Construction method for tunneling excavation through matching of down-the-hole drill and breaking hammer

A construction method and down-the-hole drilling technology, which are applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of increasing excavation time, slowing down excavation speed, and having a large impact on surrounding environmental protection, so as to improve construction efficiency and save construction. Cost and effect of reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

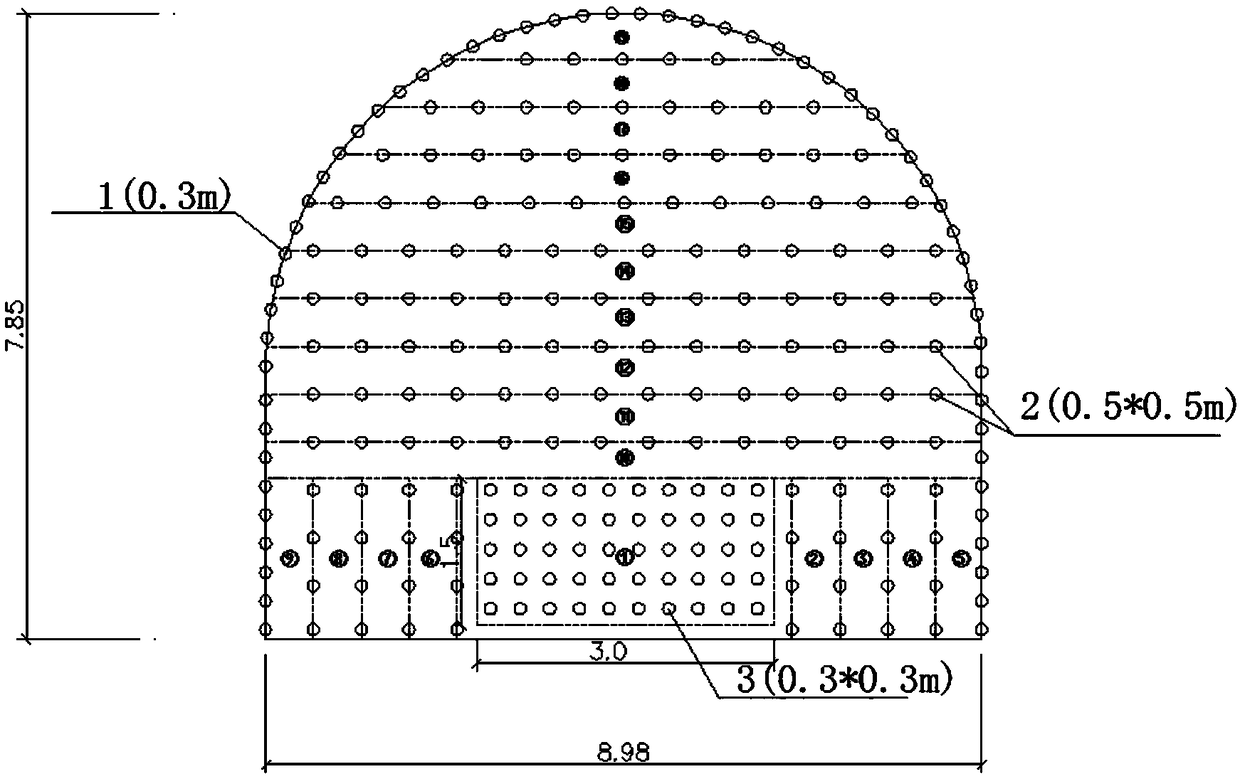

[0046] Such as Figure 1~6 As shown, the excavation method of down-the-hole drilling combined with breaking hammer excavation was applied to Zengjiayan Bridge, which connects Jiangbei District and Yuzhong District of Chongqing, and is located between Jialing River Bridge and Huanghuayuan Bridge. Because there are many old residential buildings around the construction passage, it is To ensure construction safety, mechanical development and excavation are adopted for construction.

[0047] After testing, the 5 surrounding rocks at the tunnel face of the pilot tunnel are grade III, mainly composed of sandstone and sandy mudstone, with good integrity. The uniaxial compressive strength of the rock reaches 70MPa. Since the pilot tunnel passes through the old factory area of Chang'an factory, precision processing plant, Chang'an hospital, etc., construction vibration has a high impact on it.

