN101001194ARealize the establishmentSave bandwidth resourcesNetworks interconnectionComputer scienceTunneling direction

This invention discloses a method for setting up data tunnel including: A, a first DPFn sends a data tunnel set-up request message with data tunnel direction cells to a second DPFn, B, the second DPFn returns a response message based on the value of the tunnel direction cell to set up a data tunnel between the first and second DPFn. Since tunnel direction cell is added in the message for setting up data tunnel, data tunnels of different kinds are set up between two DPFn.

Owner:HUAWEI TECH CO LTD

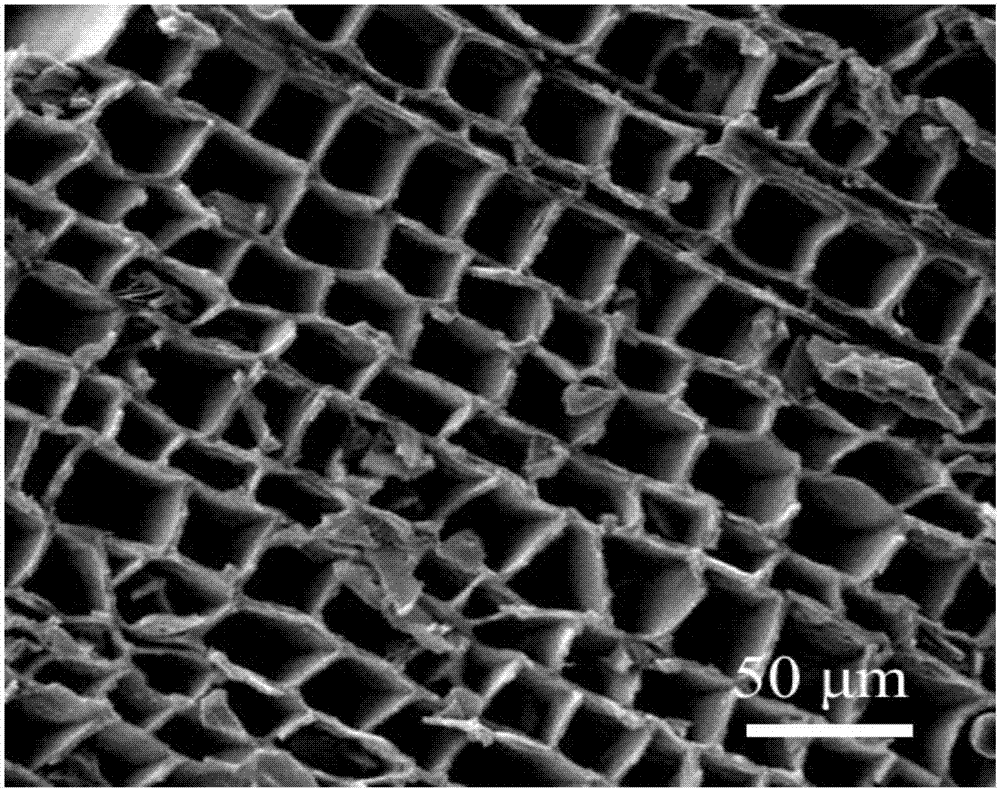

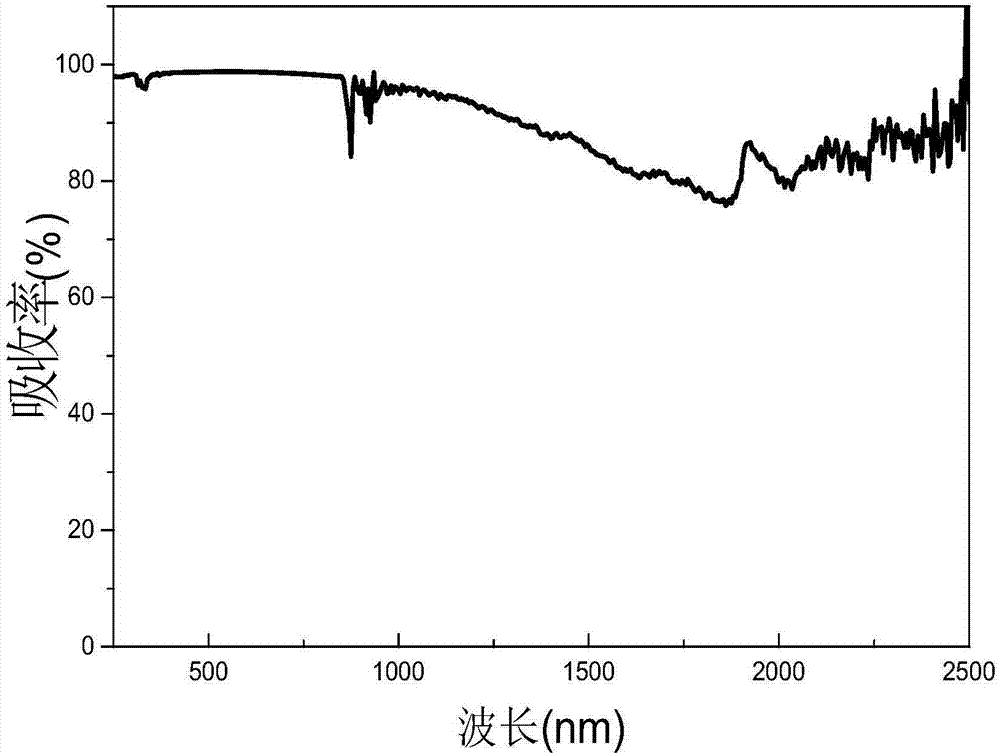

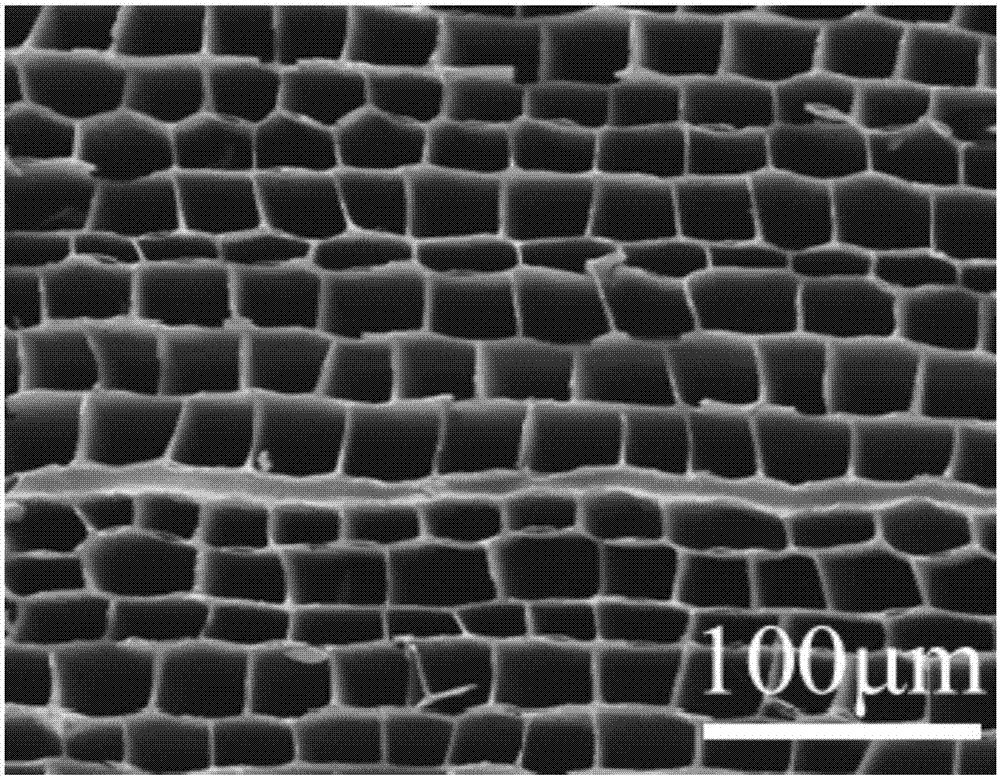

Method for preparing porous charcoal pieces capable of realizing efficient photo-thermal steam converting

ActiveCN107487801ALow costEasy to operateGeneral water supply conservationSeawater treatmentCarbonizationEngineering

The invention discloses a method for preparing porous charcoal pieces capable of realizing efficient photo-thermal steam converting. The method comprises the following steps: 1) drying wood block; placing the wood block in a quartz tubular furnace, under nitrogen atmosphere protection, performing high temperature pyrolysis at the temperature of 300-900 DEG C and carbonization to obtain the whole block of carbonized charcoal; 2) cutting the carbonized charcoal obtained in the step 1) along a vertical charcoal tunnel direction or polishing the carbonized charcoal to obtain the charcoal pieces with thickness being 1-3 mm; and 3) using deionized water to performing ultrasonic cleaning on the charcoal pieces obtained in the step 2), and drying the material to obtain the porous charcoal pieces. The obtained charcoal pieces have regular tunnels, are beneficial for steam flowing, have good adhesiveness with water, and can guarantee for transferring the heat to water. The charcoal pieces have light absorptivity being more than 95% in a 250-2500 nm scope, and under light intensity of 1 kW.m<-2>, the photo-thermal steam efficiency can reach as high 91.2%. The porous charcoal pieces have the advantages of low cost, simple operation, and environmental protection, and can be used for sewage processing and seawater desalination.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method of constructing shallow tunnel underground passage variable-cross section cross mid-partition wall

ActiveCN103334761AAvoid duplicationAvoid occupying spaceUnderground chambersTunnel liningRebarMechanical engineering

The invention provides a method of constructing a shallow tunnel underground passage variable-cross section cross mid-partition wall. The method is characterized by comprising the following steps of 1) dividing a first cross section of a passage into a plurality of guide holes along a tunneling direction; 2) finishing primary supporting for the first cross section to the third cross section by the CRD method; 3) dividing a fourth cross section into a plurality of guide holes; 4) respectively replacing the supporting of each temporary inverted arch surface of the upper layer, the middle layer and the lower layer among the second cross section to the fourth cross section with new temporary inverted arches; 5) paving and firmly welding longitudinal reinforcing steel bars on the third new temporary inverted arch surface according to requirements; 6) finishing underground passage primary supporting for the fourth cross section to the fifth cross section by the CRD method by taking the two new temporary inverted arch surfaces of the middle layer and the lower layer as construction walking passages; and 7) detaching the temporary inverted arch supports section by section, and meanwhile lining the underground passage for the second time section by section, so that the main body structure is formed. Due to the fact that the procedure conversion of variable-cross section passage support change is adopted, the CRD method can be used for continuously operation according to the requirements all the way, the cost can be saved, and the efficiency is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

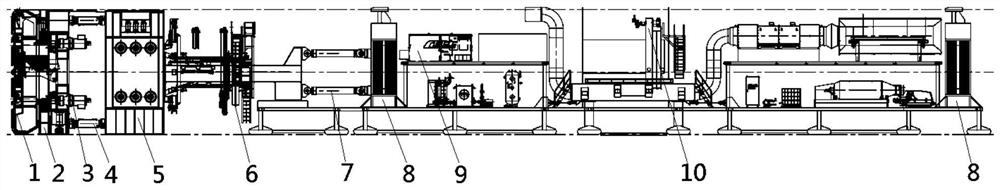

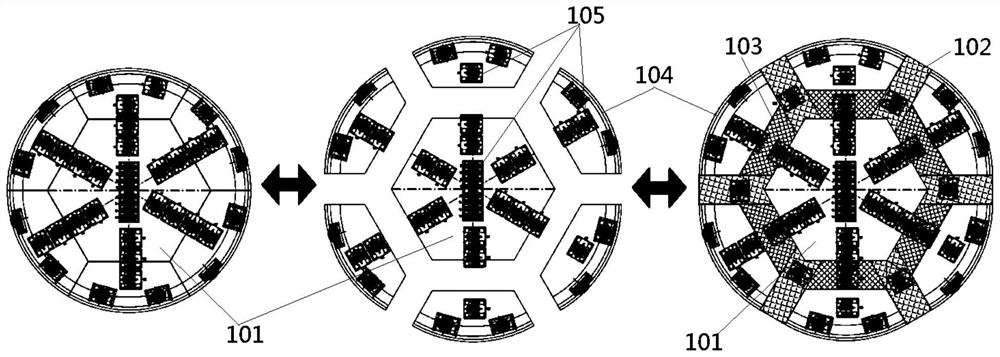

Inclined shaft TBM suitable for small curve turning

PendingCN111663947AGuaranteed stabilityRealize the control of the direction of excavationTunnelsMachineControl theory

The invention discloses an inclined shaft TBM suitable for small curve turning. The inclined shaft TBM suitable for small curve turning comprises a variable-diameter cutterhead, a variable-diameter front shield and a main propelling mechanism, and the cutterhead is used for excavating a tunnel; the front shield is connected with the cutterhead, and the front shield can abut against the wall of thetunnel; and the main propelling mechanism is connected with the front shield and used for driving the front shield to move so as to control the tunneling direction of the cutterhead. According to theinclined shaft TBM suitable for small-curve turning, the main propelling mechanism drives the front shield to move, so that the tunneling direction of the cutterhead can be adjusted to meet the turning requirement when the tunneling direction of the tunnel needs to be changed, and meanwhile, the inclined shaft TBM can adapt to ultra-small-radius turning through reducing operation of the cutterhead and the front shield. Compared with a traditional heading machine which cannot carry out raise boring tunnel construction through a heading machine technology, the inclined shaft TBM suitable for small curve turning can adapt to heading construction of variable-diameter inclined shafts, small turning inclined shafts, forward inclined shafts and reverse inclined shafts.

Owner:CHINA RAILWAY CONSTR HEAVY IND

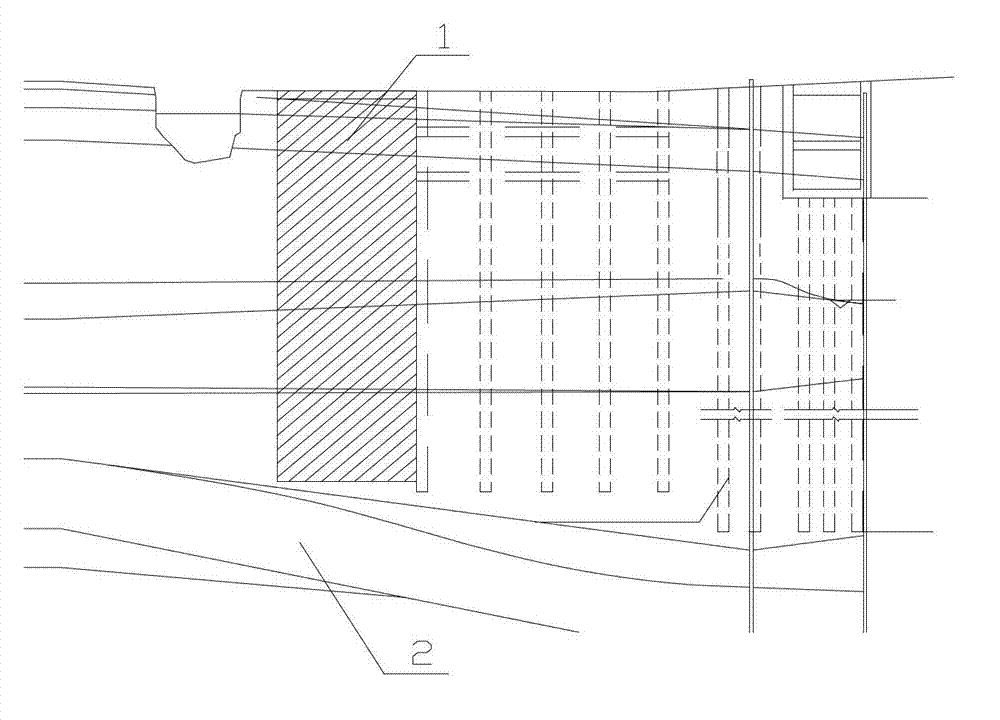

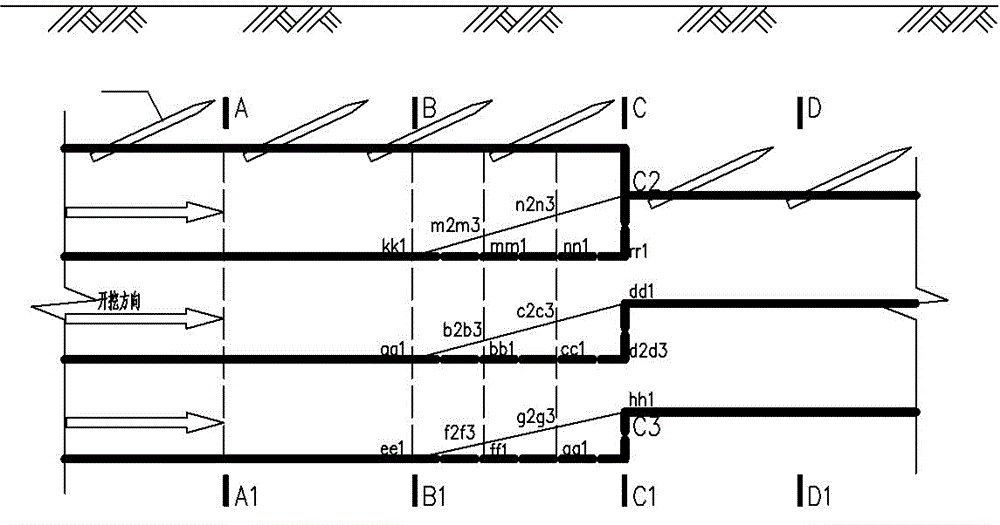

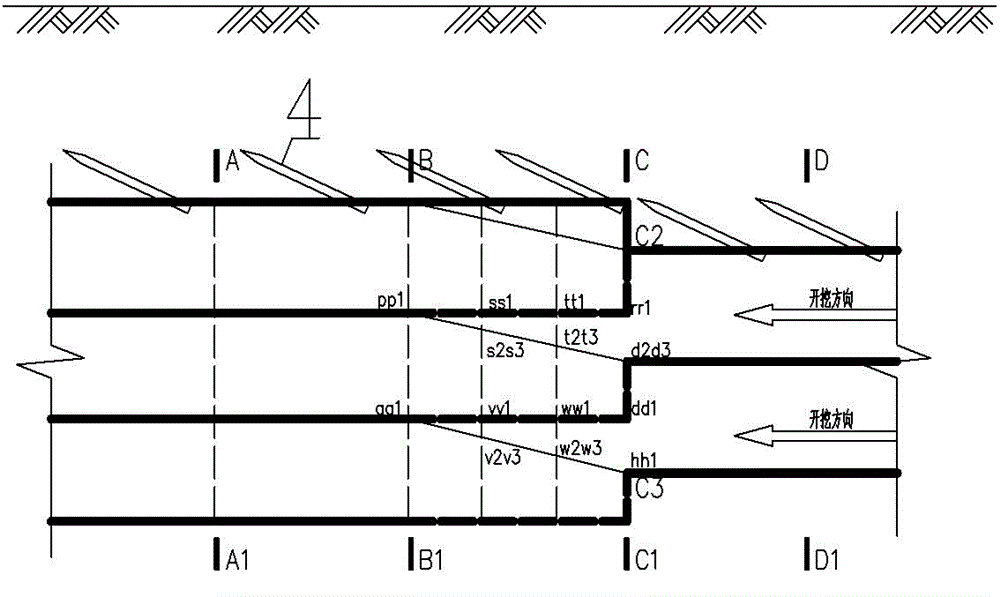

Methods for arranging and supporting wall-expanded gas extraction drill sites

InactiveCN102587962AImprove integrityAvoid loose damageUnderground chambersGas removalEconomic benefitsEngineering

The invention discloses methods for arranging and supporting wall-expanded gas extraction drill sites. A plurality of wedge-shaped walking drill sites are arranged in two walls of a stoping tunnel in a staggering manner; the spans of the walking drill sites are gradually increased along the tunneling direction of the stoping tunnel; 1 to 3 rows of extraction drilled holes are formed in the fractured zone of the local coal layer or the coal layers adjacent to a top plate and a base plate of the inner wall of each walking drill site; a hole protection tube is arranged at the orifice of each extraction drilled hole, and a gas extraction tube connected with each hole protection tube is arranged; and the spans of the drill sites are gradually increased along the tunneling direction of the stoping tunnel and distributed in the two walls of the stoping tunnel in a staggered walking manner. Due to the wedge-shaped structure, an enough working space is supplied to drilling machinery and gas extraction equipment; furthermore, the drill site construction amount is reduced greatly, and the construction difficulty is reduced; due to the staggered walking distribution and the wedge-shaped structure, the span is reduced greatly, and supporting and maintenance are facilitated; and moreover, extraction and tunneling of the stoping tunnel can be performed at the same time, the tunneling efficiency is improved, and relatively high economic benefit is achieved.

