Patents

Literature

121results about How to "Meet the rapid excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

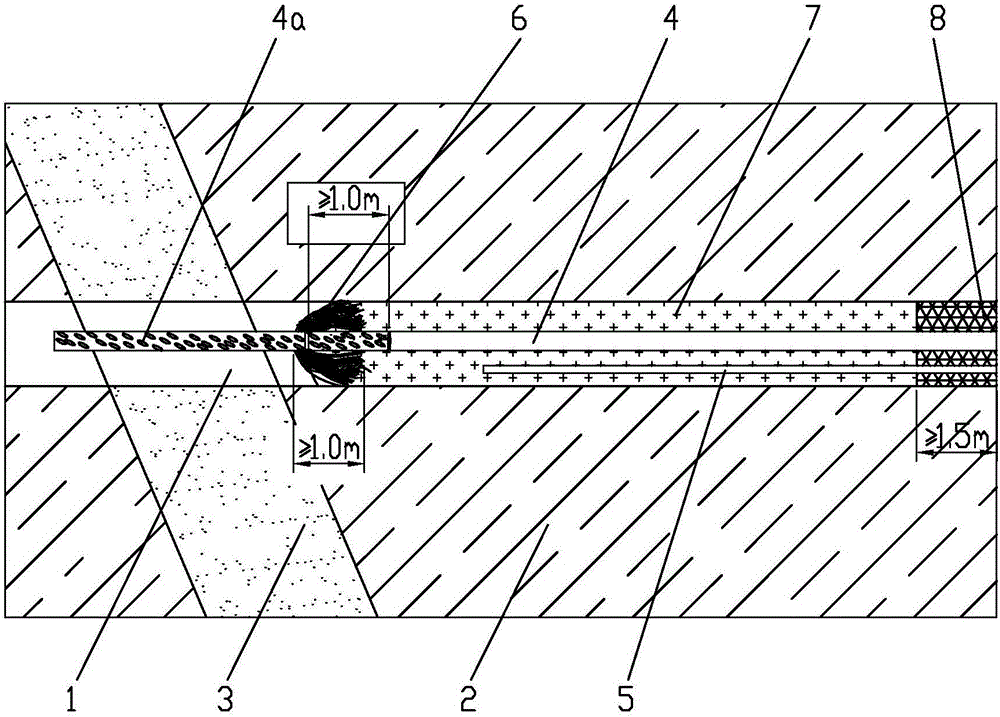

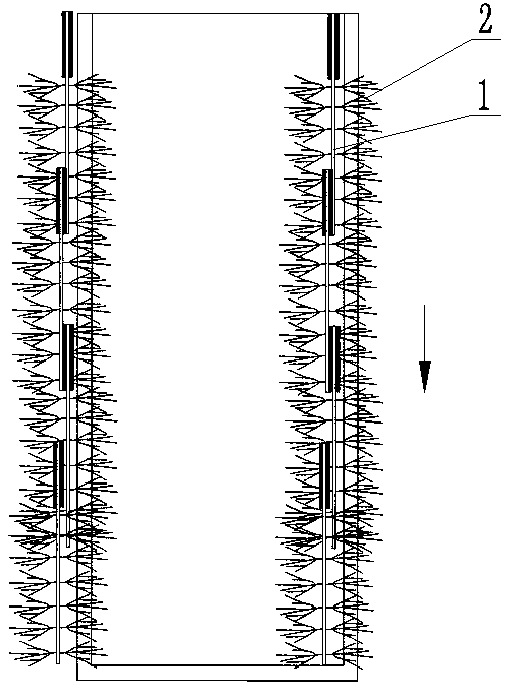

Method for gas drainage and regional outburst elimination of coal roadway strips by staged fracturing and along seam long borehole drilling in floor strata

ActiveCN106907175ANo increase in roadway engineering volumeReduce the amount of drilling workFluid removalGas removalCoalStandard time

The invention provides a method for gas drainage and regional outburst elimination of coal roadway strips by staged step-by-step fracturing and along seam long borehole drilling in a floor strata. The method is suitable for being applied to coal roadway excavating region outburst elimination, backstoping region outburst elimination and other projects. Along seam long boreholes are drilled in the hard floor strata with outburst-hazard coal seams in an existing roadway along the to-be-excavated coal roadway direction, staged step-by-step fracturing is conducted, fracturing holes are used for segmental drainage or the whole drainage, and outburst elimination is conducted on the coal roadway strips; according to the drainage amount, exhausting and mining standard evaluation is conducted, after exhausting and mining reach the standard, boreholes are drilled in the coal seams at the boundaries, in the range of regions adopting effective outburst prevention measures, on the two sides of the coal roadway, regional outburst prevention measure effect checking is conducted, drainage is then conducted, and coal roadway excavating is conducted when regional checking measures and local four-in-one measures are implemented. The method has the advantages that boreholes replace the roadway, drilling project amount is less, the fracturing range is large, the fracturing region surrounding coal stress concentration degree is low, stress relieving and permeability improving effects are good, exhausting and mining up-to-standard time is short, the coal parameter adaptability is high and the application range is wide.

Owner:CHINA UNIV OF MINING & TECH

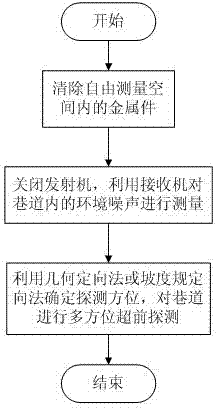

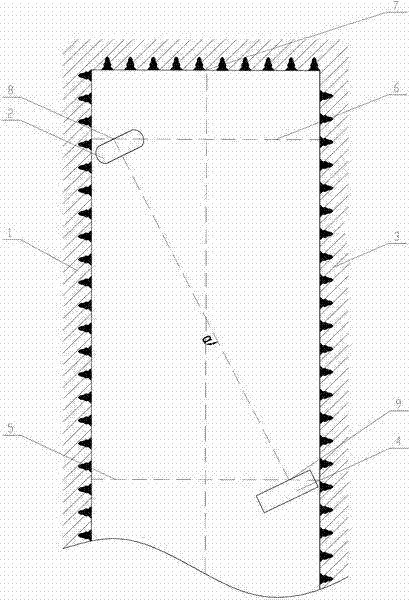

Roadway multi-azimuth advance detection method

ActiveCN102213773ADetect hidden water inrush hazardsIdentify hidden water inrush hazardsElectric/magnetic detection for well-loggingDetection using electromagnetic wavesMultidimensional scalingClassical mechanics

The invention discloses a roadway multi-azimuth advance detection method for detecting the water body or other bad geologic bodies at the head and periphery of a roadway when the roadway is excavated. The method comprises the following steps: firstly, cutting off all the commercial power supplies in the roadway and eliminating the metal pieces in the measuring space of the roadway; and then, carrying out the multi-azimuth advance detection on the roadway by adopting a distributed measuring mode by utilizing a transient electromagnetic instrument, wherein the detection azimuth is determined by utilizing a geometric orientation method or a gradient rule orientation method in the detection course. In the method disclosed by the invention, the one-dimensional detection of the conventional advance detection is expanded into the multidimensional detection; the hidden water bursting danger conditions in the excavation sweep range of the roadway can be investigated to the maximum limit, thereby providing geophysical prospecting technical basis for the excavation safety. In the method disclosed by the invention, the detection range and detection distance of the head advance detection of the roadway are expanded; the detection efficiency is greatly enhanced; and the practical significances on the aspects of guaranteeing the excavation safety, coordinating the rapid excavation of high-yield and high-efficiency mines and enhancing the production efficiency are great.

Owner:HEBEI COAL SCI RES INST

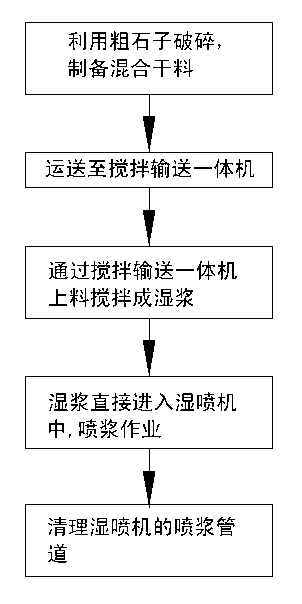

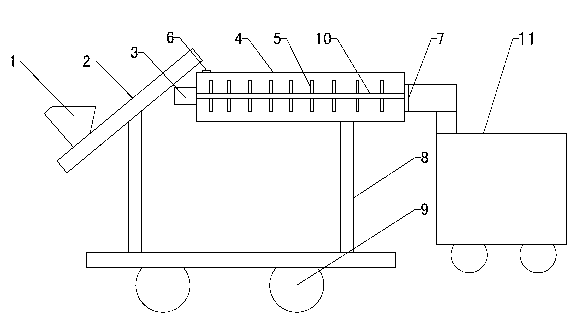

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

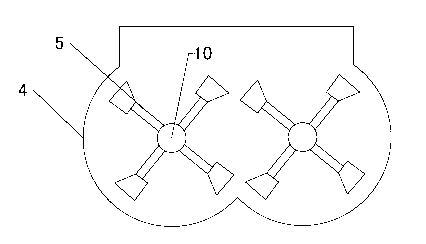

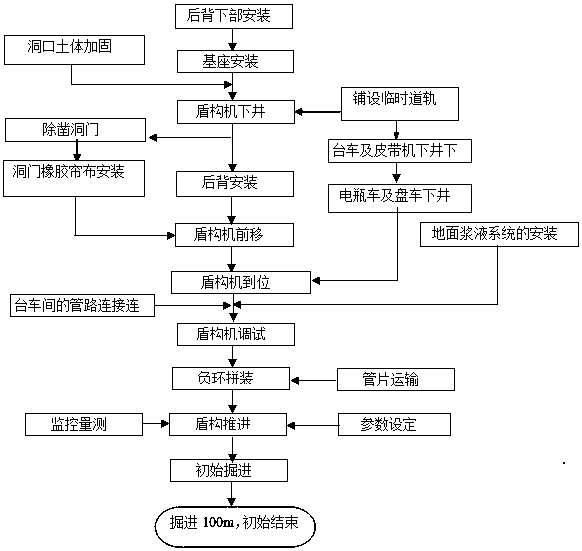

Application construction method of shield separate launching technology in urban drainage engineering

InactiveCN108952733ASmall sizeSave installation timeUnderground chambersTunnel liningSoil massUrban area

The invention relates to the technical field of civil engineering, in particular to an application construction method of a shield separate launching technology in urban drainage engineering. The application construction method of the shield separate launching technology in the urban drainage engineering is suitable for shield construction of drainage pipeline engineering in an urban area, especially for the engineering that a construction site is narrow and small, and all shield equipment cannot be mounted at a time. The application construction method of the shield separate launching technology in the urban drainage engineering comprises the steps of arranging of a launching shaft, arranging of facilities in the launching shaft, hoisting trying of a shield machine, hoisting-into-shaft ofthe shield machine, reinforcing of tunnel opening soil mass, mounting of a tunnel opening rubber cord fabric, chisel-off of a tunnel opening pouring pile, transport arrangement, shield launching preparation, initial tunneling construction, launching of a shield trolley. The application construction method of the shield separate launching technology in the urban drainage engineering adopts the shield machine separate launching technology, the size of the launching vertical shaft can be effectively decreased, the engineering cost is lowered, and meanwhile, the influence on the surrounding environment can also be reduced to the maximum limit.

Owner:SHENYANG MUNICIPAL GROUP +1

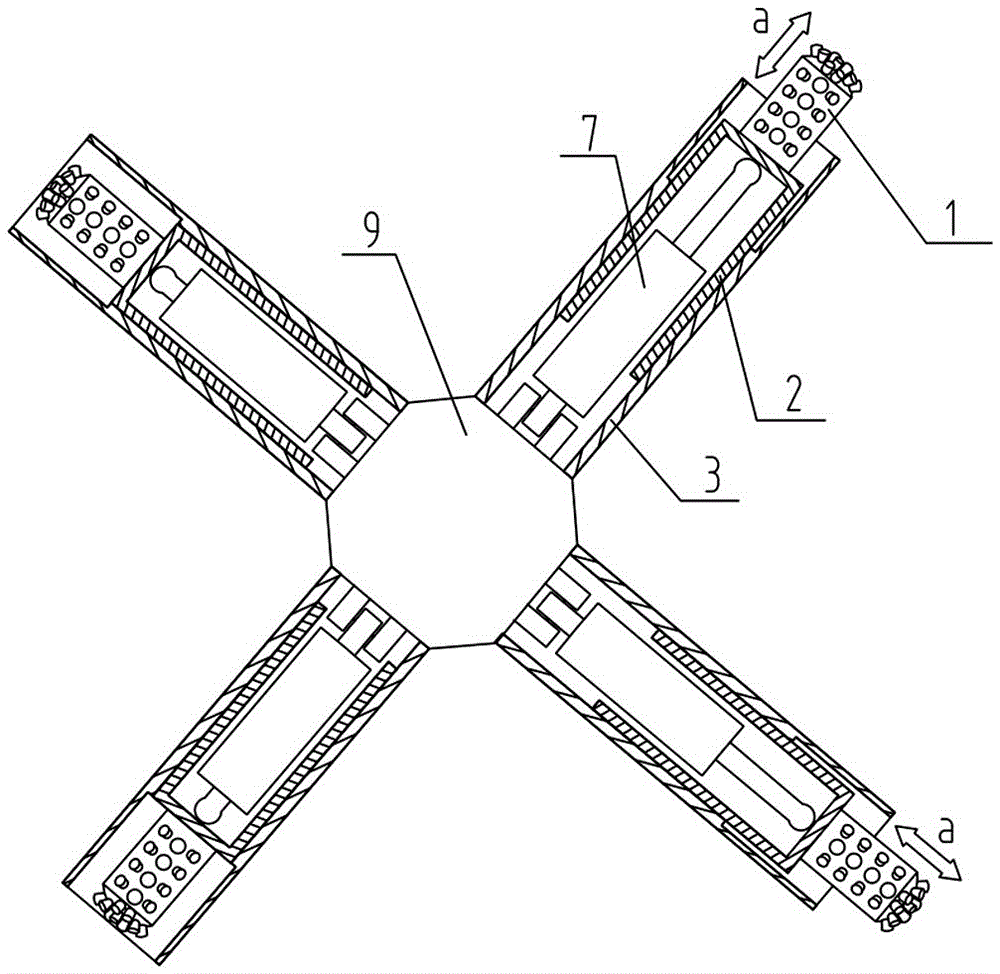

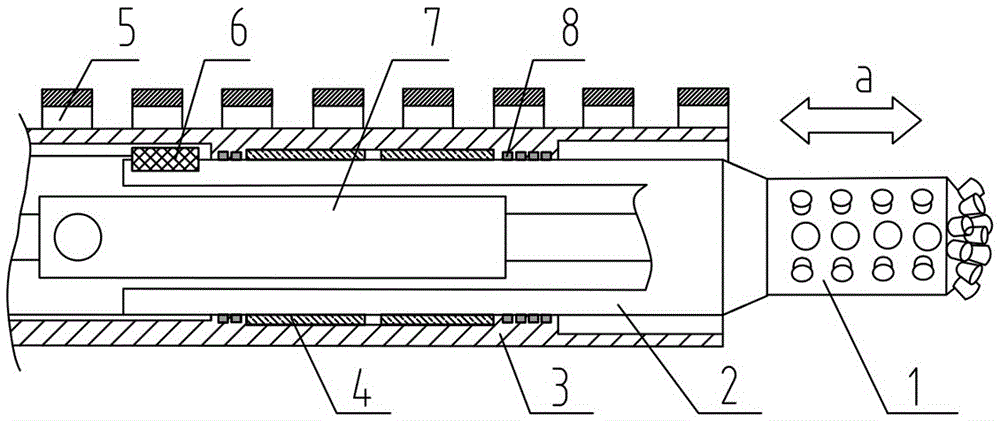

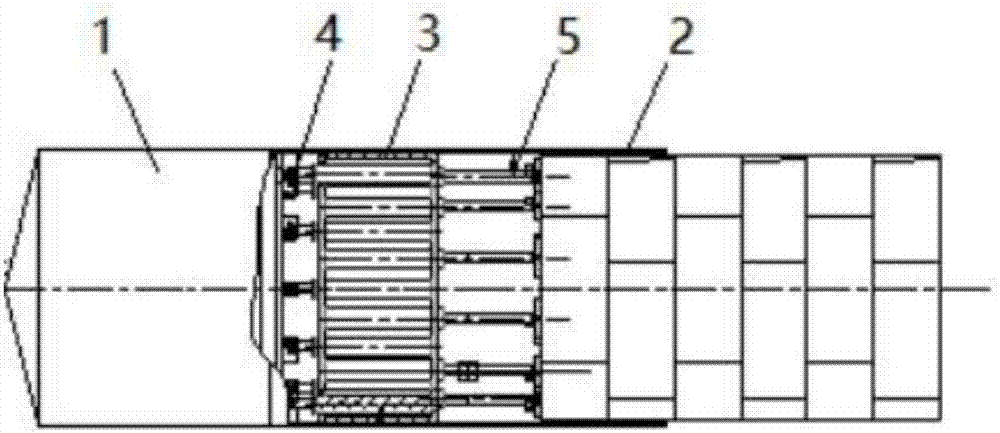

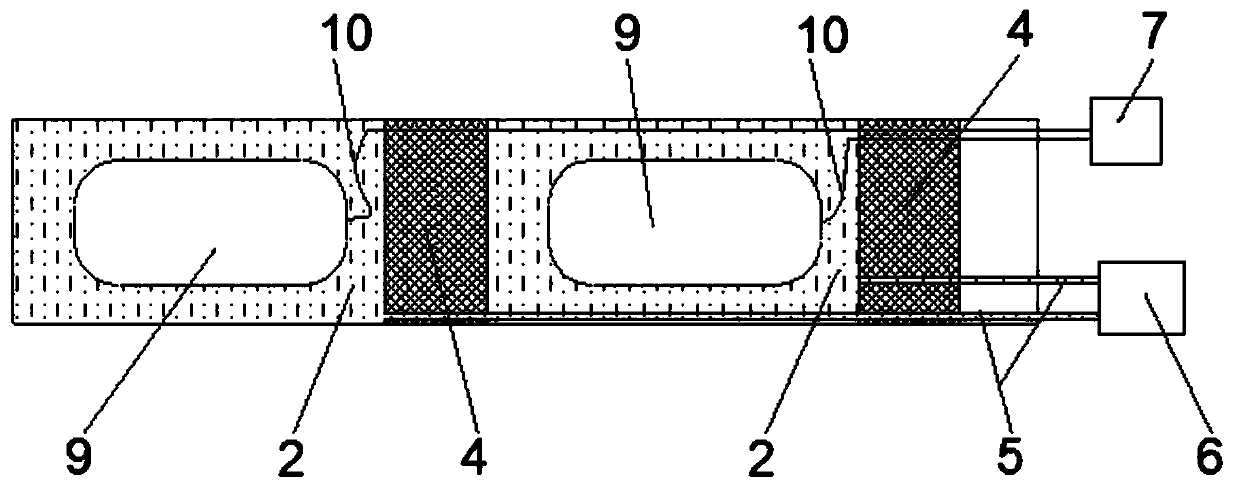

Radially telescopic type cutterhead and rectangular shield machine using cutterhead

The invention discloses a radially telescopic type cutterhead and a rectangular shield machine using the cutterhead. The radially telescopic type cutterhead comprises a cutterhead seat, a fixed spoke arm is arranged on the cutterhead seat and is of a hollow cylindrical structure, one end of the fixed spoke arm is open, and the other end of the fixed spoke arm is mounted on the cutterhead seat; a telescopic spoke arm and a telescopic driving mechanism are arranged in the cylinder body of the fixed spoke arm, one end of the telescopic driving mechanism is mounted at the bottom of the cylinder body of the fixed spoke arm, and the other end of the telescopic driving mechanism and the telescopic spoke arm are mounted together to drive the telescopic spoke arm to extend and retract from the opening end of the fixed spoke arm; the fixed spoke arm and the cutterhead seat are arranged on the same plane, and a fixed cutting head is arranged on the outer surface of the fixed spoke arm; and a telescopic cutting head is arranged at the end, facing the outside, on the telescopic spoke arm. According to the radially telescopic type cutterhead, the blind area is excavated by radial extending and retracting of the telescopic spoke arm, the telescopic spoke arm stretches out and accurately excavates the blind area according to the range of the blind area, and non-blind area and full-face excavation of the rectangular section are achieved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Hydraulic walking multi-level temporary supporting equipment for advancement of tunnel

InactiveCN102587945AImprove space utilizationEffective supportMine roof supportsSupport groupSingle support

The invention belongs to the technical field of equipment for advancement production of coal mines, and particularly relates to hydraulic walking multi-level temporary supporting equipment for advancement of a tunnel, which aims to realize safe and fast advancement of coal mine advancing tunnels. Single supports, which are located on the same side, of a walking support group and a temporary support group are serially connected onto a guide track and can slide relative to the guide track, and single supports located on the left side and the right side of the walking support group and single supports located on the left side and the right side of the temporary support group are connected with a pushing mechanism capable of pushing the single supports to move longitudinally. The hydraulic walking multi-level temporary supporting equipment has the advantages that safety of supporting operation is greatly improved; timely supporting of the supporting equipment can be guaranteed when the grade of the tunnel is changed; and the supporting equipment is an integral structure, runs independently and saves time, labor and space.

