High-pressure water jet edge cutter and combined rock breaking and escaping TBM cutterhead and method thereof

A high-pressure water jet and high-pressure water technology, used in high-pressure water jet edge cutter, combined rock-breaking and trapping TBM cutter head, hydraulic-mechanical combined rock-breaking and trapping, hydraulic-mechanical combined rock-breaking and trapping TBM cutter head, combined rock-breaking In the field of TBM cutter head, it can solve the problems of large changes, low rock breaking efficiency, waste of water resources, etc., and achieve the effect of reducing nozzle wear, reducing rock breaking energy consumption, and improving project progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

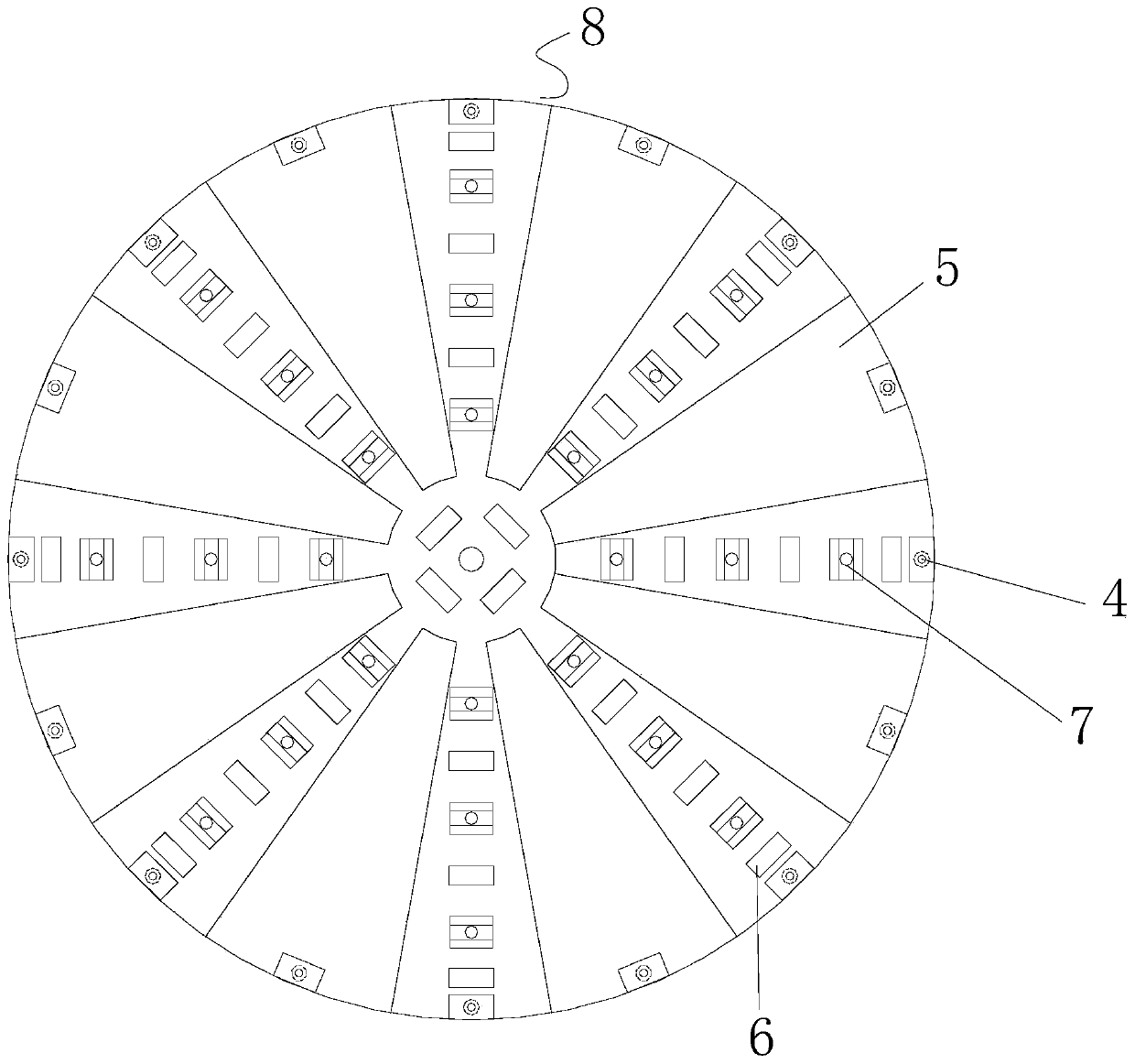

[0060] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, only for example. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