Owner:CHINA UNIV OF MINING & TECH

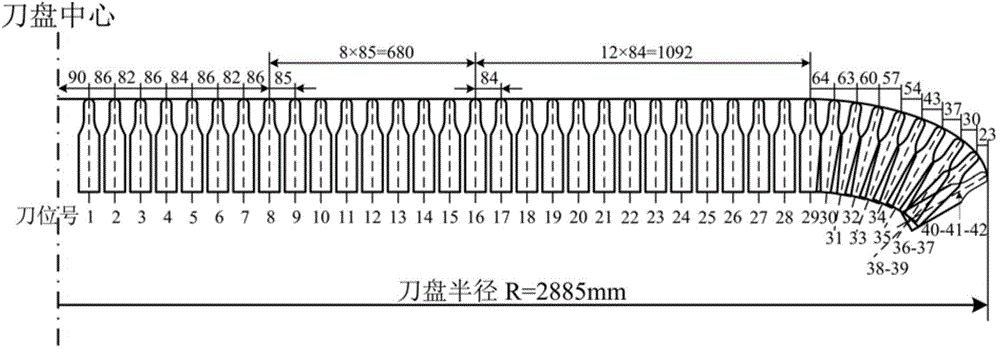

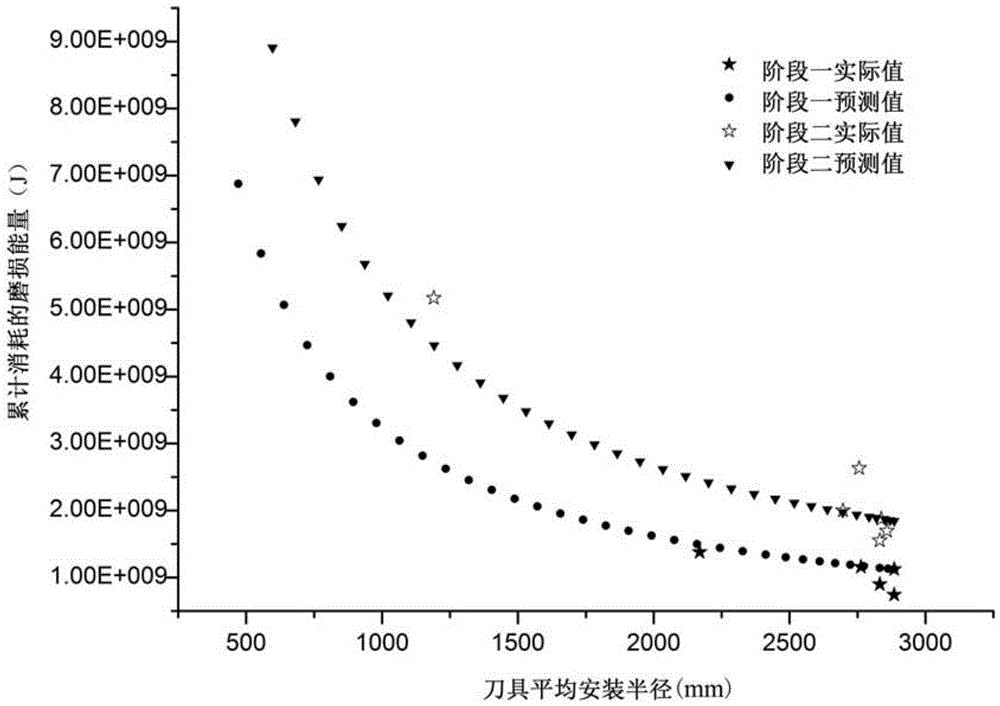

Method for real-time estimation of tool abrasion condition of cutter head tunneling system of hard rock tunnel boring machine

InactiveCN104863604APredict wear in real timeImprove the state of stressTunnelsInformaticsTunnel boring machineRock tunnel

The invention discloses a method for real-time estimation of the tool abrasion condition of a cutter head tunneling system of a hard rock tunnel boring machine (TBM), and relates to tunneling equipment construction. The method comprises the following steps: determining the change rule of energy consumption of the cutter head tunneling system in the cutter head rotation direction in the tunneling process of the hard rock TBM along with the energy consumption in the tunneling direction, determining the tool abrasion energy consumption value of the cutter head tunneling system of the hard rock TBM, determining the accumulative consumed tool abrasion energy consumption value of the cutter head tunneling system of the hard rock TBM, determining the relation of the total tool abrasion energy consumption of the cutter head tunneling system of the hard rock TBM and the total tool abrasion size of the cutter head of the hard rock TBM, judging the abrasion conditions of tools on different mounting positions of the cutter head of the hard rock TBM to determine the tools needed to be replaced, and finally realizing real-time estimation of the tool abrasion replacement of the cutter head system of the hard rock TBM. Through the adoption of the method, the defects in the prior art that the tool abrasion condition of the cutter head tunneling system of the hard rock TBM as well as real-time estimation of new to-be-replaced tools cannot be effectively reflected in real time are overcome.

Owner:TIANJIN UNIV +1

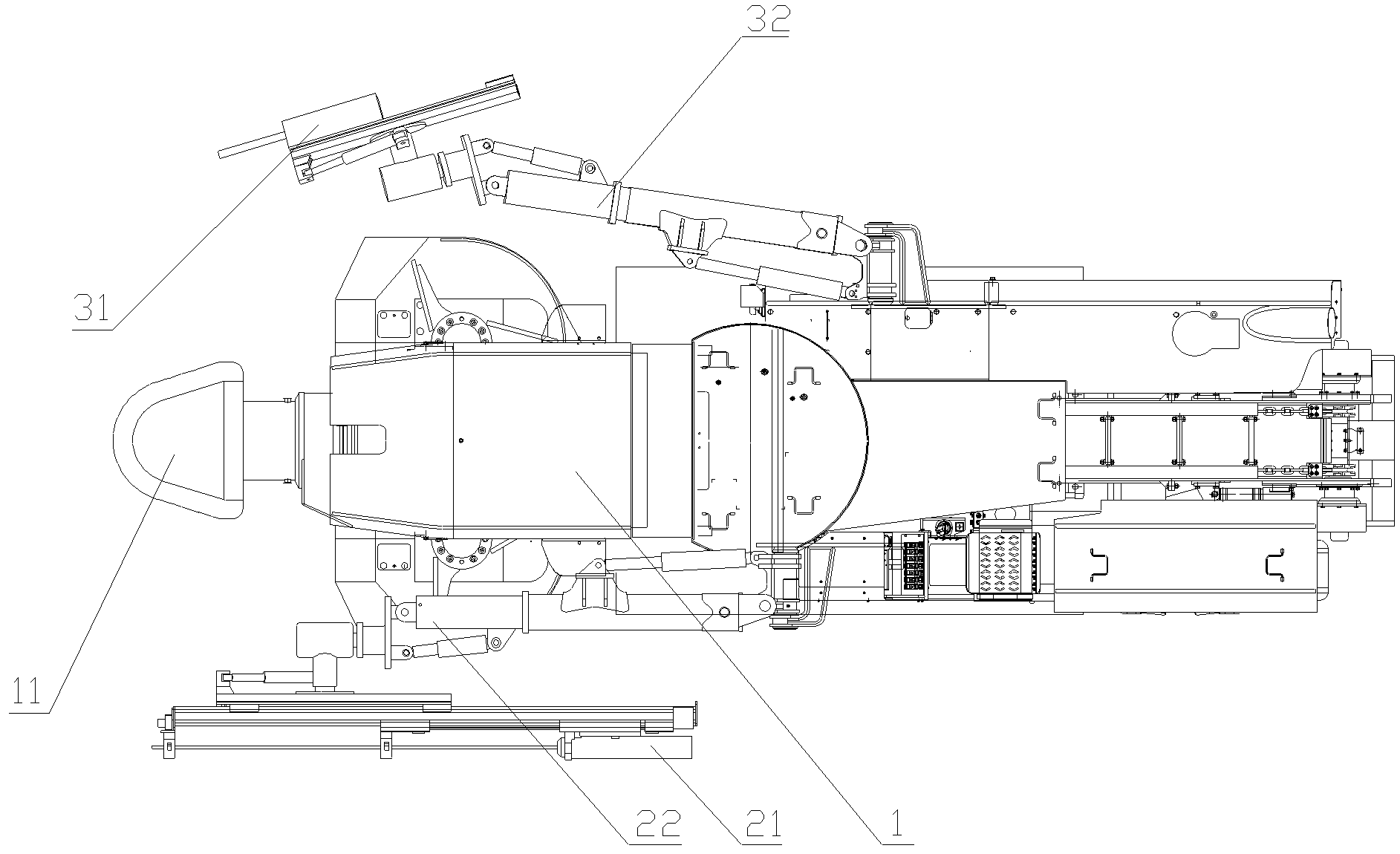

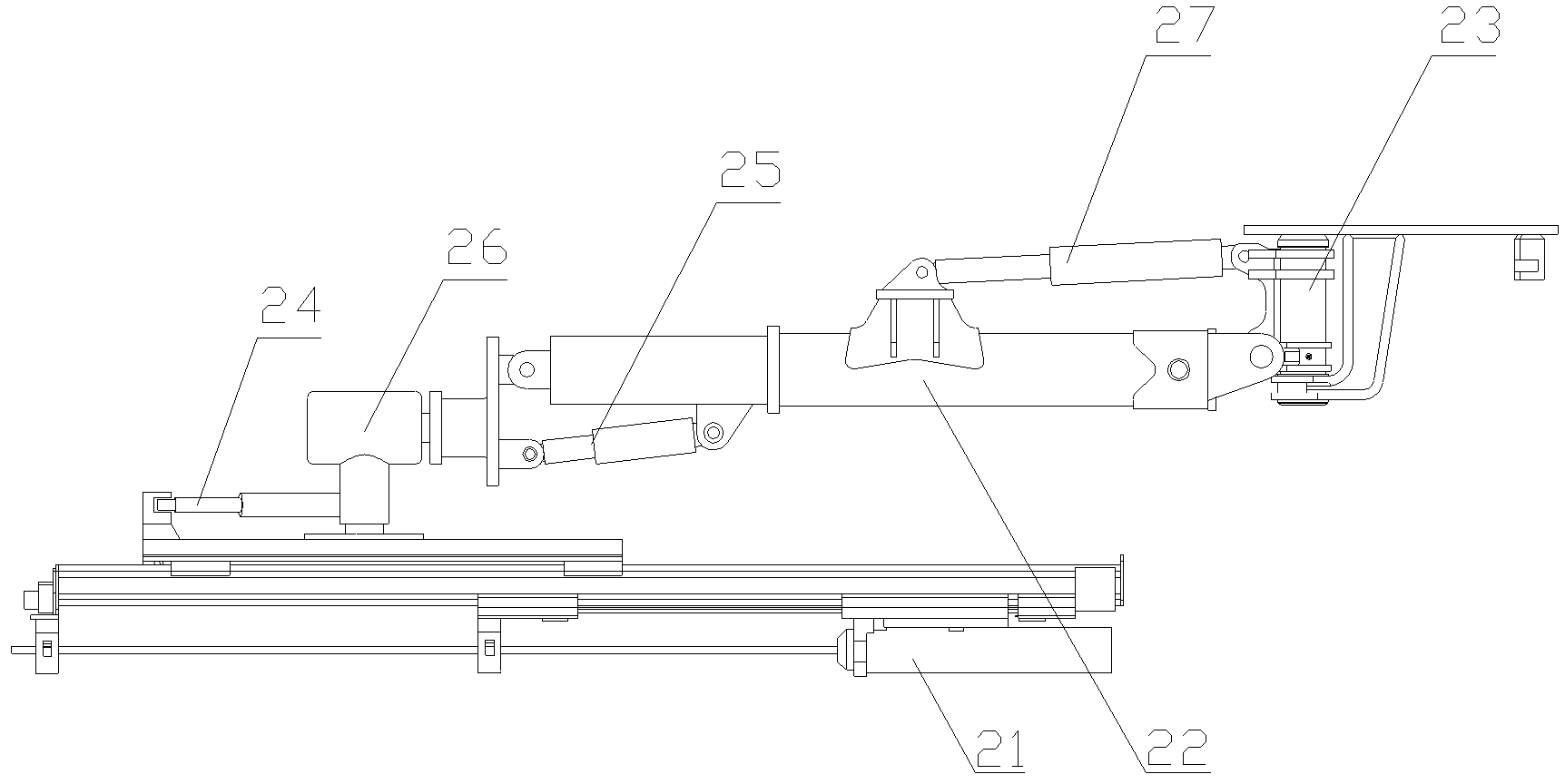

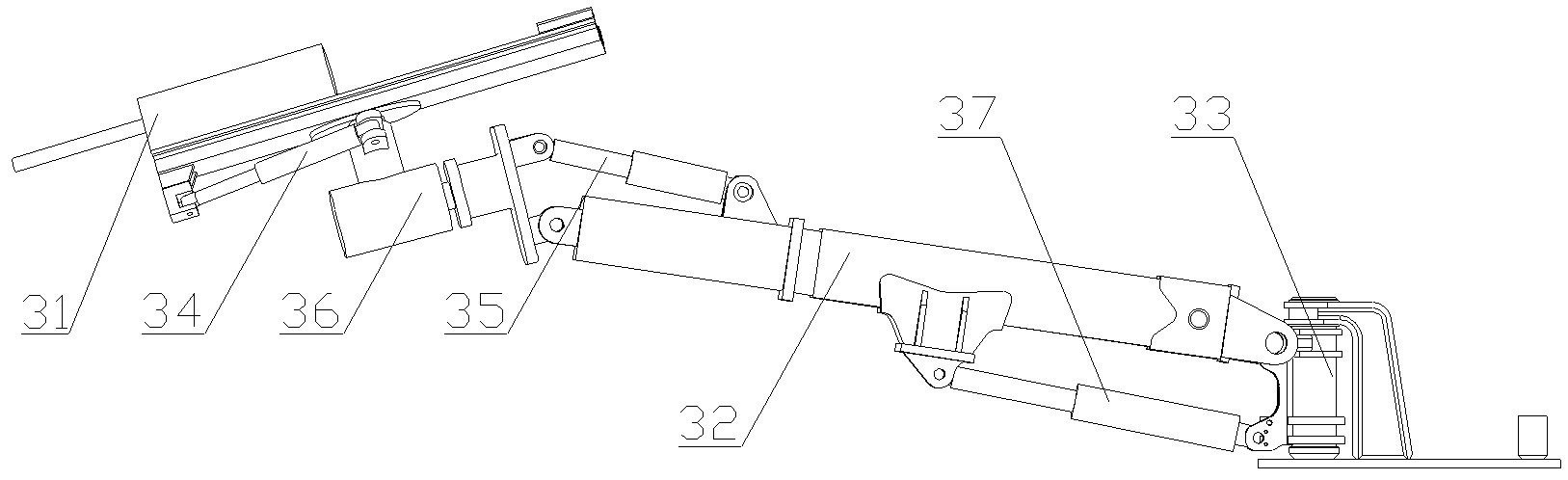

Development machine

ActiveCN102305068AEnsure safetyImprove securityDisloding machinesDerricks/mastsEngineeringRock tunnel

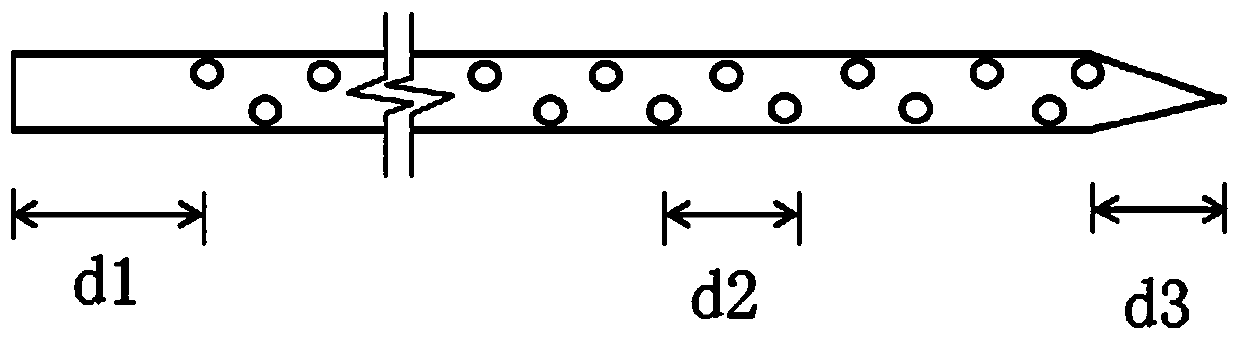

The invention discloses a development machine. The development machine comprises a tunneling main body (1), wherein an auxiliary drilling device is arranged on the tunneling main body (1), and comprises a drilling machine (21) and a first mounting rack which is connected with the tunneling main body (1); and the drilling machine (21) is arranged on the mounting rack, and the drilling direction of the drilling machine (21) is the same as the tunneling direction of the development machine. The development machine also comprises a first driving device for driving the drilling machine (21) to drill. Before the development machine drives a hard rock formation, the drilling machine can be used for drilling the rock formation to destroy the organization structure of the rock formation, so a rock formation blasting mode of the prior art before tunneling is replaced, which is favorable for guaranteeing the safety of equipment and operation staffs and improves the safety of tunneling operation; and besides, the development machine can be applied to hard-rock tunnels in which blasting cannot be implemented, and has a wide application range.

