Patents

Literature

103results about How to "Efficient excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

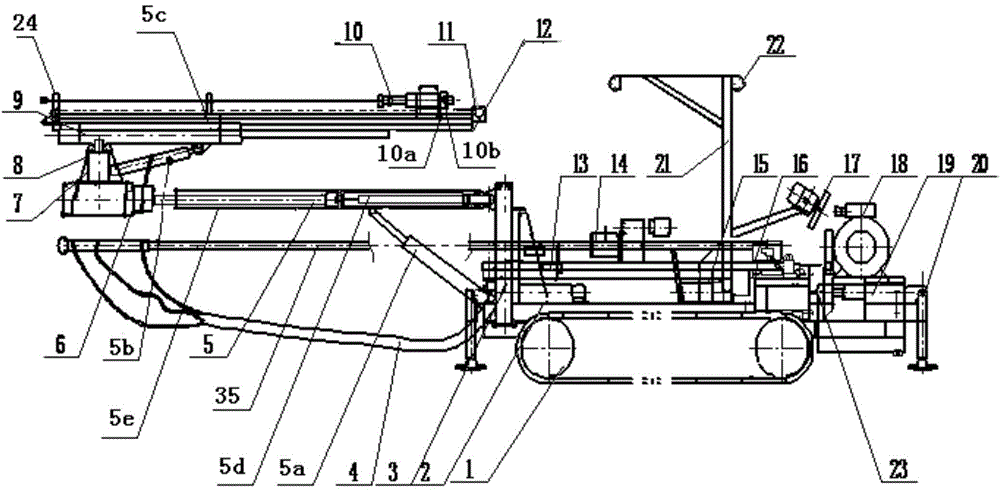

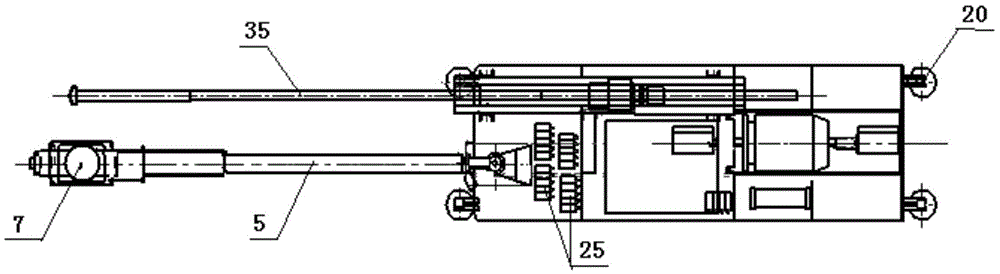

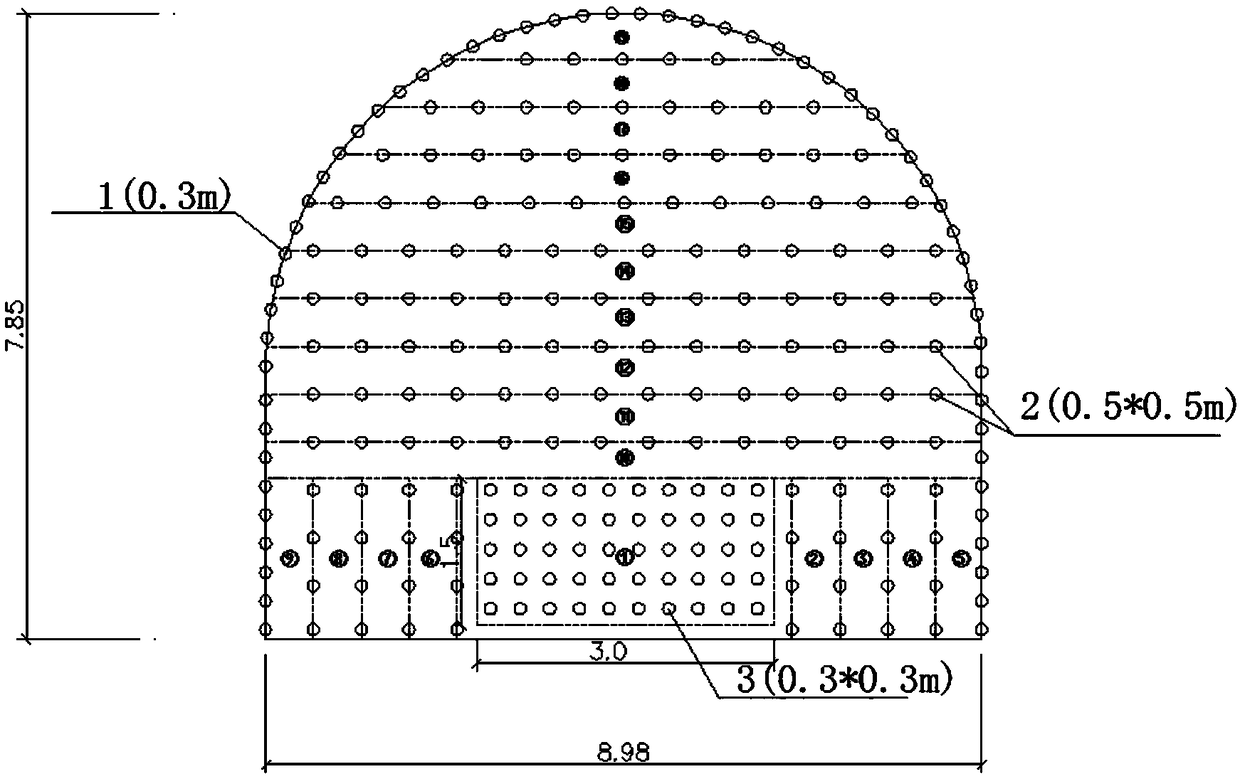

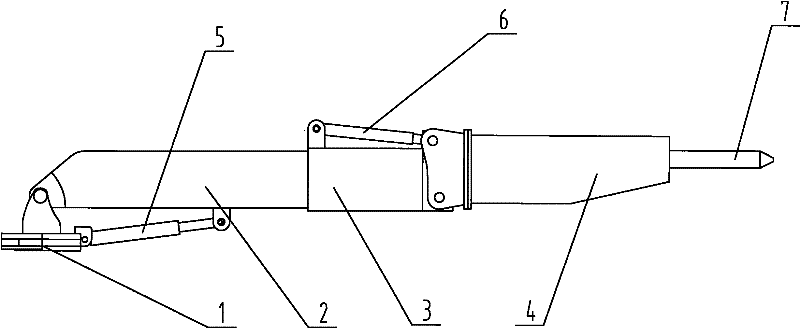

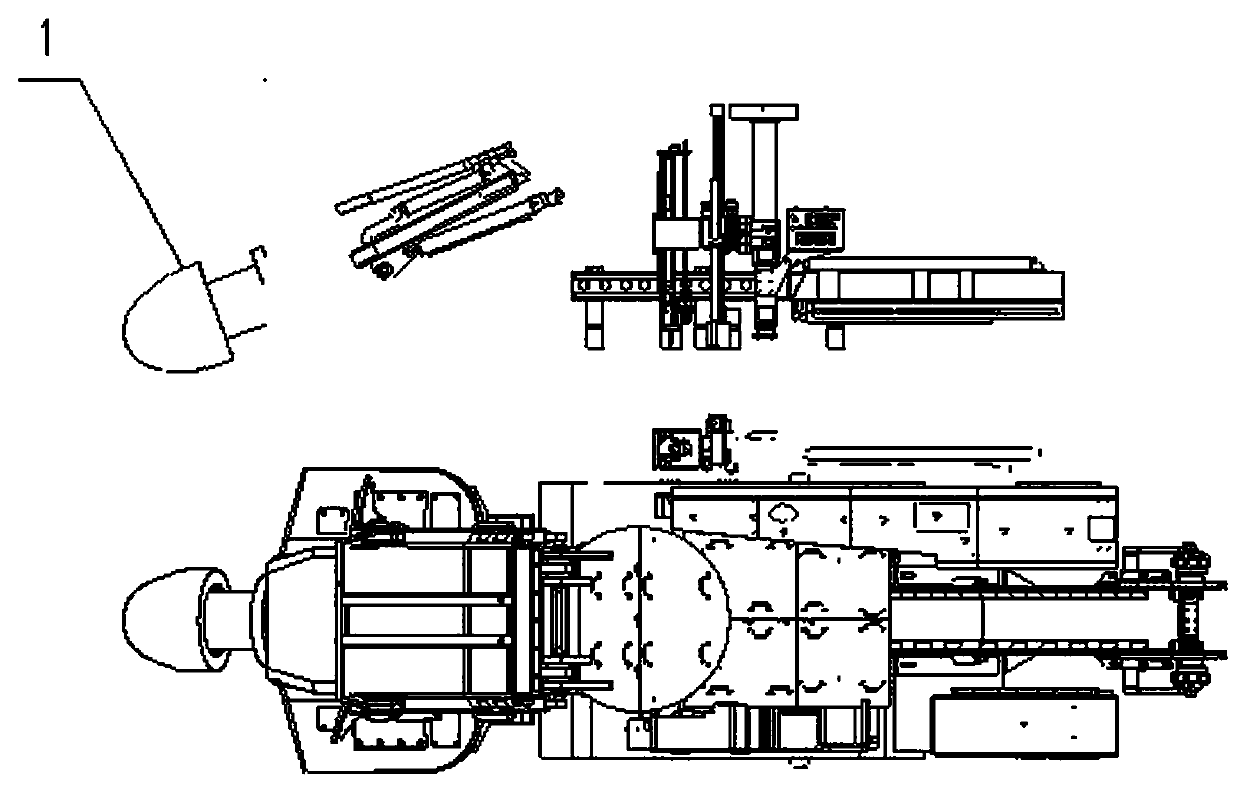

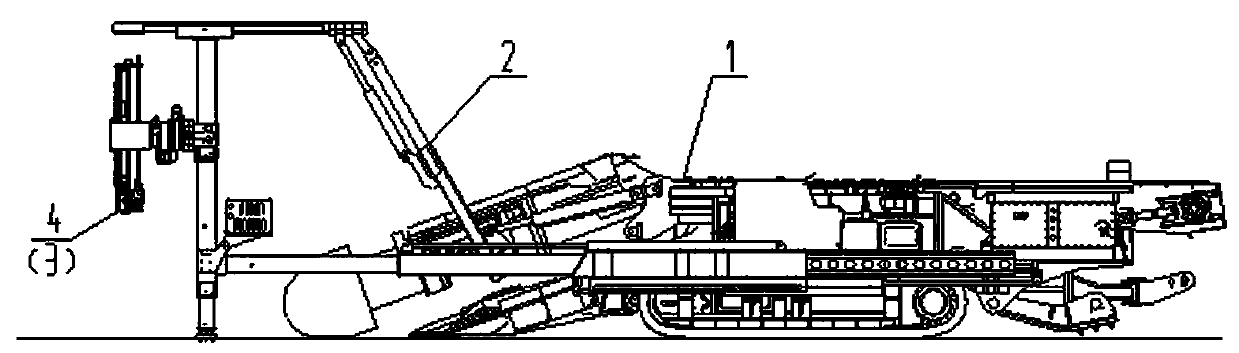

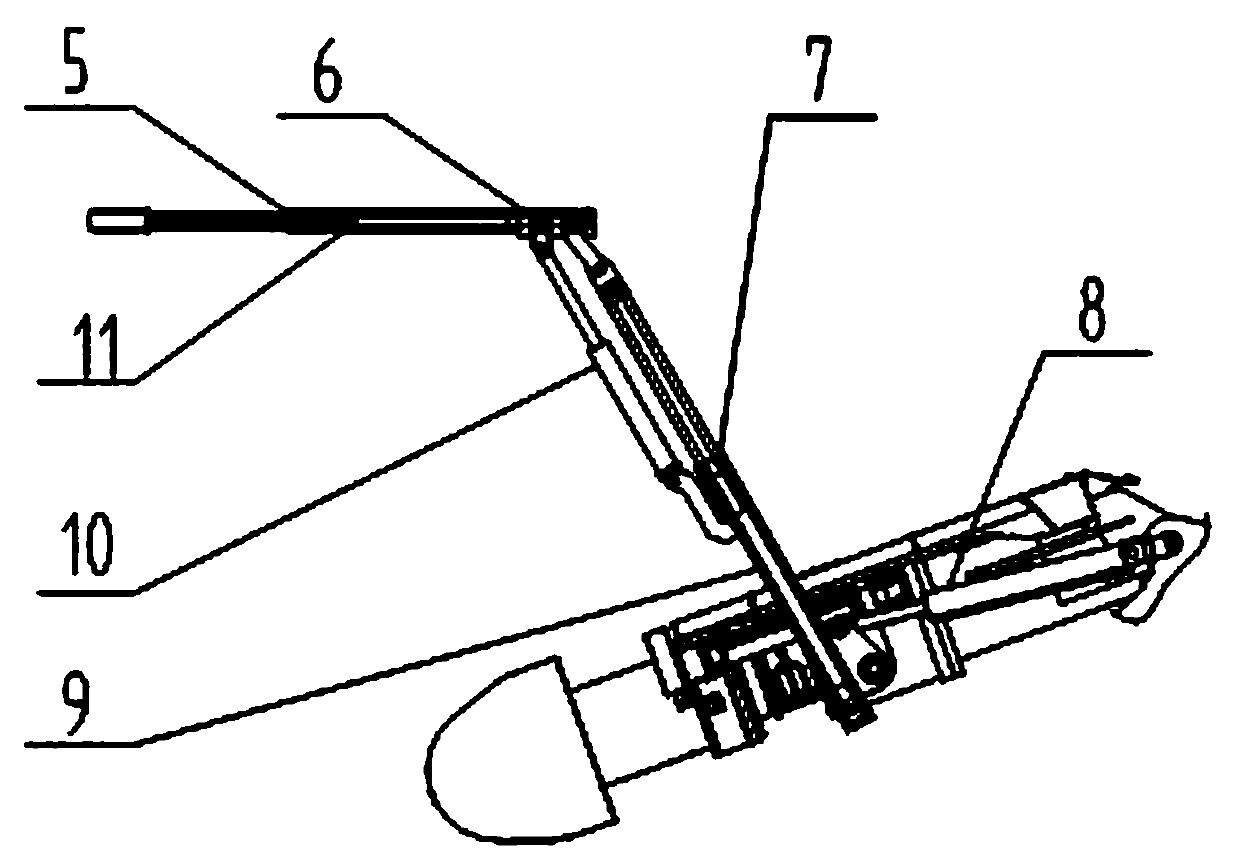

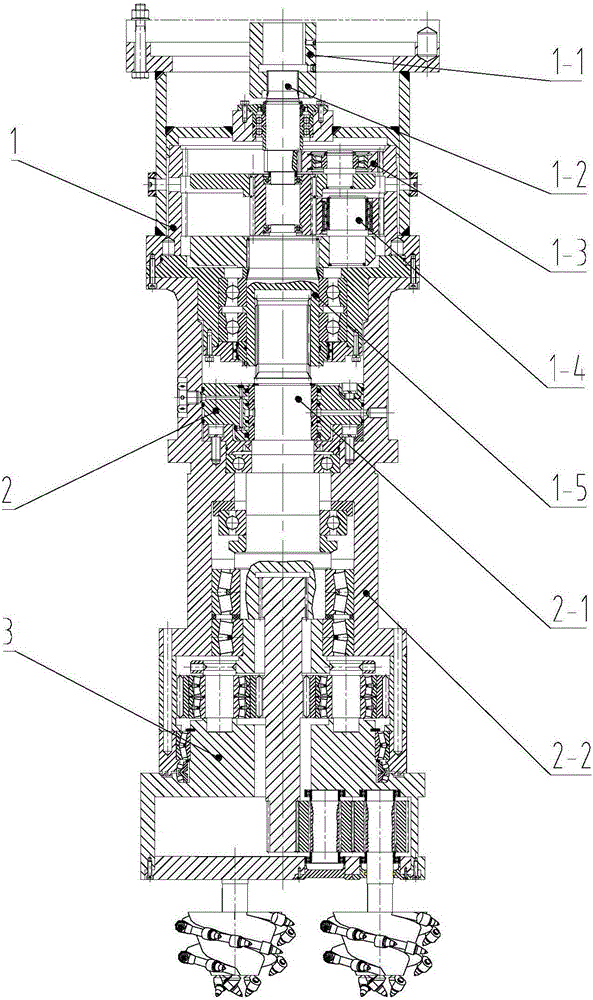

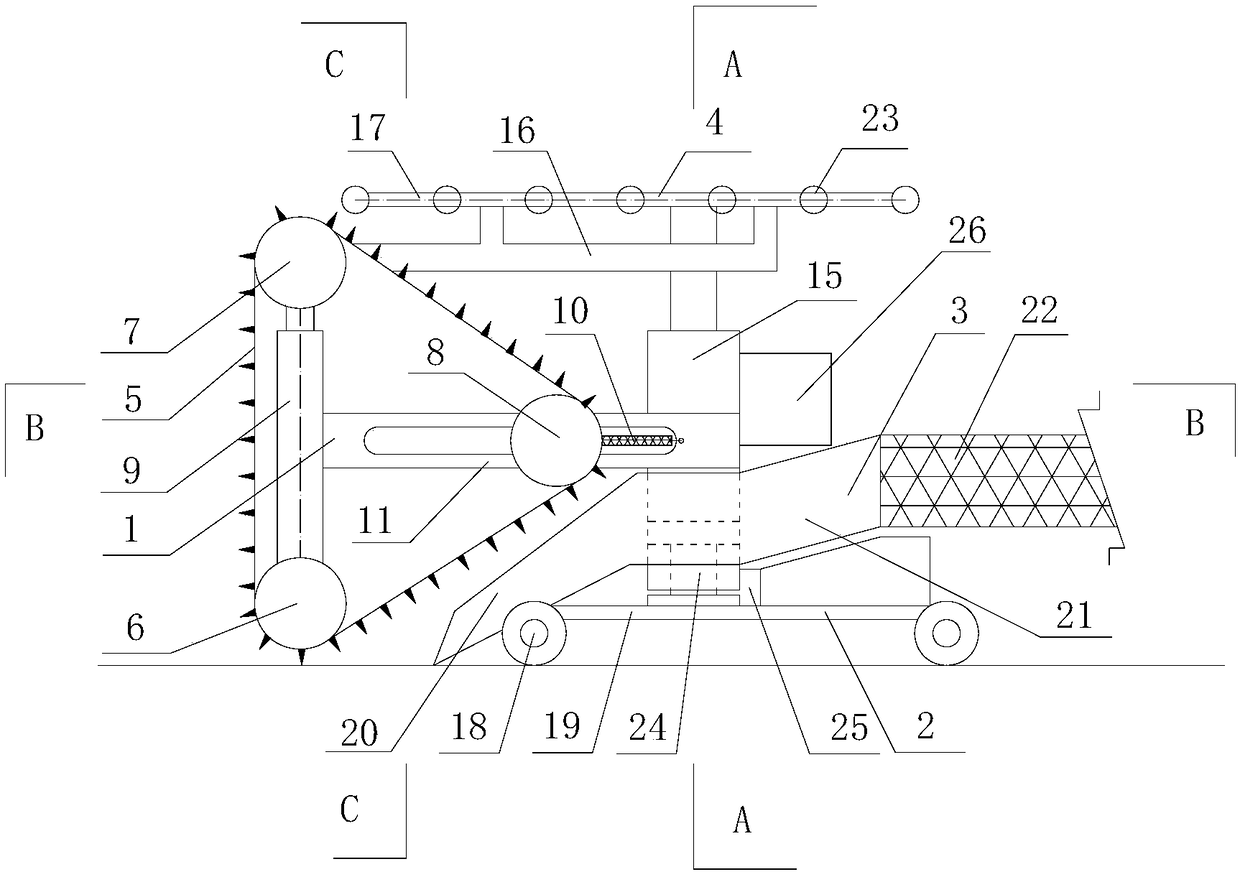

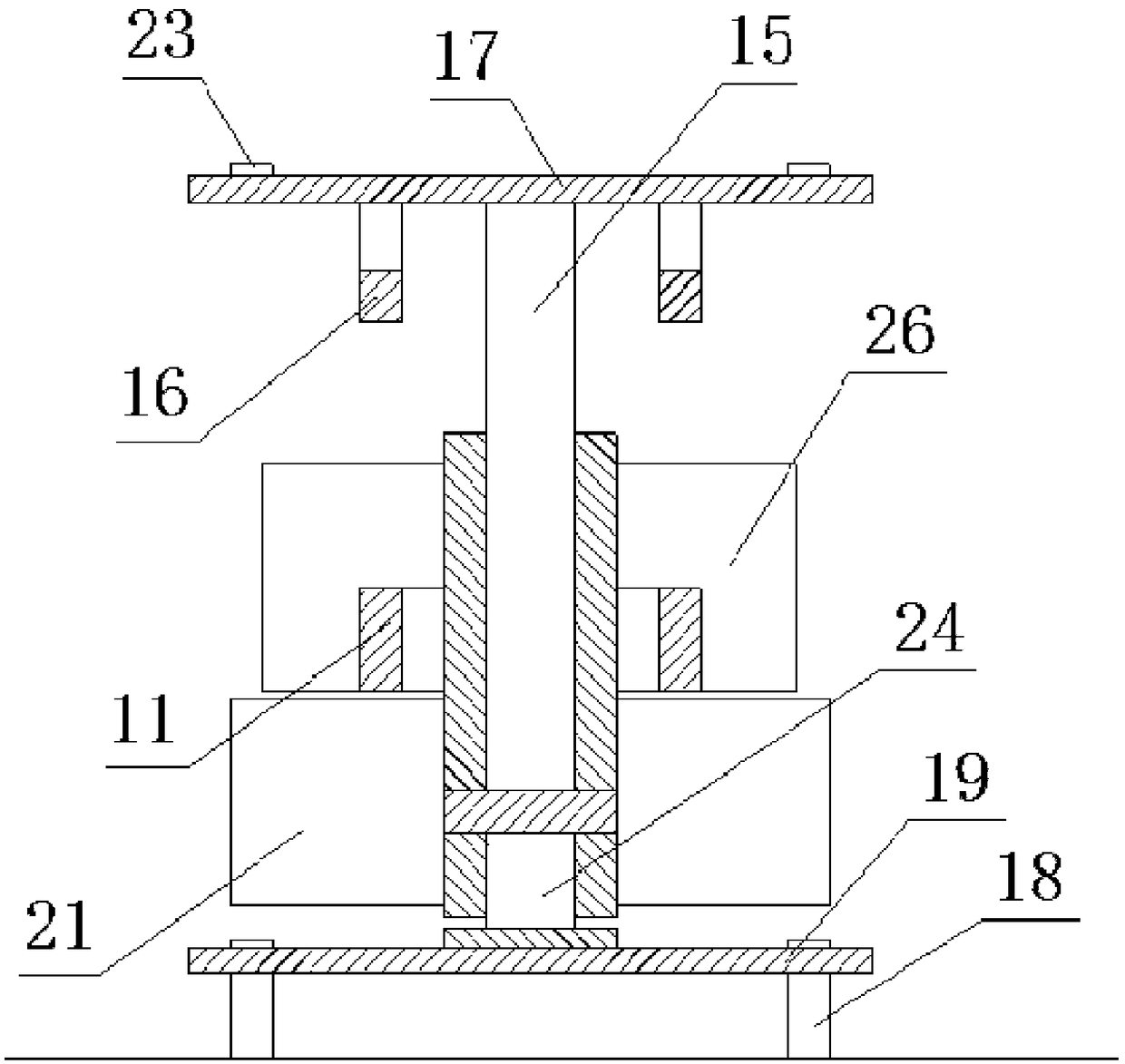

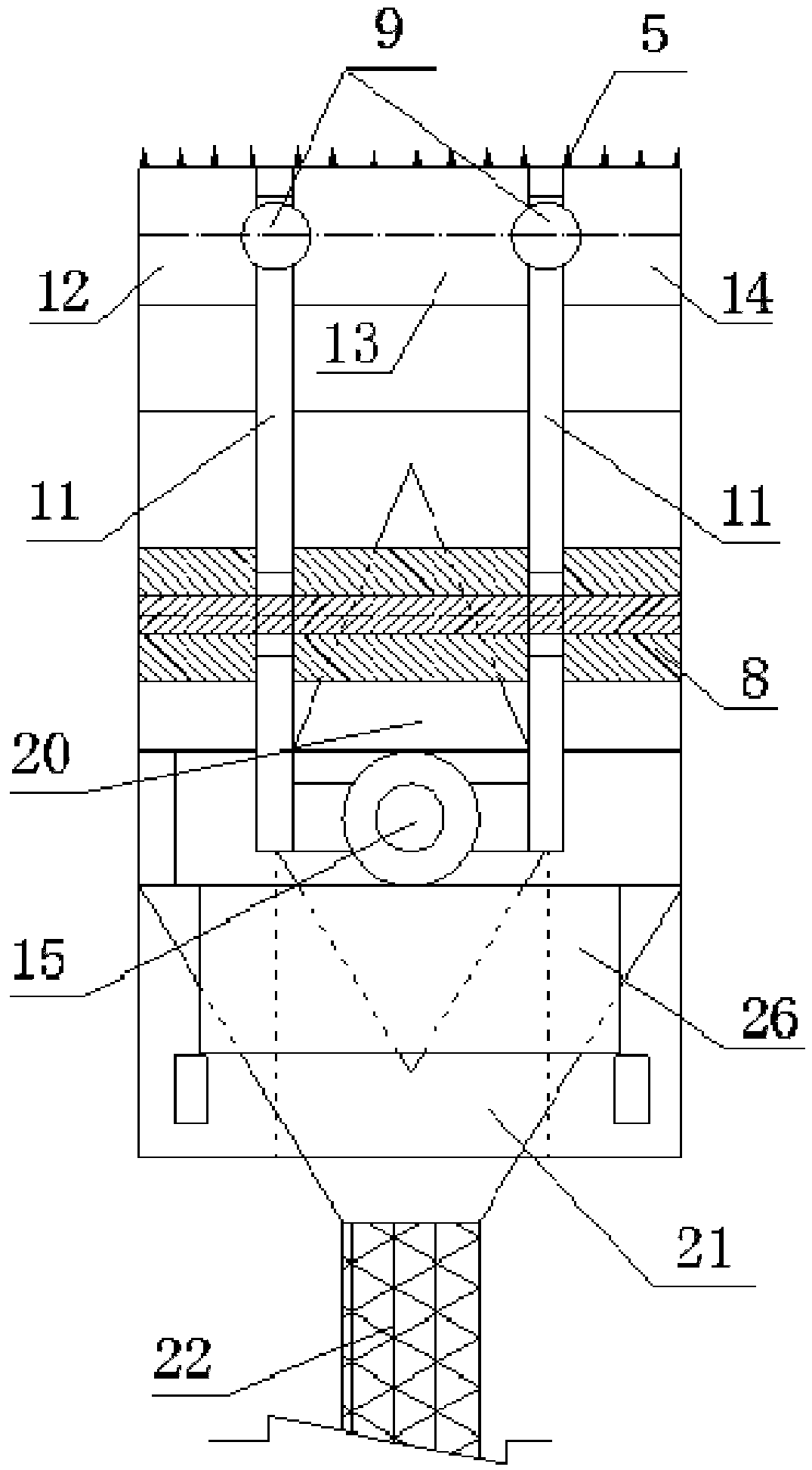

Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

ActiveCN104612586ACompact chassisCompact structureDerricks/mastsDrilling drivesHydraulic motorReducer

The invention discloses a whole-section quick-drilling drill carriage specially used for parallel cut blasting of large empty holes in a roadway. The drill carriage is composed of a walking mechanism, a carriage frame, a hydraulic system, an electrical system and two drilling devices, wherein the first drilling device is used for drilling common blasting holes, and the second drilling device is used for drilling cut holes with the diameter of 100 mm or more. In the operating process of the drill carriage, a hydraulic motor drives a main chain wheel of a crawler-type walking chassis to rotate through a speed reducer; after a carriage body is stabilized, the first drilling device and the second drilling device are manipulated to select hole locations respectively; after the first drilling device and the second drilling device are located, the common blasting holes and the empty holes with the diameter of 100 mm or more can be drilled in rock simultaneously. The drill carriage is suitable for the roadway with the minimum section of 8 square meters and the maximum section of 23 square meters; by the adoption of a building block structural design, the drill carriage is convenient and fast to disassemble and assemble and convenient to transport; as a result, the drill carriage can be used when the length of the roadway under tunneling construction is seven meters or more, and accelerates tunneling mechanization and quick and efficient tunneling modernization.

