Method for preparing porous charcoal pieces capable of realizing efficient photo-thermal steam converting

A photothermal conversion and charcoal technology, applied in the field of solar material preparation, can solve the problems of difficult large-scale survival, expensive precious metals, etc., and achieve the effects of low cost, simple operation and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Divide 3×3×1cm 3 Put the wooden blocks into a blast drying oven and dry at 60°C for 24 hours; then put them in a quartz vacuum tube under the protection of nitrogen atmosphere and keep them warm at 300°C for 2 hours, and then pyrolysis and carbonization at high temperature to obtain carbonized whole charcoal; the heating rate of the quartz vacuum tube is 5 °C / min;

[0030] 2) Utilize a diamond cutter to cut the carbonized monolithic charcoal obtained in step 1) along the direction vertical to the charcoal channel to obtain a charcoal sheet with a thickness of 3 mm;

[0031] 3) The charcoal sheet prepared in step 2) is ultrasonically cleaned with deionized water, and dried in a blast drying oven at 60-100° C. to obtain a porous charcoal sheet.

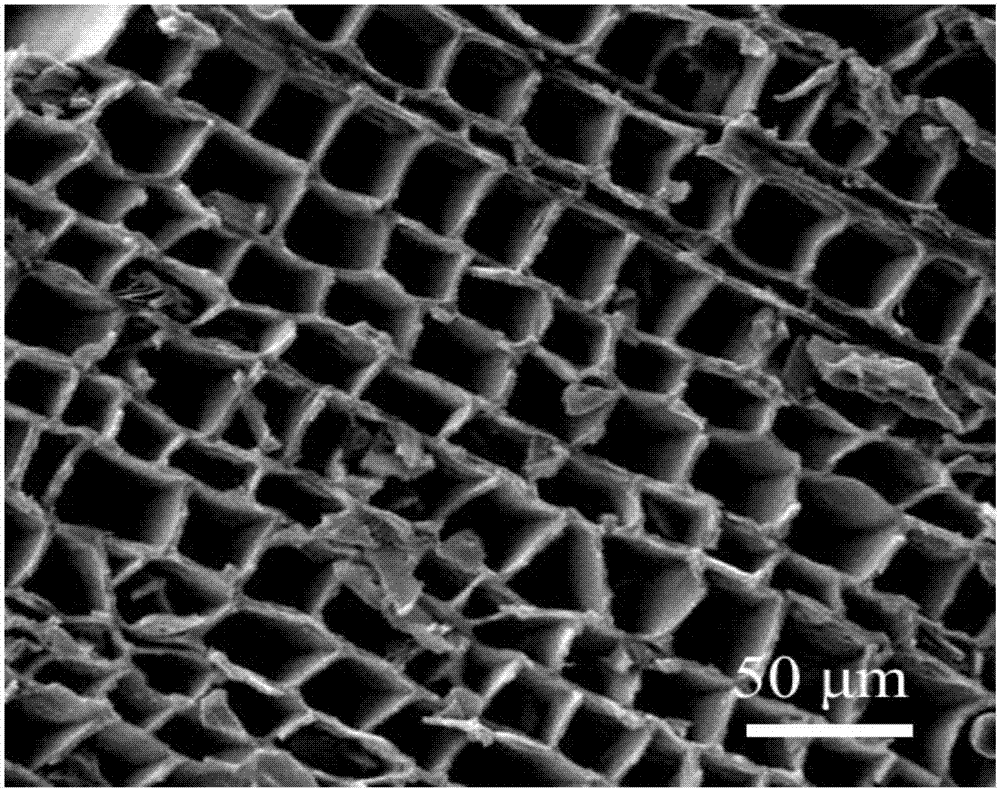

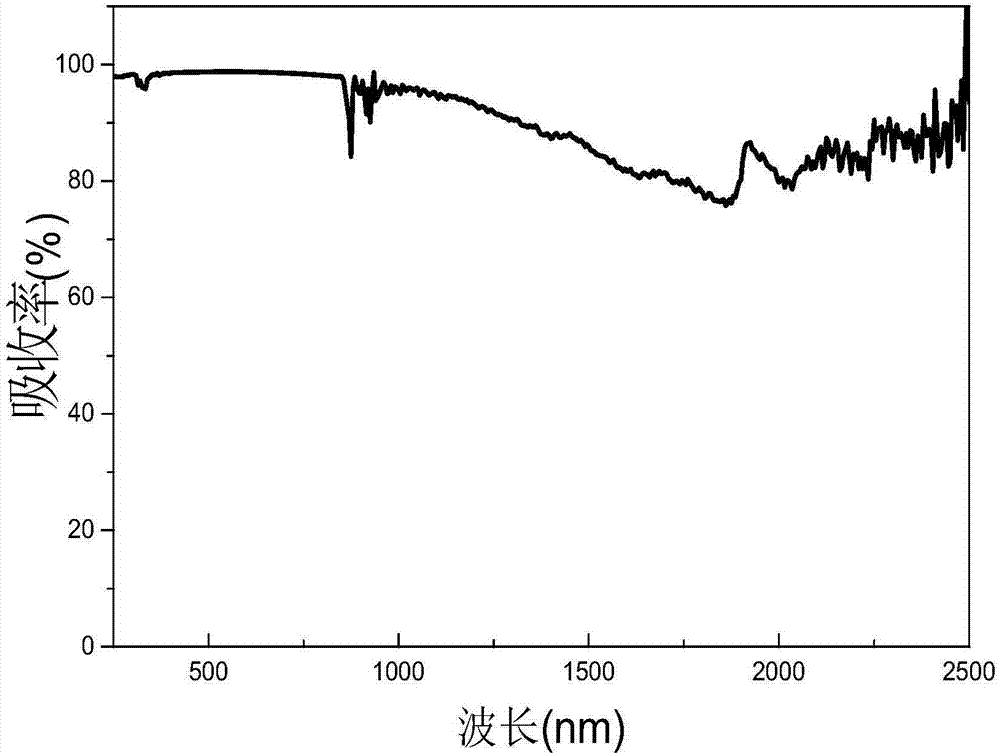

[0032] The prepared charcoal sheet has regular and vertical large pores, and the size of the pores is 35 × 35 μm (such as figure 1 ), the light absorption rate in the range of 250 ~ 2500nm is 96.70% (such as figure 2 shown...

Embodiment 2

[0034] 1) Divide 3×3×1cm 3 Put the wooden blocks into the blast drying oven and dry at 60°C for 24h; then put them into the quartz vacuum tube under the protection of nitrogen atmosphere, keep the temperature at 500°C for 2h, high-temperature pyrolysis and carbonization, and obtain carbonized whole piece of charcoal; the heating rate of the quartz vacuum tube 2°C / min;

