Construction method for tool changing under pressure in shield of water-rich silty soil and silty sand stratum under station tracks of railways

A construction method and technology of shield belts, which are applied in earth-moving drilling, tunneling, mining equipment, etc., can solve the problems affecting the safety of railway operation and the ground collapse of the upper railway track, so as to overcome the collapse of easy-flowing sand and ensure the safety of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

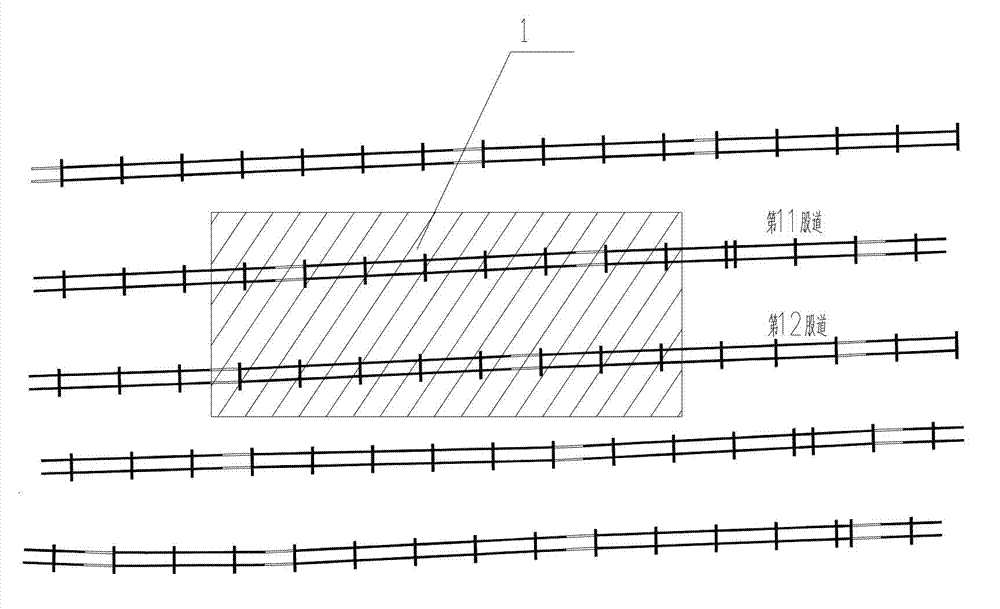

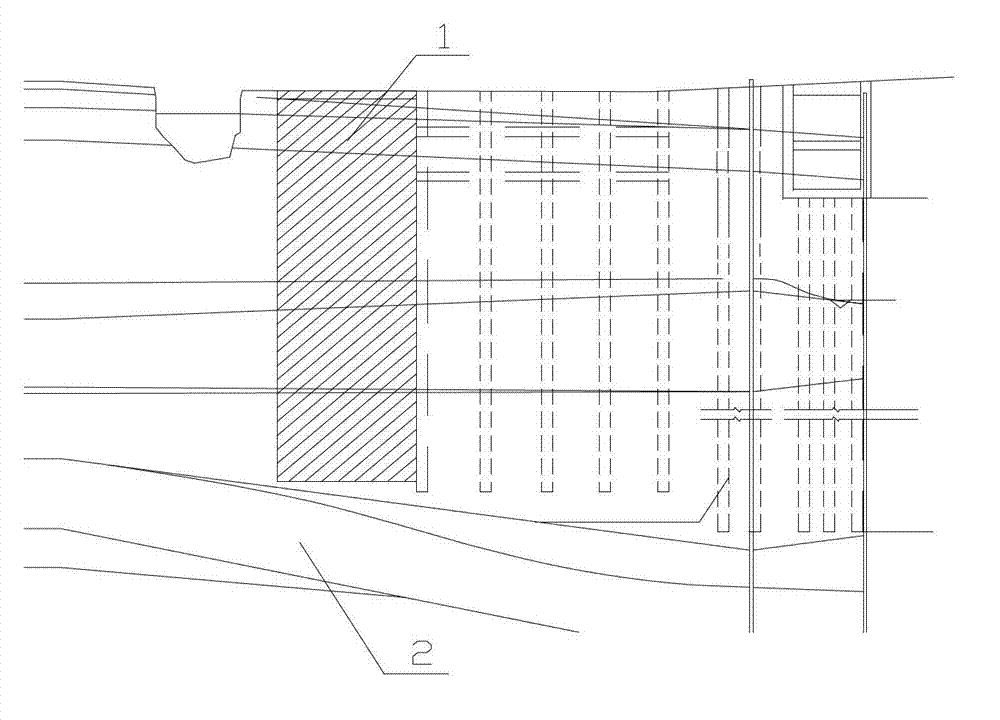

[0029] The construction method of shield tunneling under pressure for water-rich silt and silt formation under the railway track of the present invention is mainly applied to the water-rich silt and silt formation, including the following steps:

[0030] A. Preparations before tool change:

[0031] Use high-pressure rotary grouting piles to reinforce the soil at the tool change, and learn more about the settlement control standards of the railway main line from the railway department, such as the hourly uplift of the railway line ≤ 2mm; the hourly settlement ≤ 4mm; the cumulative uplift per day and night ≤ 4mm ; Cumulative settlement per day and night ≤ 10mm; level difference between the two rail tops ≤ 2mm; cumulative uplift of the final line within half a year ≤ 10mm; cumulative settlement ≤ 40mm. Before the shield machine reaches the tool change area, check whether there are holes on the ground surface in the reinforcement area to prevent the gas from escaping from the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com