Owner:SHANDONG UNIV OF SCI & TECH +1

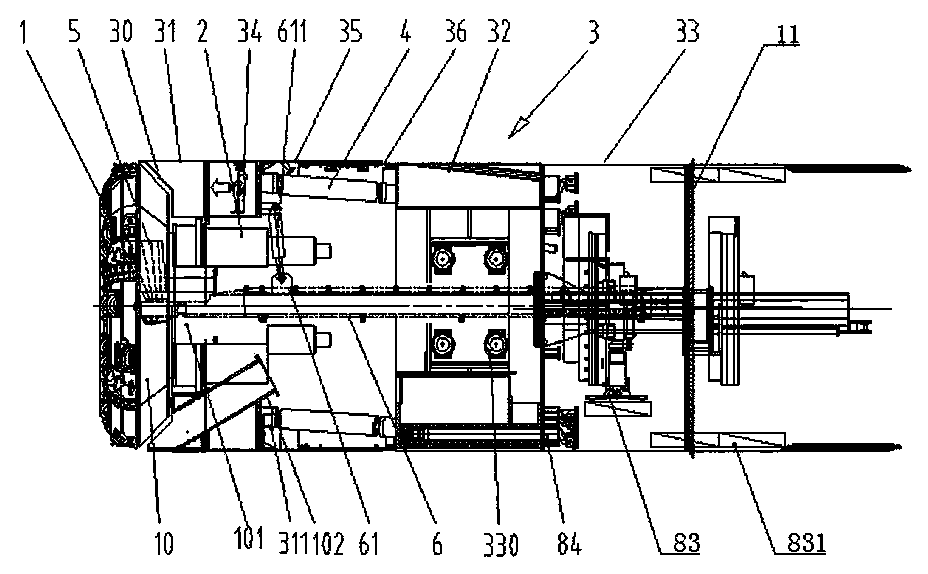

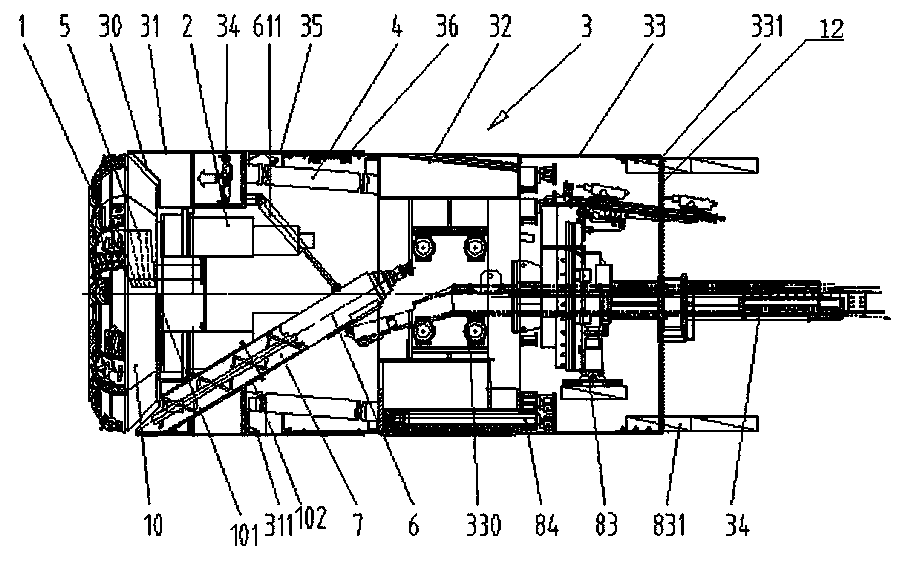

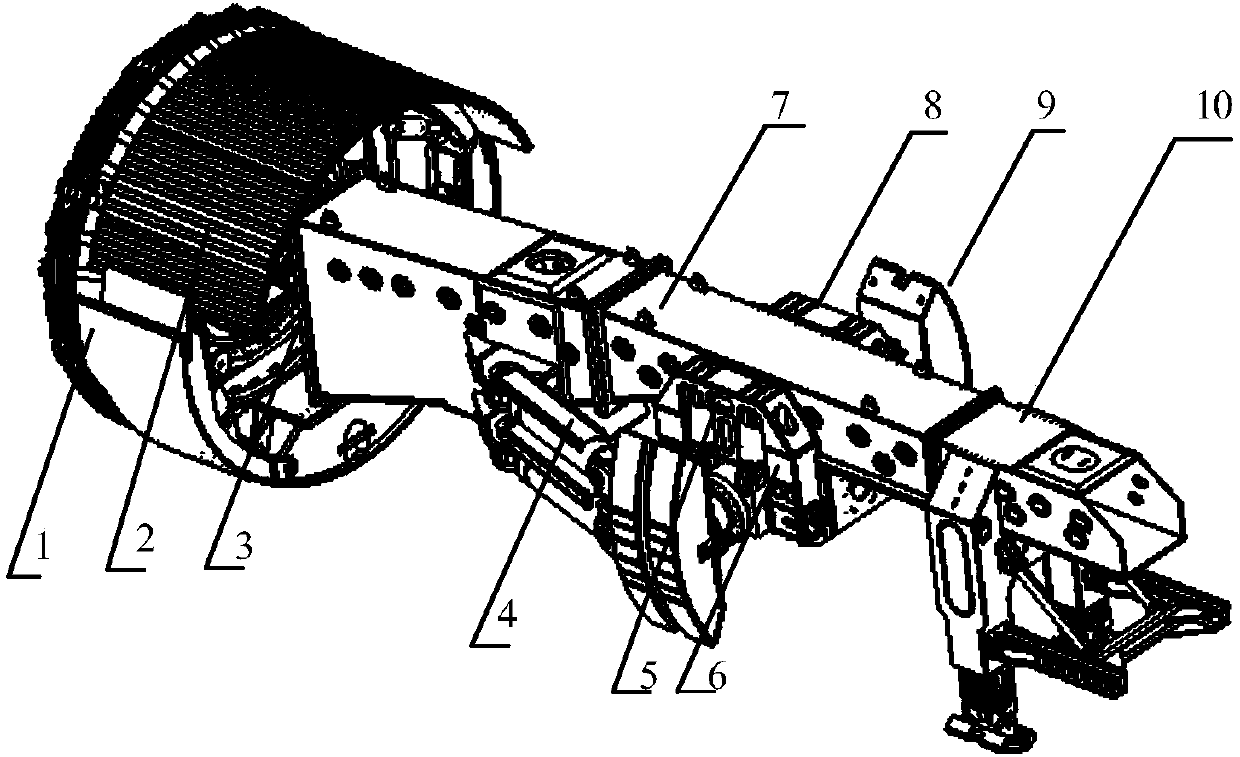

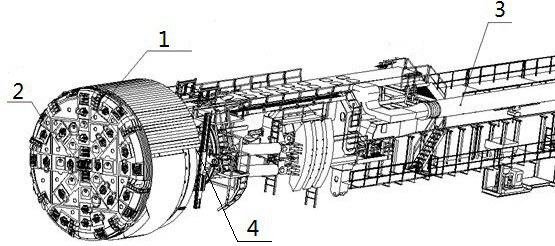

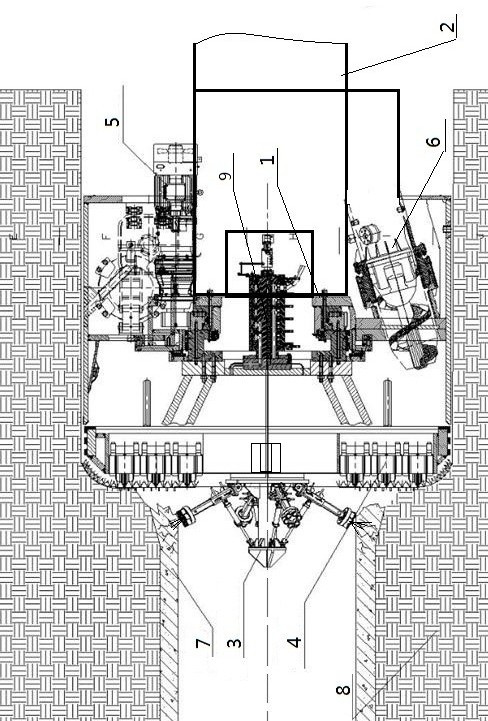

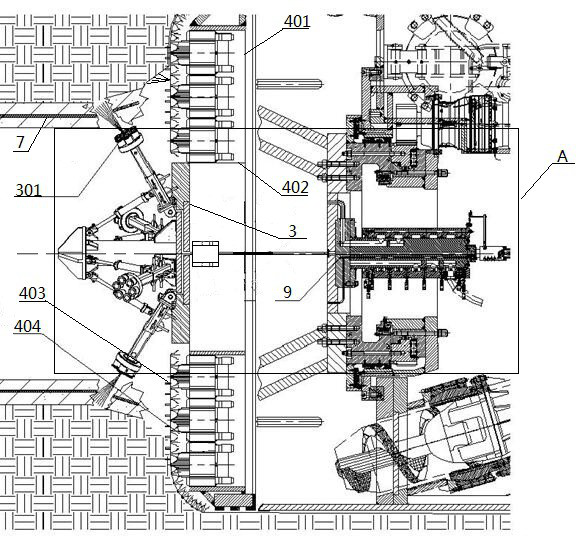

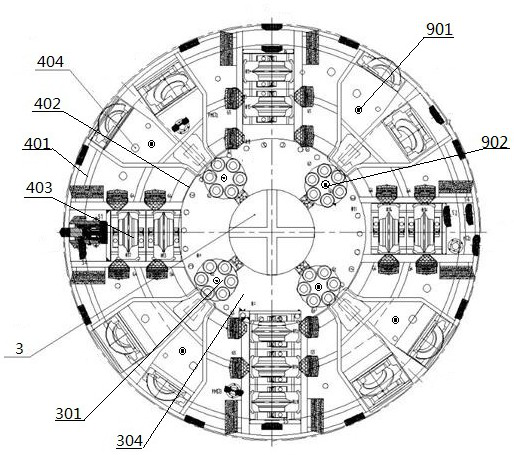

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

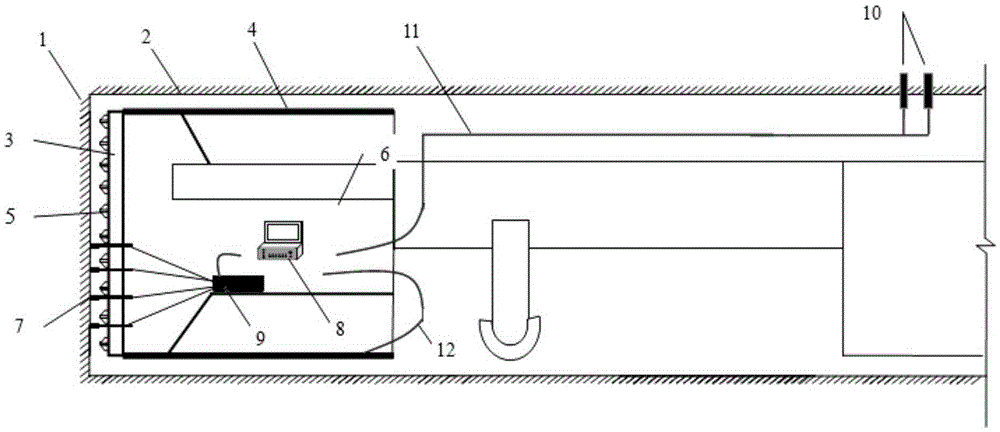

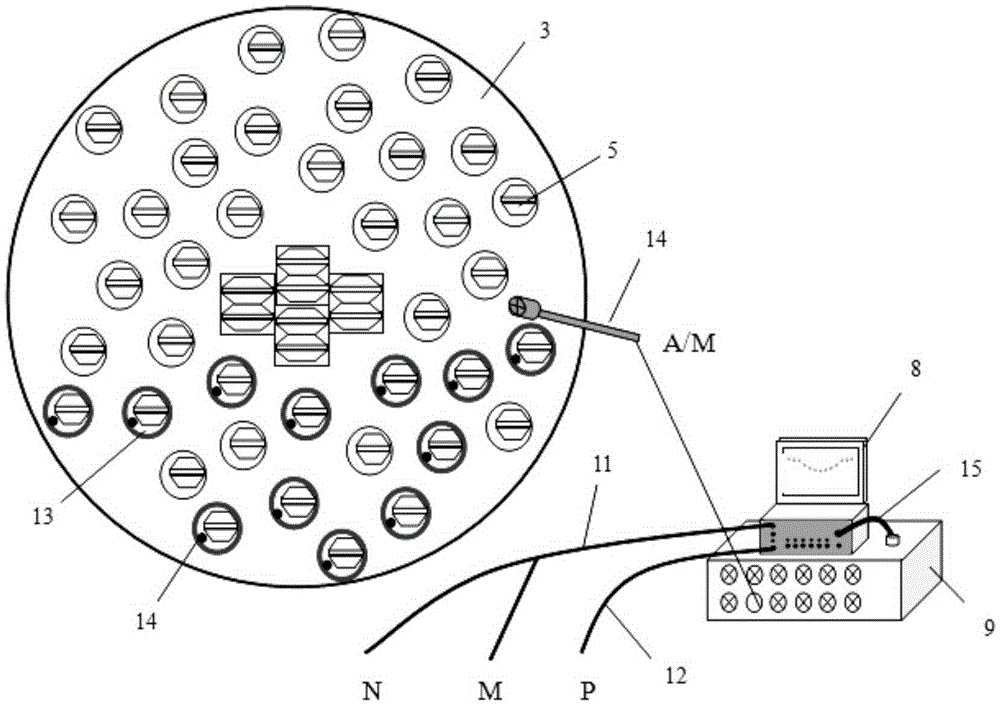

Portable resistivity method advanced forecasting system and method applicable to TBM

ActiveCN105334541AReduce volumeShort completion timeElectric/magnetic detection for well-loggingWater resource assessmentElectricityFracture zone

The invention relates to a portable resistivity method advanced forecasting system applicable to a TBM. The system comprises a plurality of non-polarized electrodes, a terminal control box and an electrode cable series. The non-polarized electrodes are electrically connected with the terminal control box. The terminal control box is electrically connected with the electrode cable series. The non-polarized electrodes are arranged to be capable of stretching out of a TBM cutterhead hob hole and making contact with a tunnel face to detect front geological signals. The terminal control box receives the signals collected by the non-polarized electrodes and predicts a front geologic body. The potential difference between a surrounding rock mass, a shield and the terminal control box is reduced and / or eliminated through electrode cables. According to the system, detection of unfavorable geologic bodies such as a fault fracture zone, a soft and hard layered stratum, a water-bearing cave and an underground river is achieved according to geologic body resistivity difference.

Owner:山东百廿慧通工程科技有限公司

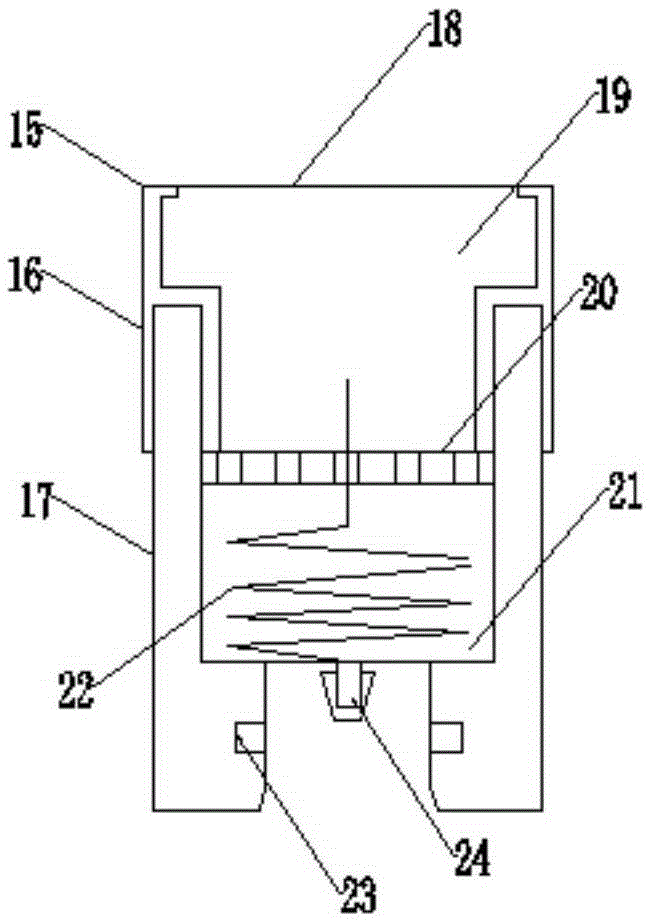

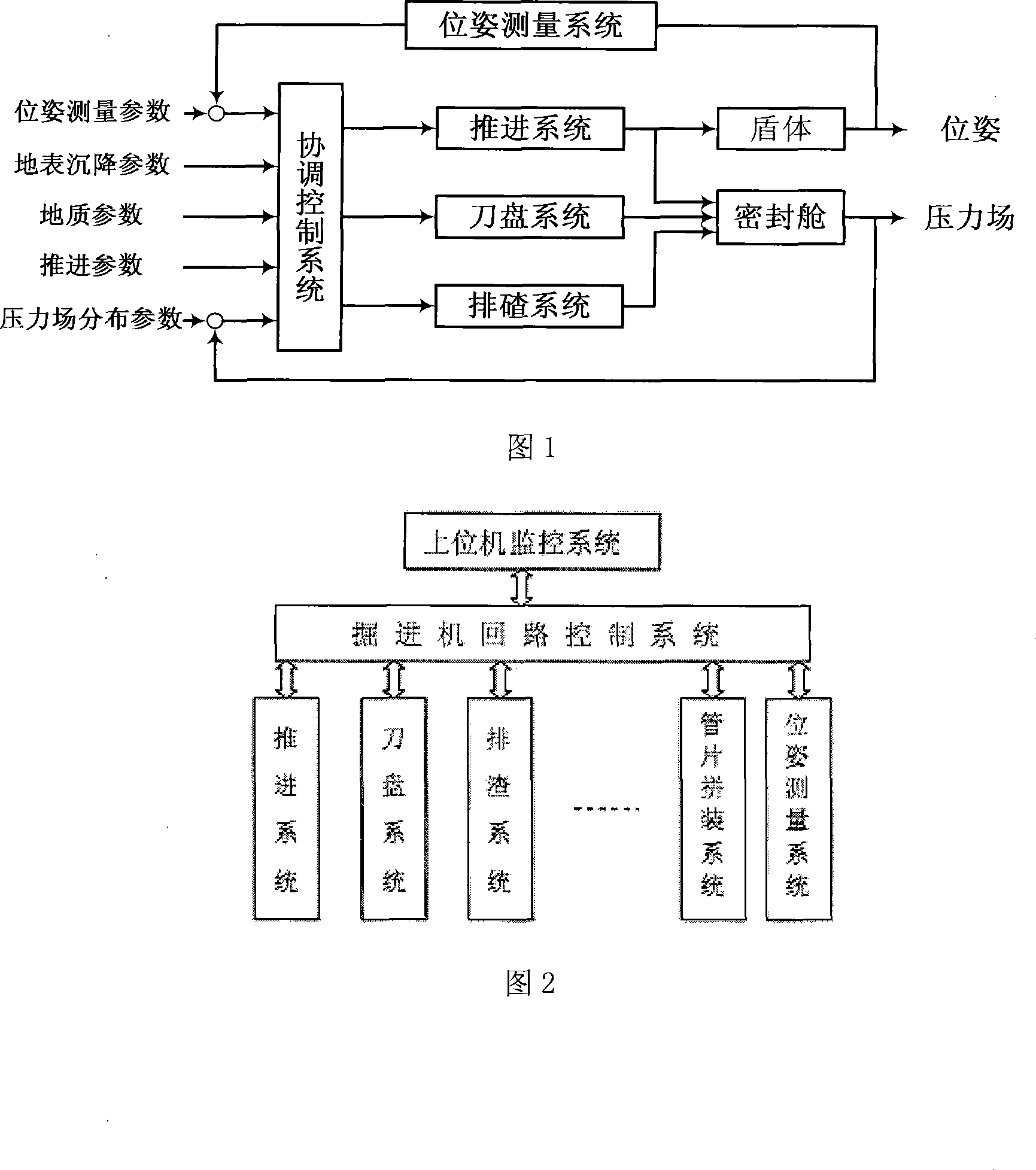

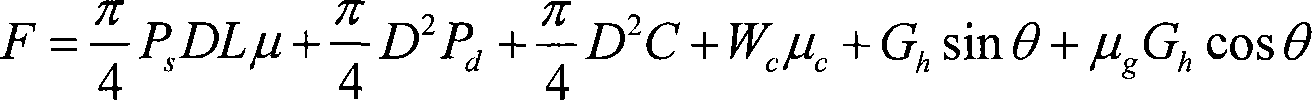

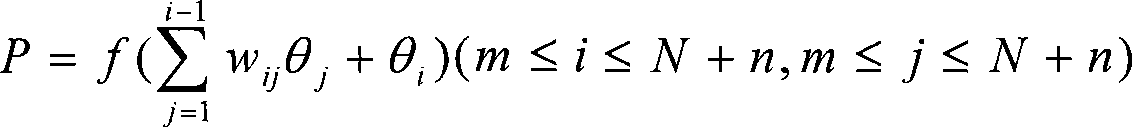

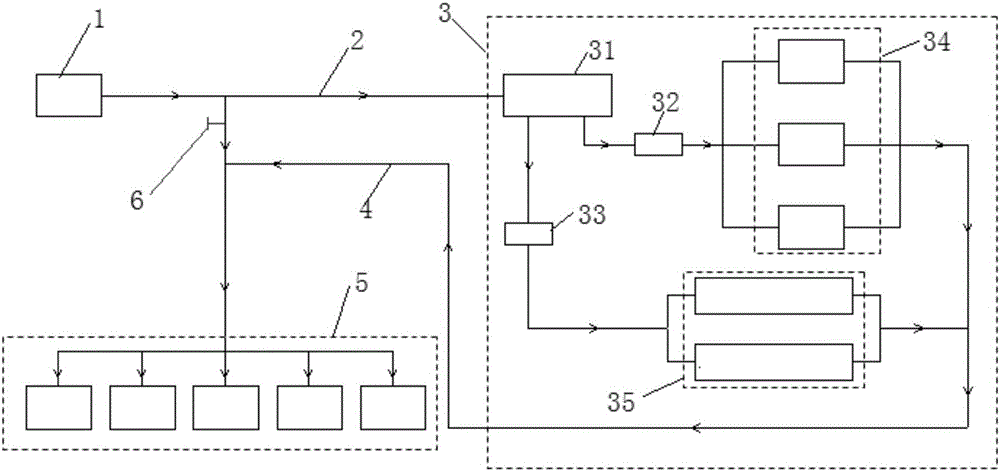

Dynamic coordination controlling system for full-section large-scale digging device

InactiveCN101210495ASafety during excavationEfficient excavationTunnelsAutomatic controlTime changes

The invention provides a dynamically-coordinated control system for a large full-face excavating device, which relates to the technical field of automatic control on tunnel excavating and resolves the problem of multi-systematic coordination and control of an excavating device under multi-field coupling. The invention comprises a coordinated control system, a propulsion system, a cutter-head system, a slag discharge system, a post measurement system and a sealed-cabin pressure graded distribution model. The invention is characterized in that by adopting methods of predictive functional control and fuzzy control, the coordinated control system provides the best operation control strategy for each subsystem respectively and modifies real-time setting values of operational parameters for the propulsion system, the cutter-head system and the slag discharge system based on the real-time changes of each parameter. The invention has the advantages of that: the three subsystems of propulsion, cutter-head and slag discharge can be harmoniously controlled, and the purposes of sealed-cabin pressure balance and shield directing rectification can be achieved, thereby ensuring the whole excavating process is safe and efficient.