[0035] 2) using a diamond cutter to cut the carbonized monolithic charcoal obtained in step 1) along the vertical direction of the charcoal channel to obtain a charcoal sheet with a thickness of 1 mm;

[0036] 3) The charcoal sheet prepared in step 2) is ultrasonically cleaned with deionized water, and dried in a blast drying oven at 60-100° C. to obtain a porous charcoal sheet.

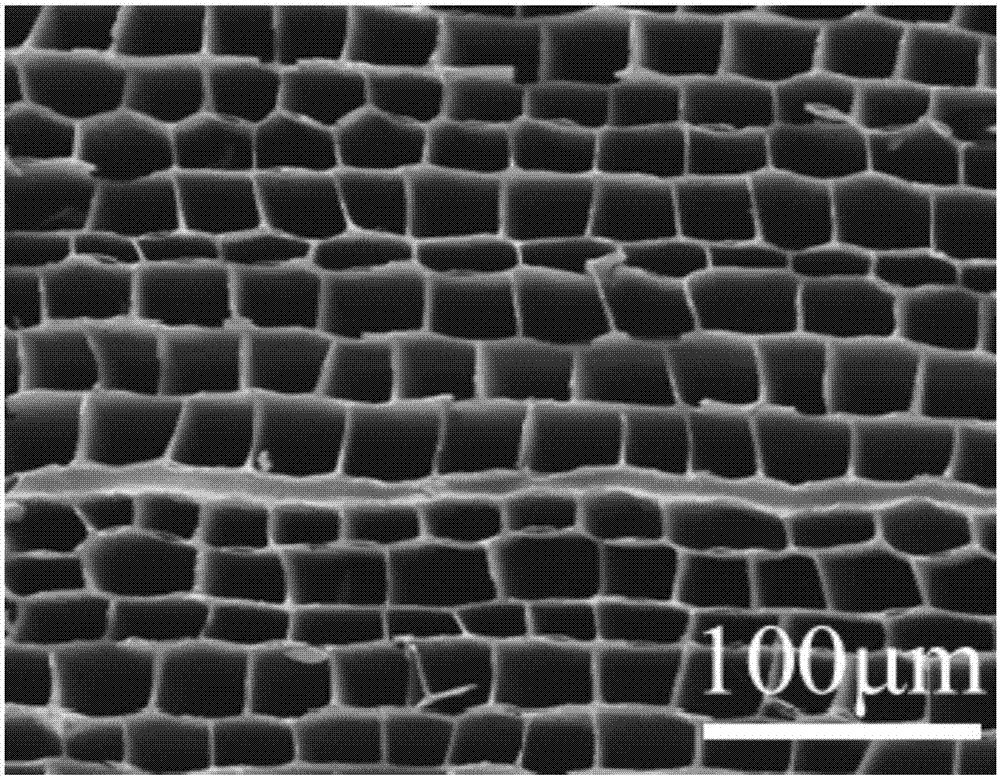

[0037] Such as figure 1 As shown, the prepared charcoal sheet has regular and vertical large pores, and the size of the pores is 20 × 30 μm (such as image 3 ), the light absorption rate in the range of 250-2500nm is 97.9% (such as...

Embodiment 3

[0039] 1) Divide 3×3×1cm 3 Put the wooden blocks into a blast drying oven and dry at 100°C for 24 hours; then put them into a quartz vacuum tube under the protection of nitrogen atmosphere, keep them warm at 900°C for 2 hours, and pyrolyze and carbonize at a high temperature to obtain a carbonized whole block of charcoal; the quartz vacuum tube is heated The rate is 2°C / min;

[0040] 2) using a diamond cutter to cut the carbonized monolithic charcoal obtained in step 1) along the vertical direction of the charcoal channel to obtain a charcoal sheet with a thickness of 1 mm;

[0041] 3) The charcoal sheet prepared in step 2) is ultrasonically cleaned with deionized water, and dried in a blast oven at 60-100° C. to obtain a porous charcoal sheet.

[0042] The prepared charcoal sheet has regular and vertical large pores, and the size of the pores is 20 × 20 μm (such as Figure 5 ), the light absorption rate in the range of 250 ~ 2500nm is 97.7% (such as Image 6 ).

[0043] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com