Belt conveyor self-moving machine tail for lapping joint with swing type rapid tunneling system

A technology of self-moving tail and belt conveyor, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high excavation cost, large roof damage, low excavation efficiency, etc., to reduce labor intensity and high efficiency The effect of fast excavation and improvement of excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

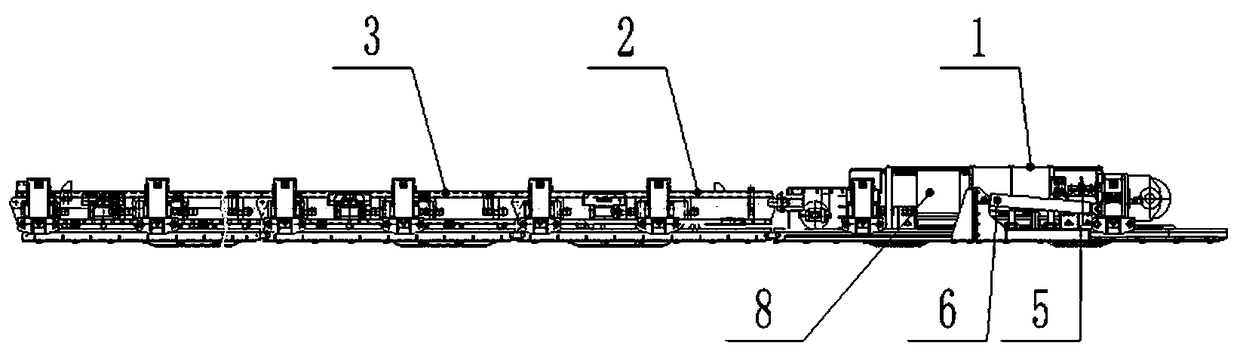

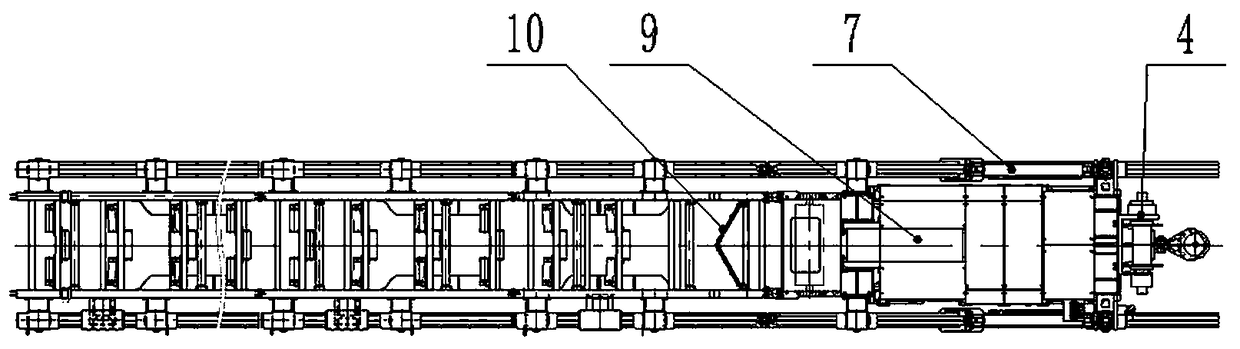

[0034] Such as figure 1 , 2 As shown, it is the overall structure diagram of the self-moving tail of the belt conveyor used in the lapping swing type rapid excavation system. The installation relationship shown in the diagram must be correct and the installation should be firm and reliable.

[0035] The self-moving tail of the self-moving belt conveyor for the lapping swing type rapid excavation system is composed of three parts: the power frame, the tail frame and the middle frame.

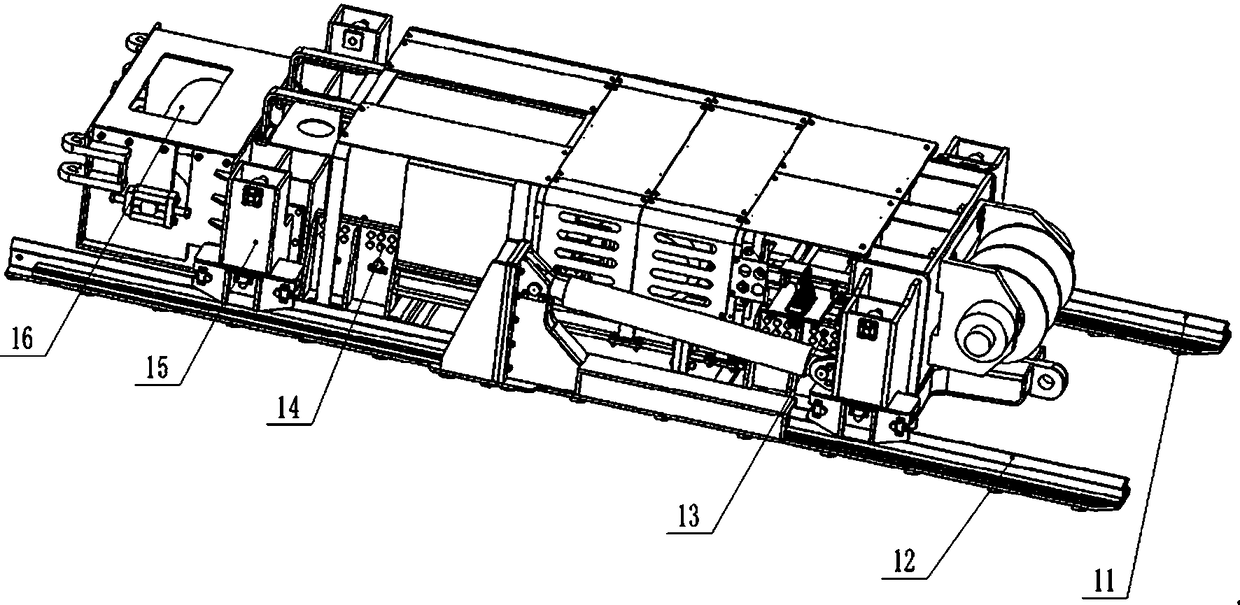

[0036]The power frame is the power center of the whole machine, which is mainly composed of hydraulic winch, hydraulic system, electric control system, telescopic operating mechanism, machine pushing mechanism, power frame lifting mechanism, deviation adjustment mechanism, reversing roller and other parts. The hydraulic winch is fixed at the tail of the power frame through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com