Method for identifying surrounding rock load of outer surface of three-dimensional TBM shield

A technology for load identification and external surface, which is applied in earth-moving drilling, testing of machine/structural components, mining equipment, etc. It can solve problems such as difficulties and narrow gaps, and achieve the effect of high calculation accuracy and good visualization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It will be described in detail below in conjunction with the embodiments and accompanying drawings.

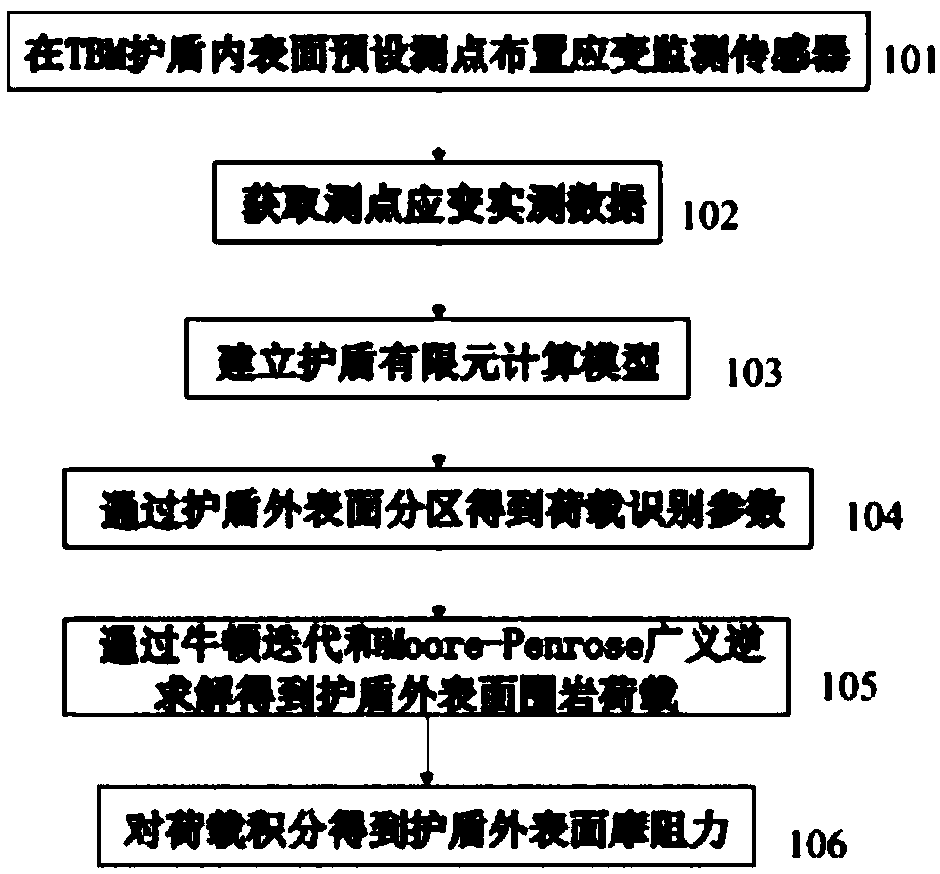

[0044] Such as figure 1 , the specific implementation steps of this method are as follows:

[0045] ① Install the strain monitoring sensor-101 at the preset measuring points on the inner surface of the TBM shield

[0046] The number of preset measuring points should be as large as possible and evenly distributed, avoiding the action area of the moving mechanical components inside the shield;

[0047] The strain monitoring sensor adopts a surface strain gauge or an optical fiber strain sensor, and the sensors are respectively arranged axially and circumferentially along the inner surface of the shield at each measuring point, or arranged along a single direction, and protective measures need to be applied to the sensors;

[0048] In this embodiment, surface strain gauges are used, and 36 measuring points are evenly arranged on the inner surface of the shield, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com