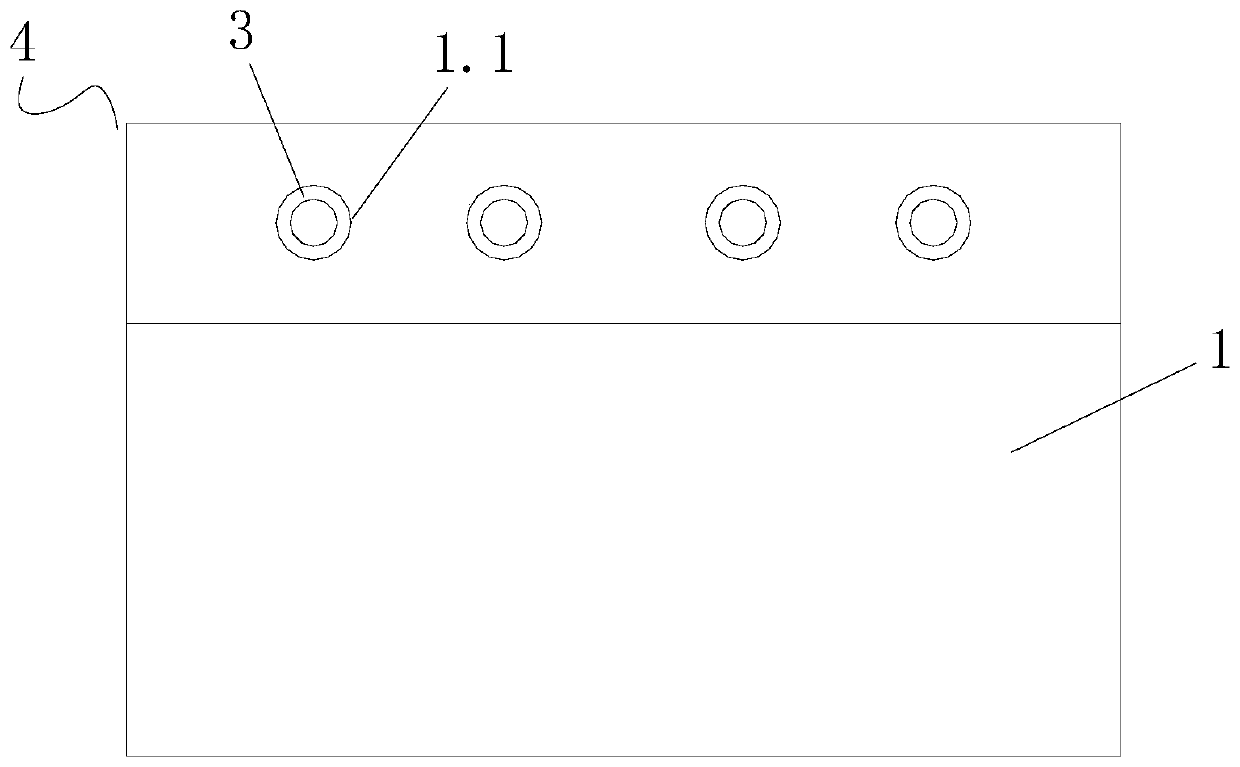

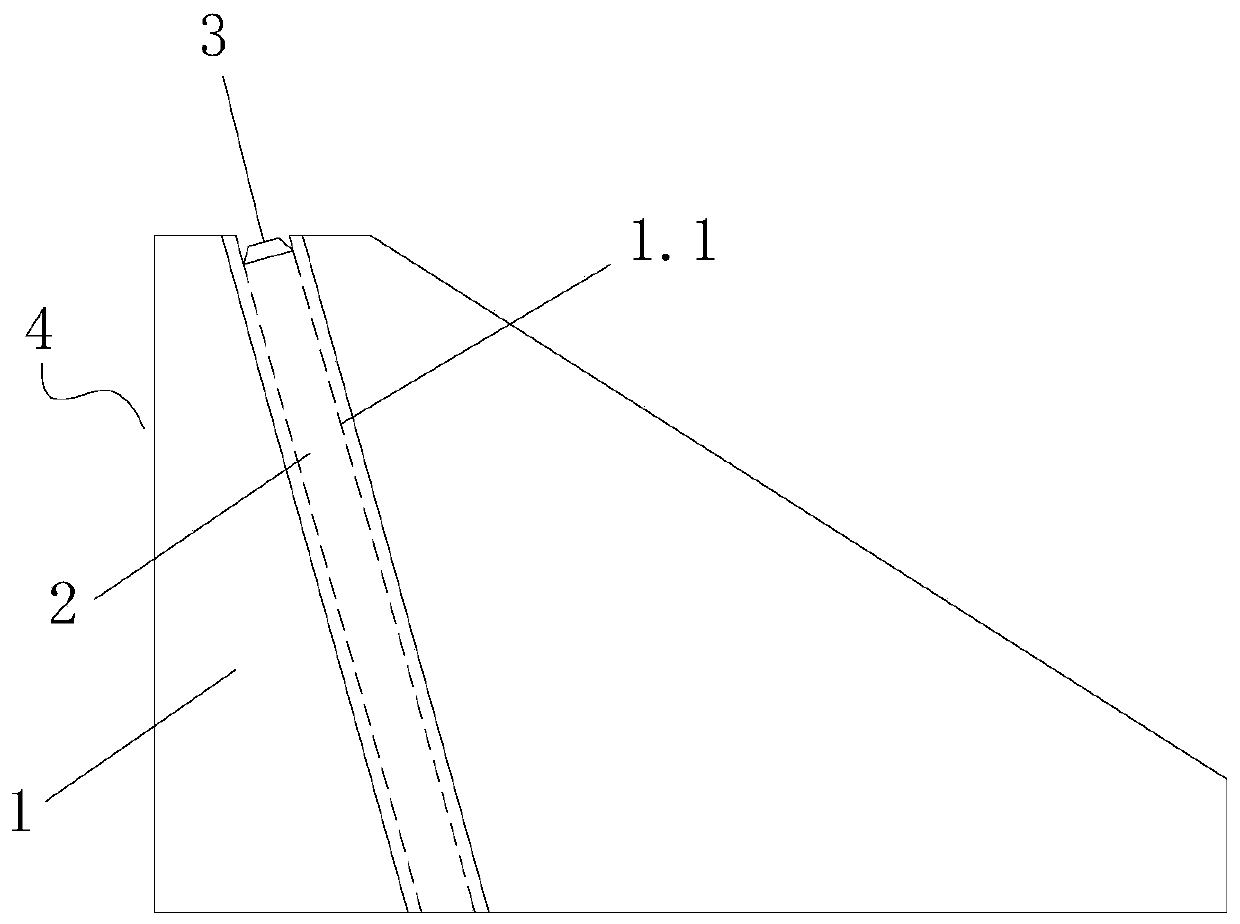

[0061] Referring to the accompanying drawings, it can be known that the high-pressure water jet side knife includes a side knife mechanical structure 1, a side knife high-pressure water jet pipeline 2 and a side knife high-pressure water jet nozzle 3;

[0062] The side knife high-pressure water jet pipeline 2 is located inside the side knife mechanical structure 1;

[0063] Described edge cutter high pressure water jet nozzle 3 is embedded in described edge cutter mechanical structure 1 inside, and is communicated with described edge cutter high pressure water jet pipeline 2; figure 2 shown).

[0064] Further, the side knife mechanical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com