Owner:SHANXI DATONG UNIV

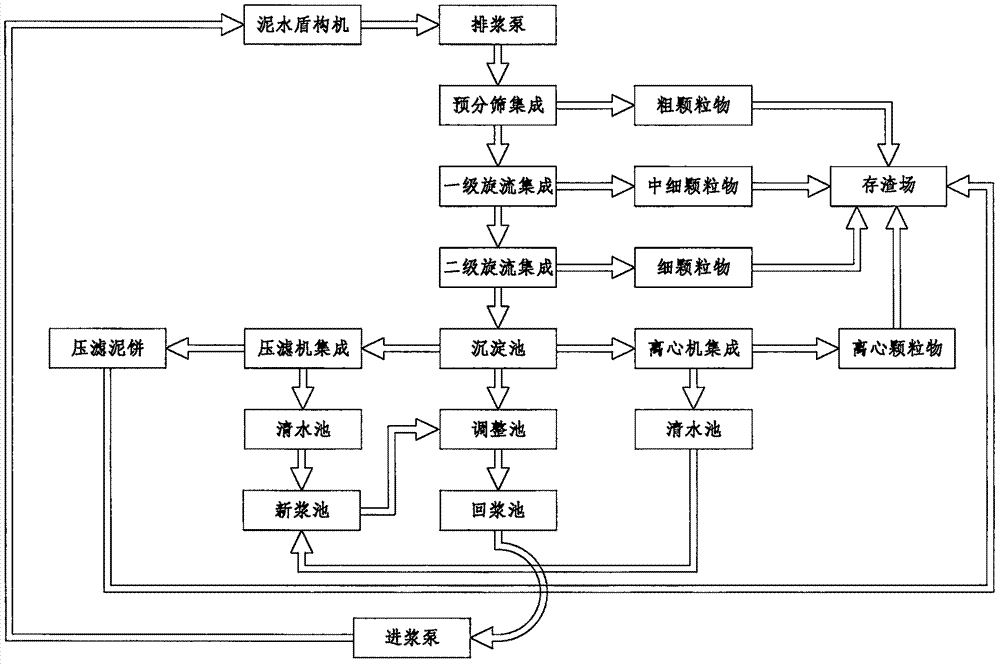

Multi-stage slurry separation method for construction of slurry shield machine in fine particle stratum

ActiveCN107416994AIncrease the areaNot subject to seasonWater/sewage treatment by centrifugal separationTreatment involving filtrationParticulatesCyclone

The invention discloses a multi-stage slurry separation method for construction of a slurry shield machine in fine particle stratum. An independent slurry treatment system is used in the multi-stage slurry separation method and comprises a pre-sieving assembly, a primary cyclone assembly, a secondary cyclone assembly, a residue storage yard, two slurry tank assemblies, a centrifugal machine assembly and a press filter assembly, wherein the two slurry tank assemblies are divided into a use group and a standby group and can be mutually switched for use; when slurry which meets demands and carries residue soil is discharged from the slurry shield machine, fine particles with the diameter being 20 mu m or larger are separated and enter the residue storage yard after being treated by the pre-sieving assembly, the primary cyclone assembly and the secondary cyclone assembly, residual slurry enters a slurry tank of the use group to be recycled, the slurry tank of the use group is stopped and a slurry tank of the standby group is started when the specific gravity or viscosity of the slurry of the use group does not meet the construction demands, at the moment, solid particles with the diameter being 20 mu m or smaller and clear water are separated from the slurry of the use group via the centrifugal machine assembly and the press filter assembly, and the clear water is stored for recycling.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Tunnel construction method with shield methodand new Austrian tunneling method being combined

ActiveCN105863651AAddress riskSolve the costUnderground chambersTunnel liningShield tunnelingRapid construction

The invention discloses a tunnel construction method with a shield method and a new Austrian tunneling method being combined. The tunnel construction method comprises the following steps: S1, excavating a tunnel; S2, carrying out preliminary bracing construction; S3, pushing a shield tunneling machine ahead for an excavation length; S4, repeating the step from S1 to the step S3, carrying out tunnel excavation cycle operation till the tunnel runs through, wherein pavement of waterproof boards in the tunnel and secondary lining construction are carried out in the tunnel excavation process. According to the tunnel construction method disclosed by the invention, the new Austrian tunneling method construction and the shield mehtodconstruction are beneficially combined to realize safe and fast construction of the tunnel, and meanwhile, the tunnel construction cost is controlled to be within an economic and reasonable range. Due to the adoption of fully-mechanized operation, the manual operation intensity is greatly reduced, the safety of a tunnel operation environment is guaranteed powerfully, and the quality of the operation environment is remarkably improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

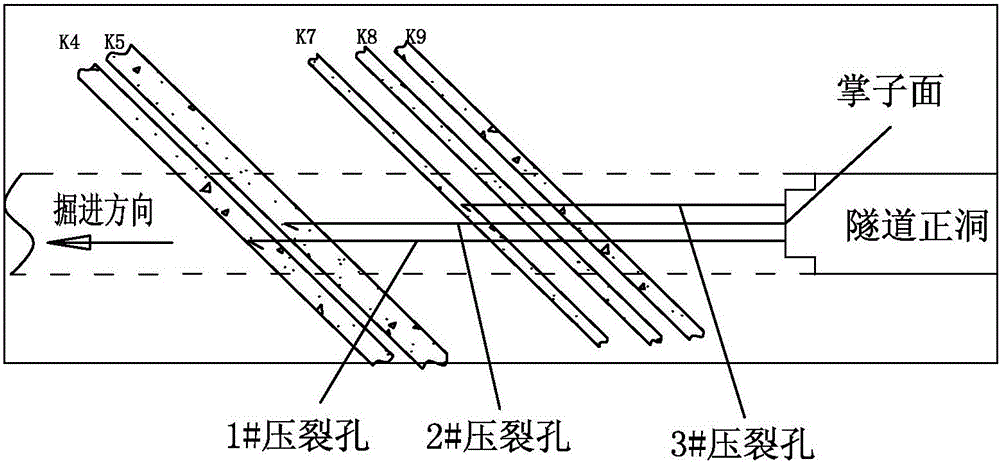

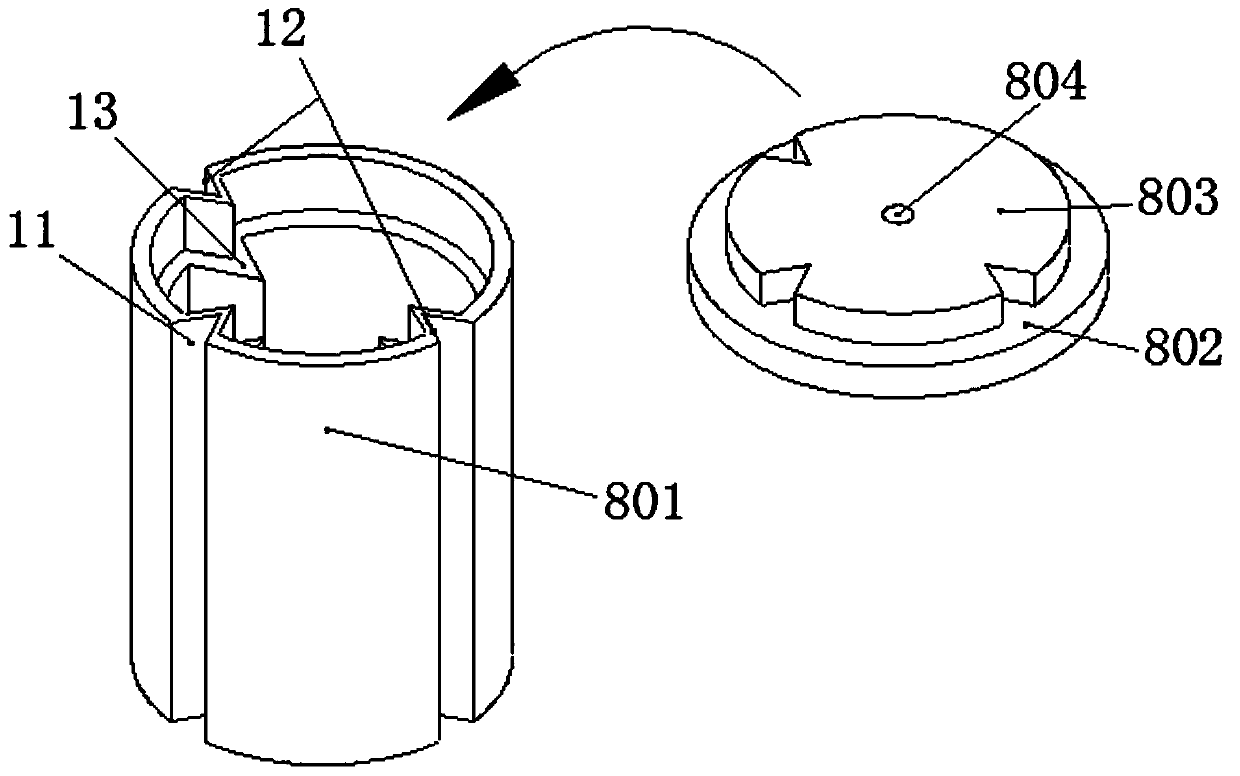

Construction method and hole sealing structure for super-large section tunnel for traversing coal measure strata section

ActiveCN105756700AReduce the number of transfersImprove tunneling efficiencyFluid removalGas removalCoal measuresGeomorphology

The invention discloses a construction method and a hole sealing structure for a super-large section tunnel for traversing a coal measure strata section. The method comprises a hydraulic fracturing step and a gas extracting step, wherein the hydraulic fracturing step comprises the following processes: carrying out concentrated fracturing on a plurality of fracturing holes in sequence by fracturing units arranged in the same region, determining the concentrating frequency for concentrated fracturing of the coal measure strata section, at least two to-be-traversed coal seams for primary concentrated fracturing before fracturing, a gas outburst seam and the drilling position and depth of primary concentrated fracturing; and the gas extracting step comprises concentrated extraction of more than two coal seams and individual extraction of a to-be-excavated coal seam. The hole sealing structure is formed through a hole sealing device; a floral tube section is formed at the inner end of a fracturing tube of the hole sealing device and is divided into an inner section of the floral tube and an outer section of the floral tube; at least one gauze is wound on the outer wall of the outer section of the floral tube; and a hole sealing section comprises a cement paste solidifying section and a polyurethane sealing section. The construction method and the hole sealing structure have the beneficial effects that the condition that the tunnel quickly and safely passes through the coal measure strata section can be ensured by a tunneling method; and the hole sealing structure is good in hole sealing effect and high in loading capacity.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

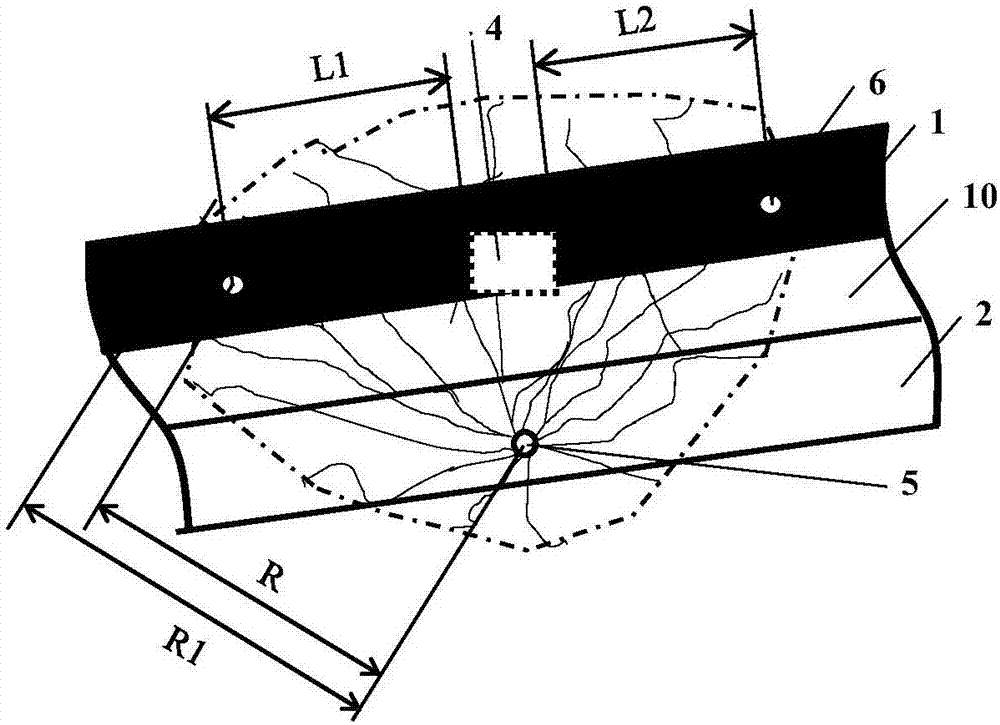

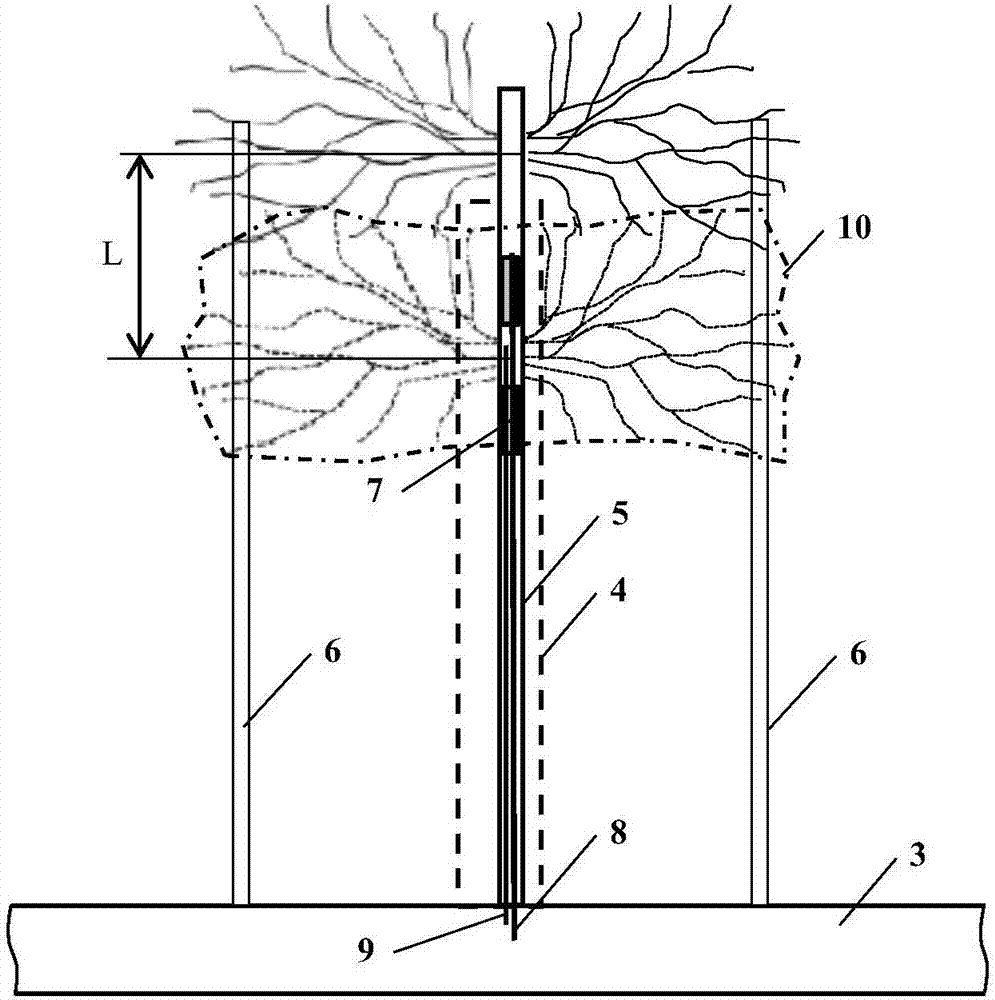

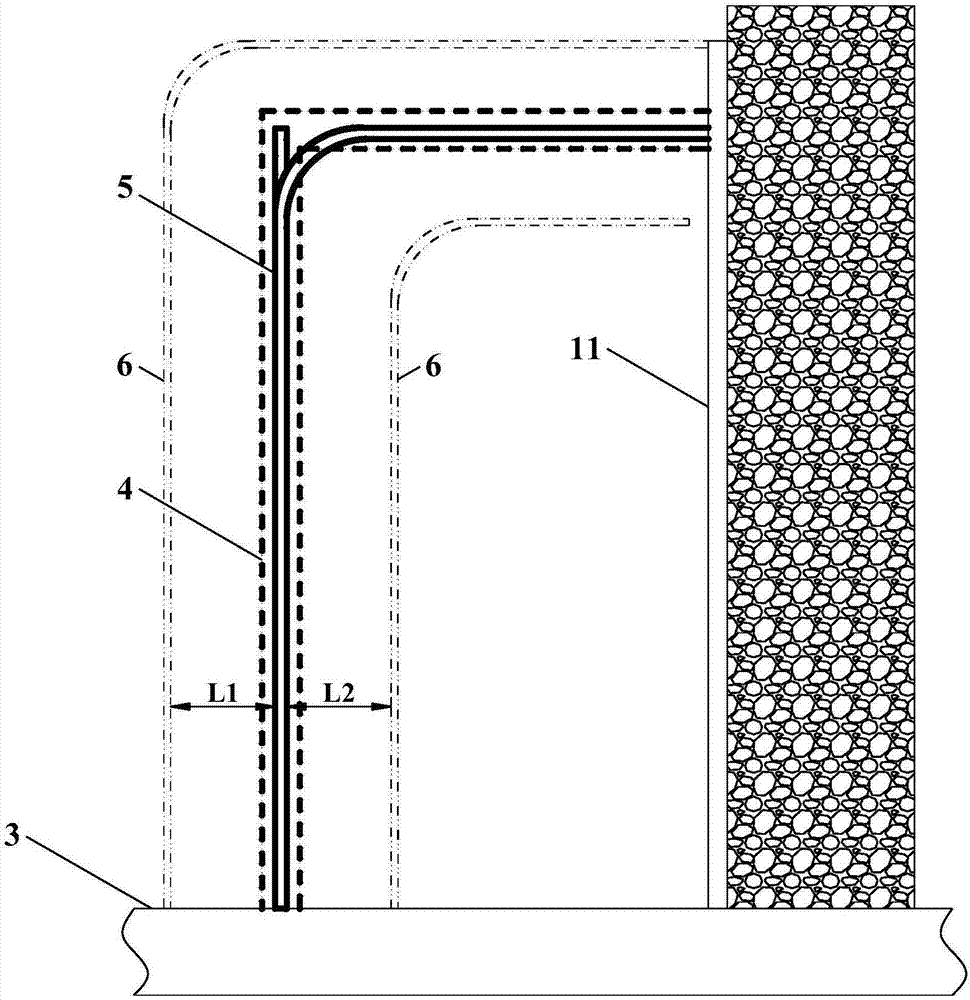

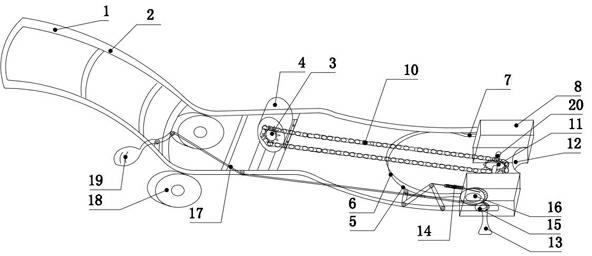

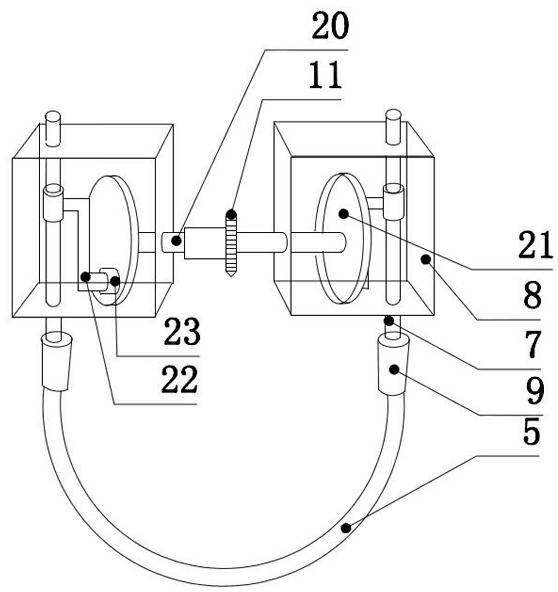

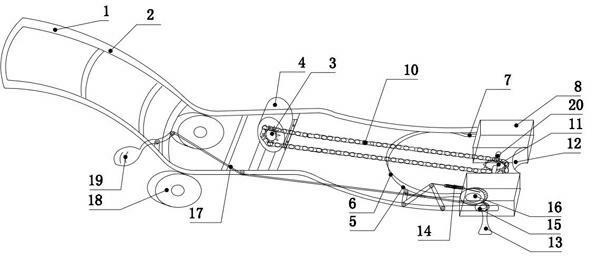

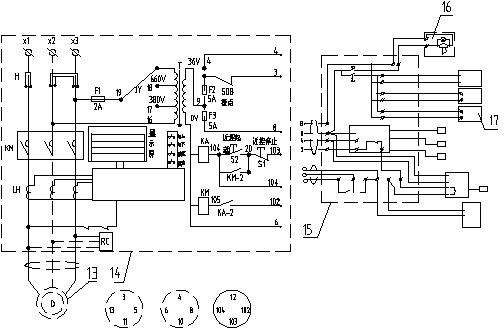

Tree-digging machine with soil balls

The invention relates to a garden tree planting tool and in particular relates to a tree-digging machine with soil balls with soil balls used in seedling transplantation. The machine comprises a rack, a power machine arranged at the upper side of the middle part of the rack and a wheel arranged at the lower side of the middle part of the rack, wherein the main shaft of the power machine is provided with a drive chain wheel; the back of the rack bends upwardly to form a handrail; the lower end of the handrail is provided with a rotary footstep; and the front part of the rack is provided with avibration box, a power shaft, a U-shaped saw trough, a U-shaped saw, a driven chain wheel, a drive gear, a driving gear, a restoring spring and a rotary bracing wire, wherein the driven chain wheel is connected with the drive chain wheel through a chain, the drive gear and the driving gear are meshed, one end of the restoring spring is fixed on the drive gear and the other end of the restoring spring is fixed on the rack, one end of the rotary bracing wire is fixed on the drive gear and the other end of the rotary bracing wire is connected with the rotary footstep. The machine has simple equipment structure and is convenient for operation, so that the mechanization and automation of seedling transplantation with soil balls in a nursery garden can be achieved, and simultaneously, the advantages that the machine for transplanting seedling, digging hole and planting trees and greatly improving labor efficiency and seedling survival rate can be met.