Owner:DALIAN UNIV OF TECH

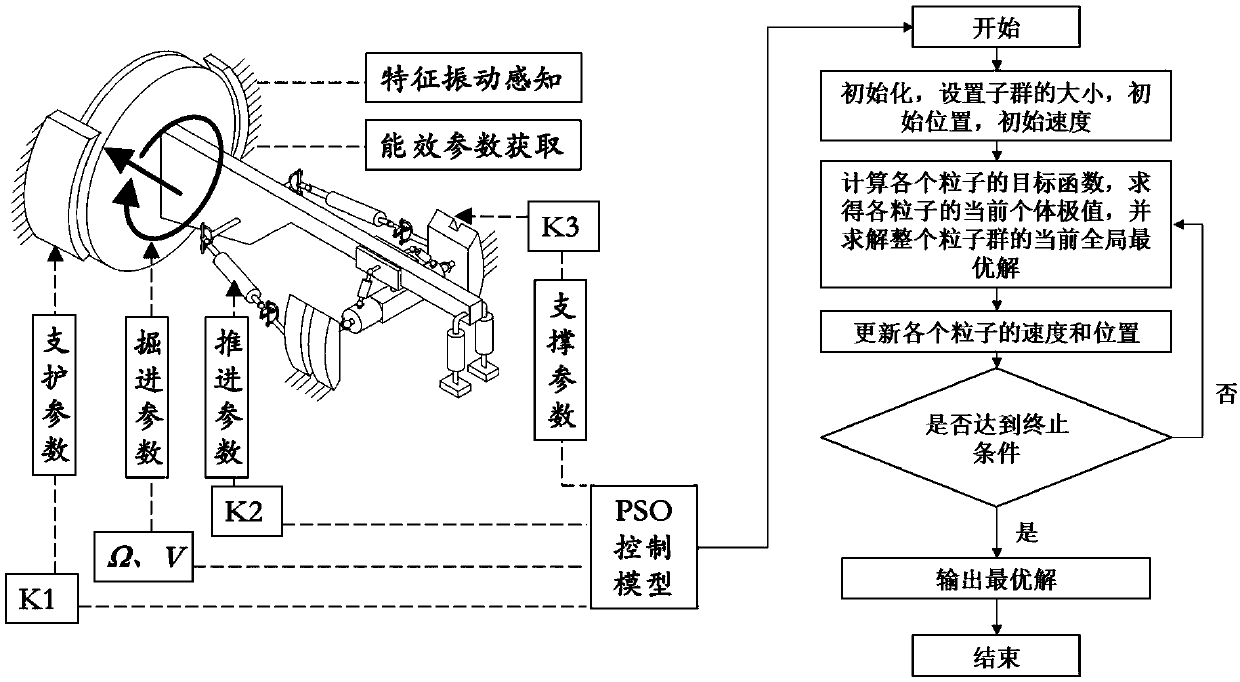

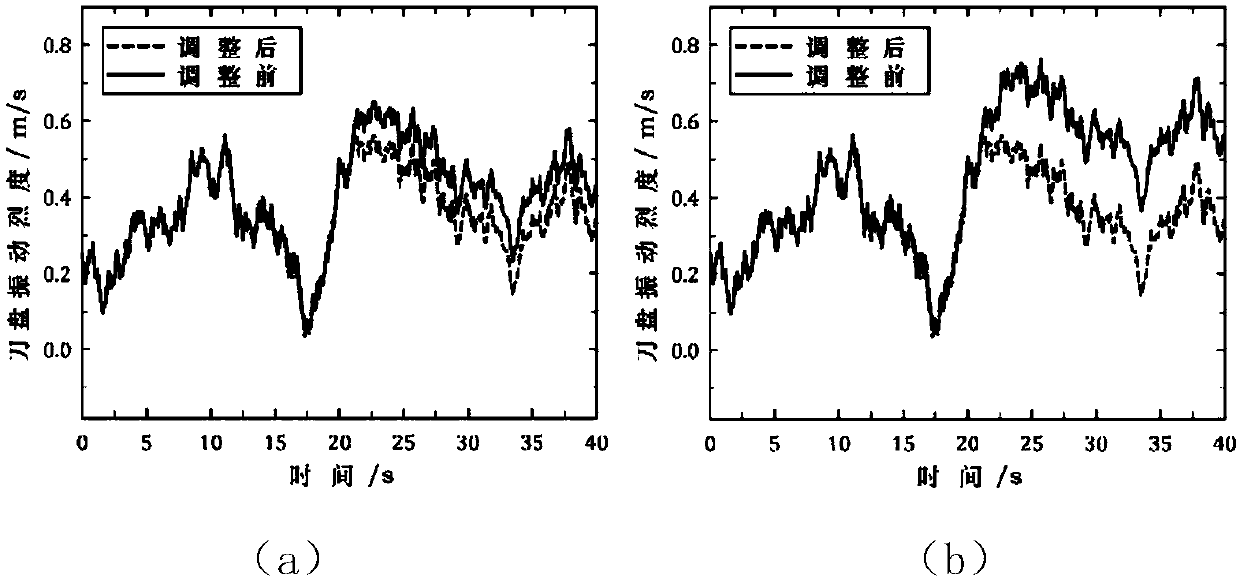

TBM vibration damping control method based on particle swarm optimization algorithm PSO

A TBM vibration damping control method based on a particle swarm optimization algorithm PSO comprises the following steps: 1, building a TBM concentration parameter dynamics model; 2, modeling each rigidity node in the TBM concentration parameter dynamics model; 3, taking the minimum TBM vibration intensity and the minimum TBM driving specific energy as targets, and building a multi-target optimization vibration damping control model; 4, using the PSO algorithm to solve the multi-target optimization vibration damping control model, comparing the real time measured vibration parameter with a theory vibration parameter calculated by the concentration parameter dynamics model, further adjusting a control parameter, related to the vibration parameter, in the multi-target optimization vibrationdamping control model; using the optimization iteration algorithm to obtain the optimal rigidity parameter and driving parameter, further adjusting the control parameter in the TBM actual operation process according to the optimal rigidity parameter and driving parameter, thus realizing optimization control of TBM vibration, and realizing the high efficiency driving target of the TBM under the low vibration level conditions.

Owner:SHANGHAI JIAO TONG UNIV

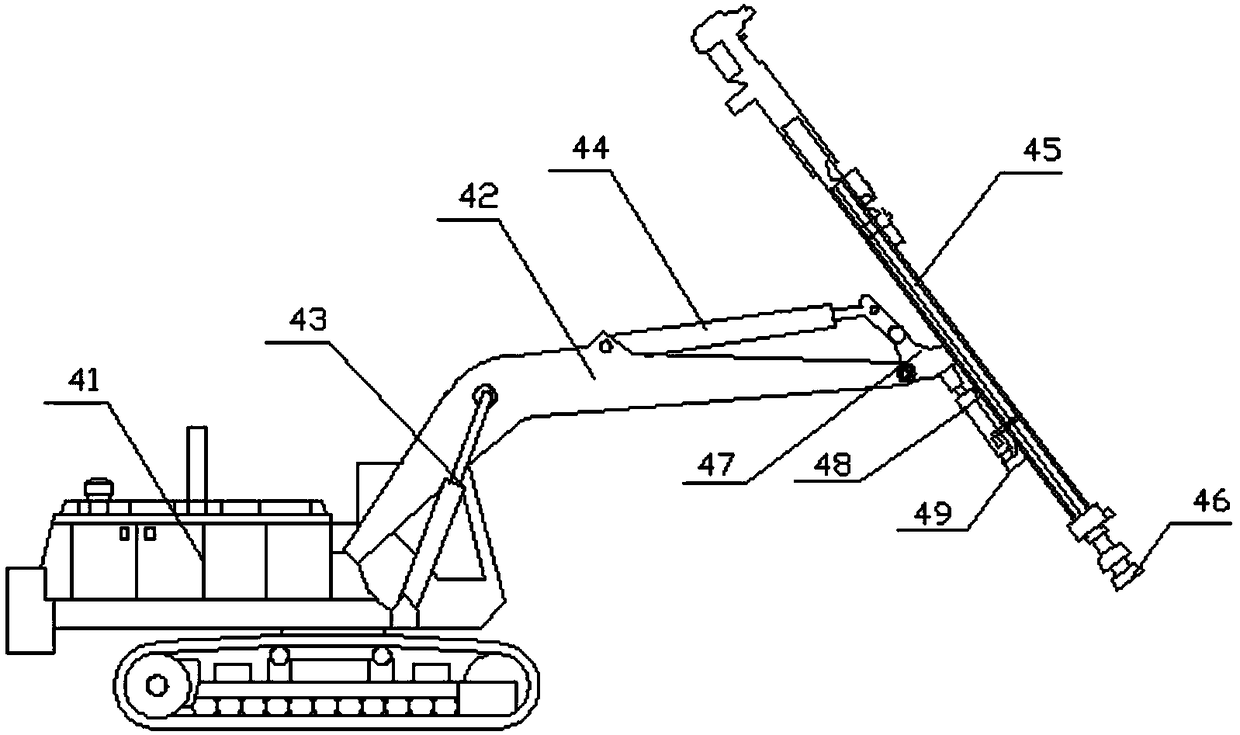

Construction method for tunneling excavation through matching of down-the-hole drill and breaking hammer

ActiveCN109296378AShorten the construction periodReduce construction difficultyTunnelsTotal stationEngineering

The invention discloses a construction method for tunneling excavation through matching of a down-the-hole drill and a breaking hammer. The construction method comprises the following steps that firstly, peripheral outline holes, slotting holes and breaking holes are formed in a tunnel face through a total station, and marks are made; secondly, the track-type hydraulic down-the-hole drill is utilized for drilling, according to the drilling sequence, the peripheral outline holes are drilled firstly, the slotting holes are formed in middle areas of a lower-middle section of the tunnel face, andthe breaking holes are formed in the rest part of the tunnel face; and thirdly, the breaking hammer is utilized to break the tunnel face from bottom to top in the vertical direction, the area with thedense hole pitch in the lower portion is broken firstly, a free face is dug out, then upward excavation is conducted layer by layer, and breaking is conducted according to the sequence of bottom, top, left, right and periphery. Interference to peripheral buildings is reduced, construction noise is controlled, tunneling of a tunnel body is accelerated, the design goal is achieved, and significantsocial benefits and economic benefits are achieved.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG +1

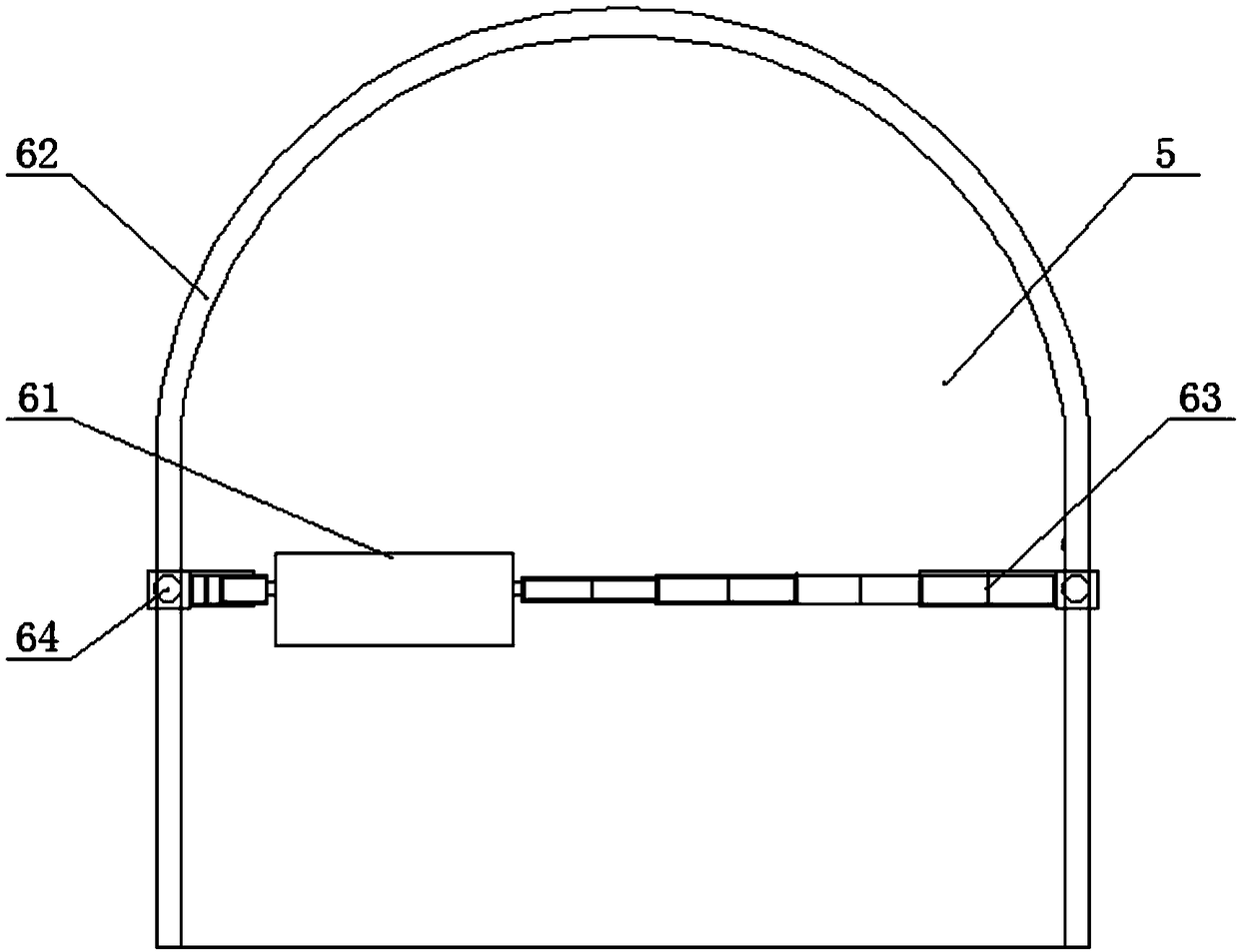

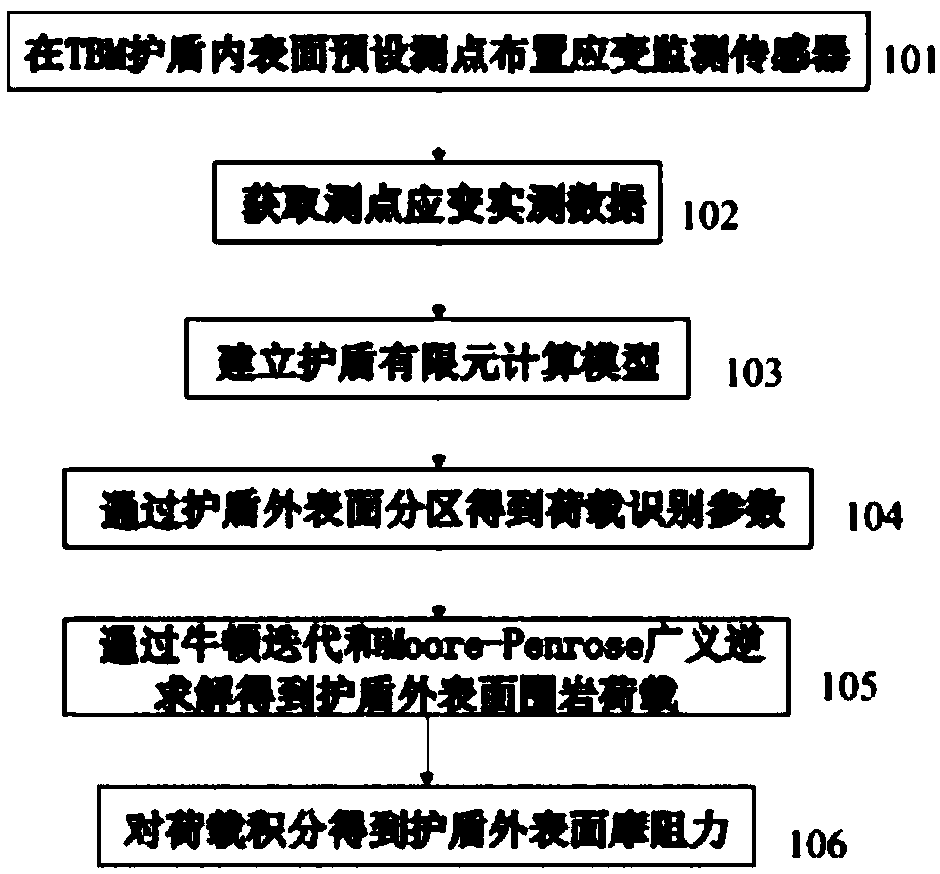

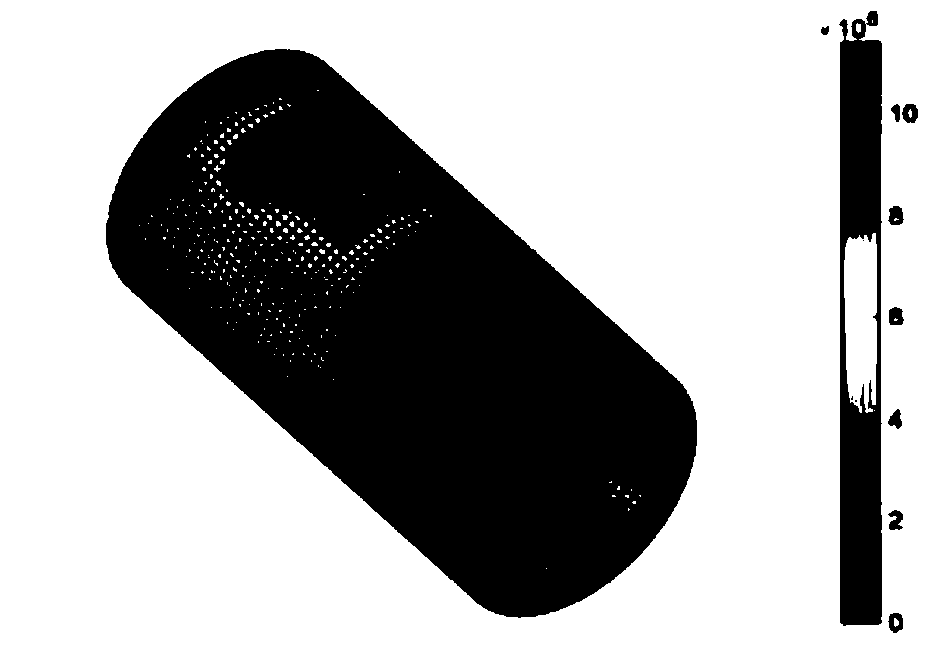

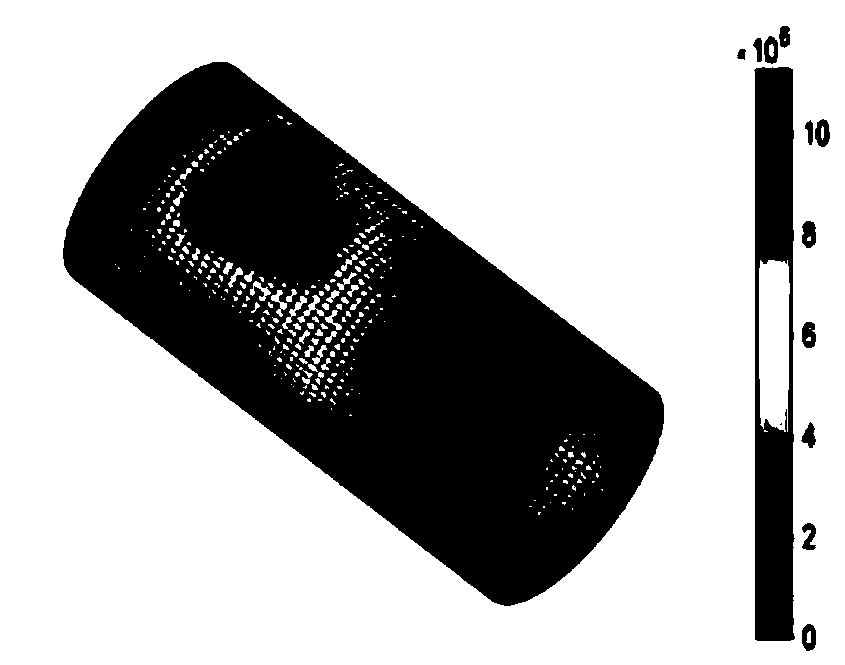

Method for identifying surrounding rock load of outer surface of three-dimensional TBM shield

ActiveCN109387385ARealize visualizationTunnel Safety Construction GuaranteeMining devicesStructural/machines measurementGeneralized inverseGreek letter epsilon

The invention discloses a method for identifying surrounding rock load on an outer surface of a three-dimensional TBM shield, and relates to the technical field of high-efficiency tunneling and safetycontrol of a deep tunnel shield type TBM. The method comprises: 1, installing a strain monitoring sensor on a preset measuring point on an inner surface of a TBM shield; 2, obtaining strain measureddata of the measuring point [epsilon]m; 3, establishing a finite element calculation model of the TBM shield; 4, obtaining a load identification parameter through partition of the shield outer surface; 5, through Newton iteration and Moore-Penrose generalized inverse solution, obtaining surrounding rock load on the outer surface of the shield; 6, performing integration on the load to obtain outersurface friction resistance of the shield. The method has high calculation precision and good visualization effect, and is suitable for identification of outer surface load of the TBM shield on site,and can provide guidance for safe construction of tunneling, early warning of a stuck machine, and accident handling.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