Owner:益阳市科技成果转化服务中心 +1

Roadway roof fracturing and outburst prevention method

ActiveCN110318674AImprove tunneling efficiencyImprove coal mining efficiencyUnderground miningFluid removalButt jointFracturing fluid

The invention discloses a roadway roof fracturing and outburst prevention method. The roadway roof fracturing and outburst prevention method is applicable to outburst prevention of deep high-gas and low-permeability coal seam roadways. According to the roadway roof fracturing and outburst prevention method, a horizontal well is drilled on the ground in the direction consistent with the roadway tunneling direction, the well path trajectory is controlled in a top plate within a certain range away from the top limit of a reserved coal pillar coal seam, and the horizontal well is in butt joint with a discharging and exploiting straight well; a perforation technology is adopted, downward perforation is carried out at fixed points in a segmented manner in the horizontal section of the horizontalwell, and perforated holes do not communicate with the reserved coal pillar coal seam; then, supercritical CO2 serves as a fracturing fluid, crushed particles of a top plate of the reserved coal pillar coal seam serve as supporting agents, large-displacement cross-interface segmented fracturing is carried out on the reserved coal pillar coal seam, and cracks are expanded on the left side and theright side in the direction perpendicular to the horizontal section of the horizontal well by 20-30m respectively, so that the high-efficiency fracturing and outburst prevention of a to-be-dug transportation flat roadway and a to-be-dug air return roadway can be realized at one time, the roadway tunneling speed can be greatly improved, defects of traditional hydraulic fracturing are avoided, the increase of the yield of coal seam gas is facilitated, and a plurality of effects are realized through one action.

Owner:TAIYUAN UNIV OF TECH

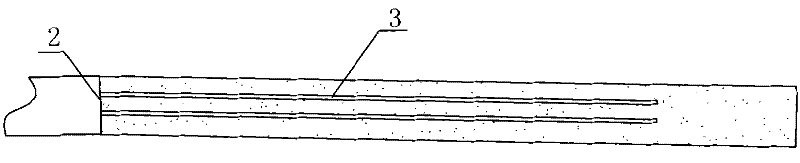

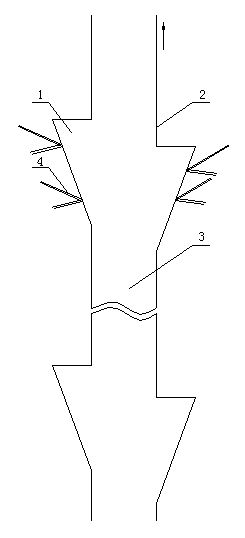

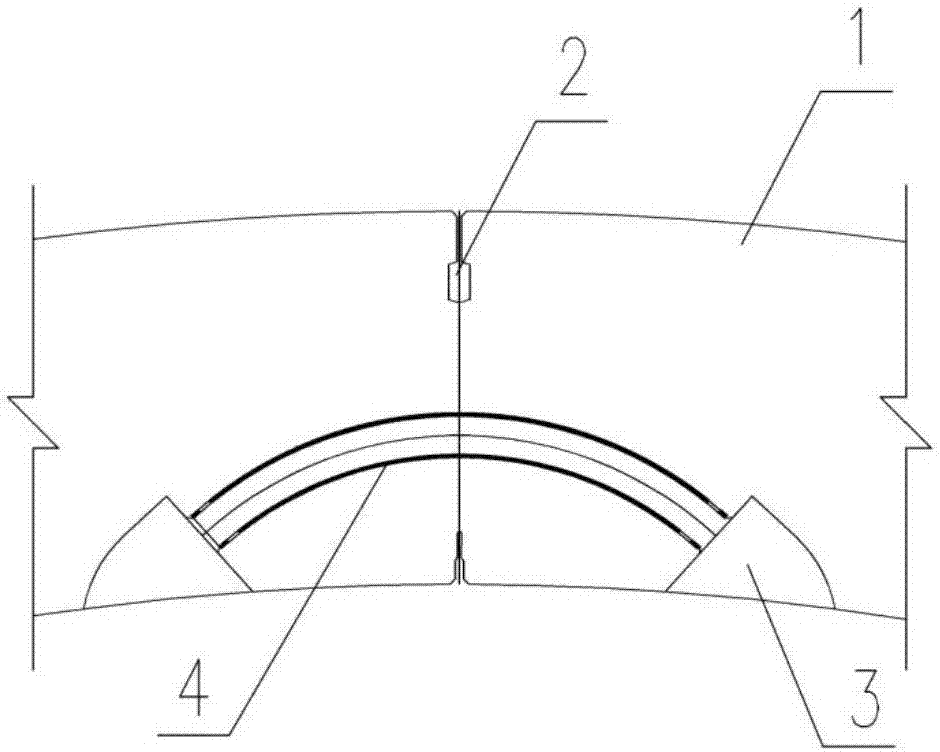

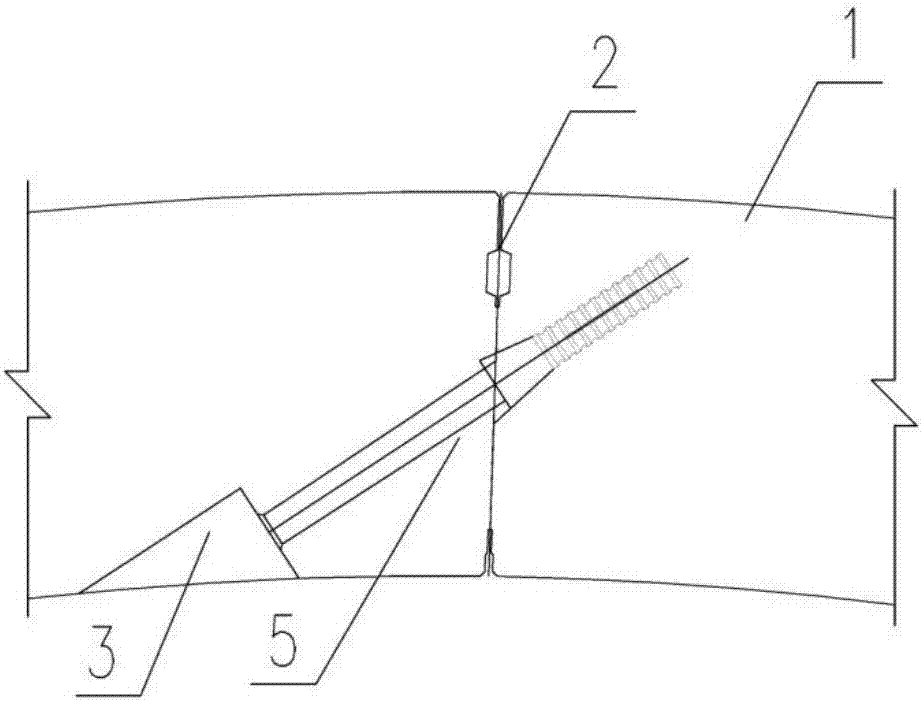

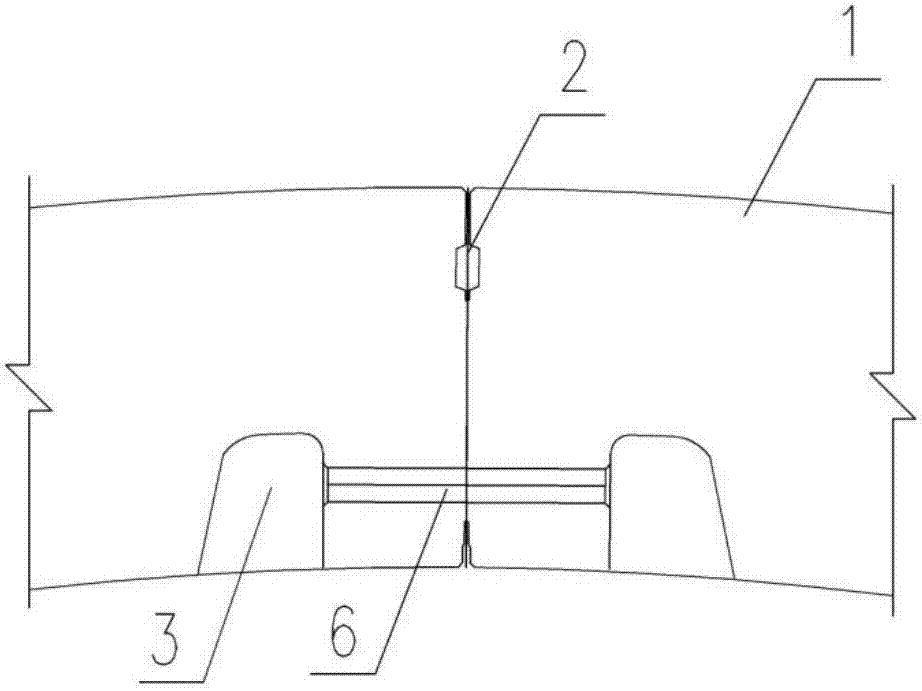

Digging guiding device of model shielding machine

InactiveCN101303815AObserve intuitivelyEasy to observeEducational modelsTunnelsWhiteboardEngineering

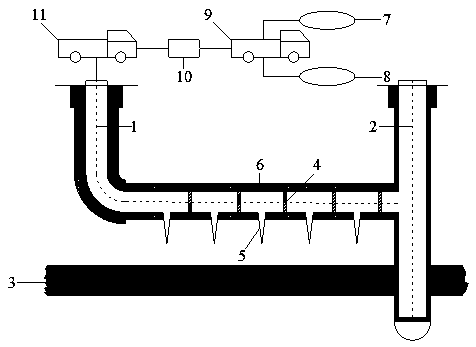

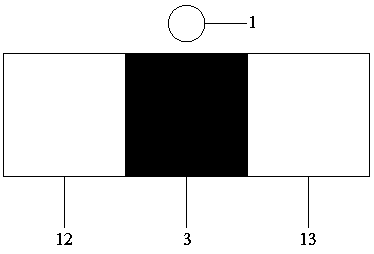

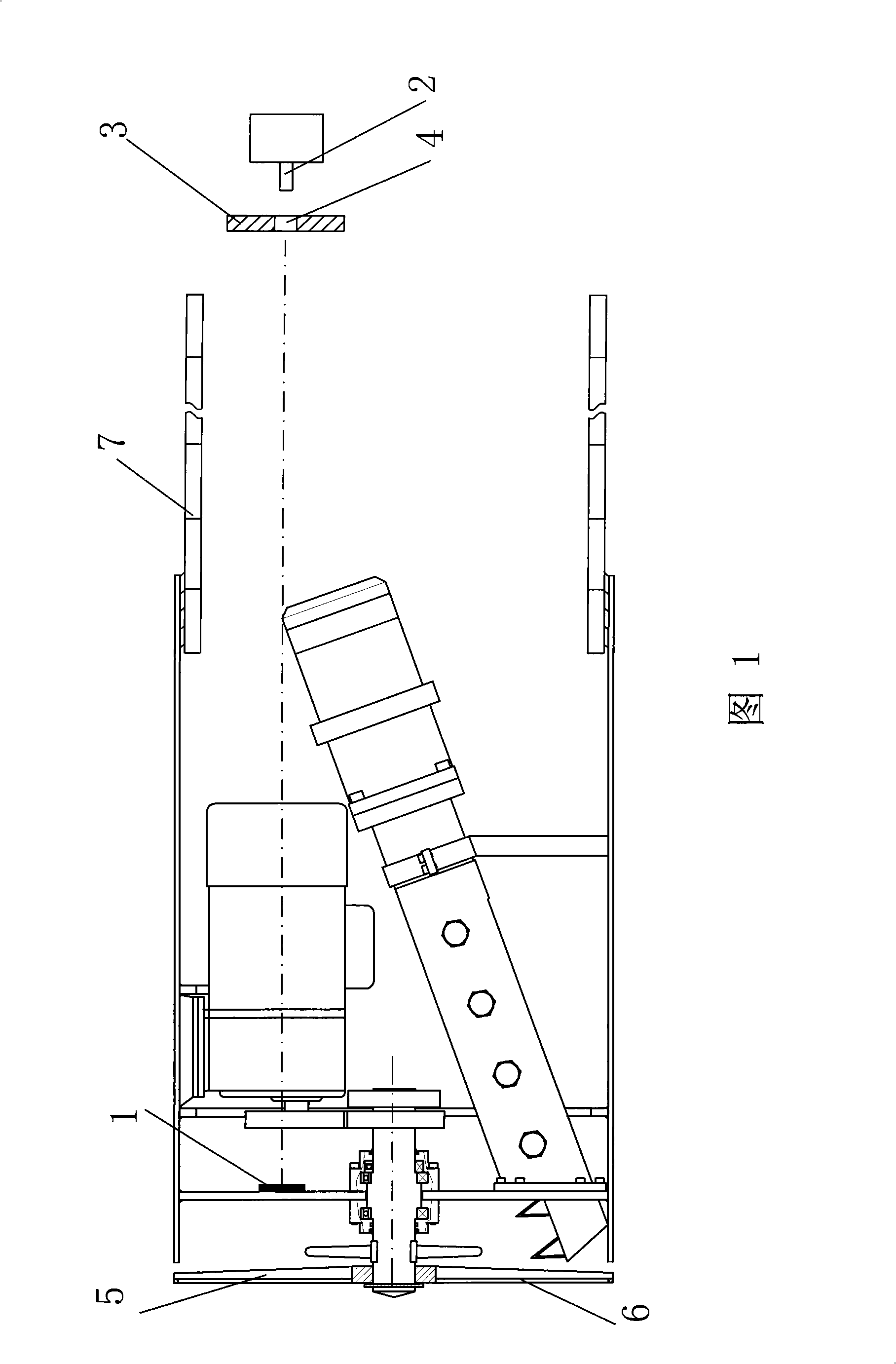

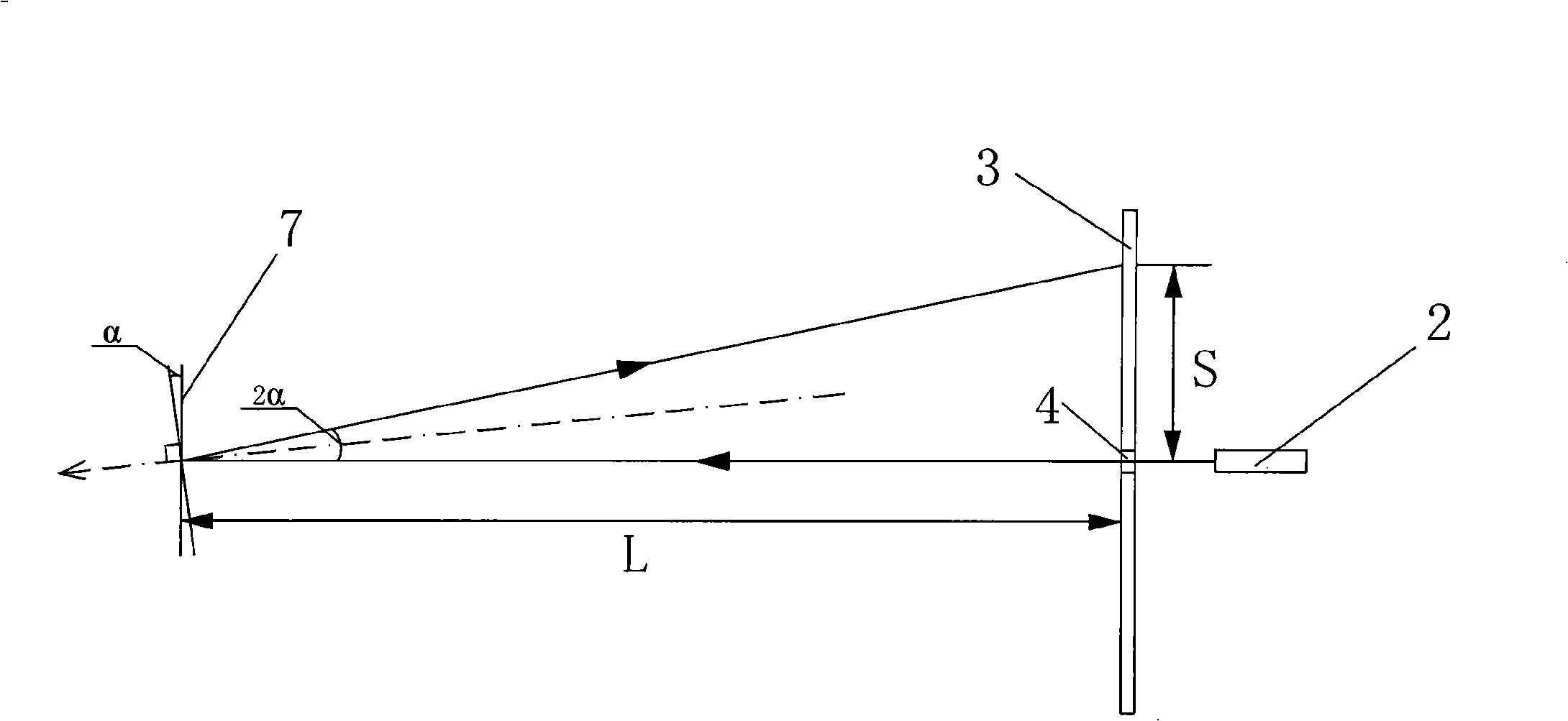

The invention relates to a tunneling guidance device of a model shield machine, which comprises a reflector (1) which is fixed on in the model shield machine body and is provided with a backward mirror surface, and the mirror surface of the reflector (1) is vertical to the axle of the model shield machine; a laser source (2) is fixed behind a tunnel (7) dug by the model shield machine, a white board (3) is arranged on the tunnel between the laser source (2) and the reflector (1), and the white board (3) is provided with a counterpoint hole (4). The connecting line between the laser source (2) and the counterpoint hole (4) is vertical to the mirror surface of the reflector (1). The convenient and real-time observation of the advancing direction of the model shield machine can be carried out through the device, thus providing a basis for the adjustment along the tunneling direction; the tunneling guidance device of a model shield machine also has the advantages of simple structure and convenient use.