Owner:XUCHANG LONGGANG POWER GENERATION

Method for constructing water-rich weak surrounding rock tunnel crossing fault broken belt

ActiveCN110924959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringRock tunnel

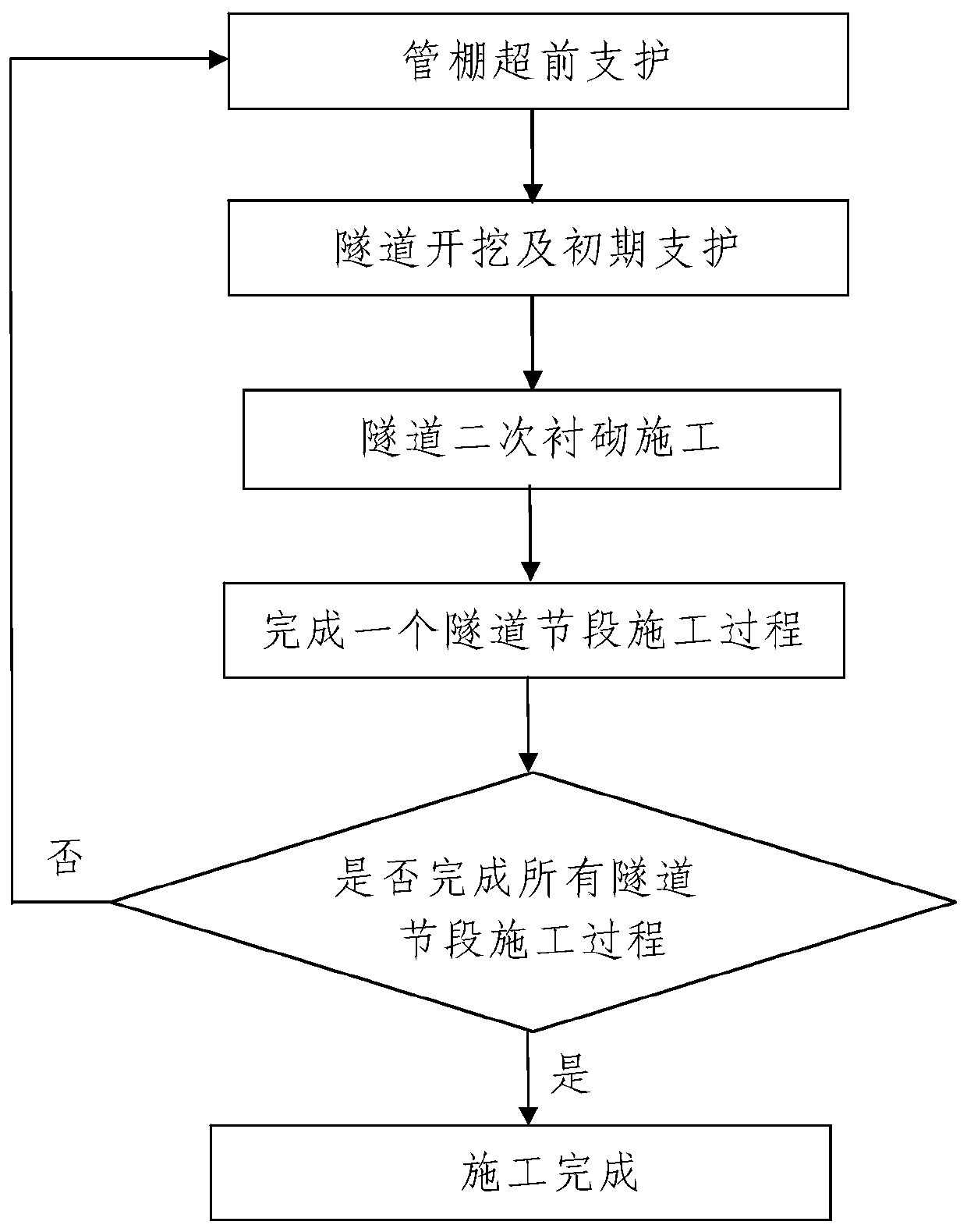

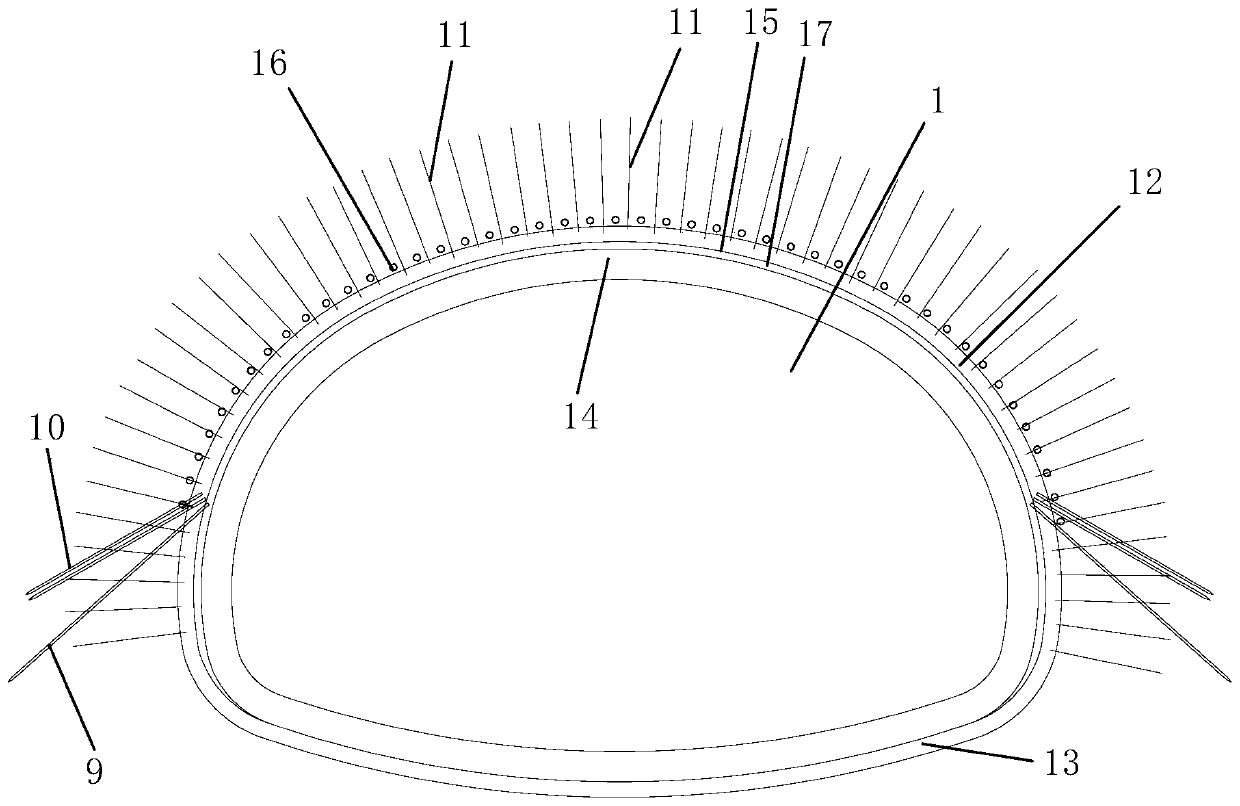

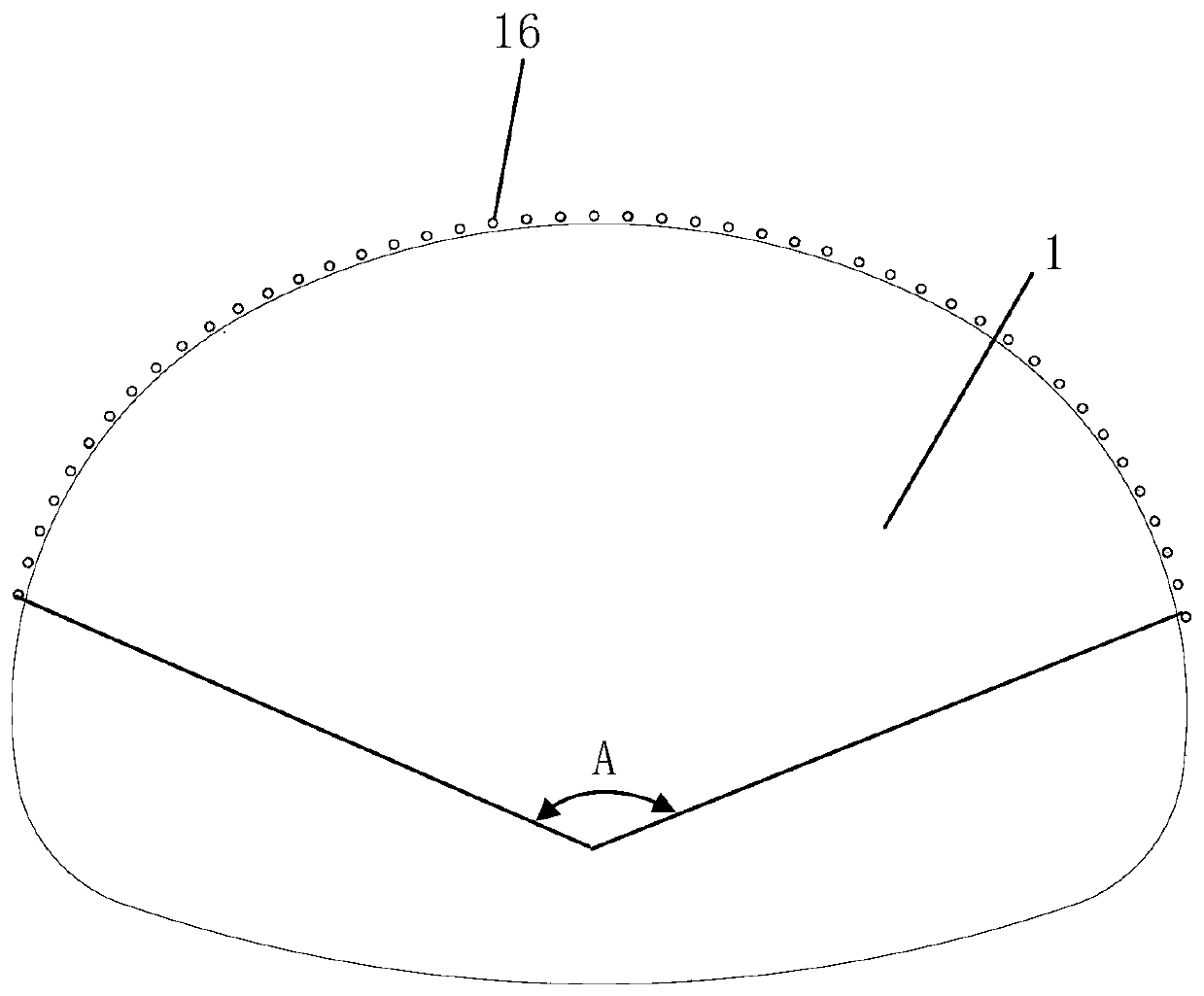

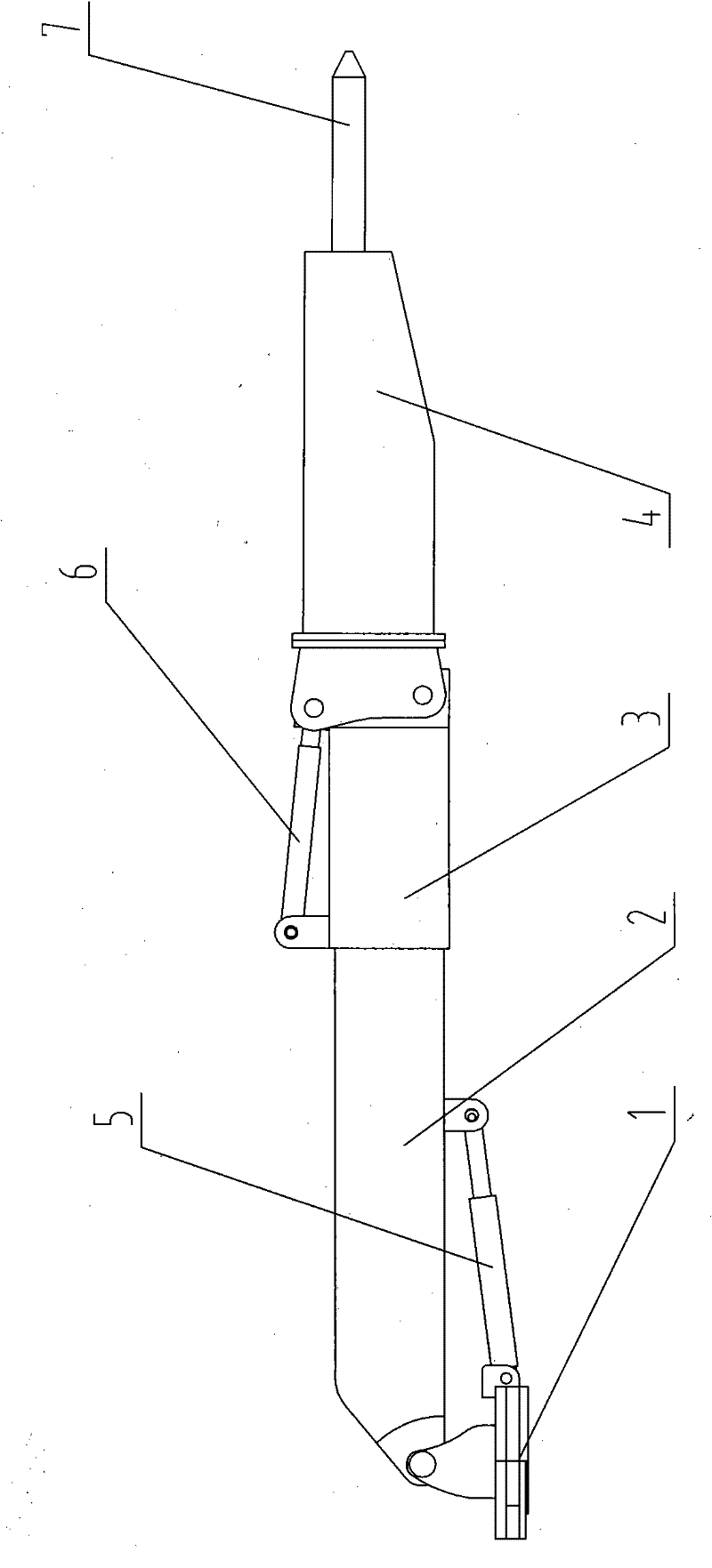

The invention discloses a method for constructing a water-rich weak surrounding rock tunnel crossing a fault broken belt. The method comprises the following steps that firstly, construction is carriedout on a plurality of tunnel sections in a construction tunnel from front to rear, and when any tunnel section is constructed, the construction method comprises the following steps that 1, advanced support is carried out on a pipe shed; 2, tunnel excavation and initial support are carried out, wherein upper peripheral side hole excavation and initial support are carried out, reserved core soil area hole excavation and initial support are carried out, first hole excavation and initial support are carried out firstly and thereafter second hole excavation and initial support is carried out; and3, tunnel secondary lining construction is carried out. The method has the beneficial effects that the design is reasonable, construction is easy and convenient, and the use effect is good; the self-drilling pipe shed is adopted to carry out advanced support on the upper hole body before excavation, and two-step method excavation is adopted, so that the construction efficiency can be effectively improved; meanwhile, the whole reinforcing structure of the hole peripheral rock, the tunnel primary support structure in holes and the tunnel secondary lining are connected to form an integral supportsystem with a stable structure, the stability of the tunnel structure can be effectively improved, and the safety of the later tunnel structure is ensured.

Owner:中铁二十局集团第二工程有限公司

a rock breaking device

InactiveCN102261251ADifferent rock breaking anglesAchieve pitchTunnelsHydraulic cylinderHydraulic motor

The invention relates to the field of excavation equipment, in particular to a rock-breaking device for tunnel construction or roadway excavation. The device is provided with a turntable, a rock-breaking arm and a breaking hammer. One end of the rock-breaking arm is connected to the turntable, and the other end of the rock-breaking arm is connected to the breaking hammer. The turntable is installed on the carrier through the slewing bearing. The turntable is driven by a hydraulic cylinder or a hydraulic motor. The rock-breaking arm is a telescopic arm structure composed of a telescopic inner arm of the rock-breaking arm and a telescopic outer arm of the rock-breaking arm. The outer end of the telescopic outer arm of the rock-breaking arm is hinged with the rotary table, and the vertical pitch of the equipment can be realized under the push of the hydraulic cylinder; the end of the telescopic inner arm of the rock-breaking arm is hinged with the breaker, and it can be flexibly Adjust the impact angle of the breaking hammer. The present invention overcomes the shortcomings of the drilling and blasting method and the comprehensive tunneling method, realizes the purpose of tunnel construction and roadway excavation with a breaker, realizes rapid and efficient tunneling of superhard whole rock roadways without blasting, and avoids major accidents from the root happened.

Owner:SANY HEAVY EQUIP

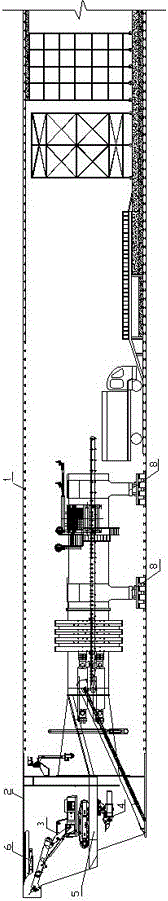

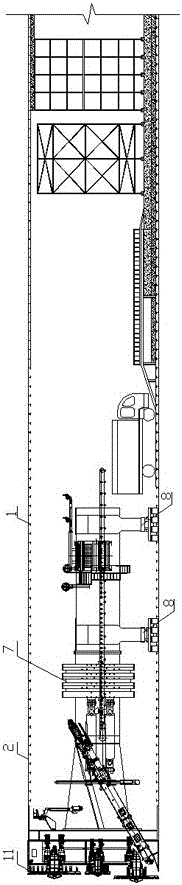

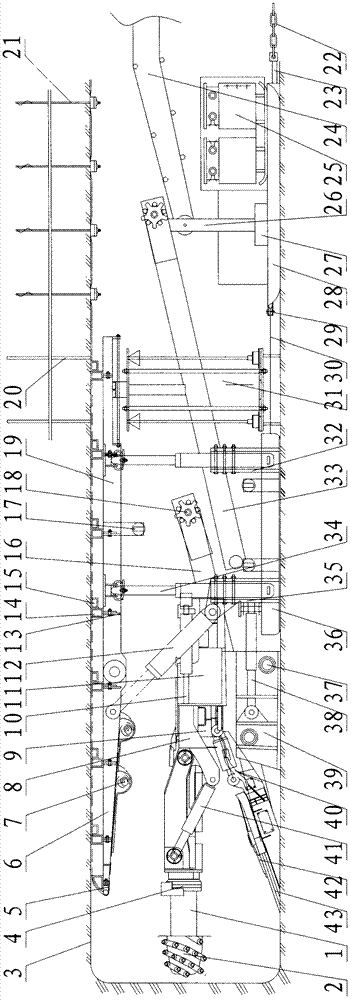

Support-type comprehensive tunneler

ActiveCN102022122BOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsEngineeringMetal mesh

The invention relates to a support-type comprehensive tunneler which comprises a non-tracked tunneler, a tunneler chassis, a left hydraulic support, a right hydraulic support, a drilling rig and scraper conveyors, wherein the tunneler is arranged on the tunneler chassis, and two advancing jacks are arranged on the tunneler chassis; the other ends of the two advancing jacks are respectively connected with the left hydraulic support and the right hydraulic support, and the two sides of the tunneler chassis are respectively provided with a lateral pushing oil cylinder; forestopes of the left and right hydraulic supports are respectively provided with a group of metal mesh storages, and the tail of a main top beam of the support is hung with the drilling rig; the tail of a first scraper conveyor is arranged on a spade plate of the tunneler, and the head of the first scraper conveyor and the tail of a second scraper conveyor are overlapped; and the head of the second scraper conveyor and the tail of a belt loader are overlapped, and sleds are arranged at the back of the two hydraulic supports. The tunneler has the advantage that the drilling support and the coal cutting of the tunneler are simultaneously carried out, and also has the automatic lapping function, thus reducing labor intensity and increasing the coal mining efficiency by over 4 times.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