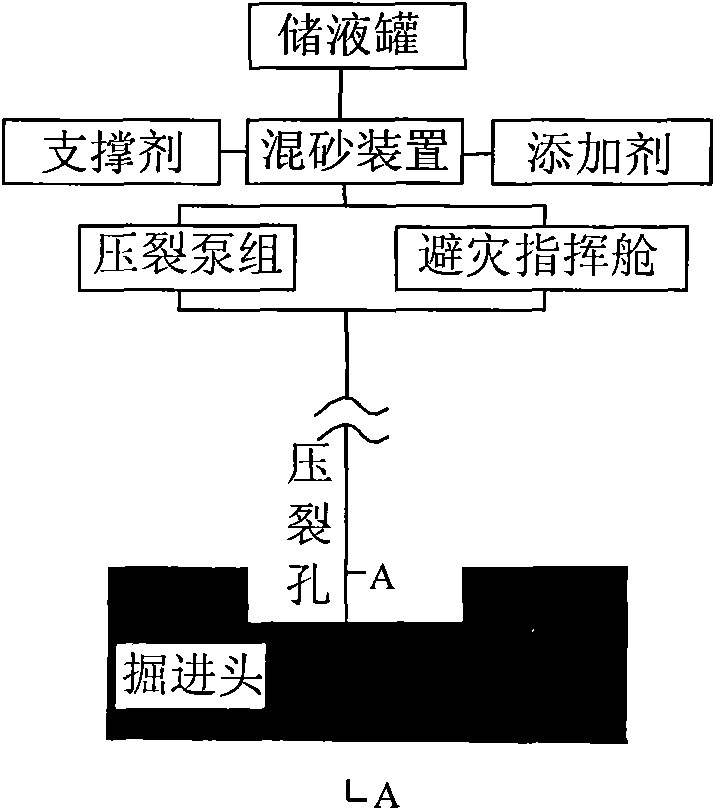

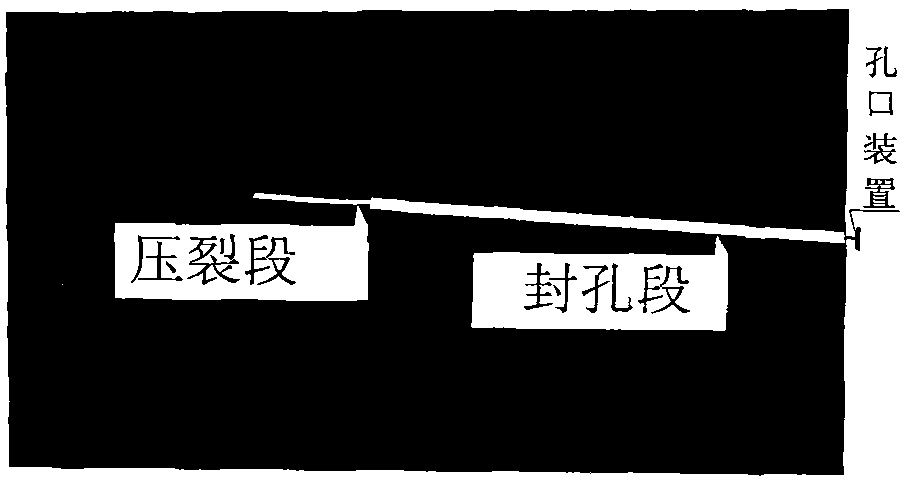

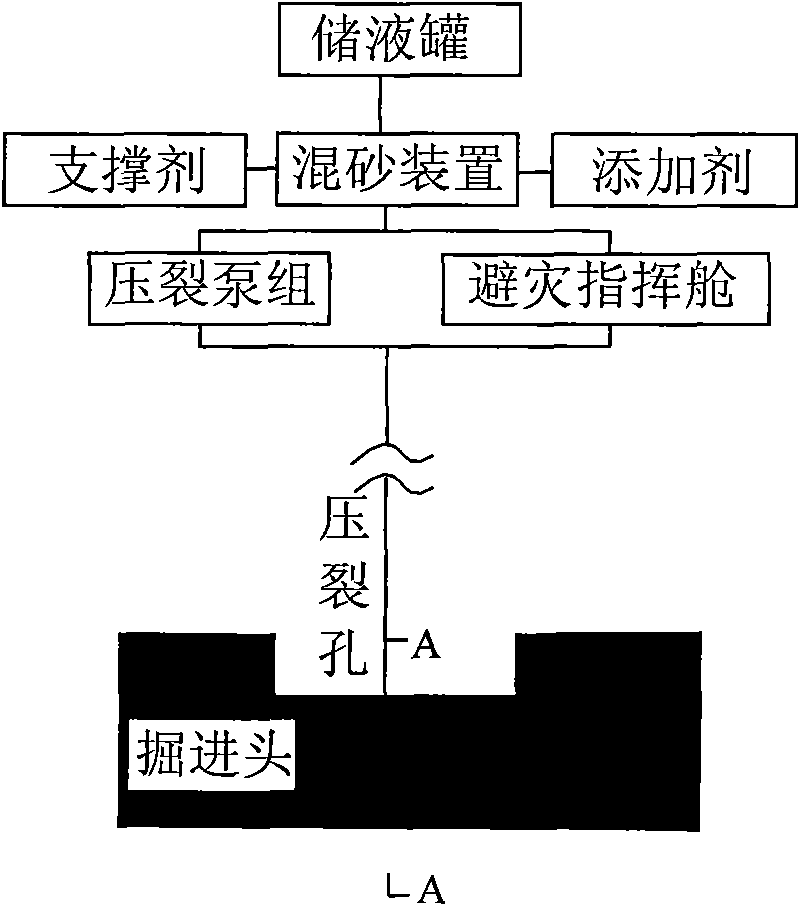

Coal-rock drift quick tunnelling method

The invention relates to a coal-rock drift quick tunnelling method. In the method, hydraulic fracturing is carried out in underground coal rock mass, so as to improve permeability and safely and quickly tunnel. Firstly long drill holes are constructed at tunnelling head, hole termination is required to be over mining pressure releasing region, long drill holes such as geologic hole and boring hole are not existed near drill hole, a hole packer special for fracturing is adopted to seal hole, hole sealing position is required to be over mining pressure releasing region, meanwhile a high pressure pipeline is arranged, and a fracturing pump set is mounted, arranged and debugged; then the hole packer special for fracturing is connected by virtue of the high pressure pipeline; and finally tunnelling hydraulic fracturing operation is carried out, underground dewatering is carried out, a gas drainage hole is constructed, and online gas drainage is carried out, thus achieving the aims of permeability enhancing, protrusion dispelling and safe tunnelling. Compared with the conventional measures, the invention is safe and effective, coal seam permeability can be improved by more than one hundred times, gas drainage effect is obvious, protrusion preventing indexes after fracturing are all not more than critical values, and finally the aim of safe and quick tunnelling is achieved.

Owner:河南省煤层气开发利用有限公司

Oxygen-free outburst-prevention green and efficient tunneling technology suitable for gas-outburst coal road

InactiveCN104790958ARealize transportationRealize in and outMining devicesGas removalIntrinsic safetyEconomic benefits

The invention provides an oxygen-free outburst-prevention green and efficient tunneling technology suitable for a gas-outburst coal road and belongs to the technical field of mining safety. The oxygen-free outburst-prevention green and efficient tunneling technology mainly relates to the outburst predicting and forecasting technique, an intrinsic-safety tunneling device, an intrinsic-safety transportation device, a noxious gas monitoring system, a dynamic variable-frequency gas drainage system, the inert gas blocking technique, and the accident emergency rescue technique. By the adoption of the oxygen-free outburst-prevention green and efficient tunneling technology suitable for the gas-outburst coal road, harm caused by coal and gas outburst accidents can be effectively controlled and eliminated, safe and efficient tunneling is achieved, asphyxia, fires and explosion caused by gas can be effectively avoided, the situation that people are injured by coal and rock flow can be prevented, life safety of personnel and equipment safety are guaranteed, gas emission is reduced, and environmental friendliness is achieved; meanwhile, production efficiency is improved, production cost is reduced, and economic benefit of enterprises are increased.

Owner:UNIV OF SCI & TECH BEIJING

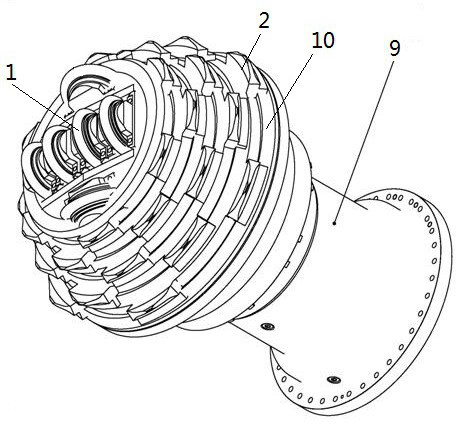

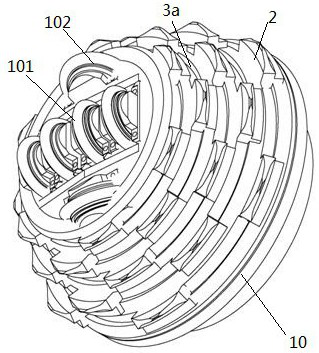

Hard rock cutterhead and cantilever heading machine comprising same

The invention provides a hard rock cutterhead and a cantilever heading machine comprising the same. The hard rock cutterhead comprises a conical cutterhead main structure; the cutterhead main structure comprises a head, spokes and a flange; the head is connected with the spokes, the spokes are connected with the flange, and the head and the spokes are provided with detachable cutters. The cantilever heading machine comprises the hard rock cutterhead. The hard rock cutterhead and the cantilever heading machine comprising the same have the advantages that the stress of the cutterhead structure is more uniform, the deformation resistance and break resistance are high, and the high-thrust high-rotation-speed excavating working condition can be borne; the cutterhead is formed by machining a complete plate or welding steel plates, and the overall strength and stiffness are better; the cutters adopt the form that end covers are located on cutter seat installation surfaces, and the rock breaking efficiency can be improved; a cutterhead center hobbing cutter can be drawn back when the cutterhead conducts swing cutting, and eccentric abrasion, cutting edge breaking and other abnormal damageoccurring to the center hobbing cutter are effectively avoided; hobbing cutters and toothed cutters are subjected to interchange installing, soft soil excavation can be achieved, and in addition, hardrock can be subjected to expanding excavation; and the cutterhead swings up and down as well as leftwards and rightwards, and round and special-shaped fracture surfaces can be excavated.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Development method of transportation through auxiliary slope ramp matched with rubber belt inclined shaft

The invention discloses a development method of transportation through an auxiliary slope ramp matched with a rubber belt inclined shaft. During the process of infrastructure construction, tunneling of the rubber belt inclined shaft and the auxiliary slope ramp is simultaneously performed; the auxiliary slope ramp comprises auxiliary slope straight ways which are arranged at 0 to 8 degrees and spiral turn-back ways which are connected alternately; the height of the auxiliary slope ramp is the same as that of the rubber belt inclined shaft in a position where the auxiliary slope ramp is adjacent to the rubber belt inclined shaft by descending along the spiral turn-back way; a connection roadway is arranged every 300 to 400m to communicate the rubber belt inclined shaft with the auxiliary slope ramp, and the shaft at the inclined end of the rubber belt is higher than that of the auxiliary slope ramp; in an ore bed, the rubber belt inclined shaft and the auxiliary slope ramp are distributed on dike, and middle section travelling roadways are distributed in the dike; the middle section travelling roadways are communicated with one another through the auxiliary slope ramp; the middle section travelling roadways are communicated with fragmented travelling roadways through a panel slope ramp; and middle section ore is lowered to the rubber belt inclined shaft through the panel slope ramp and a drop shaft and is transported to the earth surface. By adopting the method, ventilation, drainage and overhaul are facilitated during tunneling, the transportation capability is high, and the transportation cost is low.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

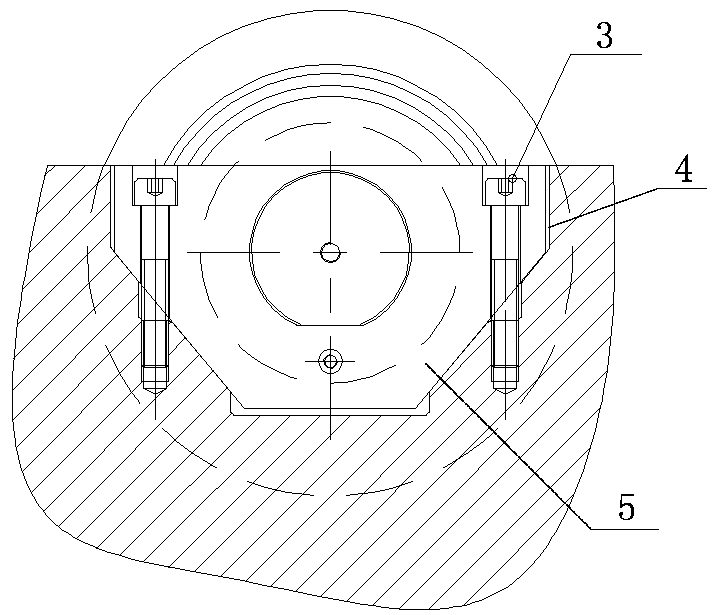

a rock breaking device

InactiveCN102261251ADifferent rock breaking anglesAchieve pitchTunnelsHydraulic cylinderHydraulic motor

The invention relates to the field of excavation equipment, in particular to a rock-breaking device for tunnel construction or roadway excavation. The device is provided with a turntable, a rock-breaking arm and a breaking hammer. One end of the rock-breaking arm is connected to the turntable, and the other end of the rock-breaking arm is connected to the breaking hammer. The turntable is installed on the carrier through the slewing bearing. The turntable is driven by a hydraulic cylinder or a hydraulic motor. The rock-breaking arm is a telescopic arm structure composed of a telescopic inner arm of the rock-breaking arm and a telescopic outer arm of the rock-breaking arm. The outer end of the telescopic outer arm of the rock-breaking arm is hinged with the rotary table, and the vertical pitch of the equipment can be realized under the push of the hydraulic cylinder; the end of the telescopic inner arm of the rock-breaking arm is hinged with the breaker, and it can be flexibly Adjust the impact angle of the breaking hammer. The present invention overcomes the shortcomings of the drilling and blasting method and the comprehensive tunneling method, realizes the purpose of tunnel construction and roadway excavation with a breaker, realizes rapid and efficient tunneling of superhard whole rock roadways without blasting, and avoids major accidents from the root happened.

Owner:SANY HEAVY EQUIP

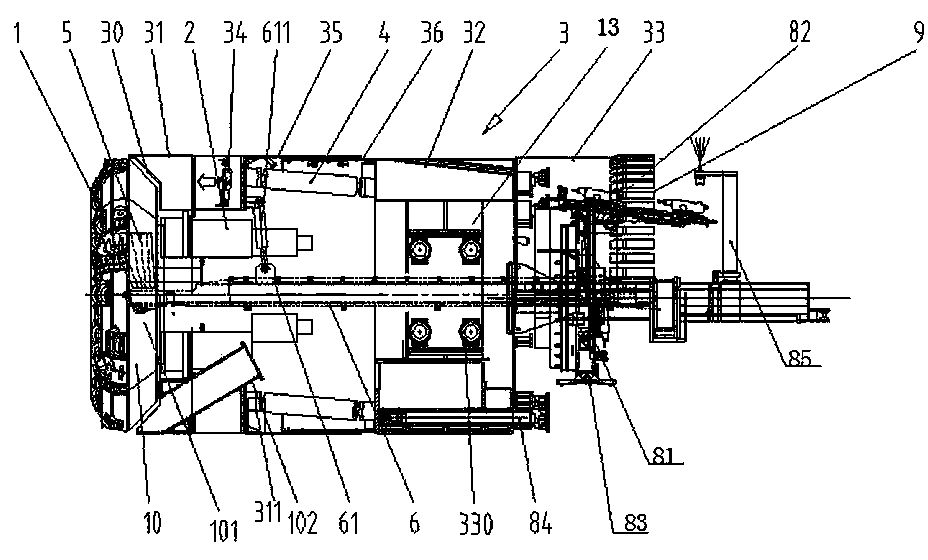

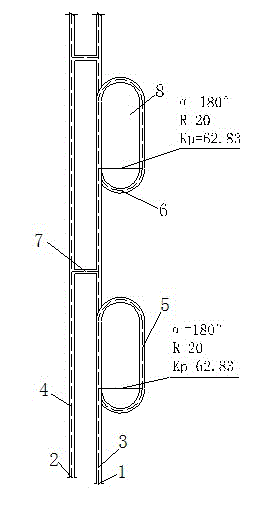

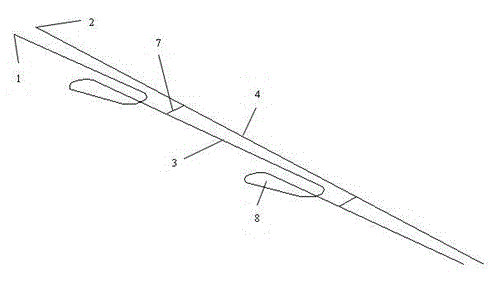

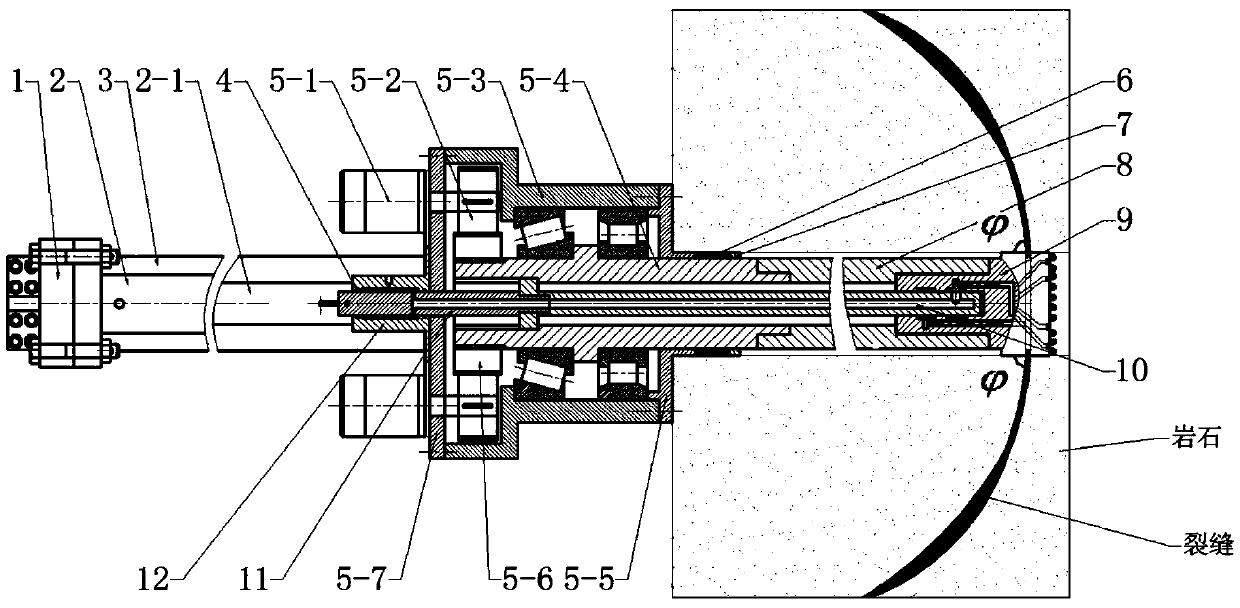

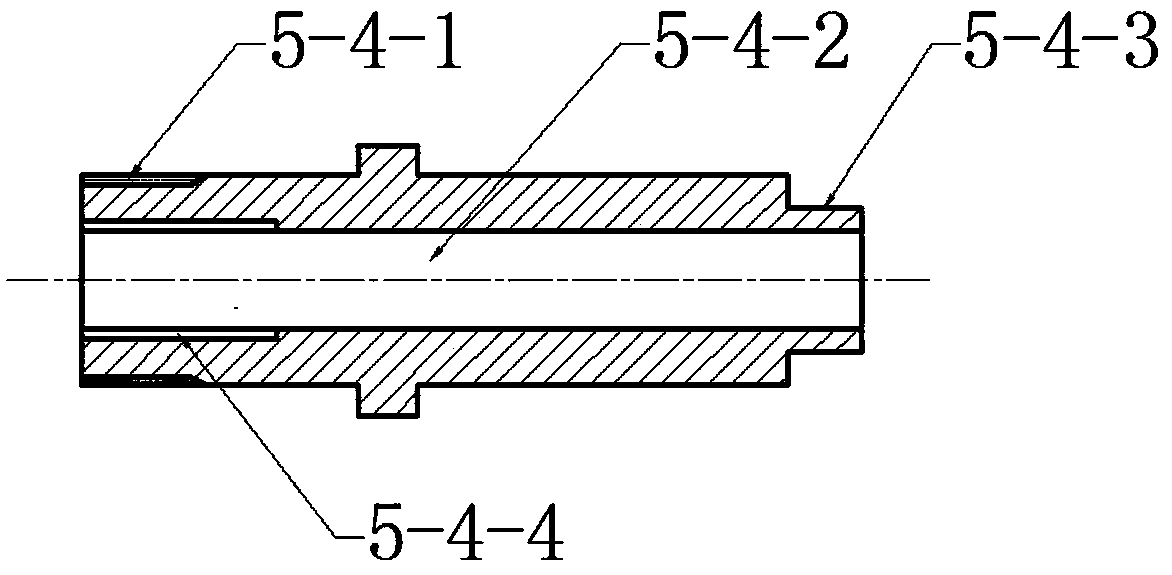

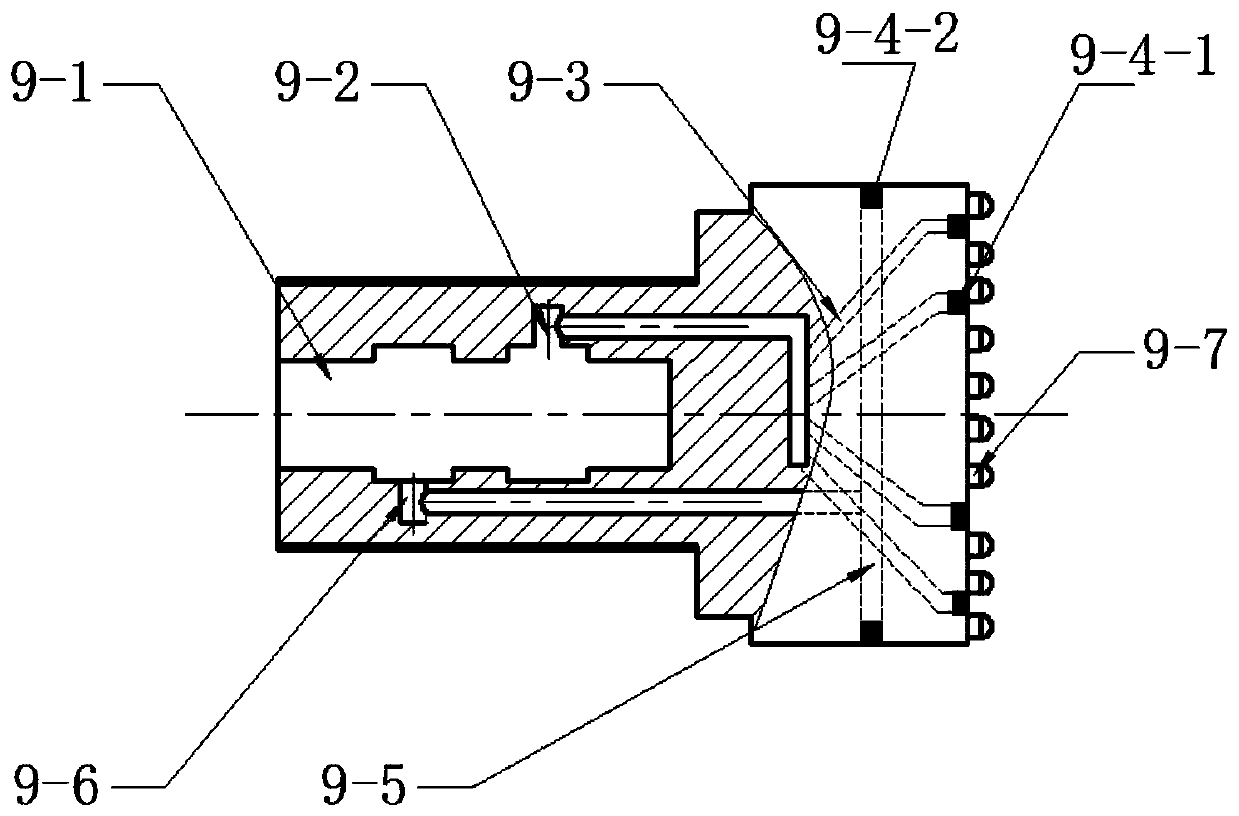

Drilling, joint-cutting and fracturing integrated device for hard rock

The invention discloses a Drilling, joint-cutting and fracturing integrated device for hard rock. The device comprises an oil cylinder supporting base, a pushing oil cylinder, a guide rail, a swing driving device, a rubber ring, a reverse extruding ring, a drill rod, a drill head, a flowing passage shaft, a rotary sealing shaft and a rotary sealing sleeve; the oil cylinder supporting base is fixedto the back end of the guide rail, the swing driving device is slidably connected with the guide rail, and the pushing oil cylinder is fixed to the oil cylinder supporting base; a piston rod of the pushing oil cylinder is connected with the swing driving device, the front end of an output shaft is separately connected with the back end of the drill rod, the front end of the drill rod and the backend of the drill head, and the flowing passage shaft installed on the output shaft and in the drill rod is connected with the back end of the drill head; the rotary sealing sleeve is fixed to the back end of the swing driving device, the rotary sealing shaft penetrating through the rotary sealing sleeve is connected with the flowing passage shaft, and the rubber ring is fixed to the front end ofthe swing driving device and connected with the reverse extruding ring. The device can achieve drilling, joint cutting and fracturing integration operation on hard rock, and has the advantages that the capacity of crushing hard rock (f)10) is high, the efficiency is high, and the quantity of produced dust is low.

