High-efficiency plastic granulator

A shredder and plastic technology, applied in the field of plastic processing, can solve the problems of excessive feeding, clogging, affecting the processing effect, etc., and achieve the effect of feeding control and avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

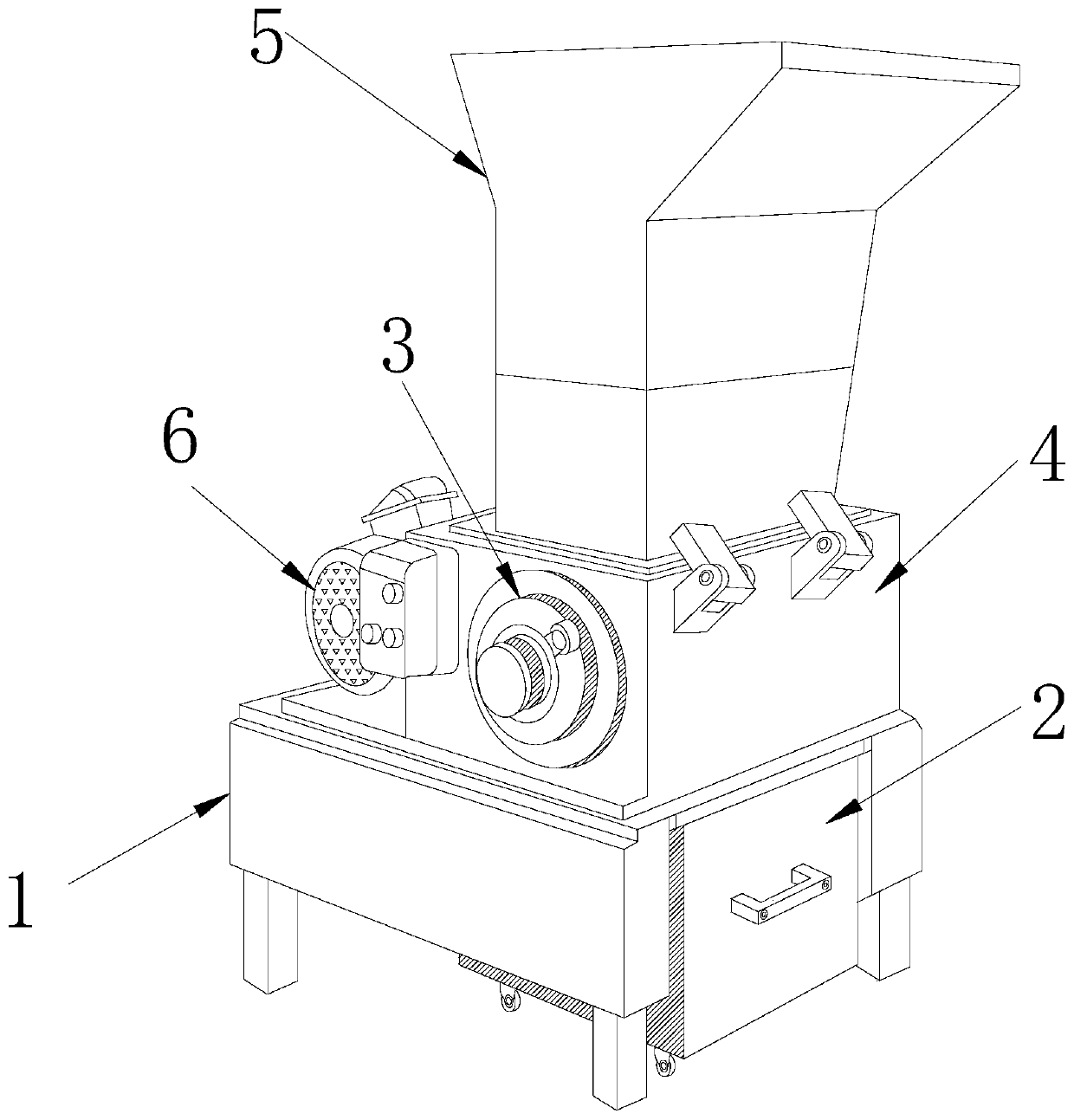

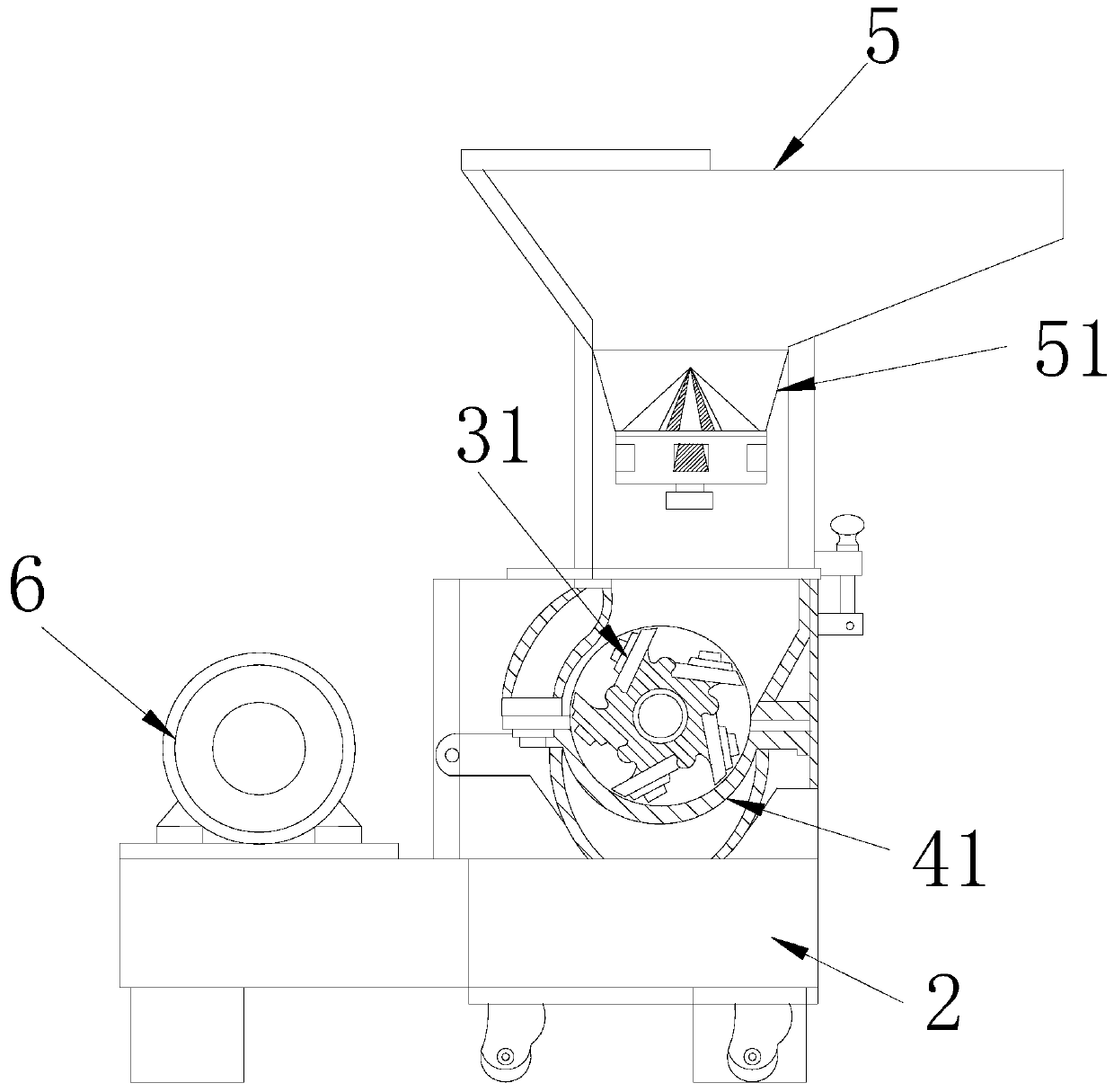

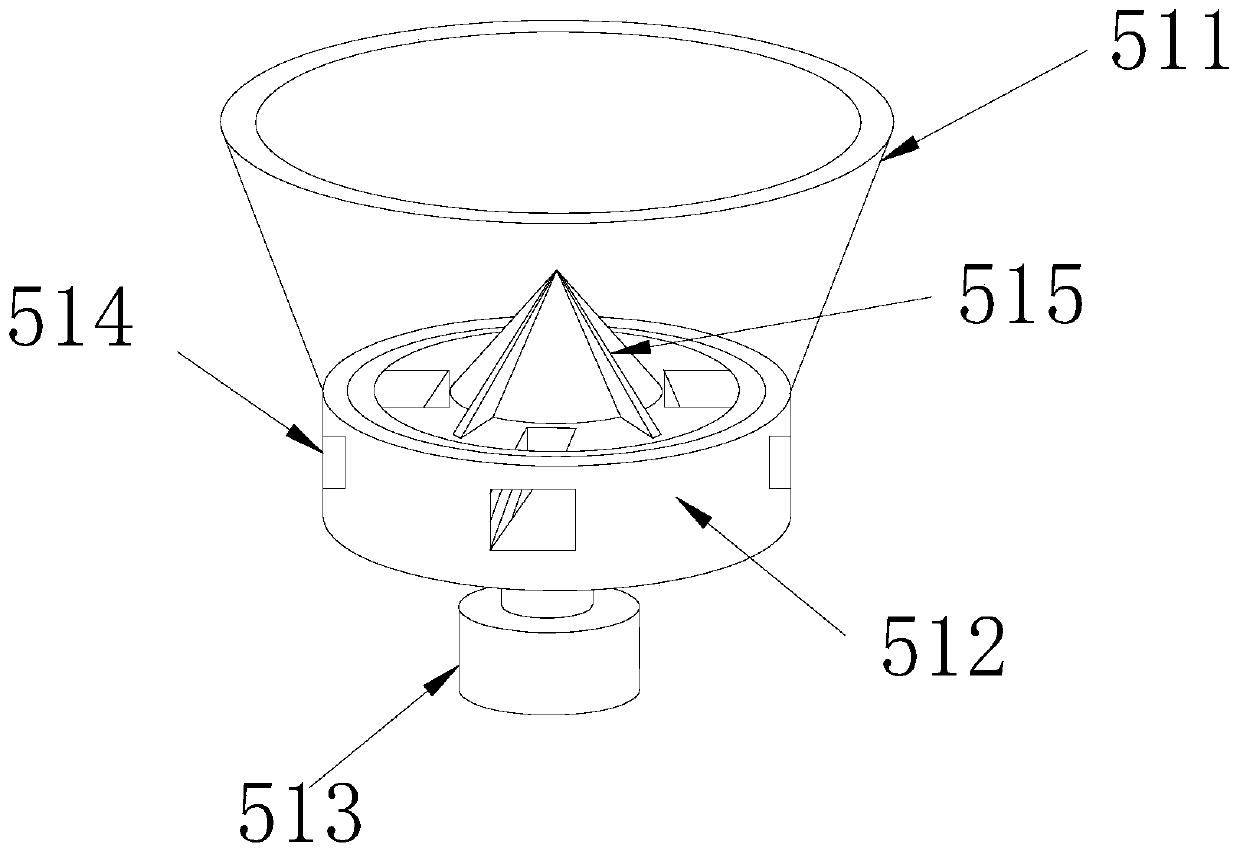

[0023] Such as Figure 1-Figure 6 As shown, the present invention provides a high-efficiency plastic granulator, whose structure includes a machine base, a material receiving box, a cutter, a processing box, a feeding bin, and a motor. The material receiving box is located at the downward position of the machine base, so The processing box and the machine base are an integrated structure, the cutter is fixed inside the processing box, the feeding bin is connected with the processing box through a hinge, the rear end of the machine base is provided with a motor, and the feeding There is a conveying control device in the warehouse. The conveying controller mainly includes a material guide plate, a conveyor, a driver, a material guide groove, and a pushing device. The material guide plate is connected to the outer ring of the conveyor, and the driver is located below the conveyor. The position is electrically connected, the push device is fixed at the center of the push device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com