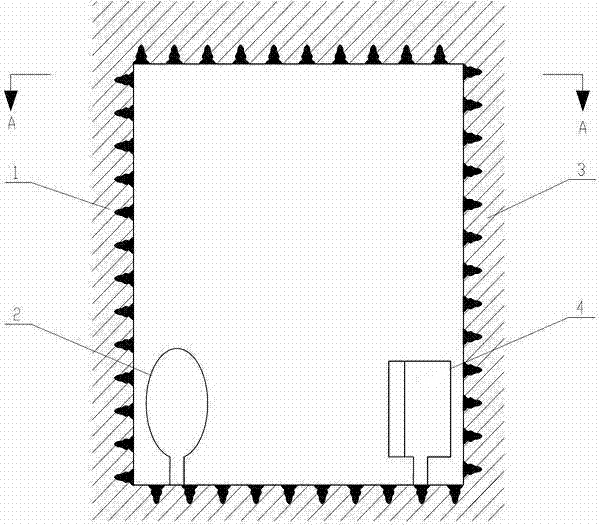

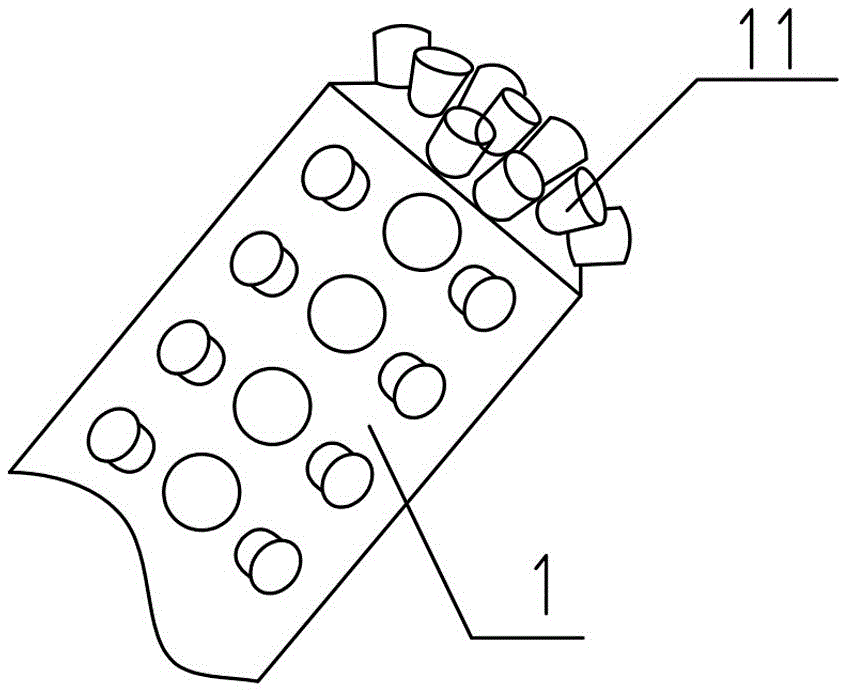

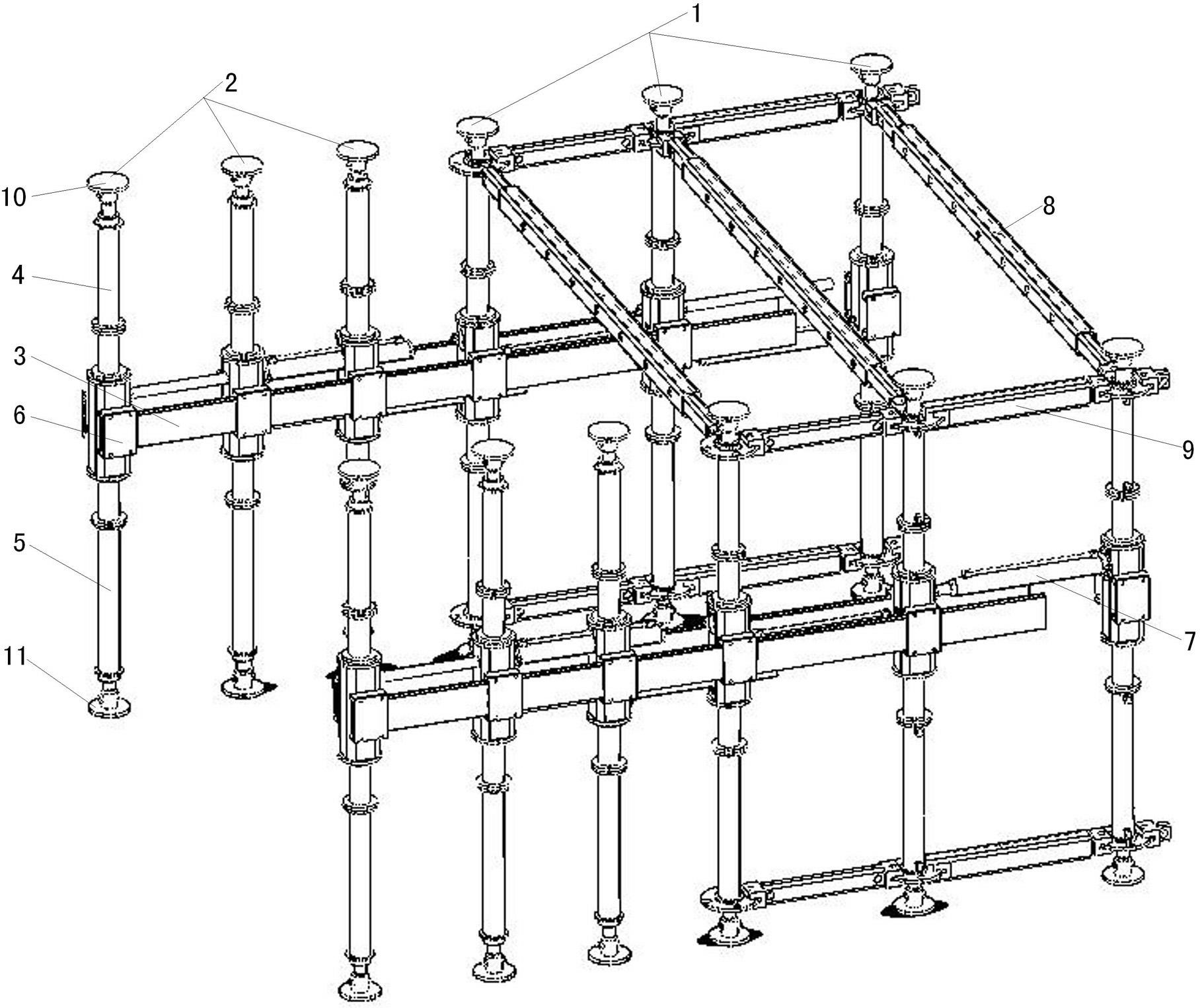

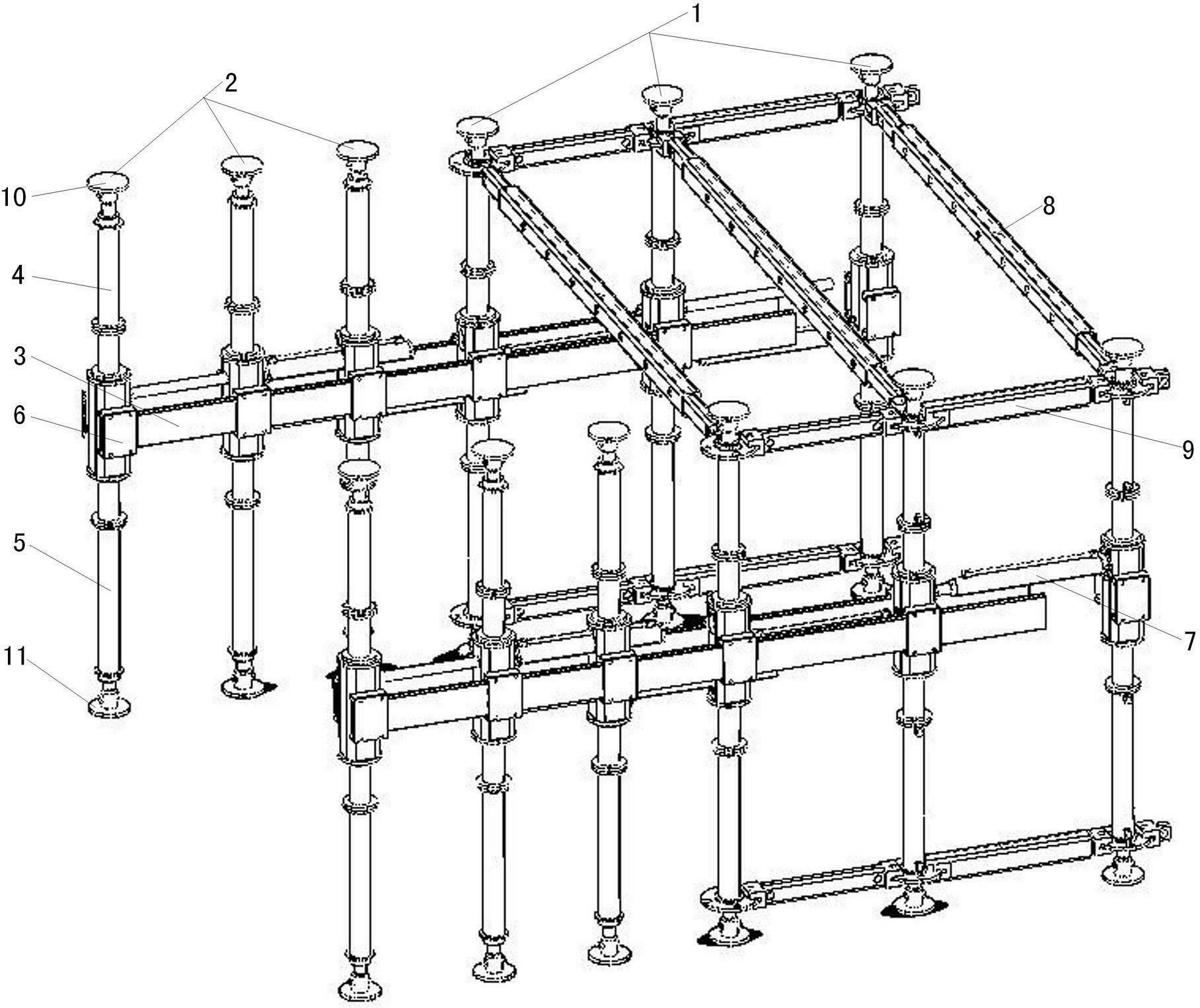

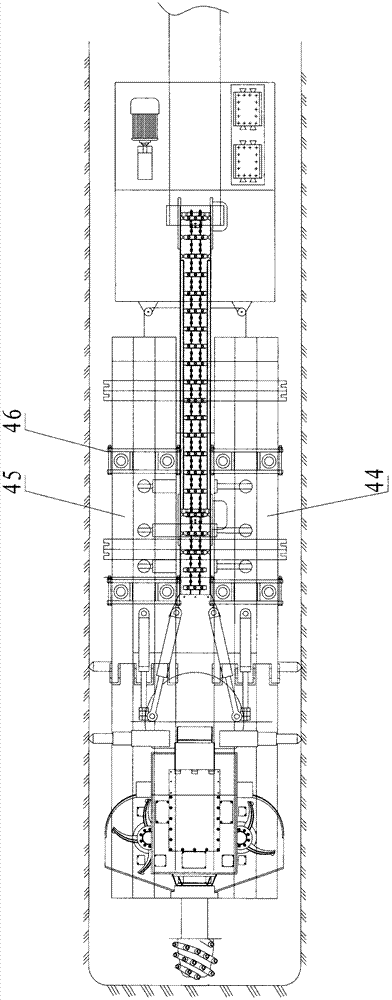

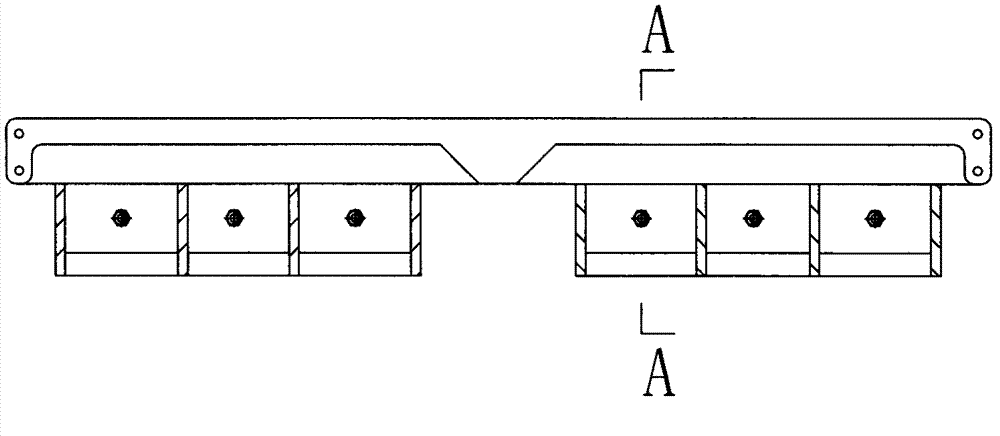

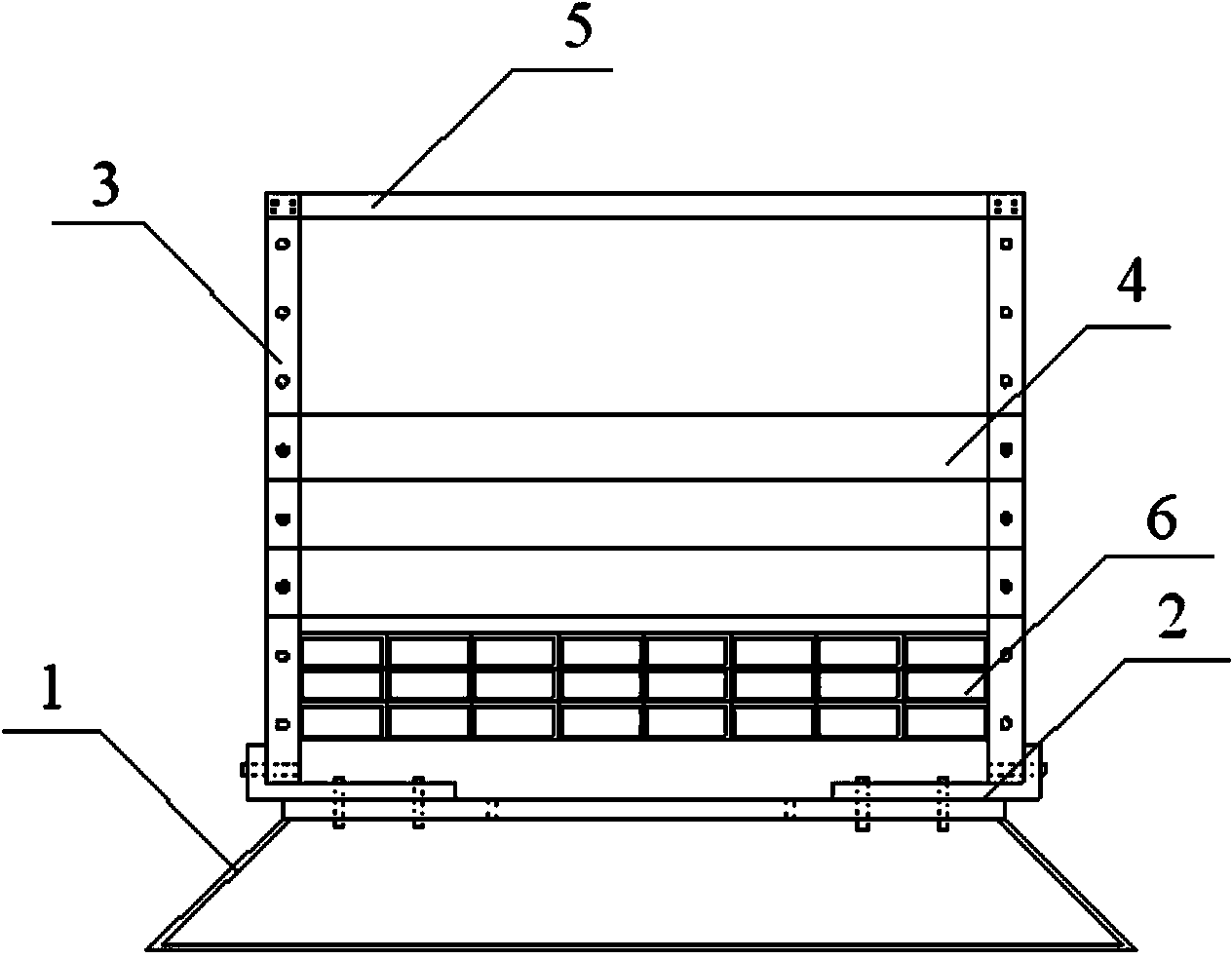

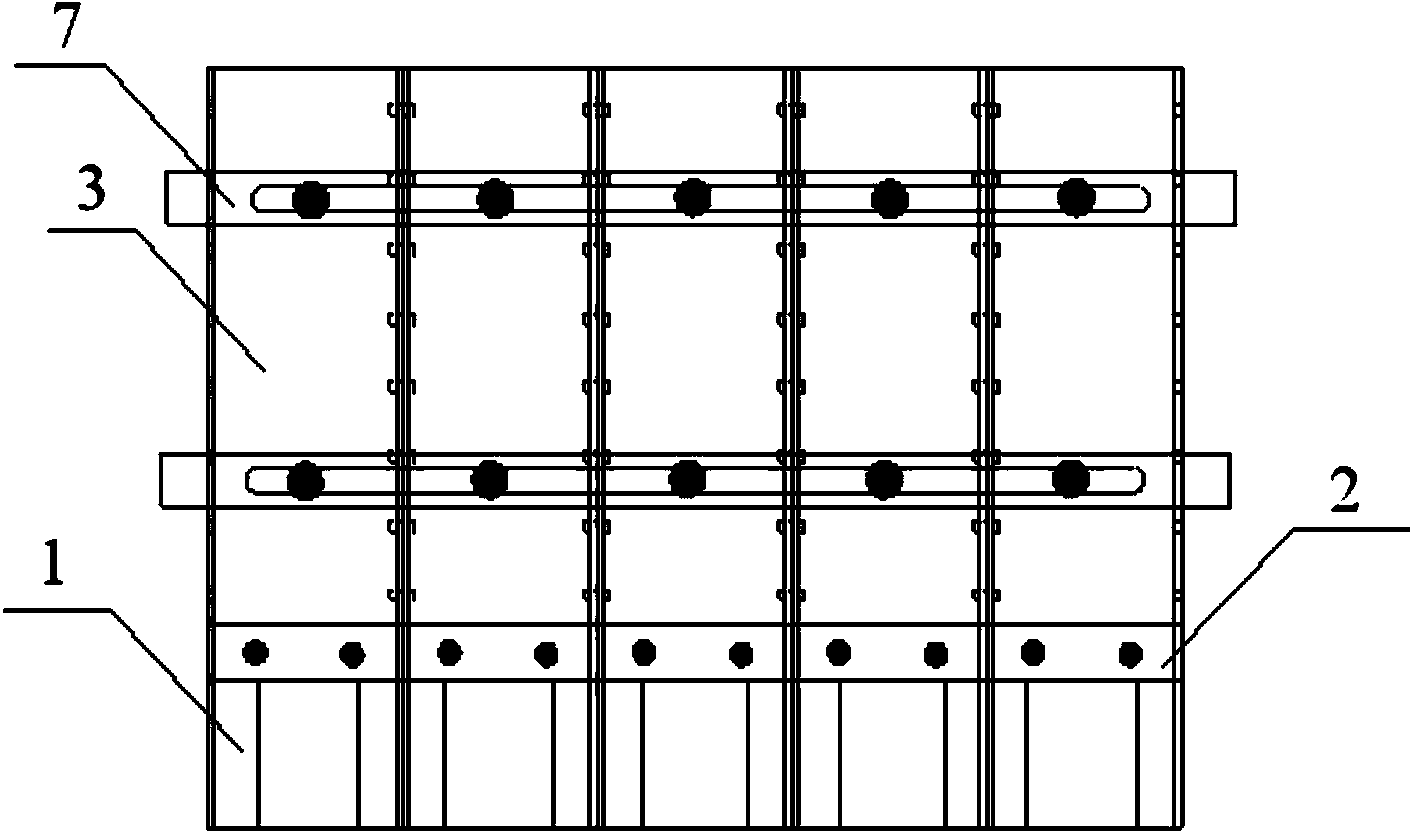

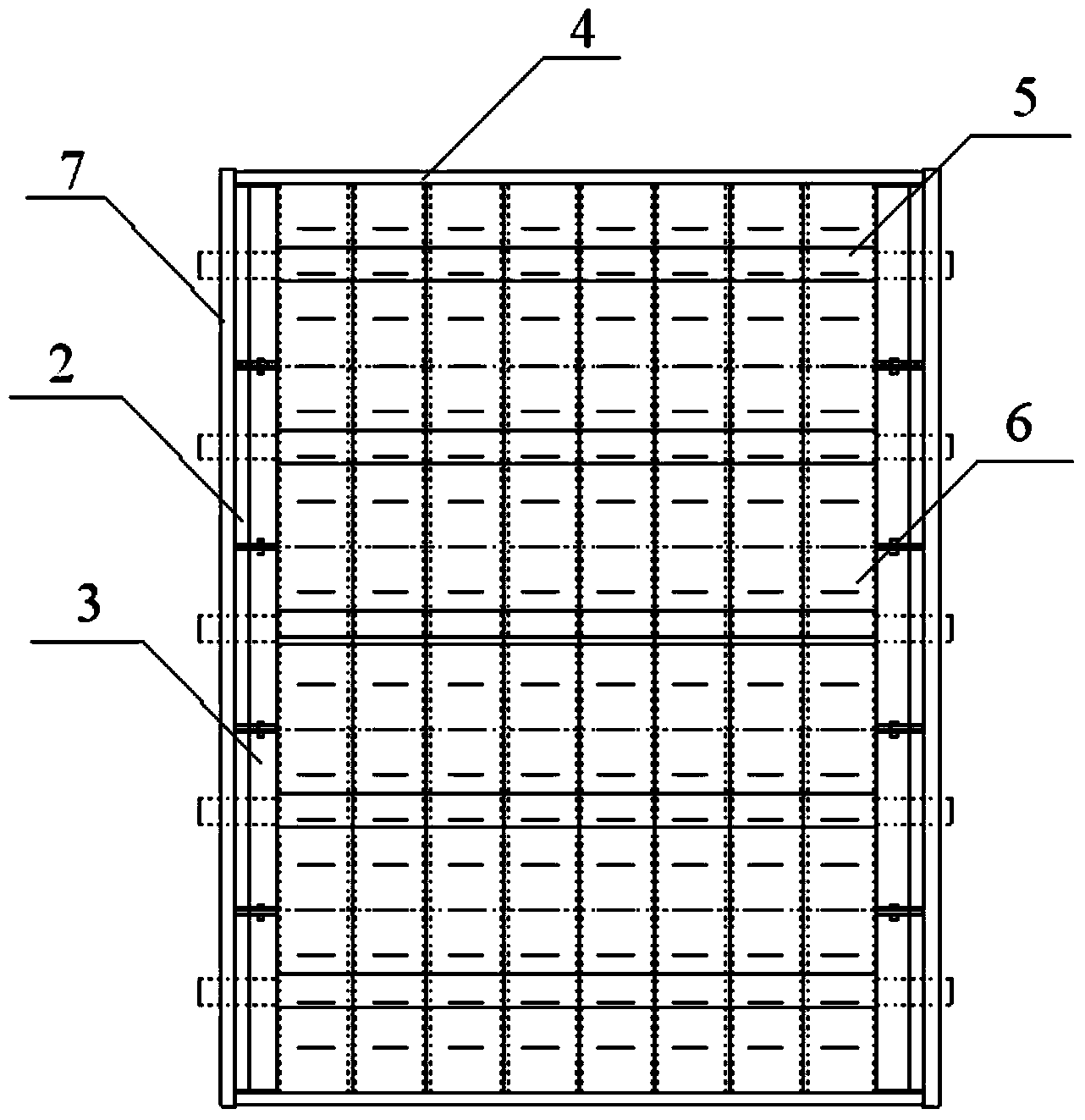

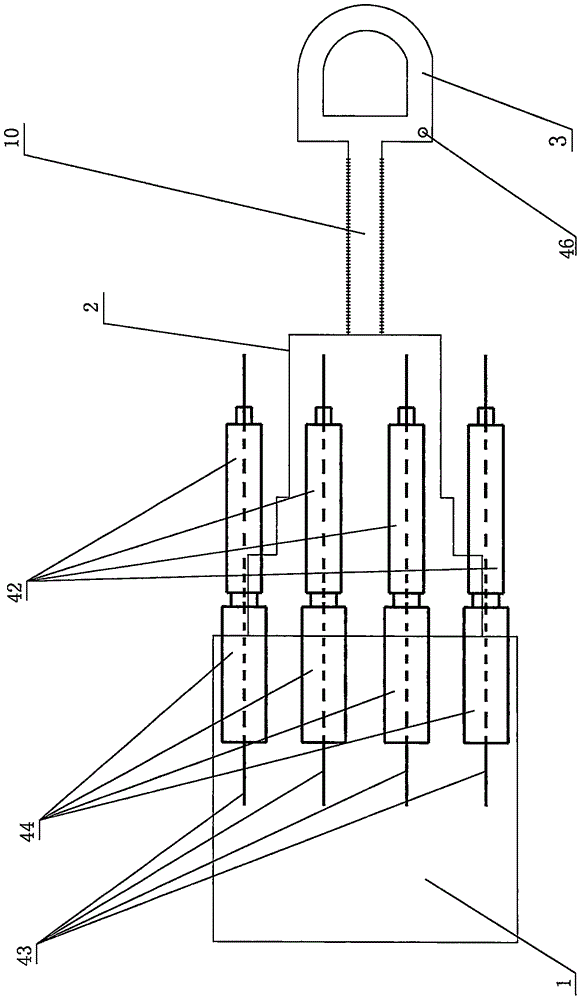

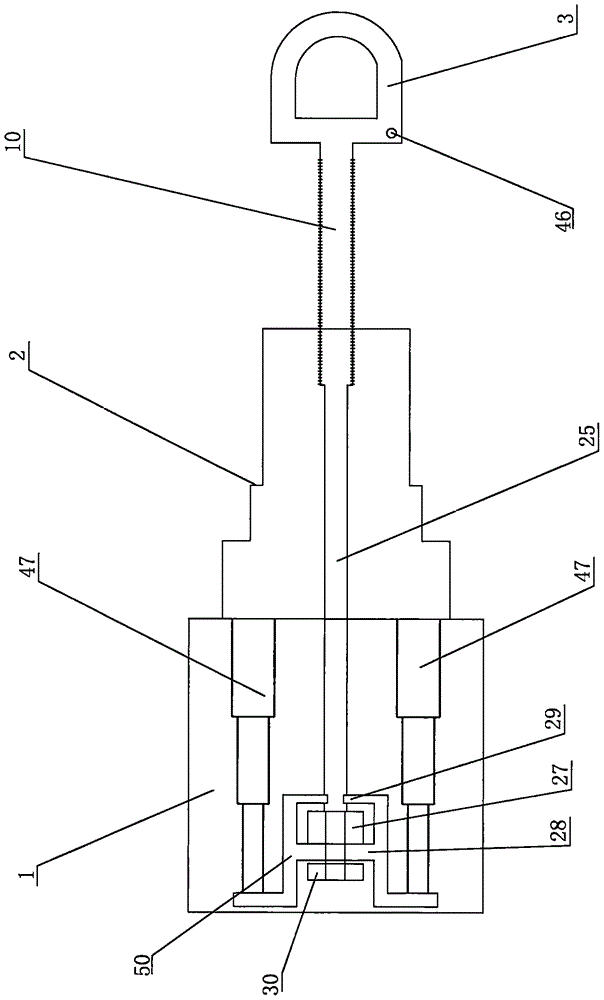

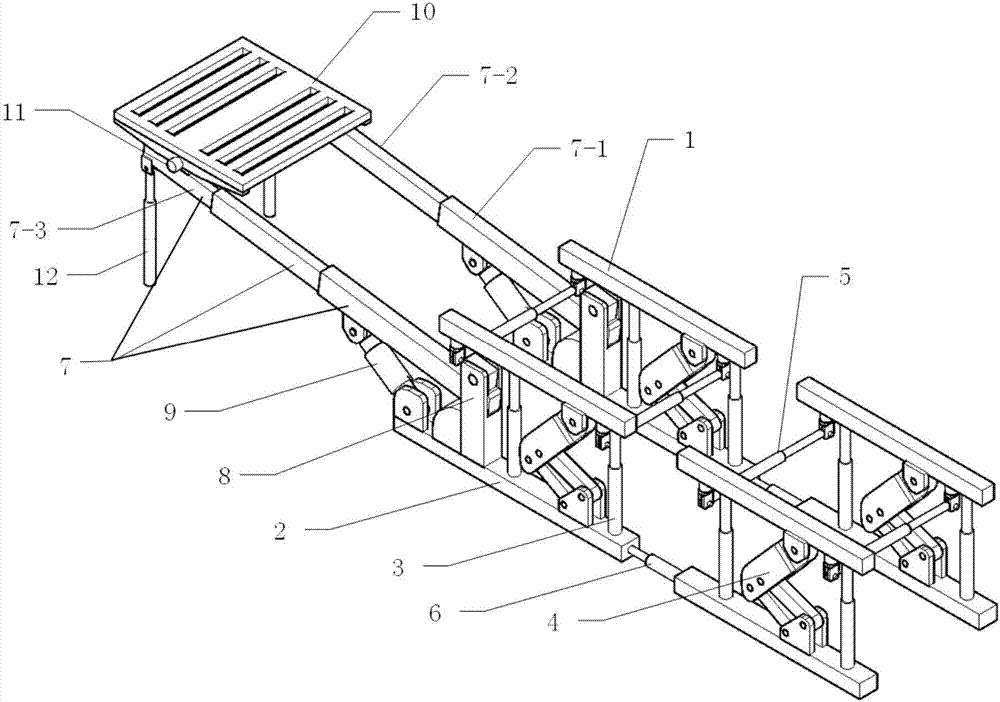

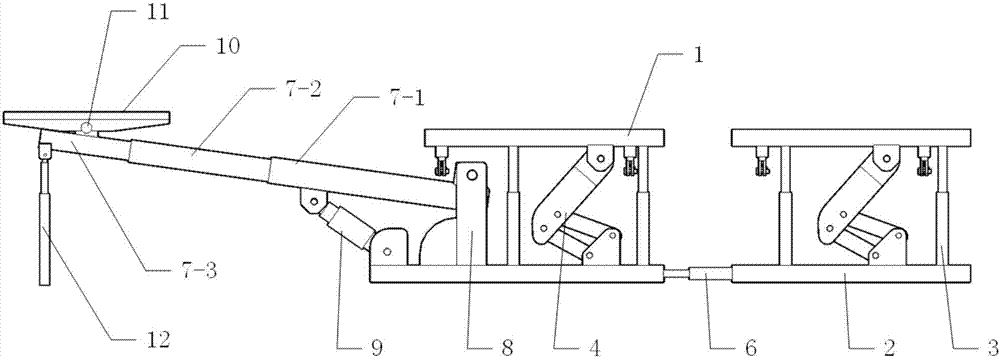

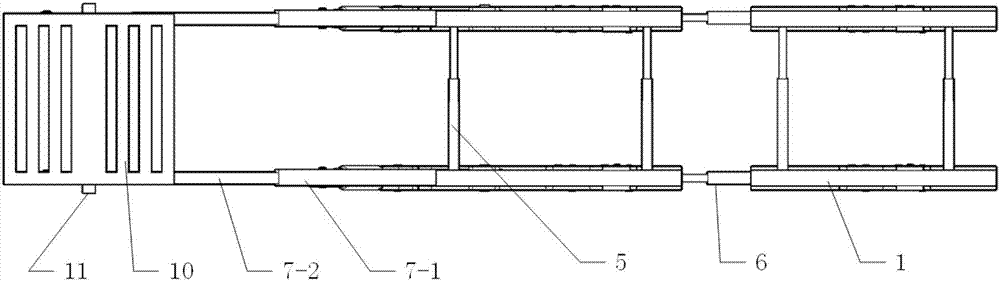

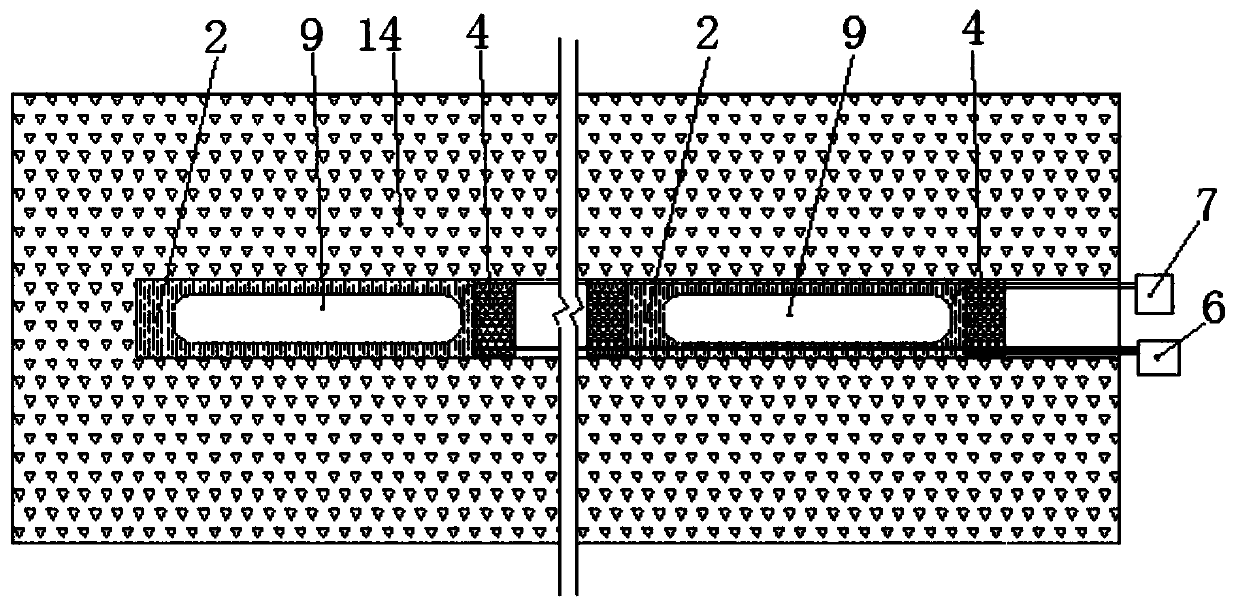

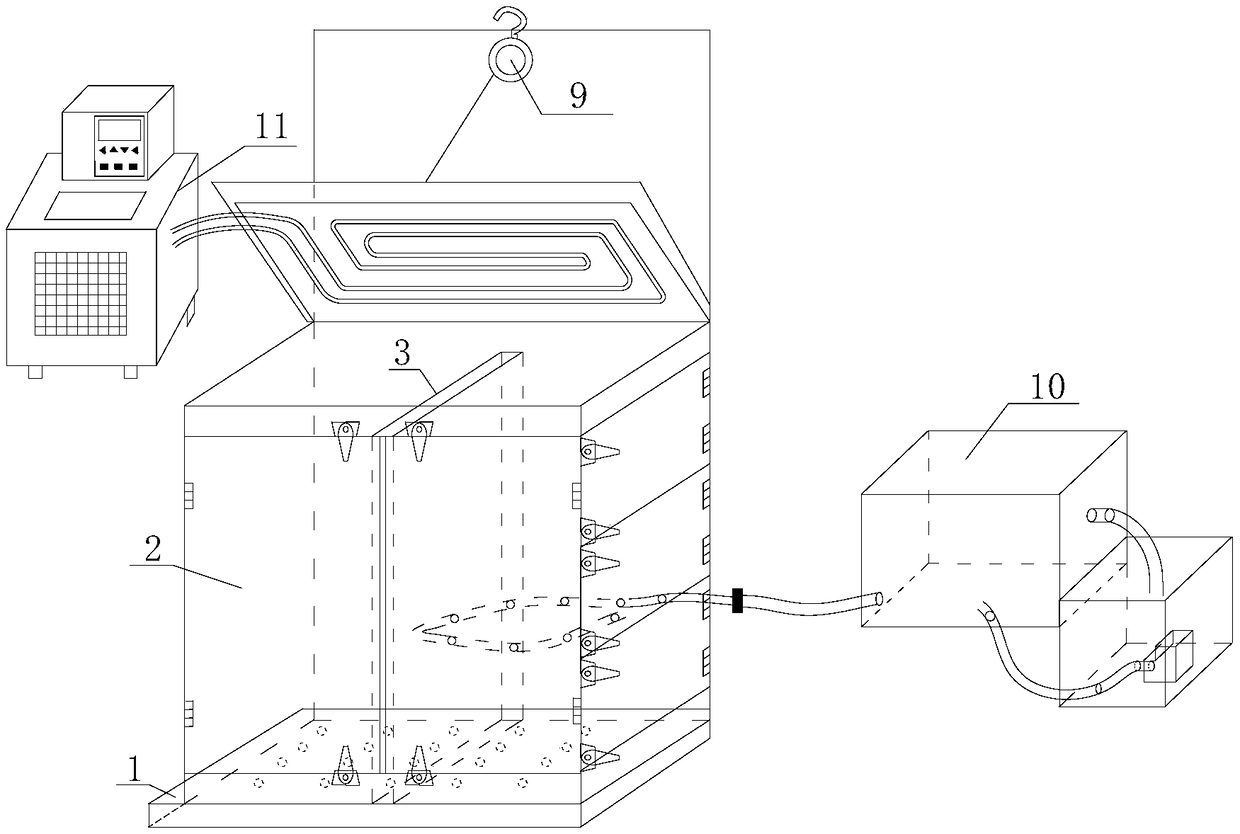

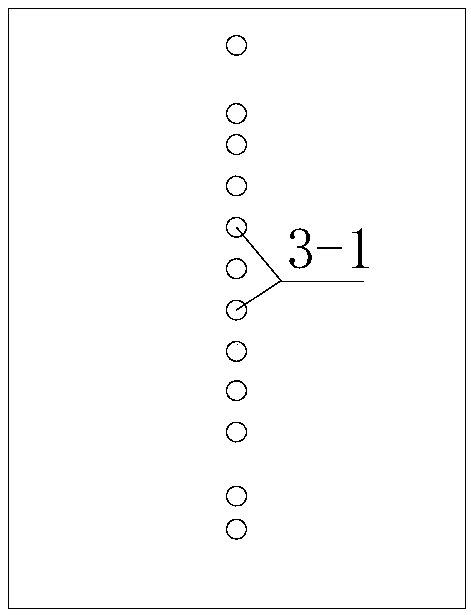

Modularized analog simulation experiment device achieving rapid installation, excavation and disassembly and operation method thereof

InactiveCN104375200AQuick pavingMeet the rapid excavationGeological measurementsTight frameEngineering

The invention discloses a modularized analog simulation experiment device achieving rapid installation, excavation and disassembly and an operating method of the modularized analog simulation experiment device. The experiment device comprises a plurality of experiment frame modules which can be combined on a foundation base to form a cube structure; each experiment frame module comprises an adjusting base beam installed on the foundation base, the two sides of the adjusting base beam are each vertically provided with a vertical arm, and the top ends of the vertical arms are connected through a cross beam; baffles are installed between every two corresponding vertical arms at different heights, the module spaces formed through partition of the baffles are densely provided with excavation layer replacing devices, and the experiment frame modules are connected and fastened through side baffles installed on the side faces of the vertical arms; the experiment frame modules are filled with similar analog experiment materials, the outer surfaces of the excavation layer replacing devices are marked with scales, the excavation layer replacing devices can be pulled outwards, and excavation of the analog simulation experiment materials is achieved by pulling the excavation layer replacing device outwards. The invention further discloses the operation method of the modularized analog simulation experiment device. The modularized analog simulation experiment device has the advantages that the size is adjustable, and installation, laying, excavation and disassembly are rapid.

Owner:SHAANXI COAL & CHEM TECH INST

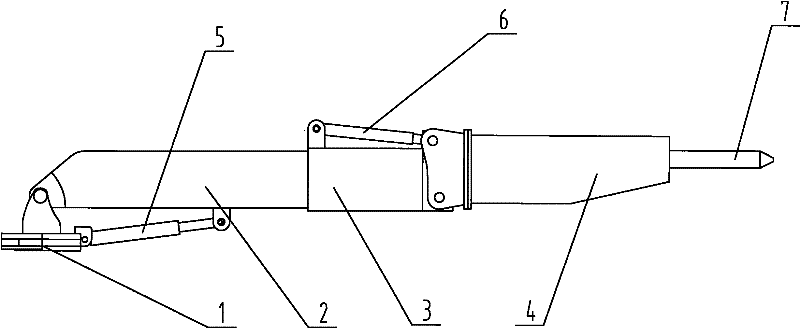

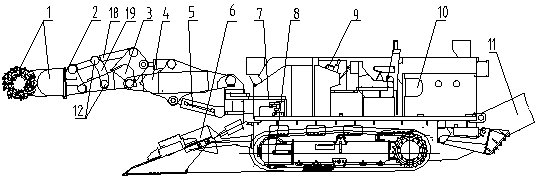

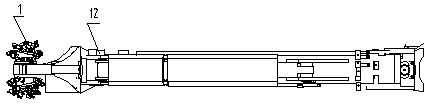

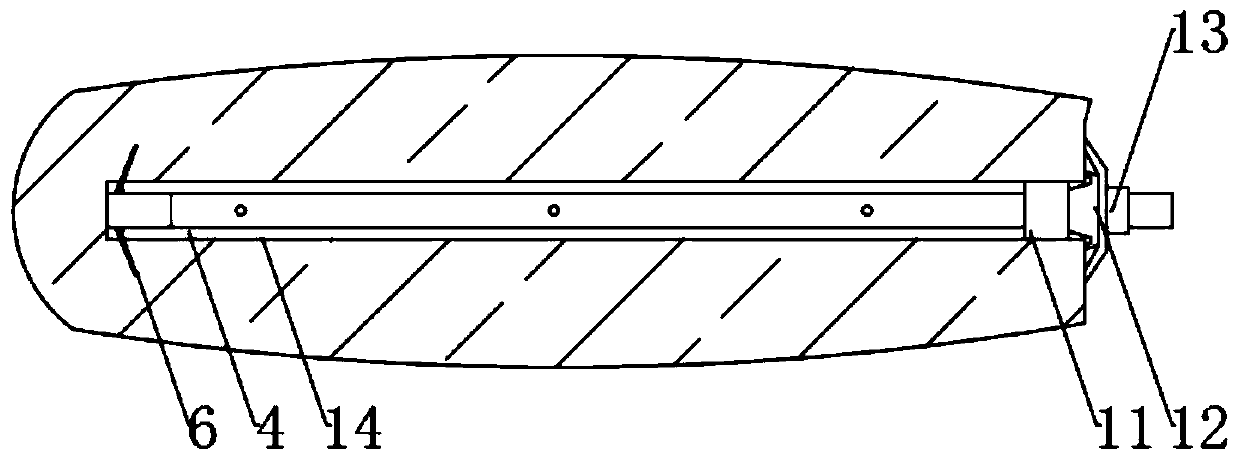

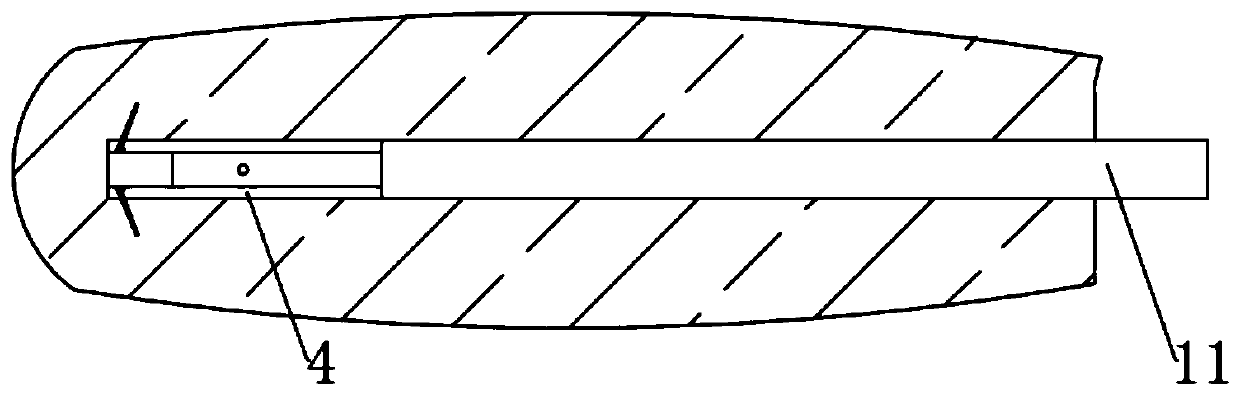

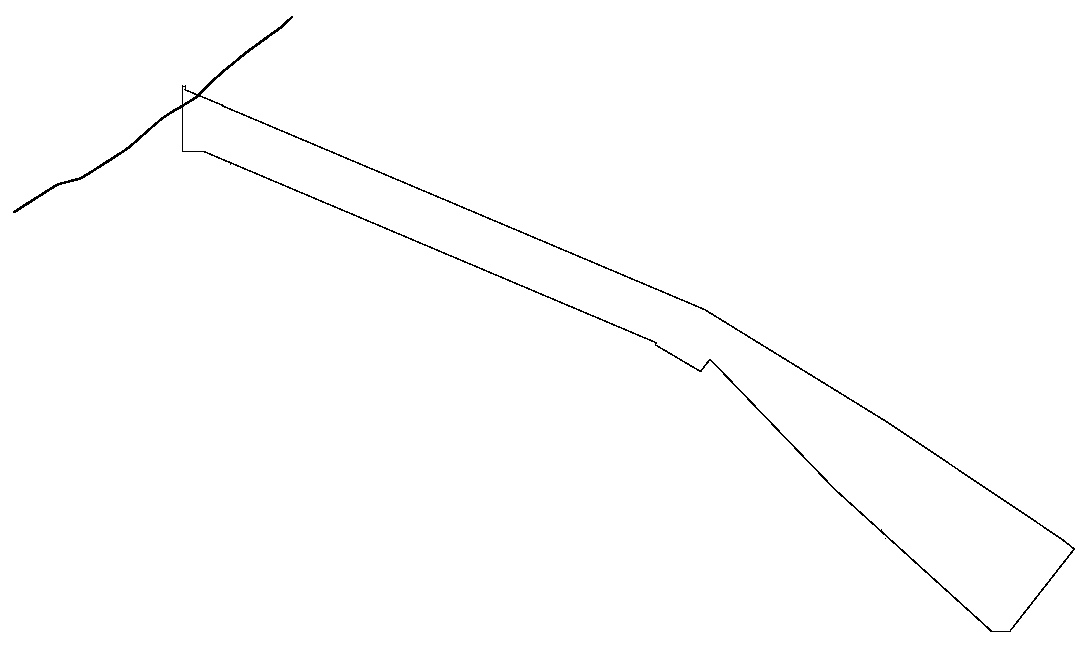

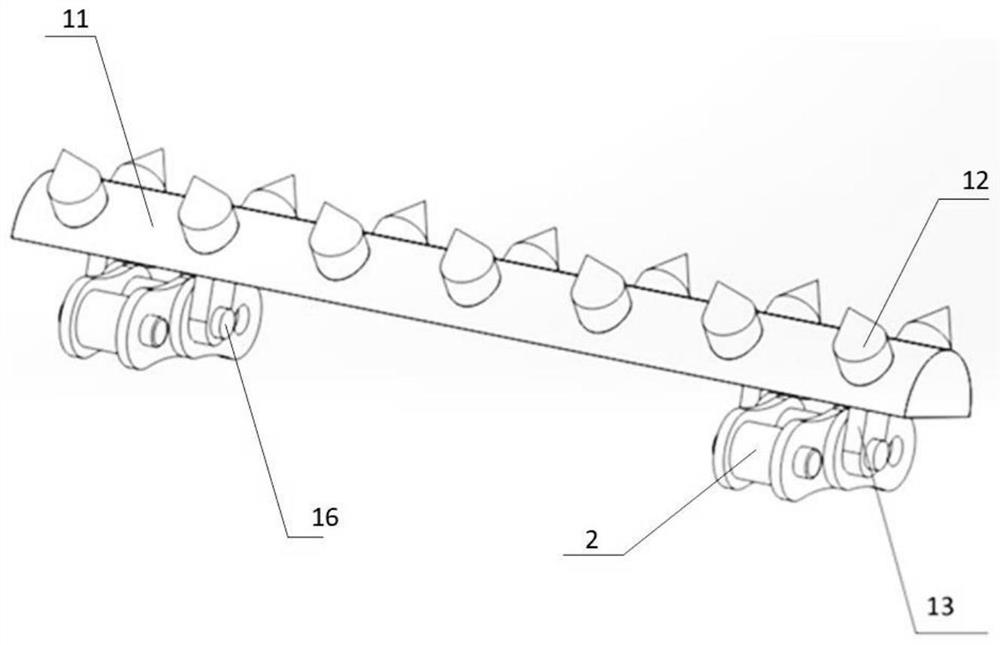

Roadheader cutting head with harrow teeth, telescopic structure thereof and accessory drilling tool