Owner:CHINA UNIV OF MINING & TECH

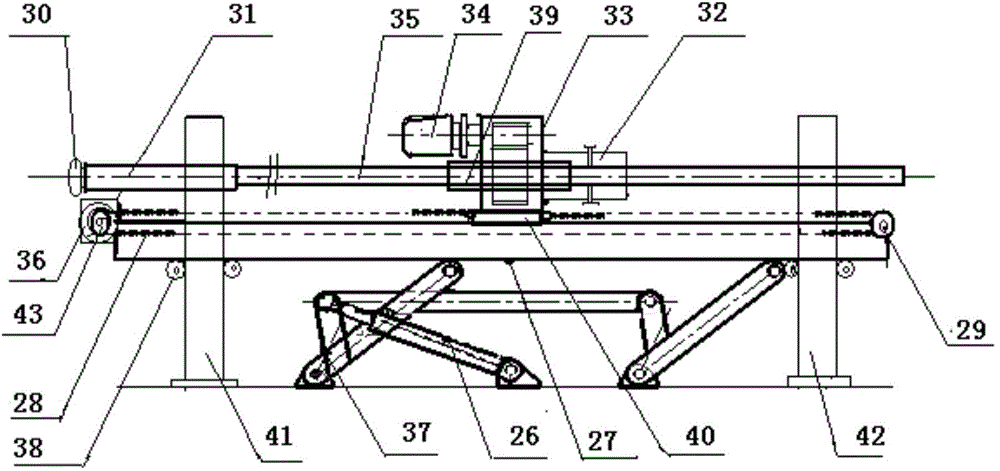

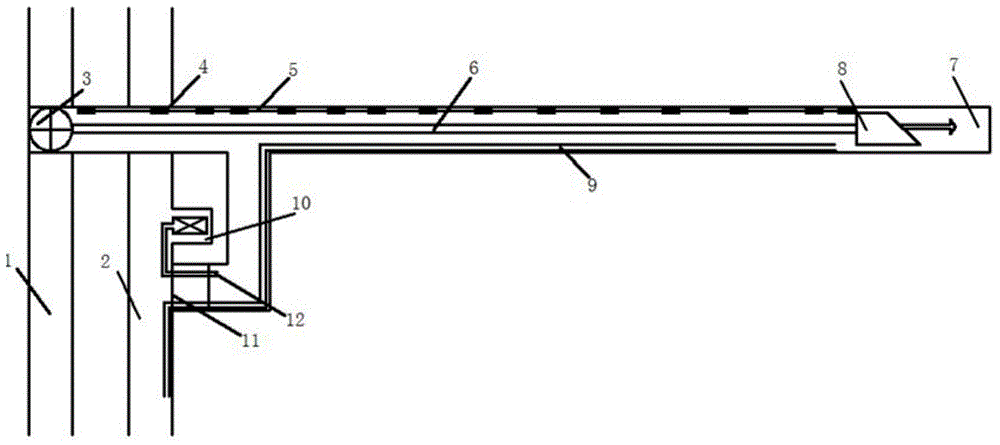

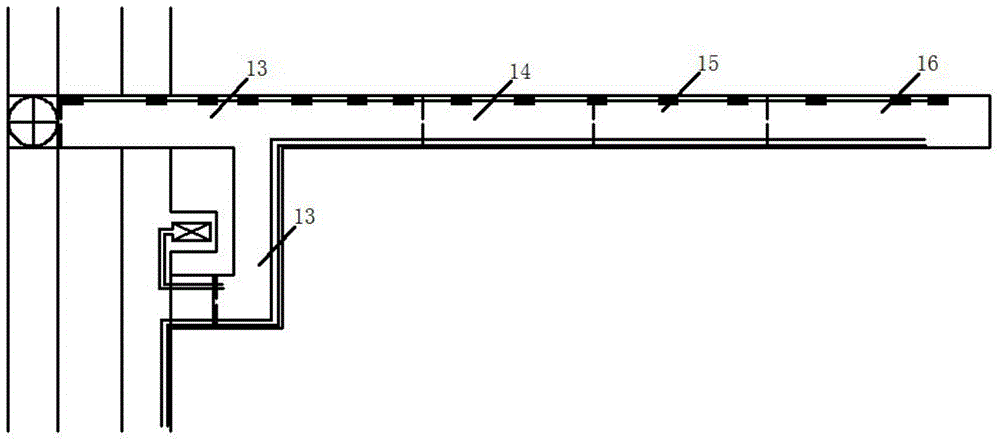

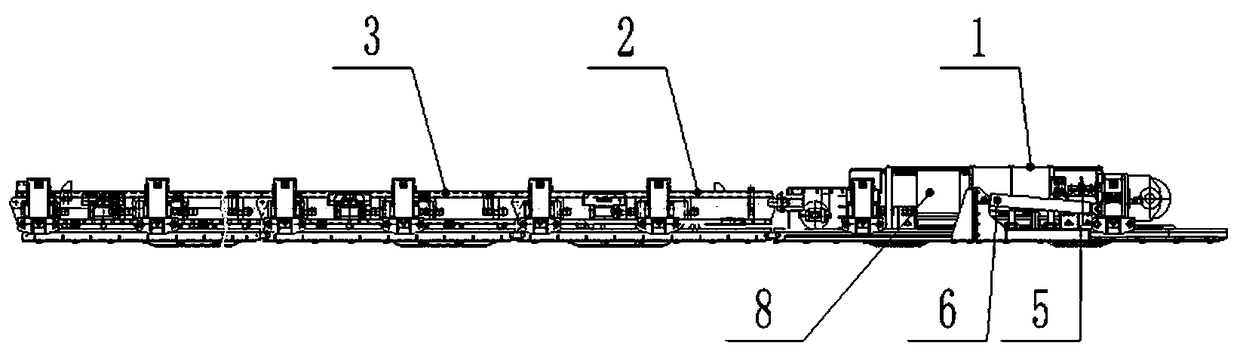

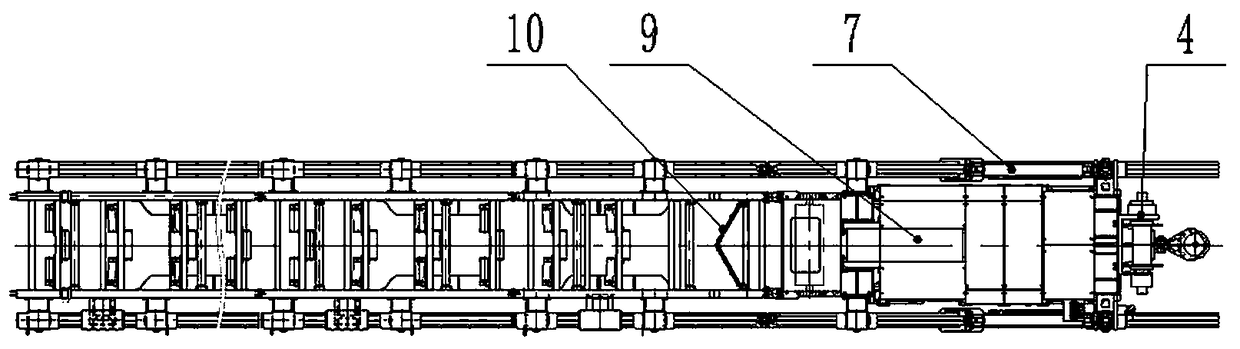

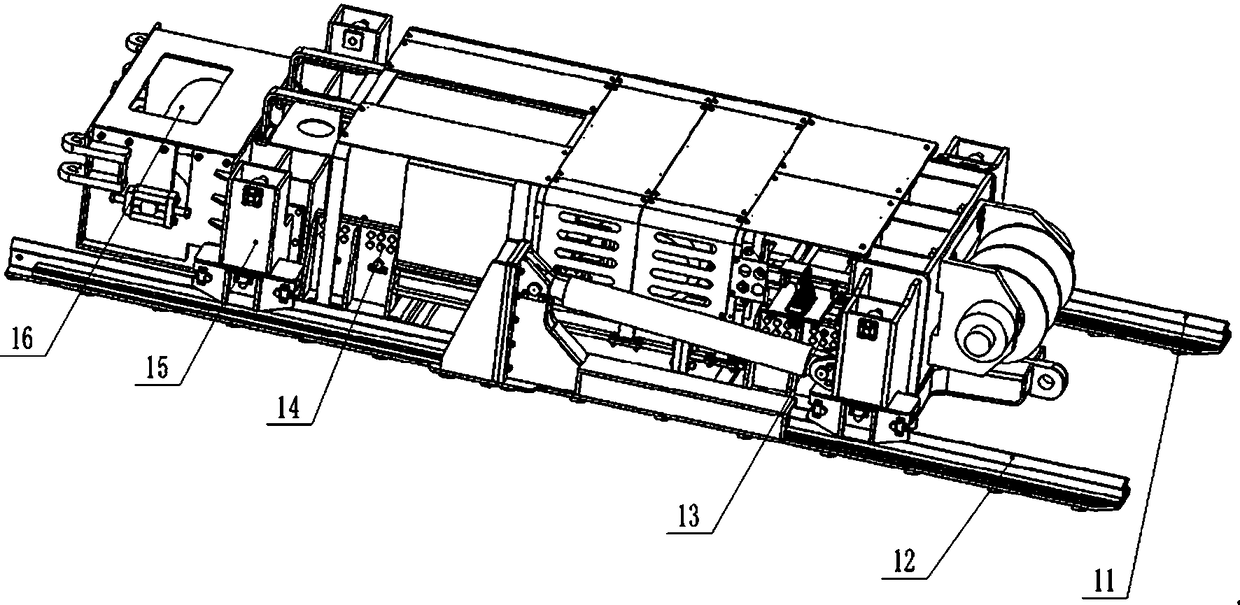

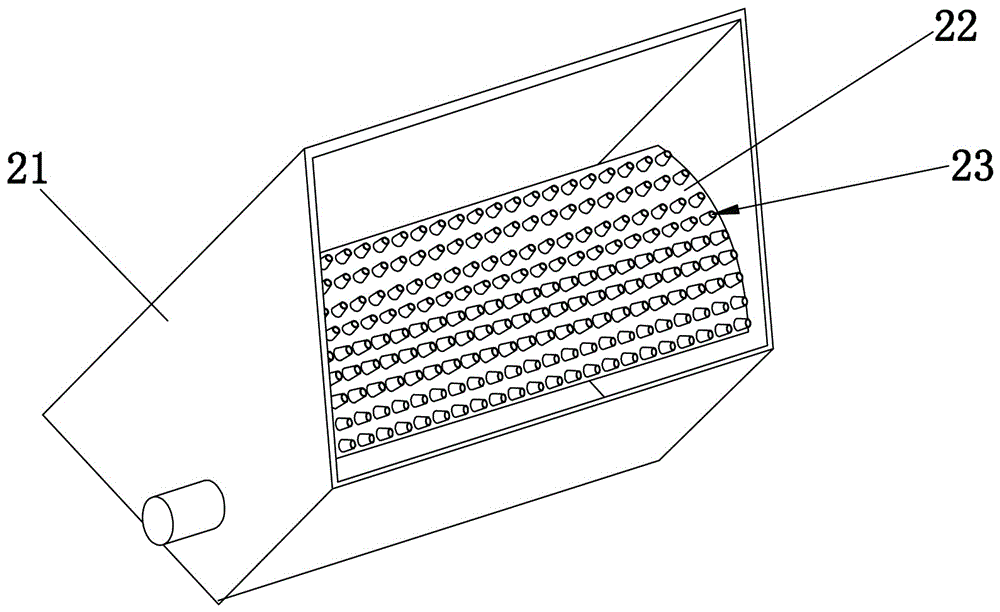

Belt conveyor self-moving machine tail for lapping joint with swing type rapid tunneling system

InactiveCN108974833AImprove tunneling efficiencyReduce labor intensityConveyorsSupporting framesEngineeringCoal

The invention belongs to the technical field of coal mine underground transportation equipment, so as to solve the problems of low tunneling efficiency, large roof damage, high tunneling cost and thelike caused by the need for repeated support of an existing self-moving machine tail. The invention provides a belt conveyor self-moving machine tail for lapping joint with a swing type rapid tunneling system. The belt conveyor self-moving machine tail comprises a power frame, a machine tail frame and a plurality of sections of intermediate frames hinged in sequence from beginning to end, whereinlifting mechanisms are respectively arranged on two sides of the power frame body, the machine tail frame body and each section of intermediate frame body; and two deflection adjusting mechanisms capable of lifting along with the frame body are symmetrically arranged at the front and rear of the bottom of the power frame body. The self-moving machine tail can realize the functions of lifting, pushing and deflection adjustment through a hydraulic system, can reduce the auxiliary transportation operation time, improve the tunneling efficiency, reduce the labor intensity of workers, and realize efficient and rapid tunneling of coal roadways.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Garbage excavation all-in-one machine

ActiveCN106013306AQuick and effective removalAvoid harmSoil-shifting machines/dredgersTherapeutic effectEngineering

The invention discloses a garbage excavation all-in-one machine, and relates to the field of garbage treatment. The garbage excavation all-in-one machine comprises a machine body. The machine body is provided with a bucket, a conveying trough, a driving cabin and a traveling mechanism, and the conveying trough is provided with a conveying belt. The garbage excavation all-in-one machine further comprises a dust precipitating system and an air purification system. The dust precipitating system comprises a water tank, an atomizer and a sprayer which communicate in sequence through pipes. The air purification system comprises air intake pipelines, an exhaust fan and an air purification box which communicate in sequence through hoses. The garbage excavation all-in-one machine has the beneficial effects that the air purification system and the dust precipitating system can rapidly and effectively remove dust generated during excavation of garbage and purify the air, thereby avoiding injury to workers and pollution to the environment; the sprayer is arranged above the feeding end of the conveying trough; two air intake pipelines are located on the left side and the right side of the bucket correspondingly; and the sprayer and the air intake pipelines are both very close to the excavation point, so that dust and harmful gas are removed immediately when not dispersing yet. The garbage excavation all-in-one machine has the advantage of good treatment effect.

Owner:DATIAN WEST ENVIRONMENTAL PROTECTION TECH CO LTD

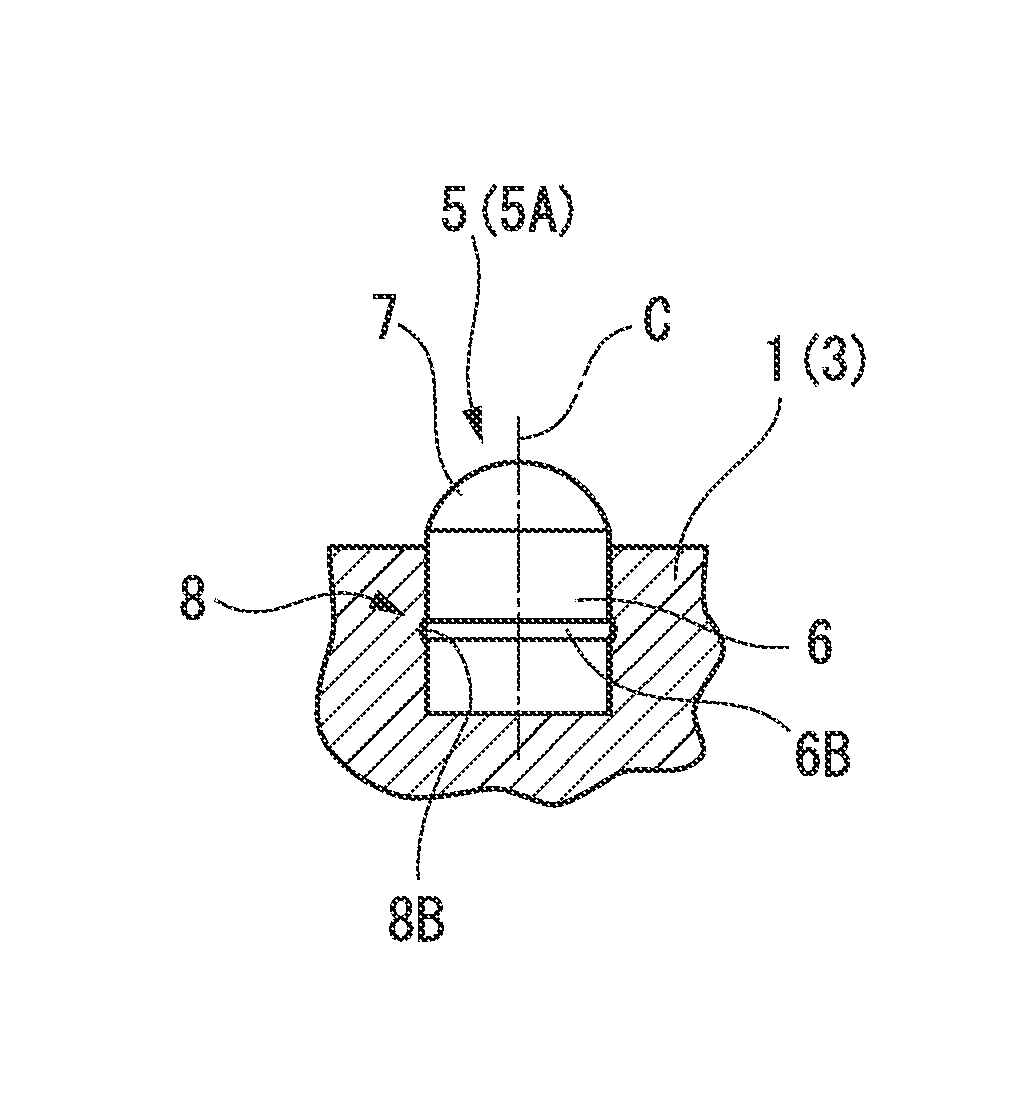

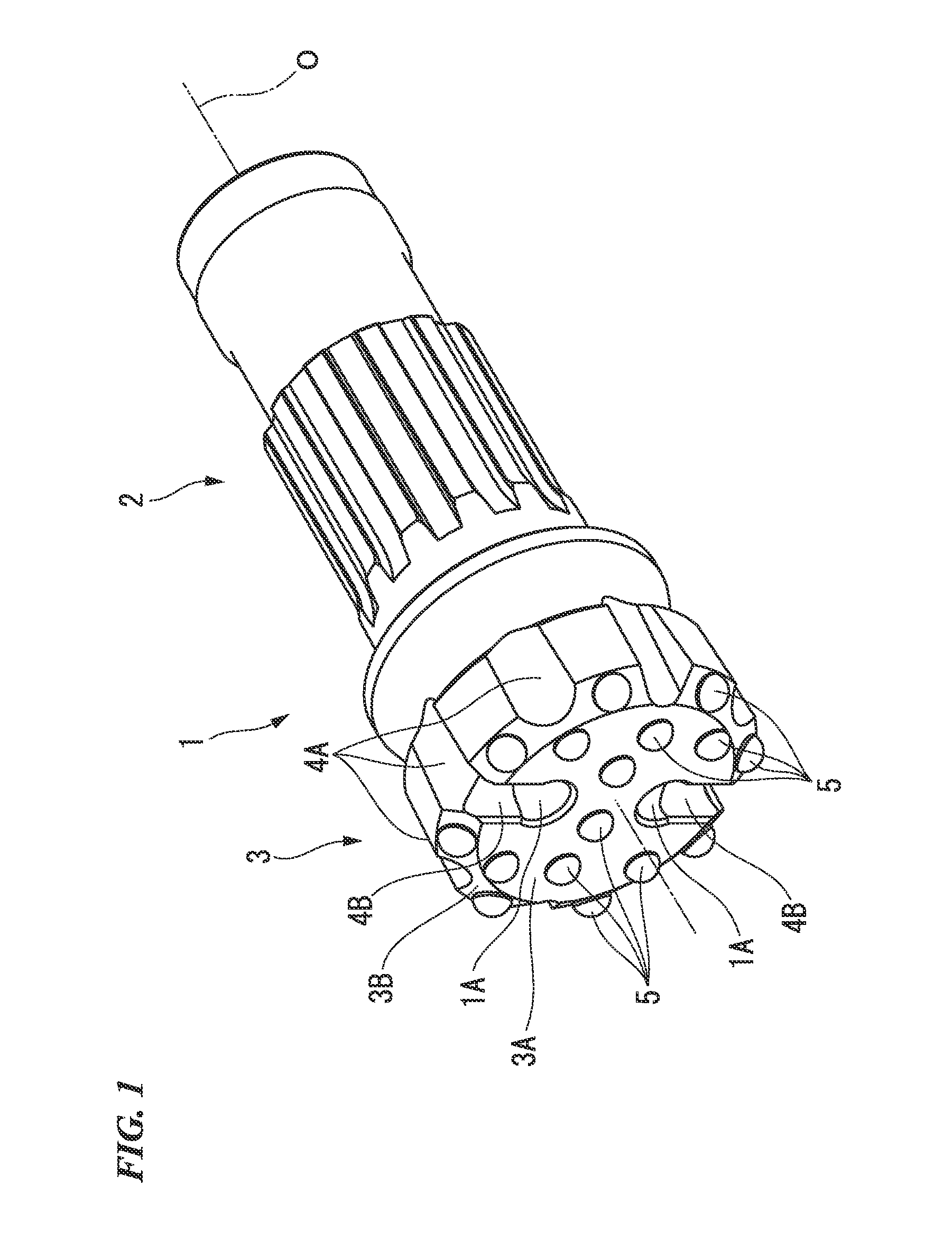

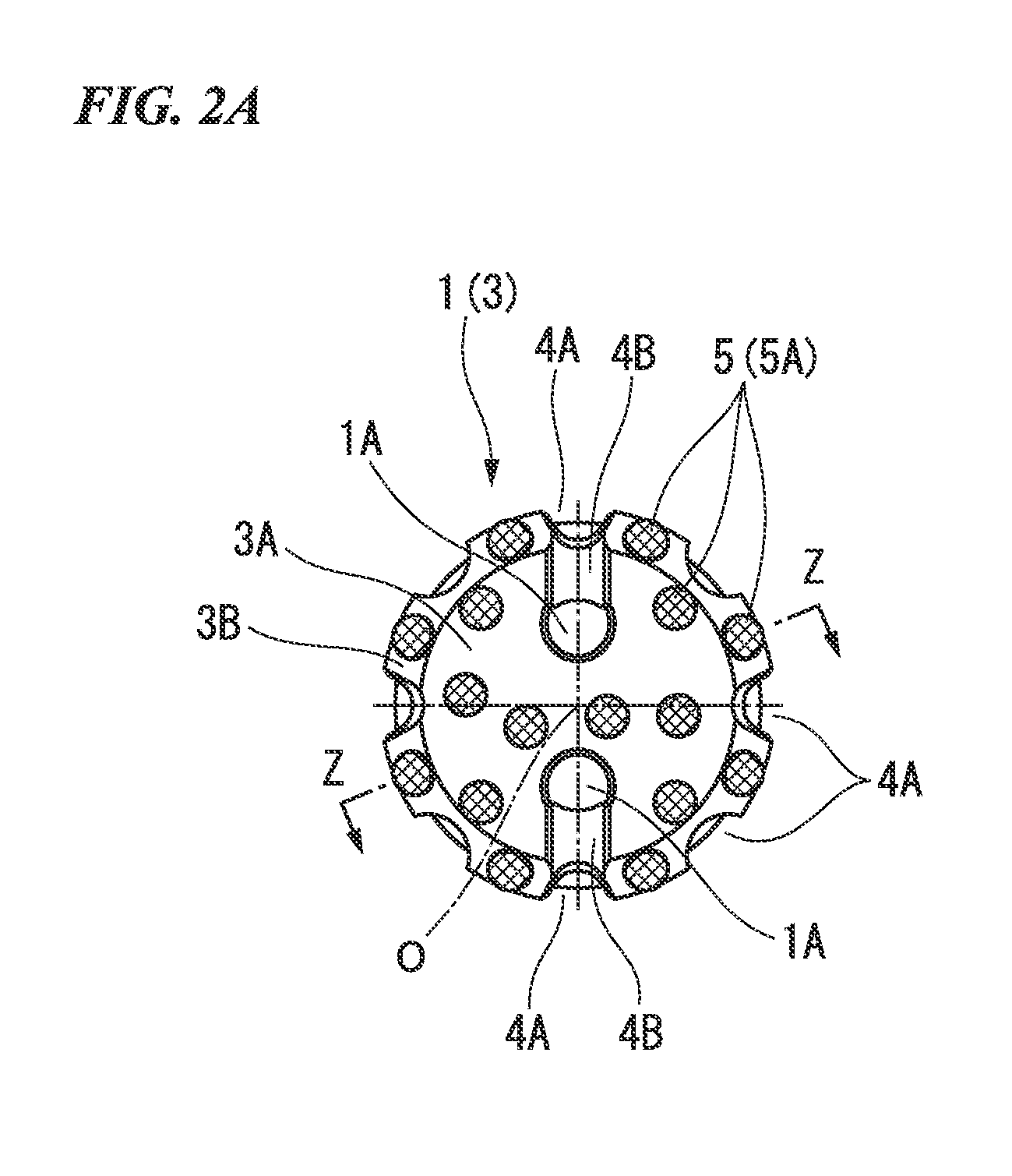

Excavation tool

ActiveUS9551190B2Uniform wearReduce excavation costsDrill bitsConstructionsEngineeringMechanical engineering

In an excavation tool of the present invention, an embedding hole is drilled in a distal end portion of a tool body which is rotated about an axis line O and is moved forward to a distal end side in a direction of the axis line O. In the embedding hole, an excavation tip in which an embedding portion having an outer cylindrical shape is formed integrally with a cutting edge portion inserts the embedding portion into the embedding hole and causes the cutting edge portion to protrude from the embedding hole. In this manner, the excavation tip is rotatable around a central axis C of the embedding portion during excavation, and is attached thereto by being locked so as not to slip toward a distal end side of the embedding portion 6 in a direction of the central axis C.