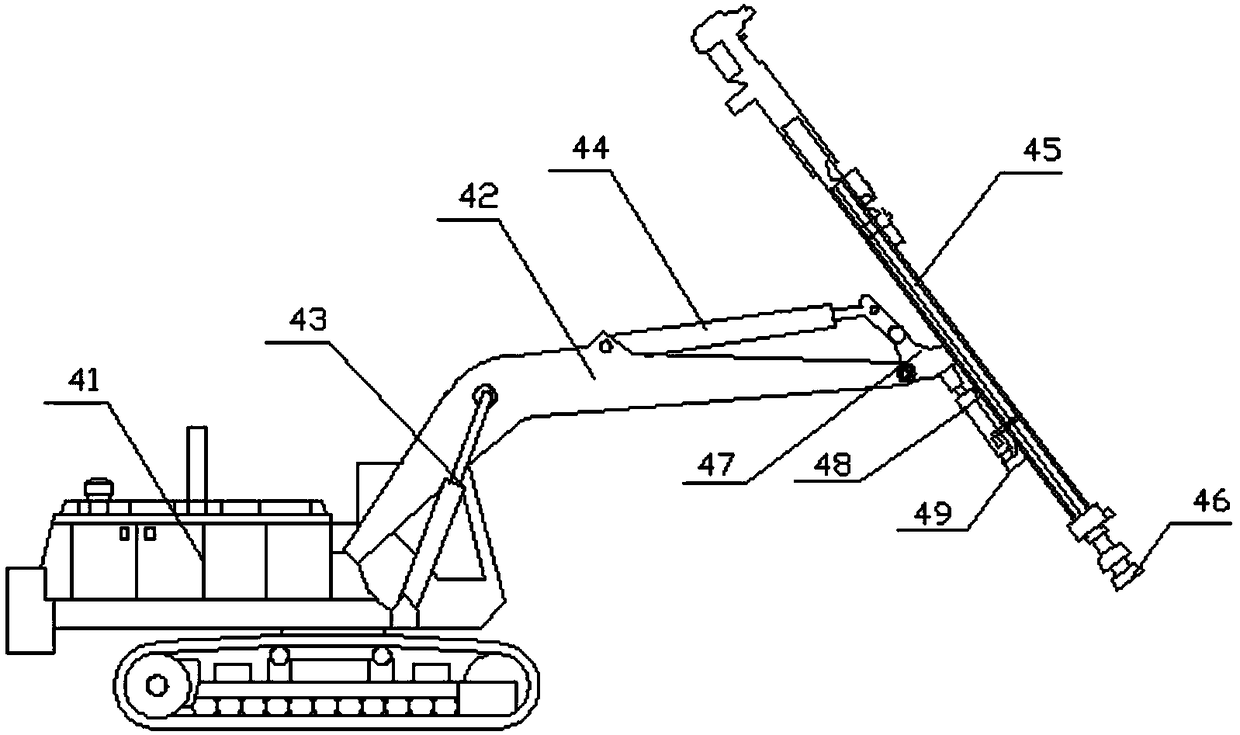

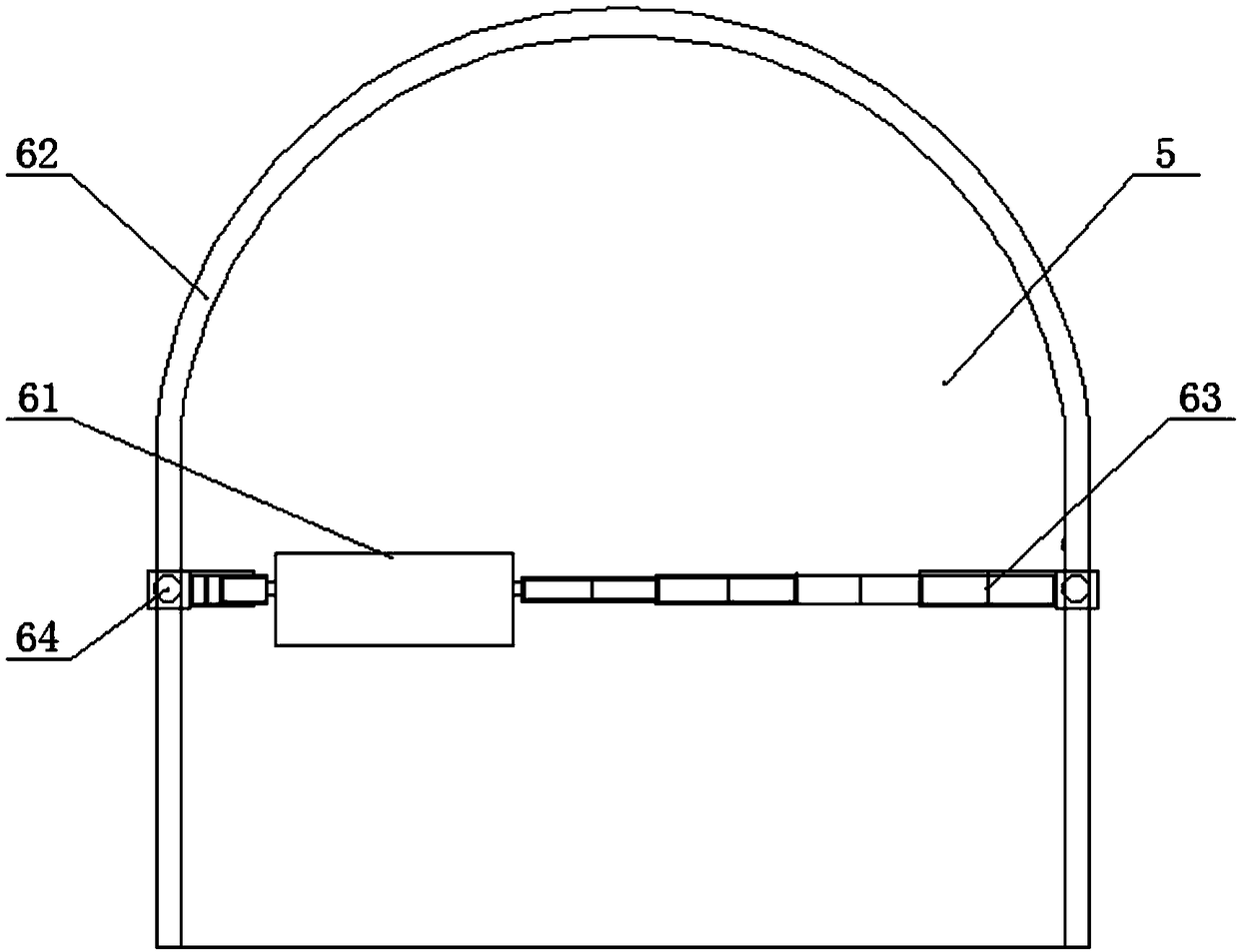

[0048] The construction method of down-the-hole drilling combined with breaking hammer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com