The invention provides a roadheader cutting head with harrow teeth, a telescopic structure thereof and an accessory drilling tool, and belongs to mine equipment. The cutting head is improved from a cutting arm and a cutting head of an existing roadheader. The cutting head is characterized in that by means of a spline type sleeve shaft structure using ball driving, the structure that the original cutting arm does not stretch and retract or one end of the original cutting arm bears pressure during stretching and retracting becomes a scientific two-position pressure bearing telescopic structure, and if outer meshing gear transmission with increased weight is used for power transmission, transverse cutting force is nearly multiplied due to rotating inertia. An outer spraying mode is changed into an inner water spraying structure. The position of a high-pressure water seal is changed to a small-outer-diameter shaft tail to reduce abrasion and effectively cool cutting teeth, two hydraulic cylinders are used for providing longitudinal push force, and the defect that pushing and pulling depend on walking in the prior art is avoided due to direct and controllable pushing and pulling; the multifunctional movable harrow teeth are additionally arranged on the cutting head, so the cutting head has the function of a slag-raking machine; a plurality of shallow hole drilling tools are additionally arranged on the cutting arm and matched with a proper explosion technology, so the overall performance is better than that of a drill loader, valuable stone can be exploited, zero-cost driving is achieved, and the updated and novel roadheader which can truly hit soft and hard rock, including ultra-hard rock, is formed as a whole.

Owner:韩自俊

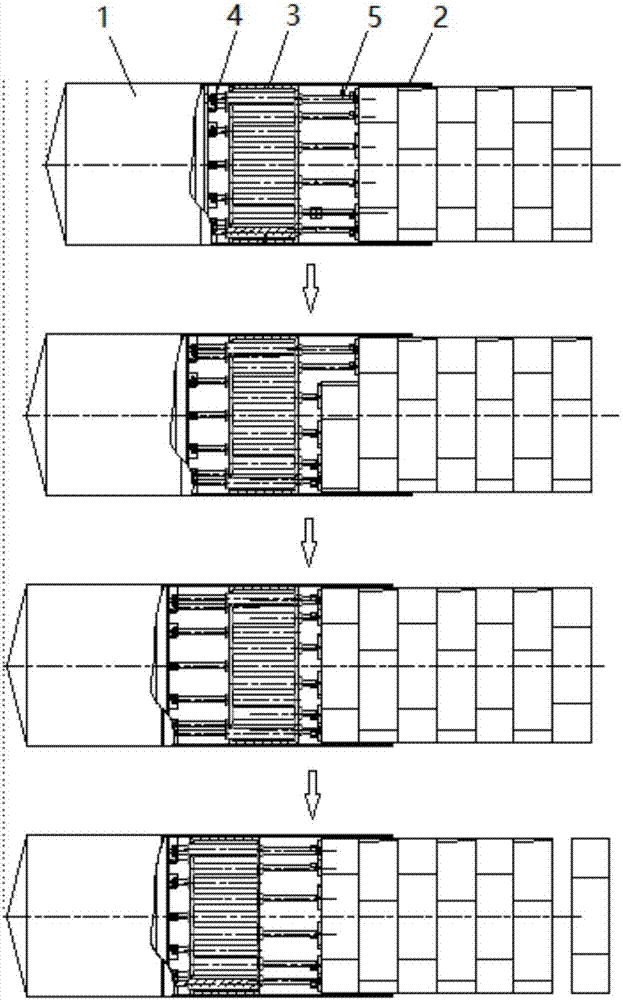

Shield tunneling machine capable of simultaneously carrying out tunneling and assembling and construction method

The invention discloses a shield tunneling machine capable of simultaneously carrying out tunneling and assembling and a construction method. The shield tunneling machine includes a shield tunneling machine body, an inner tube which can move in the axial direction of the shield tunneling machine body is arranged in a tail shield of the shield tunneling machine body, and the inner tube is providedwith an action performing device which enables the shield tunneling machine body to carry out tunneling and assembling simultaneously. According to the shield tunneling machine capable of simultaneously carrying out tunneling and assembling and the construction method, the synergistic effect of a plurality of tunneling jacks and assembling jacks is utilized by the shield tunneling machine to enable tunneling and segment assembling to be carried out simultaneously, the rapid tunneling of a shield tunnel can be realized, and the construction period of the shield tunnel is shortened; the inner tube in the tail shield of the shield tunneling machine separates the tunneling operation area and the segment assembling operation area independently, so that the safety of the operation areas is greatly improved; and when the construction method that tunneling and assembling are carried out simultaneously is not adopted and the tunneling jacks are not used, the assembling jacks can be exclusivelyused, and the traditional shield tunneling method can be recovered, namely the shield tunneling and the segment assembling can be operated alternately.

