Water jet forcible entry and diameter expansion heading machine and construction method thereof

A water jet and roadheader technology, applied in the field of pipeline expansion and excavation, can solve the problems of original pipeline demolition and low efficiency of expansion and excavation, and achieve the effect of improving construction efficiency, wide application range and good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

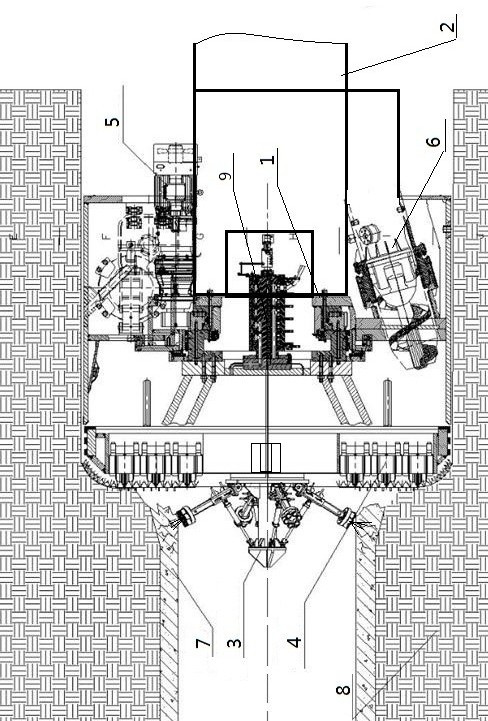

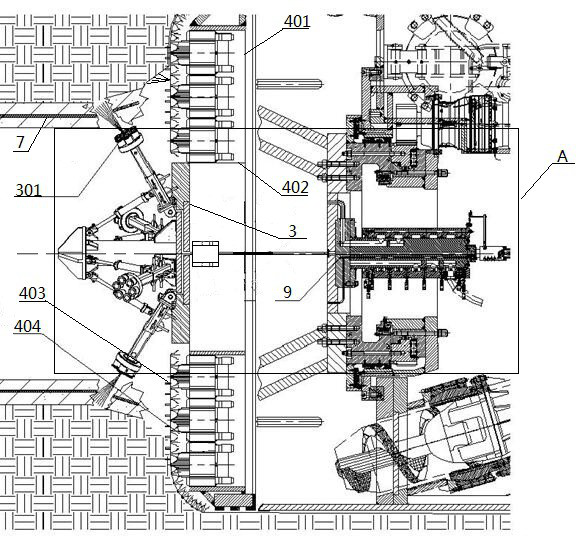

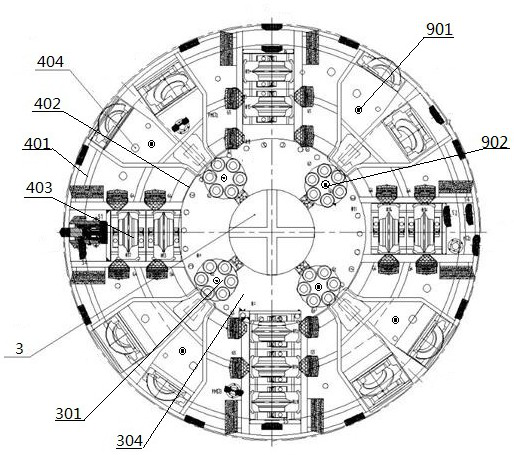

[0041] Example 3, such as Figure 6 , 7 Shown, a kind of breaking and opening, expanding diameter tunneling machine, in order to improve the efficiency, the water jet rock breaking mechanism is provided on the pipeline breaking device 3 and the expanding cutter head, and then the water jet rock breaking mechanism 9 includes the The expansion water jet nozzle 901 on the disc main body 401 and the demolition water jet nozzle 902 arranged on the suspension arm 301, the expansion water jet nozzle 901 and the demolition water jet nozzle 902 are connected with the high pressure water system through a rotary mechanism.

[0042] Further, the rotary mechanism includes a first rotary joint 903 arranged in the tunneling main engine 1, the first rotary joint 903 is arranged concentrically with the cutter head main body, and the first rotary joint 903 is provided with a radial water outlet pipe 904 and a central outlet pipe. The water pipe 905, the radial outlet pipe 904 and the center ou...

Embodiment 4

[0044] Embodiment 4, a kind of construction method of water jet demolition and expanding diameter boring machine as described in embodiment 3, the steps are as follows:

[0045] S1: Hoist the demolition and expansion boring machine to the original pipeline, and debug it to the ready-to-work state;

[0046] S2: Start the demolition and diameter-expanding roadheading machine, the pipeline rescue device 3 of the demolition and diameter-expanding roadheader first demolishes the original pipeline, and the 4 pairs of expanding cutterheads of the demolition and diameter-expanding roadheader are demolished Excavation of the tunnel;

[0047] S3: During the excavation process of the roadheader in step S2, the water jet rock-breaking mechanism 9 of the pipeline demolition device 3 cooperates with the suspension cutting hob 3013 of the pipeline demolition device 3 to perform high-pressure water jet demolition of the steel bars in the original pipeline; The water jet rock-breaking mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com