Owner:SOUTHWEST JIAOTONG UNIV

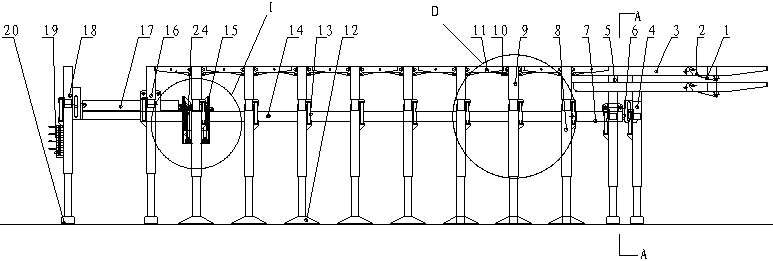

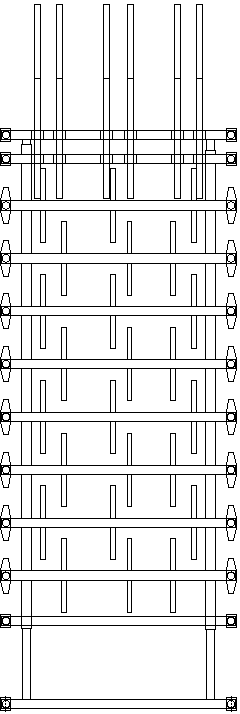

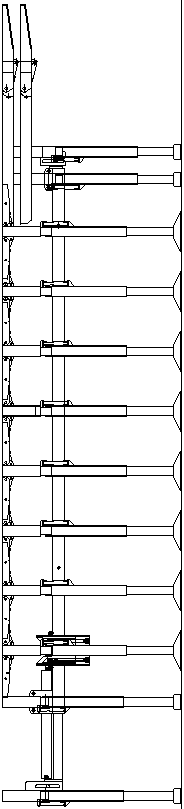

Circulating tunneling immediate support device and method

InactiveCN103993898AFit tightlyAchieve the purpose of helpingMine roof supportsHydraulic cylinderMechanical engineering

The invention discloses a circulating tunneling immediate support device and method. The circulating tunneling immediate support device comprises a walking mechanism, a sliding mechanism and an independent supporting mechanism; the independent supporting mechanism comprises supporting units arranged in the roadway tunneling direction from front to back; a longitudinal forepoling bar and a protection net hydraulic cylinder are arranged in front of the first supporting unit and connected with the first supporting unit, and the lower end of the longitudinal forepoling bar is connected with a cross forepoling bar and a hydraulic supporting column; the last supporting unit is provided with a frame moving seat, a rear hinging cross beam and a corresponding hydraulic supporting column are arranged behind the tail supporting unit, and a sliding hydraulic oil cylinder is arranged between the frame moving seat and the rear hinging cross beam; each supporting unit comprises a supporting hinging cross beam, supporting stand columns are arranged under the supporting hinging cross beam respectively, and inner sliding rods and sliding ways penetrating through the first supporting unit are arranged in the roadway tunneling direction; each supporting unit is provided with parallel hydraulic oil cylinders. The circulating tunneling immediate support device is compact in structure, and has the advantages that work efficiency is high, and time and labor are saved; frames can be automatically moved in a marching mode.

Owner:TAIAN BAIYI MACHINERY CO LTD

Drilling and blasting construction method for mechanized full-cross-section quick excavation and ring formation of weak surrounding rock tunnel

InactiveCN109723444AImprove ergonomicsReduce the time for repetitive operations in the processTunnelsDrilling machines and methodsRock tunnelGeophysics

The invention discloses a drilling and blasting construction method for mechanized full-cross-section quick excavation and ring formation of a weak surrounding rock tunnel. The construction method comprises the following steps of 1, advance pre-reinforcement of a tunnel face; 2, excavation of the tunnel face, wherein the tunnel face is subjected to mechanized drilling, powder charging and blastingexcavation, during drilling, except an inverted arch, the tunnel face is drilled in a mode of straight hole blasting, the inverted arch is drilled through a technology of postposition-free inverted arch primary support and bottom hole and slant hole blasting, bottom hole and slant hole drilling is downwards conducted in the tunneling direction, the mode of combining long and short holes is adopted, the long hole lifting height is increased, and tunnel overexcavation is controlled; outer-insertion short holes are adopted, and tunnel bottom under-excavation is controlled. Full-cross-section excavation is adopted, a cross section is subjected to one-time excavation forming, the repetitive operation time of working procedures is shortened, construction organization and management are facilitated, the labor condition is improved, and the work efficiency is high.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Safe pointing and safe distance real-time monitoring system

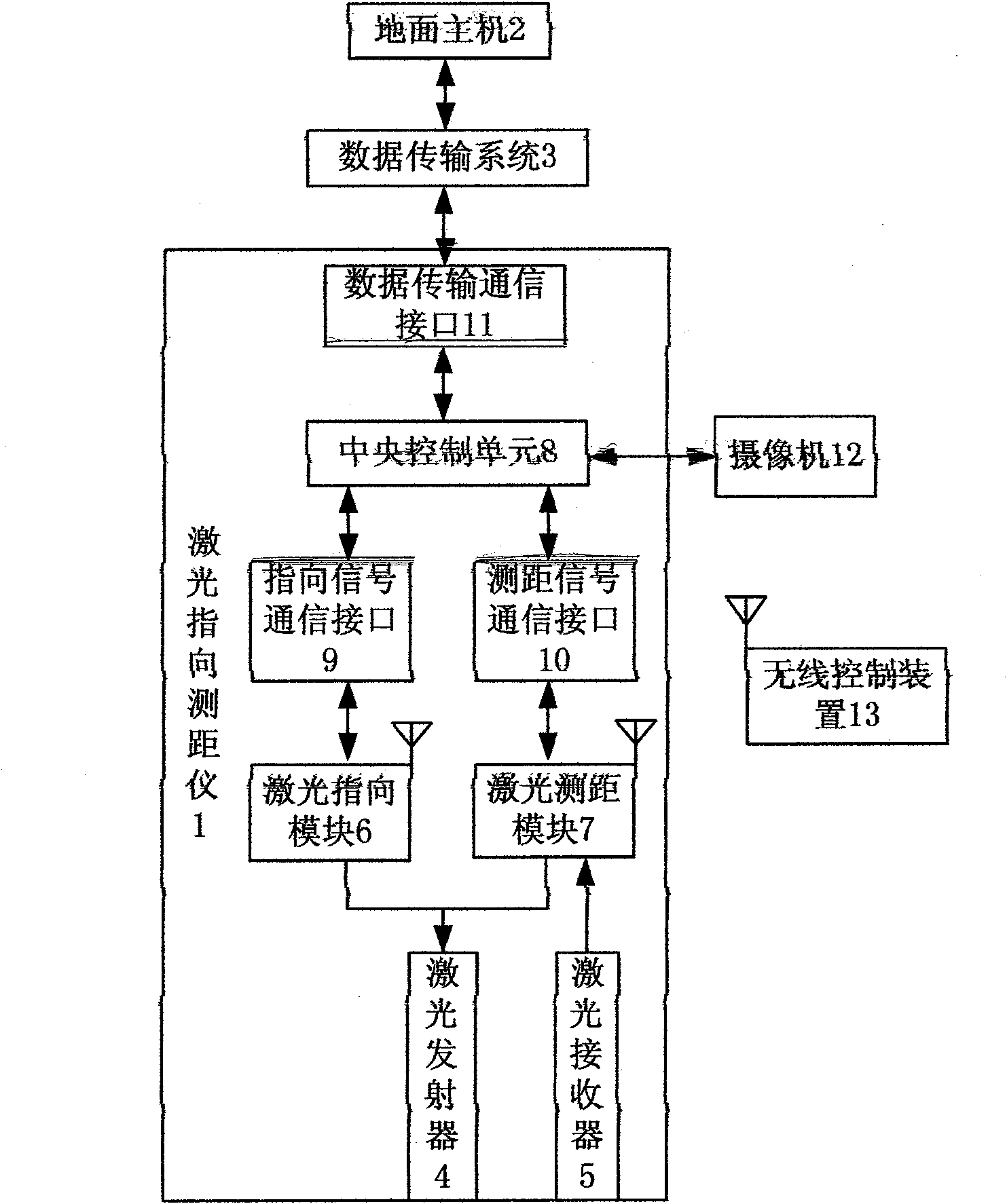

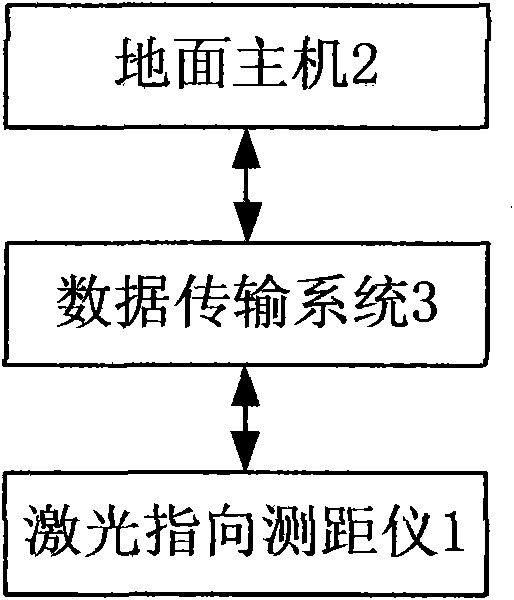

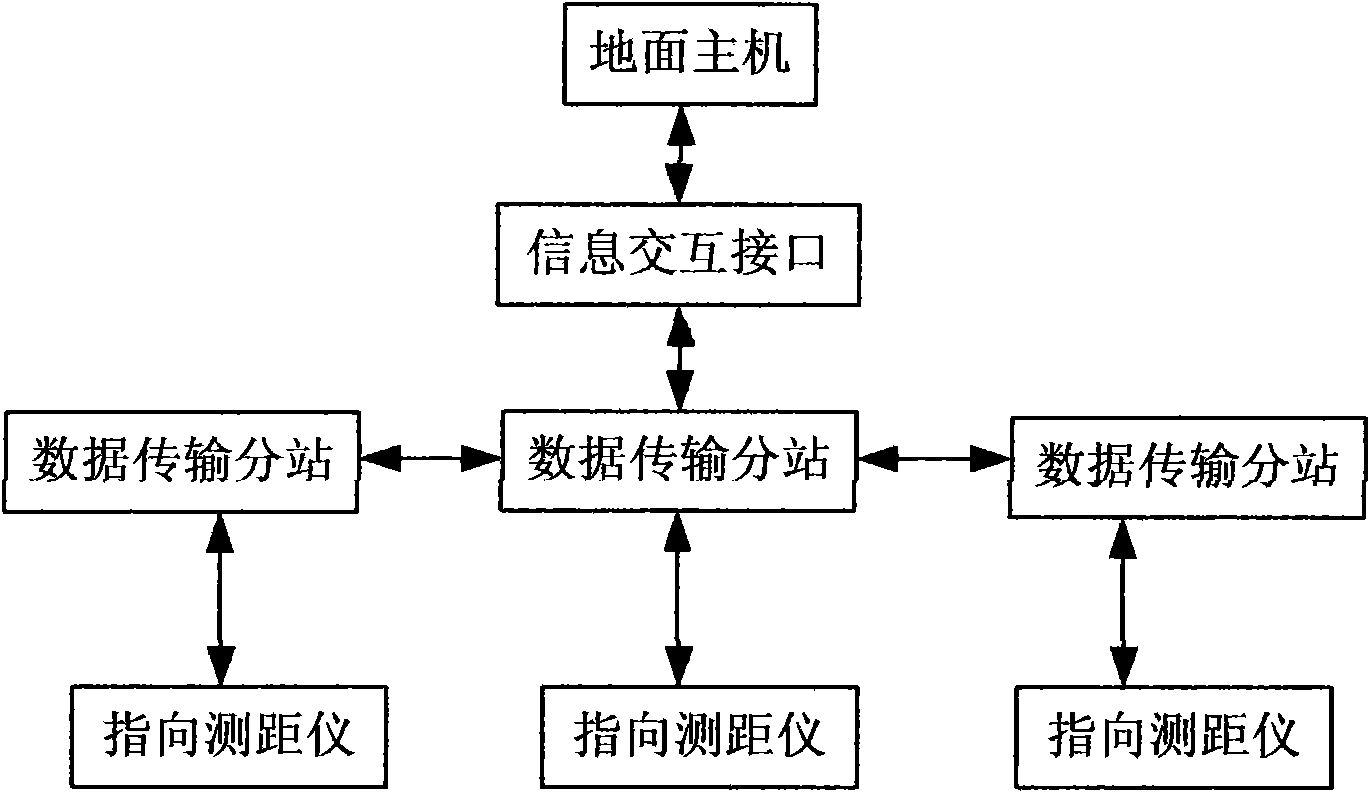

InactiveCN101915103AEnsure safe productionSave human effortSurveying instrumentsTunnelsLaser transmitterWireless control

The invention relates to a safe pointing and safe distance real-time monitoring system which comprises a laser pointing distance measuring instrument, a ground host computer and a data transmission system, wherein the data transmission system is used for the communication between the laser pointing distance measuring instrument and the ground host computer. The laser pointing distance measuring instrument comprises a laser transmitter, a laser receiver, a laser pointing module, a laser distance measuring module, a central control unit, a communication module, a time control module and a power supply module, wherein the power supply module is used for supplying power for all the parts. The system is also provided with a video camera and a wireless control device. The invention can realize the automatic pointing in a tunneling direction and the automatic real-time monitoring of a tunneling distance, not only can save the manpower, but also can improve the production efficiency, and can realize the combined monitoring of data and images, the wireless control of a working spot and the remote control working of ground managers.

Owner:BEIJING LONGDE SHIDAI TECH SERVICE

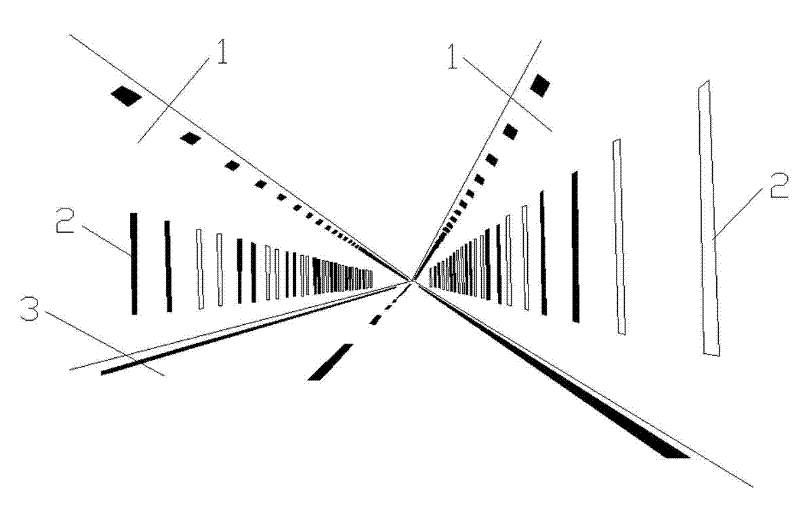

Tunnel grating system for changing speed perception of driver and method for controlling same

The invention relates to a tunnel grating system for changing the speed perception of a driver and a method for controlling the same. The tunnel grating system comprises a plurality of LED (light-emitting diode) lamps and a controller; the LED lamps are arranged on walls on two sides of a tunnel and arrayed along the tunnel direction; the controller is used for controlling the turning-on and off of the LED lamps; the LED lamps are in strip shapes; and the space between adjacent LED lamps is 1-5m. The LED lamps arranged on the same wall on one side are controlled to flash alternatively at an interval of 60-240ms with one LED lamp being bright and one LED lamp being dark alternatively or continuous N LED lamps being bright and continuous N LED lamps being dark alternatively, wherein the N is a positive integer ranging from 2 to 4. The speed perception of the driver can be affected by changing the visual perception of the driver so that the speed of the vehicle can be controlled.