Owner:MMC RYOTEC CORP

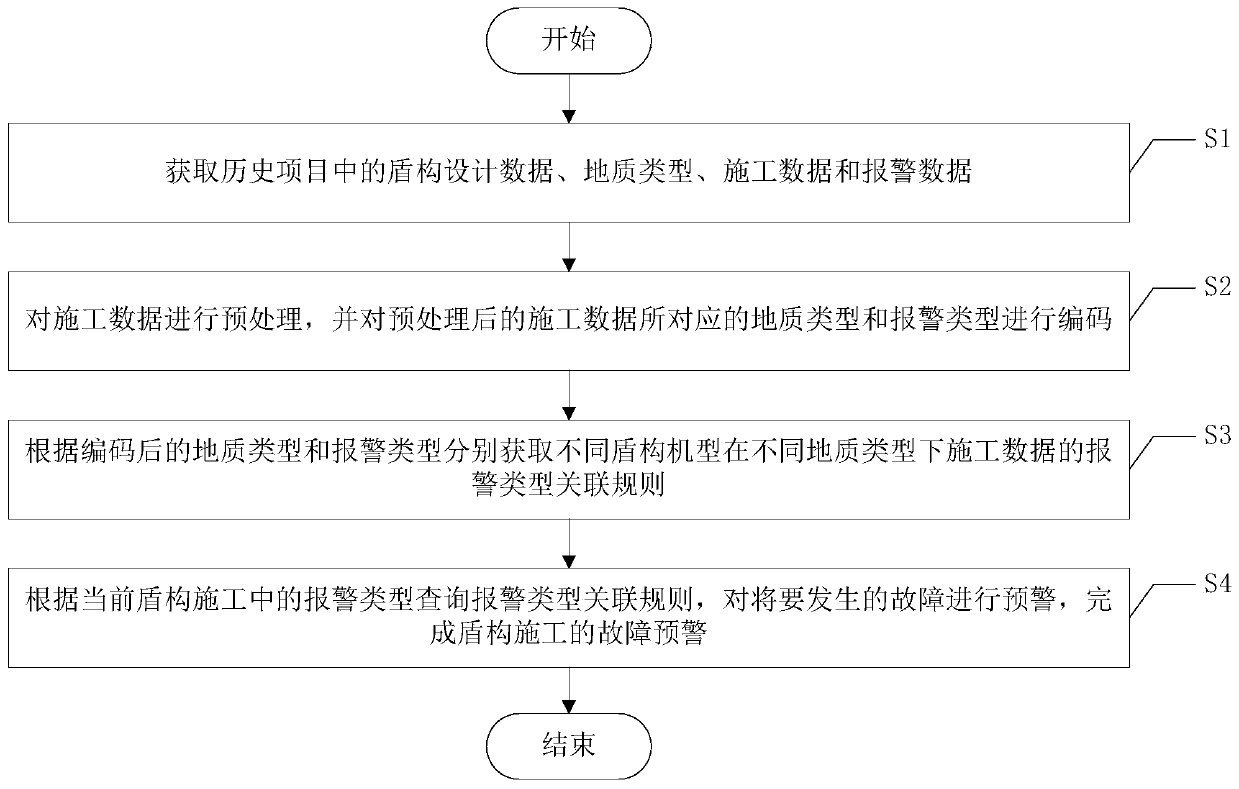

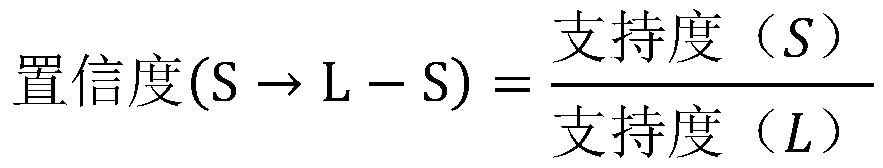

Early warning method and system of shield construction failure based on association rules

InactiveCN109870988AImprove construction qualityEfficient excavationTotal factory controlProgramme total factory controlFault handlingComputer science

The present invention discloses an early warning method and system of shield construction failure based on association rules. The method comprises the following steps: S1 acquiring shield design data,a geological type, construction data and warning data in historical projects; S2 pre-processing the construction data and encoding the geological type and a warning type corresponding to the pre-processed construction data; S3 respectively acquiring an association rule of the warning type for the construction data of different shield models under different geological types according to the encoded geological type and the warning type; and S4 querying the association rule of the warning type according to the warning type in the current shield construction, and performing an early warning on afailure to be generated, to complete the early warning of the shield construction failure. The method can effectively help construction personnel to correct improper construction operation in time ormake corresponding emergency measures in advance according to the early warning of the failure to avoid the occurrence of the failure or shorten failure processing time and effectively improve the efficiency of the shield construction.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +2

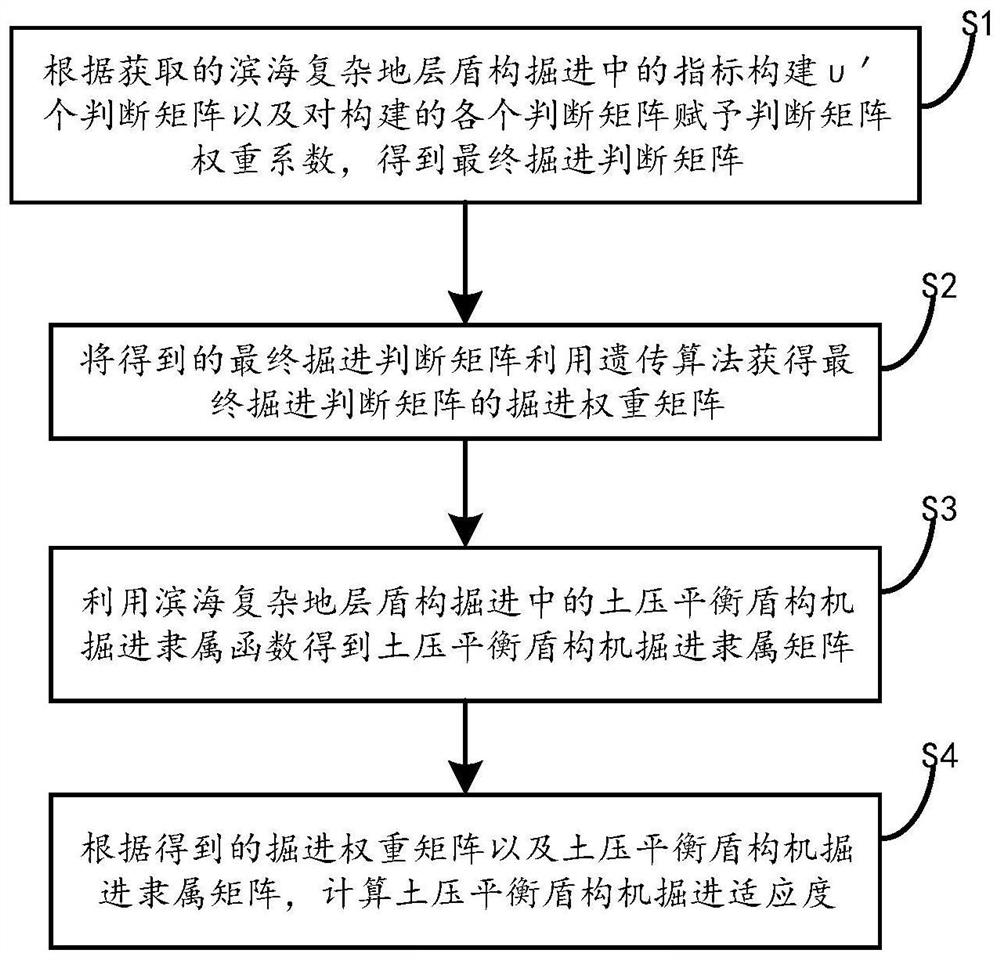

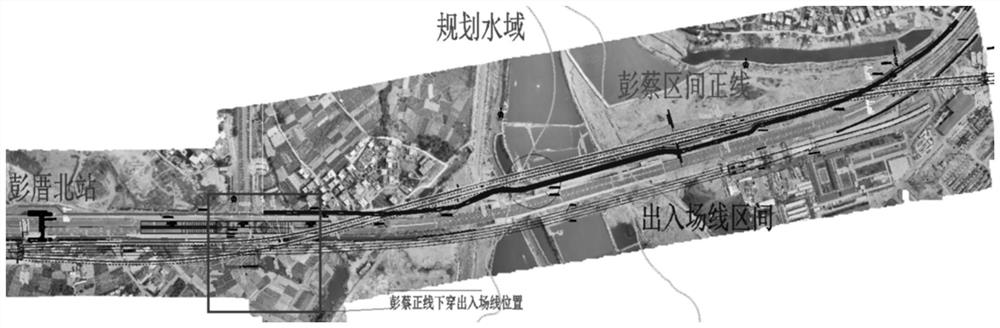

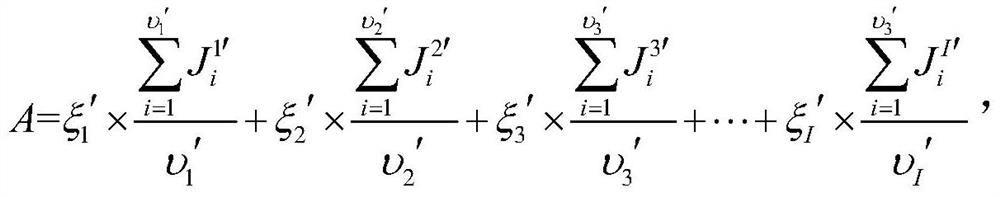

Coastal complex stratum shield tunneling adaptability evaluation method

ActiveCN111709650AEfficient excavationClimate change adaptationResourcesGenetics algorithmsEngineering

The invention provides a coastal complex stratum shield tunneling adaptability evaluation method. The method comprises the following steps of: S1, obtaining a final tunneling judgment matrix; S2, obtaining a tunneling weight matrix of the final tunneling judgment matrix obtained in the step S1 by using a genetic algorithm; S3, if the earth pressure balance shield tunneling machine is selected, executing the step S4, and if the slurry balance shield tunneling machine is selected, executing the step S5; the step S4 comprises: S41, obtaining an earth pressure balance shield tunneling membership matrix by using an earth pressure balance shield tunneling machine tunneling membership function in coastal complex stratum shield tunneling; and S42, calculating the tunneling fitness of the earth pressure balance shield tunneling machine according to the tunneling weight matrix obtained in the step S2 and the tunneling membership matrix of the earth pressure balance shield tunneling machine obtained in the step S41. According to the method, the coastal complex stratum can be tunneled in a better mode.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +2

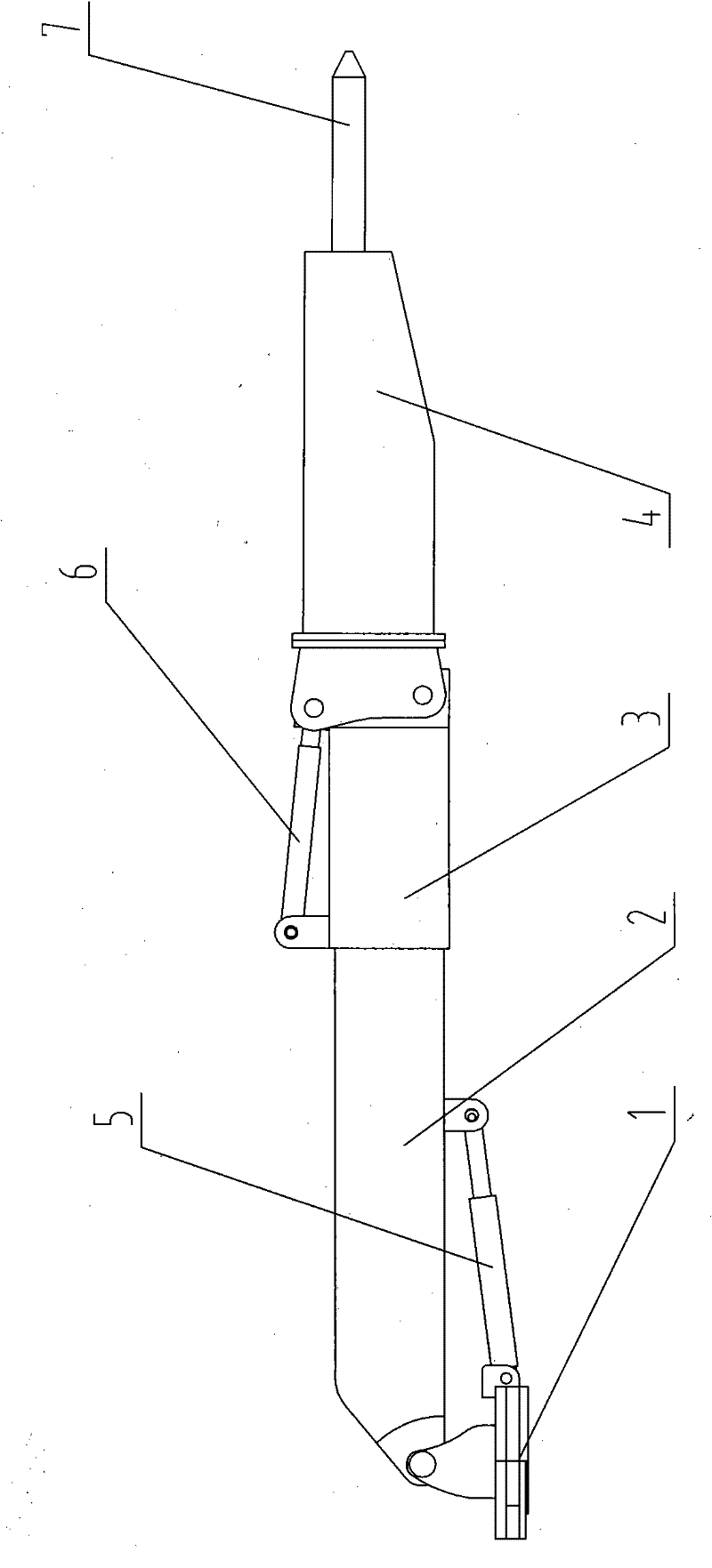

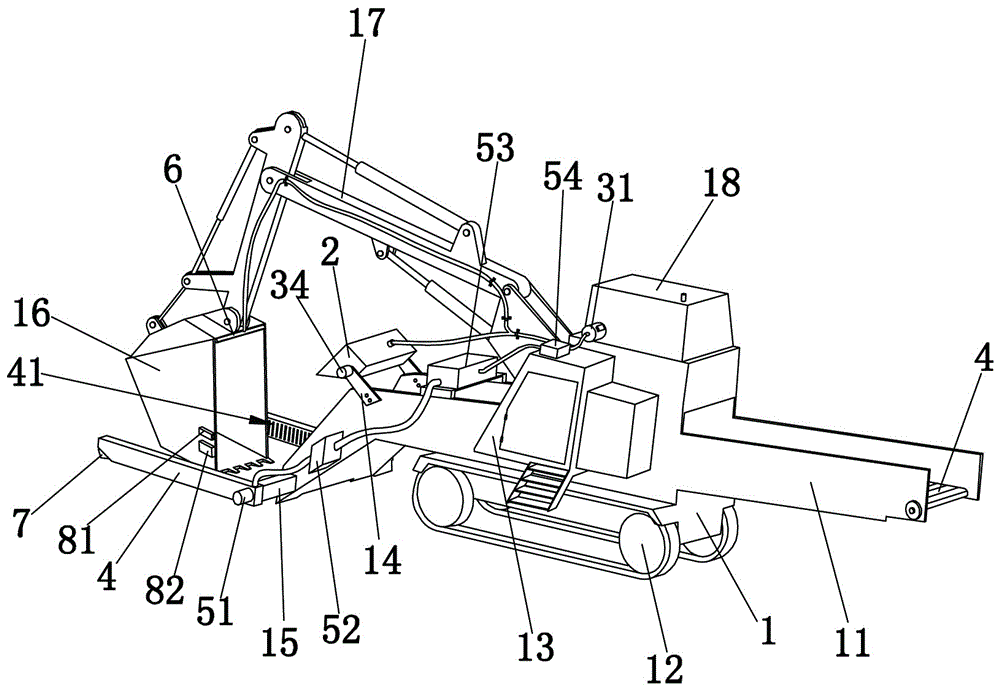

Full-face fast vertical supporting anchor digging machine

InactiveCN111425214AAchieving vertical anchor protectionDoes not affect the center of gravityDerricks/mastsDirectional drillingArchitectural engineeringExcavator

The invention discloses a full-face fast vertical supporting anchor digging machine suitable for drivage construction operations of such relevant projects as coal mining and transportation tunnel construction. The full-face fast vertical supporting anchor digging machine mainly comprises a cantilever excavator, a temporary supporting device, a left anchor rod drill device and a right anchor rod drill device, wherein the temporary supporting device is mounted on a cutting portion of the excavator, and is folded above the cutting portion during excavation, such that the vision of a driver or thetunneling performance of the excavator is not adversely affected. The temporary supporting device is unfolded to play a temporary supporting role during supporting. The left anchor rod drill device and the right anchor rod drill device are respectively mounted on two sides of a walking portion of the excavator. Each anchor rod drill device consists of a conveying mechanism, support legs, a drillposture adjustment device and an anchor rod drill, the conveying mechanism is in the structural form of a slideway, a telescopic arm, etc., the support legs are connected to the front end of the conveying mechanism and can stretch up and down.

Owner:SHENYANG NORTH MINING MACHINERY

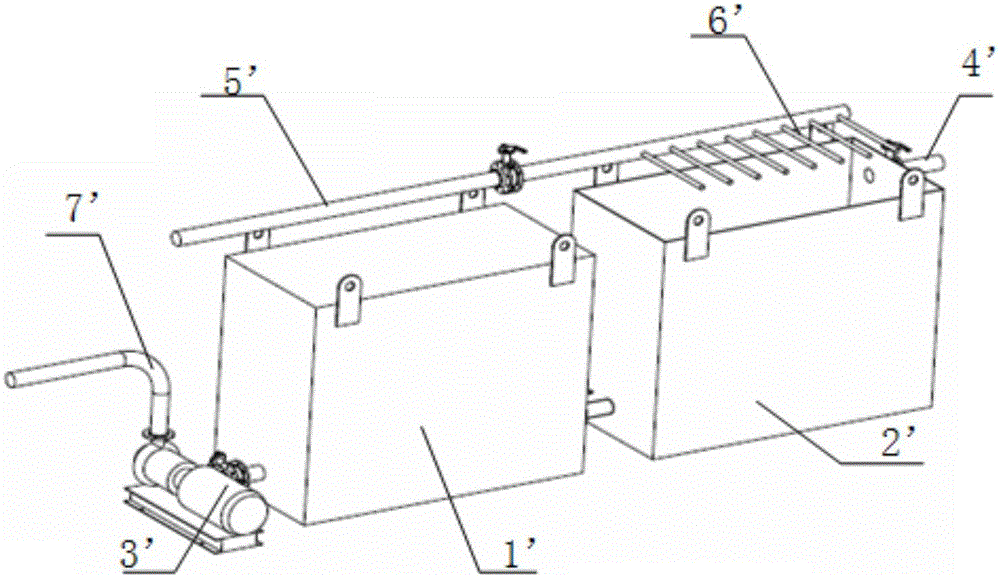

Mining TBM (tunnel boring machine) water circulation system and mining TBM water circulation method

ActiveCN106703113AReduced installation effortImprove cooling effectIndustrial water supply conservationService pipe systemsWater useWater source

The invention discloses a mining TBM (tunnel boring machine) water circulation system and a mining TBM water circulation method. The system comprises an external water source, an internal circulation water supply pipe, an internal circulation waterway, an internal circulation water outlet pipe and various mining TBM external devices. The external water source is connected with an inlet of the internal circulation water supply pipe, an outlet of the internal circulation water supply pipe is connected with an inlet of the internal circulation waterway, an outlet of the internal circulation waterway is connected with the internal circulation water outlet pipe, and an outlet of the internal circulation water outlet pipe is connected to a water inlet of each mining TBM external device. The external water source supplies water to an internal circulation tank and then distributes to each water pump; each water pump supplies water to the corresponding mining TBM internal device, and water is recycled after use and discharged to water supply pipes of the external devices to be used by the mining TBM external devices; water used by the mining TBM external devices is directly discharged to a roadway floor. Cooling effects of the water circulation system are greatly improved, water consumption and cooling requirements of the devices can be met, the operating rate of the devices is increased, and TMB quick efficient tunneling is guaranteed powerfully.

