Tunneling construction method of fully mechanized tunnelling machine for weak-cementation eugeogenous rock dip drift

A construction method and weak cementation technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor control of the head of fully mechanized excavators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

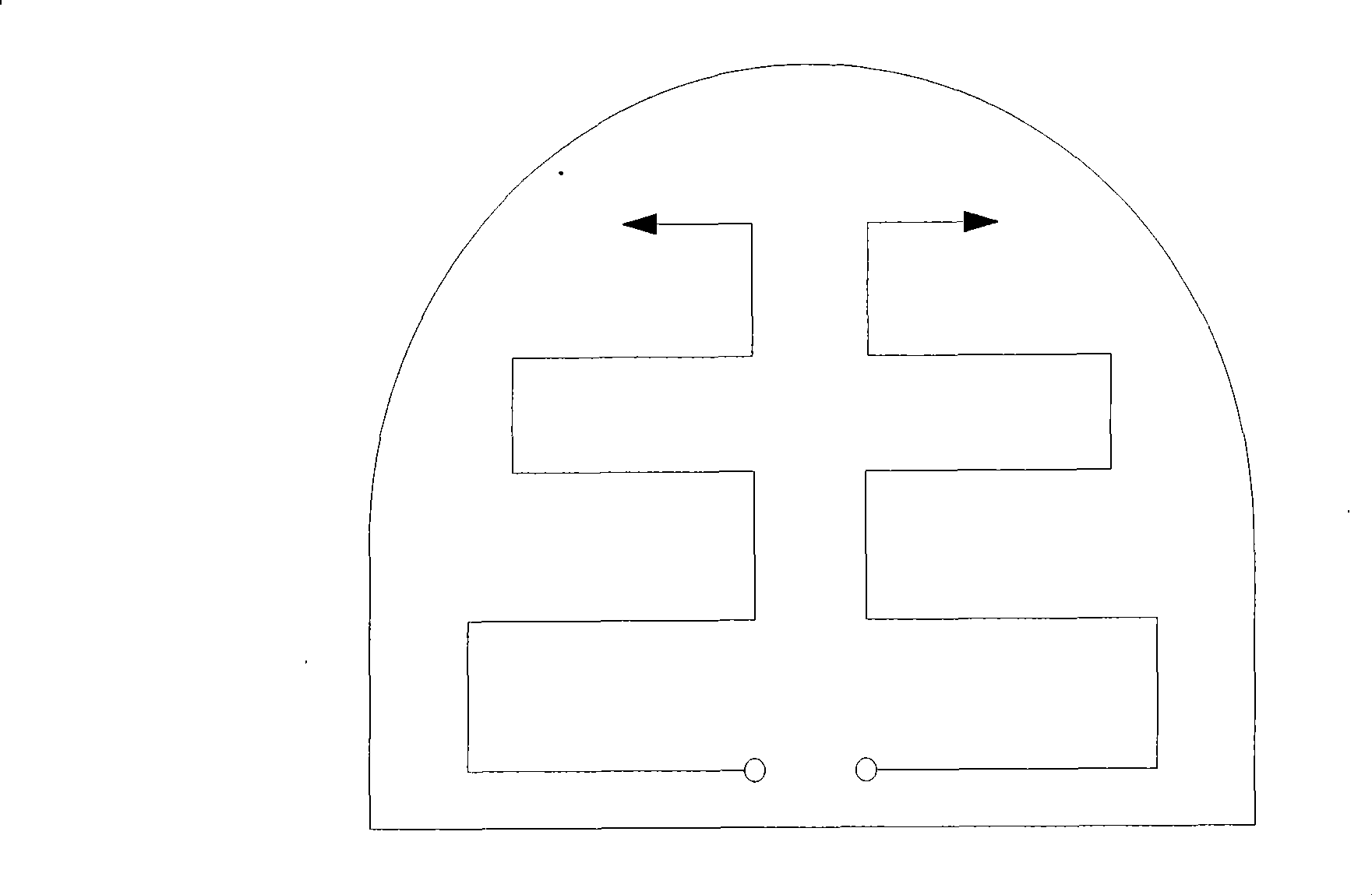

Image

Examples

Embodiment Construction

[0012] The gray-green sandstone or coarse sandstone exposed in the horseshoe-shaped roadway (-5.5°) of the auxiliary inclined shaft of Gaojialiang Coal Mine belongs to Jurassic argillaceous cementation, with low strength and uniaxial compressive strength of only 1.3MPa. 1. It is easy to weather and disintegrate after being exposed to air. After weathering, its strength is close to that of soil. The natural moisture content is 9.35-10.42%, with an average of 9.992%. The content of montmorillonite is 17.8%, and the free expansion rate is 13%.

[0013] The specific construction method is:

[0014] Before excavation, lay the pipe shed as advance support. Pipe shed specifications: diameter 45mm, length: 2500mm. Spacing 300mm, pipe shed overlapping length about 1000mm. Under the protection of the advanced support of the pipe shed, the EBZ(JA)-150 fully mechanized excavator is used for cutting. When cutting, determine the excavation profile according to the design width and height,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com