Owner:WUHAN UNIV OF TECH

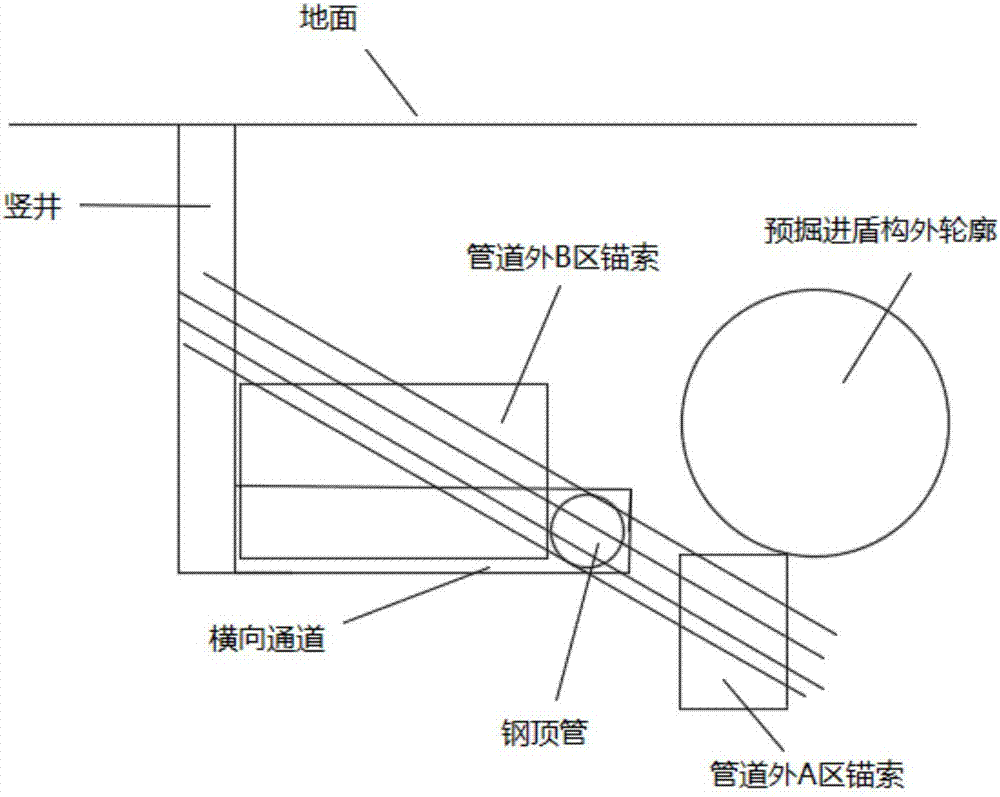

Construction technology for treating anchor cables in anchor cable obstacle area penetrated by shield tunneling machine

ActiveCN107461200AImprove securityShort construction periodTunnelsShield tunnelingTunneling direction

The invention discloses a construction technology for treating anchor cables in an anchor cable obstacle area penetrated by a shield tunneling machine . The construction technology comprises the following steps that an anchor cable concentration zone affecting shield tunneling is determined according to a shield pre-tunneling position and the position of an existing anchor cable in a construction drawing, a vertical shaft is excavated on the outer side of a shield pre-tunneling area, a transverse passageway is constructed in the vertical shaft so as to reach the concentration zone of the existing anchor cable affecting shield tunneling, a steel jacking pipe of a device which is mounted in advance for treating anchor cables conducts jacking in the shield pre-tunneling direction in the transverse passageway, the anchor cable appearing at a tunnel face of the steel jacking pipe is cut down, and a rectangular opening is cut out of the steel jacking pipe so that an anchor cable pulling device can pull out the anchor cable affecting shield tunneling outside the pipe. According to the construction technology, the steel jacking pipe of the pre-mounted device for treating the anchor cables is adopted to pull out the anchor cables, the anchor cable affecting the shield construction area in the pipe and the anchor cable affecting shield tunneling out of the pipe are pulled out, a lining can be formed directly with the help of the steel jacking pipe, and a safe space is formed in the treating process of the anchor cables; and the safety is high, the construction period is short, and the construction cost is saved.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

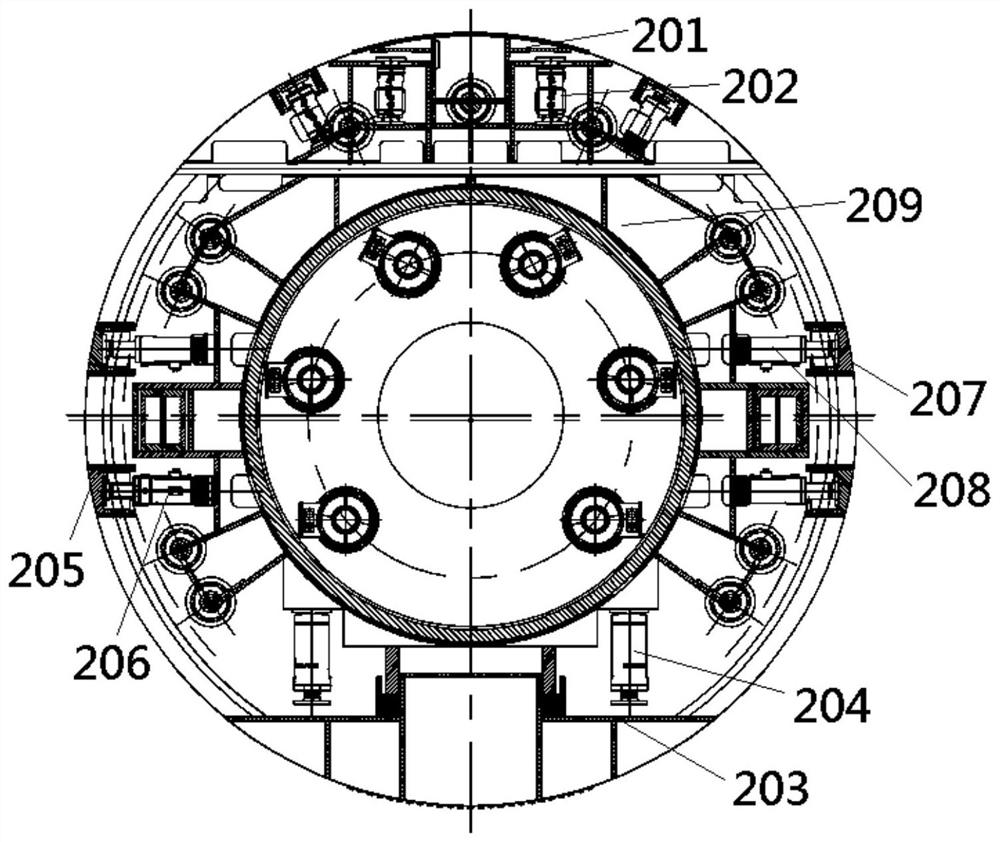

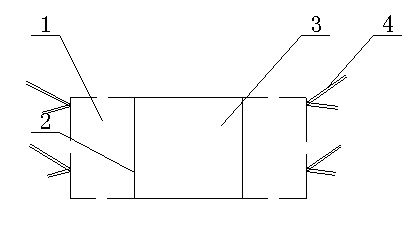

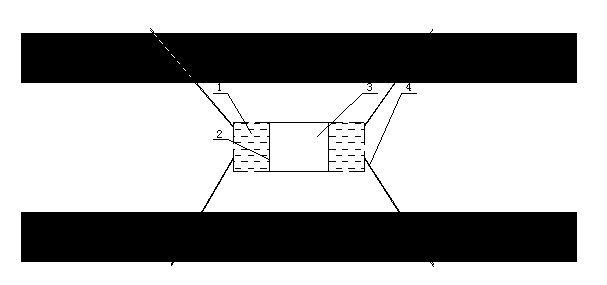

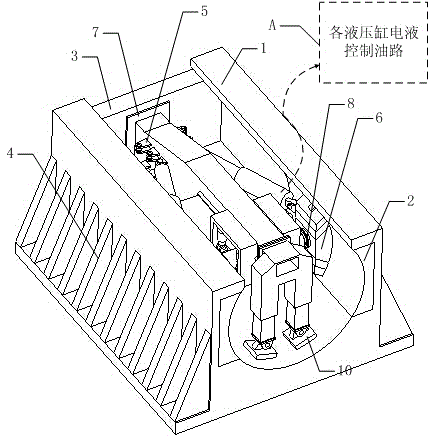

Multi-factor simulation test device for TBM gripper shoes bracing tightly against surrounding rock

The invention discloses a multi-factor simulation test device for TBM gripper shoes bracing tightly against surrounding rock. A containing box comprises a containing box shell, surrounding rock side wall simulation blocks and a front baffle of the containing box; a TBM supporting and pushing mechanism comprises a pushing hydraulic cylinder and a main beam hinged base, gripper shoes, a front connecting plate of the main beam, a gripper shoes hydraulic cylinder and a gripper shoes connecting base, four pushing hydraulic cylinders, a base of a rear supporting beam, a rear supporting beam, four saddle rack supporting hydraulic cylinders, two gripper shoes hydraulic cylinders, a saddle rack and a main beam; each hydraulic cylinder is connected with corresponding electro-hydraulic controlling oil-way. Proportional pressure reducing valve of each hydraulic cylinder controlling oil-way controls the simulation of different propulsive force, different supporting torques of the saddle rack and different supporting force of gripper shoes to be achieved; the position of the pushing hydraulic cylinder and the main beam hinged base can be changed to achieve the simulation of pushing direction and tunnelling direction in different angles; the simulation of different contact surfaces between the gripper shoes and the surrounding rock can be achieved through the detachment and installation of five parts of gripper shoes bodies. In a small space, multi-factor gripper shoes bracing tightly against surrounding rock experiment and research can be carried out with low cost.

Owner:ZHEJIANG UNIV

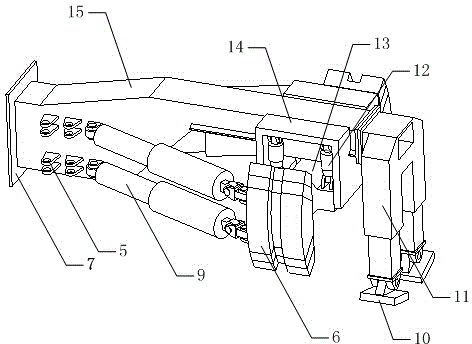

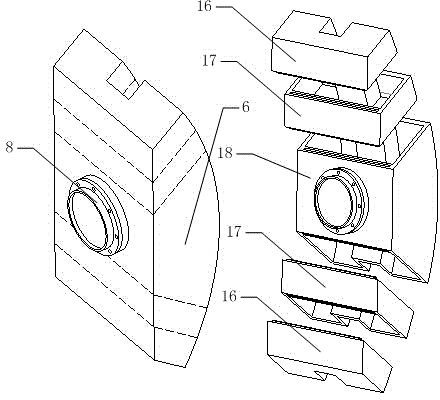

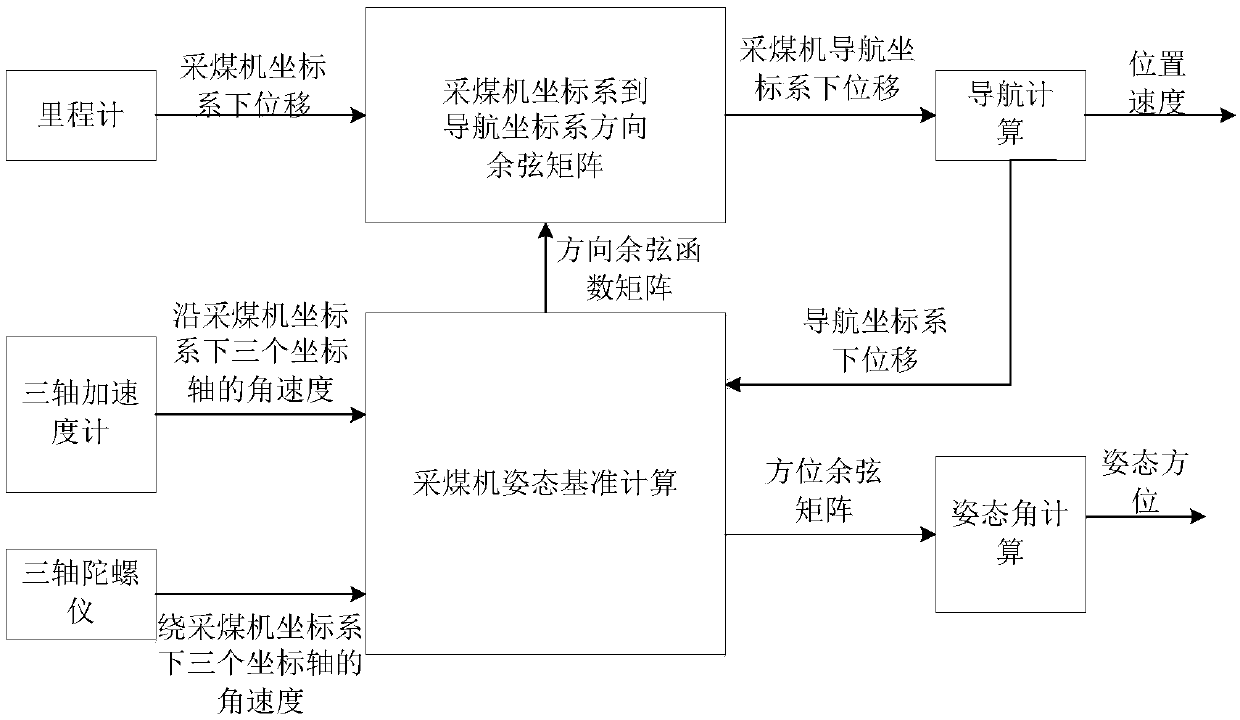

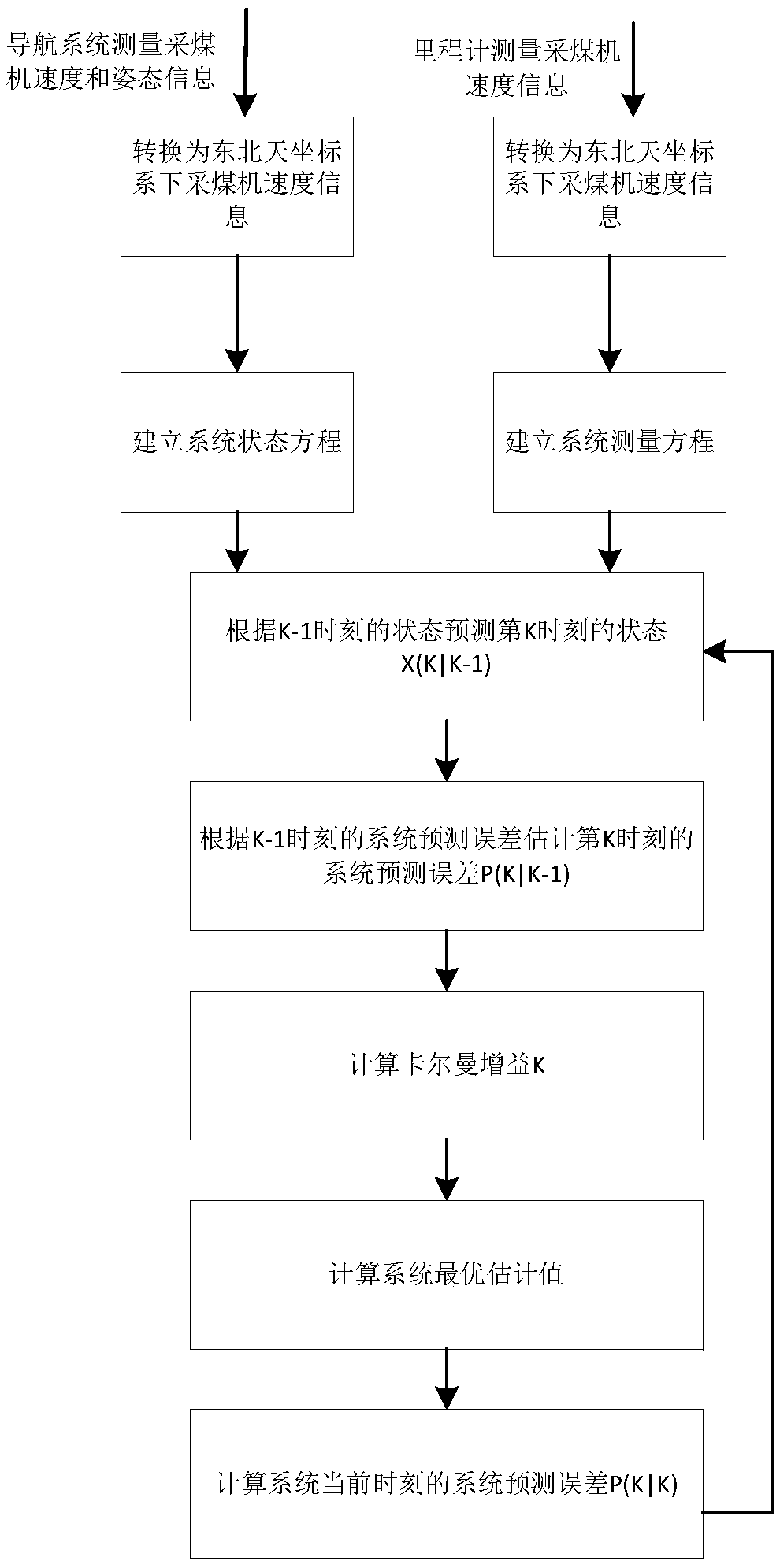

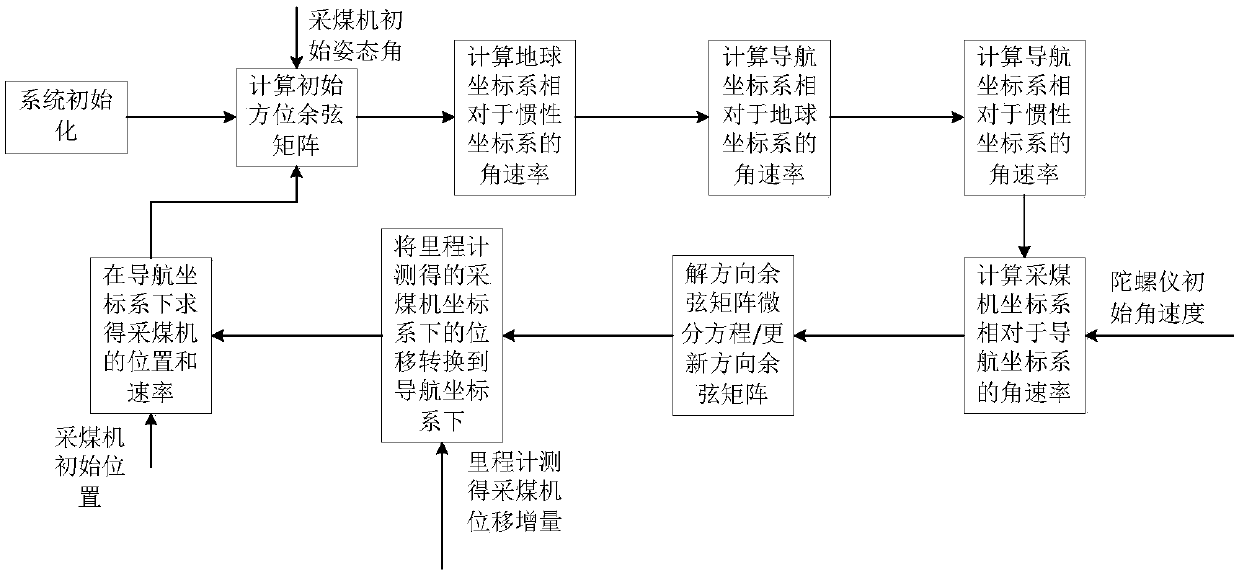

Inertial navigation positioning orientation method of continuous mining machine

PendingCN109540130AAccurate measurementSimple structureNavigation by speed/acceleration measurementsAccelerometerGyroscope

The invention provides an inertial navigation positioning orientation method of a continuous mining machine. Through the measurement of an inertial navigation system, the position information and theposture of a coal mining machine are returned to an upper computer. In this way, the straightness information of the coal mining machine in the working process is reflected in real time. An optical fiber gyroscope and an accelerometer of a strapdown inertial navigation system directly collect the rotational angular velocity and the linear acceleration of the coal mining machine in the inertial space. Through the integral operation, the movement speed, the air route, the posture and the position information of the rail coal mining machine are obtained. By means of a mileage meter installed on the walking portion of the coal mining machine, the walking speed and the walking distance of the coal mining machine are measured. Meanwhile, the information measured by the navigation system and theinformation measured by the milemeter are fused through the fast kalman fast filtering algorithm. The real-time position and the attitude information of the coal mining machine are analyzed accordingto the dead reckoning principle. After that, the tunneling direction of the coal mining machine is corrected in real time according to the real-time position and the attitude information. In this way,the coal mining machine is ensured to be driven according to a given straight line. The method is accurate in measurement result and simple in structure.

