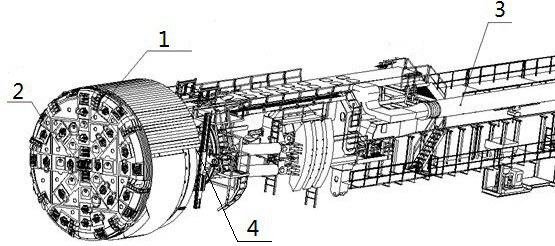

Novel TBM and construction method thereof

A new type of cutterhead technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as low excavation efficiency and cutterhead wear, and achieve the effects of improving excavation efficiency, reducing wear, and improving auxiliary rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0048] Embodiment 4: a kind of construction method of novel TBM as described in embodiment 3, the steps are as follows:

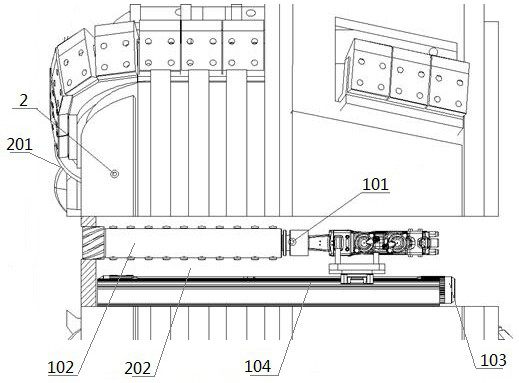

[0049] S1: During the excavation process of the cutter head 2, the anchor drill splitting device 1 is retracted into the cutter head 2, and the opening and closing sealing device 3 is closed; that is, when the drilling machine is in the initial position, the anchor drill splitting device is installed in the axial direction of the cutter head inside the hole, such as Figure 7 shown;

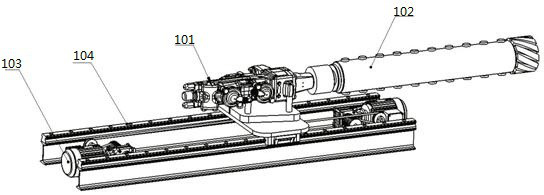

[0050] S2: When the TBM is shutting down for support and segment assembly, the opening and closing sealing device 3 is opened, and the anchor drill splitting device 1 is driven forward by the sliding drive device 103 from the axial installation hole 202 of the cutter head 2 ;like Figure 8 shown;

[0051] S3: The anchor-drill device 101 of the anchor-drill splitting device 1 drills a hole on the face. After the drilling is completed, the splitting device 102 of the anchor-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com