Double-stage drill bit

A drill bit and bit body technology, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of low ROP and poor bit stability, and achieve the effects of reducing rock strength, reducing wear and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

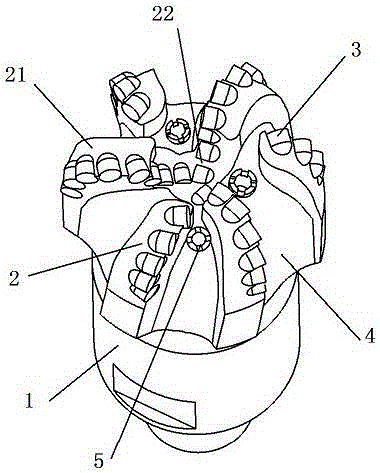

[0033] refer to figure 1 As shown, a two-stage drill bit includes a drill body (1), a fixed blade (2), a fixed cutting tooth (3), a flute (4), a nozzle (5), etc., and is characterized in that: the core of the drill bit The inner cutting structure (22) is formed by inward depression, and together with the outer cutting structure (21), a stepped two-stage drill bit is formed.

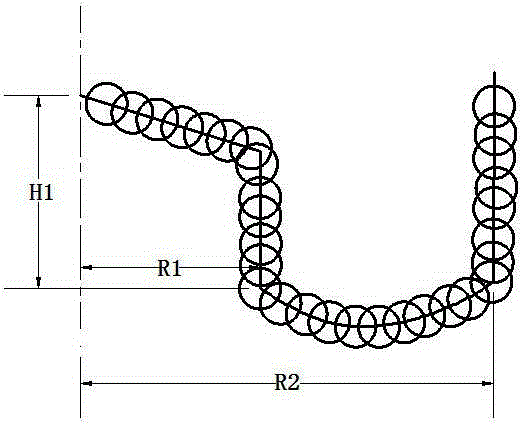

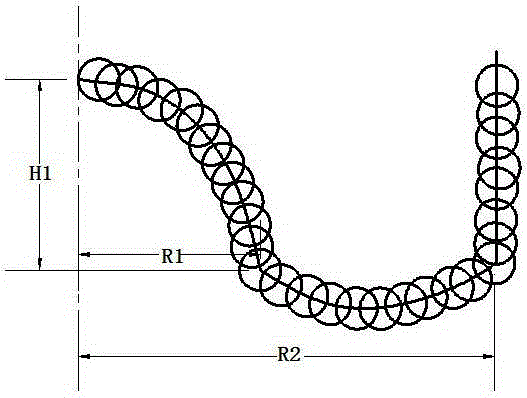

[0034] As an option, the core of the drill bit is sunken inward, and the outline of the core is a straight line, a parabola, an arc, a spline curve, etc., such as figure 2 , 3 shown.

[0035] As an option, the core of the drill bit is sunken inward, and its inner sunken depth H1≥20mm, such as figure 2 , 3 shown.

[0036] As an option, the cutting area at the core of the drill bit reaches more than 40% of the radial area of the drill bit, that is, R1 / R2≥0.4, such as figure 2 , 3 shown.

[0037] Alternatively, the drill bit diameter is 9.5 inches or greater.

[0038] Alternatively, the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com