Digging guiding device of model shielding machine

A technology of guiding device and shield machine, applied in teaching models, instruments, mining equipment, etc., can solve the problems of inconvenient operation, high cost, complex structure, etc., and achieve the effects of convenient use, convenient observation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

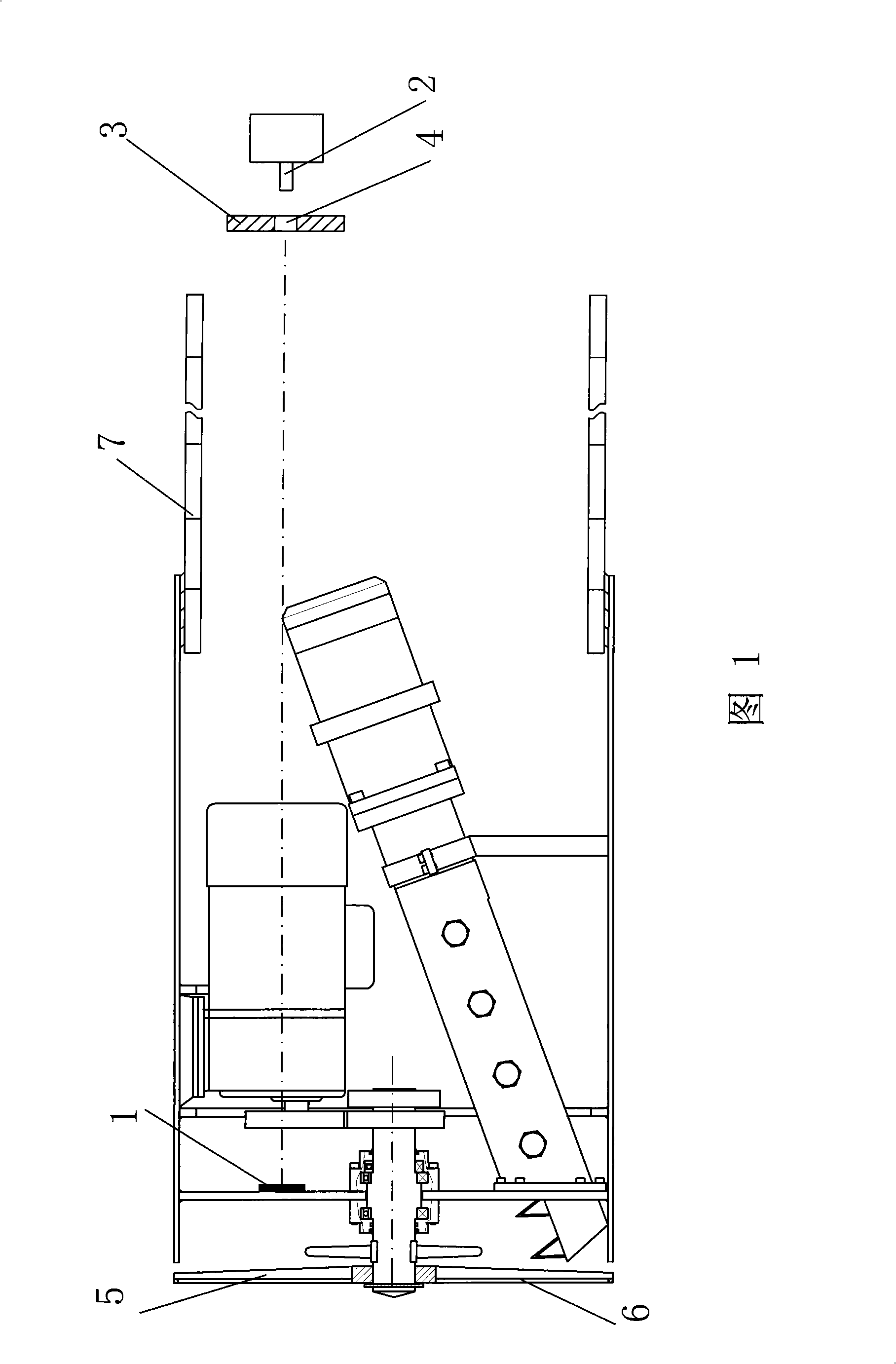

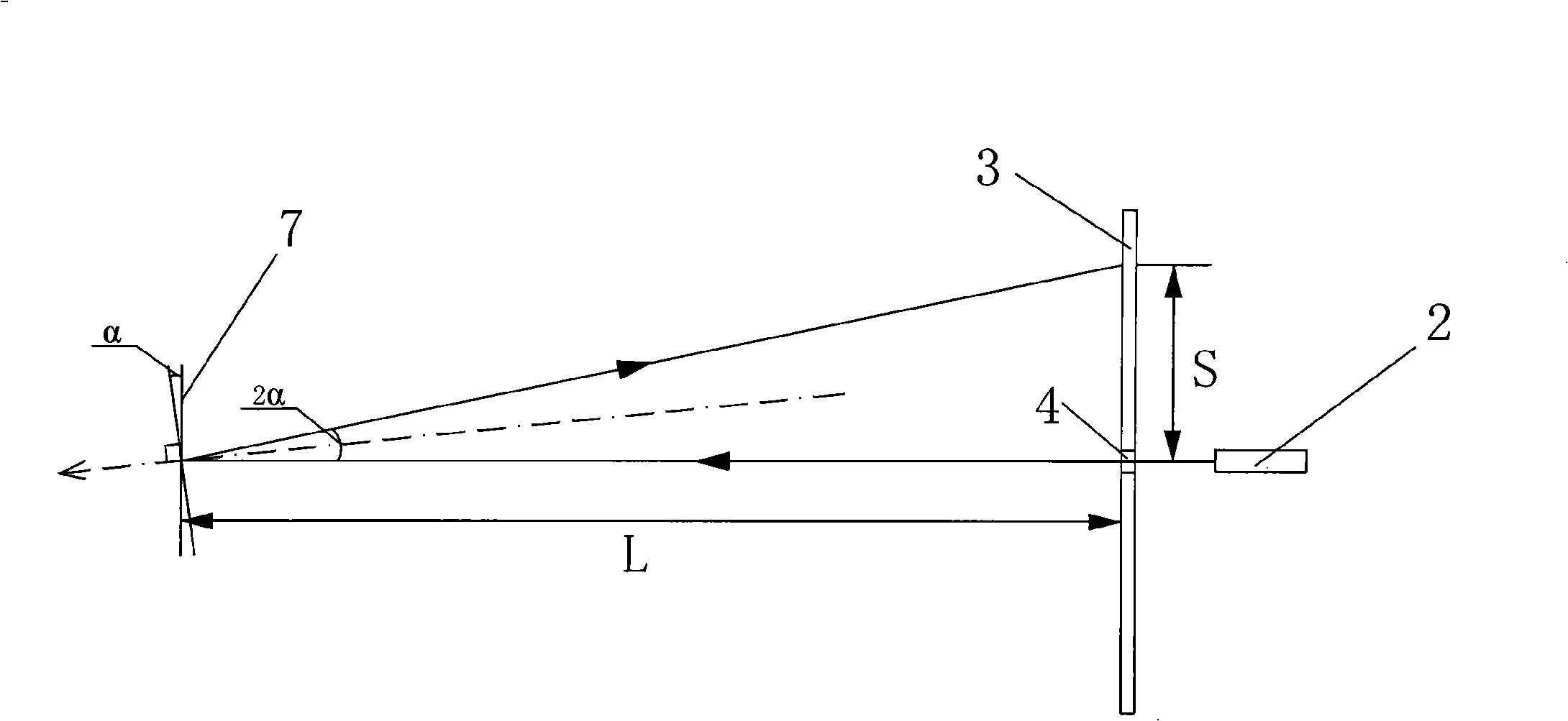

[0012] Figure 1 shows that a specific embodiment of the present invention is a tunneling guide device for a model shield machine, which consists of: a mirror 1 with a rearward mirror surface fixed on the body of the model shield machine, and the mirror 1 The mirror surface is perpendicular to the axis of the model shield machine; the laser source 2 is fixed behind the tunnel excavated by the model shield machine, and a whiteboard 3 is fixed between the laser source 2 and the reflector 1. There is an alignment hole 4 on the whiteboard 3, and the laser source 2 and the line connecting the center of the alignment hole 4 is perpendicular to the mirror surface of the mirror 1.

[0013] In this example, the reflector 1 is specifically installed on the earth bin partition 5 of the model shield machine. Because the central axis of the model shield machine is the central axis of the bearing of the cutter head 6, and the partition plate 5 of the soil bin is perpendicular to the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com