Owner:BEIHANG UNIV

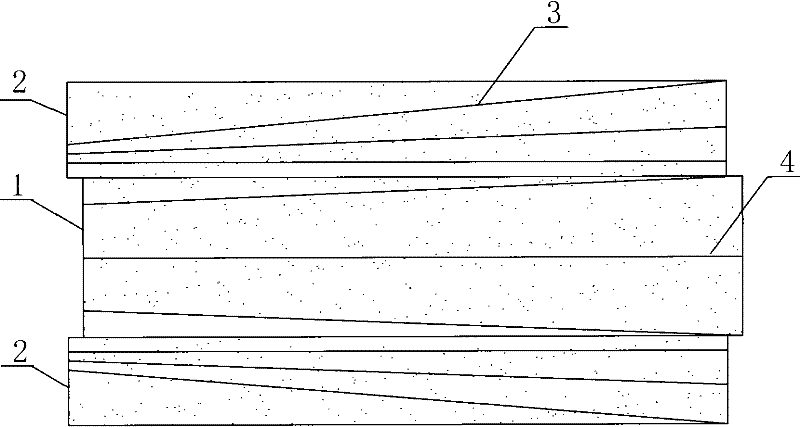

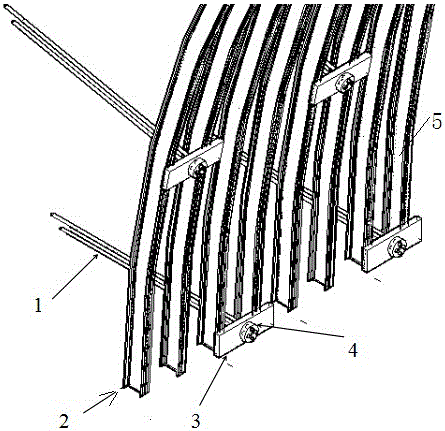

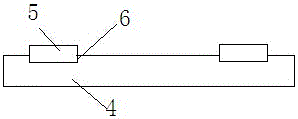

Connecting structure suitable for tunnel segment longitudinal seam

PendingCN107060816AImprove stress resistanceIncrease stiffnessUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a connecting structure suitable for a tunnel segment longitudinal seam. The connecting structure comprises a connecting tenon component and a mortise component, wherein the connecting tenon component is embedded in a to-be-assembled first segment, and the mortise is embedded in a to-be-assembled second segment; and the longitudinal seam is formed between the to-be-assembled first segment and the to-be-assembled second segment, wherein the distributed direction of the longitudinal seam is the same as the tunneling direction of a tunnel, the to-be-assembled first segment and the to-be-assembled second segment are tightly locked through the interlocking effect between the connecting tenon component in the to-be-assembled first segment and the mortise component in the to-be-assembled second segment, and connection of the first segment and the second segment is achieved. According to the connecting structure suitable for the tunnel segment longitudinal seam, hand holes of seam bolts can be reduced simultaneously under the condition that the rigidity of the seam is ensured, concrete force at the seam position is improved effectively, and the risk of damage of concrete at the seam position due to local compression is lowered.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

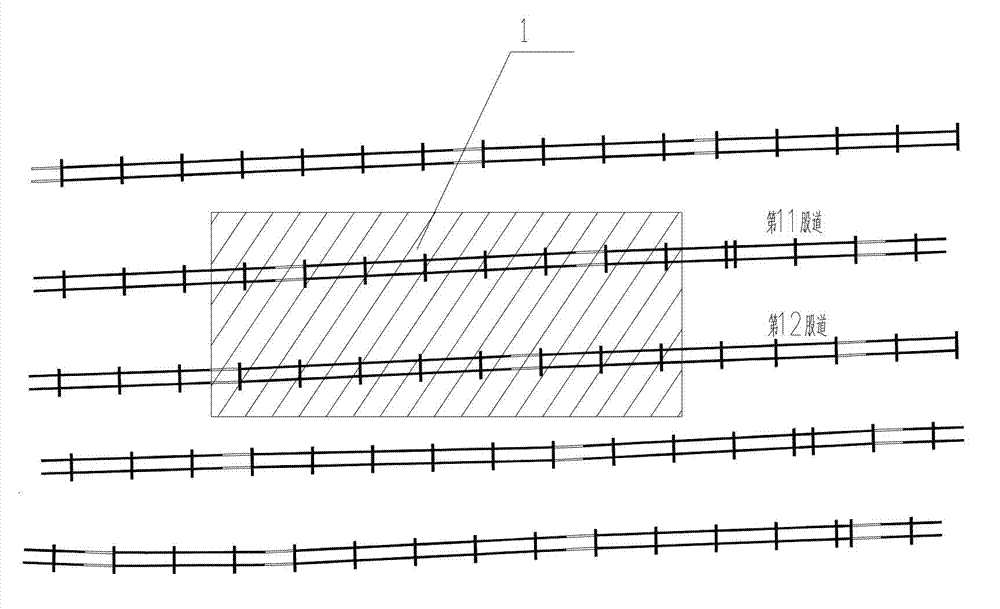

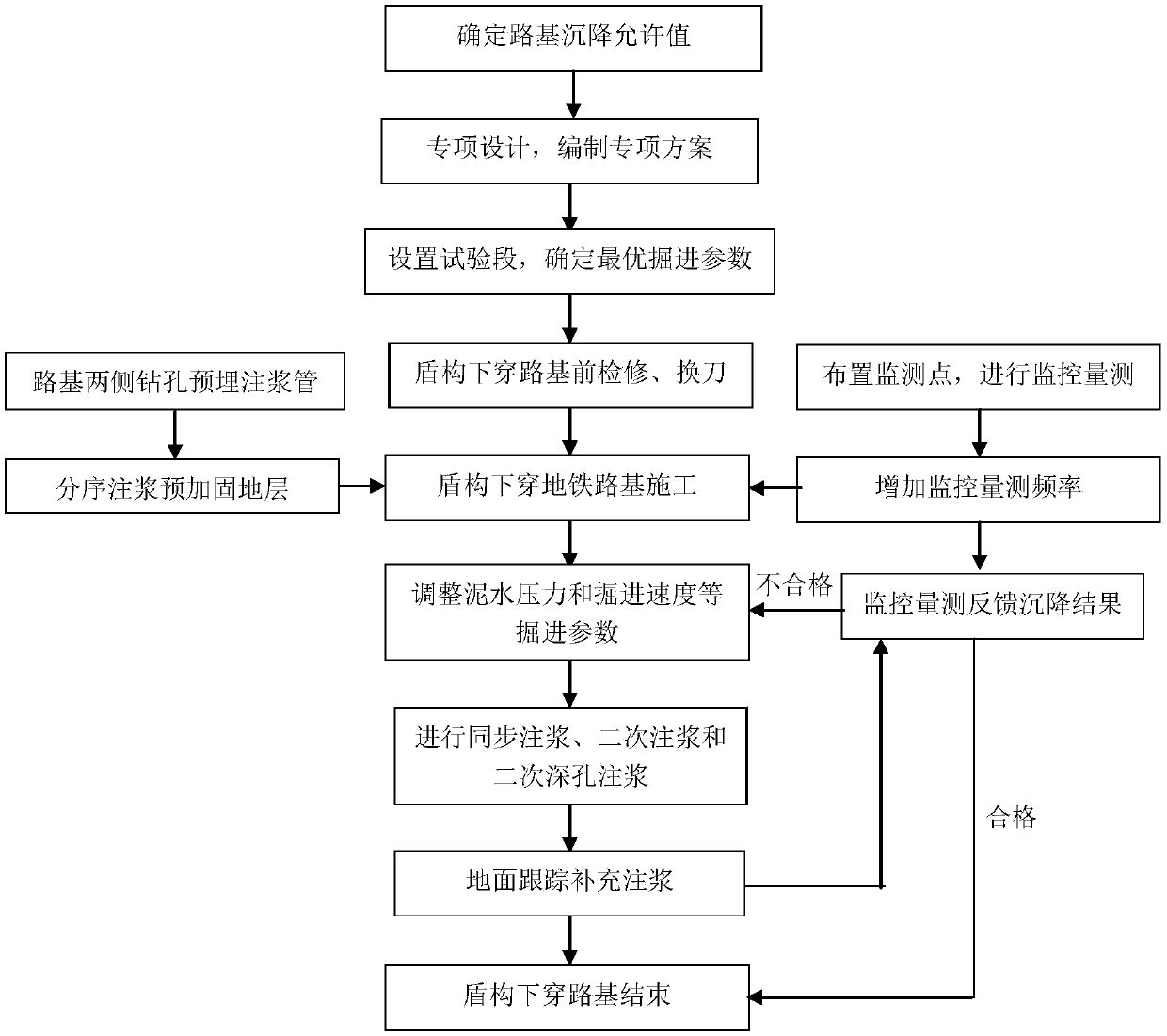

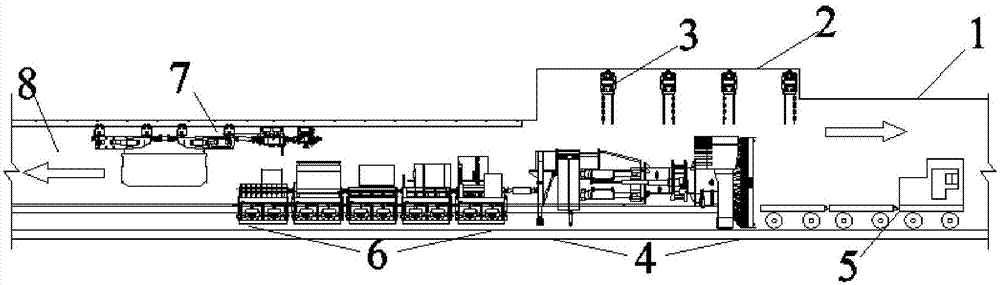

Construction method of large-diameter slurry shield zero-settlement traversing ballastless track subgrade

ActiveCN109653755AEnsure stabilityReduce settlementUnderground chambersTunnel liningGround subsidenceSlurry

The invention relates to a construction method of a large-diameter slurry shield zero-settlement down-traversing ground fast-track subgrade. The construction method includes the steps: 1 ground grouting reinforcement construction; 2 construction monitoring; 3 shield down-traversing fast-track line construction; 4 deviation correction and tunneling direction control; 5 construction measures in a shield down-traversing process hole; 6 on-site walk-around operation. The construction method has the advantages that the advantages of slurry shield are sufficiently taken, the slurry pressure of a front tunnel face is controlled by adjusting the pressure of an air cushion bin in slurry balance shield, so that the water and soil pressure of a shield front excavation face is balanced by the aid of the slurry pressure, stability of the front excavation face is ensured, ground subsidence is decreased, and existing tunnels and underground pipelines near a construction tunnel cannot be damaged.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Tunneling construction method of fully mechanized tunnelling machine for weak-cementation eugeogenous rock dip drift

InactiveCN101463725APoor controlReduce disturbanceUnderground chambersTunnel liningProblem solveDrill

The invention relates to a weakly consolidated eugeogenous rock body slant roadway road-header tunneling construction method. The existing tunneling construction of a weakly consolidated eugeogenous rock body slant roadway uses drill and blast method, while wall rocks are fragmentized and soft and the problems of out break, big perturbation, roof fall, and the like, exist widely, therefore, the timely supporting can not be ensured, and the deterioration of the wall rock state is beyond control. At present, no method for the weakly consolidated eugeogenous rock body slant roadway road-header tunneling construction exists. The technical problem solved by the invention is to provide a road-header tunneling construction technology directing at the weakly consolidated eugeogenous rock body slant roadway, having less perturbation to the wall rock and being capable of supporting the wall rock. The invention solves the problem that as all of the component forces of the huge pressure of the deadweight of the road-header in the slant roadway tunneling direction act on the head of the road-header, the head of the road-header is not easy to control. The tunneling and constructing procedures of the road-header are as follows: cutting, primary supporting, gangue loading, transfer, gangue transportation and secondary supporting.

Owner:ORDOS HAOHUA CLEAN COAL CO LTD +1

Dismantling construction method of underground mine tunnel boring machine (TBM)

The invention provides a dismantling construction method of an underground mine tunnel boring machine (TBM). The TBM dismantling construction method comprises the following steps that (1) a dismantling roadway is built, specifically, the dismantling roadway is built in the tunneling direction in front of the TBM, and the dismantling roadway is built till reaching the parking position of the underground mine TBM; (2) dismantling preparation work is conducted, specifically, one end of the dismantling roadway is subjected to expanding excavation so that an expanding excavation section can be formed, and the expanding excavation section is tightly close to one end of a TBM tunneling roadway; and (3) TBM part dismantling construction is conducted, specifically, a TBM main machine and a TBM rear auxiliary system are disconnected firstly, the TBM main machine is driven into the expanding excavation section, and meanwhile the TBM main machine and the TBM rear auxiliary system are dismantled and conveyed onto the ground from the positions from the front and the back of the TBM. According to the dismantling construction method of the underground mine TBM, the TBM is dismantled at an underground mine, TBM dismantling is conducted from the front and the back of the TBM, small machine tools such as a monorail crane and a craning pulley are adopted, and large devices such as a gantry crane do not need to be installed under a well; and the expanding excavation and transforming engineering quantities are small, the dismantling construction period is shortened, and engineering construction cost is reduced.

