Drilling and blasting construction method for mechanized full-cross-section quick excavation and ring formation of weak surrounding rock tunnel

A technology with weak surrounding rocks and full sections, applied in tunnels, drilling equipment and methods, drilling equipment, etc., can solve problems such as settlement deformation, large-scale mechanized operations, etc., to facilitate construction organization and management, reduce labor, and reduce disturbances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

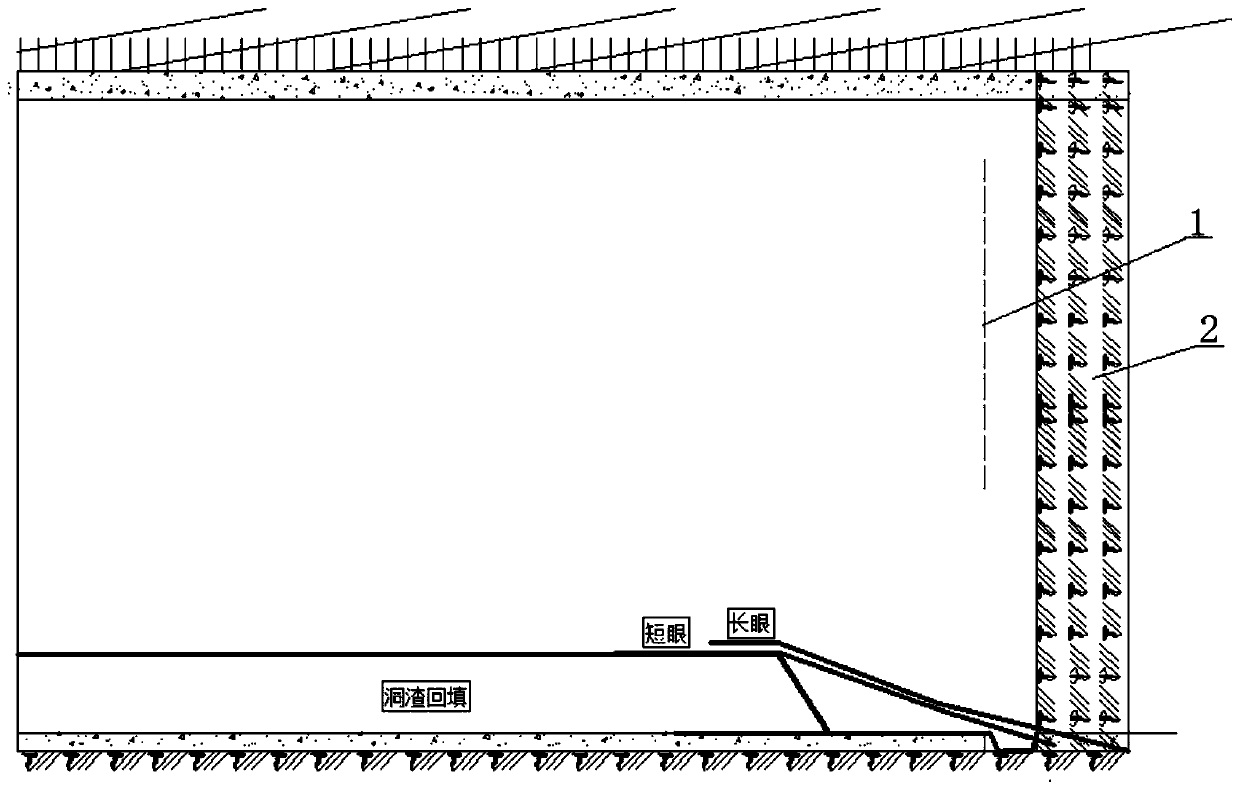

[0015] see figure 1 , a blasting construction method for mechanized full-section rapid excavation of weak surrounding rock tunnels into ring drilling blasting, which is suitable for mechanized construction of tunnels with weak surrounding rocks of grades IV and V, especially those with large settlement caused by weak surrounding rocks, labor shortage or single The tunnel with a working face length of more than 1.5km is excavated; it realizes the closure of the full-section primary support and forms a ring, which solves the deformation problem caused by the relaxation of the surrounding rock over time after the tunnel is excavated in weak surrounding rock. Include the following steps:

[0016] Step 1. Advance pre-reinforcement of the tunnel face. During the construction, the three-arm rock drilling rig is used to pre-reinforce the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com