Owner:江苏格睿特管网工程有限公司

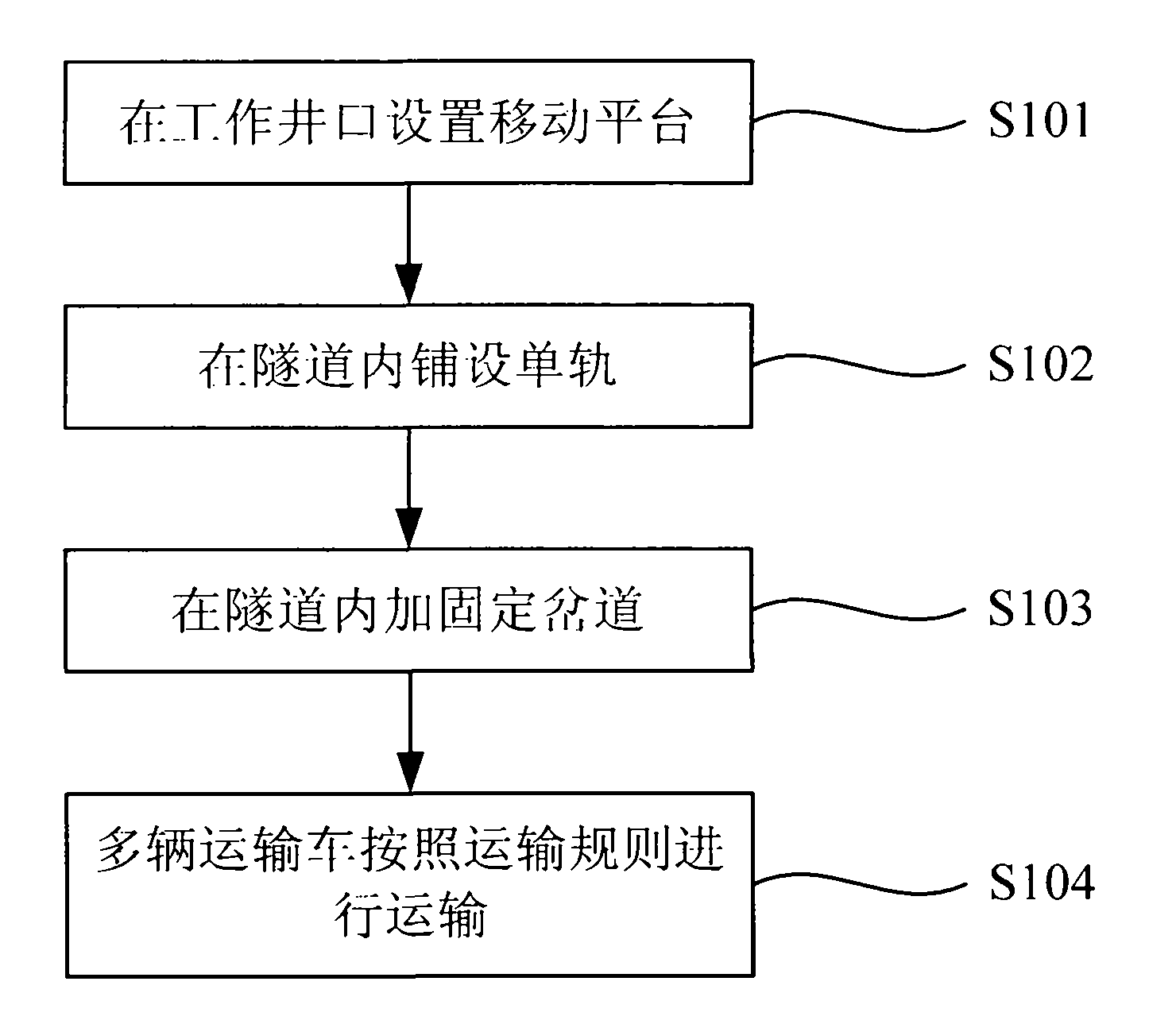

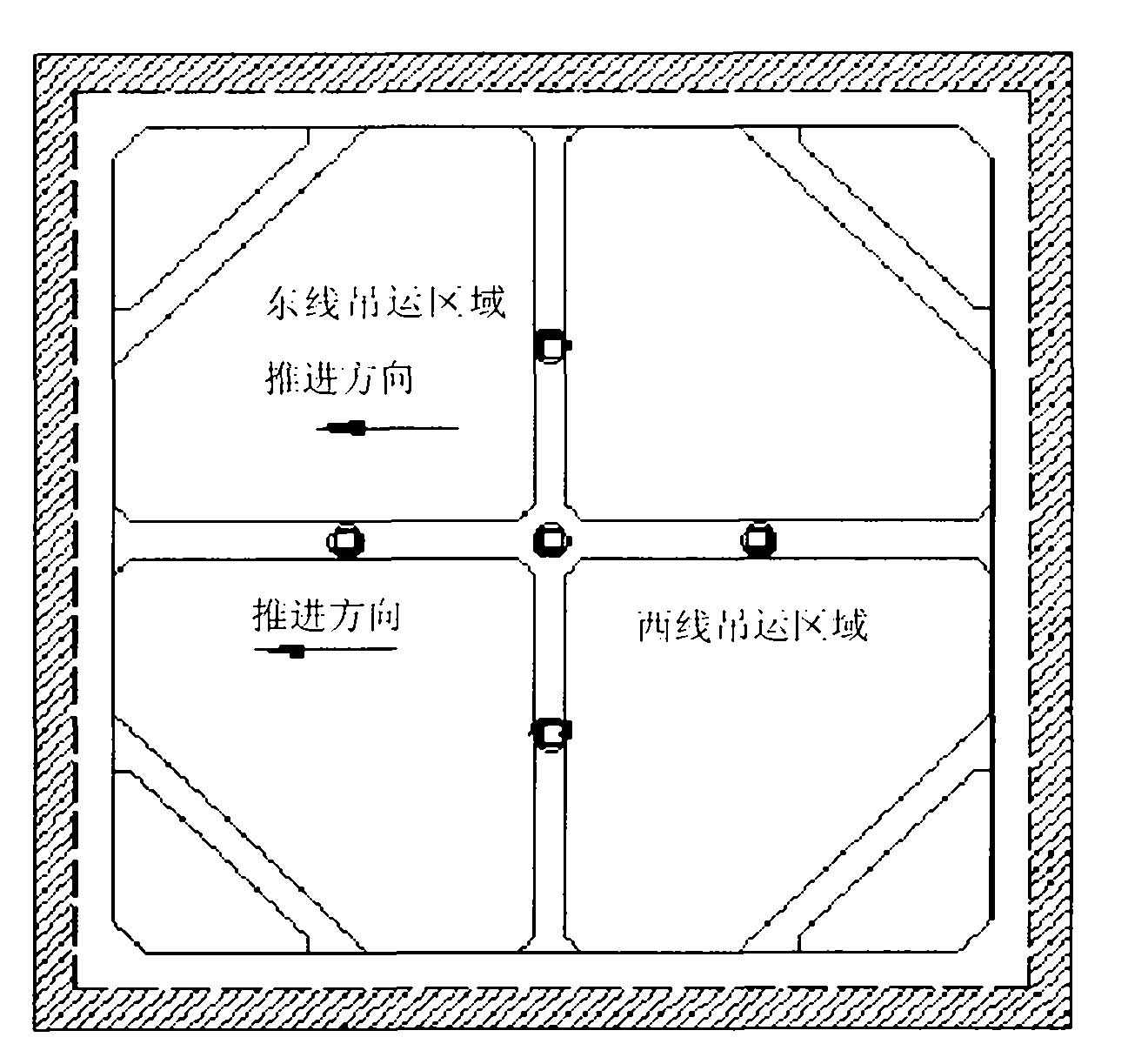

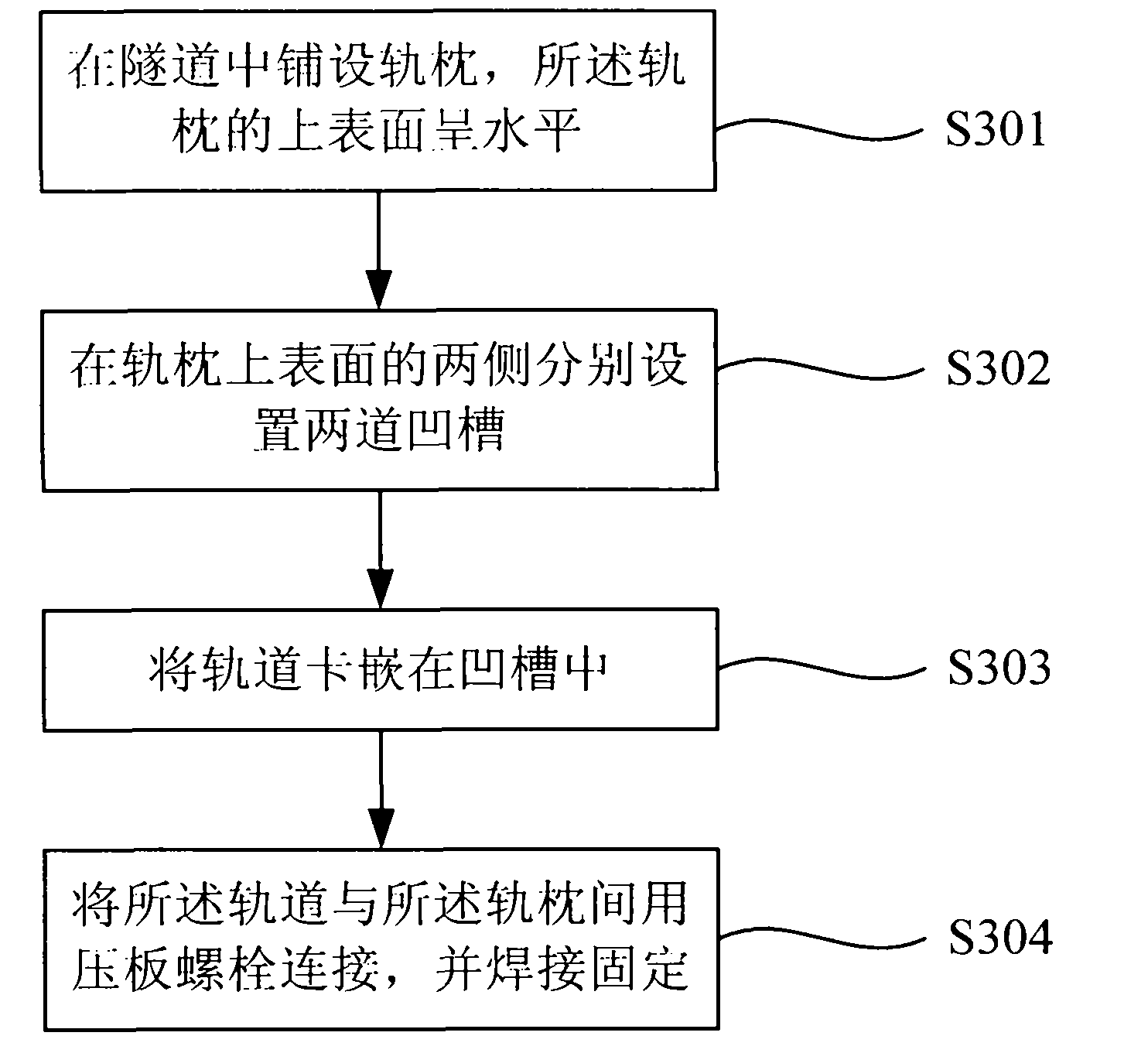

Quick transportation method in medium-diameter and long-distance tunnel shield construction

InactiveCN101881178AConvenient wrong carReasonable connectionBallastwayEarth drilling and miningTransport timeMonorail

The invention provides a quick transportation method in medium-diameter and long-distance tunnel shield construction. The method comprises the following steps of: (1) arranging a movable platform on a working well mouth to allow empty vehicles and loaded vehicles to pass mutually; (2) paving a monorail in a tunnel; (3) arranging a fixed turnout in the tunnel additionally according to the horizontal transportation time; and (4) transporting according to a transportation rule by using a plurality of transportation vehicles. By adopting the transportation method of the invention, the construction period can be shortened substantially on the premise of ensuring safety, and the transportation method has the obvious economic effect.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

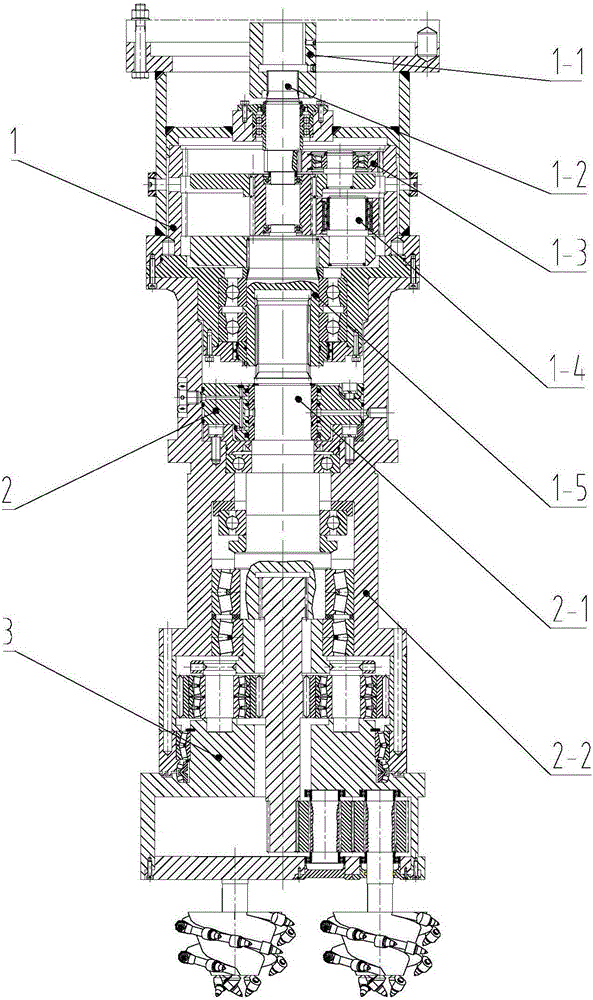

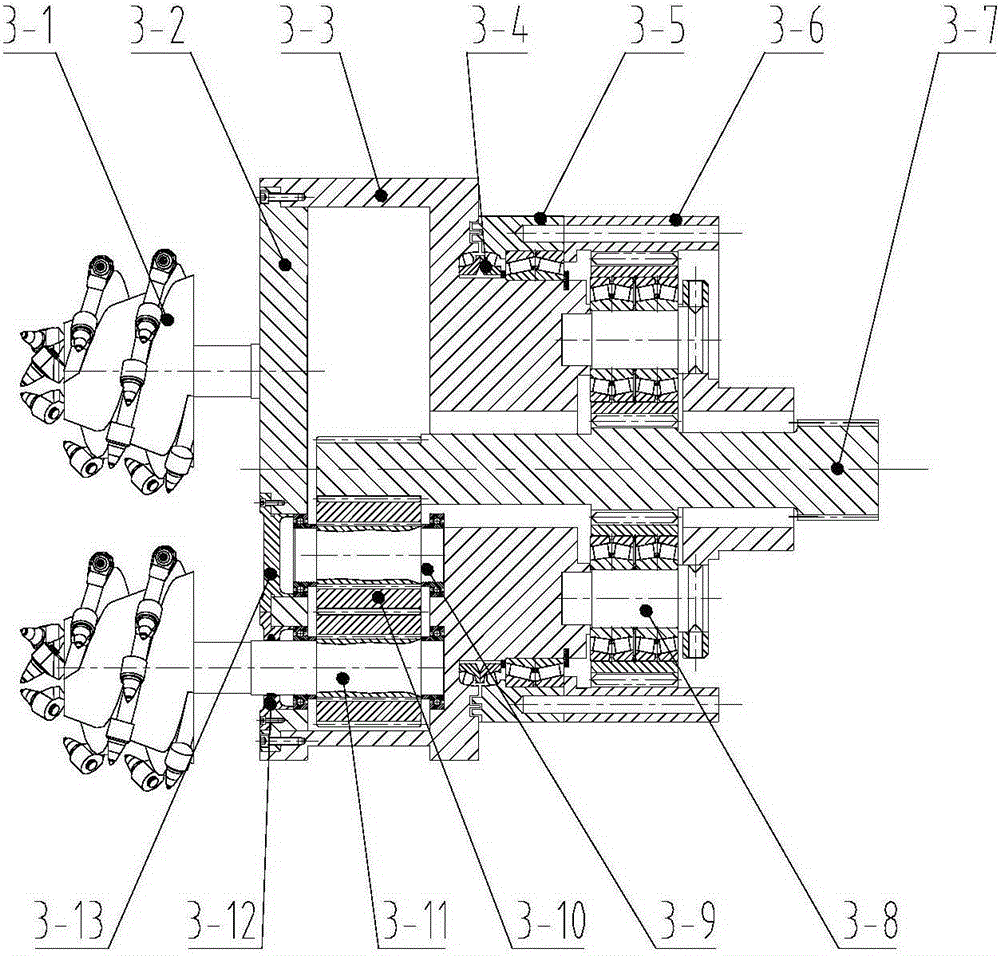

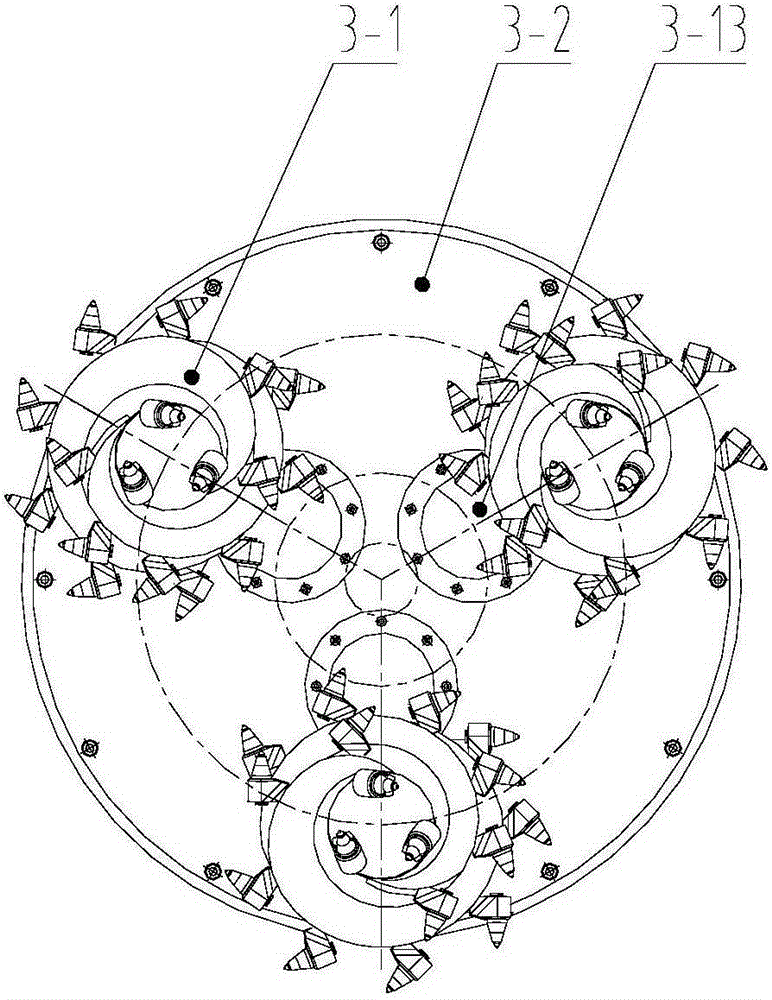

Cutting part of heading machine

ActiveCN105178977AMeet the rapid excavationExcavation method, fast for excavationTunnelsEngineeringReducer

The invention discloses a cutting part of a heading machine, and is suitable for a mine workings heading machine. The cutting part comprises a cutting speed reducer, a cutting arm and a cutting head, wherein the cutting speed reducer is fixedly connected with the cutting arm through a bolt; an output shaft of the cutting speed reducer is connected with a main shaft of the cutting arm through a spline; the cutting head consists of three rock crushing drill bits uniformly distributed by 120 degrees, a cutting head frame outer cover, a cutting head frame, a rotating seal, a bearing base, an inner gear ring, a cutting head main shaft, a planetary wheel component, a small gear pin shaft, three sets of six small gears uniformly distributed by 120 degrees, small gear output shafts, a bearing through cover and a bearing stifle; in work, a motor transfers power to the main shaft of the cutting arm and the cutting head main shaft in sequence through the cutting speed reducer; and then, the power is synchronously transferred to a cutting head planetary gear transmission mechanism and the three sets of small gears uniformly distributed by 120 degrees to respectively drive the cutting head frame and the cutting head output shaft to rotate to realize the revolving and the rotation of the three rock crushing drill bits, so that the driving speed of mine workings is largely increased. The cutting part is compact in structure and small in volume, and reduces specific energy consumption.