Owner:ANHUI UNIV OF SCI & TECH +1

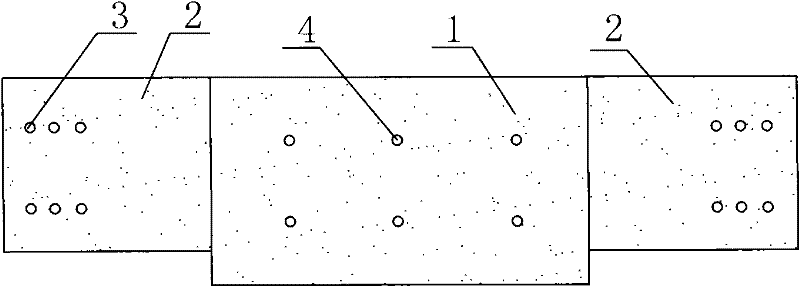

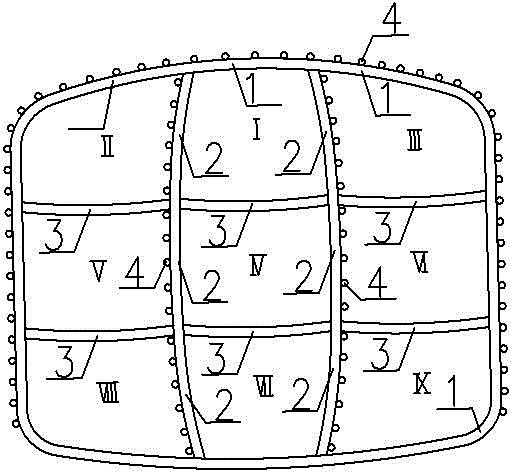

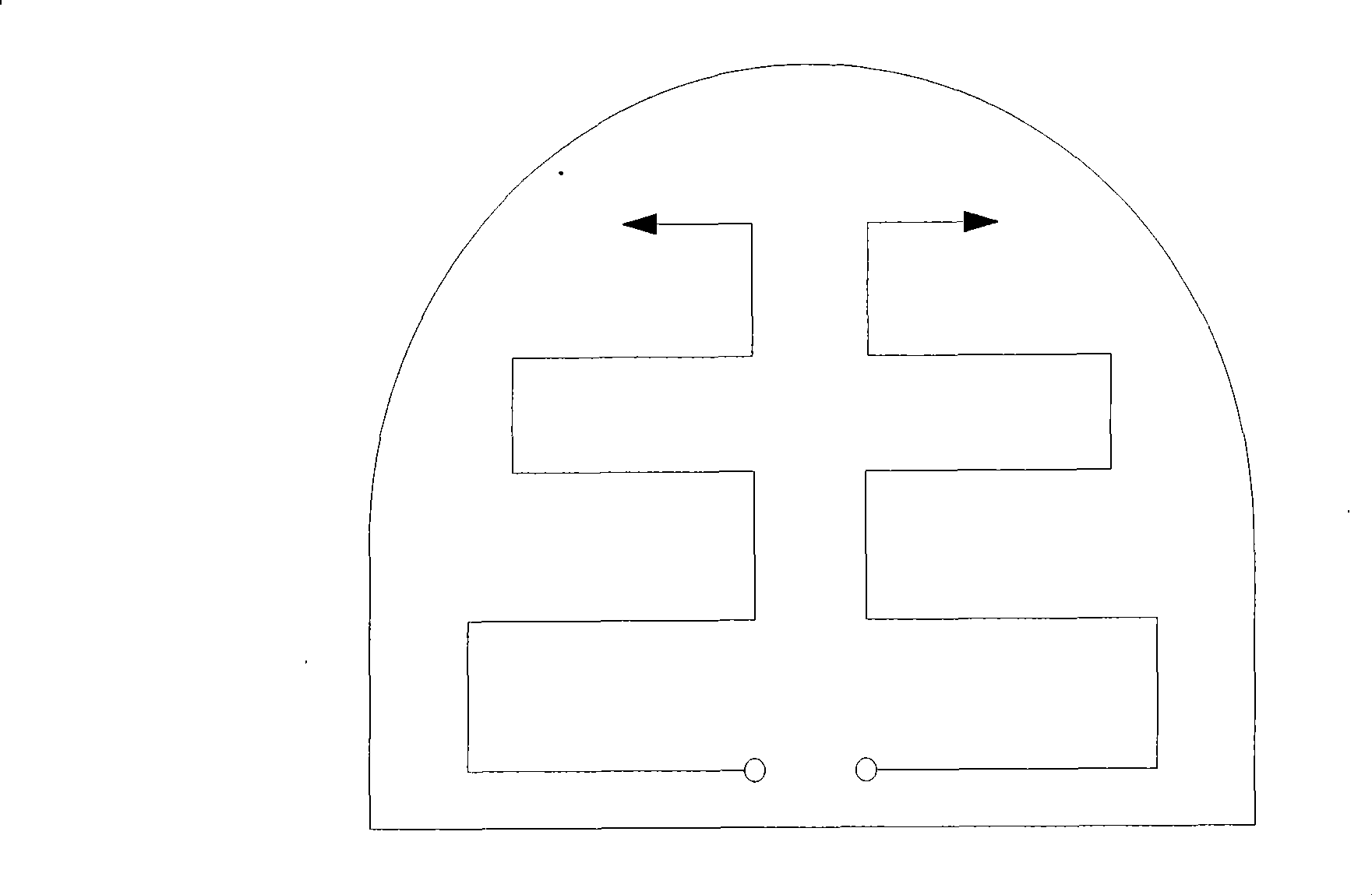

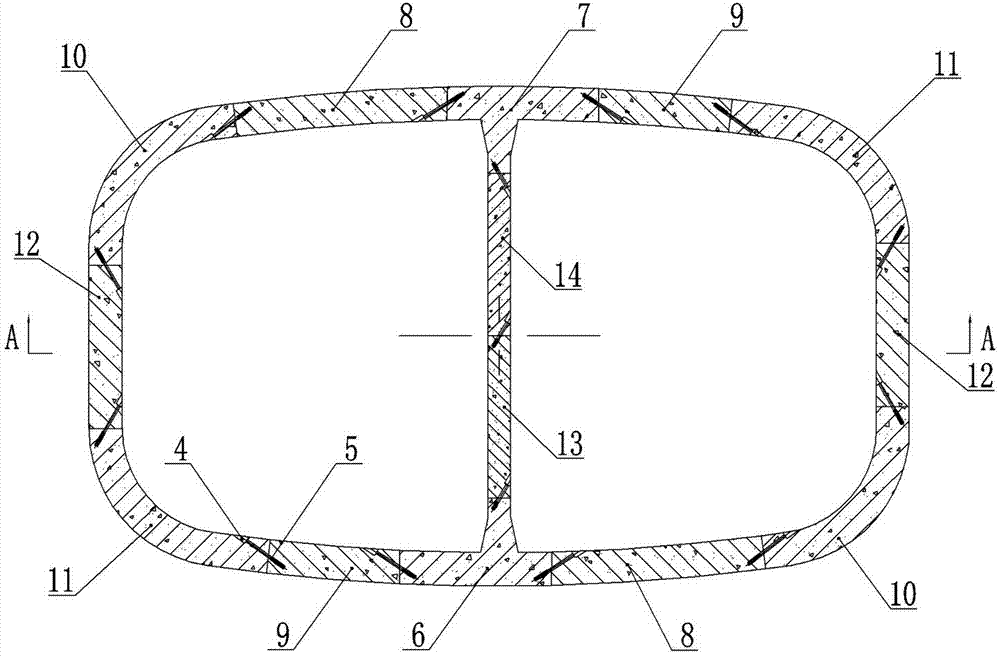

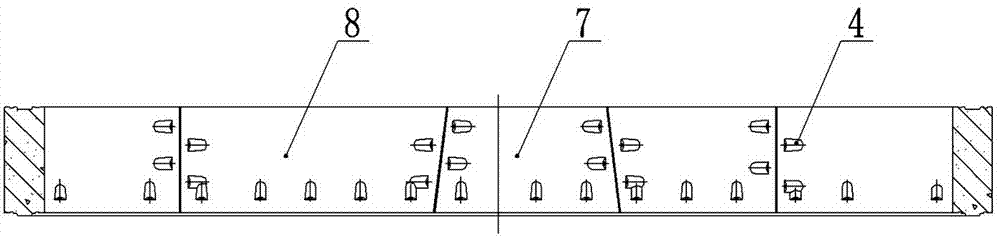

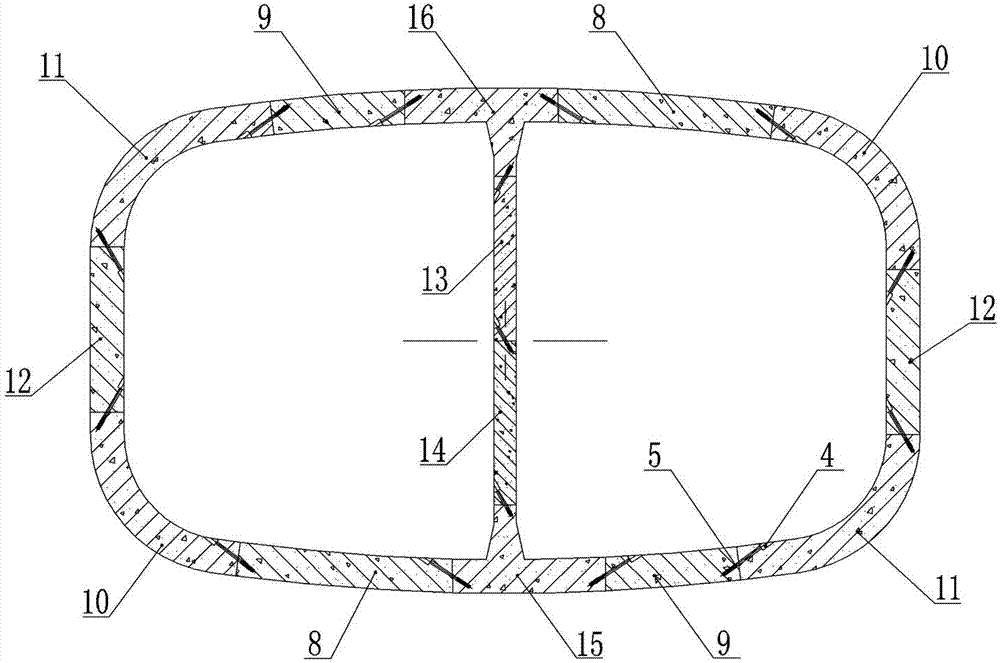

Mid-partition rectangular tunnel segmental lining and segment splicing method

ActiveCN104747207AReduce bending momentLow costUnderground chambersTunnel liningEngineeringStructural engineering

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Supporting structure for large-section weak surrounding rock tunnel construction and construction method thereof

ActiveCN106401614AReduce installationSimplified temporary support removal process requirementsUnderground chambersTunnel liningSupporting systemPre stress

The invention discloses a supporting structure for large-section weak surrounding rock tunnel construction and a construction method thereof. The supporting structure comprises a steel arch which is formed by arranging a plurality of arc-shaped I steel at intervals in the tunnel direction. Grooves of the I steel are in the tunnel direction, strip-type anchor bearing plates are arranged between the adjacent I steel and firmly attached to the inner side surfaces of the arc shapes of the I steel, and anchorages are arranged on the inner side surfaces of the anchor bearing plates and connected with pre-stressed anchor cables. According to the supporting structure for large-section weak surrounding rock tunnel construction and the construction method thereof, prestress of the pre-stressed anchor cables is transmitted to the steel arch through the strand tapered anchorages and the anchor bearing plates, so that the pre-stressed anchor cables and the steel arch serve as a part of a tunnel early support together, a cable-arch combined supporting system is formed, mounting of subsequent temporary supports is reduced, the technological requirement for dismantling of the temporary supports is lowered, the support dismantling efficiency is improved, the construction safety is guaranteed, the problems that many partitions are needed, the construction space is small, many procedure links exist, and the construction organization difficulty is high during large-section weak surrounding rock tunnel construction are effectively solved, and the construction efficiency is greatly improved.

Owner:THE FIFTH ENGEERING OF CHINA RAILWAY 5TH BUREAU GROUP

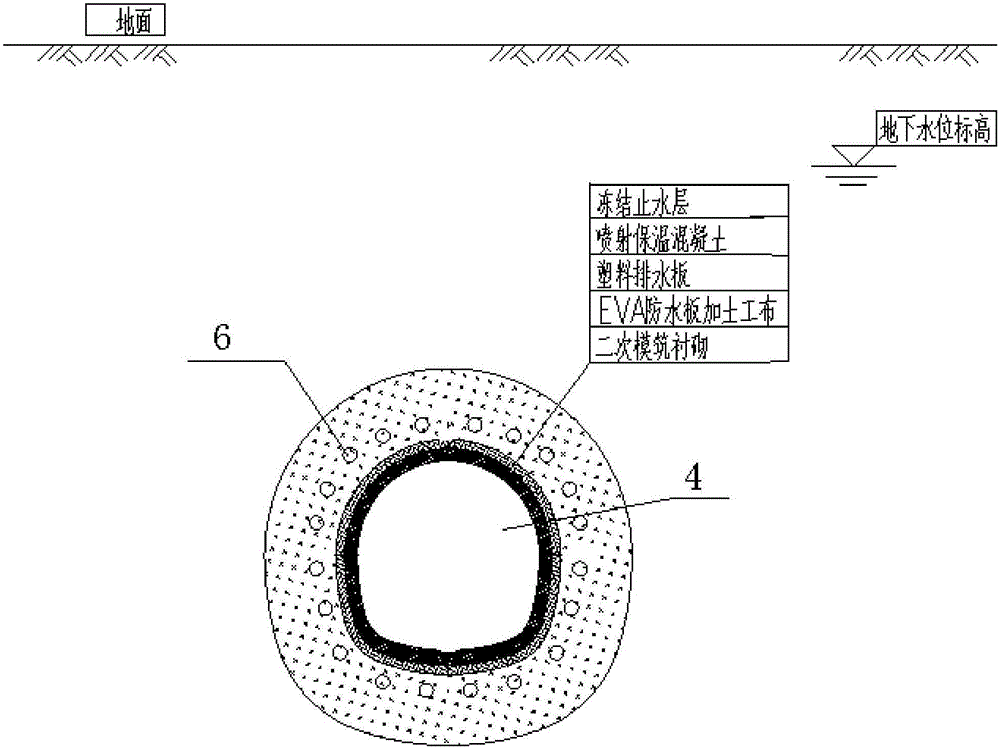

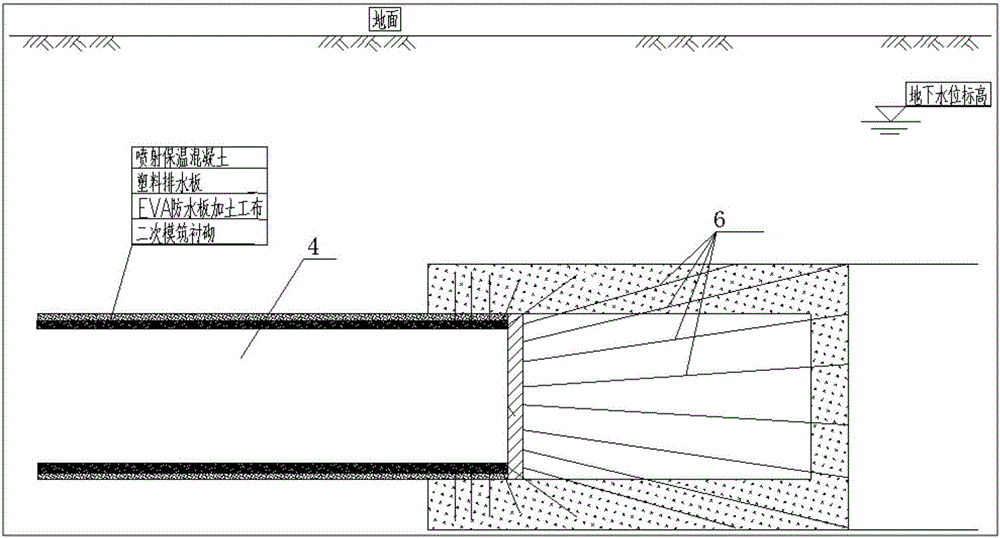

Subsurface tunnel waterstop structure used for protecting groundwater environment and construction method thereof

ActiveCN106121686AAvoid pollutionAvoid settlement deformationUnderground chambersTunnel liningWater qualityGroundwater

The invention relates to an electrified railway technology, in particular to a subsurface tunnel waterstop structure used for protecting a groundwater environment and a construction method thereof. The waterstop structure comprises a plurality of vertical frozen earth waterstop layers distributed sequentially in the tunnel direction and horizontal waterstop layers surrounding the outer contour of a tunnel, and the horizontal waterstop layers extend in the extending direction of the tunnel; the vertical frozen earth waterstop layers and the horizontal frozen earth waterstop layers intersect with each other; and the bottoms of the vertical frozen earth waterstop layers are lower than the bottoms of the horizontal frozen earth waterstop layers; and tunnel lining structures are arranged between the horizontal frozen earth waterstop layers and the tunnel. The vertical frozen earth waterstop layers and the horizontal frozen earth waterstop layers are adopted to form a cup-shaped frozen earth waterstop layer, the groundwater environment is protected, and groundwater is prevented from being polluted in the tunnel construction process. By the adoption of the frozen earth waterstop structure, large-scale drainage construction is avoided, precious groundwater resources are saved, and settlement deformation of surrounding adjacent buildings and structures caused by drainage construction is avoided at the same time.

Owner:SHANDONG GEOLOGICAL ENG INVESTIGATION INST

Extraction method adopting deep-hole presplitting blasting along seam floor for coal roadway driving

ActiveCN107120137AImprove extraction efficiencyEfficient extractionFluid removalGas removalDetonationMining engineering

The invention provides an extraction method adopting deep-hole presplitting blasting along a seam floor for coal roadway driving and relates to a blasting extraction method. The extraction method is characterized by comprising the following steps: a gas extraction hole is constructed in front of a to-be-driven coal roadway in a coal seam tunneling direction for gas extraction, then a blast hole parallel to the seam floor is constructed along a floor stratum below coal seam tunneling working face, charging and detonation are performed, and coal seam tunneling is started after gas residue content of a coal seam is qualified; after tunneling to a non-blast area, the blasting extraction work is repeated, and blasting extraction and tunneling are performed alternately. With adoption of the method, the coal seam gas extraction efficiency is high, the extraction cost is low, construction is safe and reliable, coal seam tunneling and blasting extraction are performed alternately, special construction of a floor roadway and an extraction hole across coal strata is not needed, the cost is reduced substantially, and better social and economic benefits can be produced.

