Development method of transportation through auxiliary slope ramp matched with rubber belt inclined shaft

A pioneering method and ramp technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as ventilation, drainage and safety hazards, and achieve the effects of low transportation costs, accelerated construction speed, and large transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

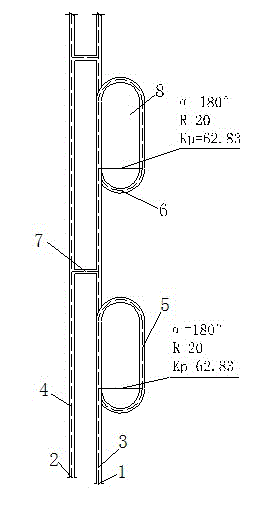

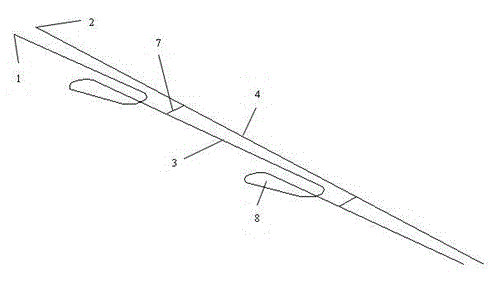

[0012] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0013] see figure 1 , figure 2 , during infrastructure construction, 0 0 Tape inclined well head 2 of tape inclined shaft 4 set at ~15° and auxiliary ramp well head 1 of auxiliary ramp 3 are excavated at the same time, and auxiliary ramp 3 is driven by 0 0 The auxiliary slope straight road 3 and the spiral return road 8 set at ~8° are alternately connected, and the auxiliary slope 3 is at the plane position adjacent to the tape slope 4 and descends through the spiral return road 8 to reach the same elevation as the tape slope 4; 300-400m set up connecting roadway 7 to connect tape inclined shaft 4 and auxiliary slope straight road 3, and the connecting roadway 7 is arranged so that the end adjacent to tape inclined shaft 4 is higher than the end adjacent to auxiliary slope straight road 3, which is used for slag discharge, ventilation and drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com