Owner:CHINA UNIV OF MINING & TECH

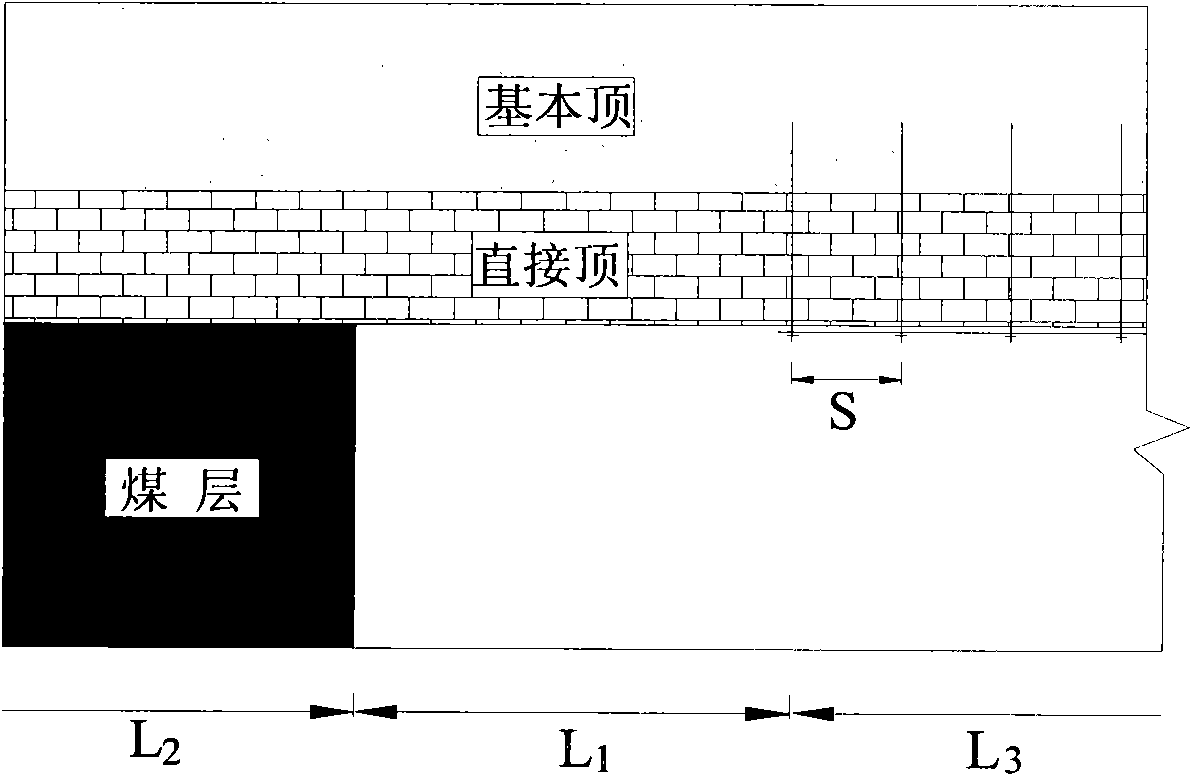

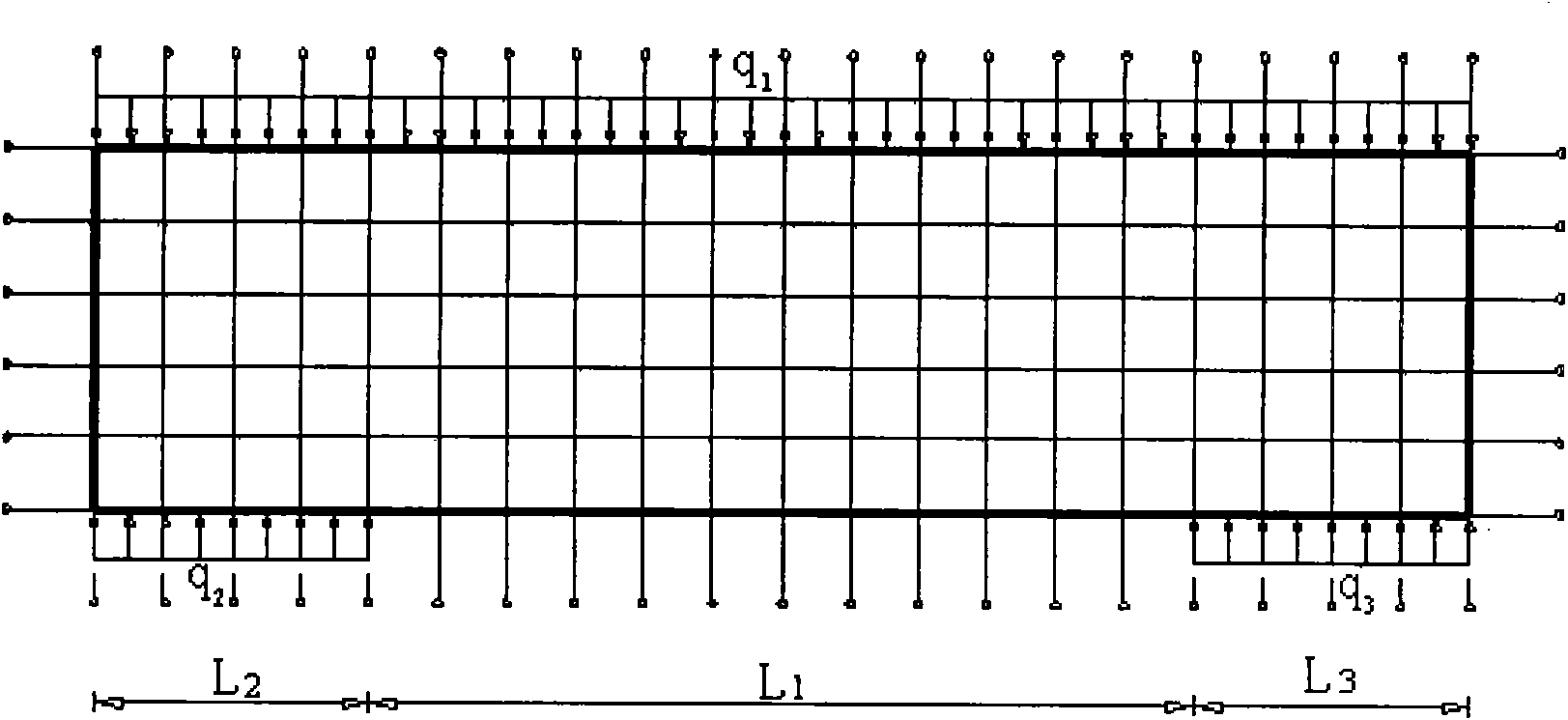

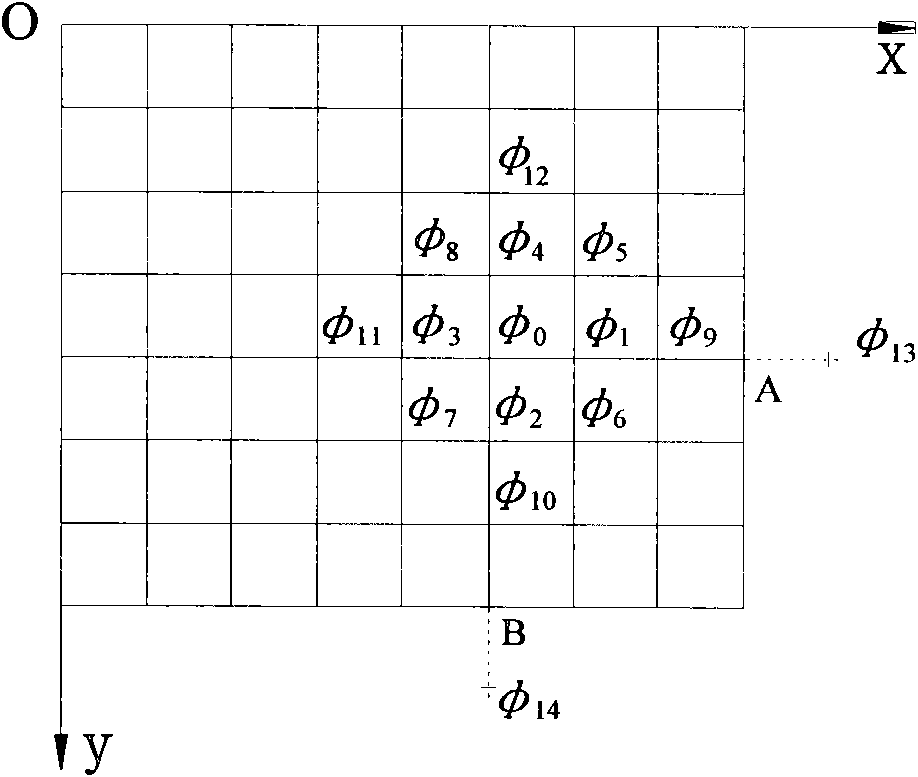

Method for determining reasonable empty-support distance of tunneling head

ActiveCN101858219AAvoid blindnessRealize quantitative analysisTunnelsAnchoring boltsMechanical modelsCompressive strength

The invention relates to a method for determining the reasonable empty-support distance of a tunneling head. The method comprises the following steps of: firstly, sampling immediate roof rock of a tunnel, measuring uniaxial compressive strength and tensile strength through mechanical tests; analyzing the stress of the immediate roof and the tunneling head, building an immediate roof mechanical model along the tunnel, carrying out stress function solution by using a difference method and mathematical software, and calculating stress component of each node in the model; judging stability of the immediate roof in the empty-support range according to the rock strength determined by the tests; and finally, selecting the reasonable empty-support distance according to the maximum tunneling length completed by a production class. The method for the head-on reasonable empty-support distance of the tunneling head overcomes blindness of selecting the empty-support distance, realizes quantitative analysis of empty-support distance selection, and provides important basis for safely and quickly tunneling tunnels. The method has the advantages of simpleness, easy practice, low cost and high reliability, and provides a new way for determining the reasonable empty-support distance.

Owner:CHINA UNIV OF MINING & TECH

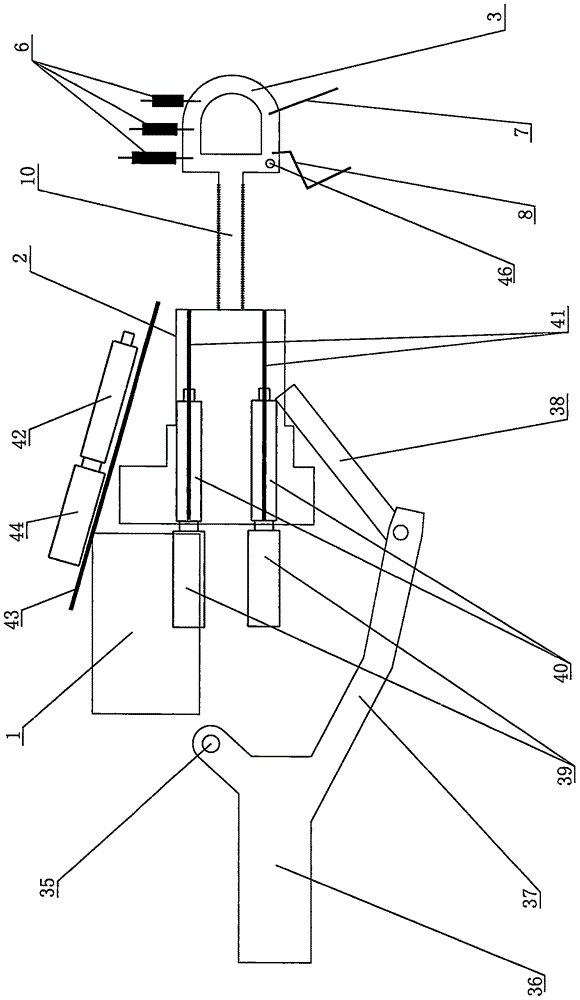

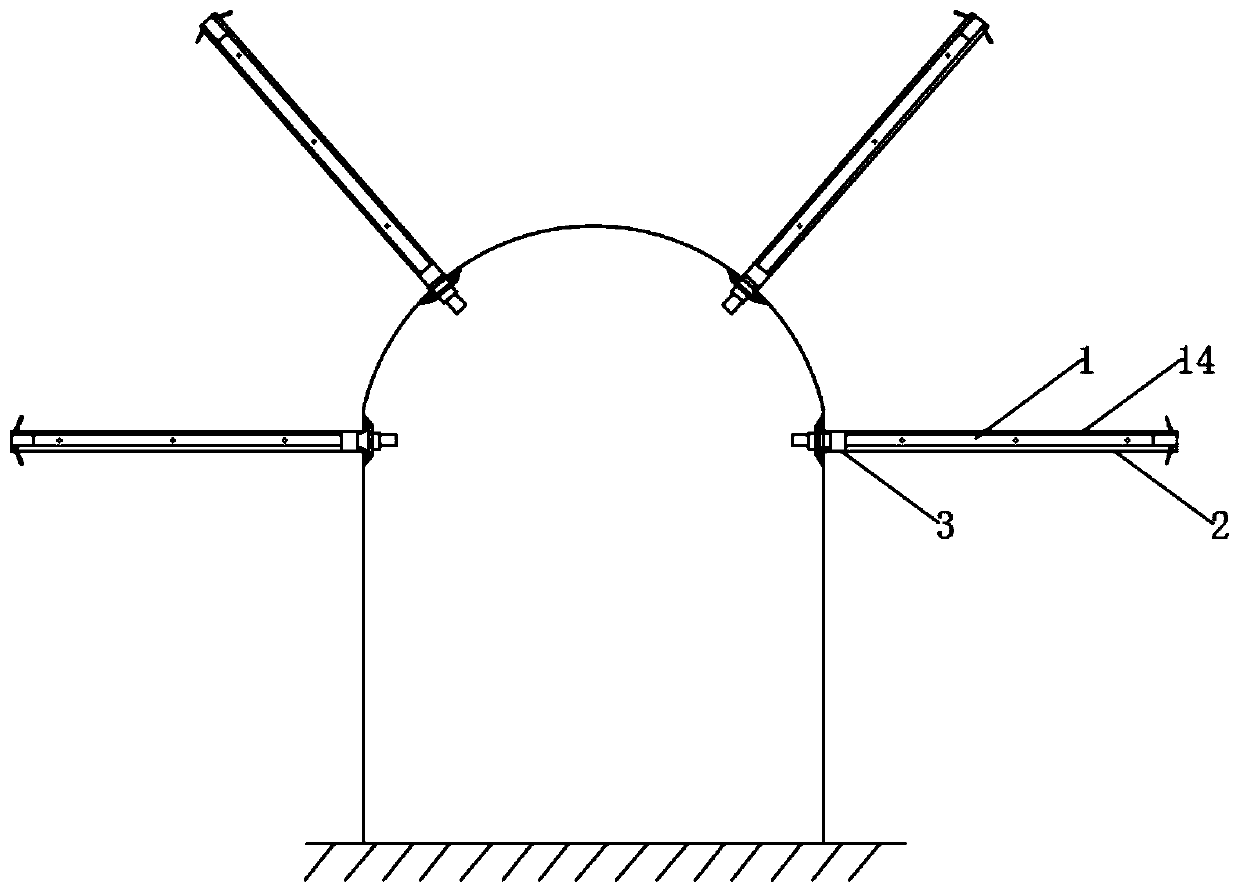

Roadway drivage advanced telescopic cantilever support device and construction method thereof

PendingCN107178384ADoes not affect the normal excavation processRealize parallel operationMine roof supportsAnchoring boltsControl systemArchitectural engineering

The invention discloses a roadway drivage advanced telescopic cantilever support device and a construction method thereof. The roadway drivage advanced telescopic cantilever support device comprises an electro hydraulic control system, a pump station, a crossheading support, a telescopic arm and a top-support grid plate; the crossheading support is formed by connecting four section support units in two rows and two columns through a horizontal oil cylinder and a longitudinal oil cylinder, and each support unit is composed of a top beam, a base, a stand column and a four-bar linkage; and the front portions of the bases of the support units in the front row are connected with one end of the telescopic arm, and the other end of the telescopic is connected with the top-support grid plate and an advanced suspended stand column. As the driving of the roadway drivage machine, the telescopic arm extends to support the top. According to the roadway drivage advanced telescopic cantilever support device, a wide range of temporary support for roadway drivage is provided, the support strength is high, anchor bolts and anchor ropes in multi rows can construct parallel, the technological requirement of one-drivage multi-anchoring is met, the staff operate under the full support condition, the safety is high, the roadway driving cost is reduced, and the construction speed is increased over 70%; and the device is suitable for the fields of coal mines, metallurgy mines, underground construction, tunnel construction and the like.

Owner:中煤能源研究院有限责任公司

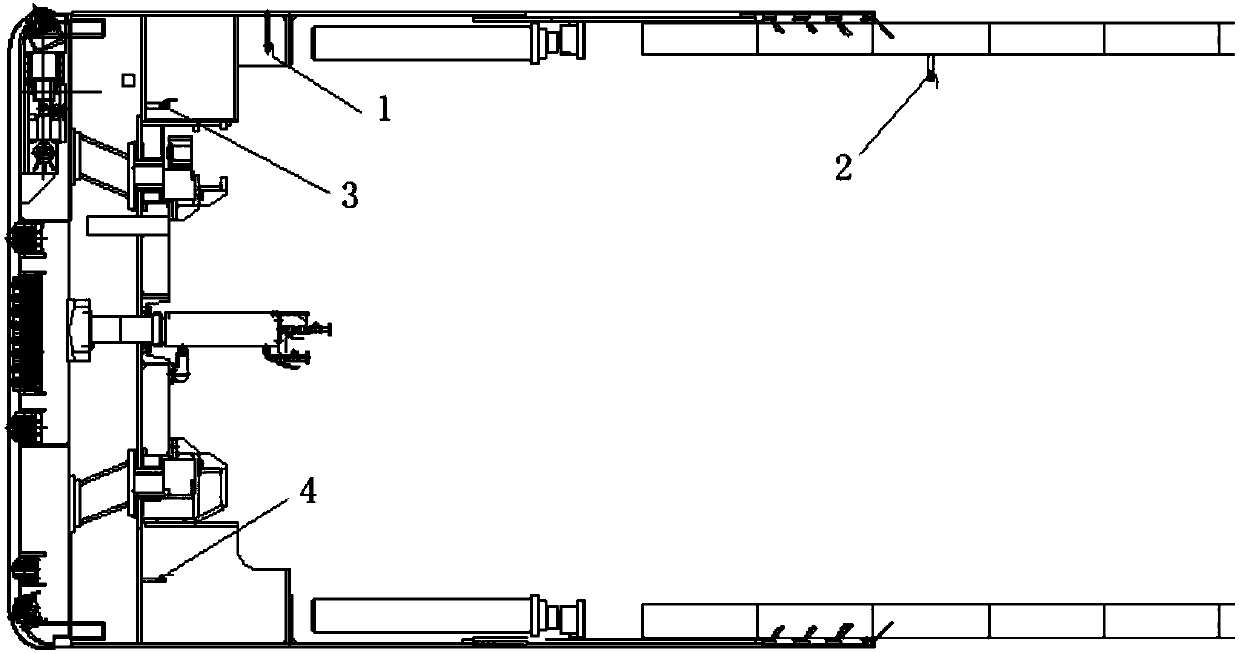

Folding-arm type tunneling machine capable of monitoring intelligently and automatically regulating rotate speed of cutting head

InactiveCN103628872ARealize remote controlSafe Excavation OperationsSlitting machinesCutting machinesRemote controlEngineering

The invention discloses a folding-arm type tunneling machine capable of monitoring intelligently and automatically regulating the rotate speed of a cutting head. The folding-arm type tunneling machine comprises a working arm, a conveying mechanism (11), an electrical system (10), a hydraulic system (5), a travelling mechanism (8) and a vehicle body (7); the working arm comprises the cutting head (1), a spraying frame (2) and a large arm (4); one end of the working arm is movably connected with the vehicle body; sensors used for monitoring gas, dust and displacement are arranged on the cutting head respectively; a temperature sensor and a pressure sensor are arranged on a pipeline of the hydraulic system; monitored data of the sensors is transmitted to the network through an optical fiber cable, so that real-time on-line monitoring and remote control are realized, the rotate speed of the cutting head can be regulated automatically, and the feed rate can be reduced, so as to ensure that the tunneling machine performs tunneling operation safely; when the rigidity of a to-be-cut object is higher than the cutting rigidity, the tunneling speed is reduced, and when fluffy coal is cut, the rotate speed of the cutting head is increased automatically, and the feed rate is increased, so that not only can the tunneling rate be ensured, and damage to equipment can be lowered, but also the construction safety can be ensured.

Owner:江西华煤重装有限公司

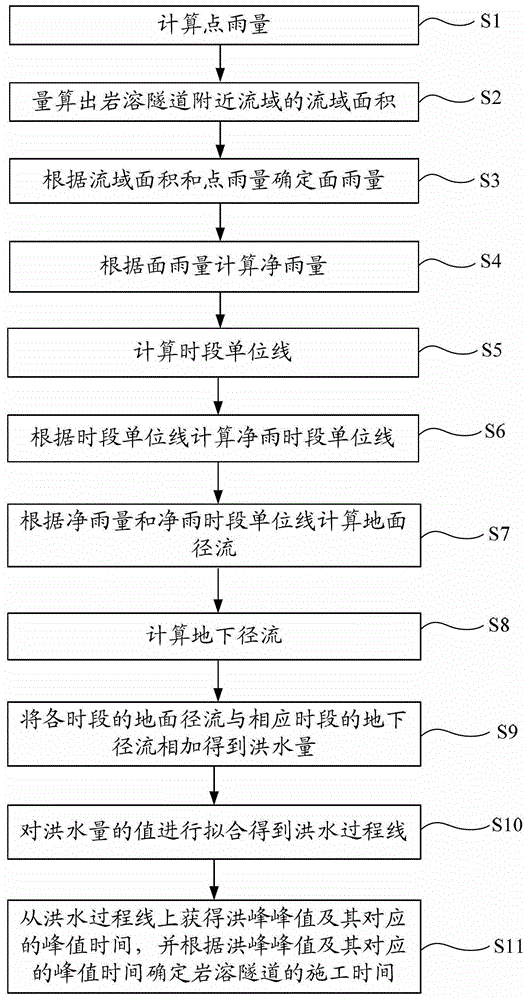

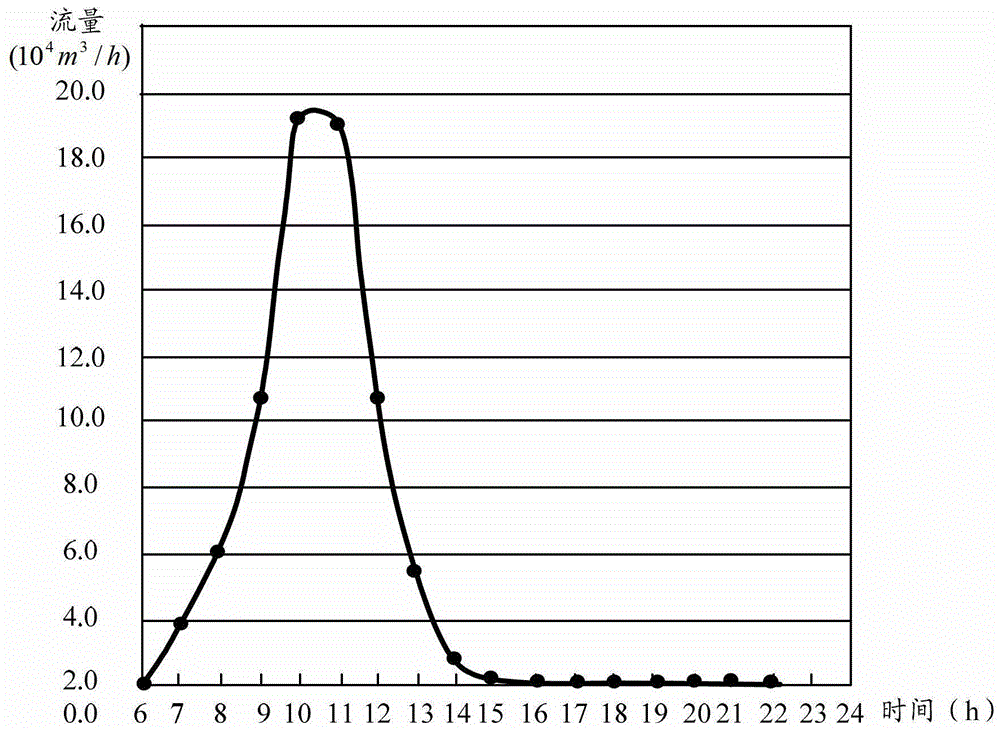

Prediction method of flood peak value and peak time of storm water inrush from underground river in karst tunnel