Owner:ANHUI UNIV OF SCI & TECH

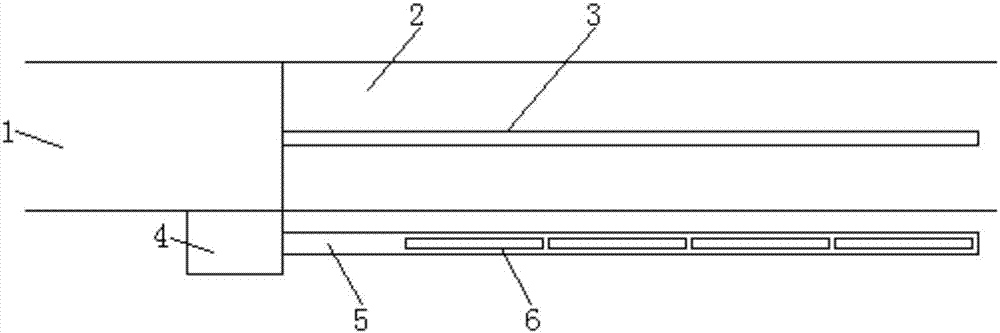

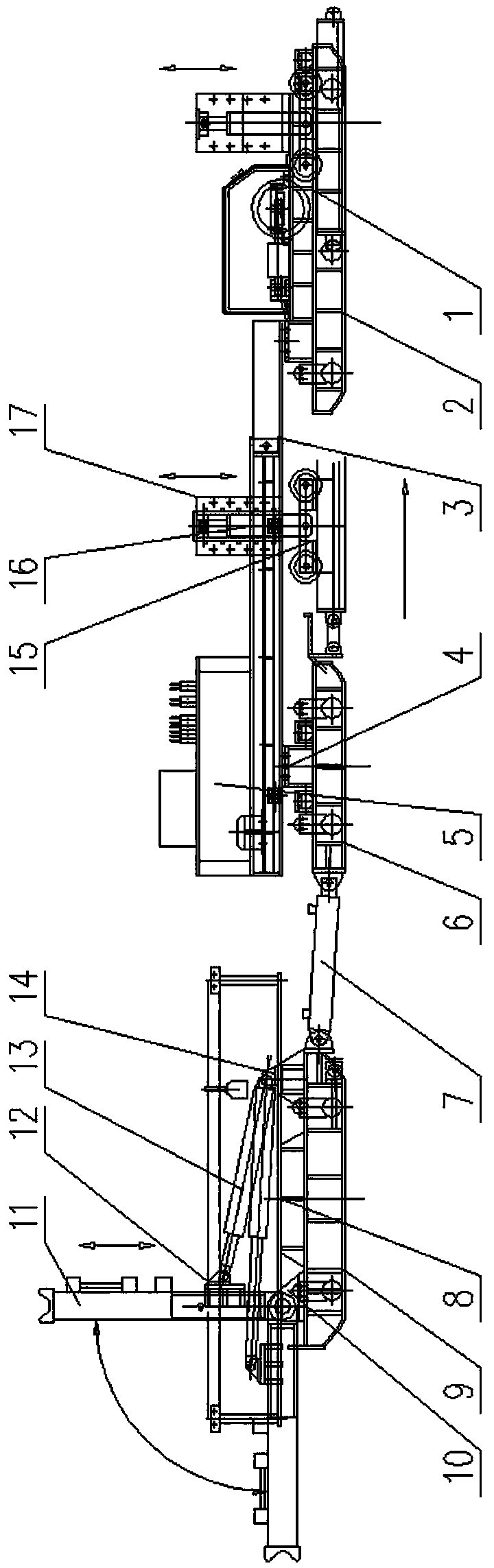

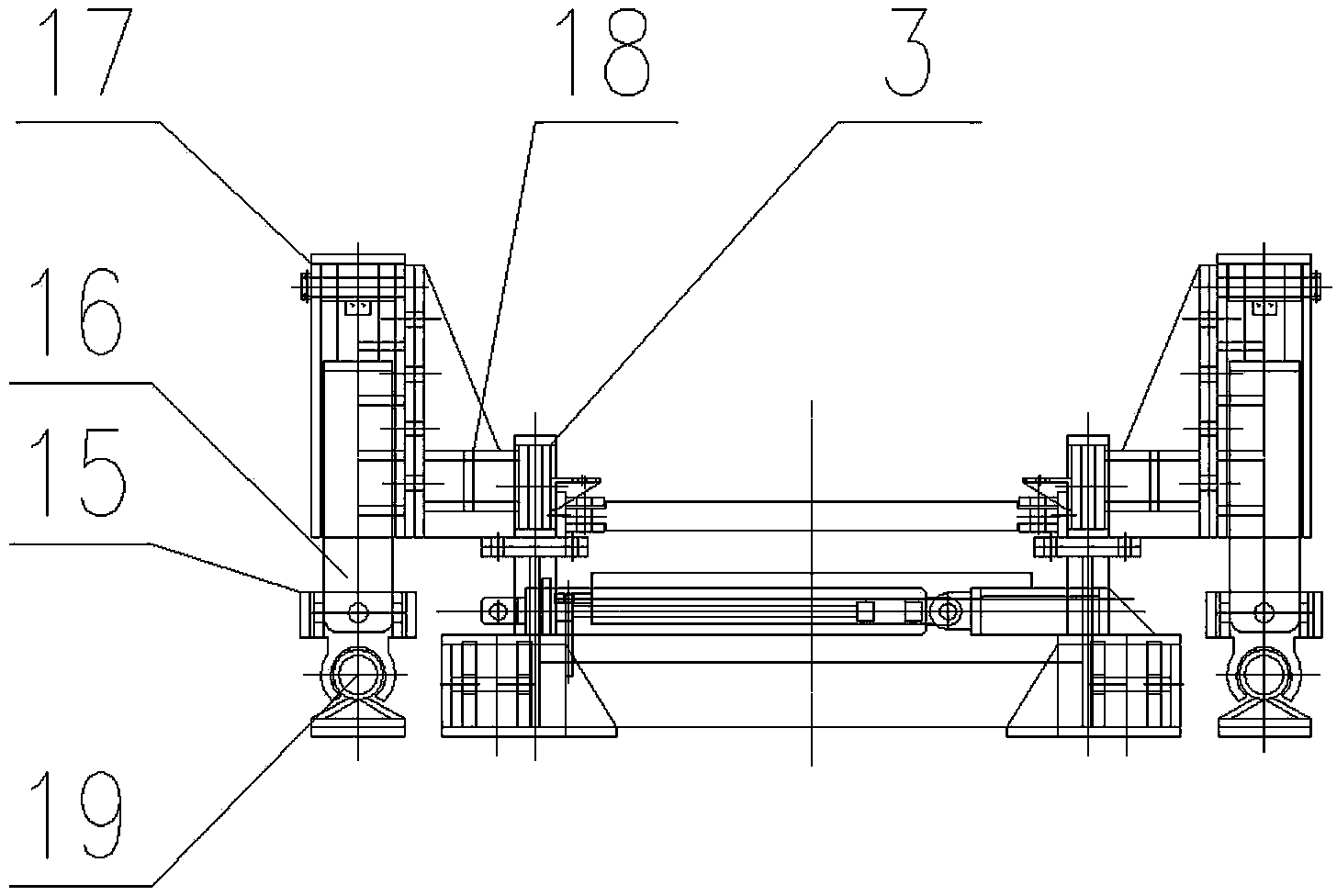

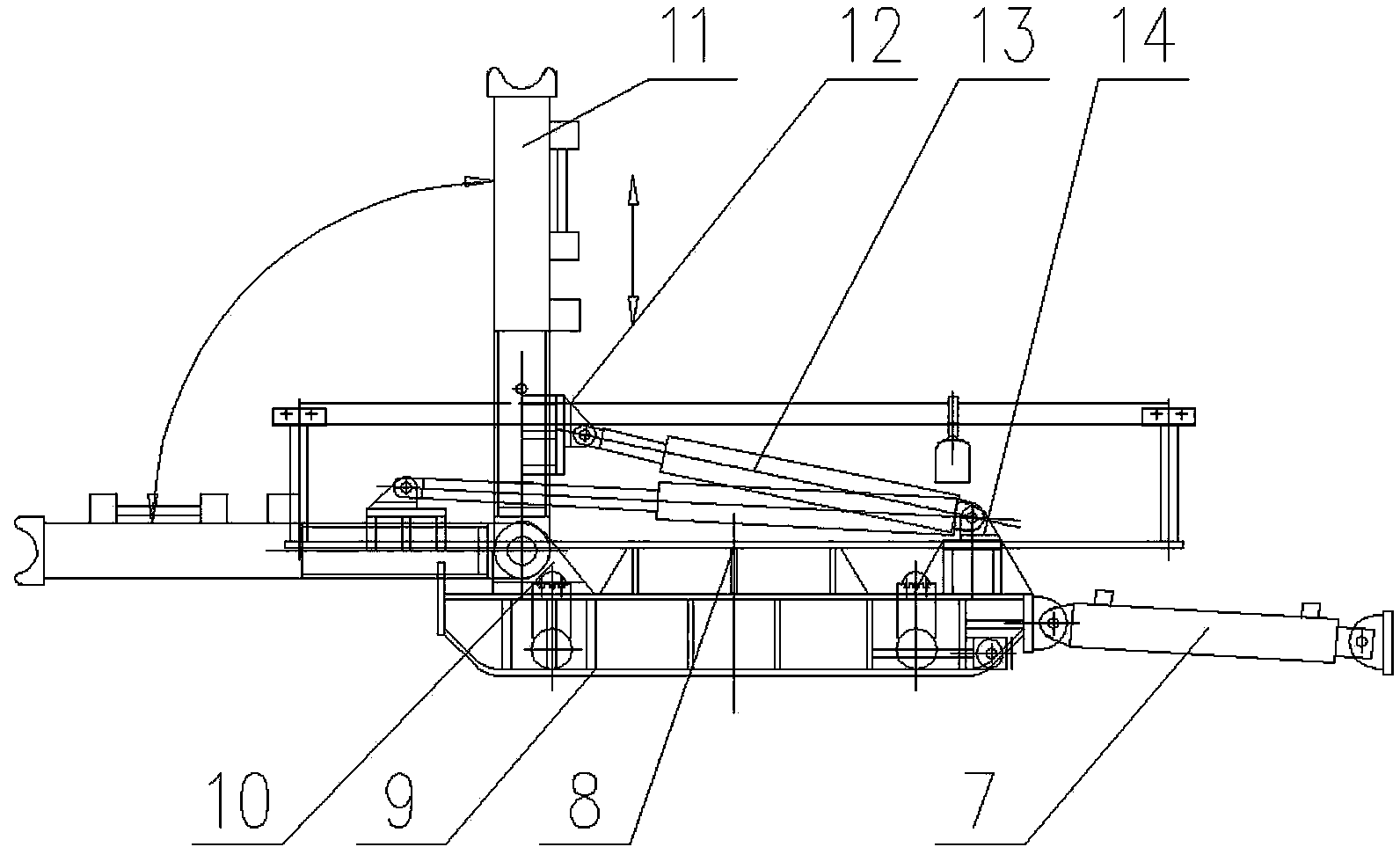

Self-moving belt conveyor tail

ActiveCN103410561AReduce the number of demolitionImprove work efficiencyEarth drilling and miningUnderground transportDislocationBelt conveyor

The invention relates to belt conveyor moving devices, particularly to a self-moving belt conveyor tail. The self-moving belt conveyor tail comprises a conveyor tail, a middle portion, a driving portion and a hydraulic system and is characterized by further comprising a moving oil cylinder, one end of the moving oil cylinder is hinged to the base of the driving portion, the other end of the moving oil cylinder is hinged to the middle portion, and a beam arranged on a middle portion base is connected with a conveyor tail base. The self-moving belt conveyor tail further comprises tracks which are arranged on two sides of the conveyor tail and the middle portion, and the rear ends of the tracks are connected with the base of the driving portion; the middle portion and the conveyor tail portion is provided with a lifting mechanism, the driving portion is provided with an anti-slipping fixing mechanism which can personally achieve fixation to prevent dislocation of the conveyor tail during transportation, the middle portion is provided with an offset regulating mechanism which can solve the off-tracking problem of belts, the conveyor tail is provided with a roller offset regulating mechanism which can solve the deviation of a conveyor tail roller. The self-moving belt conveyor tail can move by itself, each movement distance maximally reaches 1.8 meters, the lifting mechanism and the moving oil cylinder enable the conveyor tail and the middle portion to move along the tracks; and the tacks can smoothly move in two side tunneling directions of the conveyor tail portion.

Owner:山西潞安环保能源开发股份有限公司常村煤矿

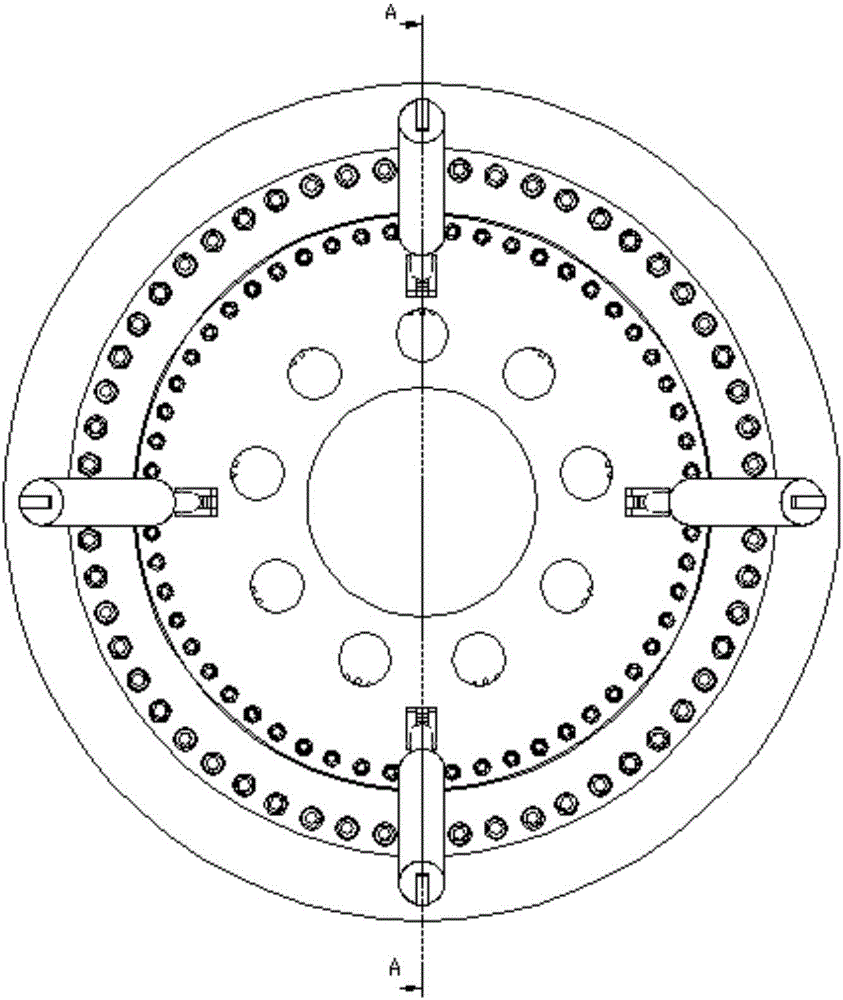

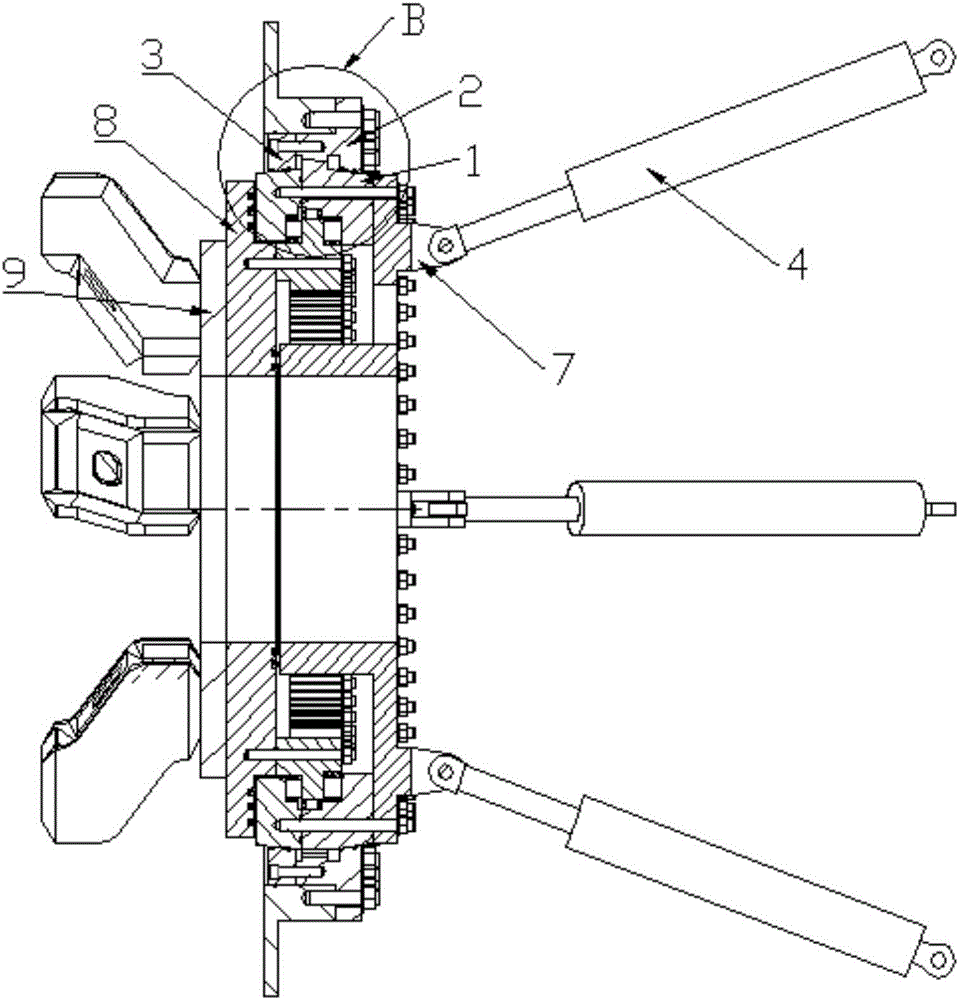

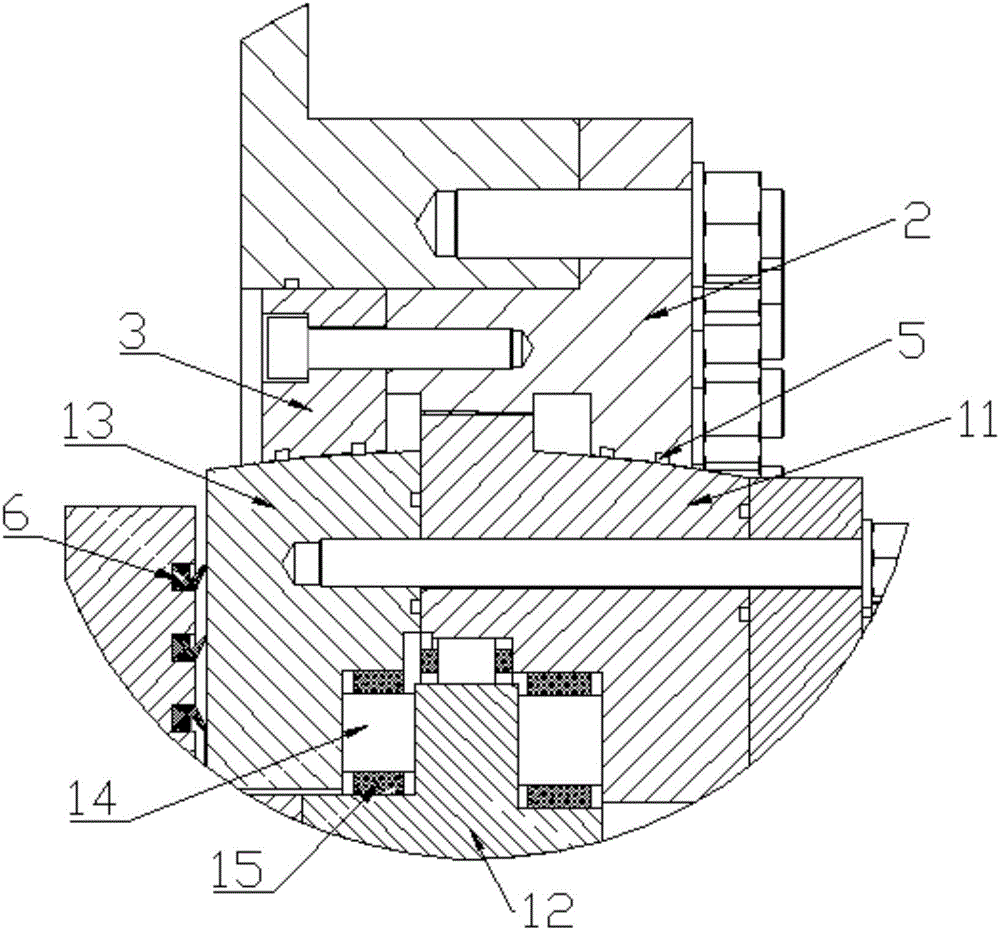

Main driving device of angle adjustable shield tunneling machine

ActiveCN106437736AControl the direction of excavationSimple structureTunnelsEngineeringShield tunneling

The invention discloses a main driving device of an angle adjustable shield tunneling machine. The main driving device comprises an outer spherical surface main bearing, a first inner spherical surface main bearing mounting seat, a second inner spherical surface main bearing mounting seat, angle adjusting cylinders, a cylinder mounting seat and a sealed mounting seat, wherein the first and second inner spherical surface main bearing mounting seats are respectively matched with the outer spherical surface main bearing through spherical surfaces; totally four angle adjusting cylinders are uniformly distributed on the same circle, one end of each of the angle adjusting cylinders is hinged with the outer spherical surface main bearing, and the other end of each of the angle adjusting cylinders is hinged with the shield tunneling machine. According to the device, rising or sinking of a cutter head of the shield tunneling machine is controlled by adjusting the stroke difference of an upper cylinder and a lower cylinder, a tunneling posture of the shield tunneling machine is adjusted, a phenomenon that segment damage in a thrust posture is adjusted by a thrust cylinder is avoided, and the tunneling direction of the shield tunneling machine can be accurately controlled; meanwhile, the over-excavation amount of the cutter head can be adjusted by adjusting the stroke difference of the left and right two cylinders, so that an aim of smoothly turning the shield tunneling machine is achieved, use of the cylinders and other assemblies is avoided, the manufacturing cost is reduced, and the cutter head structure is simplified.

Owner:JIANGSU KAIGONG TUNNEL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com