Owner:HUAINAN MINING IND GRP

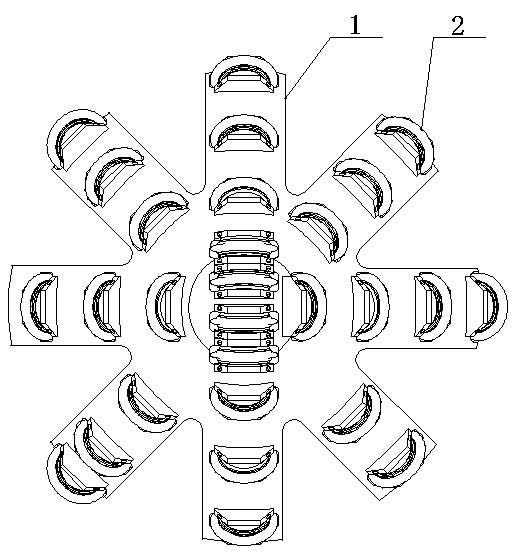

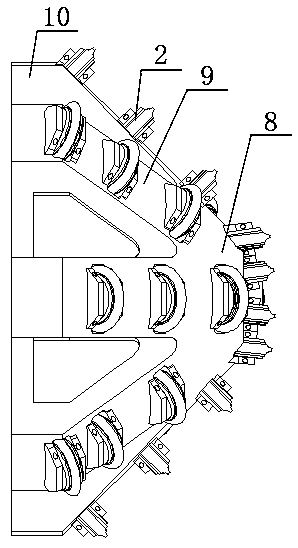

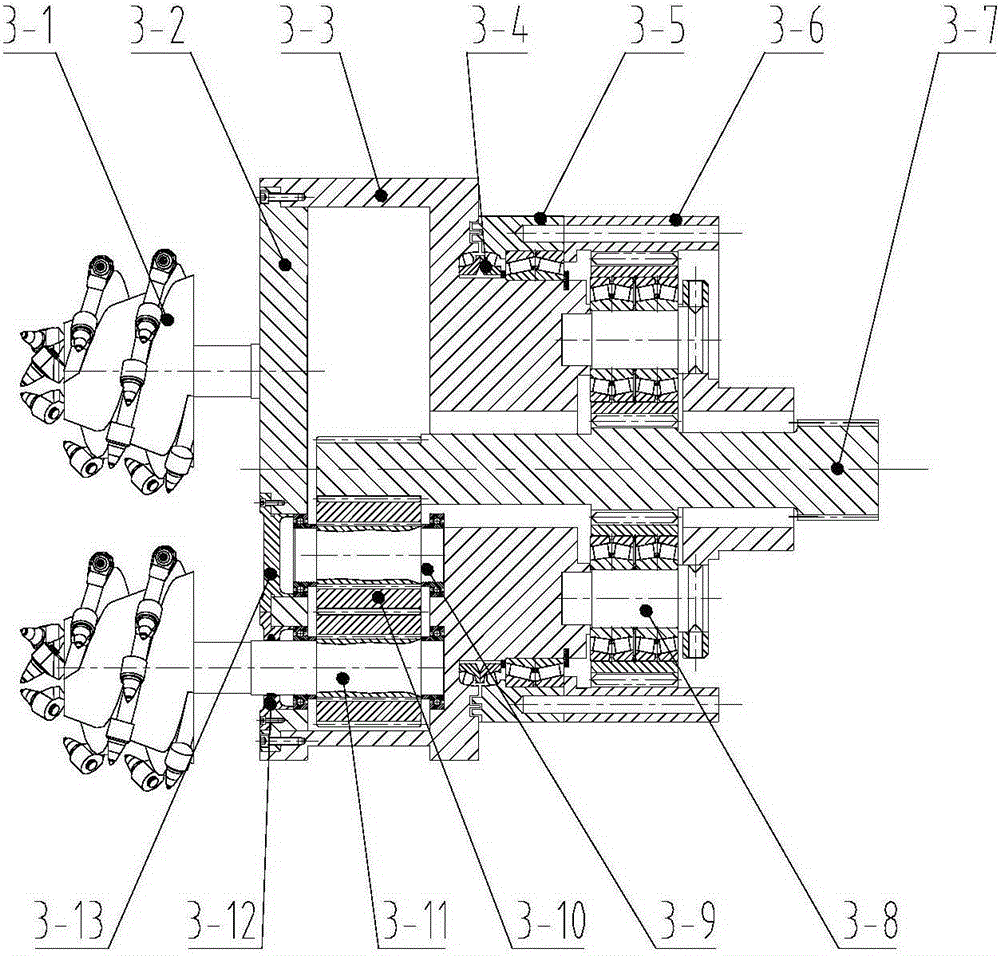

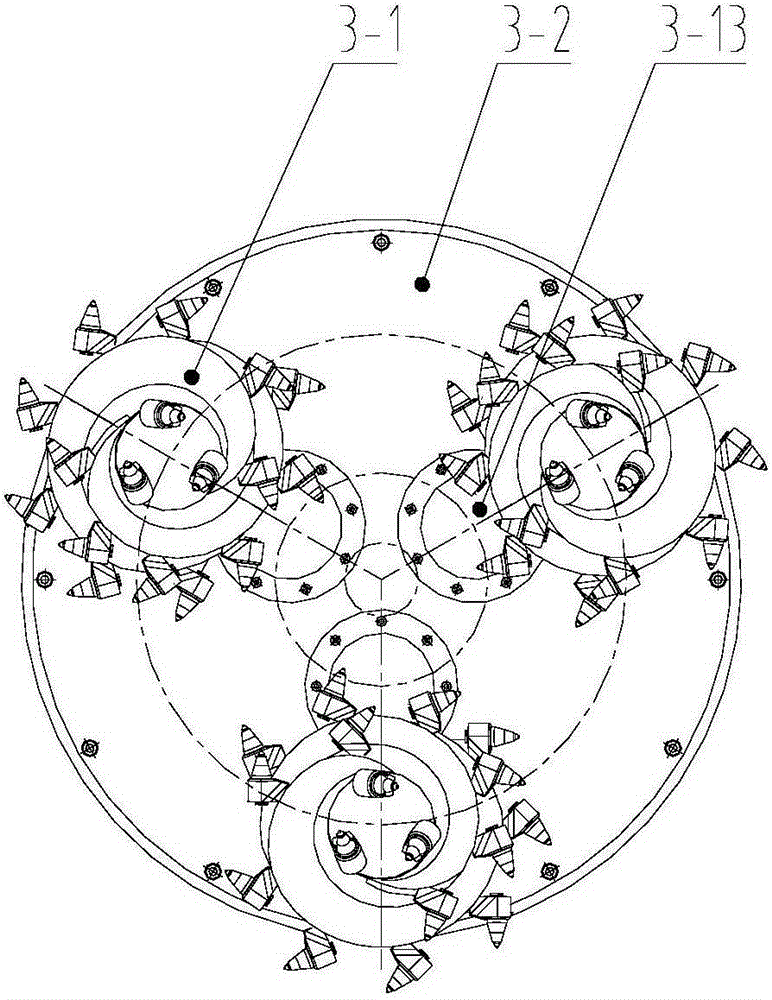

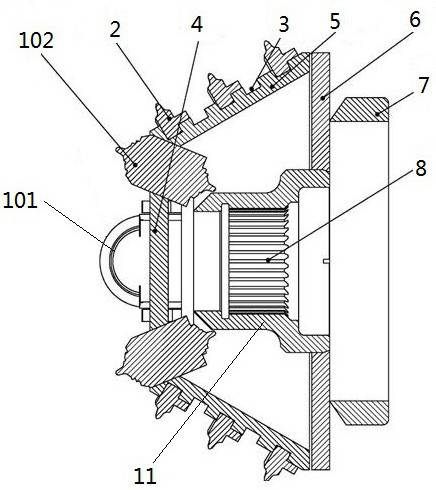

Cutting part of heading machine

ActiveCN105178977AMeet the rapid excavationExcavation method, fast for excavationTunnelsEngineeringReducer

The invention discloses a cutting part of a heading machine, and is suitable for a mine workings heading machine. The cutting part comprises a cutting speed reducer, a cutting arm and a cutting head, wherein the cutting speed reducer is fixedly connected with the cutting arm through a bolt; an output shaft of the cutting speed reducer is connected with a main shaft of the cutting arm through a spline; the cutting head consists of three rock crushing drill bits uniformly distributed by 120 degrees, a cutting head frame outer cover, a cutting head frame, a rotating seal, a bearing base, an inner gear ring, a cutting head main shaft, a planetary wheel component, a small gear pin shaft, three sets of six small gears uniformly distributed by 120 degrees, small gear output shafts, a bearing through cover and a bearing stifle; in work, a motor transfers power to the main shaft of the cutting arm and the cutting head main shaft in sequence through the cutting speed reducer; and then, the power is synchronously transferred to a cutting head planetary gear transmission mechanism and the three sets of small gears uniformly distributed by 120 degrees to respectively drive the cutting head frame and the cutting head output shaft to rotate to realize the revolving and the rotation of the three rock crushing drill bits, so that the driving speed of mine workings is largely increased. The cutting part is compact in structure and small in volume, and reduces specific energy consumption.

Owner:CHINA UNIV OF MINING & TECH

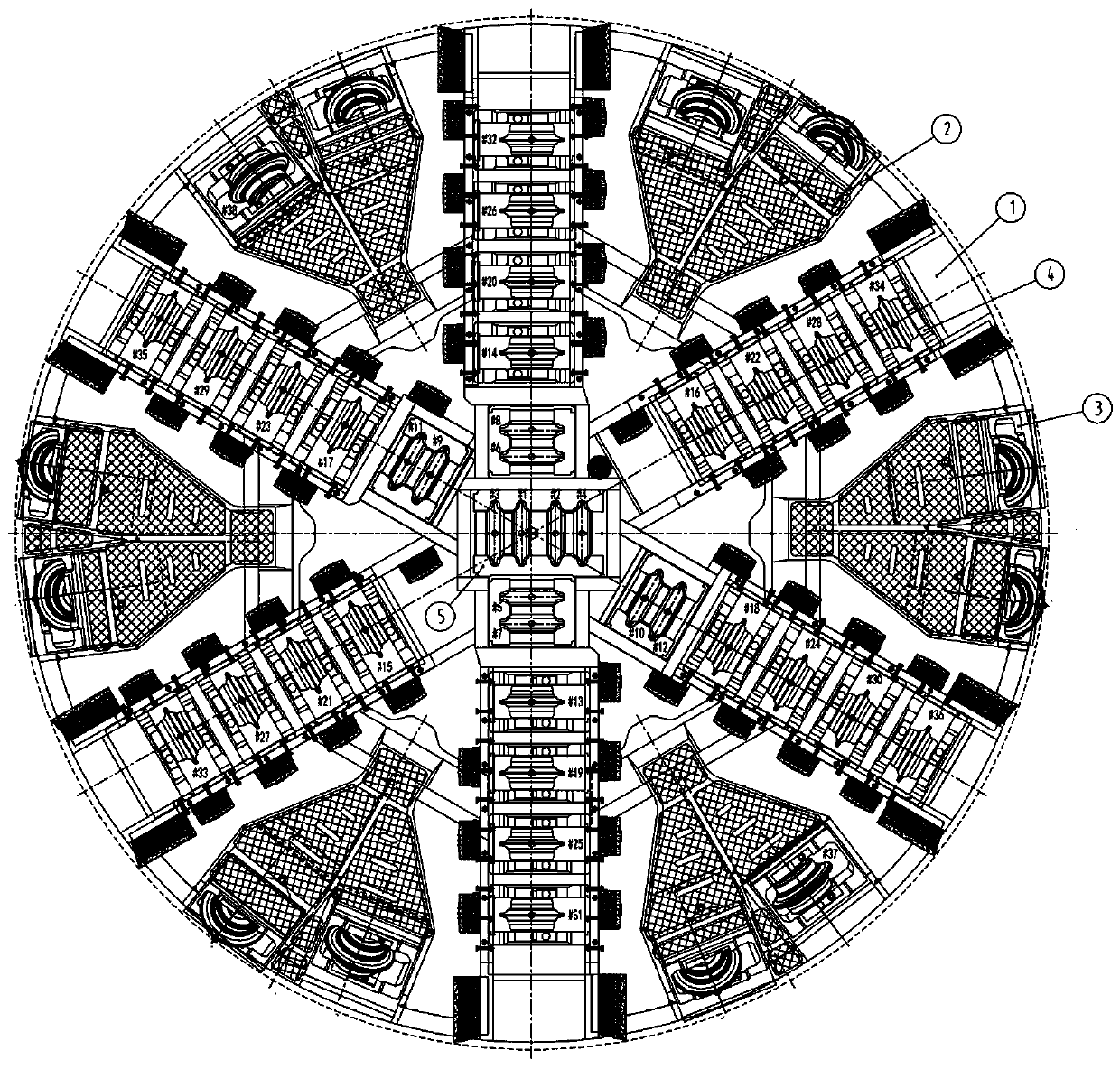

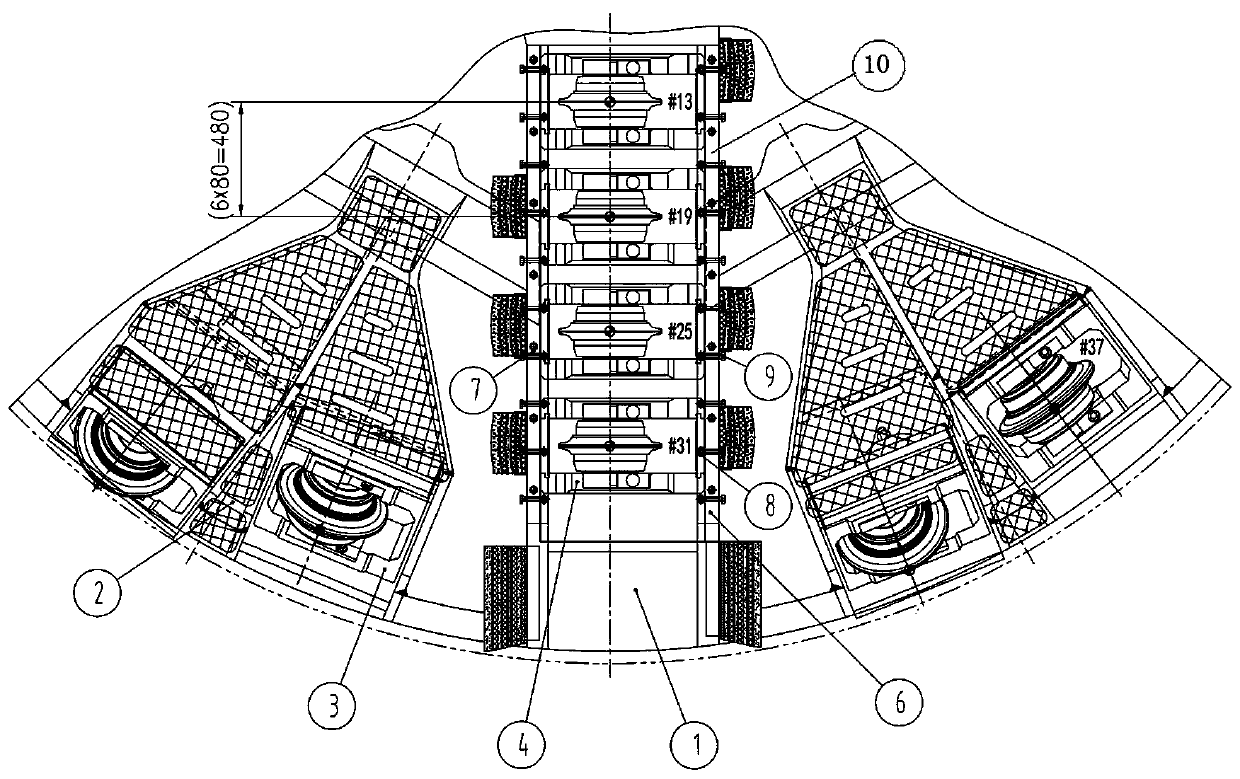

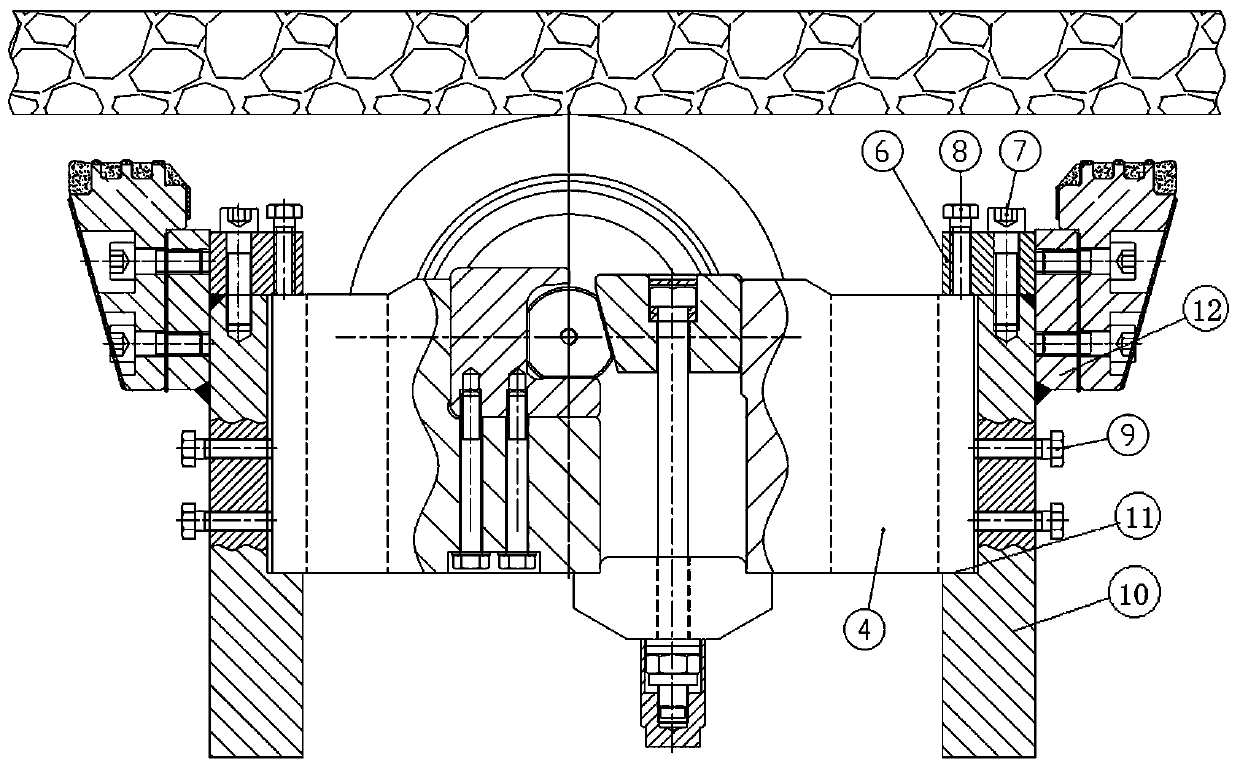

Shield machine cutter head with variable cutter spacing

ActiveCN110454181AEnsure rock breaking efficiencyEfficient excavationTunnelsRock breakingShield machine

The invention discloses a shield machine cutter head with variable cutter spacing, and solves the technical problem that the hob spacing on the existing shield machine cutter head is not variable. Theshield machine cutter head comprises a cutter main beam, wherein a hob assembly is arranged in the cutter main beam, and a compression bolt set for fixing the hob assembly is arranged on the cutter main beam at interval. The invention realizes the function of adjusting the cutter spacing of the hob correspondingly according to the construction geological change through changing the fixing mannerof the hob assembly, and achieves the efficient matching of the cutter spacing arrangement and the construction geology, and can ensure the rock-breaking efficiency of the hob in different geologies,reduces the construction difficulty, speeds up the construction progress, prolongs the cutter life, reduces the number of inspections and cutter change; meanwhile, the construction cost is reduced, the adaptability of the shield cutter is improved, and the long distance, efficient and reliable tunneling of the shield machine is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

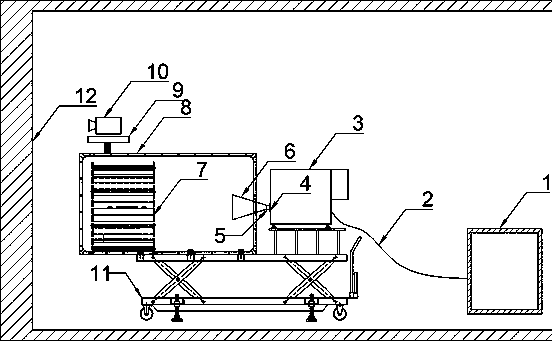

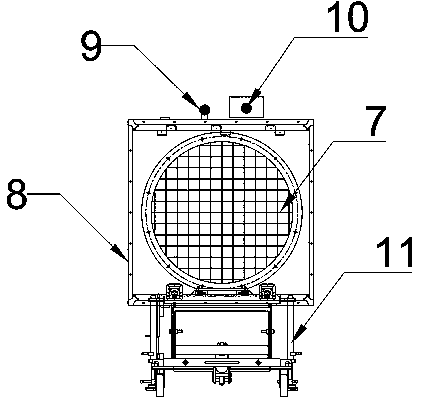

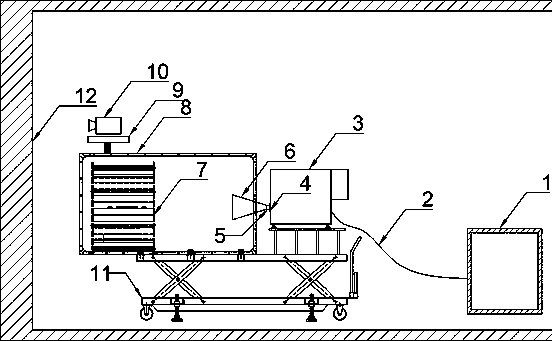

Metal lens antenna microwave radiation device for hard rock tunnel excavation

ActiveCN111163545AEfficient excavationExcavation economyMicrowave heatingTunnelsThermographic cameraEngineering

The invention discloses a metal lens antenna microwave radiation device for hard rock tunnel excavation. The metal lens antenna microwave radiation device comprises a universal mobile platform vehicle, a microwave power supply, a microwave generator, a connecting waveguide, a horn mouth antenna, a metal lens antenna, a shielding box, a laser displacement sensor, an infrared thermal imager and thelike. The microwave power supply is connected with the microwave generator through a power supply connecting wire; the microwave generator is connected with the horn mouth antenna through the connecting waveguide and the flange plate; the laser displacement sensor and the infrared thermal imager are fixed on the shielding box; the horn mouth antenna, the metal lens antenna and the shielding box are fixed on the universal mobile platform vehicle; microwaves generated by the microwave generator are focused on a tunnel face through the metal lens antenna, the position and the height of the universal mobile platform car are adjusted, and therefore the metal lens antenna microwave radiation device acts on a preset heating point on the tunnel face, and efficient and economical excavation of thehard rock tunnel is achieved.

Owner:SOUTHEAST UNIV

Novel TBM and construction method thereof

ActiveCN111963192ADoes not affect the excavation functionReduce wearTunnelsAnchoring boltsSupporting systemArchitectural engineering

The invention discloses a novel TBM and a construction method thereof. The problems of low tunneling efficiency and serous wear to a cutterhead when a TBM is used for excavating hard rocks in the prior art are solved. The novel TBM comprises a tunneling mainframe and a rear supporting system. The tunneling mainframe comprises a cutterhead. The cutterhead is a master driver arranged in the tunneling mainframe. The cutterhead is provided with an excavation tool and an anchor drilling and splitting device used for conducting anchor drilling and splitting to assist in rock breaking. The novel TBMintegrates the functions of a jumbolter and a hydraulic splitting rod, drilling holes in a tunnel face through an anchor drilling device, bursts the drilled holes through the splitting device, conducts anchor drilling and splitting to drill and break the hard rocks on the tunnel face in advance of the cutterhead, then conducts excavation on the drilled and broken tunnel face through the cutterhead, reduces wear to the excavation tool and improves the excavation efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

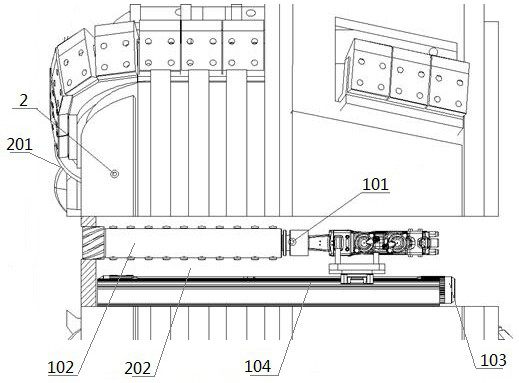

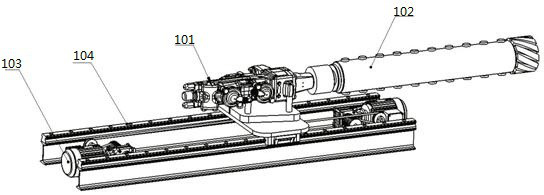

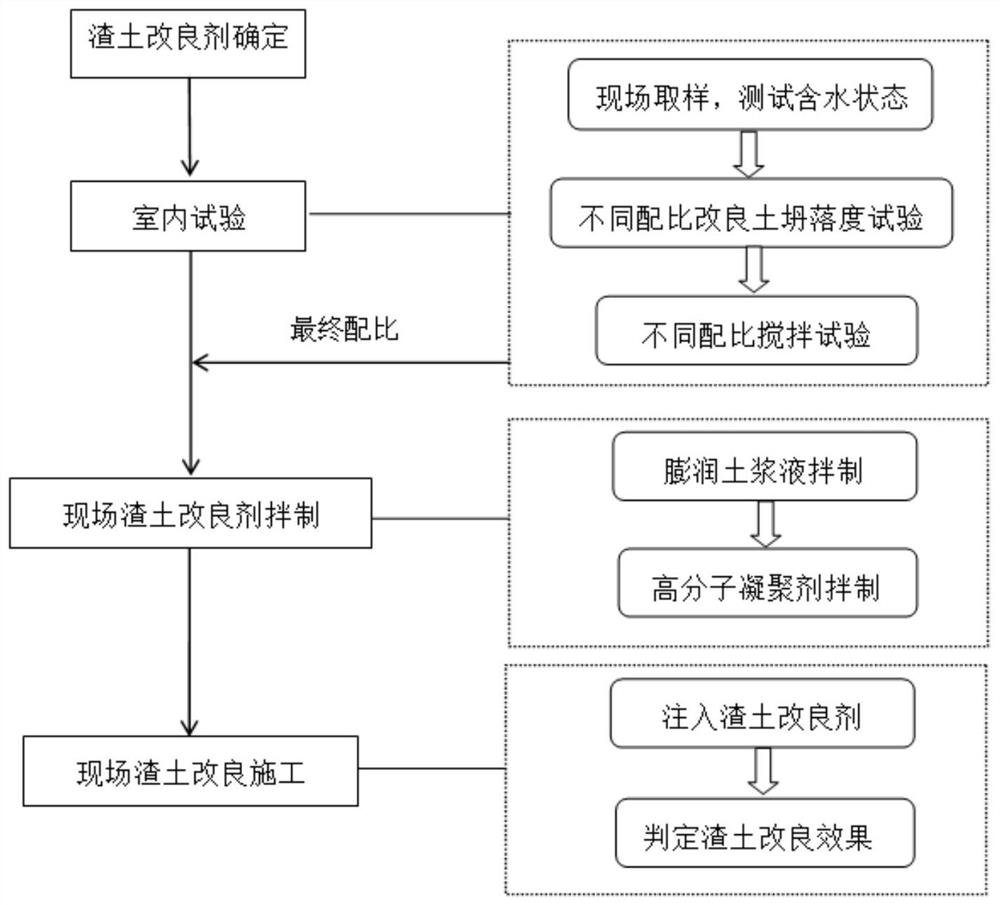

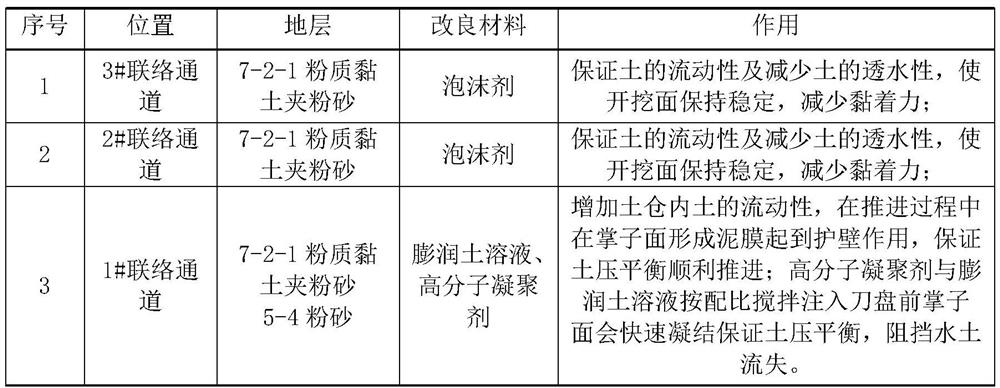

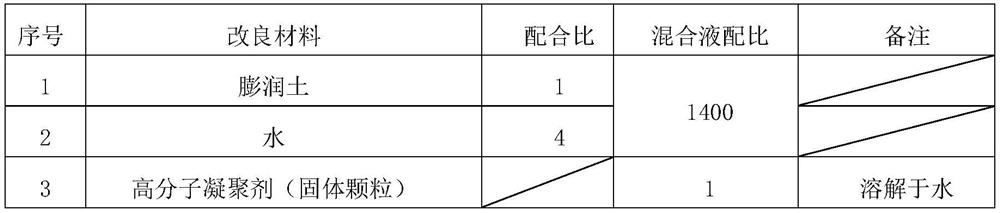

Method for improving full-section muck in silt soil layer during construction of contact channel pipe jacking machine

PendingCN113775345AChange the permeability coefficientNot easy to gushSilicon compoundsTunnelsSoil sciencePolymer solution

The invention relates to a method for improving full-section muck in a silt soil layer during construction of a contact channel pipe jacking machine. The method comprises the following steps of: S1, determining a muck improver; S2, performing an indoor test; S3, mixing the muck improver on site; and S4, performing site construction. The method has the beneficial effects that the muck is improved by adopting a bentonite improver (a bentonite solution and a high-molecular flocculant), a high-molecular polymer solution has relatively high adhesion and can well absorb soil moisture, and the permeability coefficient of the muck is changed through cutter head cutting and screw machine stirring, so that the muck is fully improved. The improved muck is not easy to gush and cake, the permeability of the muck in a soil bin is effectively reduced, and the gushing is further inhibited, so that shield tunneling is smooth and efficient, the shutdown time is shortened, the muck in a screw machine is prevented from being solidified, and the construction safety and smoothness are guaranteed.

