High-efficiency tunneling gas control method for high outburst mine coal roadway

A technology for coal lanes and mines, which is applied in the field of coal mine gas control, can solve problems that affect the balance of mine excavation, long gas drainage time, and unfavorable high-efficiency production, and achieve the goals of shortening drainage time, solving low efficiency, and reducing support costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

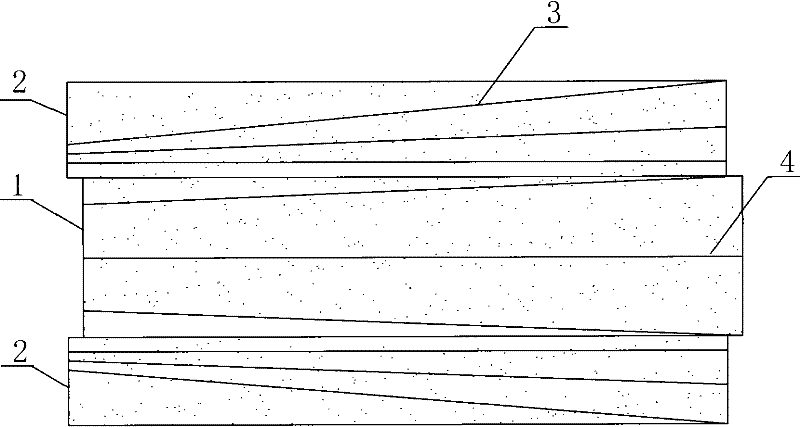

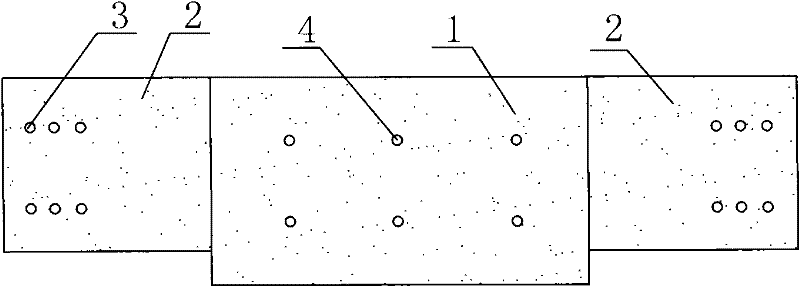

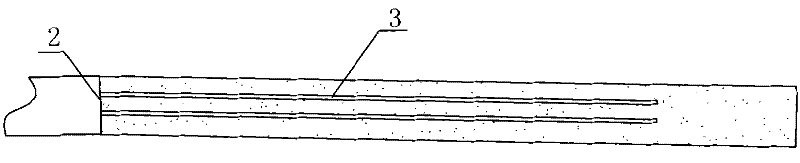

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the high-efficiency tunneling gas control method for coal roadways in high-outburst mines specifically includes: first, setting eighteen boreholes in the working face, of which six advanced drilling holes 4 are set in the coal roadway working face 1, and two advanced boreholes 4 are set in the two sides of the coal roadway. Six ultra-long deep holes 3 are respectively set in the drilling field 2, and the super-long deep holes 3 are inclined downward, and the angle is kept between 1° and 2°. Estimated excavation length. Grouting the two super long deep holes 3 to block the passage between the coal seam 1 of the working face and the outside coal seam, and at the same time, using the six advanced boreholes 4 distributed on the working face 1 of the coal roadway to carry out the gas control in the coal roadway Pumping and decompression treatment. After the treatment is completed, high-efficiency excavation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com