ActiveCN102930357BSimple structureEasy to calculateClimate change adaptationForecastingPredictive methodsKarst

The invention discloses a method for forecasting water burst flood peak and peak time for a karst tunnel underground river. The method comprises the following steps: (1) computing point rainfall; (2) determining areal rainfall according to the point rainfall; (3) computing effective precipitation according to the areal rainfall; (4) computing time interval unit hydrograph; (5) computing effective precipitation unit hydrograph according to the time interval unit hydrograph; (6) computing surface runoff according to the effective precipitation and the effective precipitation unit hydrograph; (7) computing subsurface runoff; (8) adding the surface runoff at each time interval and the subsurface runoff at the corresponding time intervals to obtain flood discharge; (9) performing fitting on value of the flood discharge to obtain a flood hygrograph; and (10) obtaining the flood peak and the corresponding peak time on the flood hygrograph and determining construction time for a karst tunnel according to the flood peak and the corresponding peak time. According to the method provided by the invention, the water burst flood peak in the tunnel and the arrival time of the flood peak can be accurately forecasted, so that the construction time for the tunnel can be reasonably arranged, and the lives of people and the safety of mechanical equipment can be ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

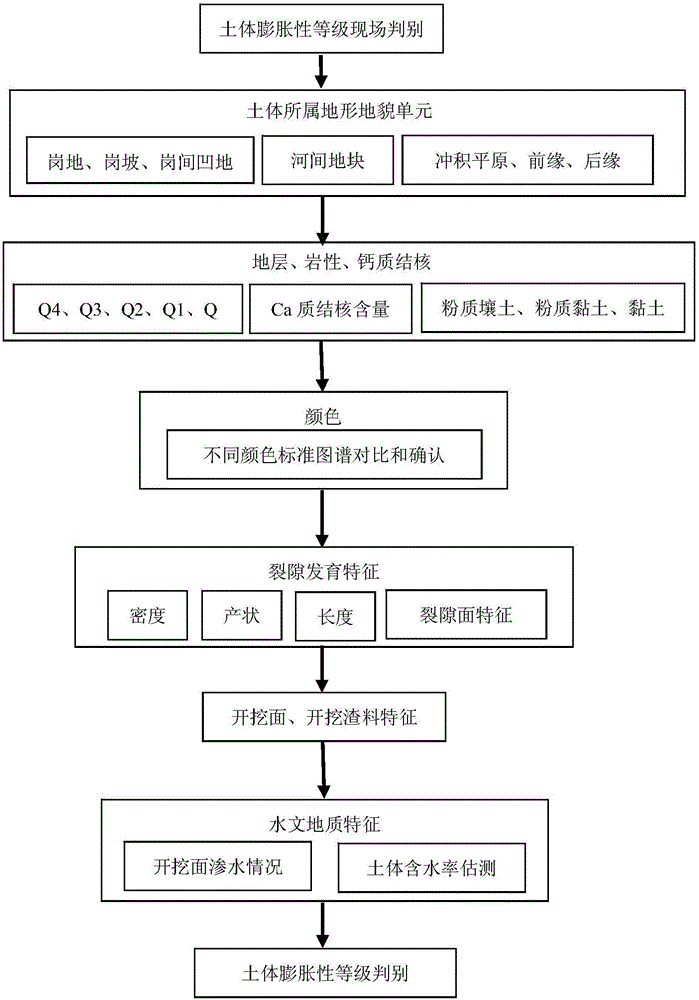

Macroscopic method capable of distinguishing expansibility grade of soil mass during construction

InactiveCN106156486AComply with macro-geological factors cyberneticsSimple methodEarth material testingSpecial data processing applicationsSwelling ratioSoil science

The invention discloses a macroscopic method capable of distinguishing expansibility grade of soil mass during construction. The method is characterized in that before project implementation, a representative sample in a work area is selected and is subjected to an indoor test of a free swelling ratio, the relation among the expansibility, the lithological character, the soil mass structure, colors, crack development characteristics and the like is established, and the accuracy and the scientificity of on-site rapid distinguishing are realized; a macrocontrol index for rapid distinguishing of the expansibility grade of the soil mass is selected, and classified description and research of a control index are carried out; a soil mass expansibility distinguishing model is established, the weight of each influence factor is determined, besides, an indoor verification test is carried out, and the reliability of the model and the accuracy of the test are improved; rapid distinguishing work of the expansibility grade of the soil mass in the work area is performed on site according to the soil mass expansibility distinguishing model. The defects that a treatment scheme and treatment strength cannot be adjusted timely in the implementation process of a project according to the expansibility grade in the prior art are overcome, and the method has the advantages of capability of rapidly distinguishing expansive soil in the on-site construction process.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

Hydraulic fracturing combined hydraulic blasting roadway large-size tunneling method and fracturing device

PendingCN110725685AAvoid randomnessEffective isolationFluid removalBlastingMining engineeringHydraulic fracturing

The invention belongs to the technical field of roadway tunneling, and particularly relates to a hydraulic fracturing combined hydraulic blasting roadway large-size tunneling method and a fracturing device. Firstly, contour blasting holes are arranged on a working contour surface, a combined fracturing method combining hydraulic fracturing-burst fracturing-hydraulic fracturing is adopted, a largecrack is formed on the working contour surface of a tunnel firstly, a mining area and a non-mining area are separated, the expansion of cracks in other directions is effectively prevented, the depth and the width of the crack extension are greatly improved, the hard coal rock becomes more loose, mining is facilitated, and the air permeability of coal seams can be improved. In addition, multiple sections of the fracturing device can be arranged on the length of the whole blast hole, sealing is carried out in a sectional mode, millisecond delay blasting is achieved in the blasting holes, then multiple disturbances on the coal rock mass are achieved, the method is suitable for super-long drilling and large-size blasting construction, and rapid tunneling of the roadway can be achieved.

Owner:HENAN POLYTECHNIC UNIV

Low-air-permeable coal bed static blasting anti-reflection gas extraction method

ActiveCN109458214AGuaranteed stabilitySlow generationMining devicesDisloding machinesHydration reactionEngineering

The invention discloses a low-air-permeable coal bed static blasting anti-reflection gas extraction method. Multiple roof bedding drill holes are constructed along the coal bed top plate, the drill holes are filled with silent breakers which are subjected to a hydration reaction to generate radial compressive stress and tensile stress to hole walls, when the tensile stress exceeds tensile strengthof coal bed roof rock, the coal bed roof starts to generate cracks, that is to say, a gas migration and output passage is built in the coal bed roof rock, the roof bedding drill holes are subjected to repairing, hole sealing and networking extraction, and coal bed gas is extracted indirectly. Meanwhile, a group of coal bed bedding drill holes are constructed in a coal bed, and migration of the coal bed gas to the roof bedding drill holes is accelerated. After it is determined that extraction reaches the standard, progressive cover type tunneling is conducted, and finally rapid tunneling of alow-air-permeable coal bed coal rod is achieved. Accordingly, by conducting static blasting fracture on the roof bedding drill holes, the gas migration and output passage is built in the coal bed roofrock, and the extraction amount and extraction rate of the low-air-permeable coal bed gas are increased.

Owner:HENAN POLYTECHNIC UNIV

Construction method of below-sensitive-building water-enriched rock stratum full-section grouting shield

ActiveCN107642364AEasy to excavateMeet the rapid excavationUnderground chambersTunnel liningBedrockSodium Bentonite

Provided is a construction method of a below-sensitive-building water-enriched rock stratum full-section grouting shield. The construction method of the below-sensitive-building water-enriched rock stratum full-section grouting shield includes the construction steps of reinforcing shield sealing, filling the periphery of the shield with bentonite, supplementing grout to gaps behind duct-piece walls, replacing muck with gas, replacing the gas with grout, grouting full sections, detecting grouting effects and conducting shield tunneling. By the adoption of the construction method of the below-sensitive-building water-enriched rock stratum full-section grouting shield, base-rock gap channels can be effectively sealed in all directions, loss of underground water is reduced, tunneling environment is improved, soil transporting of a screw conveyor is facilitated, so that the shield tunnels rapidly, and descending of buildings on the earth surface can be effectively controlled.

Owner:YSD RAIL TRANSIT CONSTR CO LTD

Deep roadway prestress full-anchor supporting construction equipment and construction method thereof

ActiveCN111379581ARealize temporary supportSave manpower and material resourcesUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses deep roadway prestress full-anchor supporting construction equipment and a construction method thereof. The deep roadway prestress full-anchor supporting construction equipmentcomprises an anchor bolt for being inserted into a roadway anchor hole, an injection machine for providing primary grout and secondary grout for the anchor bolt, and a pressure maintaining pipeline for being connected with the anchor bolt and the injection machine. The anchor hole is provided with an inner end and an outer end opposite to the inner end, the anchor bolt is coaxially inserted intothe anchor hole, and the anchor bolt is provided with a first end and a second end opposite to the first end. After the anchor bolt is coaxially inserted into the anchor hole, the first end is locatedat the inner end, and the second end is located at the outer end. An injection clearance exists between the periphery of the anchor bolt and the anchor bolt, and the injection clearance at the innerend of the anchor holt is used for allowing the first grout to be injected into, so that the first end of the anchor bolt is anchored; and the injection clearance at the other positions of the anchorhole is used for allowing the secondary grout to be injected into, so that the anchor bolt is anchored in the whole length direction. And a layered grouting manner is adopted, so that the more than 90% of the clearance in the anchor holt is filled with the grout, the compactness is high, and whole-length anchoring of the anchor bolt is achieved.

Owner:淮南东华欧科矿山支护设备有限责任公司

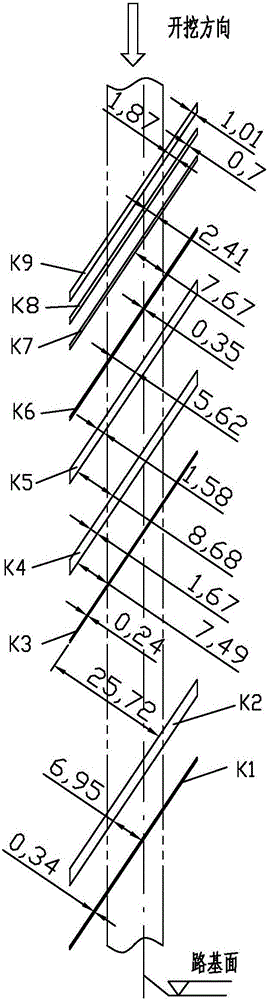

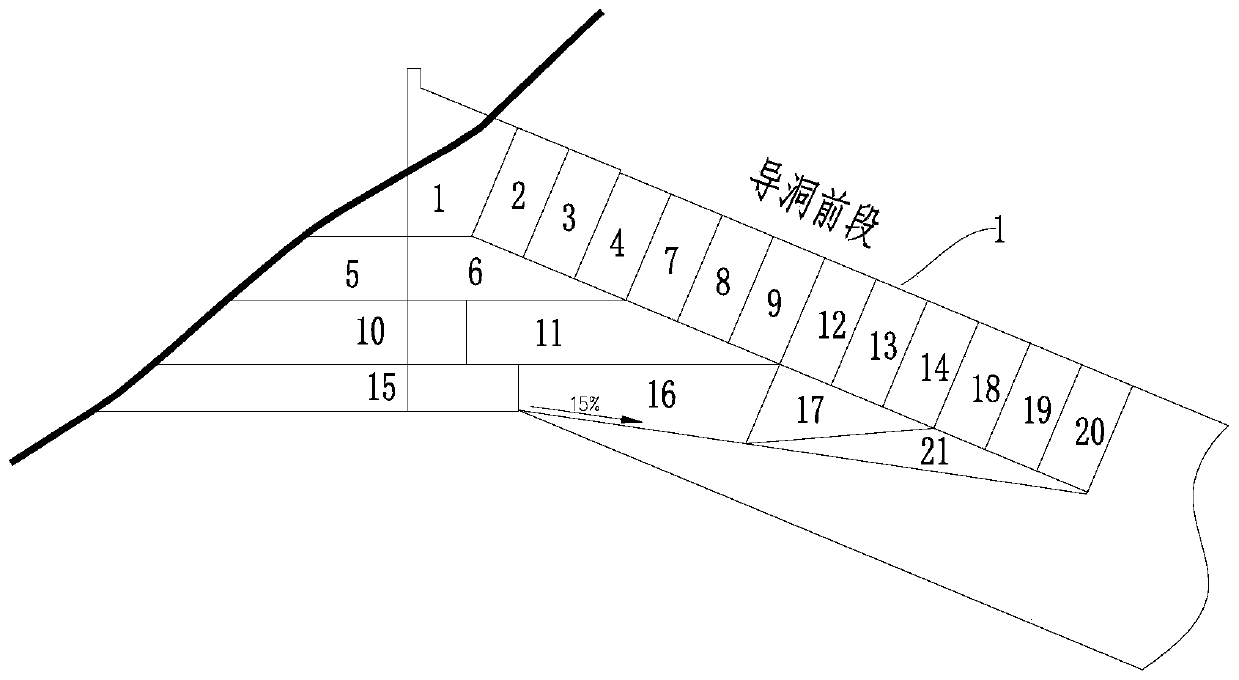

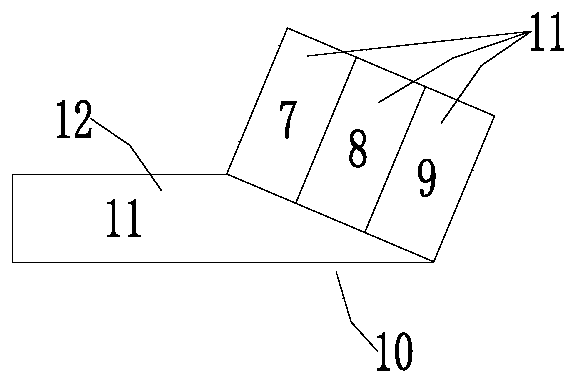

Rapid excavation method for suspension bridge tunnel anchor

InactiveCN111074781AReduce the degree of difficultyMeet the rapid excavationBridge structural detailsBridge erection/assemblyArchitectural engineeringEngineering

The invention discloses a rapid excavation method of a suspension bridge tunnel anchor. The method is used for blasting excavation of a mountain rock stratum, and comprises the following steps: dividing a first tunnel into a plurality of first sections in advance, equally dividing each first section into a first arc part and a first bottom, and performing two-step blasting excavation on every first section, wherein the first arch part is excavated forwards for M times in sequence according to the inclination angle of the first section, and then the first bottom is excavated downwards for one time; and dividing a second tunnel into a plurality of second sections in advance, equally dividing each second section into a second arch part and a second bottom, and performing two-step blasting excavation, wherein the second arch part is excavated forwards for N times in sequence according to the inclination angle of the second section, and then the second bottom is excavated downwards according to the section of the second section; and M and N are natural numbers, and the second tunnel is communicated with the first tunnel, and the section and inclination angle of the second tunnel are larger than those of the first tunnel. The method is suitable for large-section and large-inclination-angle tunnel type anchors, rapid construction can be achieved, and the construction period is shortened.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

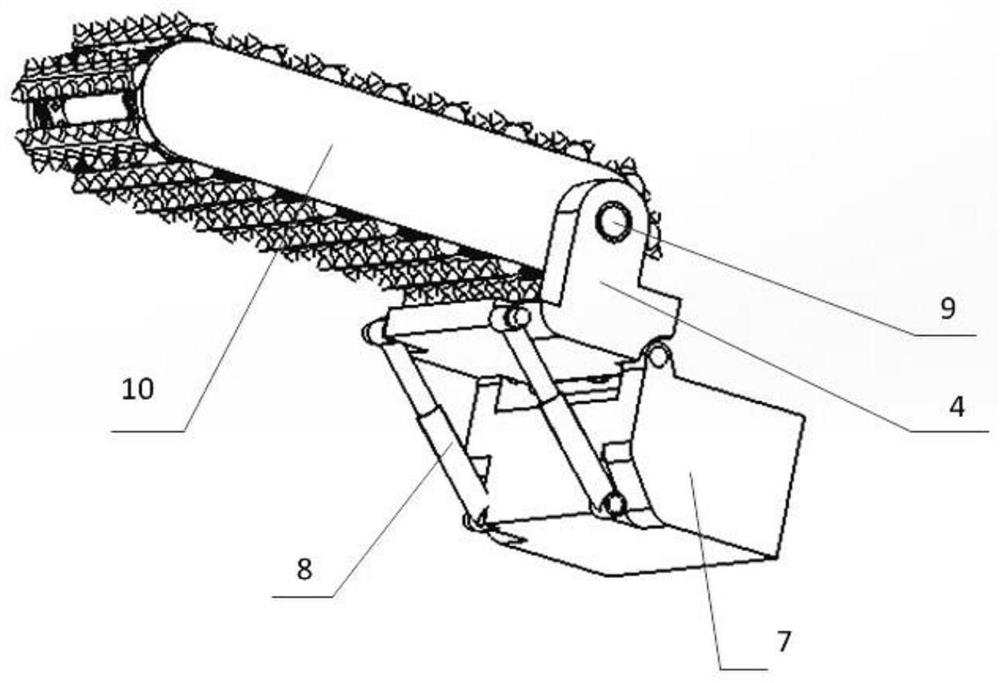

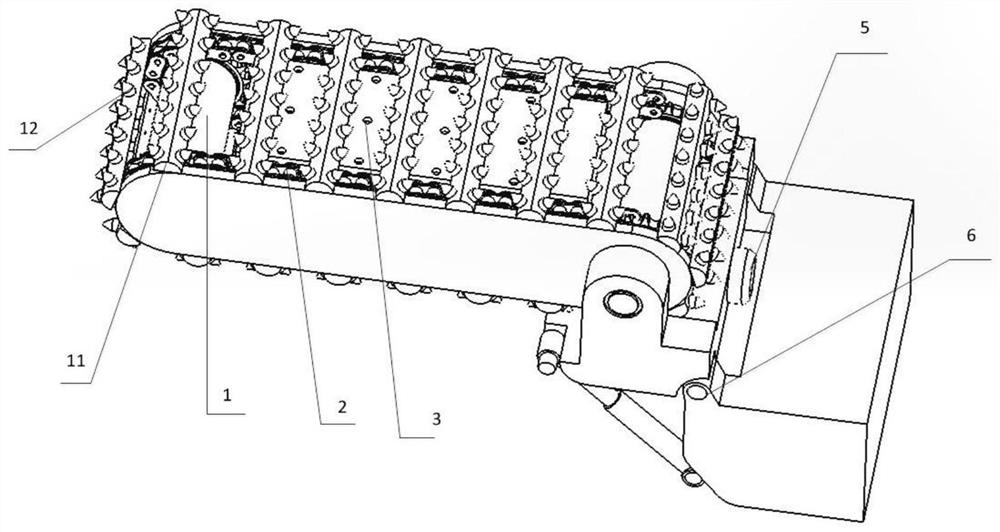

Novel heading machine cutting device and working method thereof

ActiveCN112943283AMeet the rapid excavationLarge cutting areaTunnelsHydraulic cylinderReduction drive

The invention relates to a novel heading machine cutting device and a working method thereof, and belongs to the field of coal rock crushing of a heading roadway of a stope face. The novel heading machine cutting device comprises a body, a support driving device and an adjusting hydraulic cylinder; the body is provided with a chain wheel, a chain and a scraper; a motor and a speed reducer are arranged in the support driving device; an output shaft of the speed reducer is connected with the chain wheel; the chain wheel is meshed with the chain and drives the chain to rotate; the multiple scrapers are arranged on the chain; cutting teeth for cutting are arranged on the scrapers; one end of the support driving device is rotationally connected with a connecting lug plate at the upper part of a vehicle body of a heading machine through a pin shaft; the other end of the support driving device is connected with the lower part of the heading machine through the adjusting hydraulic cylinder; the upper surface, the lower surface and the end, away from the support driving device, of the body are all working faces; and the ratio of the length to the width of the body is 2:1-3:1. According to the novel heading machine cutting device and the working method thereof, coal rock can be cut by adopting various angles and various cutting areas, so that the cutting area is large, and the purpose of rapidly tunneling a roadway can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

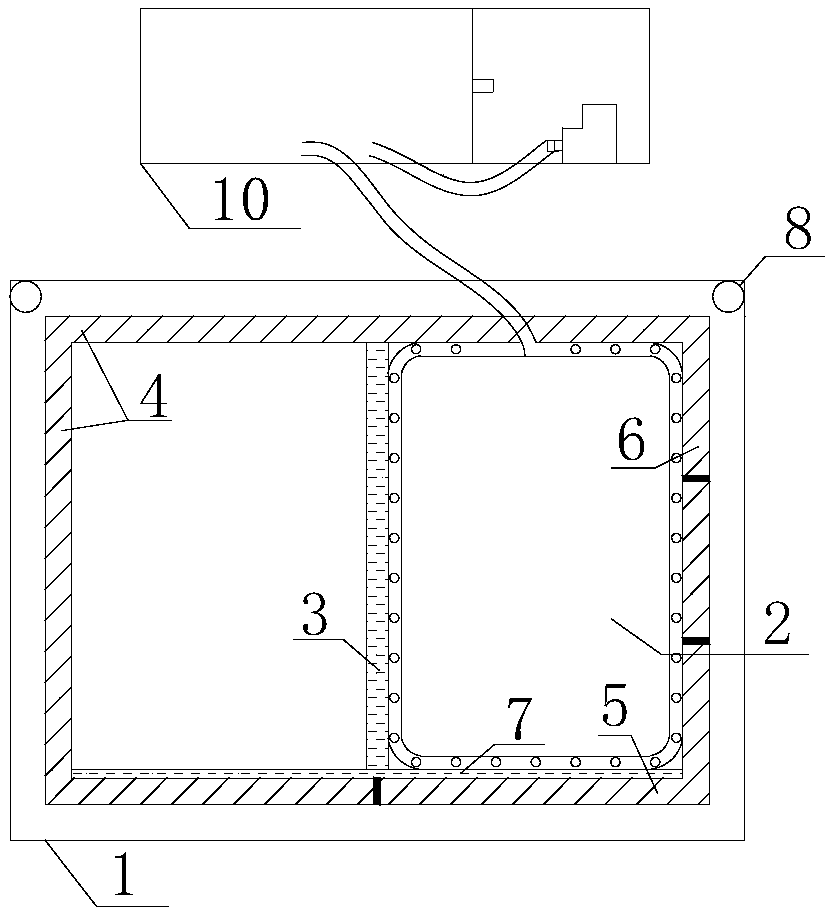

Model test device and method for foundation pit supporting system

PendingCN109469117AReduce the temperatureImprove test efficiencyFoundation testingSupporting systemWater storage tank

The invention discloses a model test device and method for a foundation pit supporting system. The model test device comprises a base, a model box, a model plate, a water supply device, a cooling system, a temperature sensor and a data acquisition instrument. A water storage tank is arranged on the base. The model box is arranged on the base. A bottom plate of the model box is located in the waterstorage tank of the base. A plurality of water seepage through holes are formed in the bottom plate. The model plate is fixedly arranged inside the model box. A plurality of displacement sensors andpressure sensors are fixedly arranged on the model plate. The water supply device comprises a water supply tank and a water supply pipe. The water supply can be provided to the model box through the water supply tank and the water supply pipe. The temperature of the model box can be reduced by the cooling system. By means of the model test device and method for the foundation pit supporting system, an indoor model test of a foundation pit can be carried out, and the effects of supporting construction, groundwater and temperature can be considered in the simulation test.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com