Owner:浙江杭海城际铁路有限公司 +2

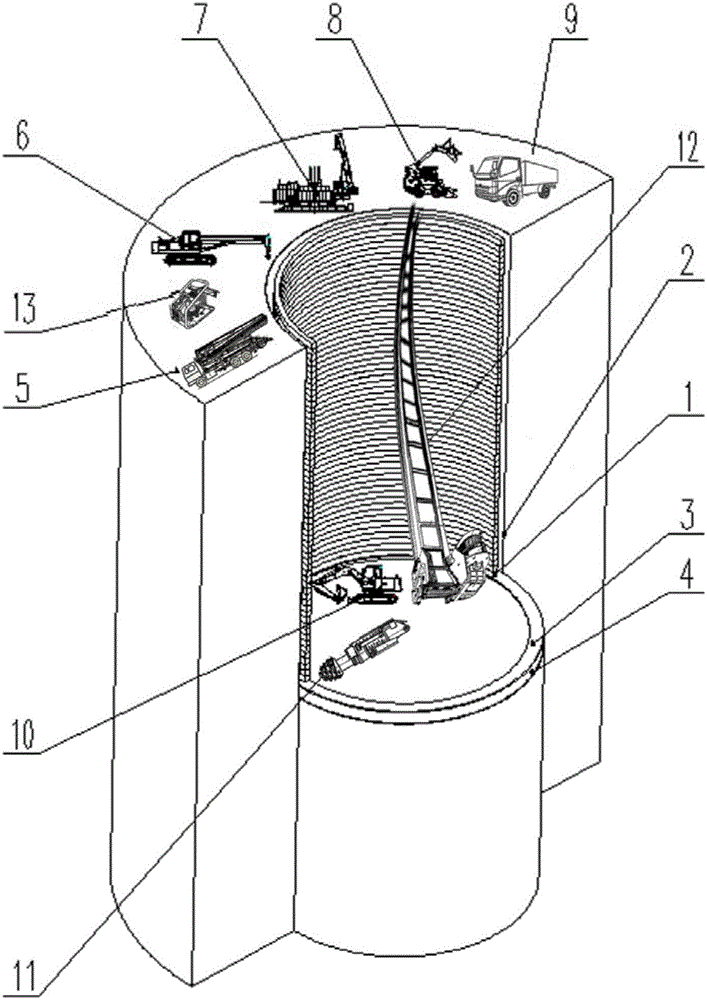

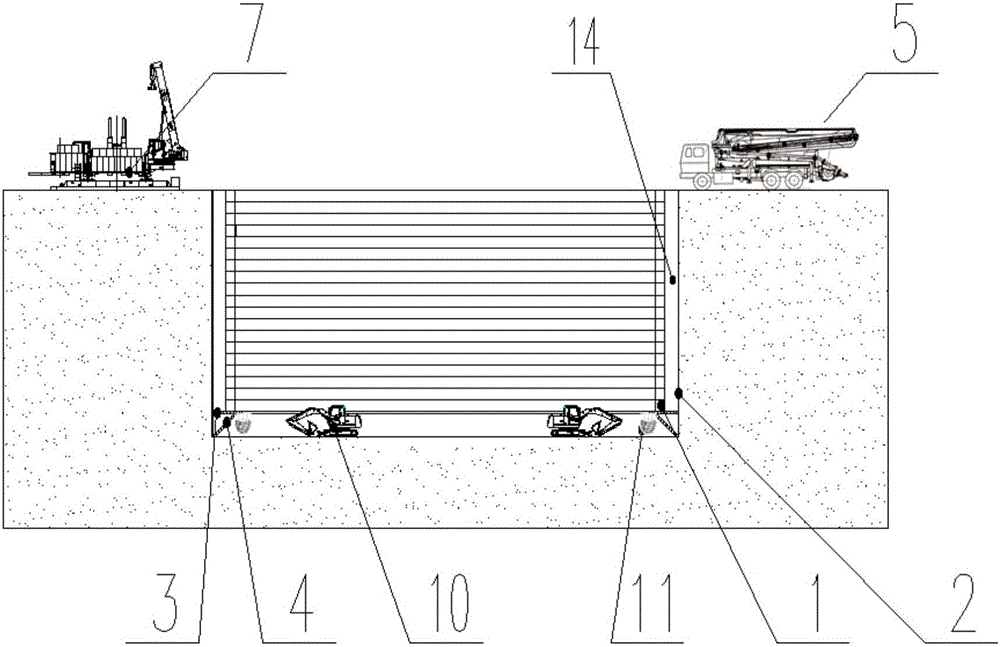

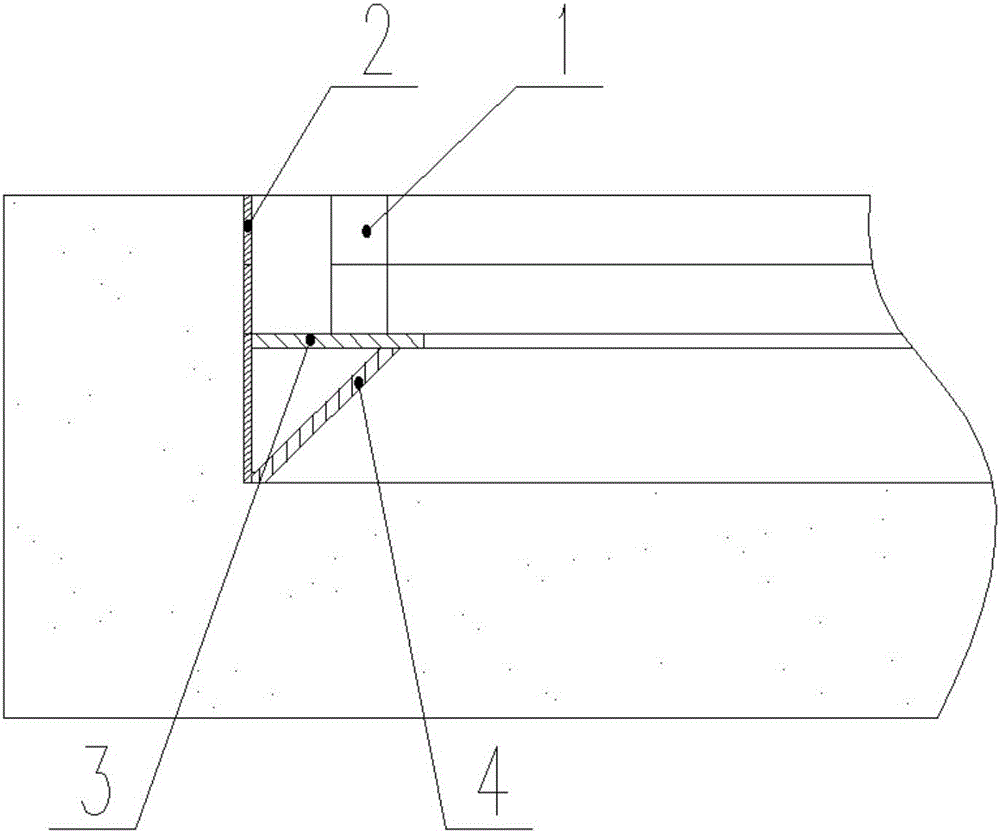

Super-large-diameter deep shaft simple shield device and shielding method

ActiveCN106761764AImprove the support effectEfficient excavationShaft sinkingShaft liningSlagExcavator

The invention provides a super-large-diameter deep shaft simple shield device and a shielding method. The simple shield device comprises a soil cutter, a pipe piece supporting base, an excavating cutter head, a steel plate ring shaft wall, a concrete pipe piece and matched construction devices. A concrete pump truck, a crane, a pipe piece pressing machine, a loader, a slag stone vehicle, a welding machine and other matched devices are arranged above a shaft. An excavator is matched with the bottom of a shaft, and a slag stone conveying device is installed on the position from the bottom to the top of the shaft. The method is simple, the property is reliable, the devices are mutually matched, the mechanical construction requirements of the super-large-diameter deep shaft are met, work efficacy and construction speed of the super-large-diameter deep shaft are greatly improved, the supporting effect of shaft construction is greatly improved, and the collapse risk is reduced.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

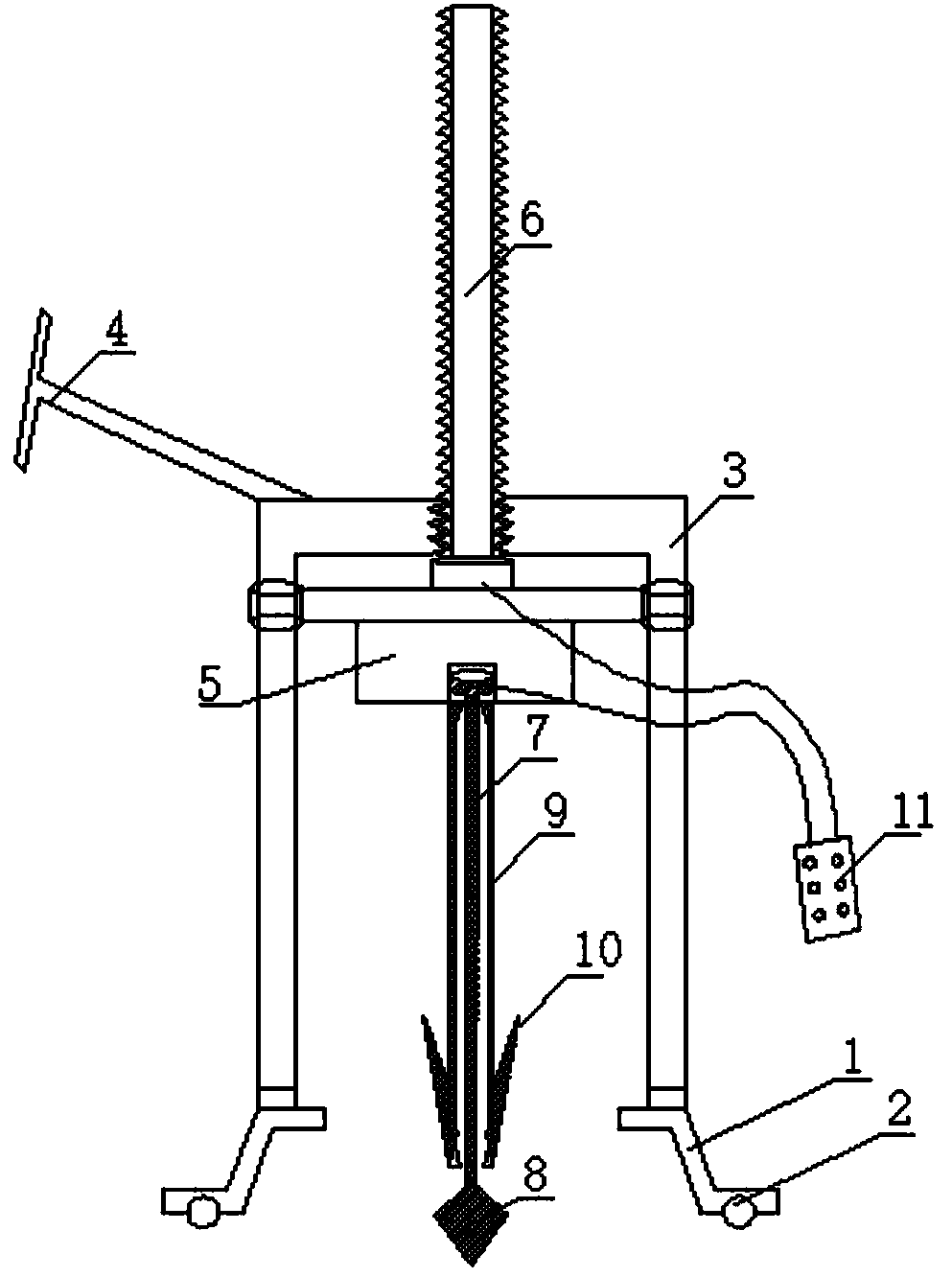

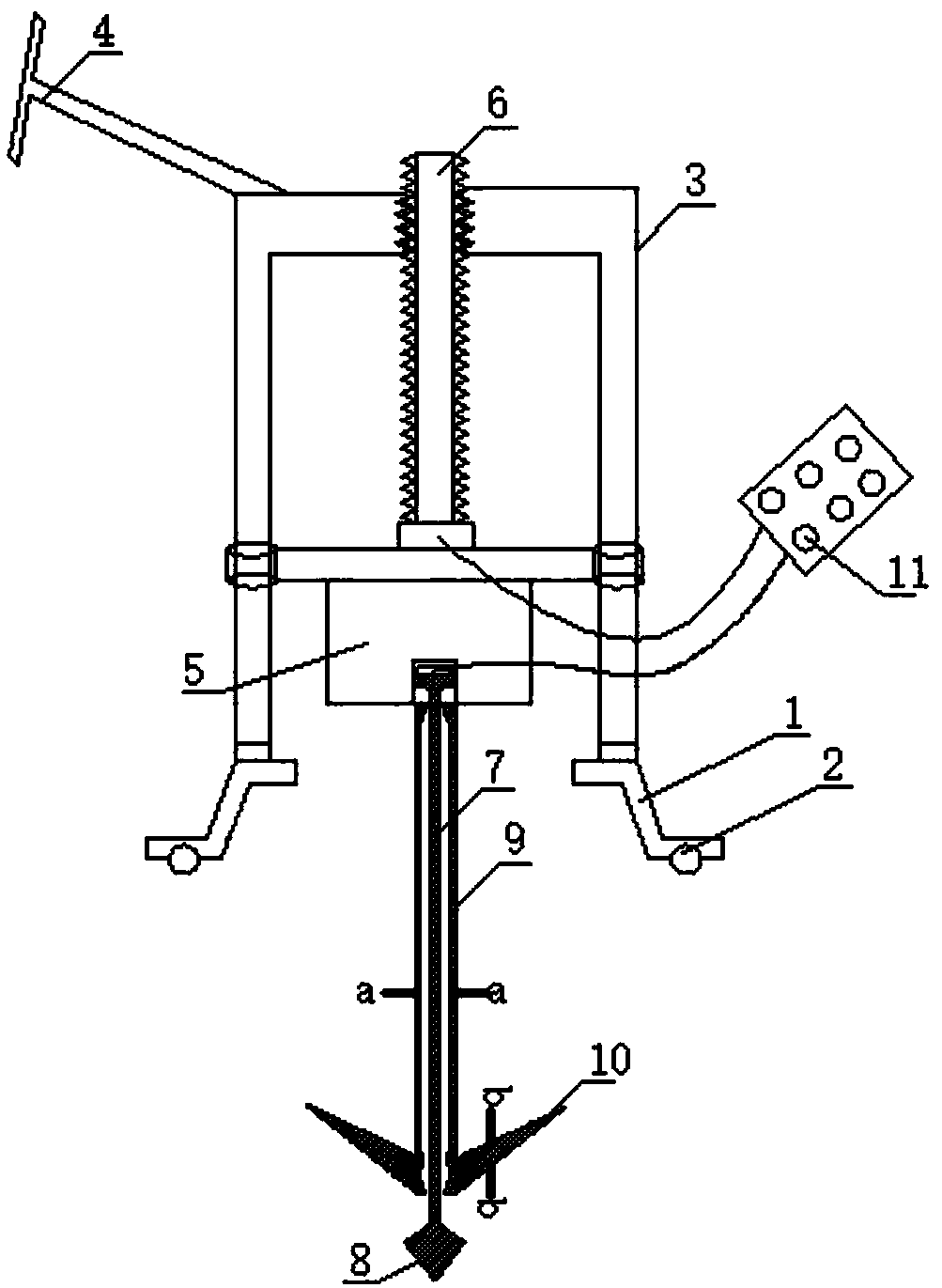

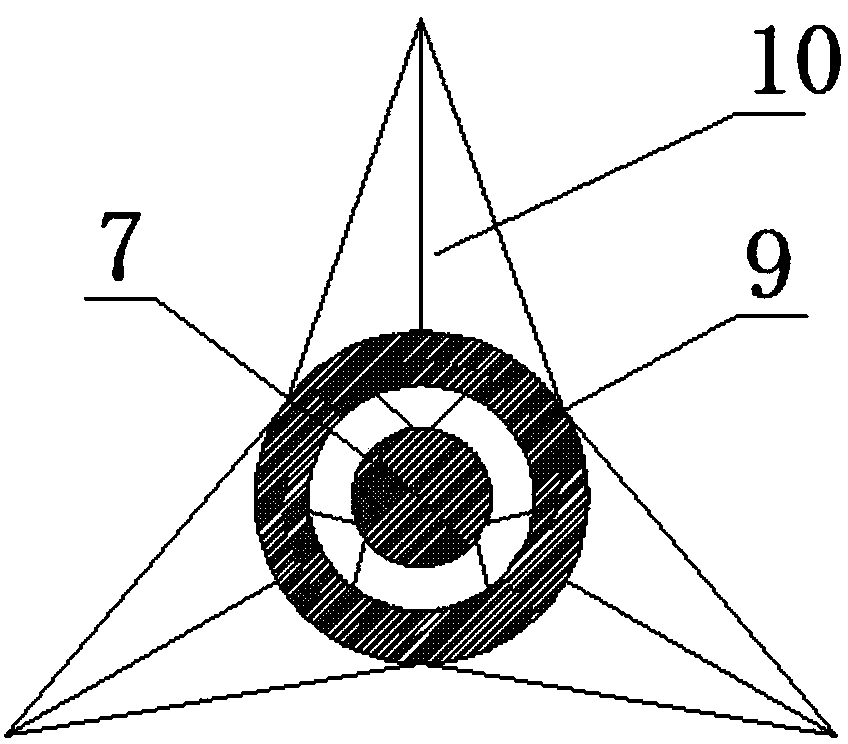

Frozen soil digging machine

PendingCN107701102AEfficient excavationSimple structureIce drillingBorehole drivesTerrainEngineering

The invention discloses a frozen soil digging machine. The frozen soil digging machine is characterized in that the frozen soil digging machine comprises a bottom tray, a door type supporting frame, arotating motor, a soil digging casing pipe and a drill pipe. The bottom tray is a steel tray with the top end being provided with a circular hole, four rolling wheels are installed at the bottom of the bottom tray, the door type supporting frame is arranged on the bottom tray, and a movable handle is installed at the top end of the door type supporting frame; and the rotating motor is installed on the door type supporting frame, a control switch is connected to the rotating motor, a threaded connection rod capable of rotating is arranged at the top end of the rotating motor, and lifting of the rotating motor is controlled through rotation of the threaded connection rod. According to the frozen soil digging machine, the frozen soil digging machine is more efficient and more practical, thestructure is simple, the amount of dug soil is large, frozen soil can further be heated, impact digging is conducted, and the frozen soil under complex terrain conditions can be thoroughly and efficiently dug and removed.

Owner:山东能源集团鲁西矿业有限公司

Water jet forcible entry and diameter expansion heading machine and construction method thereof

ActiveCN112031788AReal-time adjustable demolitionImprove rock breaking efficiencyLiquid/gas jet drillingSoil-shifting machines/dredgersHigh pressure waterRock breaking

The invention discloses a water jet forcible entry and diameter expansion heading machine and a construction method thereof, and solves the problem of low working efficiency of forcible entry and expanding excavation of an original pipeline in the prior art. The water jet forcible entry and diameter expansion heading machine comprises a tunneling main machine and rear corollary equipment, an expanding excavation cutterhead is arranged at the front end of the tunneling main machine, the expanding excavation cutterhead is connected with a main drive arranged in the tunneling main machine, a pipeline forcible entry device is arranged on the expanding excavation cutterhead, and a water jet rock breaking mechanism is arranged on the pipeline forcible entry device and / or the expanding excavationcutterhead; and the water jet rock breaking mechanism is connected with a high-pressure water system, and the expanding excavation cutterhead corresponds to a deslagging system. According to the water jet forcible entry and diameter expansion heading machine, the pipeline forcible entry device and the water jet rock breaking mechanism are used for conducting suspension cutting and water jet typerock breaking on an original pipeline in advance for forcible entry, the expanding excavation cutterhead and the water jet rock breaking mechanism are used for conducting extrusion and water jet typerock breaking on an original pipeline tunnel later for diameter expansion, forcible entry and diameter expansion one-time forming is completed, the rock breaking efficiency is high, and the construction efficiency is greatly improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Medium-soft rock cutterhead and cantilever tunneling machine with same

The invention discloses a medium-soft rock cutterhead and a cantilever tunneling machine with the same, and solves the problem that in the prior art, a cutterhead is low in tunneling efficiency of medium-soft rock strata. According to the technical scheme, the medium-soft rock cutterhead comprises a frustum cutterhead body; a disc-shaped hob is arranged on the front end face of the frustum cutterhead body; wedge tooth cutters are arranged on the conical face of the frustum cutterhead body; and a cutting arm is connected to the rear end part of the frustum cutterhead body. According to the invention, swing and axial tunneling can be conducted under the action of the cutting arm. During rock breaking by forward pushing, the disc-shaped hob installed on a front panel of the cutterhead extrudes and cuts rocks on a tunnel face, and the rocks are stripped off from the tunnel face. During rock breaking by free section swing, mainly, the wedge tooth cutters installed on a conical panel of the cutterhead are used for breaking the rocks in a suspension cutting manner; and extrusion type rock breaking of the disc-shaped hob is matched with suspension cutting type rock breaking of the wedge tooth cutters, so that flexible and efficient rock breaking of medium-soft rock strata is realized, and the tunneling efficiency is improved.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

Three directional exploiting robot for tests and three directional exploiting robot test coal cutting system

ActiveCN109209368AAchieve recyclingRealize temporary supportPropulsionCutting machinesCoalEngineering

The invention discloses a three directional exploiting robot for tests and a test coal cutting system. The three directional exploiting robot comprises a cutting device, a walking device, a gangue discharging device, and a supporting device. The cutting device and the gangue discharging device are arranged on the walking device. The supporting device is arranged above the cutting device and the gangue discharging device. The cutting device cuts a test coal layer in a three dimensional physical simulation test. The walking device is used to carry or steer the cutting device, the gangue discharging device, and the supporting device. The gangue discharging device is communicated with an external dust collector and discharges broken materials cut by the cutting device to a work plane of the three dimensional physical simulation test. The supporting device comprises a shielding part for shielding the cutting device and a telescoping part, which drives the shielding part and the cutting device to stretch out and draw back along a direction that is perpendicular to the walking device, and the shielding part is arranged on the telescoping part. The provided robot can efficiently and precisely carry out multi-seam mining in a mining area in a three dimensional physical simulation test.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com